Page 1

2400DSV

Service Manual

___________________________________________________________________

Page 2

PREFACE

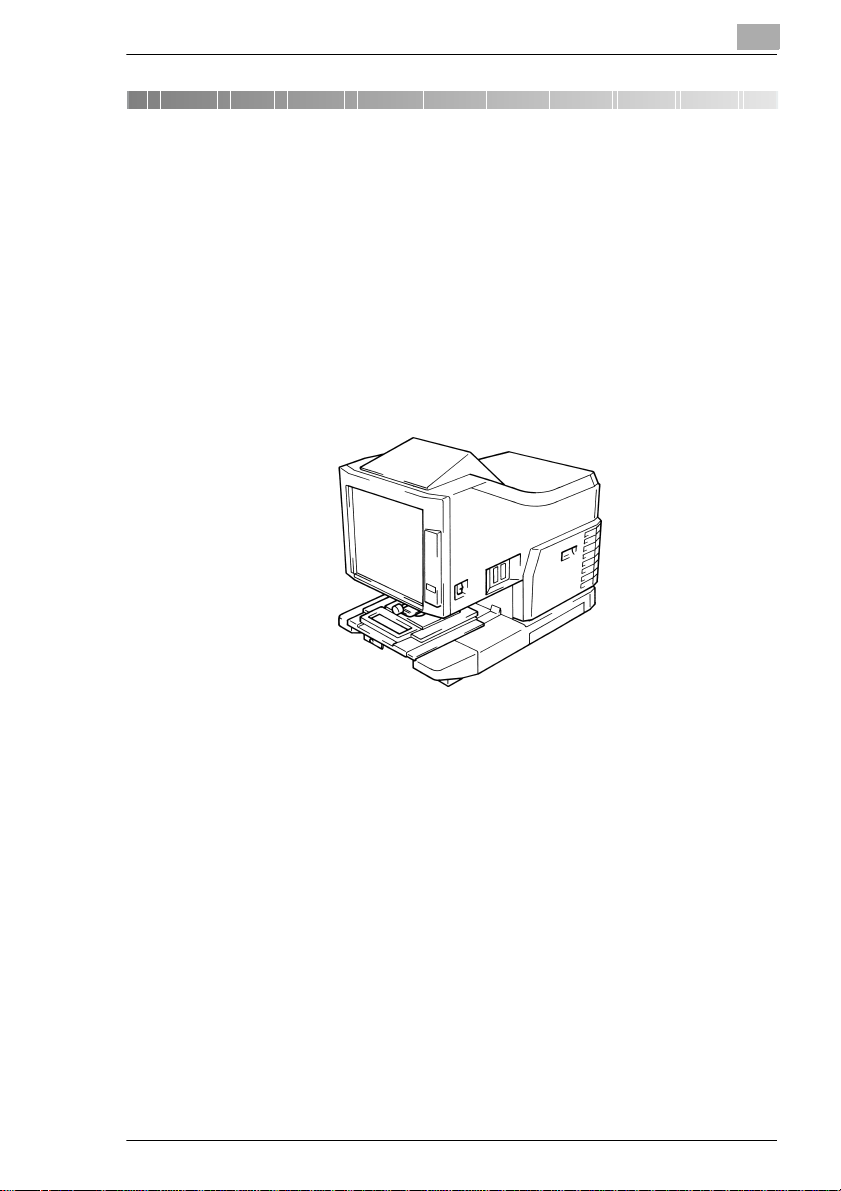

This Service Manual explains the Microfilm Scanner already put on the

market.

It is hoped that this Service Manual will help to provide for more effective

machine maintenance in the field there by ensuring optimum machine

performance.

Microfilm Scanner MS6000

All information in this Manual is subject to change without prior notice.

This manual has not described the printer section.

Separately, refer to the Service Manual of the Printer.

i

Page 3

Contents

1 Safety Precautions for Inspection and Service

1.1 WARNING.............................................................................................. 1

1.2 CAUTION............................................................................................... 4

1.3 Other Precautions................................................................................ 6

1.4 Used Batteries Precautions ................................................................ 7

2 Installation

2.1 Installation Environment ..................................................................... 8

2.2 Usage Environment ............................................................................. 8

2.3 Installing The Power Supply............................................................... 9

2.4 Installation Space................................................................................. 9

3 General Information

3.1 Specifications..................................................................................... 10

3.1.1 MS 6000 ........................................................................................ 10

3.1.2 MS 6000 & MSP3000 Printer System ........................................... 12

3.1.3 MS 6000 & MSP2000 Printer System ........................................... 12

3.2 System Configuration........................................................................ 13

3.3 Connection Mode............................................................................... 14

3.3.1 PR Mode (Scanner + Printer)........................................................ 14

3.3.2 PC Mode (Scanner + Personal Computer).................................... 14

3.4 Parts Identification............................................................................. 15

3.5 Component Layout ............................................................................ 16

3.6 Electrical Components Layout ......................................................... 17

3.7 Electrical Parts Function................................................................... 20

3.8 Connectors Layout ............................................................................ 22

3.9 Electrical Service Parts on P.W.Boards........................................... 24

3.9.1 Main Control Board (PWB-BB)...................................................... 24

3.9.2 I/F Board (PWB-EE) ...................................................................... 24

3.9.3 I/F Board (PWB-SS) ...................................................................... 25

3.9.4 Main Power Unit (PU1).................................................................. 25

3.9.5 Projection Lamp Regulator (PU2) ................................................. 25

3.9.6 Optional Power Unit (PU3)............................................................ 25

Contents

ii

Page 4

Contents

3.10Explanation of Control Panel ............................................................26

3.10.1 Control Panel (Basic).....................................................................26

3.10.2 Control Panel (Shift Function)........................................................33

3.11Image Processing...............................................................................35

4 Mechanical and Electrical

4.1 Illumination Mechanism.....................................................................37

4.1.1 Overview........................................................................................37

4.1.2 Projection Lamp (LA1) ...................................................................37

4.1.3 Projection Lamp Voltage Control Circuit........................................38

4.1.4 Thermostat (TS1)...........................................................................39

4.1.5 Condenser Lens.............................................................................40

4.1.6 Projection Lens ..............................................................................41

4.2 Image Rotation....................................................................................42

4.2.1 Prism Rotation ...............................................................................42

4.2.2 Auto Image Rotating Motor (M5) Control Circuit............................42

4.3 Optical Section ...................................................................................43

4.3.1 Overview........................................................................................43

4.3.2 Reader Path...................................................................................44

4.3.3 Scan Path ......................................................................................44

4.3.4 Scan Table Drive Mechanism........................................................45

4.3.5 Scan Mirror Motion Control ............................................................46

4.3.6 Mirror Scan Motor (M1) Control Circuit..........................................47

4.4 CCD Section........................................................................................48

4.5 Image Bus ...........................................................................................49

4.6 Auto Masking ......................................................................................52

4.6.1 Overview........................................................................................52

4.6.2 Masking Area Detection.................................................................52

4.6.3 Requirements for Auto Masking.....................................................52

4.7 Auto Image Skew Correction.............................................................55

4.7.1 Overview........................................................................................55

4.7.2 Requirements for Auto Skew Correction........................................55

4.8 Manual Frame Masking......................................................................56

4.9 2 to 1 Printing Function ..................................................................... 57

4.9.1 Overview........................................................................................57

4.9.2 Operation .......................................................................................57

4.9.3 Identification Marks ........................................................................58

5 Disassembly and Cleaning

5.1 Precautions .........................................................................................59

iii

Page 5

Contents

5.1.1 Precautions for Disassembly and Cleaning................................... 59

5.2 Handling of P.W.Boards .................................................................... 60

5.2.1 Precautions regarding transportation and storage ........................ 60

5.2.2 Precautions when replacing PWBs ............................................... 60

5.2.3 Precautions when checking PWBs................................................ 60

5.3 Maintenance and Inspection............................................................. 61

5.3.1 Preventive Maintenance Schedule List ......................................... 61

5.3.2 Details of readjustments needed when parts are replaced ........... 61

5.4 Disassembly and Cleaning Procedure............................................. 62

5.4.1 Removal of the Outer Covers........................................................ 62

5.4.2 Replacing of the Projection Lamp ................................................. 65

5.4.3 Cleaning of the Projection Lamp ................................................... 66

5.4.4 Cleaning of the Condenser Lens and Mirrors................................ 66

5.4.5 Cleaning of the each Mirrors ......................................................... 67

5.4.6 Cleaning of the CCD Filter ............................................................ 68

5.4.7 Removal of the CCD Assy............................................................. 69

5.4.8 Removal of the Power Unit............................................................ 71

5.4.9 Removal of the P.W.Boards. ......................................................... 72

5.4.10 Replacing Scan Motor bushing and friction plate.......................... 73

5.4.11 Replacing the Fuse of the Power Unit........................................... 73

5.4.12 Replacing the Main Fuse............................................................... 74

5.4.13 Exchanging the Oscillator Chip ..................................................... 75

6 Function Mode and Adjustment

6.1 Precautions......................................................................................... 77

6.2 Overview ............................................................................................. 77

6.3 Function Mode List ............................................................................ 78

6.3.1 S mode (Setting Function 1).......................................................... 78

6.3.2 y mode (Setting Function 2) .......................................................... 79

6.3.3 o mode (Setting Function 3) .......................................................... 80

6.3.4 F mode (machine operation checks)............................................. 81

6.3.5 b mode (machine operation checks) ............................................. 81

6.3.6 About the Function Mode Setting Label ........................................ 82

6.4 Operation of the Function Mode....................................................... 83

6.4.1 Entering the Function Mode .......................................................... 83

6.4.2 Execution method in F and b mode (except F4, F8 and b6) ......... 83

6.4.3 Execution method in F and b mode (F4, F8 and b6)..................... 84

6.4.4 Execution method in S, y and o mode........................................... 84

6.4.5 Leaving the Function Mode........................................................... 84

6.5 S mode Operations ............................................................................ 85

6.5.1 S1: Auto Reset .............................................................................. 85

6.5.2 S2: Auto Power Save .................................................................... 85

iv

Page 6

Contents

6.5.3 S3: Auto Projection Lamp OFF......................................................85

6.5.4 S4: Coin Vender / Foot Switch Setting...........................................85

6.5.5 S5: Fine Mode Setting ...................................................................86

6.5.6 S6: Paper Tray feed size (MSP 3000 Printer)................................86

6.5.7 S7: Machine ID Printing .................................................................86

6.5.8 S8: Cycle print mode......................................................................87

6.5.9 S9: Nega Contrast Adjustment ......................................................87

6.5.10 SA: Posi Contrast Adjustment........................................................87

6.5.11 Sb: Scan Table Stop Position Adjustment (Scan Position)............88

6.5.12 SC: Scan Table Stop Position Adjustment (Reader Position)........88

6.5.13 Sd: Auto image rotation 90 degree rotation function......................89

6.5.14 SE: The print function at the time of Toner Empty detection .........89

6.6 y mode Operations .............................................................................90

6.6.1 y2: Auto Paper Source Switching ..................................................90

6.6.2 y3: Auto Film Format Select Print ..................................................90

6.6.3 y5: Memo Image Masking..............................................................90

6.6.4 y6: Prescan Operation...................................................................91

6.6.5 y7: Auto Skew Correction Retain...................................................91

6.6.6 yb: Magnification Warning Display.................................................91

6.6.7 yC: Print Reserve Function ............................................................91

6.7 o mode Operations.............................................................................92

6.7.1 o1: Inch/Metric Select ....................................................................92

6.7.2 o2: N-P Auto Exposure Coarse Adjustment...................................92

6.7.3 o3: P-P Auto Exposure Coarse Adjustment...................................93

6.7.4 o4: Scan Speed Adjustment ..........................................................94

6.7.5 o5: Adjustment of the image area Lengthwise Position.................95

6.7.6 o6: Adjustment of the Top and Bottom Frame Black Band Width.. 96

6.7.7 o7: Adjustment of the Right and Left Frame Black Band Width..... 97

6.7.8 o8: Projection lamp burn out detection (L2) setting .......................98

6.7.9 oA: Host Driver Setting ..................................................................98

6.7.10 ob: Vender/Model Name Setting....................................................98

6.8 F mode Operations.............................................................................99

6.8.1 F1: ROM Version Check ................................................................99

6.8.2 F2: Scan Counter...........................................................................99

6.8.3 F3: Print Counter............................................................................99

6.8.4 F4: Counter Clear ..........................................................................99

6.8.5 F5: Control Panel LED Check........................................................99

6.8.6 F6: For Factory use........................................................................99

6.8.7 F7: Projection Lamp Voltage Adjustment.....................................100

6.8.8 F8: Reset the Setting Data..........................................................101

6.9 b mode Operations...........................................................................102

6.9.1 b1: Checking the Scan Table Unit Function.................................102

6.9.2 b2: Scanning mirror operation check ...........................................102

6.9.3 b3: For Factory use......................................................................102

v

Page 7

6.9.4 b4: Prism rotation operation check.............................................. 103

6.9.5 b5: Single scan operation check ................................................. 103

6.9.6 b6: Shading Correction................................................................ 104

6.9.7 b7: Test Print Function ................................................................ 105

6.9.8 b8: For Factory use ..................................................................... 105

7 Troubleshooting

7.1 How to Use This Section ................................................................. 106

7.2 Malfunction Indications................................................................... 107

7.3 Malfunction Detection Timing......................................................... 108

7.3.1 L2: Projection Lamp malfunction................................................. 108

7.3.2 C1: Scan Unit Drive malfunction ................................................. 108

7.3.3 C2: Scan Mirror Drive malfunction .............................................. 108

7.3.4 C3: Shading Correction malfunction............................................ 109

7.3.5 C4: Cooling Fan Motor malfunction............................................. 109

7.3.6 Cb: Communication Error............................................................ 109

7.3.7 CL: Printer Clock malfunction...................................................... 109

7.4 Troubleshooting for malfunction code .......................................... 110

7.4.1 L2: Projection Lamp malfunction................................................. 110

7.4.2 C1: Scan Unit Drive Malfunction ................................................. 110

7.4.3 C2: Scan Mirror Drive malfunction .............................................. 110

7.4.4 C3: Shading Correction malfunction............................................ 111

7.4.5 C4: Cooling Fan Motor malfunction............................................. 111

7.4.6 Cb: Communication Error............................................................ 111

7.4.7 CL: Printer Clock malfunction...................................................... 112

7.5 Troubleshooting for malfunction.................................................... 113

7.5.1 No Power..................................................................................... 113

7.5.2 The Projection Lamp does not Light Up...................................... 113

7.6 Electrical Components Check ........................................................ 114

7.6.1 LA1: Projection Lamp.................................................................. 114

7.6.2 M3: Power Unit Cooling Fan Motor ............................................. 114

7.6.3 M4: Projection Lamp Cooling Fan Motor..................................... 114

7.6.4 PC1: Image Leading Edge Sensor.............................................. 114

7.6.5 PC2: Scan Mirror Position Sensor............................................... 114

7.6.6 PC3: Reader Position Sensor ..................................................... 115

7.6.7 PC4: Scan Position Sensor......................................................... 115

7.6.8 PU1: Power Unit.......................................................................... 115

7.6.9 PU2: Projection Lamp Regulator................................................. 115

7.6.10 S1: Power Switch ........................................................................ 115

7.6.11 S201: Interlock Switch................................................................. 116

7.6.12 TS1: Thermostat.......................................................................... 116

7.7 Image Troubleshooting ................................................................... 117

Contents

vi

Page 8

Safety Precautions for Inspection and Service

1

1 Safety Precautions for Inspection and

Service

When performing inspection and service procedures, observe the

following precautions to prevent accidents and ensure utmost safety.

*Depending on the model, some of the precautions given in the following

do not apply.

Different markings are used to denote specific meanings as detailed

below.

Indicates a potentially hazardous situation which, if

WARNING

CAUTION

The following graphic symbols are used to give instructions that need to

be observed.

Used to call the service engineer attention to what is graphically

represented inside the marking (including a warning).

not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

Used to prohibit the service engineer from doing what is

graphically represented inside the marking.

Used to instruct the service engineer to do what is graphically

represented inside the marking.

1.1 WARNING

1. Always observe precautions.

• Parts requiring special attention in this product will include a

• Be sure to observe the “Safety Information” given in

label containing the mark shown on the left plus

precautionary notes. Be sure to observe the precautions.

Operator’s Manual.

1

Page 9

1

Safety Precautions for Inspection and Service

2. Before starting the procedures, be sure to unplug the power cord.

• This product contains a high-voltage unit and a circuit with a

large current capacity that may cause an electric shock or

burn.

• The product also contains parts that can jerk suddenly and

cause injure.

• If this product uses a laser, laser beam leakage may cause

eye damage or blindness.

3. Use the specified parts.

• For replacement parts, always use the genuine parts

specified in the manufacturer’s Parts Manual. Installing a

wrong or unauthorized part could cause dielectric

breakdown, overload, or undermine safety devices resulting

in possible electric shock or fire.

• Replace a blown electrical fuse or thermal fuse with its

corresponding genuine part specified in the manufacturer’s

Parts Manual. Installing a fuse of a different make or rating

could lead to a possible fire. If a thermal fuse blows

frequently, the temperature control system is probably of a

problem and action must be taken to eliminate the cause of

the problem.

4. Handle the power cord with care and never use a multiple socket.

• Do not brake, crush or otherwise damage the power cord.

Placing a heavy object on the power cord, or pulling or

bending it may damage it, resulting in a possible fire or

electric shock.

• Do not use a multiple outlet to which any other appliances

or machines is connected.

• Be sure the power outlet meets or exceeds the specified

capacity.

5. Be careful about the high-voltage parts.

• A part marked with the symbol shown on the left carries a

high voltage.

Touching it could result in an electric shock or burn. Be sure

to unplug the power cord before servicing this part or the

parts near it.

6. Do not keep your hands wet when performing the procedures.

• Do not unplug or plug in the power cord, or perform any

kind of service or inspection with wet hands. Doing so could

result in an electric shock.

2

Page 10

Safety Precautions for Inspection and Service

7. Do not touch a high-temperature part.

• A part marked with the symbol shown on the left and other

parts such as the exposure lamp and fusing roller can be

very hot while the machine is energized. Touching them

may result in a burn.

• Wait until these parts have cooled down before replacing

them or any surrounding parts.

8. Make a ground connection at all times

(This item may not be effected in USA).

• Be sure to connect a ground wire to the ground terminal

even when performing an inspection or repair. Without

proper grounding, electrical leakage could result in an

electric shock or fire.

• Never connect the ground wire to a gas pipe, water pipe,

telephone ground wire, or a lightning conductor.

9. Do not remodel the product.

• Modifying this product in a manner not authorized by the

manufacturer may result in a fire or electric shock. If this

product uses a laser, laser beam leakage may cause eye

damage or blindness.

1

10. Restore all parts and harnesses to their original positions.

• To promote safety and prevent product damage, make

sure the harnesses are returned to their original positions

and properly secured in their clamps and saddles in order

to avoid hot parts, high-voltage parts, and sharp edges, or

being crushed.

• To promote safety, make sure that all tubing and other

insulating materials are returned to their original positions.

Make sure that floating components mounted on the

circuit boards are at their correct distance and position off

the boards.

3

Page 11

1

1.2 CAUTION

1. Precautions for Service Jobs

• A toothed washer and spring washer, if used originally, must

• When reassembling parts, make sure that the correct

• Take great care to avoid personal injury from possible burrs

• When moving the product or removing an option, use care

2. Precautions for Servicing with Covers and Parts Removed

• Wherever feasible, keep all parts and covers mounted when

• If energizing the product with a cover removed is absolutely

• Never place disassembled parts or a container of liquid on

• Never use a flammable spray near the product. This could

• Make sure the power cord is unplugged before removing or

• Always use the interlock switch actuating jig to actuate an

Safety Precautions for Inspection and Service

be reinstalled.

Omitting them may result in contact failure which could

cause an electric shock or fire.

screws (size, type) are used in the correct places. Using the

wrong screw could lead to stripped threads, poorly secured

parts, poor insulating or grounding, and result in a

malfunction, electric shock or injury.

and sharp edges on the parts, frames and chassis of the

product.

not to injure your back or allow your hands to be caught in

mechanisms.

energizing the product.

unavoidable, do not touch any exposed live parts and use

care not to allow your clothing to be caught in the moving

parts. Never leave a product in this condition unattended.

the product parts falling into, or the liquid spilling inside, the

mechanism could result in an electric shock or fire.

result in a fire.

installing circuit boards or plugging in or unplugging

connectors.

interlock switch when a cover is opened or removed. The

use of folded paper or some other object may damage the

interlock switch mechanism, possibly resulting in an electric

shock, injury or blindness.

4

Page 12

Safety Precautions for Inspection and Service

DANGER

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE

TO BEAM

0947-7127-01

1144D270AA

3. Precautions for Working Environment

• The product must be placed on a flat, level surface that is

stable and secure.

• Never place this product or its parts on an unsteady or

tilting workbench when servicing.

• Provide good ventilation at regular intervals if a service job

must be done in a confined space for a long period time.

• Avoid dusty locations and places exposed to oil mist or

steam.

• Avoid working positions that may block the ventilation port

of the product.

4. Precautions for Handling Batteries

• Replace a rundown battery with the same type as specified

in the manufacturer’s parts manual.

• Before installing a new battery, make sure of the correct

polarity of the installation or the battery could burst.

• Dispose of used batteries according to the local regulations.

Never dispose of them at the user’s premises or attempt to

try to discharge one.

5. Precautions for Laser Beam (Products Employing Laser Only)

1

.

• Removing the cover marked with the following caution label

could lead to possible exposure to the laser beam, resulting

in eye damage or blindness. Be sure to unplug the power

cord before removing this cover.

• If removing this cover while the power is ON is unavoidable,

be sure to wear protective laser goggles that meet

specifications.

• Make sure that no one enters the room when the machine

is in this condition.

• When handling the laser unit, obser ve the “Precautions for

Handling Laser Equipment.

1167P001AA

5

Page 13

1

Safety Precautions for Inspection and Service

1.3 Other Precautions

• To reassemble the product, reverse the order of disassembly unless otherwise

specified.

• While the product is energized, do not unplug or plug connectors into the circuit

boards or harnesses.

• The magnet roller generates a strong magnetic field. Do not bring it near a

watch, floppy disk, magnetic card, or CRT tube.

• An air gun and vacuum cleaner generates a strong electrostatic charge that can

destroy the ATDC sensor and other sensors. Before cleaning a component with

one of these devices, be sure to remove all the sensors. Otherwise, use a

blower brush and cloth when cleaning parts.

• When handling circuit boards with MOS ICs, observe the “INSTRUCTIONS

FOR HANDLING THE PWBs WITH MOS ICs” (applicable only to the products

using MOS ICs).

• The PC Drum is a very delicate component. Observe the precautions given in

“HANDLING OF THE PC DRUM” because mishandling may result in serious

image problems.

• Note that replacement of a circuit board may call for readjustments or resetting

of particular items, or software installation.

• After completing a service job, perform a safety check. Make sure that all parts,

wiring and screws are returned to their original positions.

• Check the area surrounding the service site for any signs of damage, wear or

need of repair.

• Do not pull out the toner hopper while the toner bottle is turning. This could

result in a damaged hopper motor or locking mechanism.

• If the product is to be run with the front door open, make sure that the toner

hopper is in the locked position.

6

Page 14

Safety Precautions for Inspection and Service

1.4 Used Batteries Precautions

(ALL Areas)

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the

manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

(Germany only)

VORSICHT!

Explosinsgefahr bei unsachgemäßen austausch der batterie.

Ersatz nur durch denselben oder einen vom hersteller empfohlenen

ähnlichen typ.

Entsorgung gebrauchter batterien nach angaben des herstellers.

(France)

ATTENTION

Ily a danger d’explosion s’ily a remplacement incorrec de la batterie.

Remplacer uniquement avec une batterie du meme type ou d’un type

équivalent recommande par le constructueur.

Mettre au rebut les batteries usageés conformément aux instructions du

fabricant.

(Denmark only)

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering Udskiftning må

kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

(Norway only)

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av

apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens instruksjoner.

(Sweden only)

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av

apparattillverkaren.

Kassera använt batteri enligt fabrikantens instruktion.

(Finland only)

VAROlTUS

Paristo voi räjähtää, los se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä Käytetty paristo valmistajan ohjeiden mukaisesti.

1

7

Page 15

2

2 Installation

2.1 Installation Environment

To ensure safety and utmost performance of the machine, the machine

should not be used in a place.

1. Where it will be subject to extremely high or low temperature or

humidity.

2. Which is exposed to direct sunlight.

3. Which is in the direct air stream of an air conditioner, heater, or

ventilator.

4. Which puts the operators in the direct air stream of exhaust of the

machine.

5. Which has poor ventilation.

6. Where ammonia gas might be generated.

7. Where it will be subject to sudden fluctuations in either temperature or

humidity.

8. Which is near any kind of heating device.

9. Which does not have stable, level floor.

10. Where it may be splashed with water.

11. Which is dirty or where it will receive undue vibration.

12. Which is near volatile flammables or curtains.

Installation

NOTE:

If the machine is placed near a window, insure that the Screen faces

➜

inside, not the window.

2.2 Usage Environment

In order to make sure the machine functions in good condition, please

make sure the ambient environment satisfies the following requirements:

Temperature: 10-35°C Temperature fluctuation: ±10°C per hour or less

Humidity: 15-85% Humidity fluctuation: ±20% per hour or less

8

Page 16

Installation

2.3 Installing The Power Supply

1. Do not plug the Power Cord into a power outlet via an extension cord

supplying electricity to more than one unit.

2. Do not connect the machine to a power outlet used for other

equipment or appliances.

3. More than one appliance connected to a single outlet could cause a

drop or surge in the electrical supply, resulting in operational problems

for the machine.

Voltage fluctuation:Specified voltage: ±10%

G

Frequency fluctuation:Specified frequency: ±3Hz

G

4. The following items should be checked periodically:

Make sure the power supply plugs do not feel warm.

G

Power supply cords should be free of cracks and scratches.

G

Power supply plugs should be firmly plugged into outlets.

G

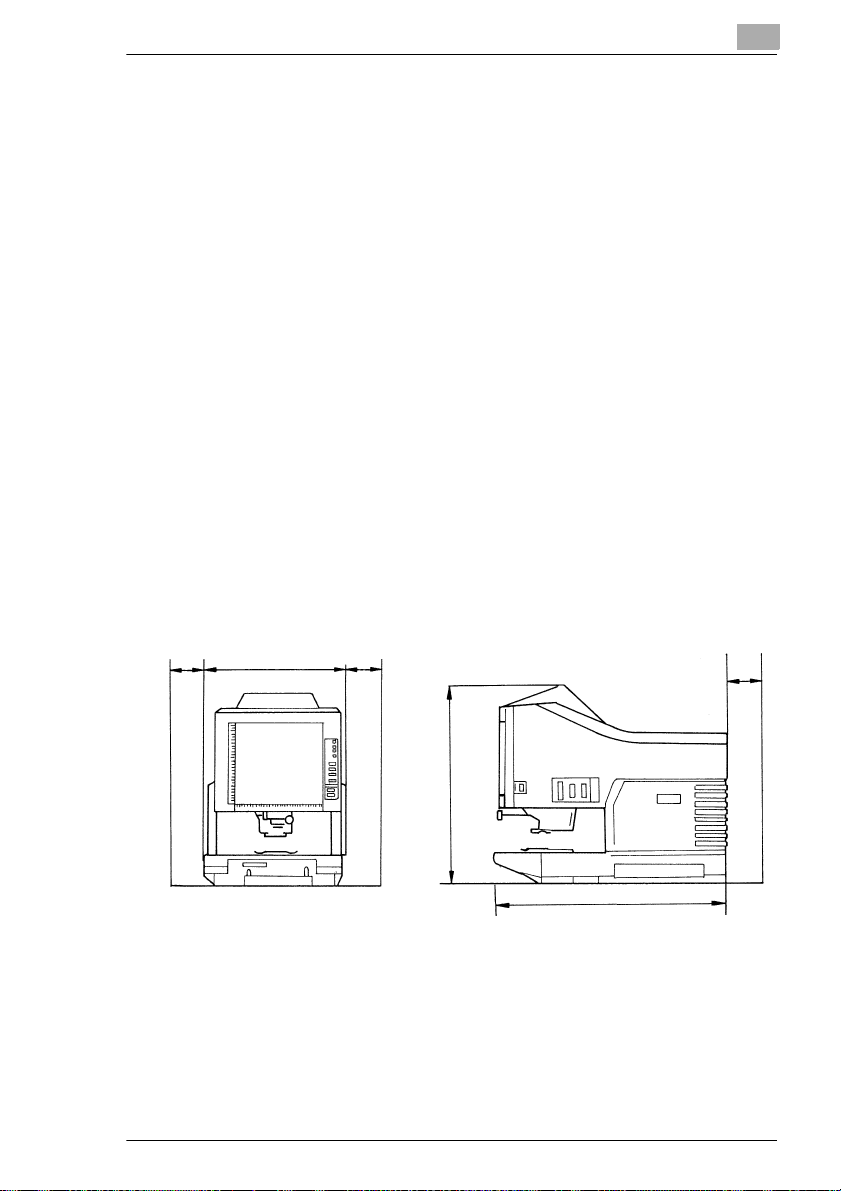

2.4 Installation Space

To ensure easy machine operation, replacement of consumables, and

maintenance service jobs, provide the following space for the installation

of the machine.

Allow the enough space around the louver to keep the good ventilation.

2

100 mm

or 4”

503 mm or

19-3/4”

100 mm

or 4”

100 mm or 4”

716 mm or 28- 1/4”

821 mm or 32-3/8”

9

Page 17

3

3 General Information

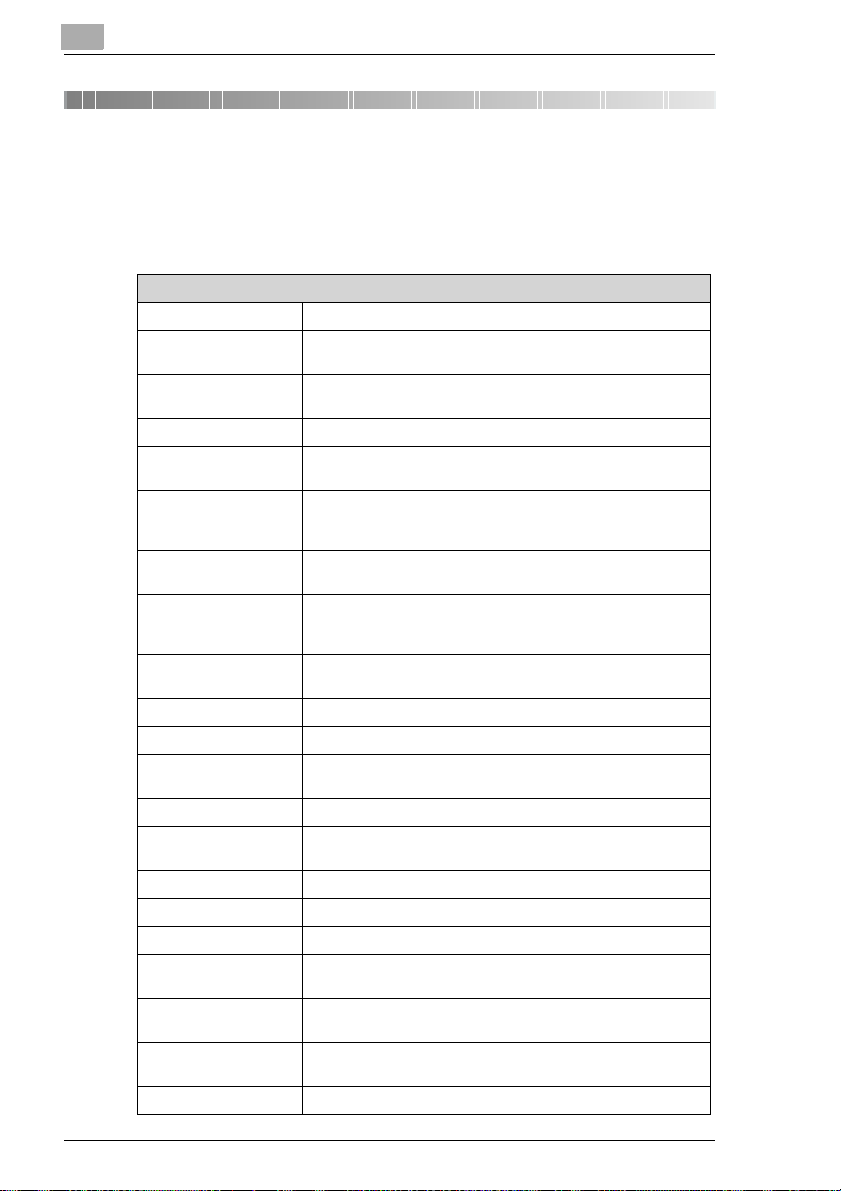

3.1 Specifications

3.1.1 MS 6000

Specifications

Type: Desk-Top Type Microfilm Scanner

Type of Film: Microfiche, Aperture Card, Jacket, Roll Films (16 mm, 35 mm),

Magnification: Single Lens......... 7.5X

Screen Size 300 mm X 300 mm or 12" X 12" (Scanning Area)

Image Rotation Prism Rotation

Resolution: 200, 300, 400, 600, 800 dpi (PC Mode)

Scanning Method Scanning/Scanning direction: CCD scanning

Scanning Speed 6.5 sec./1 frame scanning

Exposure Setting 2 way Settings:

N-P/P-P Select Auto/Manual Select

Scanning Mode Text/Photo/Fine

Output Scale: PC Mode: Binary, Grayscale (Option)

PC Interface: SCSI-2 (Option)

Auto Edit Function Auto Frame Masking, Auto Centering, Auto Skew Correction, Fit,

Light Source Halogen Lamp (20V 150W DDL Type)

Power Requirement 120VAC (60Hz), 220/240VAC (50-60Hz)

Power Consumption Less than 350W (with all options)

B.T.U

(British Thermal Unit)

Acoustic noise 53 dB or less (Scanning)

Dimensions 503 mm (W) x 821 mm (D) x 716 mm (H) or

Weight 39 Kg or 86 lbs

16mm Cartridge Film both Positive and Negative

Zoom Lens......... 9X-16X, 13X-27X, 23X-50X

Carrier Rotation (Fiche Carrier 5 only)

400, 600 dpi (PR Mode: When MSP 3000 Printer is connected)

400 dpi (PR Mode: When MSP 2000 Printer is connected)

Scanning/Feeding direction: Mirror scanning

5.5 sec./Multi-frame scanning

(8-1/2" X 11" or A4 Lengthwise, 400dpi, AE)

Automatic Control & Manual Control

PR Mode: Binary

Trimming, Masking, Electrical Zoom, Electrical Image Rotation

900 BTU (Reader Mode)

850 BTU (Scan Mode)

50 dB or less (Reader)

19-3/4" (W) x 32-3/8" (D) x 28-1/4" (H)

General Information

10

Page 18

General Information

Specifications

Standard Accessories Power Cord, Printer Cable, Operator’s Manual

Options: Lenses, Prism Unit, Fiche Carrier 5, Universal Carrier UC-2, Roll

Film Carrier 9B, Roll Film Carrier 15A/15M, Roll Film Carrier 21,

MARS Controller 4, MARS Mini Controller 2, Manual Frame

Masking Kit, Counter Kit, Foot Switch Kit, PC Interface Kit,

Grayscale Memory Board

3

11

Page 19

3

General Information

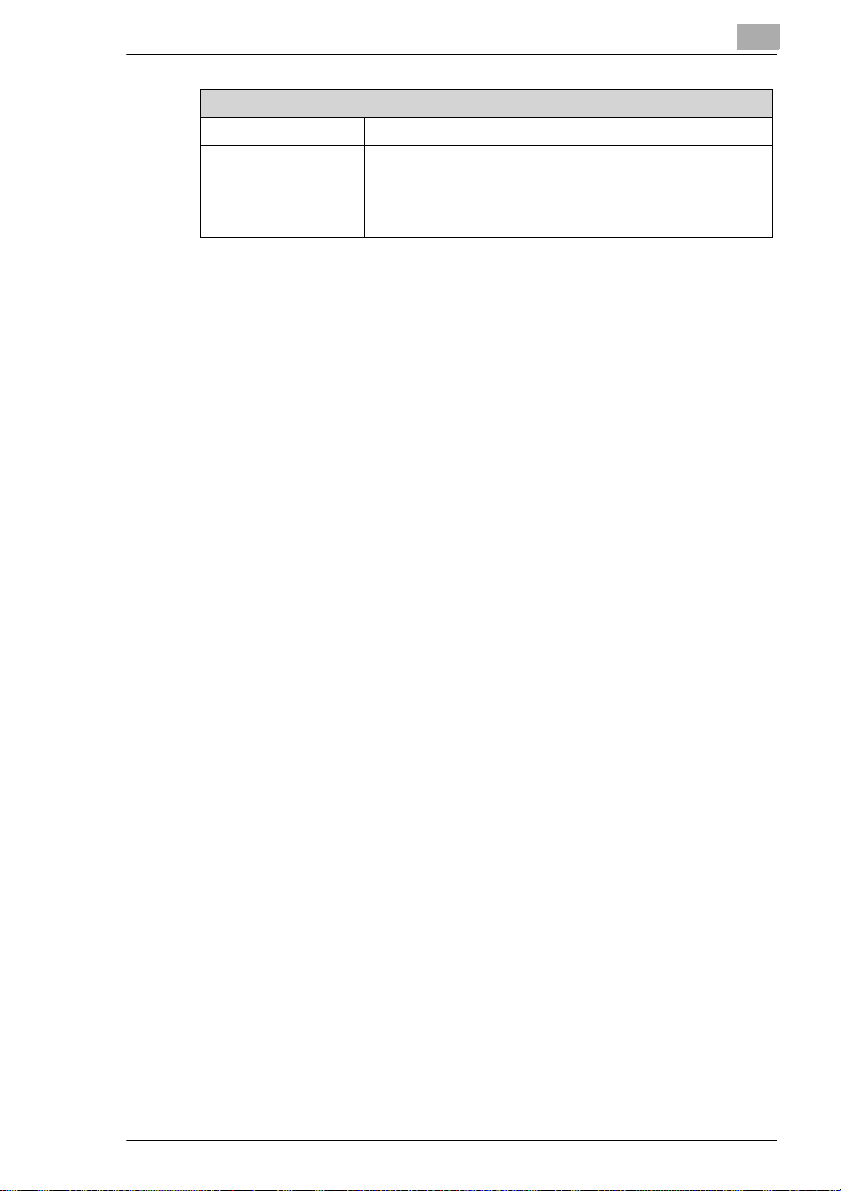

3.1.2 MS 6000 & MSP3000 Printer System

Specifications

Type: Microfilm Scanner Printer System

Printing Method: Laser Electrostatic

Resolution: 400, 600 dpi

Print Size: 8-1/2" × 11" (or A4) Crosswise, 11" × 17" (or A3) Lengthwise

Print Speed: 20 sheets per minute (8-1/2" × 11" or A4: Crosswise)

First Print Time: 13 seconds (8-1/2" × 11" or A4: Crosswise)

Warm-up Time: Less than 70 seconds

Multiple Printing: 1-19 sheets (LED countdown identification)

Paper Supply: Automatic Feeding System

Power Consumption: Less than 1100W (Scanner: 350W, Printer: 750W)

Printer‘s Dimensions 561mm (W) x 521mm(D) x 409 mm (H) or

Printer‘s Weight 28 Kg or 61-3/4 lbs (including Imaging Cartridge)

Printer’s Option: Second Paper Cassette Unit

8-1/2" × 11" (or A4) Lengthwise, 8-1/2" × 14" (or B4) Lengthwise

Paper Feeding Tray (250 sheets max.)

Paper Cassette 1 (250 sheets max.)

Paper Cassette 2 (250 sheets max.): Option

22" (W) x 20-1/2" (D) x 16" (H)

12

3.1.3 MS 6000 & MSP2000 Printer System

Specifications

Type: Microfilm Scanner Printer System

Printing Method: Laser Electrostatic

Resolution: 400 dpi

Print Size: 8-1/2" × 11" (or A4)

Print Speed: 8 sheets per minute (8-1/2" × 11" or A4)

First Print Time: 19 seconds (8-1/2" × 11" or A4)

Warm-up Time: Less than 20 seconds

Multiple Printing: 1-19 sheets (LED countdown identification)

Paper Supply: Automatic Feeding System

Multipurpose tray (150 sheets max.)

Power Consumption: Less than 930W (Scanner: 350W, Printer: 580W)

Printer’s Dimensions 394 mm(W) x 446 mm(D) x 328 mm(H) or

15-1/2"(W) x 17-1/2"(D) x 13"(H)

Printer’s Weight 17 lbs. (7.8kg) <Including Toner/Drum Cartridge>

Printer’s Option: Face-Up Tray

Page 20

General Information

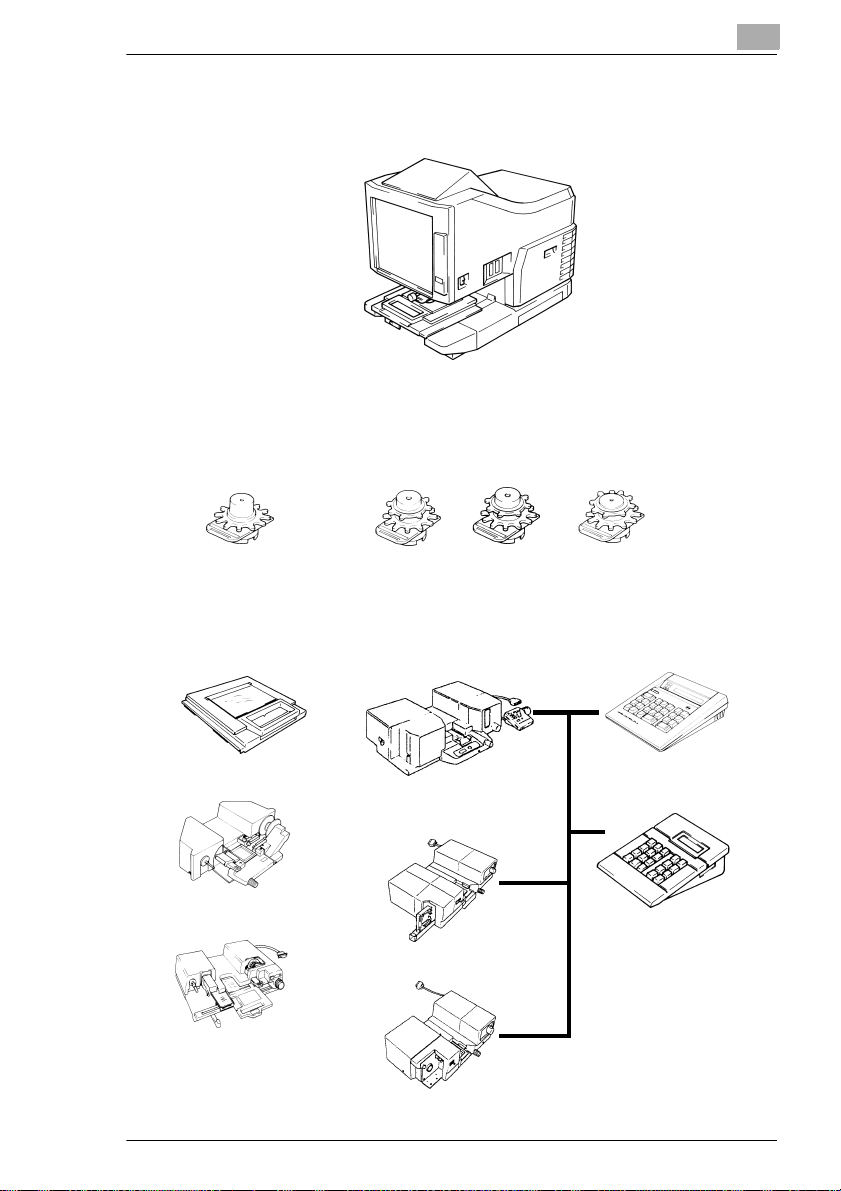

3.2 System Configuration

Scanner

Projection Lens

-Single Lens

- Zoom Lens

3

7.5X

FC-5

RFC-9B

UC-2

9-16X 13-27X 23-50X

Film Carrier Auto Retrieval Controller

RFC-21

RFC-15A

RFC-15M

MARS C-4

MARS MINI 2

13

Page 21

3

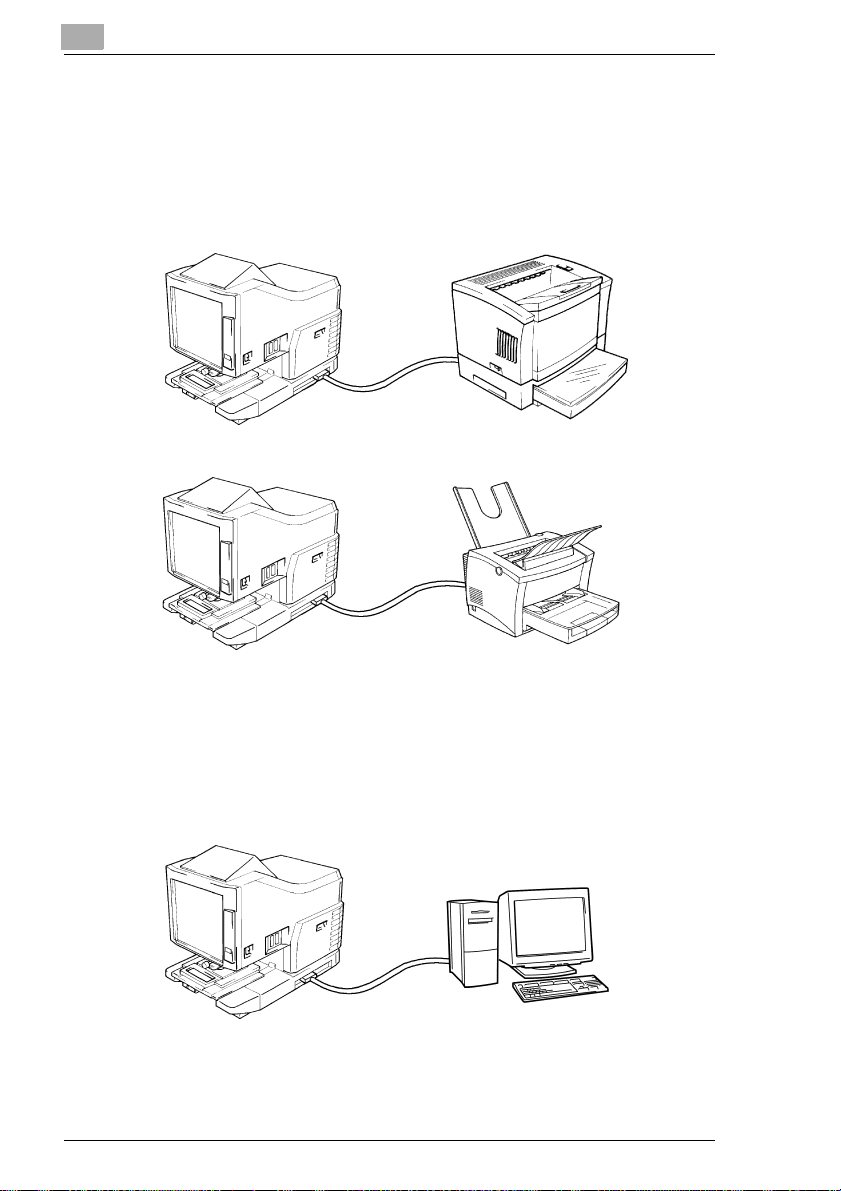

3.3 Connection Mode

This Scanner is available in the following configurations.

3.3.1 PR Mode (Scanner + Printer)

The Scanner is connected to a dedicated printer, allowing scanned

images to be printed out directly.

General Information

MSP3000 Printer

14

MSP2000 Printer

Each scanner is designed exclusively for use with its respective Printer.

3.3.2 PC Mode (Scanner + Personal Computer)

The Scanner is connected to a personal computer and the scanned

images can be uploaded to the computer. An optional PC interface kit

required for connection to a personal computer.

Connection to a personal computer and printer can be switched using

Control Panel.

Page 22

General Information

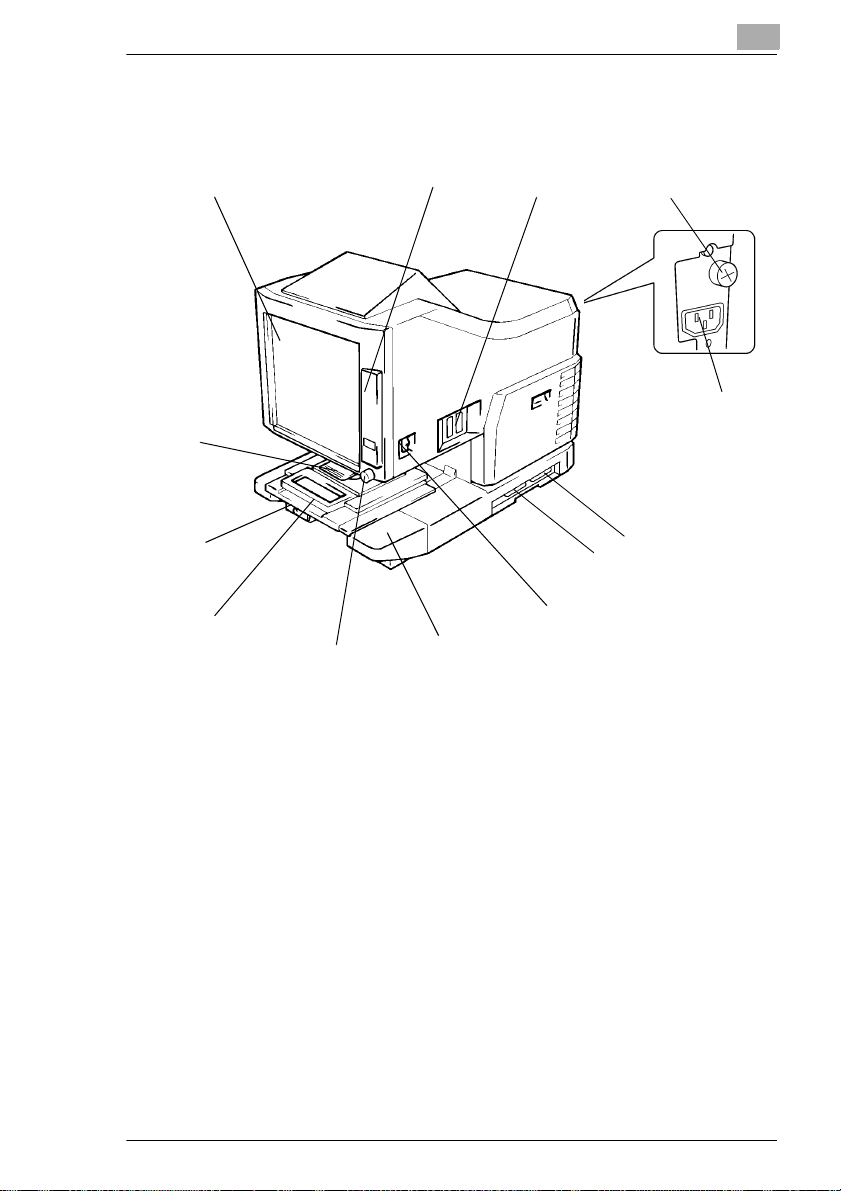

3.4 Parts Identification

3

1 2

13

12

11

10

1. Screen

2. Control Panel

3. Option Interface Connector (option)

4. Fuse Holder

5. Power Cord Socket

6. Printer Connector

7. SCSI Connector

8. Power Switch

9. Projection Unit

10. Image Rotation Knob

11. Fiche Carrier 5 (option)

12. Brightness Select Lever

13. Projection Lens (option)

3

4

5

6

7

8

9

15

Page 23

3

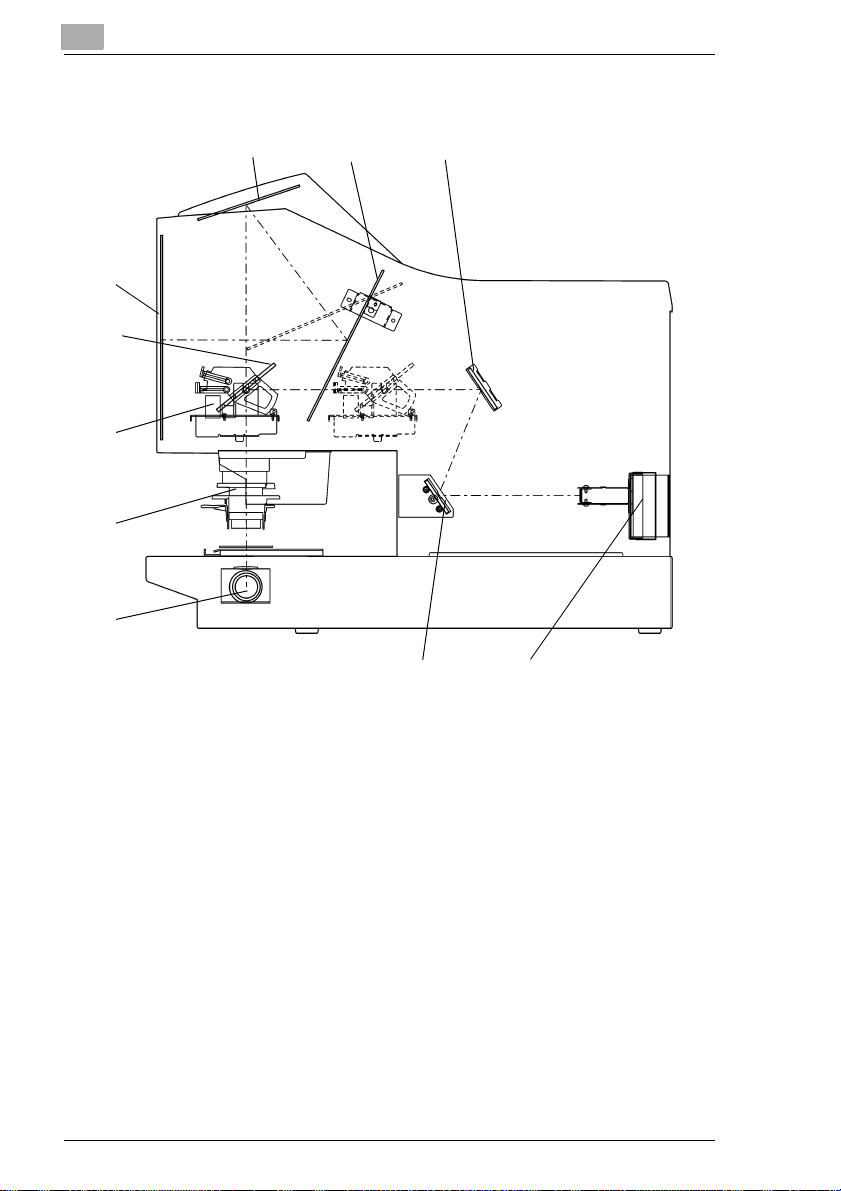

3.5 Component Layout

General Information

13

2

4

5

6

7

8

910

16

1. 1st Reader Path Mirror

2. 2nd Reader Path Mirror

3. 2nd Scan Path Mirror

4. Screen

5. 1st Scan Path Mirror

6. Scan Table

7. Projection Lens

8. Projection Lamp

9. 3rd Scan Path Mirror

10. CCD Assy

Page 24

General Information

3.6 Electrical Components Layout

3

F1

PWB-A

PWB-BB

PWB-T

PU2

L1

M4

PU1

M3

PWB-J

PWB-EE

PWB-SS

LA1

S201

TS1

M1

M2

PC3

PWB-G

PC2

PC1

PC4

S1

PWB-C

17

Page 25

3

General Information

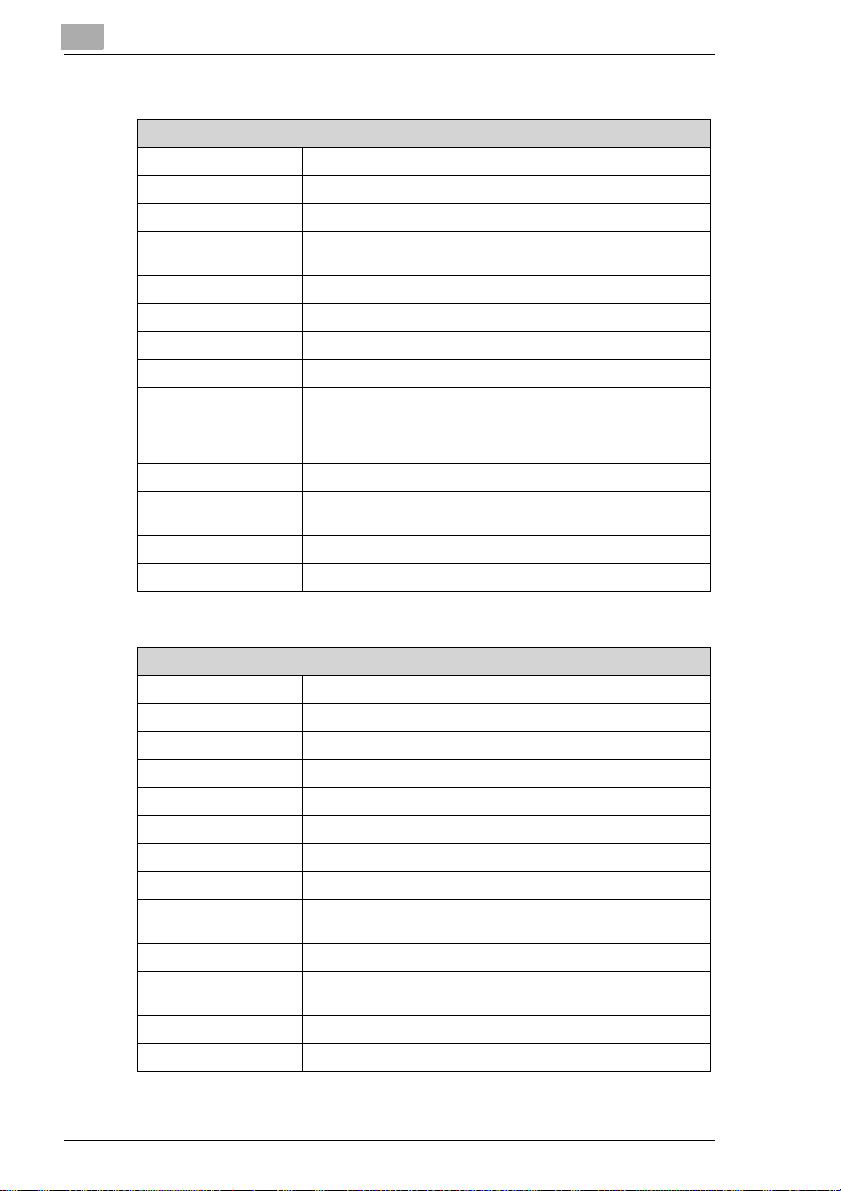

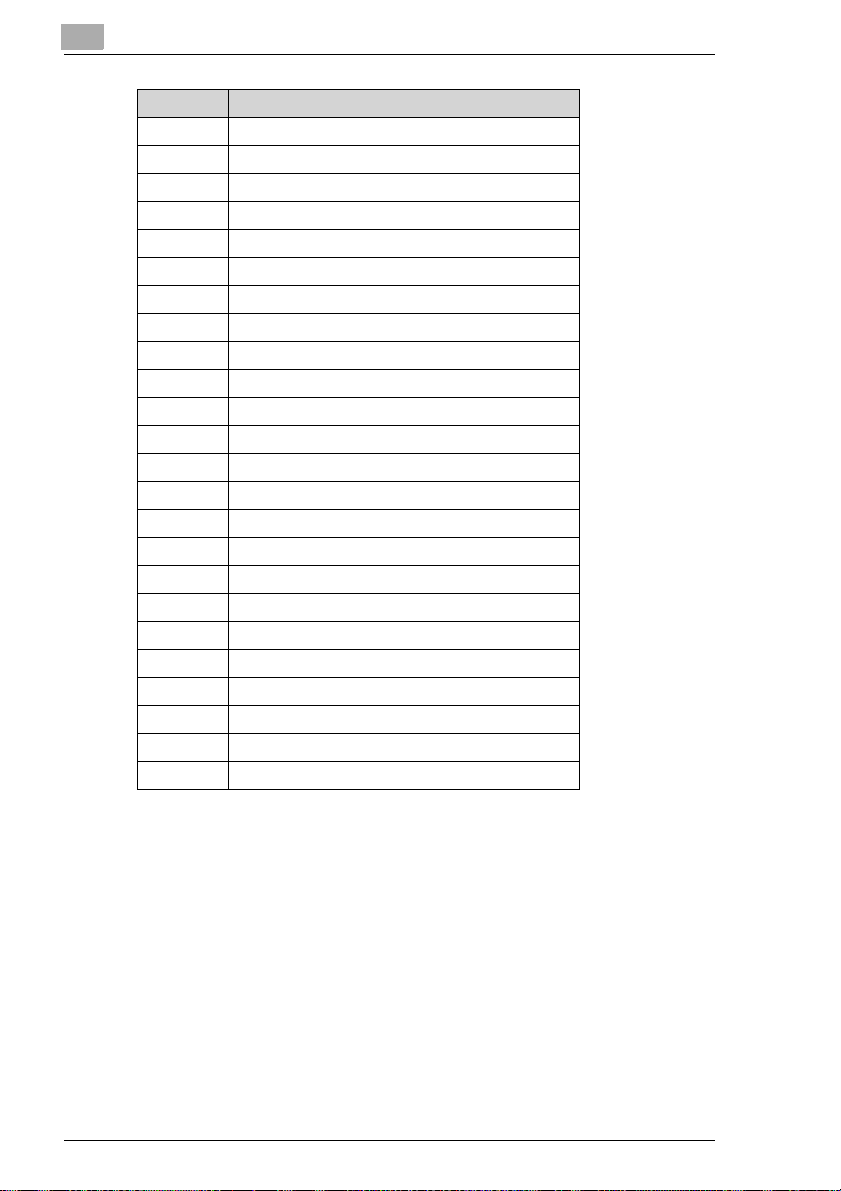

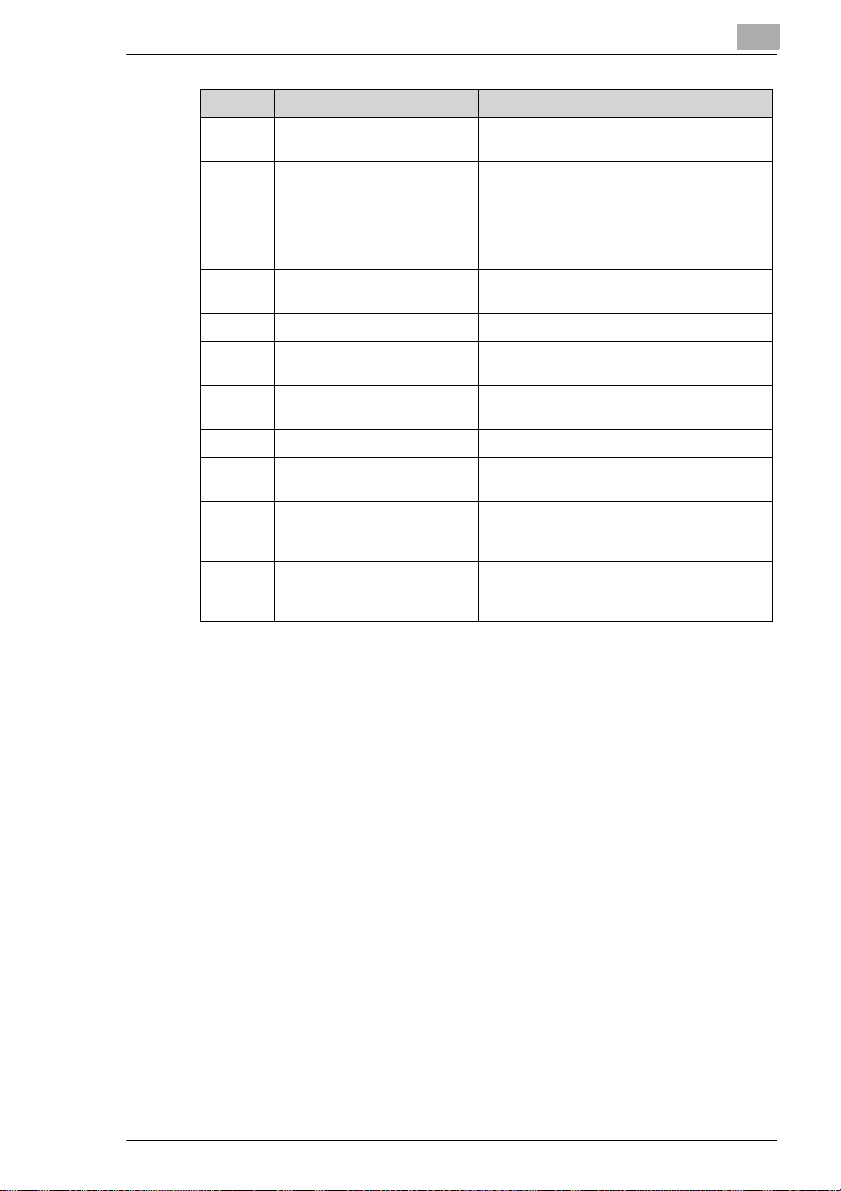

Symbol Name

F1 Fuse

L1 Filter Coil

LA1 Projection Lamp

M1 Scan Motor

M2 Scan Table Motor

M3 Power Unit Cooling Fan Motor

M4 Projection Lamp Cooling Fan Motor

PC1 Image Leading-Edge Position Sensor

PC2 Scan Mirror Position Sensor

PC3 Reader Position Sensor

PC4 Scan Position Sensor

PU1 Main Power Unit

PU2 Projection Lamp Regulator

PWB-A CCD Board

PWB-BB Main Control Board

PWB-C Control Panel Board

PWB-EE Printer I/F Board

PWB-G Scan Table Connecting Board

PWB-J Grayscale Memory Board

PWB-SS PC I/F Board

PWB-T Motor Drive Board

S1 Power Switch

S201 Interlock Switch

TS1 Thermostat

*PWB-J, PWB-SS : Option

18

Page 26

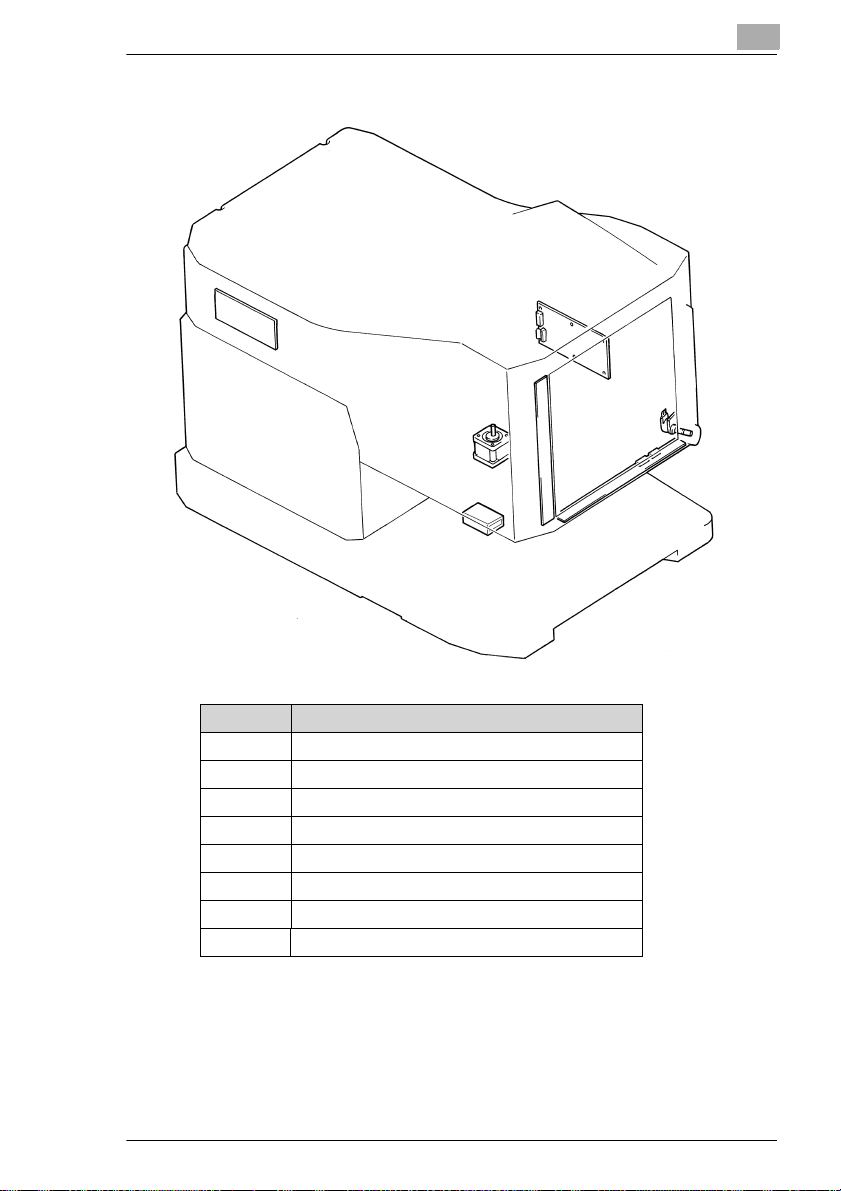

General Information

3

PWB-D

(PWB-F)

PU-3

PWB-Y

M5

CNT1

Symbol Name

CNT1 Total Counter

M5 Auto Image Rotation Motor

PU3 Option Power Unit (for RFC-21)

PWB-D Option I/F Board (for RFC-15A/M, UC-2, MARS)

PWB-F Option I/F Board (for RFC-21, UC-2, MARS)

PWB-X Manual Masking Board

PWB-Y Manual Masking Board

VR1 Auto Image Rotation Volume

*CNT1, PU3, PWB-D, PWB-F, PWB-X, PWB-Y : Option

VR1

PWB-X

19

Page 27

3

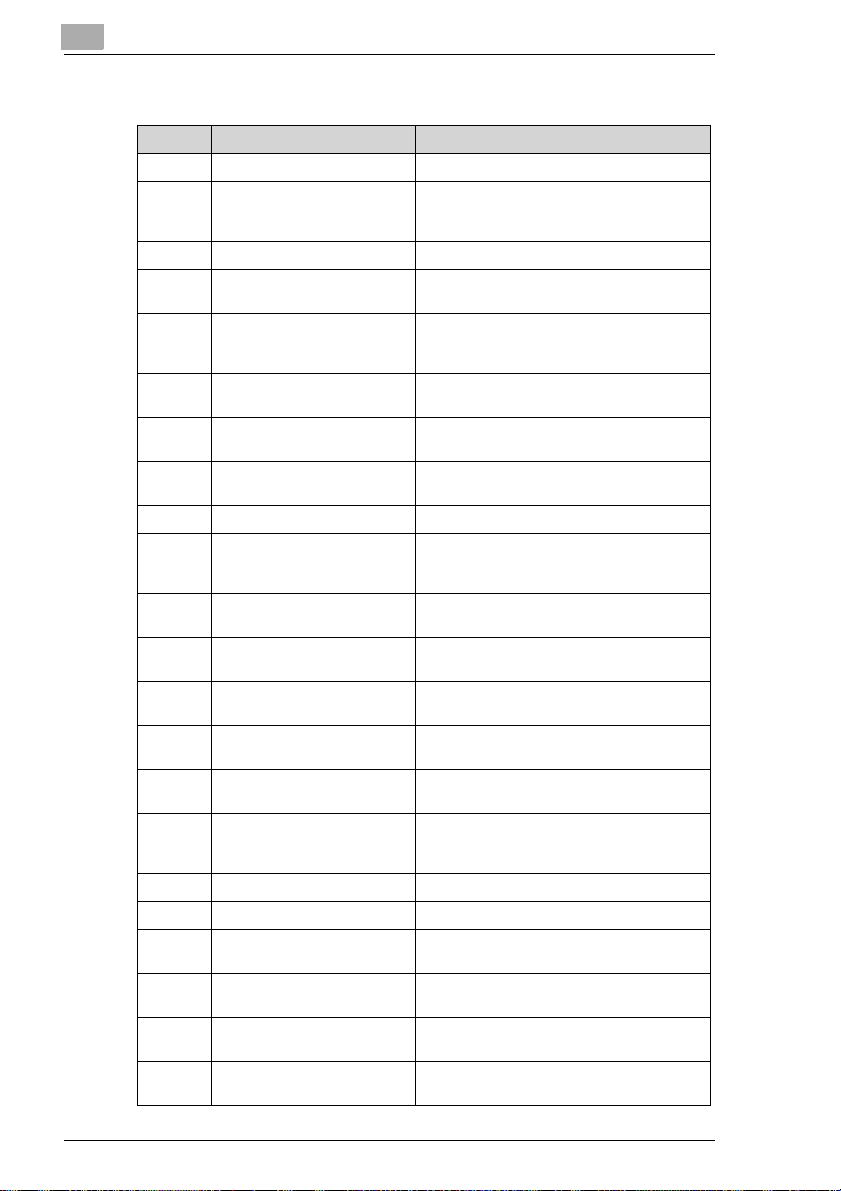

3.7 Electrical Parts Function

Symbol Name Function

CNT1 Total Counter Counts the number of prints.

F1 Fuse Power Fuse

L1 Filter Coil Power-supply noise filter

LA1 Projection Lamp The source of the light for projecting the film

M1 Scan Motor The motor which rotate the 1st scanning

M2 Scan Table Motor The motor for moving a scanning table to a

M3 Power Unit Cooling Fan Motor Exhausts the heated air surrounding the

M4 Projection Lamp Cooling Fan

Motor

M5 Auto Image Rotation Motor The motor which rotate a prism.

PC1 Image Leading-Edge Position

Sensor

PC2 Scan Mirror Position Sensor Detects the home position of the Scan Mirror.

PC3 Reader Position Sensor Detects the reader position of the Scan Table.

PC4 Scan Position Sensor Detects the scan position of the Scan Table.

PU1 Main Power Unit Converts the power voltage from AC voltage

PU2 Projection Lamp Regulator Converts the power voltage from AC voltage

PU3 Option Power Unit

(for RFC-21)

PWB-A CCD Board The CCD reads the film image.

PWB-BB Main Control Board Controls all machine operation.

PWB-C Control Panel Board The keys and LEDs which make operation of

PWB-D Option I/F Board The Interface board which connects an option

PWB-EE Printer I/F Board Communicates with the Main Control Board

PWB-F Option I/F Board Communicates with the Main Control Board

General Information

100/120V Area: 250V, 10A

220-240V Area: 250V, 6.3A

image

mirror when carrying out scan of the film

image to CCD.

reader position and a scanning position.

Power Unit out of the machine.

Exhausts the heated air surrounding the

Projection Lamp out of the machine.

Detects the slit on the Scan Mirror mounting

plate.

Leading-edge detect :L

Scan Mirror home position detect :L

Reader position detect :L

Scan position detect :L

into DC voltage.

into DC voltage and supplies that to LA1.

Converts the power voltage from AC voltage

into DC voltage (DC-24V) and supplies that to

optional RFC21.

the machine possible are included.

(RFC, MARS).

and printer.

and option (MARS, RFC).

20

Page 28

General Information

Symbol Name Function

PWB-G Scan Table Connecting Board Connects the Scan Table Section and Main

PWB-J Grayscale Memory Board PC Mode:

PWB-SS PC I/F Board Communicates with the Personal Computer

PWB-T Motor Drive Board The substrate which controls the motors.

PWB-X Manual Masking Board

(Horizontal)

PWB-Y Manual Masking Board

(Vertical)

S1 Power Switch Turns ON or OFF the machine.

S201 Interlock Switch Detects the removing or installing of the

TS1 Thermostat Cuts off the current to the Projection Lamp

VR1 Auto Image Rotation Volume The Volume which adjusts the rotation

CNT1, PU3, PWB-D, PWB-F, PWB-J, PWB-SS, PWB-X, PWB-Y: Option

Harness of the machine.

Memory used when image is read with

Grayscale.

PR Mode:

Memory used when image is read by print

reserve function.

and machine.

The substrate which specifies the Masking

position of the horizontal direction.

The substrate which specifies the Masking

position of the vertical direction.

Projection Unit.

(LA1) when it detects overheating.

(Rating: 195°C)

direction and the speed of an auto image

rotation motor (M5).

3

21

Page 29

3

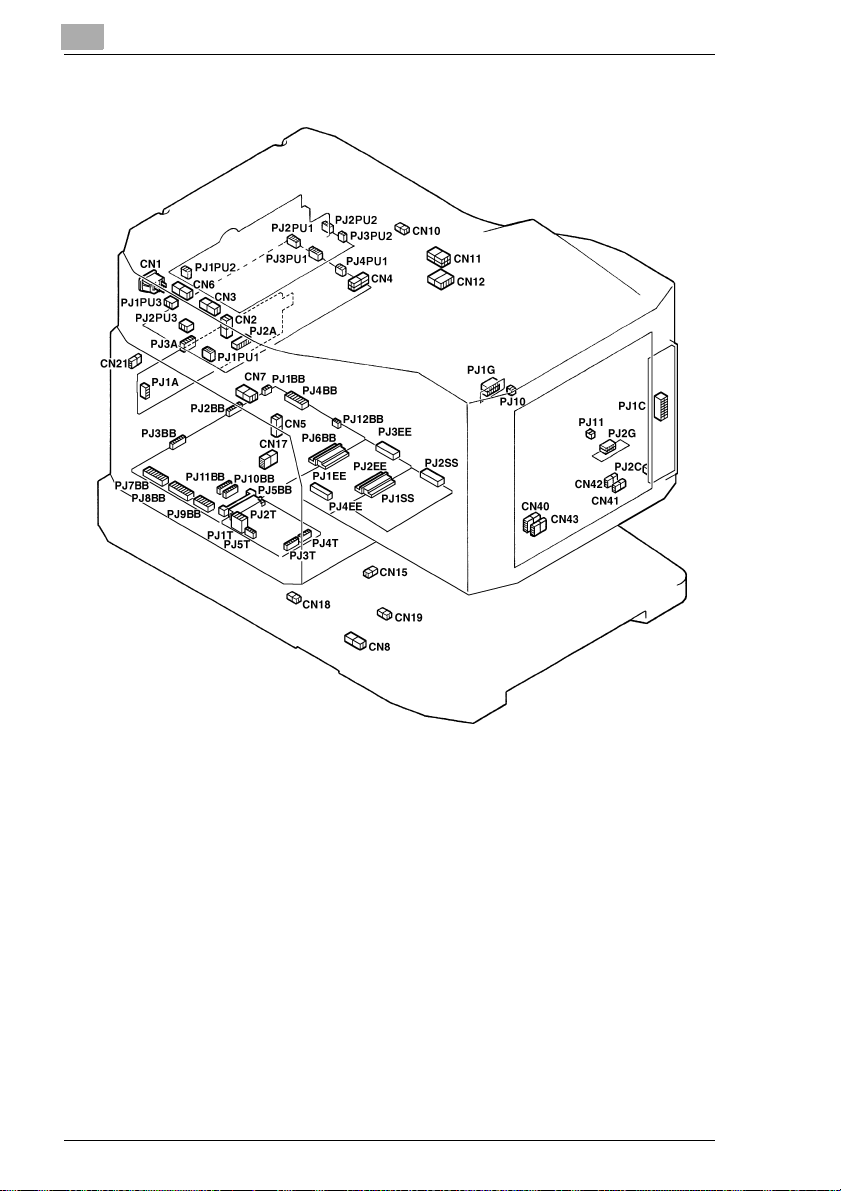

3.8 Connectors Layout

General Information

CN1 3P

CN2 2P

CN3 2P

CN4 4P

CN5 2P

CN6 2P

CN7 3P

CN8 2P

CN10 3P

CN11 6P

CN12 12P

CN15 3P

CN17 5P

CN18 3P

CN19 2P

CN21 4P

CN40 6P

CN41 3P

*PJ9BB, PJ12BB: Not Used

22

CN42 3P

CN43 6P

PJ10 3P

PJ11 3P

PJ1A 4P

PJ2A 20P

PJ3A 10P

PJ1BB 3P

PJ2BB 20P

PJ3BB 10P

PJ4BB 24P

PJ5BB 32P

PJ6BB 60P

PJ7BB 26P

PJ8BB 30P

PJ9BB 18P

PJ10BB 7P

PJ11BB 11P

PJ12BB 4P

PJ1C 28P

PJ2C 3P

PJ1T 4P

PJ2T 32P

PJ3T 9P

PJ4T 8T

PJ5T 6T

PJ1PU1 3P

PJ2PU1 4P

PJ3PU1 6P

PJ4PU1 3P

PJ1PU2 3P

PJ2PU2 4P

PJ3PU2 2P

PJ1PU3 5P

PJ1PU3 6P

PJ2PU3 4P

PJ1EE 60P

PJ2EE 80P

PJ3EE 50P

PJ4EE 40P

PJ1G 20P

PJ2G 20P

PJ1SS 80P

PJ2SS 50P

Page 30

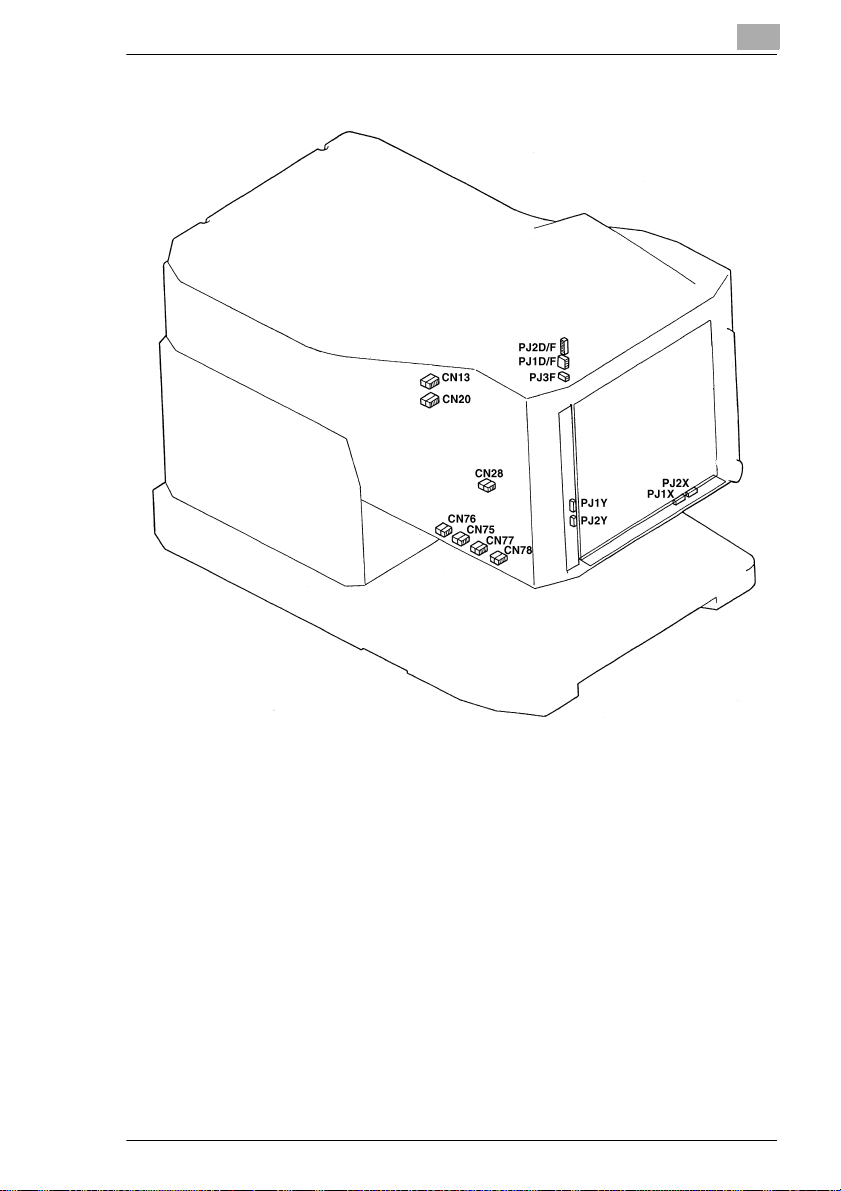

General Information

3

CN13 9P

CN20 11P

CN28 6P

CN75 8P

CN76 9P

CN77 8P

CN78 9P

PJ1D/F 5P

PJ2D/F 13P

PJ3F 2P

PJ1X 8P

PJ2X 9P

PJ1Y 8P

PJ2Y 9P

23

Page 31

3

General Information

3.9 Electrical Service Parts on P.W.Boards

NOTE

Do not touch the electric parts which has not indicated of this section.

3.9.1 Main Control Board (PWB-BB)

DSW1

DSW1...For Factory Use Only

(Normally all switches are OFF position.)

*Do not change to ON position.

24

3.9.2 I/F Board (PWB-EE)

OSC2

OSC1 ...Oscillator (42.3158MHz): For 400dpi Printer

OSC2 ...Oscillator (95.2106MHz): For 600dpi Printer

OSC1

Page 32

General Information

3.9.3 I/F Board (PWB-SS)

RSW1

.. For SCSI ID setting

3.9.4 Main Power Unit (PU1)

3

RSW1

VR61

VR62

F1

3.9.5 Projection Lamp Regulator (PU2)

F1

VR63

3.9.6 Optional Power Unit (PU3)

VR63

VR61

VR62

VR1

VR61: For Factory use *Do Not Touch

VR62: For Factory use *Do Not Touch

VR63: For Factory use *Do Not Touch

F1: Fuse

AC250V 12A (100/120V area)

AC250V 6.3A (220/240V area)

VR61: Projection Lamp voltage adjustment

VR62: For Factory use *Do Not Touch

VR63: For Factory use *Do Not Touch

F1: Fuse

AC125V 5A (100/120V area)

AC250V 5A (220/240V area)

VR1: For Factory use *Do Not Touch

25

Page 33

3

3.10 Explanation of Control Panel

3.10.1 Control Panel (Basic)

Output

Tray

Cassette1

Cassette2

Text

Fine

Photo

Auto

Nega

Posi

9

Selection

Auto Skew

Correction

Centering/Fit

Auto

Masking

Manual

Print Mode

Resolution

Film Type

Job Recall

Darker

Zoom +

Auto

Zoom clr

Lighter

Zoom -

General Information

1

2

3

4

5

6

7

8

7

10

26

11

15

PC/PR

Start

12

13

C

14

Shift

16

Page 34

General Information

1. Size Selection Key: Select the paper feeding source according to the format

of the film image that is being reflected in the screen.

: when this lamp is lit:

A 90 degree image rotation is performed during printing.

The image on the screen will be rotated 90

degrees. Consequently, the screen image

will be oriented horizontally on paper that is

positioned lengthwise, and vertically on paper that is positioned crosswise.

when this lamp is blink:

The Auto Film Format Select Print function is

available when Letter (or A4) size paper is

placed in both lengthwise and crosswise positions in the paper feeding tray and paper

feeding cassette. Paper that best suits the

format of the image on the screen will be

used for printing.

Tray: Prints the film image on paper fed from the

print tray.

Cassette1: Prints the film image on paper fed from the

cassette 1.

Cassette2: Prints the film image on paper fed from the

cassette 2. (when the Tray and Cassette1

indicators are both lit)

2. Auto Skew

Correction Key:

This key is used to turn the Auto Skew Correction function ON or OFF. When this function is applied, the Auto

Skew Correction indicator will turn on and the system

will correct any skew of the image during printing.

* After printing, the skew can be reset or retained.

3

27

Page 35

3

3. Centering/Fit Key: When this key is pressed, the setting rotates from OFF

to the Centering and Fit functions.

When Auto Masking, Trimming, or Masking are set to

off, Auto Masking will automatically be enabled when

Centering is selected.

Centering:

Places a screen image that had been searched

using Auto masking or an image that has been

trimmed in the center of the page.

Fit:

Enlarges a screen image that had been searched

using Auto masking or an image that has been

trimmed to fit the page.

*When Masking is selected or when the

Scanner is connected to the PC, this mode cannot

be used.

General Information

28

Page 36

General Information

4. Masking Key: When pressed, this key rotates from OFF to the Auto,

Trimming or Masking functions.

Each time this key is pressed, selection is switched in

order of "OFF → Auto Masking → Manual Trimming

Manual Masking → OFF."

Auto Masking:

The Auto Masking function will omit the frame

(non-image area) of a printed film image.

• The previous Centering/Fit setting is applied when-

ever ON is selected from the OFF state.

• If OFF is selected from the ON state, Centering/Fit

is disabled.

* Auto Masking is not applicable with the Masking or

Trimming settings.

Trimming:

When ON is selected, the image is printed

(scanned) with the non-image area (frame) automatically masked.

Masking:

Prints only the image outside of the area that is defined on the Screen.

• If Trimming is selected from the OFF state, the pre-

viously entered settings for Centering/Fit and Manual Masking are applied.

• From Trimming, when Masking is selected, the

Centering/Fit setting is disabled and the previous

settings for the Masking area are applied.

• The manual masking area will be cancelled when-

ever OFF is selected from the Masking state.

* Neither Trimming nor Masking are available through

the Auto Masking function.

* Trimming and Masking cannot be set when the

Scanner is connected to the PC.

5. Print Mode Key: Allows you to fine tune the image quality of the print according to the original being used. Rotate between

Text, Fine and Photo with every press of this key.

Text: For use with text images.

Fine: For use with lower grades of film.

Photo: For use with photo images.

3

→

29

Page 37

3

6. Film Type Key: Rotates between Auto, Nega, and Posi each time the

key is pressed.

Auto: The scanner automatically determines be-

tween the film type options of negative or positive for print production.

Nega: Select when using negative film. Dark and

light values of the print will be reversed.

Posi: Select when using positive film. Dark and light

values of the print will be consistent with the

image on film.

7. Exposure

Adjustment Keys:

8. Exposure Mode

Key:

9. Exposure Display: Indicates the current density level of the printed image.

10. Exposure Mode

Indicator:

Use this key to adjust the image density of the image to

be printed during the Auto or Manual Exposure mode.

The Darker key supports darker image density and the

Lighter key supports lighter image density.

Press to select between the Auto or Manual Exposure

mode.

Auto Exposure mode is indicated when the green Auto

light is on. The green Auto light turns off when the Scanner is in the Manual Exposure mode.

General Information

30

Page 38

General Information

11. Multi-Print Display: Shows the number of prints set to be made. Also displays corresponding codes in the event of a malfunction

or paper misfeed. The blinking number in this display

indicates the Scanner in operation.

Display Contents Unit

L2 Projection Lamp malfunction Scanner

C1 Scan Unit Drive malfunction

C2 Scan Mirror Drive malfunction

C3 Shading Correction malfunction

C4 Cooling Fan Motor malfunction

C6 Fusing malfunction Printer

C7 Laser Diode malfunction

C8 Polygon Motor malfunction

C9 Main Motor malfunction

CA Cooling Fan Motor malfunction

Cb Communication Error Scanner

CL Printer Clock malfunction Scanner

PE Paper Empty Printer

P0 Paper Size Error

P1 Paper Misfeed

P2 Paper Misfeed

P3 Paper Misfeed

E1 Printer Power OFF or Cable

E2 Top Cover Open

(Paper Take-up Section)

(Paper Transport Section)

(Fusing Section)

disconnect

Printer

3

12. Add Toner Indicator: Blinks when the Imaging Cartridge or Toner Cartridge

of the Printer is running out of toner and lights up when

the cartridge has completely run out of toner.

31

Page 39

3

13. Memory Input Key: To store one of the following functions into the memory

of the Scanner, first set one of the functions on Control

Panel and then press this button with the head of a pen

or other device. The next time the scanner is turned

ON, that function will appear as a default setting until a

new one is entered. (Maximum three kind of setting can

be memorized.)

1) Film Type

2) Print mode

3) Output Selection

4) Print image density

5) Exposure mode

6) Centering or Fit

7) Masking

8) Auto Skew Correction

9) Horizontal Area setting

10) Vertical Area setting

11) Electrical Zoom

12) Resolution

General Information

If you do not press the pinhole for at least 60 seconds

after a setting has been made with the Auto Reset function set to ON, the previous setting remains valid.

14. Clear/Stop Key: Press to clear the setting on the Multi-Print Display, resetting it to “1” or to stop a multi-print cycle.

15. Multi-Print Keys: This key is used to set the number of prints when printing continuous, multiple pages.

The value of this setting increases by one (1, 2, 3...)

with every push of the key. (Maximum 19)

* PR mode only.

16. Start Key: Press to make a print (scan) of the image shown on the

Screen.

32

Page 40

General Information

3.10.2 Control Panel (Shift Function)

Tray

Cassette1

Cassette2

Auto

Manual

Text

Fine

Photo

Auto

Nega

Posi

3

Output

Selection

Auto Skew

Correction

Centering/Fit

1

Masking

Print Mode

2

Resolution

Film Type

3

Job Recall

Darker

Zoom +

Auto

4

Zoom clr

Lighter

Zoom -

C

6

PC/PR

Start

Shift

5

33

Page 41

3

1. Lamp Illuminance Key: When this key is pressed together with the Shift

Key, the illumination of the screen is adjusted.

When this key is continuously pressed, the screen

is gradually darkened until it is turned OFF. When

any key is pressed then, the illumination returns to

the maximum level.

2. Resolution Key: When this key is pressed together with the Shift

Key, the resolution of the Scanner is set.

When the Scanner is connected to the Printer: 4H

and 6H

When the Scanner is connected to the PC: 2H, 3H,

4H, 6H and 8H

* 4H represents 400dpi and 6H represents 600dpi.

3. Job Recall Key: When this key is pressed together with the Shift

Key, the program registration locations (1J, 2J and

3J) are called. Each time this key is pressed while

the Shift Key is held down, the display is switched

in order of 1J → 2J → 3J.

4. Zoom Key: When this key is pressed together with the Shift

Key, the electrical zoom magnification is set.

Zoom+: When this key is pressed together with

the Shift Key, the magnification is

increased by an increment of 0.01X

(up to 2.00X).

Zoom clr: When this key is held down together

with the Shift Key for one second, the

standard magnification is resumed.

Zoom-: When this key is pressed together with

the Shift Key, the magnification is

decreased by a decrement of 0.01X

(down to 0.50X).

5. Shift Key: Executes an expansion function when being

pressed together with the intended function key.

6. PC/PR Key: When this key is pressed together with the Shift

Key, the connection to the PC or to the Printer is

selected.

*This key is not valid unless the PC interface kit

(optional) is installed.

General Information

34

Page 42

General Information

3.11 Image Processing

3

Screen Image

Auto Masking The system masks the black bands that run

Trimming The system masks everything but the center of

Masking The system masks the center of the image

Centering The system generates an image that is

Print Image Explanation

→

→

→ →

along the edges of the image.

the image.

The Manual Frame Masking Kit (option) is

required.

appearing on the screen through the Manual

Frame Masking Panel function.

The Manual Frame Masking Kit (option) is

required.

centered on the printed page, from an image

on the screen with a masked frame.

Fit Fit the image on the Screen onto the entire

Auto Skew Correction The machine automatica lly correct any skew of

surface of the print.

the image when printed.

35

Page 43

3

General Information

Screen Image

Auto Format Print The machine automatically determines the

Electrical Zoom The system magnifies the screen image

Print Image Explanation

→

→

→ →

format (portrait or landscape) of the image on

the Screen and prints it as necessary.

according to the size of paper being used. The

range of standard magnification is 1.41X for

A3, 1.55X for Ledger, 1.27X for Legal and

1.22X for B4 sized paper.

36

Page 44

Mechanical and Electrical

4 Mechanical and Electrical

4.1 Illumination Mechanism

4.1.1 Overview

The Illumination Mechanism efficiently uses the light produced by the

Projection Lamp to supply the most suitable amount of light for the

projection of the Microfilm. This amount of light is determined by the size

of the Microfilm and by the magnification ratio of the Lens selected for use.

4.1.2 Projection Lamp (LA1)

A DC20V, 150W halogen Lamp is used as the light source for the reader

and printer functions.

The Projection Lamp is integrated with a Lamp Reflector which is a

polygon mirror to ensure even illuminance.

NOTE

1. Whenever the Projection Lamp Unit is removed, Make sure that the

Power Switch is turned OFF.

2. Never touch the Projection Lamp immediately after it is turned OFF:

be careful, it is extremely hot.

3. Do not touch with hand or dirty with grease the surfaces of the

Projection Lamp and Lamp Reflector.

4

Projection Lamp (LA1)

37

Page 45

4

Mechanical and Electrical

4.1.3 Projection Lamp Voltage Control Circuit

The intensity of the light emitted by the Projection Lamp is adjusted to a

level optimum for the image density by controlling the voltage applied to

the Projection Lamp.

The exposure data optimum for film image density is determined through

auto exposure data sampling made during prescan.

This exposure data is output as a Projection Lamp clock from the Main

Control Board (PWB-BB) to the Projection Lamp Regulator (PU2).

The ON and OFF periods of the Projection Lamp clock extending 606

µsec. are varied to control the Lamp voltage. The longer the OFF time,

the

higher the Lamp voltage.

Projection Lamp clock

ON OFF

H

L

38

606 µsec

.

Page 46

Mechanical and Electrical

4.1.4 Thermostat (TS1)

To avoid any of the troubles accompanying an excessive rise in the

temperature inside the machine caused by a failure of the Cooling Fan to

dissipate heat produced by the Projection Lamp, there is a Thermostat

installed at the back of the Projection Lamp.

When the ambient temperature of the Projection Lamp exceeds 122°C the

Heat-Sensitive Plate expands pushing up the Pusher Pin, which in turn

cuts off the current to the Projection Lamp Circuit.

The Circuit is reset by pushing the Reset Pin.

4

Thermostat

Reset Pin

Bi-metal

Pin

39

Page 47

4

Mechanical and Electrical

4.1.5 Condenser Lens

Overview

G

Not only must the amount of light projected onto the Screen or CCD

remain even despite changes in the microfilm or magnification ratio, but

also the light coming from the Projection Lamp must be efficiently

condensed. To accomplish this, the machine is equipped with two

Movable Condenser Lens: one convex and one concave.

Movable Condenser Lenses

G

The Brightness Shift Lever is moved manually according to the

magnification of the Projection Lens being used so that the Movable

Condenser Lenses are moved to the set position. The set position is colorcoded, TYPE 1 to 3, each defined by a corresponding magnification of the

Projection Lens.

TYPE Lens Magnification Color Code

TYPE1 7.5X Blue

TYPE1 9X-16X Blue

TYPE2 13X-27X Green

TYPE3 23X-50X Yellow

Condenser Mirror

G

Light from the Projection Lamp after having passed through the Movable

Condenser Lenses strikes this Mirror and is reflected onto the Fresnel

Lens.

Fresnel Lens

G

The Fresnel Lens, which is an acrylic plate with stepped setbacks,

ensures even illuminance from the Lamp.

Fresnel Lens

Movable Condenser

Lenses

40

Projection

Lamp

Condenser Mirror

Brightness

Shift Lever

Page 48

Mechanical and Electrical

4.1.6 Projection Lens

The Projection Lens enlarges the image of the Microfilm and projects it

onto the Screen or CCD.

Each Projection Lens comes in a unit. The Focus Ring and Zoom Ring of

the Unit are used to bring the image on the Screen into focus and enlarge

or reduce it, respectively.

The Prism Lens for image rotation is installed in the Prism Holder fixed to

the machine.

The Projection Lens Unit is slid into position in the Lens Holder of the

machine. To insert the Unit, raise the Prism Holder and, at the same time,

push it into position.

When a Projection Lens Unit is installed, the Brightness Shift Lever must

be moved as required according to each magnification.

4

Prism Unit

Prism Holder

Lens Holder

Zoom Ring

Focus Ring

Projection Lens Unit

41

Page 49

4

4.2 Image Rotation

The Prism Unit is rotated to correct any tilt of the image microfilm projected

on the Screen.

4.2.1 Prism Rotation

The Auto Image Rotating Knob is linked to the Auto Image Rotating

Variable Resistor (VR1). Turning the Knob clockwise or counterclockwise

turns the Auto Image Rotating Motor (M5) whose drive is transmitted via

a belt to the Prism Gear, thus turning the Prism Unit.

Pulley

Auto Image

Rotating Motor

(M5)

Prism Unit

Prism Gear

Mechanical and Electrical

Belt

Auto Image Rotating

Variable Resistor (VR1)

Auto Image

Rotating Knob

42

4.2.2 Auto Image Rotating Motor (M5) Control Circuit

When the Auto Image Rotating Knob is at the home position (center),

voltage at PJ2C-2 is set at DC2.5V and the Auto Image Rotating Motor

(M5) remains stationary.

PJ2C-2 reads fluctuations of the input voltages as the Auto Image

Rotating Knob is turned, there by determining the direction of rotation of

the Auto Image Rotating Motor.

Page 50

Mechanical and Electrical

4.3 Optical Section

4.3.1 Overview

The basic function of the Optical Section is to project an enlargement of

the image on the microfilm onto the Screen when in the Reader Mode and

onto the CCD when in the Scan Mode.

There is a unique light path formed in each of these modes.

The light path formed in the Reader Mode is called the Reader Path and

that formed in the Scan Mode is called the Scan Path.

Each light path is formed by two Reader Path Mirrors and three Scan path

Mirrors.

Reader

Path

4

1st Reader Path Mirror

2nd Reader Path Mirror

2nd Scan Path Mirror

1st Scan Path

Mirror

Scan Path

CCD

Projection Lamp 3rd Scan Path Mirror

43

Page 51

4

Mechanical and Electrical

4.3.2 Reader Path

The Reader Path is established when the Power Switch is turned ON and

remains formed except during a scan movement.

The image on the microfilm is projected onto the entire area of the Screen

by means of the two Reader Path Mirrors.

The light path between the Projection Lamp and Screen measures

1,293mm.

4.3.3 Scan Path

When in the Scan mode, the 1st Scan Path Mirror moves to a position that

will block the Reader Path.

It then turns to direct the film image through the four Scan Path Mirrors

onto the CCD so that it can read the image data in the sub-scanning

direction.

The light path between the Projection Lamp and CCD measures

1,298mm.

44

Page 52

Mechanical and Electrical

4.3.4 Scan Table Drive Mechanism

The Reader Path is switched from the Printer Path, or vice versa, by

moving the Scan Table to the respective positions.

The Scan Table is driven from the Scan Table Drive Motor (M2). The

direction and speed of rotation of the Scan Table Drive Motor (M2) are

controlled by the outputs from pins 3, 4, 5 and 6 (øA, øB, øA

PJ5T on the Motor Drive Board (PWB-T).

Reader Position

Scan Table Drive

Motor (M2)

4

, and øB) of

Reader Position

Sensor (PC3)

Scan Position

Scan Position

Sensor (PC4)

To switch from the Reader Path to the Printer Path, the Scan Table Drive

Motor M3 is energized there by moving the Scan Table toward the Printer

Position.

The Scan Table at the Reader Position is detected by the Reader Position

Sensor (PC3) and that at the Printer Position is detected by the Scan

Position Sensor (PC4).

It takes less than 1.3 sec. for the Scan Table to move from the Reader to

Printer Position.

45

Page 53

4

4.3.5 Scan Mirror Motion Control

The motion of the Scan Mirror is controlled by the Scan Lever and Shaft

as the Shaft is driven by the Scanning Motor (M1).

The Scan Mirror scans the image of the microfilm at a speed 1/631.6 of

the Scanning Motor (M1).

Once the prescan motion is initiated, the leading edge of the image is

synchronized with that of the paper, and the completion of the scan motion

is detected, by the Scan Start Position Sensor (PC1) which are activated

and deactivated by the cutouts in the light blocking Lever.

Scan Mirror first makes a prescan motion for reading the data before

making the scan motion.

Scan Mirror Position

Image Leading-Edge

Position Sensor (PC1)

Sensor (PC2)

Scan Mirror

Mechanical and Electrical

Light blocking Lever

Scanning Motor (M1)

46

Shaft

Scan Lever

: Scan: Prescan

The Image Leading-Edge Position Sensor (PC1) and Scan Mirror Position

Sensor (PC2) detect the cutouts in the light blocking lever.

The starting position for the prescan or scan motion is determined by

particular states of these sensors, blocked (activated) or unblocked

(deactivated), as detailed below.

Scan Motion PC1 PC2

Prescan ON (blocked) OFF (unblocked)

Scan ON (blocked) ON (blocked)

Page 54

Mechanical and Electrical

4.3.6 Mirror Scan Motor (M1) Control Circuit

Drive of the Scanning Motor (M1) is controlled by the signals which are

input to the Motor Driver Board (PWB-T) from the Main Control Board

(PWB-BB).

These signals determine the direction (forward or backward) and speed of

rotation of the Scanning Motor when the Scan Mirror makes a prescan

and scan motion.

These signals cause the Scanning Motor drive pulses to be output from

the pins (A, B, A

Scanning Motor (M1).

Motor Step A B A B

A

DC24V

A

, B) of the Motor Driver Board (PWB-T), which turns the

1 L HHH

2 LLHH

3HLHH

4 HLLH

5 HHL H

B

6 HHL L

7 HHHL

8 L HHL

B

N

S

SN

DC24V

4

Motor Step Speed (Full Size)

Scan(800dpi) 1

Scan(600dpi) 1

Scan(400dpi) 1→2→3→4→→5→6→7→8→1→..... 165 mm/sec.

Scan(300dpi) 1

Scan(200dpi) 2

Prescan 8→6→4→2→8→..... 330 mm/sec.

→2→3→4→→5→6→7→8→1→

→2→3→4→→5→6→7→8→1→

→2→3→4→→5→6→7→8→1→

→4→6→8→2→

..... 330 mm/sec.

..... 82.5mm/sec.

..... 110mm/sec.

..... 220 mm/sec.

47

Page 55

4

4.4 CCD Section

There are five 960-pixel CCD sensor chips arranged in a zigzag as

illustrated below.

The total number or pixels that can be read is 4,800 with a resolution of

400dpi.

Mechanical and Electrical

Reading With: 304.8 mm or more

Pixel Size: 63.5 µm x 63.5 µm

48

Page 56

Mechanical and Electrical

4.5 Image Bus

The image data read by the CCD goes through analog-to-digital

conversion before being output.

CCD

PWB-A

4

The CCD (Charge Coupled Device) reads the data

on the Film.

PWB-BB

Shading correction

A/D conversion

The elemental output signals are evened out in

compensation for uneven illuminance of the

Projection Lamp and sensitivity variations among

CCD cells and Projection Lens.

Shading Correction

If the CCD were to read the reflected light from an

original having a uniform density, the outputs along

the length of that CCD may vary individually due to

uneven light distribution along the length of the

Lamp and varying sensitivities of different CCD

chips. These variations are corrected through

shading correction.

Black

White

Image

White

CCD output

Black

White

Black

The analog image signals output from the CCD are

converted to digital image signals.

After Shading Correction

Line memory

Density conversion

A

The pixel signals from the five CCD chips are

output serially in the order of CCD1, CCD2, CCD3,

CCD4, and CCD5.

The data read by the CCD is proportionate to the

intensity of the light that has passed through the

film. A conversion formula is used to convert the

data read by the CCD into the image density data

which has a characteristic linear to the film density.

49

Page 57

4

Mechanical and Electrical

A

Resolution conversion

Magnification Change

in main scanning

direction

Centering in main

scanning direction

MTF correction

Linear γ conversion

Converts the output resolution

(from 400 dpi to 800, 600, 300 or 200 dpi).

Enlargement or reduction in the main scanning

direction.

Centers the image data by shifting it in the main

scanning direction.

Edge emphasis and smoothing are carried out.

• Edge Emphasis (Text Image)

The outlines of characters and fine lines are made

sharper as they appear on the copy by correcting the

MTF (modulation transfer function) characteristics

(resolution).

*MTF: Modulation Transfer Function

• Smoothing (Photo Image)

Image noise contained in the solid area of the image

is reduced to smooth the image, thereby improving

image quality of photos.

Contrast fine-adjustment

(γ : Density reproduction curve)

Nonlinear conversion

Conversion into binary

Converts 8-bit image data into

binary image data by

to a certain threshold.

PWB-BB

Binary Image

B

50

Enhances reproduction of characters and fine lines

that are low in contrast.

comparing

Grayscale Image

C

Page 58

Mechanical and Electrical

4

B

Binary Image

Erases the frame to prevent

the areas outside the image

from being output.

Serial-to-parallel

conversion

Converts pixel-by-pixel

serial image data into a

corresponding set of

parallel data for 8 pixels.

Image memory (standard)

Binary: Stores every 8 pixel temporarily.

Grayscale: Stores every 1 pixel temporarily.

PWB-BB

PWB-EE

Frame Masking

Image rotated 90

Serial-to-parallel conversion

The image data is rotated by

90 degrees and converts

pixel-by-pixel serial image

data into a corresponding set

of parallel data for 8 pixels.

PWB-J

Image memory (option)

Grayscale Image

°

C

Parallel-to-serial

conversion

Converts parallel data for 8

pixels into a corresponding set

of pixel-by-pixel serial image

data.

Printer I/F

Transfers parallel image data

for 8 pixels to the Printer.

Printer

PWB-SS

SCSI I/F

Transfers parallel image data for

8 pixels to the host computer.

Host Computer (PC)

51

Page 59

4