Knight Equipment UT 502WX Installation Manual

UniTech Warewash

Instruction Manual

0900591 Rev: A (07/04) Page 1 of 24

TABLE OF CONTENTS

Specifications .......................................................................................................3

Pre-Installation ......................................................................................................4

Installation

►

Mounting

►

Electrical

►

Plumbing

Operation ..............................................................................................................8

Programming ........................................................................................................9

Titration Graphs ..................................................................................................13

Adding a Sanitizer Pump .................................................................................... 14

Changing the Circuit Board

►

Procedures

►

Jumper Settings

Parts Diagrams

►

All Configurations

........................................................................................................4

........................................................................................................5

........................................................................................................7

................................................................................................... 15

........................................................................................... 15

......................................................................................... 16

►

Liquid Detergent

►

Dry Detergent (Brass)

►

Dry Detergent (Plastic)

........................................................................................... 17

................................................................................... 18

.................................................................................. 19

Wiring Diagrams

►

Single Transformer

►

Dual Transformer

►

European Models

....................................................................................... 20

.......................................................................................... 21

.......................................................................................... 22

Declaration of Conformity ................................................................................... 23

Warranty Information .......................................................................................... 24

Knight Locations ................................................................................................. 24

CAUTION: Wear protective clothing and eyewear when dispensing chemicals or

other materials. Observe safety handling instructions (MSDS) of chemical mfrs.

CAUTION: To avoid severe or fatal shock, always disconnect main power when

servicing the unit.

CAUTION: When installing any equipment, ensure that all national and local

safety, electrical, and plumbing codes are met.

Page 2 of 24 0900591 Rev: A (07/04)

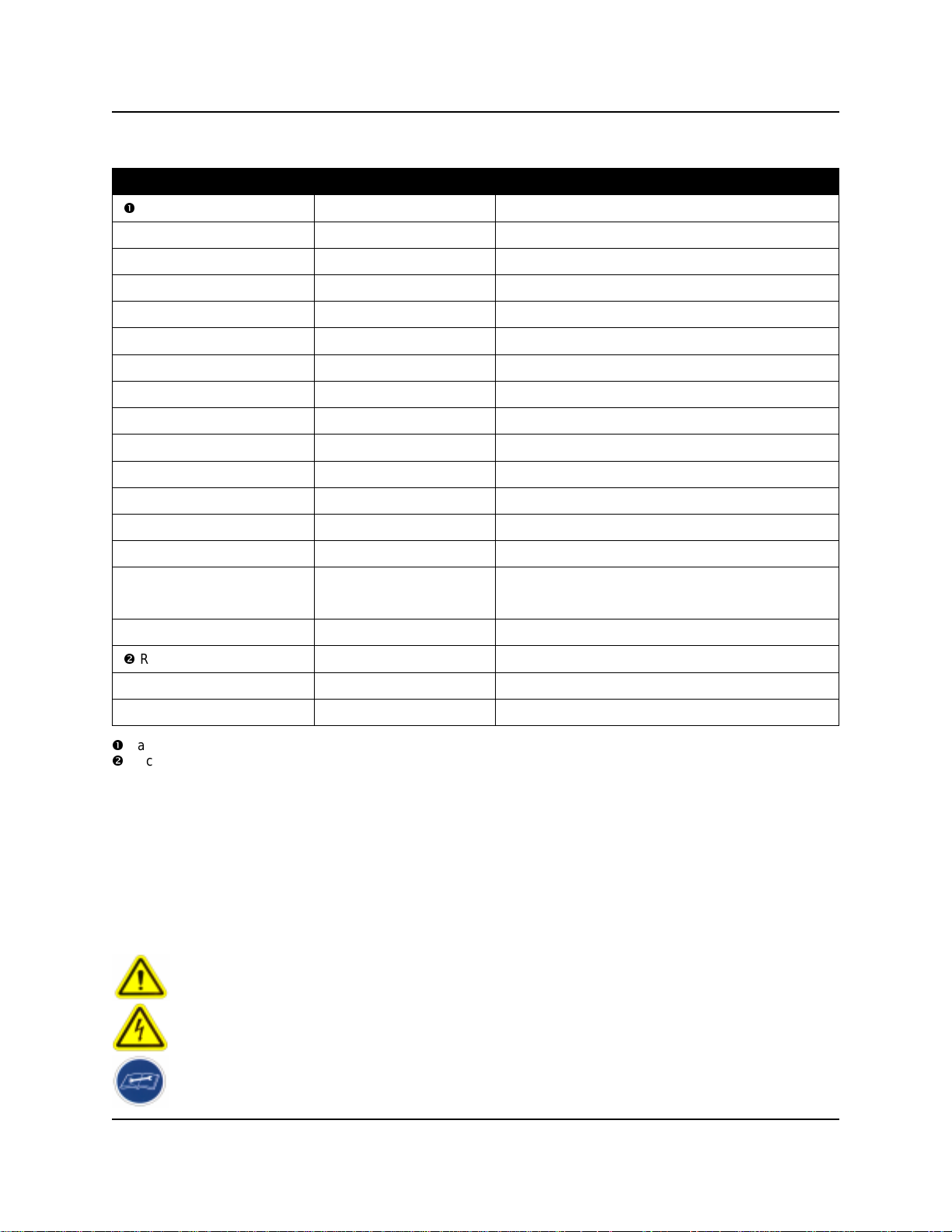

SPECIFICATIONS

Parameters Default Value Range

Pass Code 0000 0 – 9, A – Z

Language English English, Spanish, French, German, Dutch, Italian

Rinse Pump Speed 50% 0%-100% (of full speed)

Rinse Limit 60 0 – 60 sec

Rinse Delay 0 sec 0 – 60 sec

Machine Type DOOR DOOR/CONVEYOR

Rack Time 10 sec 10 – 255 sec

Detergent Mode Probe Probe/Probeless

Detergent Type Liquid Liquid / Dry / Small Tank

Detergent Speed 100% 100% (always runs at full speed)

Detergent Concentration 25 0 — 100 Knight units

Alarm Delay 180 sec 0 – 512 sec

Sani Pump Runs With Rinse Rinse/Detergent

Sani Pump Speed 50% 0%-100% (of full speed)

Initial Detergent Charge 1 sec

Detergent Recharge Time 1 sec 0 – 255 sec

Rack Count 0 0 – 65536

Recharge after n Racks 1 1 – 99

Det Feed Limit Off On/Off

Pass code does not change when clearing all programmed settings

Rack count has its own menu to allow resetting back to zero

1 — 64 sec (Door Mode)

1 — 128 sec (Conveyor Mode)

SAFETY SYMBOL EXPLANATIONS

Listed below are explanations of the safety symbols that appear either on the unit, in the instruction manual, or both.

Please familiarize yourself with the meaning of each symbol.

GENERAL CAUTION: This symbol indicates a general safety caution.

SHOCK HAZARD: This symbol indicates that hazardous voltages are inside the

enclosure.

READ MANUAL: This symbol indicates to read the manual for important

instructions and procedures related to safety.

0900591 Rev: A (07/04) Page 3 of 24

PRE-INSTALLATION

Check all applicable plumbing and electrical codes before installation. This will help to ensure that the system is

installed in safe and suitable manner. A wiring schematic of the dishwasher is useful. This is provided by the

dishwasher manufacturer or may be on the machine itself.

Plan to mount the unit on a nearby wall. Try to keep the unit within three feet from the final rinse line to avoid long

tubing runs. Do not

unit. Mounting the unit on the side, on the back, or on the vents of the dishwasher may cause thermal overload and

damage the performance of the unit.

If you are going to add a sanitizer pump (optional) to a two-product system, then it should be attached to the unit prior

to installation (see page 14).

mount the unit in the direct path of steam. This can short-circuit and permanently damage the

Before beginning the installation, make sure you have the following tools and materials ready...

• Flat and Phillips screwdrivers. One screwdriver needs

to have a long (20 cm) shank to reach the bottom

mounting screw on the dispenser.

• Drill and drill bits.

• 18 gauge wire for power, signals, and probe (check

local codes).

• Wire cutters, wire strippers, and pliers.

INSTALLATION — MOUNTING

(1) Remove existing dispenser, if any.

(2) Use the mounting bracket to mark where the holes

need to be drilled. Drill the three holes.

• Wire terminal connectors and a crimping tool.

• Voltmeter (or multi-meter).

• Dry wall inserts and mounting screws.

• Electrical tape.

• Titration kit.

• Dispenser accessory kit.

(3) Press in the dry wall anchors and mount the

bracket.

(4) Hang the dispenser and mark where the bottom

hole goes.

(5) Drill last hole and press in final dry wall insert. Do

not install the unit on the wall yet.

Page 4 of 24 0900591 Rev: A (07/04)

INSTALLATION — ELECTRICAL

Review the wiring diagrams on pages 20 - 22 to

familiarize yourself with the wiring connections that

apply to the UniTech model you have.

Important note for pre-wired units:

color coded wires for power, signals, and probe. Be sure

to use the correct wires for the following electrical

connections. The transformer connections in these

models are pre-wired for 230V (as shown in the wiring

diagrams). This must be changed inside the unit

prior to installation for 115V or 208V applications!

European models will always be 230V only!

Make sure that all power is off to the dishmachine. Open

the cover and locate an appropriate source for the wash

pump and rinse pump signals, plus a main power

source (for single transformer units). Consult the wiring

diagram for the dishmachine, if available.

These models have

Main Power

A main power connection only applies to single

transformer systems (typical). Disregard this section for

dual transformer systems.

Connect leads to a 115, 208, or 230 VAC power source

that is “on” when the dishmachine is “on.” This will

provide power for both detergent and rinse however,

UniTech will only pump chemical when electrically

signaled. Whenever possible, use the dishmachine’s

ON/OFF switc h as the main power s ource. Avoid using

the dishmachine’s washpump motor as main power.

Rinse Signal

In addition to running the rinse pump, the rinse power

signal triggers detergent recharge injection if probeless

mode is selected. The rinse signal can also be used to

trigger the detergent initial charge if using probeless/

door mode.

Check the dishwasher for a power source that is active

during the rinse cycle only, for example, the rinse

solenoid or rinse cycle light.

• Single transformer: Connect leads to the rinse signal

source. Signal voltage range is 14 - 240 VAC.

• Dual transformer: Connect leads to the rinse power

source (must be 115, 208, or 230 VAC).

Probe Installation (if required)

Drain the dishmachine if necessary. Install the probe per

the following steps, or replace any existing probe (if

there is one). Use new probe wire in either case.

(1) Install the probe in the wash tank below the water

level. It should be away from incoming water

supplies, near the recirculating pump intake, and 3

to 4 inches from corners, heating elements, or the

bottom of the tank. If an existing mounting hole

cannot be located, cut or punch a 7/8" hole.

(2) Use 18 AWG multi-stranded copper wire for the

probe connection. Avoid running the wire near high

voltage AC lines. Do not route probe wires through

the same conduit as power and signals.

(3) Connect leads to the probe. Ring-type terminals are

recommended (be sure to connect them to the

probe terminals with “backing” nuts to prevent the

probe tips from being pulled out of the probe). The

ring terminals should be secured between

(backing) nuts and outer nuts.

the inner

Detergent Signal

A detergent signal is required to either activate the

detergent probe sensing operation, or to trigger

probeless initial charge. A detergent signal is not

normally required when using probeless/door mode, as

the rinse signal is typically used to trigger initial charge.

Check the dishwasher for a power source that is active

during the wash cycle only, for example, the magnetic

contactor that controls the wash pump motor.

• Single transformer: Connect leads to the detergent

signal source. Signal voltage range is 14 - 240 VAC.

• Dual transformer: Connect leads to the detergent

power source (must be 115, 208, or 230 VAC).

0900591 Rev: A (07/04) Page 5 of 24

Connecting Power/Signals & Probe to UniTech

Steps 1 - 6 pertain to typical installations, where final

electrical connections must be completed inside the

UniTech dispenser. Disregard steps 1 - 6 for models

that are “pre-wired”.

(1) Ensure that all power sources are turned off before

proceeding with the following steps.

(2) Pull the power and signal wires through the conduit.

Do not route probe wires through the same conduit.

(3) Remove the rinse pump from the left side of the

dispenser to make room. Remove knockout plug for

the conduit by twisting with pliers. Remove

knockout plug for the probe wires. Install wire

grommet for probe wires.

(4) Pull wires through the pump case and into the

control box. Loosen the end of the conduit so that

the male piece can freely rotate. Clearance is tight

in the pump case, and you cannot easily rotate the

conduit nut. Instead, hold the conduit nut with a

wrench and rotate the male piece to tighten.

(5) Disconnect the wiring harnesses to gain easier

access to the wiring terminal strip. The terminal

strip panel can be removed by loosening one screw

(panel is slotted, therefore the screw does not need

to be removed). Slide the panel off the screw and

lift out to access. Strip the wires for power, signal,

and probe (if used) to ¼” bare ends and attach to

the appropriate terminals on the strip. See wiring

diagrams (pages 20 - 22) for further reference.

(6) Re-attach the terminal strip and tighten the screw.

Re-connect all wiring harnesses. Replace rinse

pump and attach faceplate.

(7) When all electrical wiring connections have been

performed, it will be time to hang the dispenser on

the wall. Install the final screw at the bottom of the

dispenser. Use a long shank screwdriver to reach it.

Page 6 of 24 0900591 Rev: A (07/04)

INSTALLATION — PLUMBING

Rinse & Sanitizer Plumbing

The following installation steps apply for rinse and

sanitizer pumps alike.

(1) Install the provided 1/4" tube x 1/8" NPT injection

fitting into the side or bottom of the dishwasher

rinse line between the rinse solenoid valves and the

rinse jets. If necessary, drill a 11/32" hole and tap to

1/8" NPT. Use of a saddle clamp may be desired on

copper rinse line for better support.

(2) Cut a suitable length of 1/4" OD poly tubing and

connect between the discharge (right) side of the

pump’s squeeze tube and the injection fitting.

(3) Cut a suitable length of 1/4" OD poly tubing and

connect between the suction (left) side of the

pump’s squeeze tube and the pickup tube provided.

Be sure to draw tubing through the end of the

pickup tube.

(4) Hand-tighten the compression nuts on both the

injection fitting and pickup tube. Plastic ties can be

used to cinch around the connections where the

poly tubing is inserted into the pump’s squeeze

tube.

Liquid Detergent Plumbing

(1) Install the provided bulkhead fitting through a wall

of the wash tank (above water level). If an existing

mounting hole cannot be located, cut or punch a

7/8" hole.

Dry Detergent Plumbing

(1) A powder or solid type feeder (not provided) should

be used for dispensing dry detergent products.

Follow the instructions included with the detergent

feeder for installation, and recommended water

temperature/pressure.

(2) Cut a suitable length of 1/4" OD copper tubing (not

provided) and connect between the input side of the

water solenoid and the water source. Maximum

recommended water temperature is 140°F (60°C).

(3) Cut a suitable length of 1/4" OD copper tubing (not

provided) and connect between the output of water

solenoid to a powder or solid detergent feeder.

(4) Carefully tighten the compression nuts on the water

solenoid — over tightening may cause solenoid to

leak. Tighten connections to the water source and

detergent feeder as needed.

NOTE: If there is an existing dispenser that uses dry

detergent, examine the power bowl. Make sure it is not

clogged and that the spray pressure is sufficient to

dissolve solid/powder products efficiently. Make sure the

water source is hot water. If necessary, tap into a hot

water line for a new source.

(2) Cut a suitable length of 1/4" OD poly tubing and

connect between the discharge (right) side of the

detergent pump’s squeeze tube and the bulkhead

fitting.

(3) Cut a suitable length of 1/4" OD poly tubing and

connect between the suction (left) side of the

detergent pump’s squeeze tube and the pickup

tube provided. Be sure to draw tubing through the

end of the pickup tube.

(4) Hand-tighten the compression nuts on both the

bulkhead fitting and pickup tube. Plastic ties can be

used to cinch around the connections where the

poly tubing is inserted into the pump’s squeeze

tube.

0900591 Rev: A (07/04) Page 7 of 24

OPERATION

BUTTON FUNCTIONS

Detergent — Probe Mode

With the detergent signal “on”, the conductivity probe

senses detergent concentration. When concentration

drops below the setpoint, the control automatically turns

on detergent feed. As the detergent feeds, the control

senses the rate at which the detergent concentration is

approaching the setpoint. The control then begins to

pulse feeds to prevent over-use of chemical. The pulse

feed rate will depend on how fast the setpoint is being

approached.

The detergent alarm will sound if the setpoint is not

reached within the alarm delay time period. The alarm

can be temporarily silenced. A “feed limit” feature allows

you to set the unit to automatically shut off the detergent

feed when the alarm has been activated.

Detergent — Probeless Mode

Controls detergent concentration without a probe, based

on timed detergent feed modes. Initial charge time feeds

detergent to bring the dishmachine to working

concentration when initially filled with water. The initial

charge can be activated by a detergent signal, or by the

rinse signal (of 30 seconds duration, or longer) when

using door mode. The initial charge counter will

increment for each activation.

Recharge time feeds detergent to maintain detergent

concentration as rinse water dilutes the dishmachine.

The recharge is triggered after a specified number of

racks passes through the machine.

Rinse Pump

The rinse pump will operate whenever the rinse signal is

energized. The rinse delay feature will postpone the

activation of the rinse pump until the delay time has

expired. The rinse limit shuts down the rinse pump after

the signal has been present for a selected time. Rinse

delay and rinse limit are functional with door machines

only.

• ENTER: Holding the enter button for 3 seconds

(approx.) switches between run and program modes.

Enter also advances through programming menus.

• SCROLL: The scroll button moves the position of the

cursor in menus where text or number changes are

done. The scroll button will “wrap around” at the end

of a line of characters, meaning that the cursor will

advance to the beginning of the line automatically.

The scroll button toggles between choices in menus

that have selectable settings. The scroll button also

shows the rack count and initial charge count during

normal operation.

• UP (

• DOWN (

): Increases numeric values or advances

upward through available characters. Hold the button

down to rapidly advance. The UP button also acts as

rinse prime during normal operation.

): Decreases numeric values or advances

downward through available characters. Hold the

button down to rapidly advance. The DOWN button

also acts as sanitizer prime during normal operation.

De-lime Mode

During normal operation, hold the SCROLL and DOWN

buttons simultaneously for 1 full second. When “DeLime Mode“ appears on the display, all chemical feed of

the UniTech will be halted. Press the SCROLL and

DOWN buttons again, or cycle main power to the unit, to

exit the de-lime mode. Otherwise, the unit will

automatically exit de-lime mode after 10 minutes.

Alarm Mute

During normal operation, the low detergent alarm

(probe mode) can be silenced by pressing the SCROLL

and UP buttons simultaneously for 1 full second. The

display will show “Alarm Muted” and the audio alarm will

turn off for 5 minutes.

Sanitizer Pump

A menu selection sets the sanitizer pump to operate

with detergent feed, or with rinse feed. The sanitizer

pump will run simultaneously with detergent or rinse,

whether using probe or probeless mode, rinse delay or

rinse limit.

Page 8 of 24 0900591 Rev: A (07/04)

Loading...

Loading...