Page 1

TECHNICAL DATA /

COLOR PRINT FILM

K OD AK VISION Premier

September 1998 • H-1-2393t

Color Print Film / 2393

RICHER COLORS ON THE SCREEN

Now, there’s a new choice in motion picture print films—

KODAK VISIONPremier Color Print Film. Afilm with a

different look. Richer blacks. More saturated colors.

Cleaner performance. A film worthy of the KODAK

VISION Film family name.

The upper tone scale of VISION Premier Film is

significantly higher in density than EASTMAN EXR

Color Print Film, so shadows are deeper, colors are more

vivid, and the image snaps and sizzles on the screen. The

toe areas of the sensitometric curves are matched more

closely, producing more neutral highlights on projection.

Cinematographers can be more creative with lighting and

exposure, and still see remarkable results.

BENEFITS FOR LABS

• Polyester base provides

greater tear strength,

durability, dimensional

stability, and archival

keeping

• Elimination of rem-jet (no

carbon black or prebathsoluble binder)

• Potential for reduced

chemical and water usage

in processing

• Improved cleanliness on

high-speed printers (less

white dirt)

• Protectionfromstaticmarks

prior to printing

• Reduced dirt attraction to

processed prints and static

protection prior to

processing

• Better transport

characteristics for

processed film

• Superior halation protection

(no colored fringes in titles)

• Improved safelight edgefog

protection for digital

soundtrack area

• Improved fades and

dissolves, and less

propensity to safelight fog

• Extremely rich blacks,

higher color saturation, and

more neutral highlights on

projection

• Improved laser subtitling

BENEFITS FOR

DISTRIBUTORS/

EXHIBITORS

• Polyester base allows

cleaner, more durable

prints

• No colored fringes in

titles, and improved

safelight edgefog

protection for digital

soundtrack

• Improved fades and

dissolves, and less

propensity to safelight fog

• Extremely rich blacks,

higher color saturation,

and more neutral

highlights on projection

• Improved laser subtitling

™

Likeits counterpart KODAK VISION ColorPrintFilm,

VISION Premier Film is coated on a polyester base

without rem-jet, for a cleaner process and cleaner screen

images. We’ve incorporated a processing-surviving,

anti-static layer to reduce dirt attraction, and a

scratch-resistant backing layer to improve projection life.

And there are no color shifts during fades and dissolves.

So, from set tolab to screen, day to day, you’ll have more

consistent performance.

These are not incremental improvements. They are

quantum leaps forward in film technology. And with

VISION Premier Film, you’ll have the finest motion

picture color print film Kodak has ever made.

STORAGE

Unexposed print film is not adversely affected by

short-term storage at room temperature (less than 25˚C

(77˚F).Store unexposed film at 13˚C(55˚F)orlowerwhen

storage exceeds 1 month. If refrigerated, allow the sealed

can or foil bag to equilibrate to room temperature before

opening to avoid condensation. Rebag unused raw stock

and seal it in film cans before returning it to refrigeration.

Process exposed film promptly. This film exhibits

excellent latent image keeping. When exposed film must

be kept several days before processing, the tone scale of

VISION Premier Color Print Film / 2393 shows little

change. Depending on the storage temperature, labs can

compensate for the small latent image speed loss by

increasing printer TRIMS slightly (a neutral increase of 1

to 2 printer points)ifthere is a longdelaybetween printing

and processing. You can slow changes in latent image by

storing exposed film at lower temperatures. For critical

applications, such as sensitometric exposures used for

process control, keep exposed film strips at 0˚C (32˚F) or

lower.

For short-term “active” storage and projection of

processed prints (e.g., commercial film exchanges and

theatres), store at room temperature of 20 to 25˚C (68 to

77˚F) at 50 to 60 percent relative humidity. Avoid

prolonged unconditioned storage at high temperatures or

excessive humidity. For medium-term storage, store at

10˚C (50˚F) or lower, at a relative humidity of 20 to 30

percent. For more information on long-term storage, see

KODAK Publication No. H-23, The Book of Film Care.

For extended-term storage (for preservation of material

having permanent value),store at 2˚C (36˚F)or lower, ata

relativehumidity of 20to30percent. Molecular Sieves*in

a sealed can will provide additional benefit.

©Eastman Kodak Company, 1998

Page 2

Processed prints made on this film will show less than

10-percent image dye loss, even after several decades of

storage at room temperature and 50-percent relative

humidity.

dyes, which give the raw stock emulsion its familiar

purple-blue color, are washed out during processing.

EXPOSING LIGHT

COLOR BALANCE

Color print film is balanced to be printed from a color

negative,duplicate negative, or internegative, using either

an additive or subtractive printer. Black-and-white (silver

image) negatives can be printed to yield a fairly neutral

image, although slight coloration may be seen in

highlights or shadows.

Overall filtration should include a UV-absorbing filter,

such as a KODAK WRATTEN Gelatin Filter No. 2B.

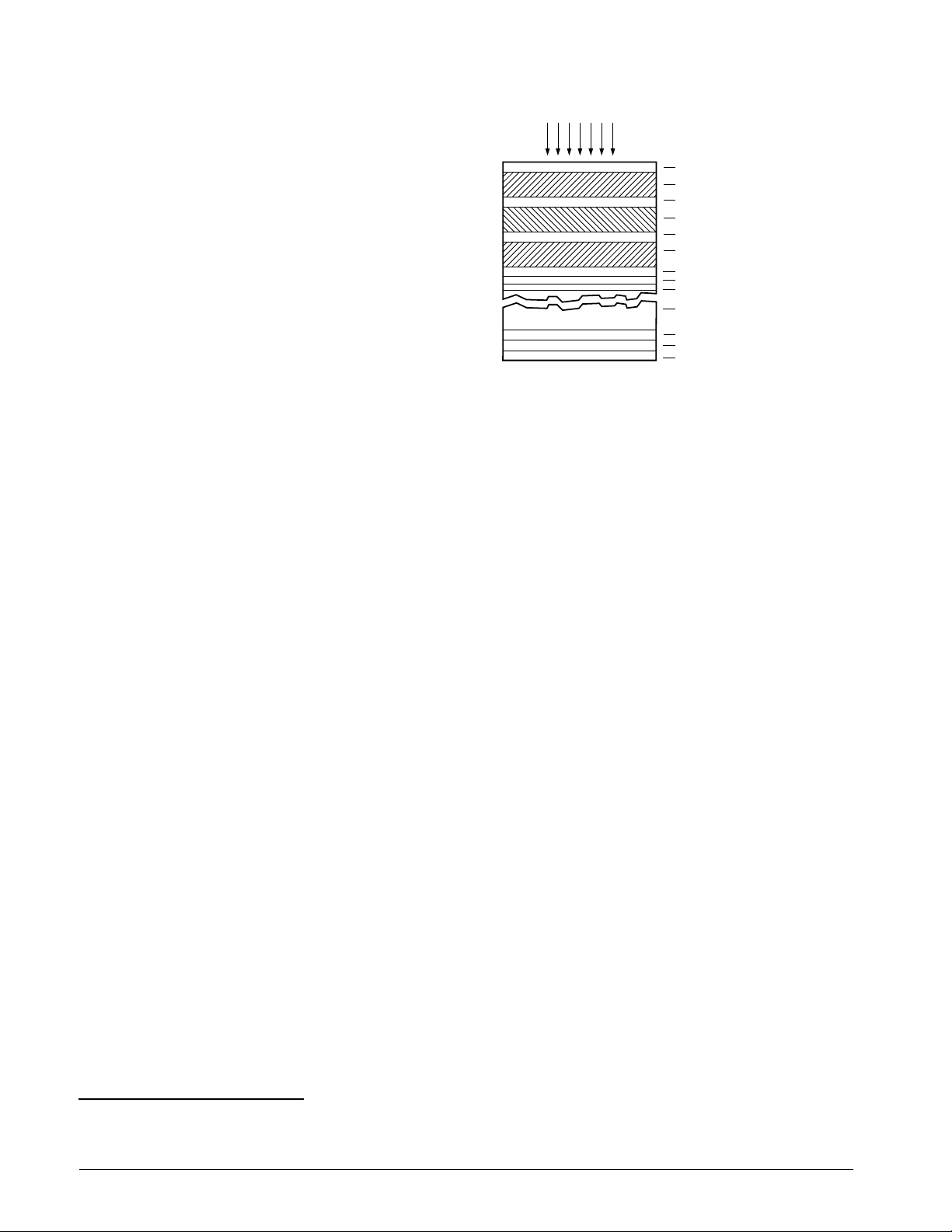

FILM STRUCTURE

KODAK VISION Premier Color Print Film / 2393 is

coated on an 120 micrometre (0.0047-inch) ESTARBase

featuring a proprietary electrically conductive anti-static

layer, a polymeric scratch-resistant backing layer, and a

process-surviving backside lubricant. Unlike rem-jet, the

anti-static layer remains with the film after processing,

eliminating the electrostatic attraction of dirt particles to

the processed print, even at very low relative humidity. A

very thin polymeric backing layer coated on top of the

anti-static layer provides superior resistance to scratches,

cinchmarks, and abrasionofbothraw stock and processed

film. The backing layer also contains process-surviving

lubricant and matte to optimize winding and transport

characteristics.

An antihalation layer containing proprietary solid

particle dyes is coated under the normal emulsion. These

dyes offer superior protection against exposure by light

reflectedbackfrom the support surfaces, minimizing color

fringing in criticalsceneslike white titlesand night scenes

with automobile headlights. The antihalation layer also

provides improved resistanceto safelight edgefog,since it

is coated between thesupportand the emulsion layers,and

absorbs any support light-piping from the edge of the roll.

The imaging layersare coated ontop of theantihalation

layer and theycontain new patented emulsion andcoupler

technology.The bottom layerissensitiveto blue light,and

produces the yellow dye image. An interlayer controls

diffusion of developer and development by-products. The

next layer is sensitizedtored light, andyieldsthe cyan dye

image. Another interlayer is coated on top of it. The top

image-forming layer is sensitized to green light, and

produces magenta dye. Theverythin topmost layer(SOC)

provides protection from scratches. Process-surviving

lubricant and matte are used in the SOC to optimize

windingand transport characteristics. Theemulsionlayers

also contain absorber dyes to precisely control film speed

and reduce intragrain light scatter, increasing sharpness

and further reducing halation. These soluble absorber

Gel Protective Coat (SOC)

Green-Sensitive Emulsion

Clear Gelatin Interlayer

Red-Sensitive Emulsion

Clear Gelatin Interlayer

Blue-Sensitive Emulsion

Anti-Halation Dye Layer

Subbing Layer

U-Coat

Safety Film Base

4.7 Mil ESTAR Base

U-Coat

Conductive Anti-Static Layer

Scratch Resistant T-Coat W/Lube

This drawing illustrates only the relative layer arrangement of the

film and is not drawn to scale.

F002_0698AC

IDENTIFICATION

KODAK VISION Premier Color Print Film / 2393 raw

stock has the typical blue-purple emulsion color of print

film.Slightbatch-to-batch variationsinrawstockcolor are

normal. The back side of the raw stock has no rem-jet,

appears dark blue to slate-gray, and has a slight

iridescence.

This film has slightly less surface gloss than processed

2386 / E / 3386 / E Film. When viewed by reflected light,

the back side exhibits a slight iridescence, with subtle

color bands due to the dichroic nature of the very thin

back-side coatings.

After processing, “2393 KODAK” is visible along the

length of the film, along with strip number and date codes.

This film is available on ESTAR base only. Most

35 mm applications use KS-1870 (ISO type “P”) print

perforations.

DARKROOM RECOMMENDATIONS

You can use sodium-vapor lamps with a KODAK No. 8

Safelight Filter / dark yellow in safelights providing

general darkroom illumination.The filtered sodium-vapor

lamp provides the best visual efficiency with the least

visual effect on the film.

If you are using a low-wattage tungsten bulb for

task-lighting, filter it with a KODAK 8 Safelight Filter /

dark yellow. You can use amber Light Emitting Diodes

(LEDs) (590 nm peak wavelength) for minimal task or

path lighting; however, do not use them for prolonged or

general darkroom illumination.

* Available from FPC, 6677 Santa Monica Boulevard,

Hollywood, California 90038, 213-468-5774.

2 KODAK VISION Premier Color Print Film / 2393™• H-1-2393t

Page 3

PROCESSING

Processthis film in Process ECP-2B.Nochangeinprocess

sequence is required.

Becausethere is norem-jettoremove, VISION Premier

Color Print Film offers the potential for eliminating the

current prebath chemicals and reducing water usage.

However, exercise care if the rem-jet removal steps are

eliminated, as replenishment rates will change

dramatically if dry film enters the developer directly.

Soluble dye buildup in the seasoned developer will also

increase. Greatly reducing water flow will lead to

increased concentrations oftotal process effluentfrom the

laboratory, which may have regulatory implications. For

further assistance, contact your Kodak engineering

representative.

The antihalation dyes used in VISION Premier Color

Print Film are decolorized and removed during

processing. Although most of the dye is removed in the

developer,complete removal isalsodependenton the “tail

end” solutions, such as the bleach.

To prevent static during projection, maintain a relative

humidity of 50 to 60 percent in the projection room.

It is important that you maintain a “clean” process:

proper solution mix and storage procedures to minimize

“tar” formation, process machine and recirculation

designed to minimize aeration (e.g., submerged racks),

periodic cleaning of racks and tanks, proper maintenance

of squeegees and wiper blades, and efficient filtration.

For more information, see KODAK Publication No.

H-24.09, Manualfor Processing KODAK Motion Picture

Films, Process ECP-2B Specifications, Module 9.

LABORATORY AIM DENSITY (LAD) CONTROL METHOD

To control your process, use Process ECP-2 control strips

for this product available through your local sales

representative.

To aid in color timing and curve placement, negative

originals should be timed relative to the Laboratory Aim

Density (LAD)Control Film supplied by Eastman Kodak

Company. The LAD ControlFilm provides both objective

sensitometric control and subjective verification of the

duplicating procedures used by the laboratory.

For print films, the LAD patch is printed to a neutral

gray of 1.0 visual density (1.00 Equivalent Neutral

Density) on the processed print at the setup lights.

The Status A densities are:

RECIPROCITY

You can print this film on a variety of printers, ranging

from slow step-optical printers to very high-speed

continuous contact printers used for release printing.

Exposuretimes may range from1/10of a second toalmost

1/3000 of a second, with little or no change in tone scale.

For printers that change exposure time during printing,

newspeed reciprocity correctionshould be used.KODAK

VISION Premier Color Print Film / 2393 has improved

fadeand dissolve characteristics. Printers withmechanical

fader cams will no longer need to use filter correction to

achieve neutral color balance with fades and dissolves.

Printers with programmable light valves will need to

reprogram the fadeanddissolve algorithm inthe printer to

obtain neutral color balance with fades and dissolves.

Consult the printer manufacturer for the proper test

procedure to obtain the appropriate corrections.

PRINTER CONDITIONS

Pictorial Printing

The printer setup for KODAK VISION Premier Color

Print Film / 2393 is similar to EASTMAN Color Print

Film 2386 / E / 3386 / E, with little or no change required.

For example, if youuseanadditive-type printer, suchas

a Bell and Howell Printer, Model 6123, to print originals,

you can use a 90 V dc lamp, a KODAK WRATTEN

Gelatin Filter No. 2B, a KODAK Heat Absorbing Glass,

No. 2043, a printer speed of 240 feet per minute, and the

printer settings in the table below:

Beam TRIM Neutral-Density Filter TAPE

Red 14 0.40 25

Green 14 0.50 25

Blue 11 0.60 25

You can also exposethis filmwith asubtractive printer

with a KODAK WRATTEN Gelatin Filter No. 2B, a

KODAK Heat Absorbing Glass, No. 2043, and suitable

color-balancing filters (KODAK WRATTEN Color

Compensating Filters).

RGB

Density 1.09 1.06 1.03

For more information, see KODAK Publication No.

H-61, LAD—Laboratory Aim Density.

KODAK VISION Premier Color Print Film / 2393™• H-1-2393t 3

Page 4

Sound-Track Printing

Analog and digital sound-track printer setup and control

procedures for KODAK VISION Premier Color Print

Film / 2393 are similar to Film 2386 / E / 3386 / E, with

little or no change required.

Analogvariable area positive soundtracksofsilver plus

dye usually restrict the exposure to the top two emulsion

layers by inserting KODAK WRATTEN Gelatin Filters

No. 12 and No. 2B* in the light beam. The optimum

variable-area sound-track density for the print is between

1.1 and 1.8 (read at 800 nm). You can achieve excellent

frequency response and a high signal-to-noise ratio in this

density range.

Note: With the same soundtrack negative, the print

density of VISION Premier Color Print Film / 2393 is

about .1 higher than VISION Color Print Film / 2383.

For a variable area positive sound track of silver plus

magenta dye only, printed from a negative sound track,

restrict the exposure to the top two emulsion layers by

inserting KODAK WRATTEN Gelatin Filter No.12 and

KODAK Color CompensatingFilter 110 Cyanin the light

beam. The optimum variable-area sound-track density for

the print is between 0.8 and 1.1 (read at 800 nm). This

print density will provide a good compromise between

signal-to-noise ratio and frequency response.

Use cross-modulation test procedures to determine the

density of the sound-track negative required to produce

minimum cross-modulation distortion at the optimum

print density.

Digital sound-on-film soundtracks (e.g., Dolby Digital

and Sony SDDS) are dye only. Consultthe systemvendor

for performance recommendations.

SPLICING

Use tape splices for this film. Since ESTAR Base is

imperviousto most solvents, cementspliceswillnot work.

Keep the knife on the tape splicer sharp and properly

aligned with the splicer platen. As the knife is lowered to

cut the film, slight leftward pressure will help ensure a

tight mesh of the cutting edges to give a clean cut. Taping

bothsides of thefilmisrecommended to minimizefold-up

or stretching. An ultrasonic weld splicer (Metric splicer)

also may be used.

You can use tape splices to intercut triacetate and

ESTAR Base film.However, because ESTARBase prints

are 20 micrometres thinner, there may be a slight focus

difference when projecting on a large screen. To assure

compatibility, order the same type of film stock for all

prints used in a production.

STANDARD PRODUCTS AVAILABLE

Format

35 mm SP666 2000 (610) KS-1870

35 mm SP779 4000 (1220) KS-1870

35 mm SP789 6000 (1829) KS-1870

Length in Feet

(Metres)

Note: For availability of non-standard products, contact

your Kodak location.

Perforation

Pitch

IMAGE STRUCTURE

This film’s excellent sharpness captures the detail in the

printing negative for projection onto the largest of theatre

screens. Fine-grained emulsions, an ultra-thin layer

structure, intragrain absorbing dyes, and superior halation

protection contribute to its performance.

MODULATION-TRANSFER CURVE

This graph showsameasure of thevisual sharpness ofthis

film. The x-axis, “SpatialFrequency,” refers tothenumber

of sine waves per millimetre that can be resolved. The

y-axis, “Response,” corresponds to film sharpness. The

longer and flatter the line, the more sine waves per

millimetre that can be resolved with a high degree of

sharpness — and, the sharper the film.

Modulation-Transfer Curves

200

100

70

50

30

20

10

7

5

RESPONSE (%)

3

2

1

F010_0058AC

SPATIAL FREQUENCY (cycles/mm)

G

R

B

1001 2 3 4 5 10 20 50 200 600

* You can omit the No. 2B Filter without affecting the sound quality.

Using this filter is an operational convenience to

conform with printer setup for other products that require it.

4 KODAK VISION Premier Color Print Film / 2393™• H-1-2393t

Page 5

SENSITOMETRIC CURVES

The curves describe this film’s responseto red,green, and

blue light. Sensitometric curves determine the change in

density on the film for a given change in log exposure.

Sensitometric Curves

6.0

5.0

4.0

3.0

DENSITY

2.0

1.0

0.0

1.0

F010_0057AC

Exposure:

Process:

Densitometry:

1/500 sec Tungsten plus KODAK

Heat Absorbing Glass, No. 2043

(plus Series 1700 Filter)

ECP-2B

Status A

B

0.0

LOG EXPOSURE (lux-seconds)

1.0

2.0

G

R

3.0

SPECTRAL-SENSITIVITY CURVES

These curves depict the sensitivity of this film to the

spectrum of light. They are useful for adjusting optical

printers and film recorders and for determining,

modifying, and optimizing exposure.

Spectral-Sensitivity Curves

1.0

Effective Exposure:

Process:

Density:

0.0

*

1.0

LOG SENSITIVITY

2.0

ECP-2B

1.0

Tungsten exp. 1/50 sec

Yellow-

Forming

Layer

Magenta-

Forming

Layer

Cyan-

Forming

Layer

DIFFUSE RMS GRANULARITY CURVES

The emulsion granularity of this film is similar to Film

2386 / E / 3386 / E. VISION Premier Color Print

Film / 2393 does have a higher level of very small matte.

The matte particles may be visible at extremely close

viewingdistance to the screen, especiallyin clear (D-min)

areas of the print.

To find the rms granularity value for a given density,

find the density on the left vertical scale and follow

horizontally to the sensitometric curve and then go

vertically (up or down) to the granularity curve. At that

point, follow horizontally to the Granularity Sigma D

scale on the right. Read the number and multiply by 1000

for the rms value.

Diffuse RMS Granularity Curves

4.0

Process:

3.8

Densitometry:

3.6

3.4

3.2

3.0

2.8

2.6

2.4

2.2

2.0

1.8

DENSITY

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0.0 1.0

F010_0061AC

1.4

1.2

1.0

0.8

ECP-2B

Status A

LOG EXPOSURE (lux-seconds)

B

G

R

B

R

G

Spectral-Dye-Density Curves

Typical densities for a midscale neutral subject

and D-min.

Process:

ECP-2B

Visual Neutral

Cyan

.100

.050

.040

.030

.020

.010

.009

.008

.007

.005

.004

.003

.002

.001

3.02.0

GRANULARITY SIGMA D

400

Yellow

WAVELENGTH (nm)

Magenta

700

750

650600550500450

3.0

700 750650600550500450400350300250

WAVELENGTH (nm)

*Sensitivity = reciprocal of exposure (ergs/cm ) required

to produce specified density

F010_0059AC

2

The spectral sensitivity of VISION Premier Color Print

Film / 2393 morecloselymatches EASTMAN EXR Color

Intermediate Film 5244, 2244. This gives a better match

0.6

0.4

DIFFUSE SPECTRAL DENSITY

0.2

0.0

350

F010_0060AC

between directprints and prints from a duplicate negative

produced on EASTMAN EXR Color Intermediate Film.

KODAK VISION Premier Color Print Film / 2393™• H-1-2393t 5

Page 6

KODAK VISION Premier Color Print Film / 2393

ADDITIONAL INFORMATION

For assistance, call the Kodak Information Center in the

U.S. at 1-800-242-2424 between 8 a.m. and 8 p.m.

(Eastern time), Monday–Friday; or in Canada at

1-800-465-6325 between 8:30 a.m. and 5 p.m. (Eastern

time).

KODAK LOCATIONS

FOR DIRECT ORDERING IN THE UNITED STATES:

1-800-621-FILM

FOR DIRECT ORDERING IN CANADA:

1-800-621-FILM

™

ATLANTA, GEORGIA

4 Concourse Parkway

Suite 300

Atlanta, Georgia 30328-5379

Information: 800-800-8398

CHICAGO, ILLINOIS

815 West Van Buren, Suite 320

Chicago, Illinois 60607

Information: 312-492-1423

DALLAS, TEXAS

11337 Indian Trail

Dallas, Texas 75229

Information: 972-481-1150 or 312-492-1423

HOLLYWOOD, CALIFORNIA

6700 Santa Monica Boulevard

P. O. Box 38939

Hollywood, California 90038-1203

Information: 323-464-6131

NEW YORK, NEW YORK

360 West 31st Street

New York, New York 10001-2727

Information: 212-631-3450

LATIN AMERICAN REGIONAL OFFICE

8600 NW 17

Miami, Florida 33126

Information: 305-507-5656

th

Street, Suite 200

MONTREAL, CANADA

Kodak Canada Inc.

4 Place du Commerce

Ile des Soeurs

Verdun, Quebec, H3E 1J4, Canada

Information: 514-761-3481

TORONTO, CANADA

Kodak Canada Inc.

3500 Eglinton Avenue West

Toronto, Ontario, M6M 1V3, Canada

Information: 416-766-8233

VANCOUVER, CANADA

Kodak Canada Inc.

4185 Still Creek Drive

Burnaby, British Columbia, V5C 6G9, Canada

Information: 604-320-1777

KODAK On Line At:

http://www.kodak.com/go/motion

KODAK VISION Premier Color Print

Film / 2393

KODAK Publication No. H-1-2393t

CAT 118 6618

™

Professional

Motion Imaging

Kodak,Vision,Estar,Eastman,EXR,2244, 2386, 2393, 3386, 5244,

Keykode, and Wratten are trademarks.

New 9-98

Printed in U.S.A.

Loading...

Loading...