Page 1

TECHNICAL DATA /

BLACK-AND-WHITE FILM

K OD AK WL Surveillance Film / 2210

May 2004 • TI-1838

KODAK WL Surveillance Film / 2210 is a high-speed,

black-and-white negative camera f ilm with extremely fine

grain and high resolving power, allowing a high degree of

enlargement. It is especially useful for dimly lit subjects

exposed in daylight or artificial light.

This 400-speed film has a wide exposure latitude, which

allows quality prints from moderately under- (EI 800) or

overexposed (EI 150) negatives. You can expose this fi lm at

speeds up to EI 3200 with push processing in KODAK

PROFESSIONAL T-MAX Developers.

KODAK WL Surveillance Film / 2210 is formatted on

ESTAR-AH base, a tough, dimensionally stable polyester

support with an optical density of 0.10 for protection against

light-piping. A fast-drying backing allows processing in

high-speed processors.

IMAGE STRUCTURE

Based on develo pment in K OD AK De veloper D-76, at 20°C

(68°F).

Diffuse RMS Granularity: 10 (Extremely Fine)

Read at a net diffuse visual density of 1.0, 48 micrometre

aperture.

Resolving Power:

ISO-RPL TOC 1.6:1 50 line pairs/mm

ISO-RP TOC 1000:1 125 line pairs/mm High

STORAGE AND HANDLING

Keep unexposed film and processed f ilm in a cool, dry place.

Process film as soon as possible after exposure.

To avoid moisture condensation on film that has been

refrigerated, allow 16 mm film to stand at room temperature

for at least 1 to 1.5 hours before removal from the package;

for 35 mm film, allow 2 to 3 hours and for 70 mm film, 4 to

5 hours.

Load and unload camera in subdued light. Process

exposed film promptly after exposure. Always protect

processed negatives from strong light and store in a cool, dry

place.

EXPOSURE

The developer you use to process this film affects the

exposure index:

Exposure Index

Arithmetic / Logarithmic*

400 / 27 T-MAX

400 / 27 T-MAX RS

400 / 27 D-76

400 / 27 D-76 (1:1)

320 / 26 HC-110 (Dil B)

400 / 27 DURAFLO RT

200 / 24 MICRODOL-X

320 / 26 MICRODOL-X (1:3)

KODAK Developer

SUPPORT

Dimensionally stable 0.004-inch (0.10 mm) ESTAR Base.

SAFELIGHT

NONE; handle in total darkness.

©Eastman Kodak Company, 2004

Reciprocity

Exposure Time

(seconds)

1/10,000 None None

1/1000 None None

1/100 None None

1/10 None None

1 +1/3 stop Change Aperture

10 +1/2 stop 15

100 +1 1/2 stop 300

Lens Aperture Or Exposure Time

Adjust Either

Page 2

PROCESSING

Notice: Observe precautionary information on product labels and Material Safety Data Sheets.

Tank development times shorter than 5 minutes may result in unsatisfactory uniformity. Do not develo p this film by

inspection—KODAK WL Surveillance Film has a higher level of green sensitizing dye that results in an increased sensitivity to

safelight illumination.

These times are starting-point recommendations. Make tests to determine the best development time.

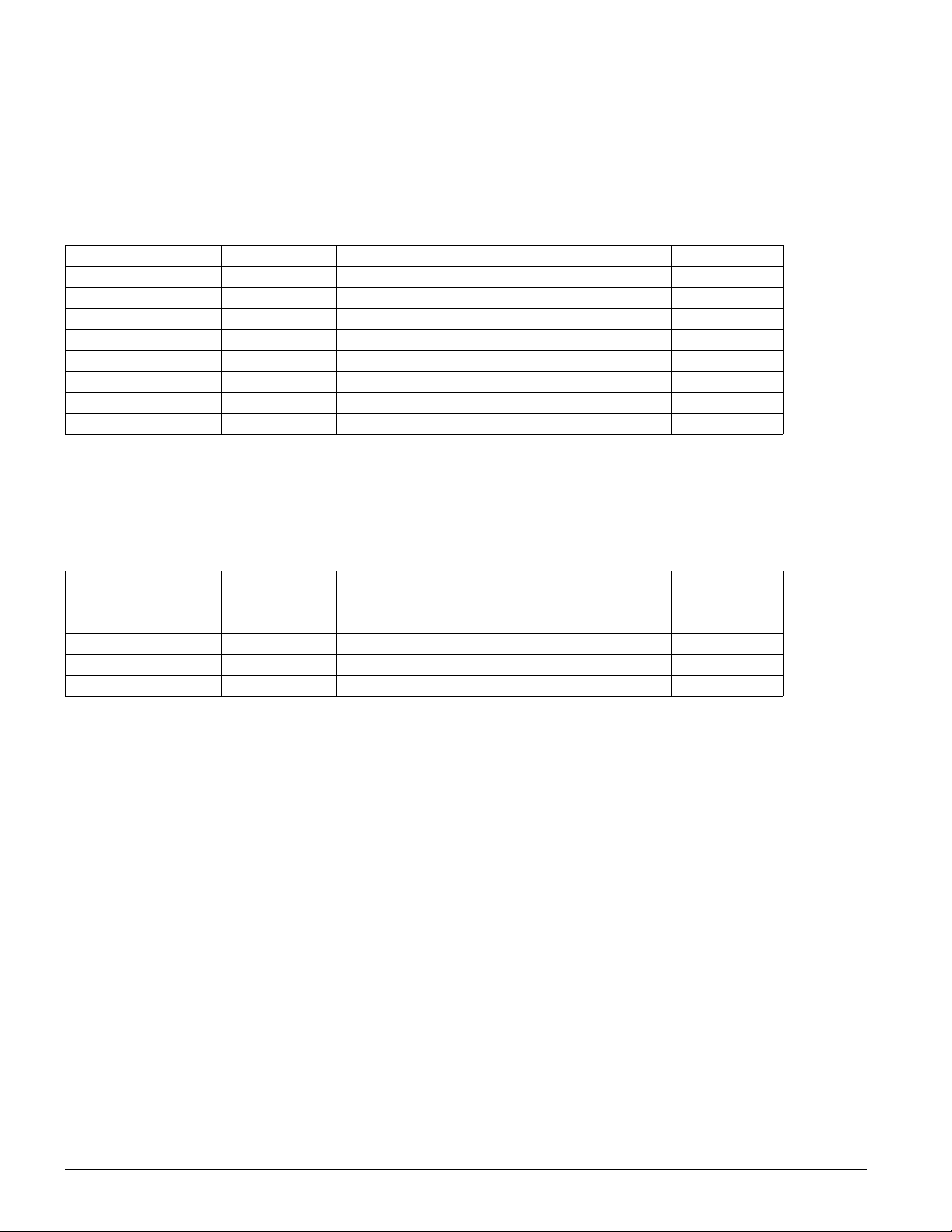

Small Tank (8- or 16-ounce), Agitation at 30-second Intervals, Development Time in Minutes

KODAK Developer 65°F (18°C) 68°F (20°C) 70°F (21°C) 72°F (22°C) 75°F (24°C)

T-MAX NR 7 6

2

61⁄

2

1

⁄

T-MAX RS NR 7 6 6 5

121⁄

*

*

2

*

6

*

2

76

11 10 9

51⁄

2

98

D-76 9 8

D-76 (1:1) 141⁄

HC-110 (dil B) 6

2

1

⁄

2

MICRODOL-X 12 101⁄

MICRODOL-X (1:3) NR NR 20 181⁄

T-MAX (1:9)

*

Primary time/temperature recommendation.

†

Using T-MAX Developer diluted 1:9 provides good processing control, slightly more speed, no change in contrast or grain, and a larger capacity of film per

gallon of developer concentrate. To mix, dilute the working solution of T-MAX Developer with an equal part of water, or dilute the concentrate by mixing one

part of the concentrate with nine parts water (1:9).

†

NR NR NR NR 15

1

⁄

2

54

1

⁄

2

2

NR = Not Recommended

51⁄

71⁄

16

*

6

*

2

1

⁄

2

2

*

*

Large Tank, Agitation at 1-minute Intervals, Development Time in Minutes

KODAK Developer 65°F (18°C) 68°F (20°C) 70°F (21°C) 72°F (22°C) 75°F (24°C)

T-MAX NR 7 6

T-MAX RS NR 81⁄

D-76 10 9

HC-110 (dil B) 8 7

MICRODOL-X 13 11

*

Primary time/temperature recommendation.

2

*

*

1

*

⁄

2

1

⁄

2

87

87

61⁄

2

61⁄

2

1

⁄

2

1

⁄

2

65

10 9 8

NR = Not Recommended

61⁄

*

6

*

7

2

2 KODAK WL Surveillance Film • TI-1838

Page 3

Rinse

Rinse at 65 to 75°F (18 to 24°C) with agitation.

KODAK Indicator Stop Bath 30 seconds

or diluted 4% acetic acid solution 30 seconds

Fix

Fix at 65 to 75°F (18 to 24°C) with frequent agitation.

KODAK Rapid Fixer

KODAK Fixer 5 to 10 minutes

KODAFIX Solution 5 to 10 minutes

*

Primary fixer recommendation.

Note: Fixer may exhaust more rapidly with this film than

with other films. Use fresh fixer . If negatives show a magenta

(pink) stain after fixing, the fixer may be near exhaustion or

a longer fix time is needed. If the stain is slight, it will have

no printing effect. If it is pronounced and irregular over the

film surface, refix the f ilm in fresh fixer. Another way to

remove the dye stain is to bathe the film in KODAK Hypo

Clearing Agent for 2 minutes at 65 to 75°F (18 to 24°C) and

follow with a 5 minute wash.

*

3 to 5 minutes

Large Tank Processing

Large tank (1/2- to 3 1/2-gallon) (Rolls), agitation at

1-minute intervals, in KODAK T-MAX RS Developer and

Replenisher:

Exposure Inde x Development Time (Minutes)

(EI) 68°F

(20°C)

400/800 8 1/2 8 7 1/2 7*

1600 12 11 10 9*

3200 NR NR NR 12*

70°F

(20°C)

72°F

(22°C)

75°F

(24°C)

* Primary time/temperature recommendation.

NR = Not Recommended.

Continuous Processing

Nominal development time, using KODAK DURAFLO RT

Chemicals, to produce a Contrast Index of 0.56 at 26.5°C

(80°F): 93 sec.

When processing this film in the KODAK VERSAMAT

Film Processor, Model 11, Model 1140, Model 5, or Model

411, using KODAK DURAFLO RT Chemicals, use the

following table.

Wash

Wash at 65 to 75°F (18 to 24°C) in running water for about

20 to 30 minutes.

Dry

Dry in a dust-free place.

Push Processing

Push-processing allows film to be exposed at higher

exposure indices. However, it does not produce optimum

quality. Prints show a slight loss of shadow detail and

increase in graininess.

The processing times to produce a CI of 0.74 for 2-stop

push-processing are given in the following tables. Use these

percentages for development not covered by the following

tables:

KODAK Developer Increased Developer

Time

T-MAX +30%

T-MAX RS +40%

HC-110 (Dil B) +30%

D-76 +20%

D-76 (1:1) +15%

MICRODOL-X (1:3) +20%

DURAFLO RT +20%

KODAK

VERSAMAT

Models 11 and 1140

(two racks)

Models 5 and 411

(one rack)

Contrast

Index

0.56

0.56

Machine Speed Setting

(feet per minute)

5.5 fpm

(approximately 93 seconds

development)

2.6 fpm

(approximately 92 seconds

development)

DIMENSIONAL STABILITY

Dimensional stability is an all-inclusive term. In

photography, it applies to size changes caused by changes in

humidity and in temperature, and by processing and aging.

The absence of solvent in ESTAR Base is one of the reasons

why ESTAR Base films show excellent dimensional

stability. The dimensional properties of ESTAR Base may

vary slightly in different directions within a sheet; the

differences that may exist, however, are not always equal in

both the length and width directions.

Differences in size change between length and width

should be within 10 percent of each other.

Note: MICRODOL-X Developer (full strength) is not

recommended for push processing.

KODAK WL Surveillance Film • TI-1838 3

Page 4

KODAK WL Surveillance Film / 2210

CURVES

3.0

Exposure: 1/50 second

Development: KODAK DURAFLO RT Developer,

80 F, 2.5 fpm (92 seconds)

2.0

DENSITY

1.0

0.0

-4.0 -3.0 -2.0 -1.0 0.0 1.0

F010_0324AA

3.0

Effective Exposure: 1.4 second

Development: KODAK Developer D-76, 68 F (20 C)

Densitometry: Diffuse Visual

2.0

*

1.0

LOG SENSITIVITY

0.0

Characteristic

LOG EXPOSURE (lux-seconds)

Spectral Sensitivity

D=0.3>Gross Fog

D=1.0>Gross Fog

Modulation Transfer Function

200

100

70

50

30

20

10

7

5

RESPONSE (%)

3

Development: KODAK Developer D-76, 68 F (20 C)

2

Densitometry: Diffuse visual

1

120502 3 4 5 10 100 200

SPATIAL FREQUENCY (cycles/mm)

F010_0326AA

MORE INFORMATION

For the latest version of technical support publications for

Kodak products, visit Kodak on-line at:

http://www.kodak.com/go/SDRproducts

If you have questions about Kodak products, call Kodak.

In the U.S.A.:

1-800-242-2424, Ext. 19, Monday–Friday

9 a.m.–7 p.m. (Eastern time)

In Canada:

1-800-465-6325, Monday–Friday

8 a.m.–5 p.m. (Eastern time)

From outside the US/Canada: 1-585-724-4000

-1.0

250 300 350 400 450 500 550 600 650 700 750

WAVELENGTH (nm)

*Sensitivity = reciprocal of exposure (erg/cm ) required

F010_0325AA

to produce specified density

NOTICE: The sensitometric curves and data in this publication represent product tested under the conditions

of exposure and processing specified. They are representative of production coatings, and therefore do not apply

directly to a particular box or roll of photographic material. They do not represent standards or specifications

that must be met by Eastman Kodak Company. The company reserves the right to change and improve

product characteristics at any time.

EASTMAN KODAK COMPANY • ROCHESTER, NY 14650

KODAK WL Surveillance Film / 2210

KODAK Publication No. TI-1838

Kodak, Kodak Professional, D-76, Duraflo, Estar, HC-110,

Kodafix, Microdol, T-Max, and Wratten are trademarks.

Note: The Kodak materials described in this publication for

use with KODAK WL Surveillance Film are available from

2

dealers who supply Kodak products. You can use other

materials, but you may not obtain similar results.

Aerial and Industrial Materials

New 4-04

Printed in U.S.A.

Loading...

Loading...