Page 1

{ServiceManual}{Production}{KodakServiceSupport}

Publication No. SM5440-1

18NOV97

Supersedes SM5440-1

13MAY97

SERVICE MANUAL

Kodak Carousel PROJECTORS

New Look PROJECTORS

Models 4200, 4200-J, 4200-KK, 4400, 4600,

Kodak Home Page

on Internet

Intranet

Table of Contents

4600-KK, 5600, 5600-J, and 5600-KK

© Eastman Kodak Company, 1999

A100_0029HA

Page 2

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special damages, resulting from any use of

this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Table of Contents

Description Page

Replacements and Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Replacing the LOWER HOUSING ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing the LOWER HOUSING ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . 4

Replacing the FAN SHAFT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing the FAN SHAFT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Replacing the MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Replacing the WORM PULLEY and MECHANISM BELT . . . . . . . . . . . . . . . . . 8

Installing the WORM PULLEY and MECHANISM BELT . . . . . . . . . . . . . . . . . . 9

Replacing the THERMAL FUSE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing the THERMAL FUSE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Replacing the LAMP MODULE RECEPTACLE. . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing the LAMP MODULE RECEPTACLE. . . . . . . . . . . . . . . . . . . . . . . . . . 11

Replacing the CYCLE SOLENOID ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the CYCLE SOLENOID ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . 12

Replacing the MECHANISM ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the MECHANISM ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Replacing the AUTO-FOCUS BRACKET ASSEMBLY . . . . . . . . . . . . . . . . . . . 14

Installing the AUTO-FOCUS BRACKET ASSEMBLY . . . . . . . . . . . . . . . . . . . . 14

Replacing the CAM STACK ASSEMBLY and CYCLE LEVER ASSEMBLY . . . 14

Installing the CAM STACK ASSEMBLY and CYCLE LEVER ASSEMBLY . . . . 17

Replacing the LAMP SOCKET TERMINAL ASSEMBLY. . . . . . . . . . . . . . . . . . 18

Installing the LAMP SOCKET TERMINAL ASSEMBLY. . . . . . . . . . . . . . . . . . . 18

Replacing the LENS MOUNT ASSEMBLY - Auto Focus Model . . . . . . . . . . . . 19

Installing the LENS MOUNT ASSEMBLY - Auto Focus Models . . . . . . . . . . . . 19

Replacing the LENS MOUNT ASSEMBLY - Non Auto Focus Model. . . . . . . . . 20

Installing the LENS MOUNT ASSEMBLY - Non Auto Focus Model . . . . . . . . . 20

Replacing the AUTO-FOCUS SWITCH ASSEMBLY. . . . . . . . . . . . . . . . . . . . . 21

Installing the AUTO-FOCUS SWITCH ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . 21

Replacing the FOCUS SHAFT ASSEMBLY - Auto Focus Models. . . . . . . . . . . 21

Installing the FOCUS SHAFT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replacing the FOCUS SHAFT ASSEMBLY - Non Auto-Focus Models. . . . . . . 23

Installing the FOCUS SHAFT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Adjusting the CYCLE SOLENOID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Adjusting the INDEXER LEVER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Adjusting the SLIDE LIFT LEVER MANUAL, with MECHANISM Out . . . . . . . . 27

Adjusting the SLIDE LIFT LEVER POWER with Mechanism Out . . . . . . . . . . . 27

2 18NOV97 – SM5440-1

Page 3

Adjusting the Focus Light Path - Auto Focus Models

Adjustment Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Adjusting the NULL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Adjusting the PHOTOCELL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adjusting the CLAMP PAD ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Adjusting the DARK SHUTTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

MAIN MOTOR Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

PHOTOCELL Voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5-PIN REMOTE CORD PLUG Voltages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

SMALL COMPONENT BOARD ASSEMBLY 256809 Voltages . . . . . . . . . . . . . 44

Voltage Specifications - General Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Power, Illumination, and Cooling Malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . 45

Slide Transport Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Focus Malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SM5440-1 – 18NOV97 3

Page 4

SERVICE MANUAL

Section 1: Replacements and Installations

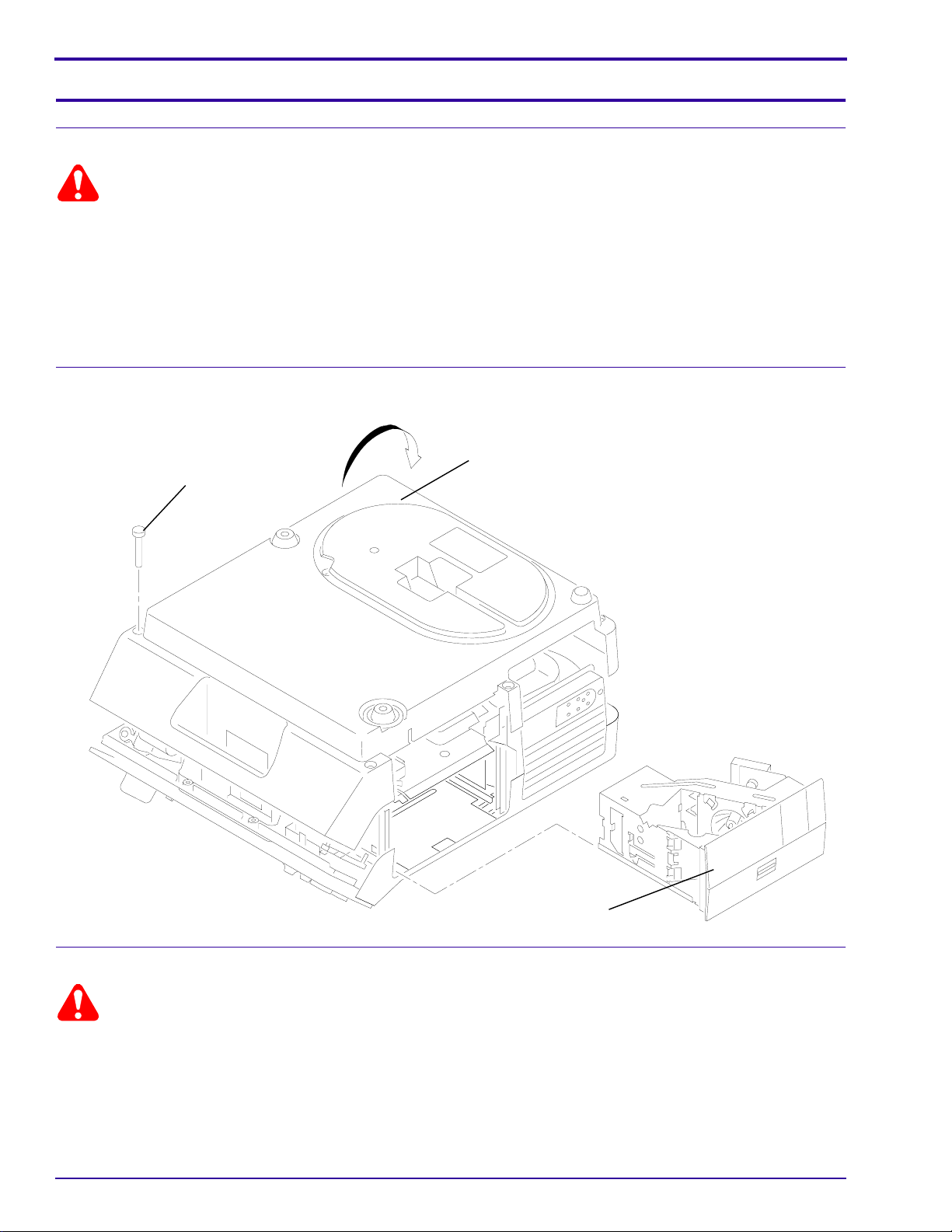

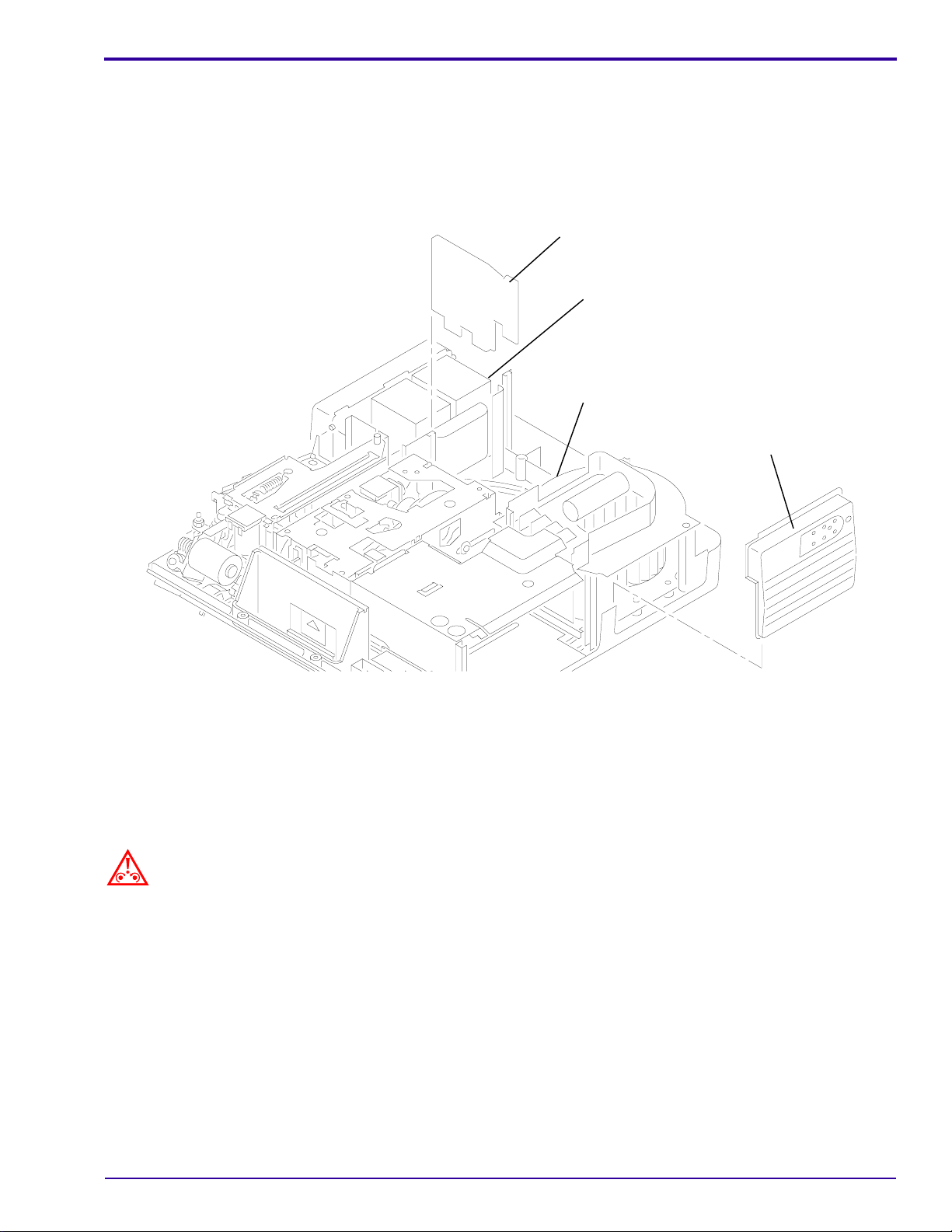

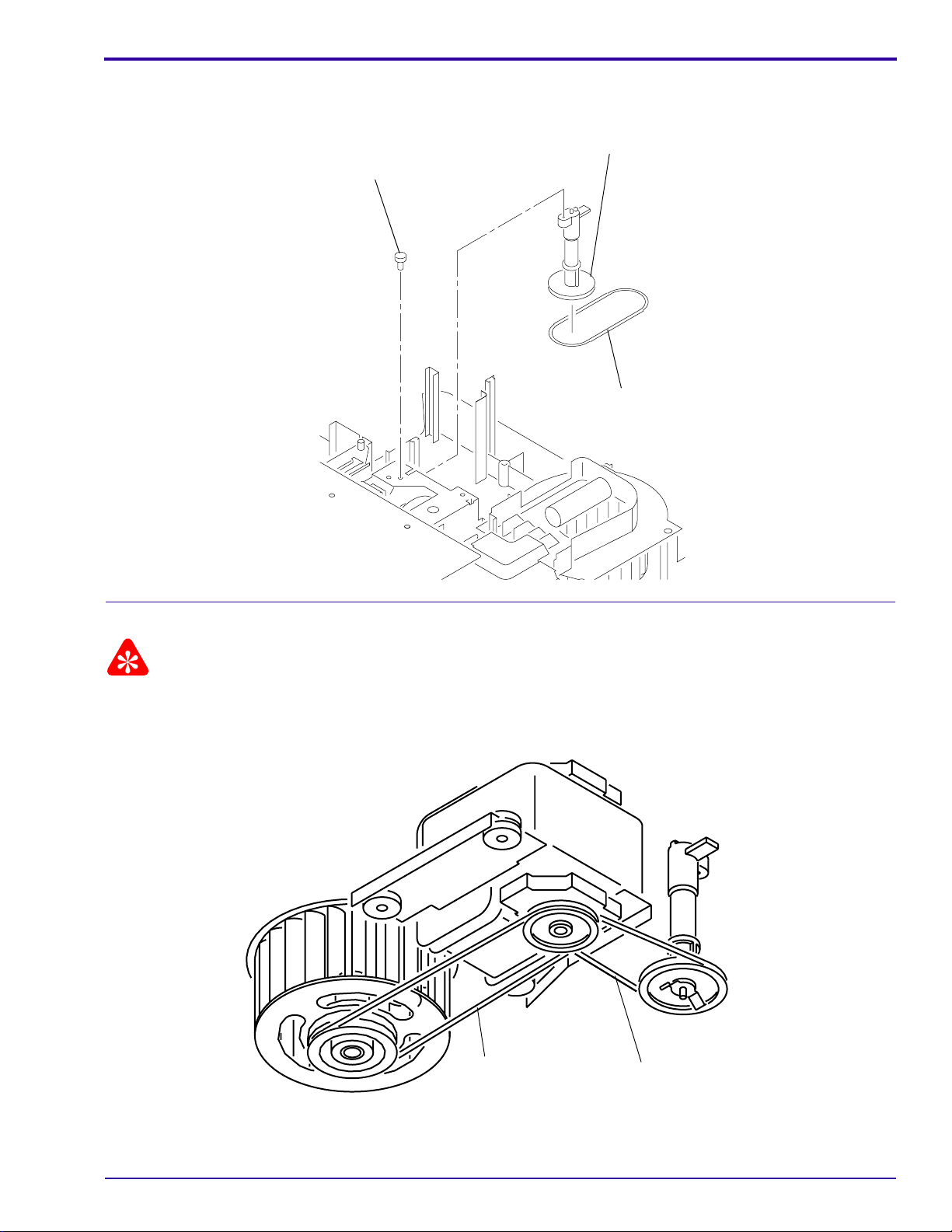

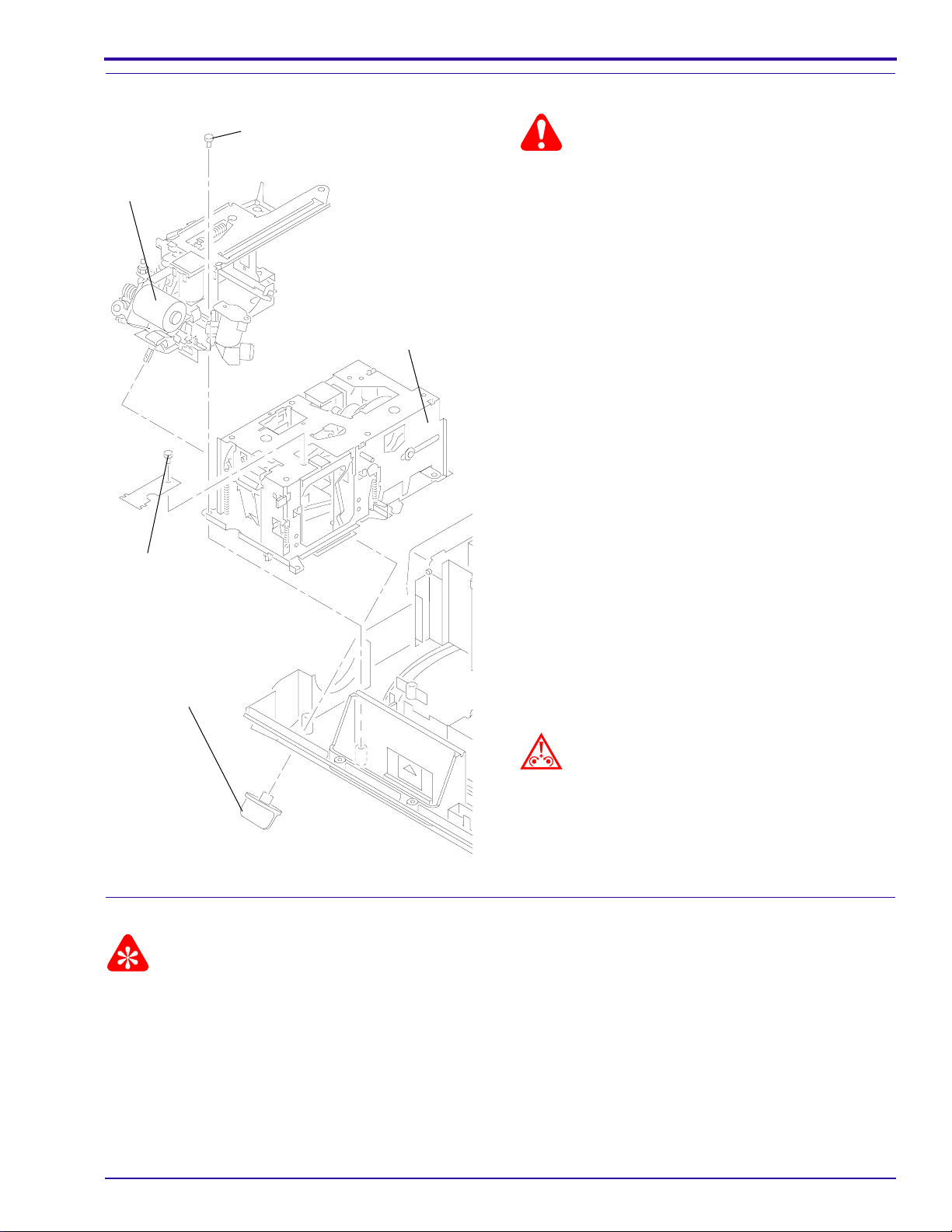

Replacing the LOWER HOUSING ASSEMBLY

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Remove the PROJECTION LENS.

[3] Remove the LAMP MODULE ASSEMBLY.

[4] Remove the 6

[5] Pull the LOWER HOUSING ASSEMBLY off the TOP HOUSING.

Installing the LOWER HOUSING ASSEMBLY

[1] Do the replacement procedure for the LOWER HOUSING ASSEMBLY in reverse order.

Torx

SCREWS from the LOWER HOUSING ASSEMBLY.

LOWER HOUSING

SCREW (6)

A100_0030HCA

A100_0030HA

LAMP MODULE

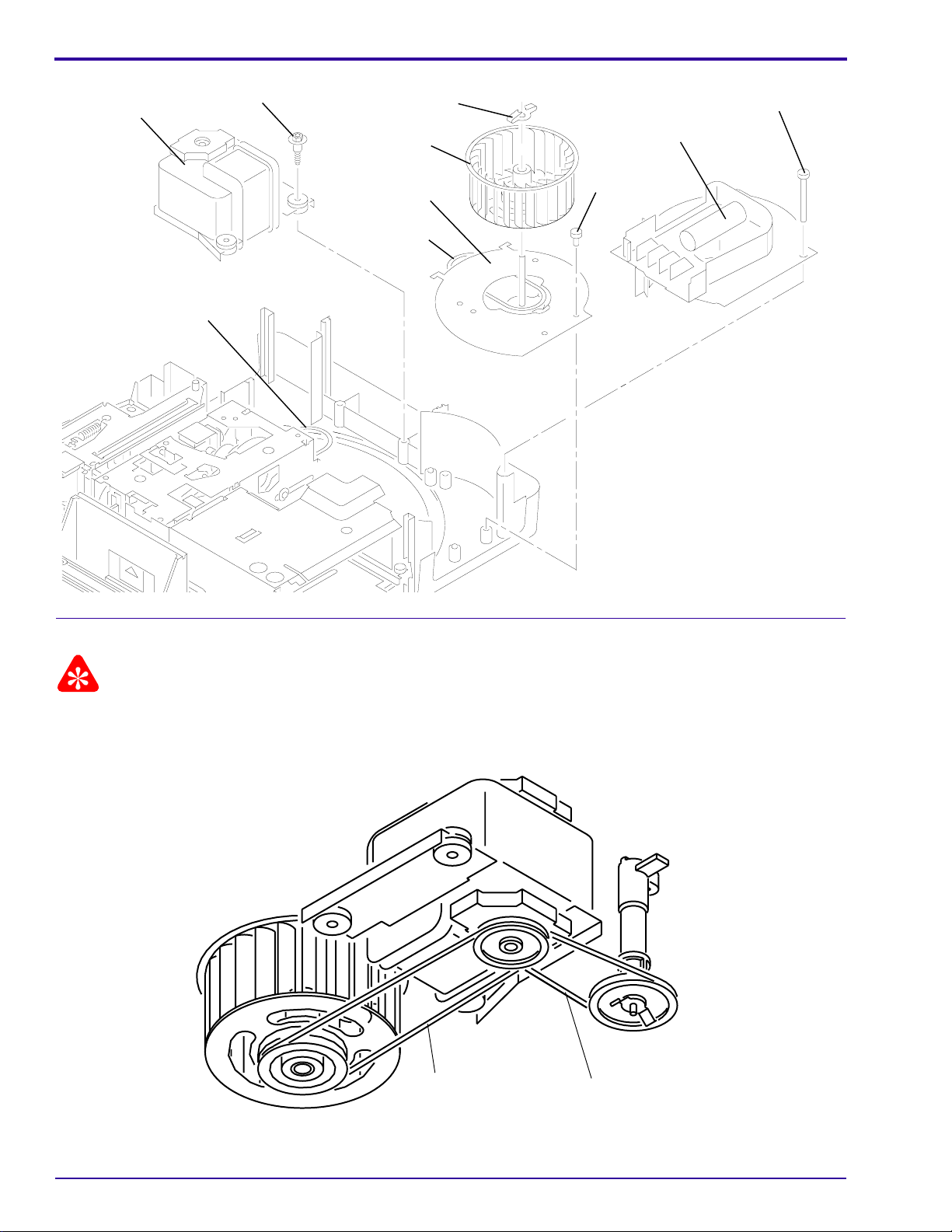

Replacing the FAN SHAFT ASSEMBLY

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER HOUSING ASSEMBLY.

[3] Cut the 3 WIRE TIES:

• 1 on BLOWER COVER wires

• 2 on SMALL CIRCUIT BOARD between the MOTOR and MECHANISM ASSEMBLY

4 18NOV97 – SM5440-1

Page 5

Replacements and Installations

[4] Disconnect the 2 wires from the CYCLE SOLENOID on the SMALL CIRCUIT BOARD.

[5] Pull the SMALL CIRCUIT BOARD up.

[6] Remove the

Torx

SCREW from the BLOWER COVER ASSEMBLY.

[7] Lift the GRILLE ASSEMBLY in front of the BLOWER COVER ASSEMBLY up.

[8] Loosen the

Torx

SCREW on the right track of the LOWER LIGHT BAFFLE ASSEMBLY appoximately half way.

[9] Lift the LOWER LIGHT BAFFLE ASSEMBLY off the TAB on the BLOWER COVER ASSEMBLY.

WIRE TIE (not shown)

KK models

BLOWER COVER WIRE TIE

GRILLE ASSEMBLY

A100_0031HCA

A100_0031HA

[10] Remove the 2 long

Torx

SCREWS from the BLOWER COVER ASSEMBLY.

[11] Lift the BLOWER COVER ASSEMBLY up.

[12] Remove the 3

Hex

1/4 in. SCREWS from the MOTOR.

[13] Lift the MOTOR until you observe the FAN BELT and MECHANISM BELT.

[14] Remove the FAN BELT and MECHANISM BELT off the MOTOR PULLEY. Use SPRING HOOK TL-1165.

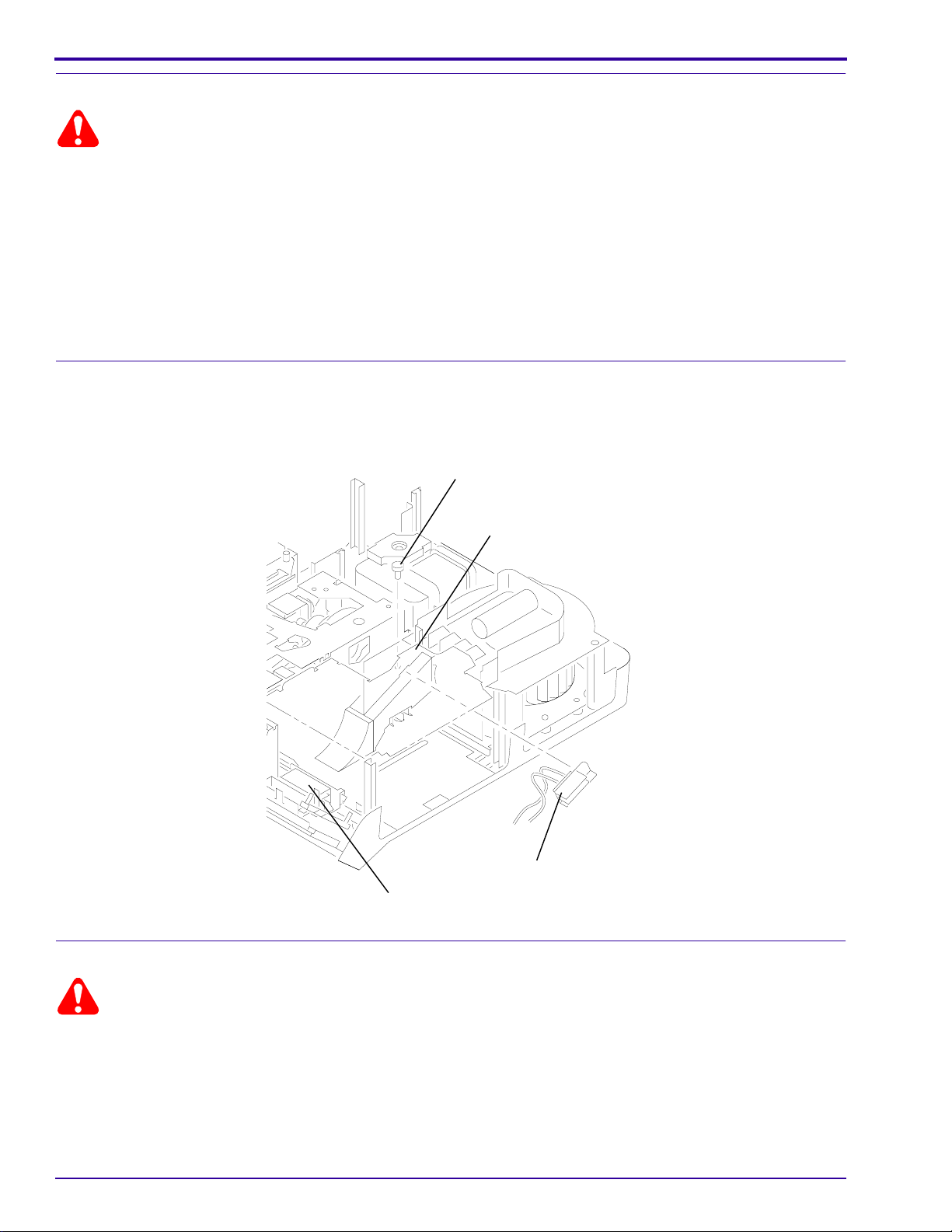

Caution

Move the MOTOR to allow access to the parts; wires are still connected to the MOTOR. Do not cause damage to

the MOTOR wires.

[15] Remove the RETAINER CLIP from the FAN SHAFT.

[16] Pull the FAN up and off the FAN SHAFT to allow access to the FAN BELT.

[17] Remove the FAN BELT.

[18] Remove the 3

Torx

SCREWS from the FAN SHAFT ASSEMBLY.

SM5440-1 – 18NOV97 5

Page 6

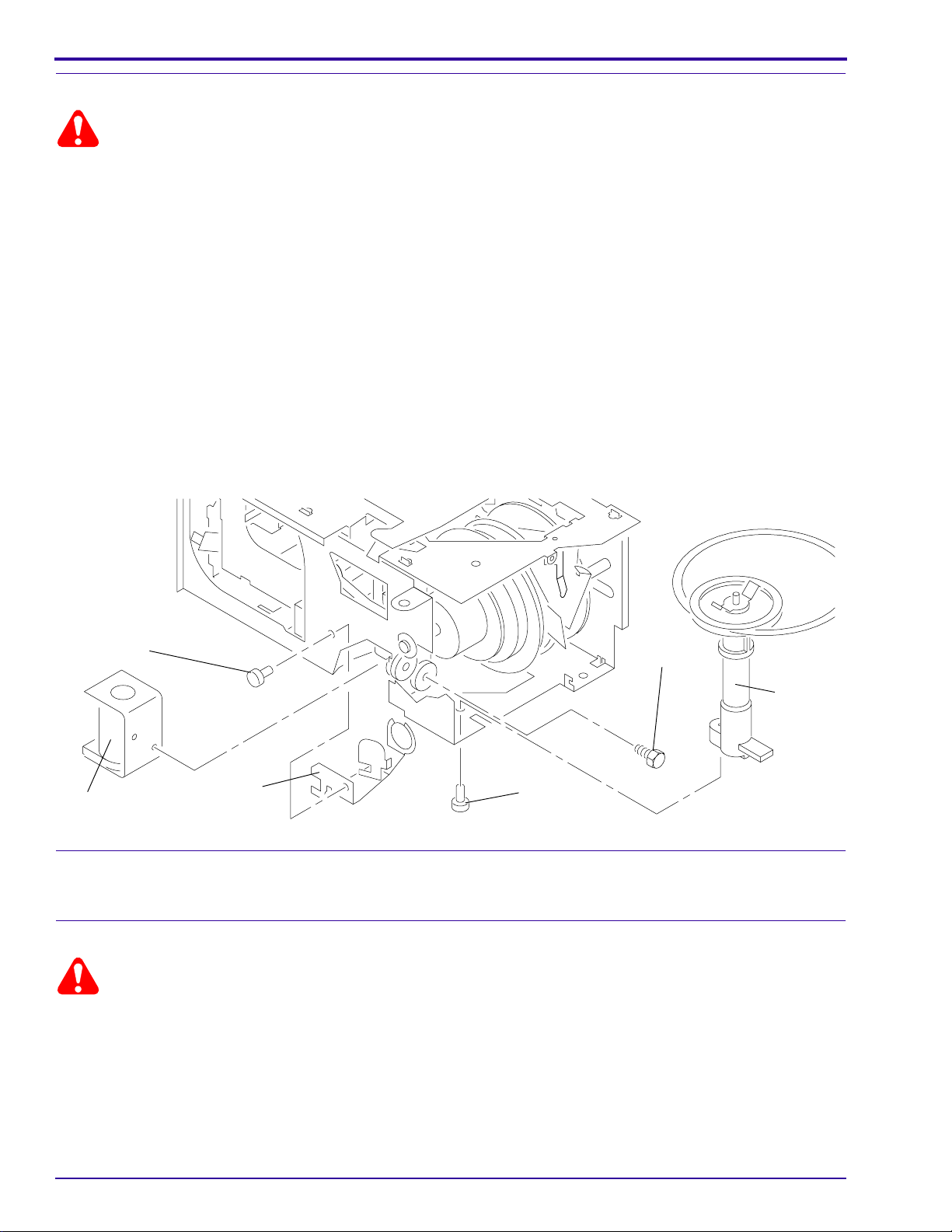

SERVICE MANUAL

[19] Lift and remove the FAN SHAFT ASSEMBLY.

MOTOR

SCREW

RETAINER CLIP

FAN

SCREW (2)

BLOWER ASSEMBLY

MECHANISM BELT

FAN PLATE

ASS4EMBLY

FAN BELT

SCREW (3)

A100_0014HCA

A100_0014HA

Installing the FAN SHAFT ASSEMBLY

Important

When installing the FAN and MECHANISM BELTS, install the MECHANISM BELT on the small MOTOR PULLEY,

and the FAN BELT on the large MOTOR PULLEY.

[1] Do the removal procedure for the FAN BELT and SHAFT in reverse order.

FAN BELT

6 18NOV97 – SM5440-1

MECHANISM BELT

A091_4015BCA

A091_4015BA

Page 7

Replacements and Installations

A091_4016GA

MOTOR

SCREW (3)

A091_4016GCA

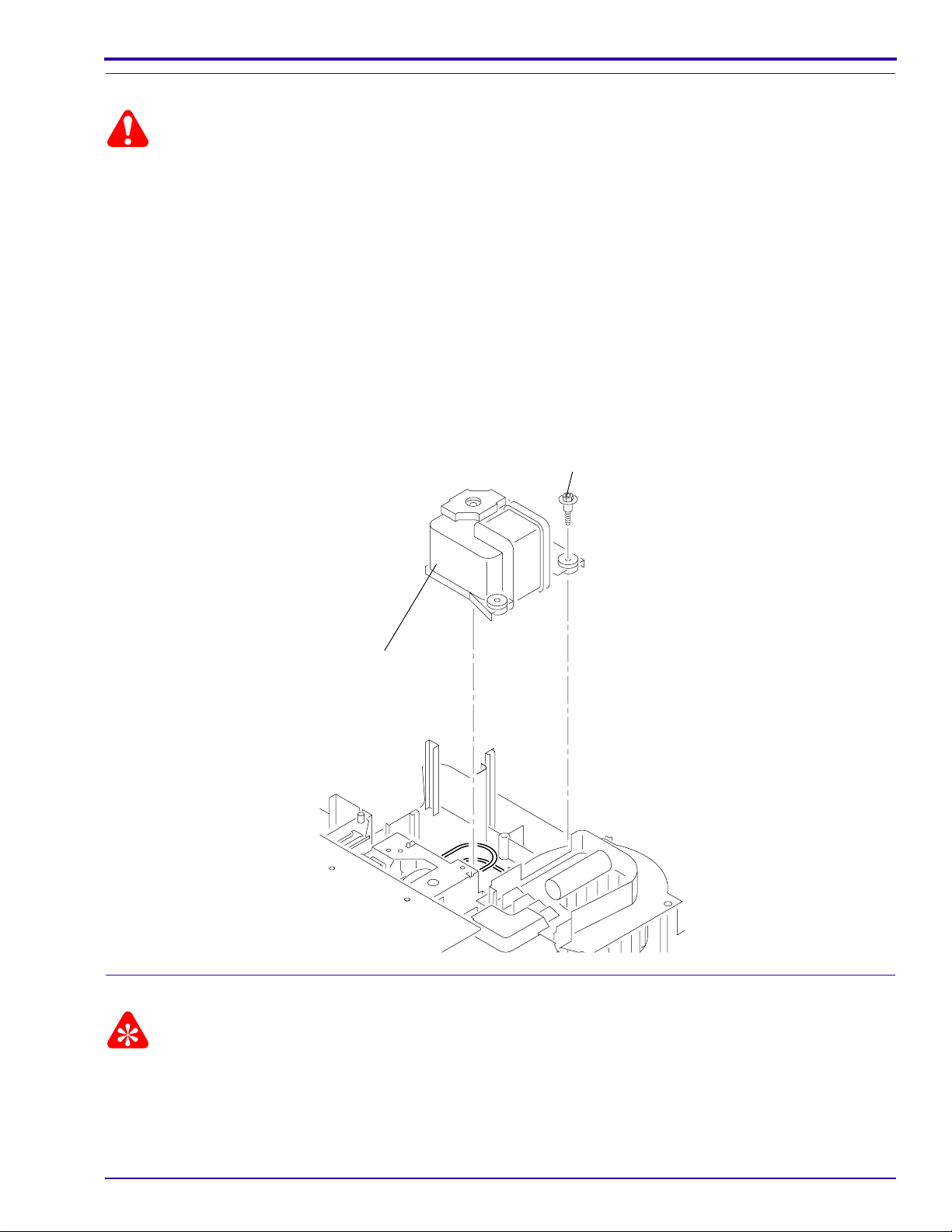

Replacing the MOTOR

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER HOUSING ASSEMBLY.

[3] Disconnect all wires from the MOTOR.

[4] Cut the 2 WIRE TIES on the SMALL CIRCUIT BOARD between the MOTOR and MECHANISM ASSEMBLY.

[5] Disconnect the 2 wires from the CYCLE SOLENOID on the SMALL CIRCUIT BOARD.

[6] Pull the SMALL CIRCUIT BOARD up.

[7] Disconnect all wires on the MOTOR.

[8] Remove 3

[9] Lift the MOTOR up to allow access to the FAN and MECHANISM BELTS.

[10] Remove the FAN and MECHANISM BELTS from the MOTOR PULLEY.

[11] Remove the MOTOR.

Hex

1/4 in. SCREWS from the MOTOR.

Installing the MOTOR

Important

When installing the FAN and MECHANISM BELTS, install the MECHANISM BELT on the small MOTOR PULLEY,

and the FAN BELT on the large MOTOR PULLEY.

[1] Do the replacement procedure for the MOTOR in reverse order.

SM5440-1 – 18NOV97 7

Page 8

SERVICE MANUAL

FAN BELT

MECHANISM BELT

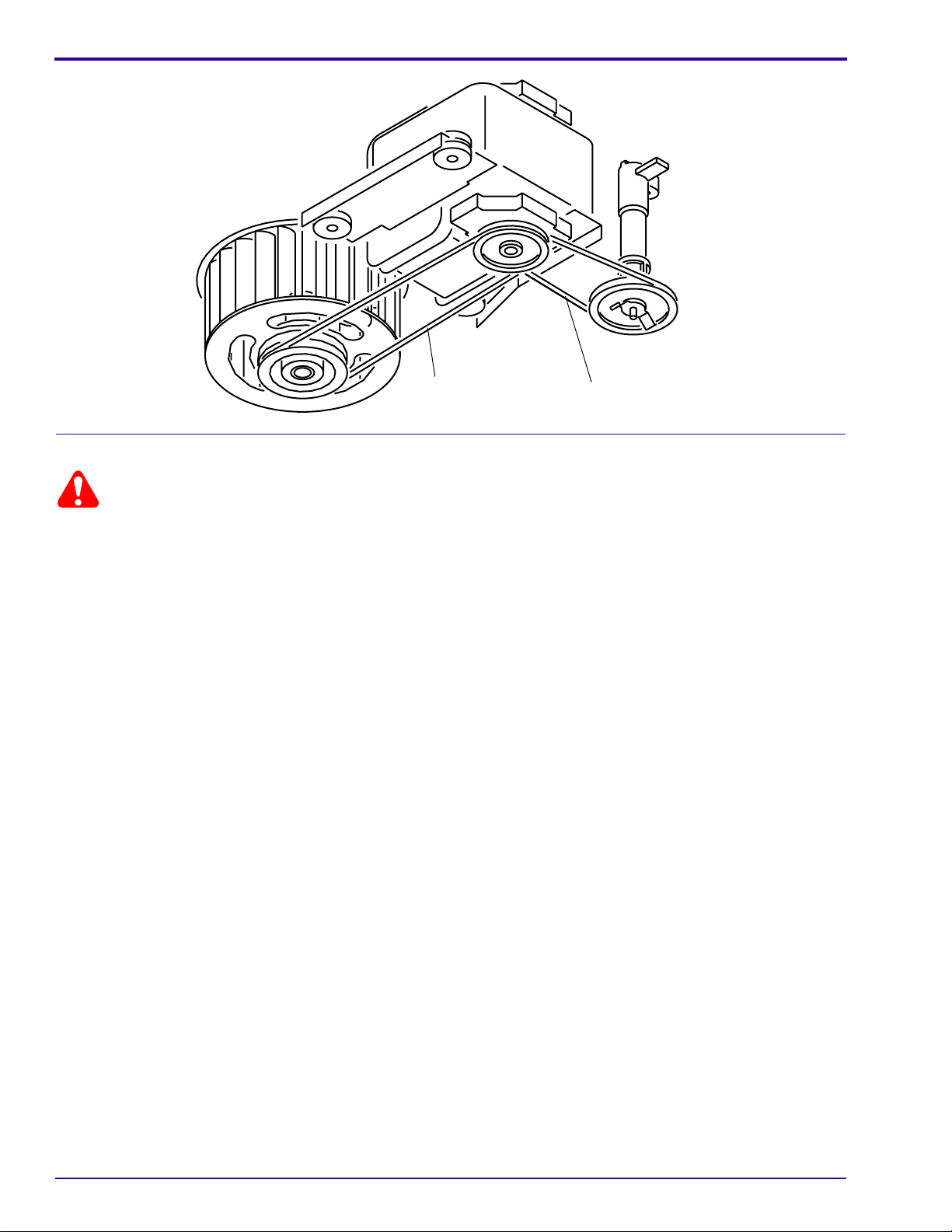

Replacing the WORM PULLEY and MECHANISM BELT

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER HOUSING ASSEMBLY.

[3] Do the replacement procedure for the MOTOR except do not disconnect the wires from the MOTOR.

[4] Remove the

[5] Move the TAB on the WORM PULLEY ASSEMBLY out.

[6] Remove the WORM PULLEY ASSEMBLY and MECHANISM BELT.

Torx

SCREW from the WORM PULLEY ASSEMBLY.

A091_4015BCA

A091_4015BA

8 18NOV97 – SM5440-1

Page 9

Replacements and Installations

A091_4017GA

WORM PULLEY

BELT

MECHANISM

A091_4017GCA

SCREW

Installing the WORM PULLEY and MECHANISM BELT

Important

When installing the FAN and MECHANISM BELTS, install the MECHANISM BELT on the small MOTOR PULLEY,

and the FAN BELT on the large MOTOR PULLEY.

[1] Do the replacement procedure for the WORM PULLEY and MECHANISM BELT in reverse order.

FAN BELT

MECHANISM BELT

A091_4015BCA

A091_4015BA

SM5440-1 – 18NOV97 9

Page 10

SERVICE MANUAL

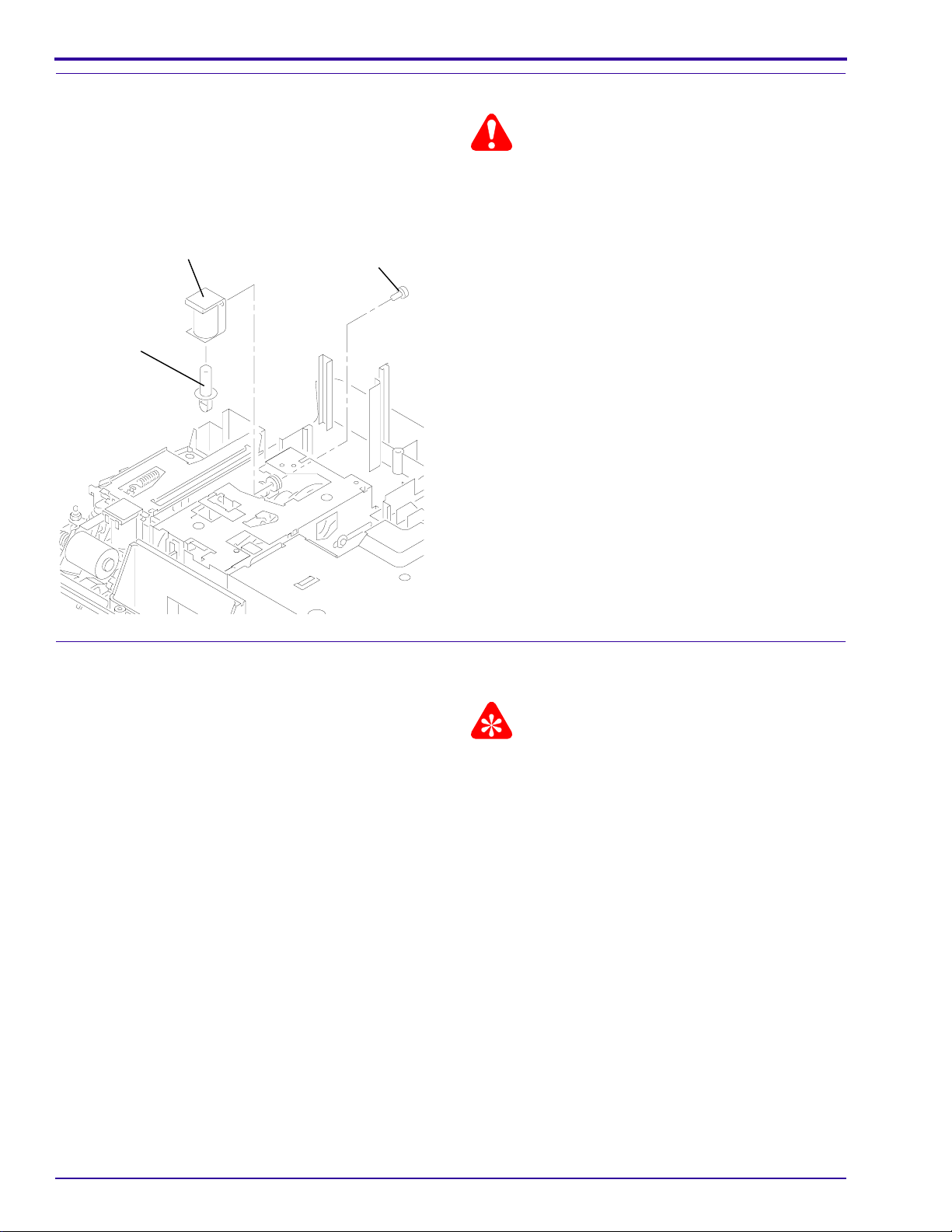

Replacing the THERMAL FUSE ASSEMBLY

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER HOUSING ASSEMBLY.

[3] Cut and remove the necessary WIRE TIES.

[4] Remove the black wire from the THERMAL FUSE ASSEMBLY on the POWER SWITCH.

[5] Remove the gray wire from the THERMAL FUSE ASSEMBLY from the POWER CORD.

[6] Loosen the

[7] Pull the THERMAL FUSE ASSEMBLY out of hole of the LOWER LIGHT BAFFLE ASSEMBLY.

Torx

SCREW on the PREHEAT DUCT approximately half way.

Installing the THERMAL FUSE ASSEMBLY

[1] Do the replacement procedure for the THERMAL FUSE ASSEMBLY in reverse order.

SCREW

A100_0015GCA

A100_0015GA

POWER SWITCH

Replacing the LAMP MODULE RECEPTACLE

PRE-HEAT DUCT

THERMAL FUSE

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER HOUSING ASSEMBLY.

[3] Cut and remove the necessary WIRE TIES.

[4] Remove the 2

[5] Loosen the

10 18NOV97 – SM5440-1

Torx

SCREWS on the left side of the LOWER LIGHT BAFFLE ASSEMBLY.

Torx

SCREW on the right side of the LOWER LIGHT BAFFLE ASSEMBLY approximately 1/2 way.

Page 11

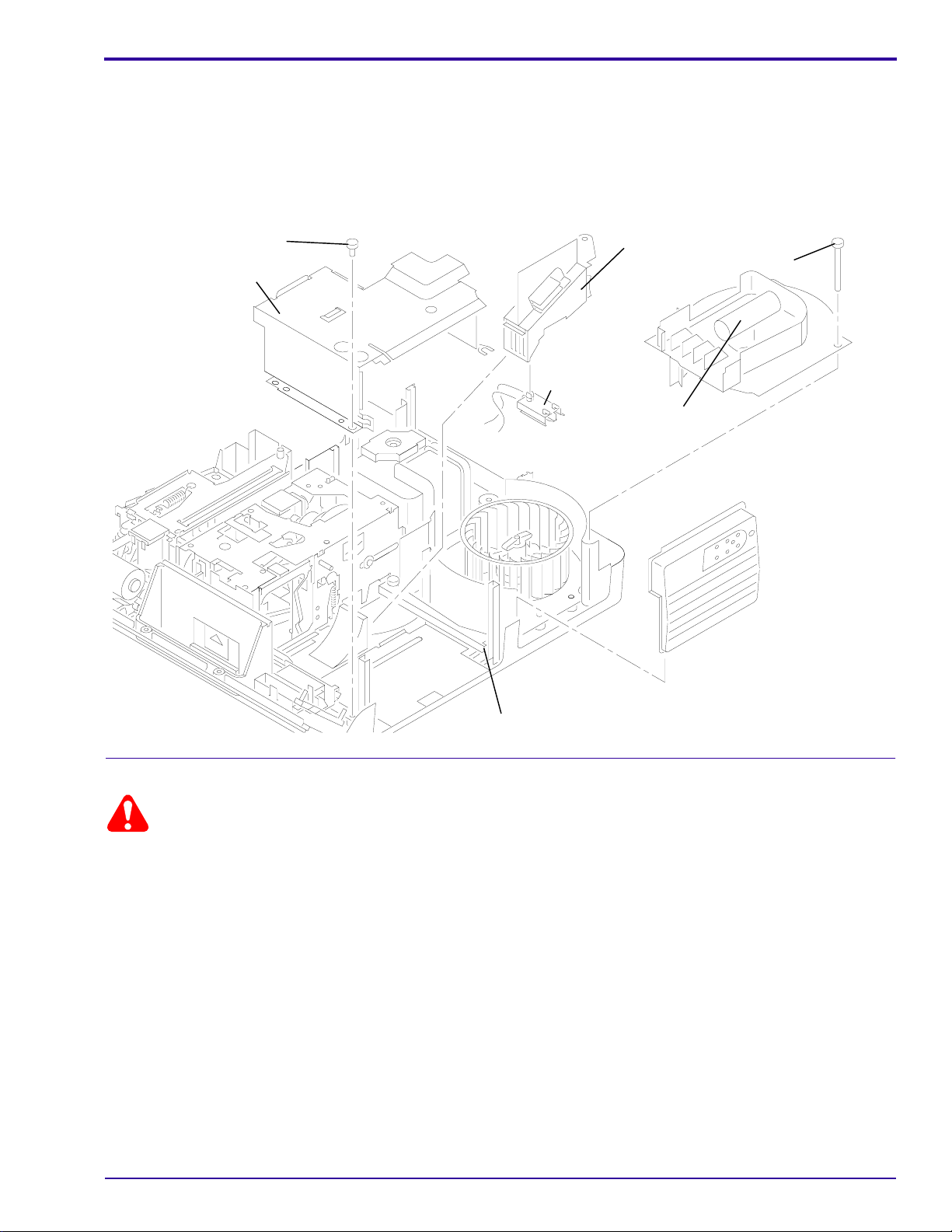

Replacements and Installations

[6] Lift and remove the LOWER LIGHT BAFFLE ASSEMBLY.

[7] Lift the GRILLE ASSEMBLY up.

[8] Remove the 2 long

Torx

from the BLOWER COVER ASSEMBLY.

[9] Lift the BLOWER COVER ASSEMBLY up.

[10] Lift and move the PREHEAT DUCT up.

[11] To remove the LAMP MODULE RECEPTACLE from thePREHEAT DUCT, compressthe 2 TABS on the LAMP

MODULE RECEPTACLE.

SCREW (2)

LOWER LIGHT BAFFLE

LAMP MODULE

RECEPTACLE

PRE-HEAT DUCT

SCREW (2)

BLOWER COVER

ASSEMBLY

A100_0032HCA

A100_0032HA

SCREW (not shown)

Installing the LAMP MODULE RECEPTACLE

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the LAMP MODULE RECEPTACLE in reverse order.

SM5440-1 – 18NOV97 11

Page 12

SERVICE MANUAL

Replacing the CYCLE SOLENOID ASSEMBLY

CYCLE SOLENOID

CYCLE

SOLENOID

PLUNGER

SCREW (2)

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedures for the LOWER

HOUSING ASSEMBLY and the MOTOR.

[3] Cut and remove the necessary WIRE TIES.

[4] Disconnect the 2 wires from the CYCLE

SOLENOID on the SMALL CIRCUIT BOARD.

[5] Pull the SMALL CIRCUIT BOARD up.

[6] Remove the

PULLEY SHAFT.

[7] Move the TAB on the WORM PULLEY

ASSEMBLY out of the MECHANISM ASSEMBLY.

[8] Lift andremove the WORM PULLEY ASSEMBLY.

[9] Remove the 2

CYCLE SOLENOID GROMMETS.

[10] Pull the CYCLE SOLENOID ASSEMBLY up and

out.

[11] If necessary, remove the CYCLE SOLENOID

PLUNGER ASSEMBLY.

Torx

SCREW from the WORM

Hex

1/4 in. SCREWS from the 2

A100_0017GCA

A100_0017GA

Installing the CYCLE SOLENOID ASSEMBLY

Important

Do the adjustment for the CYCLE SOLENOID

ASSEMBLY. See the Adjustments section.

[1] Do the replacement procedure for the CYCLE

SOLENOID ASSEMBLY in reverse order.

12 18NOV97 – SM5440-1

Page 13

Replacing the MECHANISM ASSEMBLY

Replacements and Installations

LENS

MOUNT

SCREW

FOCUS KNOB

SCREW (3)

MECHANISM

ASSEMBLY

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER

HOUSING ASSEMBLY.

[3] Cut and remove the necessary WIRE TIES.

[4] Disconnect the 2 wires from the CYCLE

SOLENOID on the SMALL CIRCUIT BOARD.

[5] Pull the SMALL CIRCUIT BOARD up.

[6] Disconnect all wires connected to the

MECHANISM ASSEMBLY:

• 1 yellow wire from CYCLE SWITCH

• 1 orange wire from WIRE NUT

• 1 green wire from POWER CORD

• 2 green ground wires from the lower

MECHANISM ASSEMBLY

[7] Remove the FOCUS KNOB from the FRONT

PANEL.

[8] Remove the 3

MOUNT ASSEMBLY.

[9] Lift and move the LENS MOUNT ASSEMBLY up.

[10] Do the replacement procedure for the MOTOR.

[11] Remove the 3

MECHANISM ASSEMBLY.

[12] Loosen the SCREW on the STABILIZER WALL

approximately half way.

Torx

SCREWS from the LENS

Torx

SCREWS from the

Caution

There might be a bind between the SELECT LEVER

and the SELECT BUTTON when removing the

MECHANISM ASSEMBLY. Do not use force; this

A091_4047CCA

A091_4047CA

might cause damage to the SELECT BUTTON.

[13] Remove the MECHANISM ASSEMBLY.

Installing the MECHANISM ASSEMBLY

Important

To insert the SELECTBUTTON into the holein the SELECT LEVERwhen installing the MECHANISM ASSEMBLY,

hold the SELECT BUTTON completely down.

[1] Do the removal procedure for the MECHANISM ASSEMBLY in reverse order.

SM5440-1 – 18NOV97 13

Page 14

SERVICE MANUAL

Replacing the AUTO-FOCUS BRACKET ASSEMBLY

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER HOUSING ASSEMBLY.

[3] Cut and remove the necessary WIRE TIES.

[4] Disconnect the 2 wires from the CYCLE SOLENOID on the SMALL CIRCUIT BOARD.

[5] Pull the SMALL CIRCUIT BOARD up.

[6] Do the replacement procedure for the MECHANISM ASSEMBLY.

[7] Remove the

[8] Remove the WORM PULLEY.

[9] Remove the 2

[10] Remove the CYCLE SOLENOID.

[11] Remove the

[12] Pull and remove the AUTO-FOCUS BRACKET ASSEMBLY through the hole where the CYCLE SOLENOID

was.

Torx

SCREW from the WORM PULLEY.

Hex

SCREWS from the CYCLE SOLENOID.

Phillips

SCREW from the AUTO-FOCUS BRACKET ASSEMBLY.

SCREW

CYCLE

SOLENOID

AUTO

FOCUS

BRACKET

ASSEMBLY

SCREW

SCREW (2)

Installing the AUTO-FOCUS BRACKET ASSEMBLY

[1] Do the replacement procedure for the AUTO-FOCUS BRACKET ASSEMBLY in reverse order.

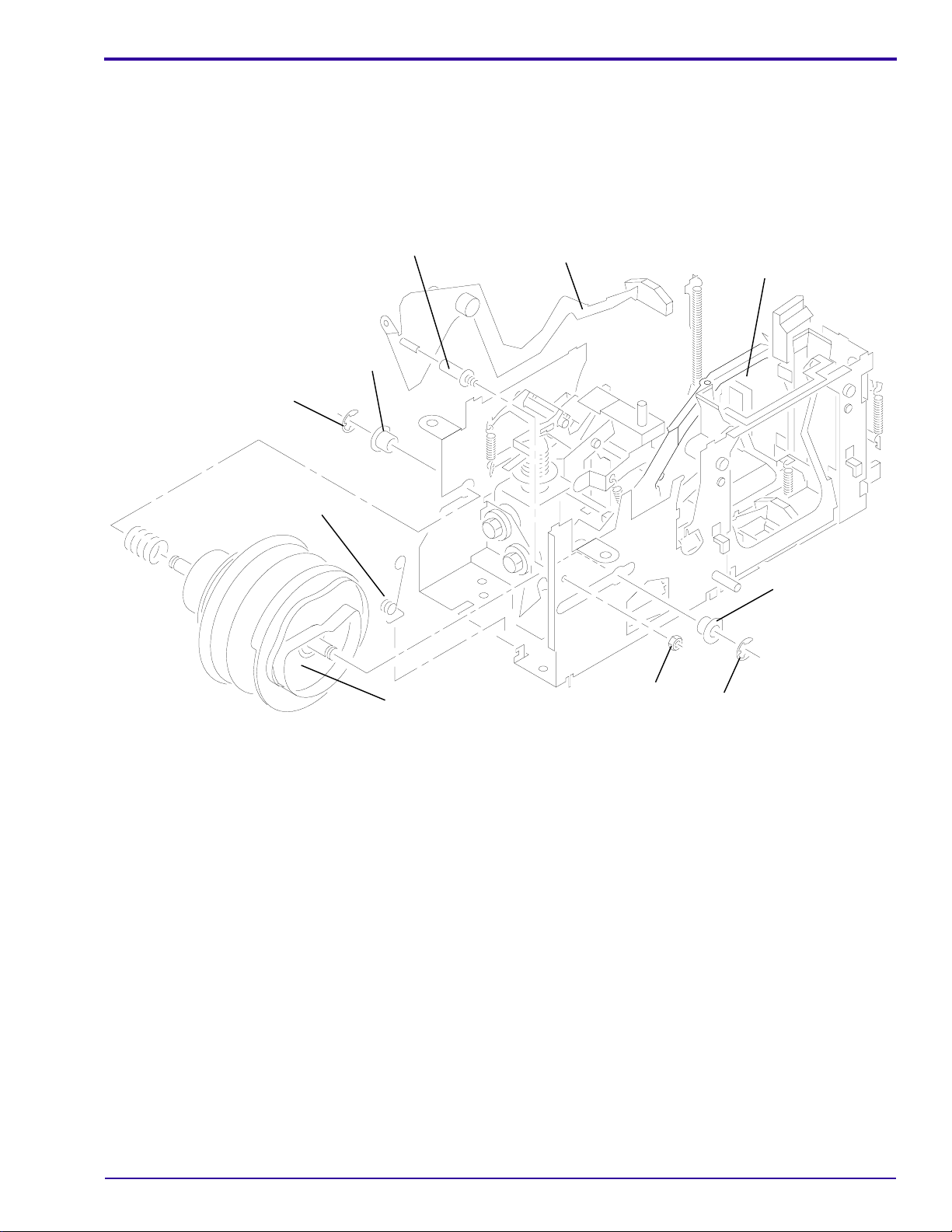

Replacing the CAM STACK ASSEMBLY and CYCLE LEVER ASSEMBLY

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the MECHANISM ASSEMBLY.

[3] Remove the INDEXER LEVER ASSEMBLY from the TOP PLATE of the MECHANISM ASSEMBLY.

[4] Remove the

[5] Remove the WORM PULLEY ASSEMBLY.

[6] Remove the DIRECTION LEVER LINK from the DIRECTION LEVER.

Torx

SCREW from the WORM PULLEY ASSEMBLY.

WORM

PULLEY

A091_4023BCA

A091_4023BA

14 18NOV97 – SM5440-1

Page 15

Replacements and Installations

[7] Remove the DIRECTION LEVER SPRING from the DIRECTION LEVER.

[8] Disconnect the LIFT LEVER SPRING from LIFT LEVER on the TOP PLATE of the MECHANISM ASSEMBLY.

[9] Remove the RETARD SPRING.

[10] Remove the 7

Torx

SCREWS from the TOP PLATE of the MECHANISM ASSEMBLY.

[11] Remove the TOP PLATE.

[12] Remove the LIGHT BAFFLE.

A100_0018HCA

A100_0018HA

E-RING

RETARD

SPRING

LIFT LEVER SHAFT

BEARING

CAM STACK ASSEMBLY

LIFT LEVER

NUT

E-RING

SELECT LEVER

(not shown)

[13] Remove the NUT from the LIFT LEVER SHAFT.

[14] Remove the LIFT LEVER and SHAFT.

[15] Remove the 2 E-RINGS from the 2 CAM SHAFT BEARINGS.

[16] Remove the 2 CAM SHAFT BEARINGS.

[17] Press and hold the SELECT LEVER down.

[18] Remove the CAM STACK ASSEMBLY.

[19] Disconnect the SELECT LEVER SPRING from the TAB and remove the SELECT LEVER.

BEARING

SM5440-1 – 18NOV97 15

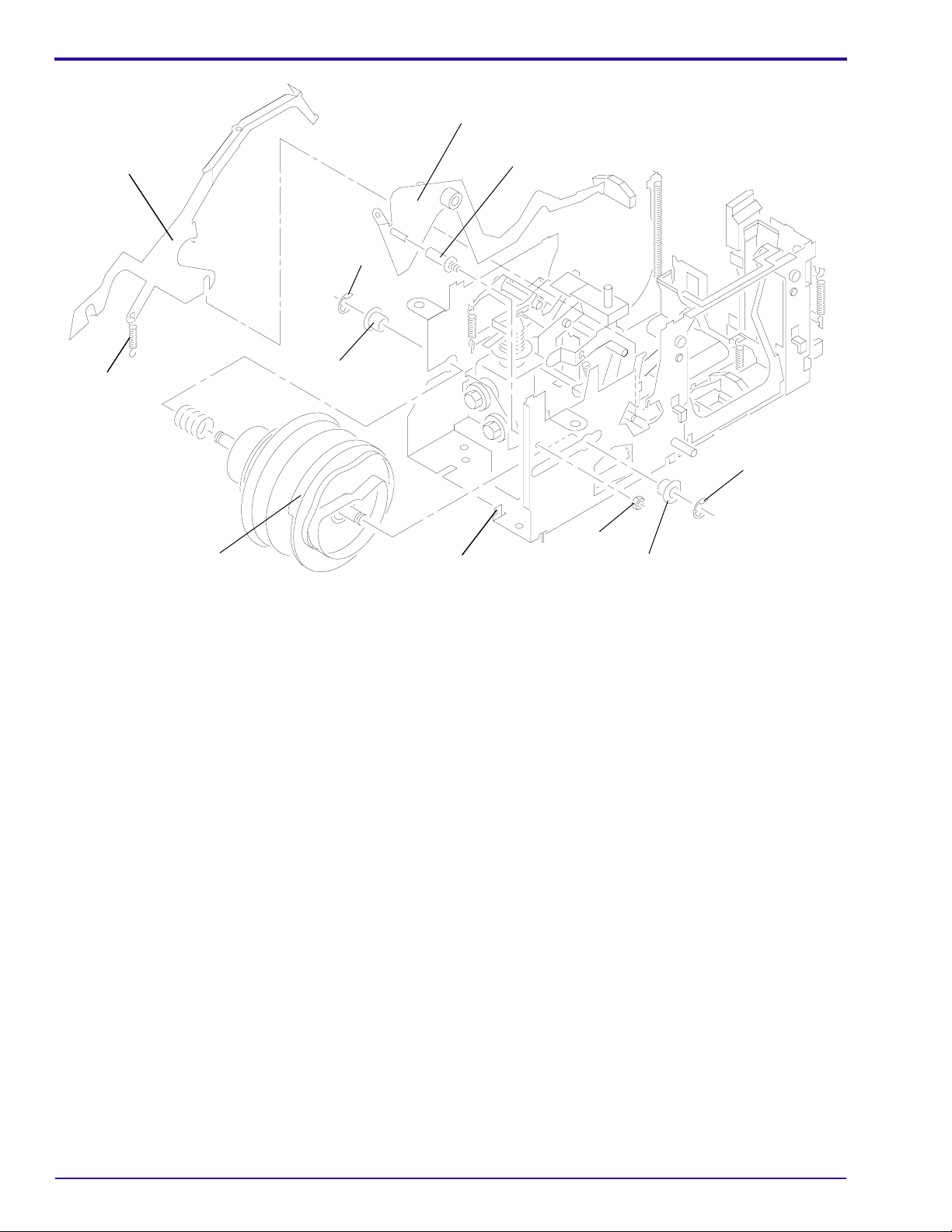

Page 16

SERVICE MANUAL

LIFT

LEVER

SELECT LEVER

SELECT LEVER

SPRING

CAM STACK

ASSEMBLY

E-RING

BEARING

LIFT LEVER SHAFT

TAB

NUT

BEARING

E-RING

A091_0010HCA

A091_0010HA

16 18NOV97 – SM5440-1

Page 17

HALF-CYCLE

LEVER SPRING

CYCLE

LEVER

PLUNGER

SPRING

HALF-CYCLE

LEVER

PLUNGER

E-RING (2)

Replacements and Installations

[20] Remove the 2 SCREWS from the CYCLE

SOLENOID.

[21] Remove the CYCLE SOLENOID.

[22] Slide the PLUNGER and PLUNGER SPRING off

the CYCLE LEVER.

[23] Remove the HALF CYCLE SPRING between the

CYCLE LEVER ASSEMBLY and the HALF

CYCLE LEVER.

[24] Disconnect the INDEX LEVER SPRING from the

MECHANISM ASSEMBLY.

[25] Push the INDEX LEVER back.

[26] Remove the 2 E-RINGS:

• 1 on the CYCLE LEVER ASSEMBLY

• 1 on the HALF CYCLE LEVER

Caution

Keep both the CYCLE LEVER ASSEMBLY and the

HALF CYCLE LEVER together and observe the

orientation of both LEVERS.

[27] Slide both the CYCLE LEVER and HALF CYCLE

LEVER off the SHAFT.

CYCLE

SOLENOID

SCREW (2)

INDEX LEVER

and SPRING

(not shown)

A091_0009CCA

A091_0009CA

Installing the CAM STACK ASSEMBLY and CYCLE LEVER ASSEMBLY

Caution

Keep both the CYCLE LEVER ASSEMBLY and the

HALF CYCLE LEVER together and observe the

orientation of both LEVERS.

[1] Do the replacement procedure for the CAM

STACK ASSEMBLY and CYCLE LEVER

ASSEMBLY in reverse order.

SM5440-1 – 18NOV97 17

Page 18

SERVICE MANUAL

Replacing the LAMP SOCKET TERMINAL ASSEMBLY

Style 1 LAMP SOCKET TERMINAL ASSEMBLY

SCREW

LAMP DOOR

PLATE ASSEMBLY

PROJECTOR

LAMP

LAMP

EJECTOR

LAMP SOCKET

TERMINAL

ASSEMBLY

Warning

Dangerous Voltage

[1] Disconnect the main power.

Important

The EXTRA BRIGHT LAMP MODULEdoes nothave a

HEAT ABSORBING GLASS and has a LABEL on the

LAMP DOOR.

[2] Remove the LAMP MODULE.

[3] Remove the PROJECTIONLAMP from the LAMP

MODULE.

[4] Remove the SCREW from the LAMP DOOR

PLATE ASSEMBLY.

[5] Release the 2 TABS on the bottom side of the

LAMP MODULE next to the LAMP MODULE

DOOR.

[6] Remove the LAMP DOOR PLATE ASSEMBLY.

Caution

Remove the CONDENSER LENS and HEAT

ABSORBING GLASS and set the parts on a clean

cloth. Do not set on a cold surface; this will cause

damage to the parts.

[7] Remove the LAMP EJECTOR.

[8] Remove the LAMP SOCKET TERMINAL

ASSEMBLY.

CONDENSER

LENS

TAB (2)

HEAT ABSORBING

GLASS

A091_0018CCA

A091_0018CA

Installing the LAMP SOCKET TERMINAL ASSEMBLY

[1] Do the replacement procedure for the LAMP SOCKET TERMINAL ASSEMBLY in reverse order.

18 18NOV97 – SM5440-1

Page 19

Replacing the LENS MOUNT ASSEMBLY - Auto Focus Model

SCREW (3)

LENS MOUNT

ASSEMBLY

Dangerous Voltage

It is necessary to push the AUTO-FOCUS BRACKET

backward and forward to allowaccess tothe SCREWS

on the LENS MOUNT ASSEMBLY.

Warning

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER

HOUSING ASSEMBLY.

[3] Remove the FOCUS KNOB.

Important

[4] Remove the 3 SCREWS from the LENS MOUNT

ASSEMBLY.

[5] Lift and remove the LENS MOUNT ASSEMBLY.

Replacements and Installations

A100_0019GCA

A100_0019GA

Installing the LENS MOUNT ASSEMBLY - Auto Focus Models

[1] Do the replacement procedure for the LENS MOUNT ASSEMBLY in reverse order.

SM5440-1 – 18NOV97 19

Page 20

SERVICE MANUAL

Replacing the LENS MOUNT ASSEMBLY - Non Auto Focus Model

SCREW (3)

LENS MOUNT

ASSEMBLY

Dangerous Voltage

Warning

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER

HOUSING ASSEMBLY.

[3] Remove the FOCUS KNOB.

[4] Remove the 3 SCREWS from the LENS MOUNT

ASSEMBLY.

[5] Lift and remove the LENS MOUNT ASSEMBLY.

A100_0019GCA

A100_0019GA

Installing the LENS MOUNT ASSEMBLY - Non Auto Focus Model

[1] Do the replacement procedure for the LENS MOUNT ASSEMBLY in reverse order.

20 18NOV97 – SM5440-1

Page 21

Replacing the AUTO-FOCUS SWITCH ASSEMBLY

Replacements and Installations

AUTO FOCUS

MOTOR BRACKET

LOCKING

TAB

AUTO FOCUS

SWITCH LEVER

AUTO FOCUS SWITCH ASSEMBLY

grey, red,

and black

wires

A091_4028GCA

A091_4028GA

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER

HOUSING ASSEMBLY.

[3] Remove the FOCUS KNOB.

[4] Remove the short, gray wire from the AUTO-

FOCUS DEFEAT SWITCH.

Important

It is necessary to push the AUTO-FOCUS BRACKET

backward and forward to allowaccess tothe SCREWS

on the LENS MOUNT ASSEMBLY.

[5] Remove the 3 SCREWS from the LENS MOUNT

ASSEMBLY.

[6] Lift and remove the LENS MOUNT ASSEMBLY.

[7] Remove the gray, red, and black wires from the

AUTO FOCUS SWITCH ASSEMBLY.

Important

Keep the AUTO-FOCUS SWITCH LEVER that is

connected to the AUTO FOCUS SWITCH so you can

install it on the new AUTO FOCUS SWITCH.

[8] To disconnect and remove the AUTO FOCUS

SWITCH,bendthe LOCKING TAB on the FOCUS

MOTOR BRACKET untilit isaligned withthe hole

in the AUTO FOCUS SWITCH.

Installing the AUTO-FOCUS SWITCH ASSEMBLY

Important

Align the 2TABS onthe AUTO-FOCUS SWITCH with the FOCUS MOTORBRACKET, checking that the endof the

AUTO-FOCUSLEVERengageswiththe CYCLE SOLENOID PLUNGER. After theAUTO-FOCUSSWITCHisinthe

correct position, bend the LOCKING TAB to hold the AUTO FOCUS SWITCH in place.

[1] Do the replacement procedure for the AUTO-FOCUS SWITCH in reverse order.

Replacing the FOCUS SHAFT ASSEMBLY - Auto Focus Models

Warning

Dangerous Voltage

[1] Disconnect the main power.

SM5440-1 – 18NOV97 21

Page 22

SERVICE MANUAL

[2] Do the replacement procedure for the LOWER HOUSING ASSEMBLY.

[3] Remove the FOCUS KNOB.

Important

It is necessary topush the AUTO-FOCUS BRACKETbackward and forward toallow access to theSCREWS on the

LENS MOUNT ASSEMBLY.

[4] Remove the 3 SCREWS from the LENS MOUNT ASSEMBLY.

[5] Lift and remove the LENS MOUNT ASSEMBLY.

[6] Remove the FOCUS SHAFT SPRING from the LENS MOUNT BRACKET.

[7] Remote models only: Remove the SPRING from the CLAMP LEVER on the LENS MOUNT BRACKET.

[8] Remove the SPRING from the PHOTOCELL BRACKET.

[9] Remove the E-RING and SPACER from the FOCUS SHAFT ASSEMBLY.

[10] Remove the SCREW from the LENS SUPPORT BRACKET.

[11] Lift and remove the LENS SUPPORT BRACKET.

[12] Remote models: Remove the AUTO-FOCUS SWITCH ASSEMBLY.

[13] Remote models: Remove the SCREW from the RACK SOLENOID ASSEMBLY.

[14] Remote models: Remove the RACK SOLENOID ASSEMBLY and PLUNGER.

[15] Remote models: Remove the SCREW from the FOCUS MOTOR BRACKET ASSEMBLY.

[16] Remove the FOCUS MOTOR BRACKET ASSEMBLY.

[17] Push the RACK LEVER away from the FOCUS SHAFT ASSEMBLY.

[18] Remove the FOCUS SHAFT ASSEMBLY.

CLAMP LEVER

SPRING

SCREW

FOCUS SHAFT

SPRING

RACK LEVER

(not shown)

FOCUS SHAFT

FOCUS MOTOR

BRACKET

SPACER

E-RING

PHOTOCELL

BRACKET

SPRING

AUTO-FOCUS

SWITCH

ASSEMBLY

SCREW

SCREW

RACK

SOLENOID

PLUNGER

LENS SUPPORT BRACKET

A091_4029HCA

A091_4029HA

22 18NOV97 – SM5440-1

Page 23

Replacements and Installations

Installing the FOCUS SHAFT ASSEMBLY

Important

Do the adjustments for thePHOTOCELL NULL and AUTO-FOCUS CLAMP after installation. See the Adjustments

section.

Replacing the FOCUS SHAFT ASSEMBLY - Non Auto-Focus Models

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the replacement procedure for the LOWER HOUSING ASSEMBLY.

[3] Remove the FOCUS KNOB.

[4] Remove the 3 SCREWS from the LENS MOUNT ASSEMBLY.

[5] Lift and remove the LENS MOUNT ASSEMBLY.

[6] Remove the FOCUS SHAFT SPRING from the LENS MOUNT BRACKET.

[7] Remove the E-RING and SPACER from the FOCUS SHAFT ASSEMBLY.

[8] Remove the SCREW from the LENS SUPPORT BRACKET.

[9] Lift and remove the LENS SUPPORT BRACKET.

[10] Remove the E-RING and SPACER from the FOCUS SHAFT ASSEMBLY.

[11] Remove the SCREW from the FOCUS MOTOR BRACKET ASSEMBLY.

[12] Remove the FOCUS MOTOR BRACKET ASSEMBLY.

[13] Remove the FOCUS SHAFT ASSEMBLY.

SCREW

FOCUS SHAFT

ASSEMBLY

FOCUS SHAFT

SPRING

FOCUS MOTOR

BRACKET

SPACER

E-RING

SM5440-1 – 18NOV97 23

SCREW

LENS SUPPORT

BRACKET

A091_0020HCA

A091_0020HA

Page 24

SERVICE MANUAL

Installing the FOCUS SHAFT ASSEMBLY

[1] Do the replacement procedure for the FOCUS SHAFT ASSEMBLY in reverse order.

24 18NOV97 – SM5440-1

Page 25

Section 2: Adjustments

Adjustment Specification

Use T-BAR TL-3003 to bend the CYCLE LEVER to adjust the CYCLE SOLENOID.

Adjusting the CYCLE SOLENOID

Warning

Dangerous Voltage

[1] Connect the main power.

Important

1. The CYCLE SOLENOID must operate correctly to do this adjustment.

2. The MECHANISM ASSEMBLY does not have to be removed to do this adjustment.

[2] Do the removal for the LOWER HOUSING ASSEMBLY.

[3] Bend the CYCLE LEVER up or down. Use T-BAR TL-3003.

[4] Energize the projector.

[5] Press the “FORWARD” BUTTON to check for correct operation.

[6] Press the “REVERSE” BUTTON to check for correct operation.

[7] Do the steps above until the FORWARD and REVERSE functions operates correctly.

Adjustments

T-BAR

TL-3003

MECHANISM

ASSEMBLY

CYCLE

BAR

A091_0007HCA

A091_0007HA

SM5440-1 – 18NOV97 25

Page 26

SERVICE MANUAL

Adjustment Specification

This adjustment adjusts the strobe and timing of the INDEXER LEVER. The gate edge of the black plastic of the

INDEXER LEVER should be between the 2 holes at position 2.

Adjusting the INDEXER LEVER ASSEMBLY

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the removal for the MECHANISM ASSEMBLY.

[3] Place the MECHANISM ASSEMBLY on the MECHANISM RUNNING FIXTURE.

[4] Check the alignment of the INDEXER LEVER with the hole in the TOP PLATE ASSEMBLY at Position 1.

[5] Bend the INDEXER LEVER to the correct position.

[6] Check the travel of the INDEXER LEVER in the FORWARD position. When the INDEXER LEVER moves in

the FORWARD position, the gate edge of the black plastic should be between the 2 holes at Position 2.

[7] Bend the INDEXER LEVER until you reach the correct position.

MECHANISM

ASSEMBLY

MECHANISM

RUNNING FIXTURE

TOP PLATE

Bend

here.

position 1 position 2

A091_0008HCA

A091_0008HA

Adjustment Specification

Use a MECHANISM RUNNING FIXTURE. Use TL-3001 to measure the height of the SLIDE LIFT LEVER. The

LEVER should make contact with the low surface of TL-3001. The LEVER should not make contact with the high

surface of TL-3001.

26 18NOV97 – SM5440-1

Page 27

Adjustments

Adjusting the SLIDE LIFT LEVER MANUAL, with MECHANISM Out

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the removal for the MECHANISM ASSEMBLY.

[3] Place the MECHANISM ASSEMBLY on the MECHANISM RUNNING FIXTURE.

[4] Press and hold the SELECT LEVER down to move the SLIDE LIFT LEVER to the highest position.

[5] Measure the height of the SLIDE LIFT LEVER. Use SLIDE LIFT LEVER GAUGE TL-3001. The SLIDE LIFT

LEVER should make contact withthe lowsurface of theSLIDE LIFTLEVER GAUGE TL-3001; theSLIDE LIFT

LEVER should not make contact with the high surface of the SLIDE LIFT LEVER GAUGE TL-3001.

[6] Bend the SLIDE LIFT LEVER until the adjustment is correct.

SLIDE LIFT

LEVER GUAGE

TL-3001

SLIDE LIFT

LEVER

SELECT

LEVER

(not shown)

A091_0016BCA

A091_0016BA

Adjustment Specification

Use MECHANISM RUNNING FIXTURE. Use TL-3001 to measure the height of the SLIDE LIFT LEVER. The

LEVER should make contact with the low surface of TL-3001. The LEVER should not make contact with the high

surface of TL-3001.

Adjusting the SLIDE LIFT LEVER POWER with Mechanism Out

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the removal for the MECHANISM ASSEMBLY.

[3] Place the MECHANISM ASSEMBLY on the MECHANISM RUNNING FIXTURE TL-3000.

[4] Energize the MECHANISM FIXTURE.

[5] Press and hold the SELECT LEVER down to move the SLIDE LIFT LEVER to the highest position.

[6] Measure the height of the SLIDE LIFT LEVER. Use SLIDE LIFT LEVER GAUGE TL-3001. The SLIDE LIFT

LEVER should make contact withthe lowsurface of theSLIDE LIFTLEVER GAUGE TL-3001; theSLIDE LIFT

LEVER should not make contact with the high surface of the SLIDE LIFT LEVER GAUGE TL-3001.

[7] Bend the SLIDE LIFT LEVER until the adjustment is correct.

SM5440-1 – 18NOV97 27

Page 28

SERVICE MANUAL

SLIDE LIFT

LEVER GUAGE

TL-3001

Adjusting the Focus Light Path - Auto Focus Models

Adjustment Specification

SLIDE LIFT

LEVER

SELECT

LEVER

(not shown)

A091_0016BCA

A091_0016BA

Seat AUTO-FOCUS TARGET SLIDE TL-3002 on the GATE MECHANISM. Use TL-3005 or TL-1165 to bend the

AUTO-FOCUS BRACKET ASSEMBLY MIRROR until the image is within the target of the TARGET SLIDE.

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Remove the PROJECTION LENS.

[3] Do the removal for the LOWER HOUSING ASSEMBLY.

Important

It is necessary to make a FAN COVER TOOL. See the Tools section.

[4] Install the FAN COVER TOOL over the FAN area and the LAMP MODULE.

[5] Energize the projector.

[6] Set the projector to the LOW LAMP position.

[7] Install the AUTO-FOCUS TARGET SLIDE TL-3002 until it is fully seated in the GATE MECHANISM.

[8] Look through the PROJECTION LENS hole and observe the focus light path on the AUTO-FOCUS TARGET

SLIDE TL-3002.

[9] Check the position of the image on the AUTO-FOCUS TARGET SLIDE TL-3002.

28 18NOV97 – SM5440-1

Page 29

Adjustments

[10] Bend the AUTO-FOCUS BRACKET ASSEMBLY MIRROR until the image is within the target on the TARGET

SLIDE. Use ADJUSTMENT TOOL TL-3005 or the SPRING HOOK TL-1165.

ADJUSTMENT TOOL

TL-3005 or

SPRING HOOK TL-1165

AUTO FOCUS

BRACKET

ASSEMBLY

light path

image

A091_4026HCA

AUTO-FOCUS TARGET SLIDE TL-3002

A091_4026HA

Adjustment Specification

Use TL-3002 to observe the focus light path and check the light image. Use T-BAR TL-3003 to bend the

PHOTOCELL BRACKET to move the NULL in the center if necessary.

Adjusting the NULL

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the removal for the LOWER HOUSING ASSEMBLY.

Important

It is necessary to make a FAN COVER TOOL. See the Tools section.

[3] Install the FAN COVER TOOL over the FAN area and the LAMP MODULE. See the Tools section.

[4] Energize the projector.

[5] Set the projector to the LO-LAMP position.

[6] Install and hold the AUTO FOCUS TARGET SLIDE TL-3002 until it is fully seated in the GATE MECHANISM.

[7] Look through the PROJECTION LENS hole and observe the focus light path on the AUTO-FOCUS TARGET

SLIDE TL-3002. Check that the light image is correct. If not, do the Adjusting the FOCUS LIGHT PATH.

[8] Check that the TAB on the CLAMP PAD ASSEMBLY is in the NULL position. If the TAB is not in the correct

position, do the adjustment procedure for the NULL.

[9] Bend the PHOTOCELL BRACKET to move the NULL in the center; use T-BAR TL-3003.

SM5440-1 – 18NOV97 29

Page 30

SERVICE MANUAL

Important

If you cannot obtain the NULL position after doing the adjustment approximately 3 times, go to the adjustment

procedure for the PHOTOCELL.

light path

T-BAR

TL-3003

NULL position

PROJECTION

LENS

AUTO-FOCUS

A091_4031BCA

A091_4031BA

TARGET SLIDE

TL-3002

Adjustment Specification

Use TL-3002 and FAN CAP 232729 to check the adjustment of the PHOTOCELL.

Adjusting the PHOTOCELL

PHOTOCELL

CIRCUIT BOARD

wratten

FILTER (2)

Dangerous Voltage

It is necessary to makea FANCOVER TOOL. Seethe

Tools section.

Warning

[1] Disconnect the main power.

[2] Do the removal for the LOWER HOUSING

ASSEMBLY.

Important

[3] Install the FAN COVER TOOL over the FAN area

and the LAMP MODULE. See the Tools section.

TAB

CLAMP LEVER

PAD

POST (2)

PHOTOCELL

HOUSING

30 18NOV97 – SM5440-1

PHOTOCELL

MASK

A091_4032GCA

A091_4032GA

Page 31

Adjustments

Warning

Dangerous Voltage

[4] Energize the projector.

[5] Set the projector to the LO-LAMP position.

[6] Install and hold the AUTO FOCUS TARGET

SLIDE TL-3002 until it is fully seated inthe GATE

MECHANISM.

[7] Look through the PROJECTION LENS hole and

observe the focuslight path on the AUTO-FOCUS

TARGET SLIDE TL-3002. Check that the light

path is correct. If not, do the adjustment

procedure for the FOCUS LIGHT PATH.

Warning

Dangerous Voltage

[8] Disconnect the main power.

[9] Heat the 2 POSTS on the PHOTOCELL

HOUSING to allow the POSTS to bend enoughto

pull the PHOTOCELL CIRCUIT BOARD up and

off the PHOTOCELL HOUSING. Use a

SOLDERING IRON.

[10] Remove the 2 Wratten FILTERS and the

PHOTOCELL MASK.

SM5440-1 – 18NOV97 31

Page 32

SERVICE MANUAL

hole

light image

FAN CAP

[11] Install the FAN CAP 232729 in the PHOTOCELL

HOUSING.

FAN CAP

A091_4033GCA

A091_4033GA

[12] Manually move the CLAMP PAD ASSEMBLY until the TAB is in the NULL position.

light path

NULL position

A091_4027BCA

A091_4027BA

Warning

Dangerous Voltage

[13] Connect the main power.

TAB

CLAMP LEVER

PAD

Important

It is necessary to make a FAN COVER TOOL. See the Tools section.

[14] Install the FAN COVER TOOL over the FAN area and the LAMP MODULE. See the Tools section.

[15] Install and hold the AUTO FOCUS TARGET SLIDE TL-3002 until it is fully seated in the GATE MECHANISM.

32 18NOV97 – SM5440-1

Page 33

Adjustments

[16] Set the projector to the LO-LAMP position.

[17] Observe the image of the focus light path on the bottom of the FAN CAP; the light path should be in the center

of the hole in the FAN CAP.

[18] Bend the CLAMP PAD ASSEMBLY until the image is in the center of the hole in the FAN CAP.

[19] Assemble the PHOTOCELL MASK, FILTERS and PHOTOCELL BOARD.

T-BAR TL-3003

CLAMP PAD

AUTO-FOCUS

ASSEMBLY

TARGET SLIDE

TL-3002

Adjustment Specification

Use TL-1744 to check that the CLAMP PAD ASSEMBLY moves forward and backward.

FAN CAP

hole

light image

A091_4030BCA

A091_4030BA

SM5440-1 – 18NOV97 33

Page 34

SERVICE MANUAL

Adjusting the CLAMP PAD ASSEMBLY

SCREW

NUT

CLAMP PAD

ASSEMBLY

A091_4041GCA

A091_4041GA

Warning

Dangerous Voltage

[1] Disconnect the main power.

[2] Do the removal for the LOWER HOUSING

ASSEMBLY.

Important

It is necessary to makea FANCOVER TOOL. Seethe

Tools section.

[3] Install the FAN COVER TOOL over the FAN area

and the LAMP MODULE. See the Tools section.

[4] Connect the REMOTE CONTROL ASSEMBLY

EC-3 to the REMOTE RECEPTACLE.

Warning

Dangerous Voltage

[5] Connect the main power.

[6] Loosen the NUT on the CLAMP PAD ASSEMBLY.

[7] Energize the REMOTE FOCUS ineither direction.

[8] Rotate the SCREW on the CLAMP PAD

ASSEMBLY to adjust the pressure of the

REMOTE FOCUS CLAMP on the CLAMP PAD

ASSEMBLY until the CLAMP PAD ASSEMBLY

does not move.

[9] Release the REMOTE FOCUS.

[10] Tighten the NUT on theCLAMP PAD ASSEMBLY.

[11] Install the AUTO-FOCUS GAUGETL-1744 in the

MECHANISM GATE. The CLAMP PAD

ASSEMBLY should move forward and backward

using TL-1744. If not, adjust the SCREW on the

CLAMP PAD ASSEMBLY again;the CLAMPPAD

ASSEMBLY adjustment is too tight and not

correct.

Adjustment Specification

The PRESSURE PAD should be aligned with the DARK SHUTTER.

Adjusting the DARK SHUTTER

[1] Do the removal for the LOWER HOUSING.

[2] Insert a thin SLIDE into the GATE MECHANISM; the DARK SHUTTER should open.

[3] Check the the PRESSURE PAD is correctly aligned with the the DARK SHUTTER.

[4] Bend the PRESSURE PAD to adjust the alignment.

34 18NOV97 – SM5440-1

Page 35

Adjustments

A091_0013GA

SHUTTER

DARK

PAD

PRESSURE

A091_0013GCA

SM5440-1 – 18NOV97 35

Page 36

SERVICE MANUAL

Section 3: Lubrication

Apply lubricant SUPER LUBE TL-4276 to the following parts and areas of the projector; see the illustrations.

• FAN

• INDEXER LEVER and TOP PLATE

• WORM PULLEY ASSEMBLY

• CAM STACK ASSEMBLY

• CYCLE LEVERS

• PIVOT SHAFT and LEVERS

• LENS MOUNT ASSEMBLY

A091_4037GA

36 18NOV97 – SM5440-1

Page 37

Lubrication

A100_0020GA

A091_0023HA

SM5440-1 – 18NOV97 37

Page 38

SERVICE MANUAL

A091_0022DA

38 18NOV97 – SM5440-1

Page 39

Tools

11.5 cm

(4.5 in.)

A091_0024GA

TOOL

A091_0024GCA

COVER

FAN

Cut here.

Section 4: Tools

Tools

Tool Description

TL-1744 AUTO-FOCUS GAUGE

TL-2264 FOCUS TEST (flat field)

TL-3002 AUTO-FOCUS TARGET SLIDE

TL-3003 ADJUSTMENT T-BAR

TL-3005 ADJUSTMENT TOOL

TL-3255

TL-4276 SUPER LUBE

The LOWER HOUSING ASSEMBLY is a part of the cooling function. To operate the projector with the LOWER

HOUSING removed, make a FAN COVER TOOL.

Torx

DRIVER SET

DIGITAL MULTIMETER

SM5440-1 – 18NOV97 39

Page 40

SERVICE MANUAL

Section 5: Specifications

Item Desription

Electrical Supply Standard U.S. Models: 110 - 125 V ac

Japan J Models: 100 V AC, 60 Hz only

Korea KK Models: 220 V AC, 60 Hz only

Power Consumption 400 W

Dimensions • Height: 119 mm (4.69 in.) without TRAY

• Width: 238 mm (12.93 in.)

• Length: 295 mm (11.6 in.)

Slide size 35 mm, 50 x 50 mm (2 x 2 in.)

Slide change time 1 second

LAMP and voltages • EXR 82 V, 300 W, 35 hours average life

• EXW 82 V, 300 W, 15 hours average lamp

life

• FHS 82 V, 300 W, 70 hours average life

• EXY 82 V, 300 W, 200 hours average life

• On Long Life models, the LAMP voltage is

74 V AC

Lumen Output • 800 minimum with EXR lamp

• EXTRA BRIGHT LAMP MODULE has a

30% increase in lumen output

• Lowest corner to center ratio is 55%

minimum

• Test method:

–

Ektagraphic

aperture (24 x 36 mm), compatiblewith

European specification DIN 19027

Operating temperature • 4.5 C (40 F), 15% humidity in low

• 49 C (120 F), 15% humidity in high

• 21 - 27 C (70 - 80 F), 20 - 60% humidity

optimum

Cooling Fan speed is 2780 or 3000 RPMs, 1360 BTUs

per hour to cool projector

Approvals UL

Environmental storage Complies with storage test specifications (TS

172)

Environmental operation Complies with climactic test specifications (TS

218)

Safety • 3 GROUNDED POWER CORDS,

detachable

• Heat sensitive interrupt fuses

• 117 C power to motor (lamp fuse)

• 171 C MOTOR

Dielectric strength Apply 1200 V AC, 60 Hz for 1 second;

maximum leakage current is 2.5 mA.

102 mm, F/2.8 LENS

40 18NOV97 – SM5440-1

Page 41

Item Desription

1

2

3

4

5

6

7

A100_0023AA

Y

W

N

O

G

N

K

7-PIN PLUG

A100_0023ACA

24 V AC

24 V AC

24 V AC

0 V AC

Common

Unloaded

82

V AC

Automatic Timer Operates between the following times:

• Fast = 3 1 second

• Slow = 22 6 seconds

Elevation 14 maximum front elevation assembly.

Auto Focus System • After the initial focus adjustment, the auto-

focus system will adjust for the difference in

the slide position from slide to slide. This

focus adjustment will occur within 1second

after the slide is inserted into the GATE.

• The focus adjustment variation should not

change from the focus and reverse

specifications by more than 3 times the

focus and reverse specifications.

Reliability The projector can operate for 2000 hours or

2,000,000 cycles. The projector has a MTBF

(mean time between failures) of 7500 operation

hours.

Maintenance Preventive maintenance by a qualified service

person is recommended every 1500 hours of

operation, or after 1 year.

Warranty See the owner’s manual.

7-PIN REMOTE CONTROL

(See illustration on next page.)

• PIN 1 - Black, REMOTE FOCUS

• PIN 2 - Green, FORWARD TRAY CYCLE

• PIN 3 - Orange, REVERSE TRAY CYCLE

• PIN 4 - Brown, RACK SOLENOID

• PIN 5 - Yellow, COMMON

• PIN 6 - Brown, LAMP CONTROL

• PIN 7 - White, LAMP CONTROL

Specifications

REMOTE INLET

SM5440-1 – 18NOV97 41

Page 42

SERVICE MANUAL

Section 6: Diagnostics

MAIN MOTOR Voltages

12

11

10

9

8

7

MOTOR

MAIN MOTOR PIN Colors

PIN Color

12 brown

11 red

10 violet

9 yellow

8 blue

7 not used

brown

white

black

84.2 V

1.6

117 V AC

6.1

LAMP VOLTAGE is

74 V AC

between brown

and white for

LONG LIFE MODELS

A091_0006BCA

A091_0006BA

MAIN MOTOR PIN Voltages

PIN Resistance Voltage

8-9 3.1 W 24.4 V AC

10-11 4.3 W 14.1 V AC

11-12 4.2 W 14.1 V AC

10-12 8.0 W 28.2 V AC

9-10 O.L.

42 18NOV97 – SM5440-1

Page 43

PHOTOCELL Voltages

1

2

3

A091_4036AA

A091_4036ACA

PHOTOCELL

PHOTOCELL Voltages

Diagnostics

PINS Voltage

1-2 14.5 V ac

2-3 14.5 V ac

1-3 29 V ac

5-PIN REMOTE CORD PLUG Voltages

REV

WHITE

KODAK

EC-3 REMOTE CONTROL

A100_0001BC_

FWD

RED

BLACK

BRN

FOCUS

YELLOWYELLOW

5-PIN REMOTE PLUG Voltages

PIN Description

white Reverse

red Forward

yellow Common

brown RACK SOLENOID

black Focus - REMOTE

SM5440-1 – 18NOV97 43

Page 44

SERVICE MANUAL

SMALL COMPONENT BOARD ASSEMBLY 256809 Voltages

WBWK R A V V O B Y

CR2

Q2

R3

R4

Q1

R6

CR3

R5

J1

C4

CR4

C5

R17

SLIDE PROJECTOR BOARD

J2

F1

R7

Q3

WWRNGYR

CR5

C1

CR1

++

C3

C2

R12

R11

R10

R13

R14

CR6

R15

Q4

Description Component RED +, BLACK - Voltage

TIMER Circuit CR3 + to - 32 V DC

TIMER Circuit Q3 - G to + A 32 V DC

TIMER Circuit Q4 - G to + K 18.1 V DC

CYCLE HOLD DOWN

CR4 + to - 18.0 V DC

REVERSE

FOCUS CR2 + to - 28.0 V DC

FOCUS RACK USE

CR5 + to - 18.0 V DC

REMOTE

FOCUS Q1 - B to + C 23.3 V DC

FOCUS Q2 - G to + A 28.0 V DC

A091_4034DC

44 18NOV97 – SM5440-1

Page 45

Voltage Specifications - General Parts

Part Procedure Voltage

FOCUS MOTOR ------ 6.7 V AC

CYCLE SOLENOID Press the REVERSE

BUTTON.

RACK SOLENOID ------ 39 W, 10 V AC

LAMP RECEPTACLE ------ Standard Models:

DROPPING RESISTOR Move to the LO LAMP

position.

39 W, 10 V DC

82 V AC, approximately 85-86

V AC without a LAMP

MODULE installed

Long Life Models:

74 V AC, 76 V AC without

LAMP

3.0 W, 10.4 V AC drop across

Power, Illumination, and Cooling Malfunctions

Diagnostics

Malfunction Check

The MOTOR does not operate. 1. Check thecontinuity across theTHERMAL

FUSE ASSEMBLY, and MOTOR FUSE.

2. Check that the primary voltageonthe MAIN

MOTOR is correct.

3. Check that the voltage on POWER

SWITCH is correct.

The FAN does not operate, MOTOR operates. 1. Check that the FAN BELT is not broken.

2. Check andremove obstructionsin theFAN

area.

There is excessive noise in the FAN. 1. Check andremove obstructionsin theFAN

area.

2. Check that the tension is correct on the

FAN BELT.

3. Check that the FAN BELT is clean.

4. Check thecondition ofthe BEARING in the

FAN ASSEMBLY.

The LAMP does not operate. 1. Check the LAMP for damage.

2. Check the LAMP RECEPTACLE

3. Check the LAMP TERMINAL ASSEMBLY

in the LAMP MODULE ASSEMBLY for

damage.

There is an obstruction in the light path. 1. Check the DARK SHUTTER for correct

operation. See the adjustment for the

DARK SHUTTER.

2. Check the LIGHT BAFFLE in the

MECHANISM for damage; it should not

cause a jam in the SHUTTER.

SM5440-1 – 18NOV97 45

Page 46

SERVICE MANUAL

Slide Transport Malfunctions

Malfunction Check

Forward and reverse do not operate using the

FRONT PANEL BUTTONS or REMOTE

CONTROL.

Forward does not operate, reverse operates,

voltages are correct.

Reverse does not operate, forward operates,

voltages are correct.

Projector does not complete a cycle; FAN

operates.

Projector has continual cycle. 1. Check the CYCLE LEVER for correct

1. Check that the secondary voltage on the

MAIN MOTOR is correct.

2. Check that the W across the CYCLE

SOLENOID COIL are correct.

3. Check that the voltage across the CYCLE

SOLENOID is correct.

1. Check that the CYCLE LEVER and

RATCHET PLATE are clean. Clean and

lubricate the parts as necessary. Use

SUPER LUBE TL-4276.

2. Install a new CAM STACK ASSEMBLY; the

malfunction is within the CAM.

1. Do the adjustment for the CYCLE

SOLENOID.

2. Check that the DIRECTION LEVER

SPRING is on the DIRECTION LEVER.

3. Check the DIRECTION LEVER for binds.

Excessive lubrication and dirt can cause

binds.

1. Check for a broken MECHANISM DRIVE

BELT.

2. Check the CYCLE LEVER and RATCHET

LEVERon theCAM SHAFTASSEMBLYfor

the following:

• correct alignment of the CYCLE LEVER

• damage to parts

• lubrication of the CYCLE LEVER (use

SUPER LUBE TL-4276)

3. Check the CYCLE SOLENOID for correct

operation. See the Voltage chart.

alignment. See the adjustment for the

CYCLE LEVER.

2. Check for damage to parts.

3. Check for a short•circuit in the wires:

• Use a tool to hold the CYCLE LEVER

down on the RATCHET LEVER. If

there is a short•circuit causing the

malfunction, the SOLENOID will be

energized. If there is a bind, the CAM

will not rotate.

4. Check that the CAM SHAFT ASSEMBLY

RATCHET SPRING is installed correctly.

5. If there is a bind in the CAM STACK, install

a new CAM.

46 18NOV97 – SM5440-1

Page 47

Malfunction Check

The projector does not change cycles when

using a DISSOLVE CONTROL; the REMOTE

CONTROL and CONTROL PANEL BUTTONS

operate correctly.

1. The CYCLE LEVER and the RATCHET

PLATE are dirty.

• Clean and apply lubricant SUPER

LUBE TL-4276 to the CYCLE LEVER

and RATCHET PLATE.

2. If this does not correct the malfunction:

• Install a newCAM SHAFT ASSEMBLY.

SLIDE TRAY does not advance smoothly. 1. Check the SLIDE TRAYLATCH for correct

alignment.

2. Operate the projector in the forward

direction.

• Check that the INDEXER LEVER

ASSEMBLY is in the correct alignment

with the holes at positions A and B.

• Do the adjustment for the INDEXER

LEVER ASSEMBLY.

• Check the condition of the LOCATOR

LEVER, it should not be bent.

• Check the height of the SLIDE LIFT

LEVER; the lower corner of the LIFT

LEVER RAMP is parallel with the TOP

HOUSING. If the height is not correct,

do the adjustment for the MANUAL and

POWER SLIDE LIFT LEVER

ECCENTRICS.

SLIDE TRAY advances when “REVERSE” is

pressed.

1. Do the adjustment for the CYCLE

SOLENOID.

2. Check that the SPRING is on the

DIRECTION LEVER.

3. Check for a bind in the DIRECTION LEVER

ASSEMBLY.

4. Check that the DIRECTION LEVER LINK is

in the correct position.

SLIDE TRAY does not rotate freely when the

SELECT BUTTON is pressed down. The

projector has power.

1. Press and release the SELECT BUTTON.

• Check that the LOCATOR LEVER

moves correctly and is not bent.

2. Press and hold the SELECT BUTTON

down.

• Check the SLIDE LIFT LEVER RAMP

for damage.

3. Check the height of the SLIDE LIFT

LEVER; the lower corner of the LIFT

LEVER RAMP is parallel with the TOP

HOUSING. If the height is not correct, do

the adjustment for the MANUAL and

POWER SLIDE LIFT LEVER

ECCENTRICS.

Diagnostics

SM5440-1 – 18NOV97 47

Page 48

SERVICE MANUAL

Malfunction Check

TIMER does not operate 1. Check the VARIABLE RESISTOR for

correct operation and install a new part if

necessary.

2. Move the TIMER BUTTON forward and

backward; use a DVM to check for changes

in W.

3. Energize theprojector andmovethe TIMER

to “S”.

• Check the voltages on CR3, Q3, and

Q4, see the voltage table.

DARK SHUTTER SWITCH does not operate 1. Energize the projector and release the

DARK SHUTTER to allow projection.

2. Check forcontinuity between PINS4 and 5

on the SPECIAL APPLICATIONS PLUG.

3. Press the “FORWARD” or “REVERSE”

BUTTONS to close the DARK SHUTTER.

4. In the closed position, the DVM should

measure 0 W.

5. If this procedure does not correct the

malfunction,installanewDARKSHUTTER

SWITCH.

After the FOCUS MOTOR energizes and

moves, the FOCUS MOTOR oscillates.

1. Remove R3and install a new 68K W1/4 W

RESISTOR (part 220040).

2. If there is still a malfunction, install a new

PHOTOCELL.

Focus Malfunctions

Malfunction Check

No manual focus 1. Check the FOCUS SHAFT SPRING for the

correct tension.

2. Check the LENS SUPPORT SPRING for

correct tension.

3. Check the LENS DRIVE GEAR on the

FOCUS SHAFT ASSEMBLY for damage

and install a new part if necessary.

No remote focus (Non Auto Focus models) 1. Check the REMOTE CORD for damage;

use a REMOTE CORD that has no

damage.

2. Actuate andhold the REMOTECONTROL.

3. Check that the voltage across the FOCUS

MOTOR is 6.7 V AC. If the voltage is

correct, install a new FOCUS MOTOR.

4. Check that the secondary voltage on the

MAIN MOTOR is correct.

48 18NOV97 – SM5440-1

Page 49

Malfunction Check

No remote focus, RACK SOLENOID

ASSEMBLY operates (Auto Focus Models)

1. Check that the REMOTE CORD operates

correctly; use a REMOTE CORD you know

is good (EC 3).

2. Actuate andhold the REMOTECONTROL.

3. Check that the voltage across the FOCUS

MOTOR is 6.7 V AC. If the voltage is

correct on the FOCUS MOTOR, the

FOCUS MOTOR is defective. Installa new

FOCUS MOTOR.

4. Check the AUTO FOCUS SWITCH

ASSEMBLY for correct operation.

5. Check the secondary voltagesonthe MAIN

MOTOR.

No auto-focus 1. Check that the AUTO-FOCUS DEFEAT

SWITCH is in the “ON” position.

2. Check thatthe MAIN PROJECTIONLAMP

operates correctly.

3. Insert the TARGET SLIDE TL-3002 in the

GATE MECHANISM.

• Check that the TARGET is correctly

aligned. If not, see the Adjustment

section.

4. Check that the voltages across the

PHOTOCELL are correct. The voltage

from 1 to 2 is 13.8 V ac. The voltage from

2 to 3is 13.8V ac. The voltagefrom 1 to 3

is 28 V ac.

5. Make a short• between 1 and 2; the

FOCUS MOTOR should rotate.

6. Make a short•circuit between 2 and 3; the

FOCUS MOTOR should rotate in the

reverse direction.

7. If the FOCUS MOTOR operates correctly,

install a new PHOTOCELL. If the FOCUS

MOTOR does not operate correctly,

measure the voltages on the CIRCUIT

BOARD.

Slow auto-focus movement 1. Check that the alignment of the FOCUS

LIGHT PATH and NULL is correct.

2. Check theresolution of the FOCUS LIGHT

PATH. Clean the AUTO FOCUSMIRROR

and BRACKET ASSEMBLY.

3. Install a new PROJECTION LAMP if

necessary.

4. Install a new PHOTOCELL.

5. Check the components on the CIRCUIT

BOARD for damage.

Diagnostics

SM5440-1 – 18NOV97 49

Page 50

SERVICE MANUAL

Malfunction Check

AUTO FOCUS MOTOR operates continually 1. Install the TARGET SLIDE TL-3002 in the

GATE MECHANISM.

2. Check that the alignment of the TARGET

and NULL is correct. If not, see the

Adjustments section.

3. Check for a light leak:

• Install a different LAMP MODULE

ASSEMBLY. If the FOCUS MOTOR

stops operating continually, install a

new LAMP MODULE ASSEMBLY.

4. Check that the voltages across the

PHOTOCELL are correct. The voltage

from 1 to 2 is 13.8 V ac. The voltage from

2 to 3is 13.8V ac. The voltagefrom 1 to 3

is 28 V ac.

5. Check that the PHOTOCELL HOUSING

has 2 FILTERS.

6. Install a new PHOTOCELL.

7. Check the components on the CIRCUIT

BOARD for damage.

AUTO FOCUS MOTOR operates continually in

forward only or reverse only and does not

operate (stops) in the null position.

1. Check that the wires of the AUTO FOCUS

MOTORare in the correctposition; the blue

wiregoes to themarkon the AUTOFOCUS

MOTOR.

AUTO FOCUS adjusts after REMOTE use 1. Do the adjustment for the CLAMP LEVER

ASSEMBLY.

50 18NOV97 – SM5440-1

Page 51

Printed in U.S.A. • sm5440_1.fm

EASTMAN KODAK COMPANY

Rochester, NY 14650

Kodak, Carousel,

and

Wratten

are trademarks.

Loading...

Loading...