Knight Equipment SINK BOWL Installation Manual

INSTRUCTION MANUAL

WARNING: DUE TO THE TYPICAL INSTALLATION REQUIREMENTS AND THE CAUSTIC CONTENT OF MANY

CHEMICAL PRODUCTS, IT IS REQUIRED THAT ALL WATER SUPPLIES BE SHUT OFF BEFORE CONNECTING

OR SERVICING THE SINK BOWL.

INSTALLATION / OPERATION

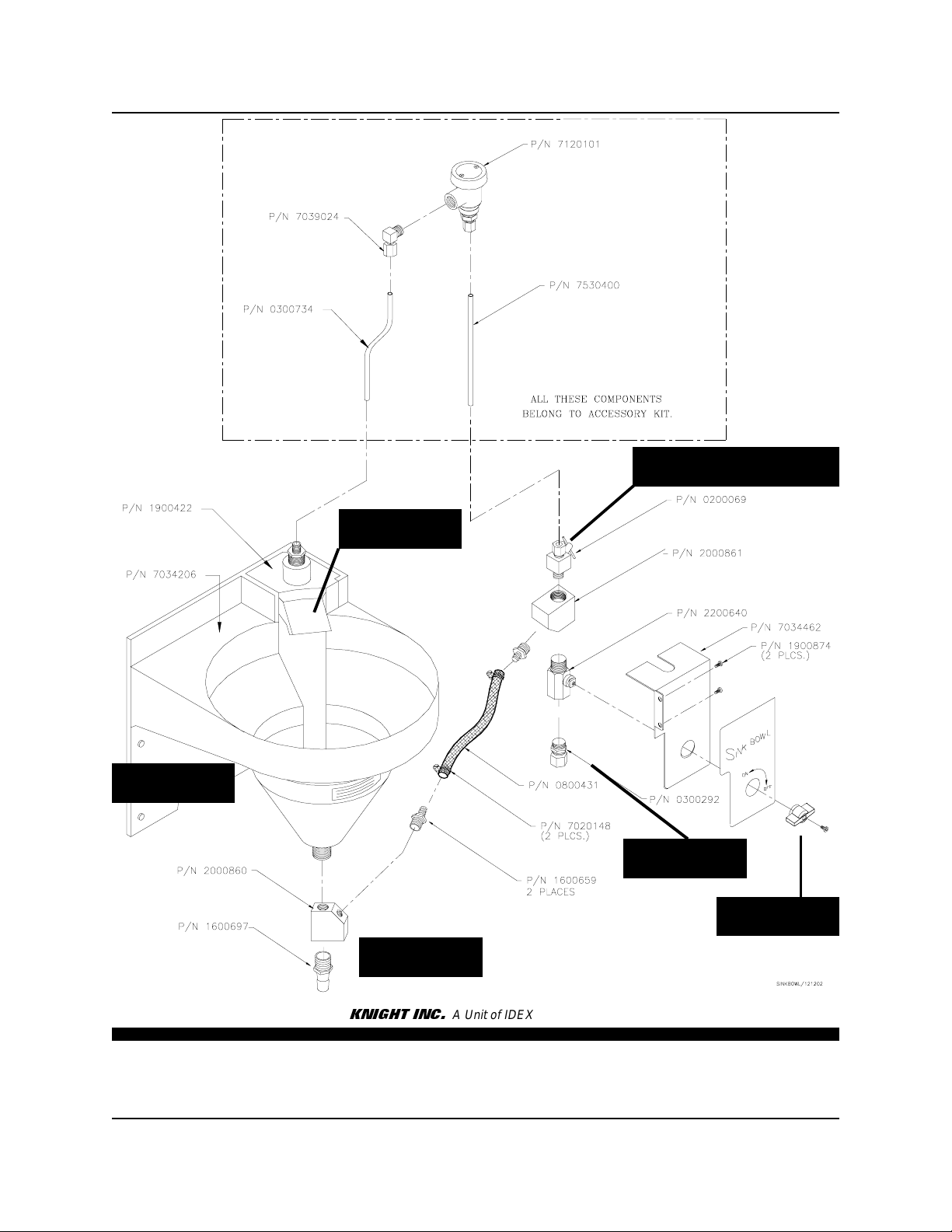

See the diagram on the following page for reference to the installation and calibrating steps below.

(1) Mount the Sink Bowl to the wall, use the wall anchors and screws provided with the accessory kit.

(2) Run flow tubing from the output fitting on the bottom end of the bowl body into the sink. The first 12" of the

tubing run should be vertical to prevent liquids from backing up into the bowl.

(3) Connect 3/8" OD tubing from the water source to the input fitting of the Sink Bowl and tighten carefully. The

compression fitting can be removed for direct hard-plumbing with a 3/8" NPT connection, or can be substituted

by a barb fitting or garden hose adapter.

IMPORTANT NOTES:

140°F. Use of 1/4” water supply line is not recommended.

(4) Insert a detergent container into the Sink Bowl, ensuring the container presses down the paddle valve lever. The

paddle valve is a safety feature that will shut off water spray into the bowl if the container is removed.

(5) Rotate the water valve T-handle counter-clockwise (vertical) to turn on water flow. Water will spray up inside the

container (to dissolve detergent) and will also flow into the j unction fitting at the bowl bottom where it will mix

with the dissolved detergent that exits the bowl. Turn the T-handle clockwise (horizontal) to shut off.

Incoming water pressure must be 25 - 80 PSI. Do not use water temperature higher than

CALIBRATING DETERGENT CONCENTRATION

The c oncentration of dissolved detergent is adjusted by regulating flow to the spray jet with the needle valve. A

special tool is provided for adjusting the needle valve — the tool is a 3” long brass tube with one end slotted for

gripping the T-handle of the needle valve. Removing the metal cover from the Sink Bowl is not required.

(6) Insert the slotted end of the tool through the access hole on the right side of the metal cover and close the

needle valve by turning clockwise until it stops. Then turn counter-clockwise 3 full turns to adjust the needle

valve to its mid-point (6 full turns is maximum). Turn the water valve “on” to verify detergent is dissolving.

(7) Check the solution strength of the water/detergent mixture dispensed by the Sink Bowl. Adjust the needle valve

as needed to achieve the desired mix (clockwise for less detergent, counter-clockwise for more detergent).

DISCLAIMER

Knight Inc. does not accept responsibility for the mishandling, misuse, or non-performance of the described items

when used for purposes other than those specified in the instructions. For hazardous materials information consult

label, MSDS, or Knight Inc.

WARRANTY

All Knight controls and pump systems are warranted against defects in material and workmanship for a period of

ONE year. All electronic control boards have a TWO year warranty. Warranty applies only to the replacement or

repair of such parts when returned to factory with a Knight Return Authorization (KRA) number, freight prepaid, and

found to be defective upon factory authorized inspection. Bearings and pump seals or rubber and synthetic rubber

parts such as “O” rings, diaphragms, squeeze tubing, and gaskets are considered expendable and are not covered

under warranty. W arranty does not cover liability resulting from performance of this equipment nor the labor to

replace this equipment. Product abuse or misuse voids warranty.

0900994 Rev: C (12/02)

STEP 4

NOTE: If there is a leak at the

top of vacuum breaker you

should fully tighten the cap.

STEPS 6 & 7

STEP 1

STEP 3

STEP 2

KNIGHT INC.

World Headquarters: 20531 Crescent Bay Drive, Lake Forest, CA92630-8825 (USA) TEL: 949-595-4800, FAX: 949-595-4801, www.knightequip.com

Atlanta Branch:

415 GeesMill Business

Court NE, Suite 200

Conyers, GA30013 USA

TEL: 770-760-8777

FAX: 770-761-0199

Toronto Branch:

2880 Argentia Road,Unit 6

Mississauga, Ontario

L5N 7X8 Canada

TEL: 905-542-2333

FAX: 905-542-1536

London Branch:

#15 Brunel Centre

Newton Road, Crawley

West Sussex UK RH10 9TU

TEL: 44-1293-615570

FAX: 44-1293-615585

A Unit of IDEX Corporation

Sydney Branch:

Unit 28,317-321

Woodpark Rd., Smithfield

NSW Australia 2164

TEL: 61-29-725-2588

FAX: 61-29-725-2025

0900994 Rev: C (12/02)

AmsterdamBranch:

Marssteden 68

7547 TDEnschede

The Netherlands

TEL: 31-53-428-58-00

FAX: 31-53-428-58-09

STEP 5

Spain Branch:

Port Ginesta, Local 210

08860 Sitges

Barcelona Spain

TEL: 34-936-342-130

FAX: 34-936-643-477

Loading...

Loading...