Page 1

Product Application AP05013001E

Effective February 2013

Supersedes April 2005

easyRelay applications

Contents

Showroom and store window lighting

Operating description ......................2

Control circuit ............................2

List of operands ...........................3

Benefits .................................3

Examples ................................3

Floor lighting

Operating description ......................4

Control circuit ............................4

List of operands ...........................4

Benefits .................................5

Examples ................................5

Belt sequence control for three

conveyor belts with motor monitoring

Operating description ......................6

Control circuit ............................6

Load circuit ..............................6

List of operands ...........................7

Benefits .................................7

Examples ................................7

Greenhouse temperature and

ventilation control

Operating description ......................9

Control circuit ...........................10

Load circuit .............................10

Sample switching points ...................10

List of operands ..........................10

Benefits ................................11

Examples ...............................11

Lighting control in a production room

Operating description .....................12

Control circuit ...........................13

Load circuit .............................13

Switching points of the daylight control switch. . 13

List of operands ..........................13

Benefits ................................13

Examples ...............................14

Booster pumps

Operating description .....................15

Control circuit ...........................16

Load circuit .............................16

Pressure diagram. . . . . . . . . . . . . . . . . . . . . . . . . 16

Switching points .........................16

List of operands ..........................16

Benefits ................................17

Examples ...............................17

Tank installation level indicator

Operating description .....................18

Control circuit ...........................19

List of operands ..........................19

Benefits ................................19

Examples ...............................20

Access monitoring for a parking garage

Operating description .....................21

Control circuit ...........................21

List of operands ..........................22

Benefits ................................22

Examples ...............................22

Time-controlled lighting system

Operating description .....................23

Control circuit ...........................23

List of operands ..........................24

Benefits ................................24

Examples ...............................24

Refrigeration control system

Operating description .....................26

Control circuit ...........................26

Load circuit .............................26

List of operands ..........................26

Benefits ................................27

Examples ...............................27

Perimeter advertising in a stadium

Operating description .....................28

Control circuit ...........................28

List of operands ..........................28

Benefits ................................29

Examples ...............................29

Rolling door control

Operating description .....................30

Control circuit ...........................31

Load circuit .............................31

List of operands ..........................31

Examples ...............................32

Page 2

Product Application AP05013001E

Effective February 2013

easyRelay applications

Showroom and store window lighting

Task

To automatically switch the showroom lights, store window lighting,

and external advertising display for a retail store on or off. The on/off

function must take into account the day of the week, the time, and

a daylight control switch. The connection times for the store window

lighting can be set as required. It must also be possible to switch

all the lights on and off manually. The showroom and store window

lighting must turn on in the event of an alarm.

Overview drawing

Showroom lighting

Mon–Fri 8:55 a.m. to 1:05 p.m.

Time switch 3

1:55 a.m. to 6:35 p.m.

Sat 8:55 a.m. to 2:05 p.m.

The flush-mounted switches S1, S2, and S3 can be used to activate

the showroom lighting outside the programmed times.

In the event of an alarm, the showroom and store window lights are

turned on by contact S6.

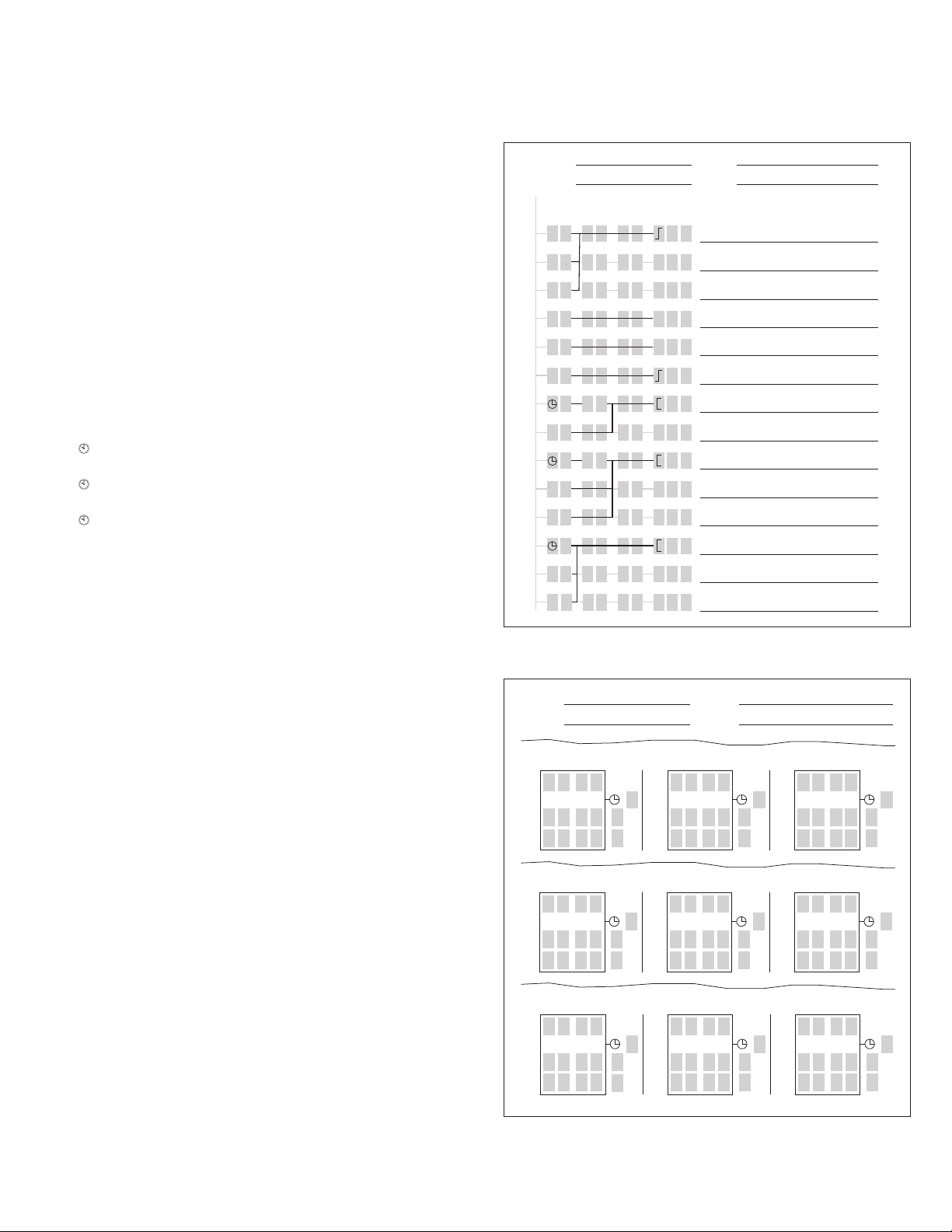

Control circuit

F1

L1

N

S5

S2

S1

S3

S4

I1 I2 I3 I4 I5 I6 I7 I8

L

NN

S6

ALT

DEL

Figure 1. Overview

Operating description

External advertising display

Mon–Sun 6:00 a.m. to 11:00 p.m.

Time switch 1

The daylight control switch causes the advertising display to turn off

as the light level rises and to turn on at dusk.

It must also be possible to manually turn the advertising display on

and off at any time. The P2 (Up arrow) and P4 (Down arrow) function

buttons on the easyRelay are used for this purpose.

ote:N The P buttons are activated in the Special system menu. Press ALT

and DEL simultaneously to change to the Special menu. See also the User

Manual MN05013003E.

Store window lighting

Mon–Fri 8:00 a.m. to 10:00 p.m.

Time switch 2

Sat 8:00 a.m. to 11:00 p.m.

Sun 10:00 a.m. to 10:00 p.m.

The store window lighting is also controlled by the daylight control

switch. It is turned off as the light level rises and is turned on when

it starts to get dark.

The S5 button is used to turn the store window lighting on and off

manually outside the programmed times.

In the event of an alarm, potential-free contact S6 in the alarm

system turns the store window lighting on.

Once time switch 2 has been enabled, it can be used to change

the on/off times, even if a password was activated up in the Special

menu. The time switch is enabled by programming the “+” symbol.

OK

EASY512-AC-RC

12 12 12 12

Q1 Q2 Q3 Q4

H1

S1–S3 Light switches for showroom lighting

S4 Connection contact for daylight control switch

S5 Light switch for store window lighting

S6 Connection contact for alarm system

H1 External advertising display

H2 Store window lighting

H3 Showroom lighting

F1 16A char. B miniature circuit breaker

ESC

H3

H2

Figure 2. Control Wiring Diagram

CAUTION

THE SAFETY REQUIREMENTS OF THE APPLICABLE VDE, IEC, UL,® AND CSA®

STANDARDS REQUIRE THE PHASE THAT IS USED FOR THE POWER SUPPLY

TO BE USED FOR THE INPUTS AS WELL. IF THIS IS NOT THE CASE, THE

easyRELAYS WILL NOT DETECT THE CONNECTION LEVEL AND CAN BE

DAMAGED BYOVERVOLTAGES.

2

EATON CORPORATION

Page 3

easyRelay applications

Product Application AP05013001E

Effective February 2013

List of operands

I1 Input, light switch 1, showroom lighting

I2 Input, light switch 2, showroom lighting

I3 Input, light switch 3, showroom lighting

I4 Input, connection contact, daytime control switch

I5 Input, light switch, store window lighting

I6 Input, connection contact, alarm system

M1 Marker relay, buffer memory, external advertising

display ON/OFF

M2 Marker relay, buffer memory, store window lighting ON/OFF

M3 Marker relay, buffer memory, showroom lighting ON/OFF

P2 Up arrow cursor key = external advertising display ON

P4 Down arrow cursor key = external advertising display OFF

Q1 Output relay, external advertising display

Q2 Output relay, store window lighting

Q3 Output relay, showroom lighting

1 Connection contact, time 1 = time switching,

external advertising display

2 Connection contact, time 2 = time switching,

store window lighting

3 Connection contact, time 3 = time switching,

showroom lighting

Benefits

t

Implemented functions:

t 3 x single-channel time switches with weekly

and daily programs

t 3 x impulse changeover relays

t

Less wiring required

t

Takes up less space than conventional systems

t

Password function protects against unauthorized access

Examples

Art Deco

Customer: Program:

1/4/13

Date: Page:

Comment:

I

I2

I3

P2

P4

I5

M1

M2

I6

M3

I6

1

1

I4

2

I4

3

M3

Flush-mounted switch S1, S2, S3

for showroom lighting

M1S

Set external advertising display switch

M1R

Reset external advertising display switch

M2

Switch for store window lighting

Q1

External advertising display which is dependent

on daytime control switch I4

Q2

Store window lighting which is dependent

on daytime control switch I4, switch

and alarms

Q3

Showroom lighting which is dependent on

flush-mounted switch

and alarms

Figure 3. easyRelay Display Diagram

Customer: Program:

Date: Page:

Art Deco

1/4/13

Lighting, example 1

1

Lighting, example 1

2

Time switches

MO S

06 00 A

ON

OFF

23 00

Time switches

MO S A S UFR

08 00

ON

OFF

22 00

Time switches

MO F R

08 55

ON

OFF

13 05

U

-

1

:

:

-

:

:

-

:

:

ON

–

OFF

222

A

ON

+

OFF

3

A

ON

OFF

–

-

:

:

-

08 00

:

23 00

:

MO F R

-

13 55

:

18 35

:

Figure 4. easyRelay Display Parameters

EATON CORPORATION

-

ON

OFF

B

ON

+

OFF

3

B

ON

OFF

–

:

:

-

10 00

:

22 00

:

SA

-

08 55

:

14 05

:

C

+

3

C

–

3

Page 4

Product Application AP05013001E

Effective February 2013

easyRelay applications

Floor lighting

Task

To enable the corridor lights on each floor of a multi-story building

to be switched on and off at various flush-mounted switches. In

parallel, there should also be a central switch from which all the

lights can be turned on and off. In the event of a fire, it must be

possible to turn on all the corridor lights. To save energy, the corridor

lights should be turned off altogether at certain times.

Overview drawing

Figure 5. Overview

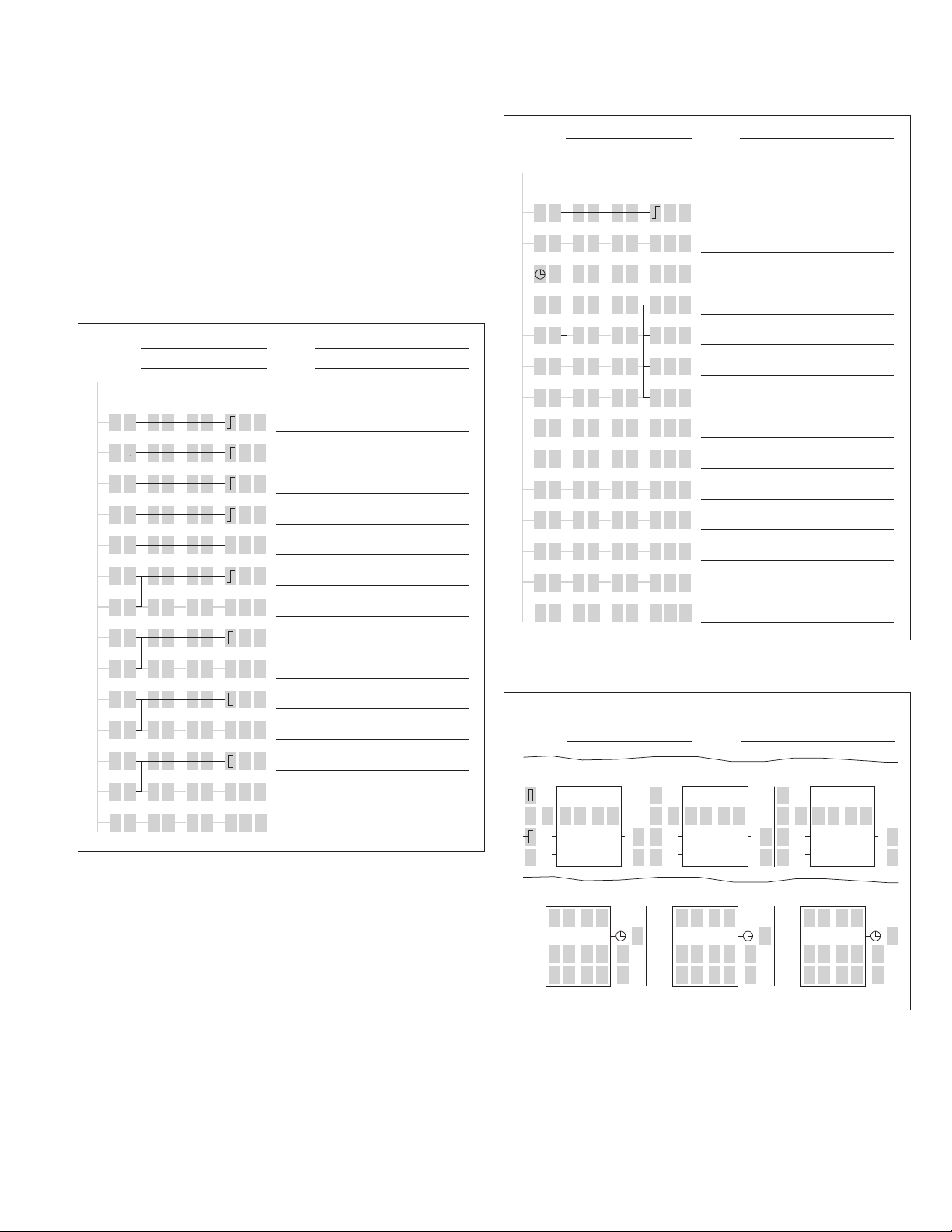

Control circuit

F1

L1

N

S2

S1

S3

S4

S5

S6

L

NN

EASY512-AC-RC

12 12 12 12

Q1 Q2 Q3 Q4

H1

F1 16 A, char. B miniature circuit breaker

H1–H4 Lights on 1st–4th floors

S1–S3 Light switches, 1st floor

S4–S6 Light switches, 2nd floor

S7–S9 Light switches, 3rd floor

S10–S12 Light switches, 4th floor

S13 Central ON switch

S14 Central OFF switch

K1 Contact, fire alarm system

S7

S8

S9

S10

I1 I2 I3 I4 I5 I6 I7 I8

ALT

DEL

OK

ESC

H2

H3

S12

S11

H4

S13

S14

K1

Operating description

On each of the four floors, the corridor lights can be turned on

andoff (three-wire control) at three flush-mounted switches

(S1through S12).

If necessary, for example, for cleaning, the corridor lights on every

floor can be turned on at switch S13 and turned off at switch

S14 in the maintenance personnel’s quarters or the building

superintendent’s room.

In the event of a fire, contact K1 in the fire alarm system turns on all

the corridor lights.

To save energy, all corridor lights are turned off at 6:30 p.m. Monday

through Friday and at 2:30 p.m. Saturday.

CAUTION

THE SAFETY REQUIREMENTS OF THE APPLICABLE VDE, IEC, UL, AND CSA

STANDARDS REQUIRE THE PHASE THAT IS USED FOR THE POWER SUPPLY

TO BE USED FOR THE INPUTS AS WELL. IF THIS IS NOT THE CASE, THE

easyRELAYS WILL NOT DETECT THE CONNECTION LEVEL AND CAN BE

DAMAGED BYOVERVOLTAGES.

Figure 6. Control Wiring Diagram

List of operands

I1 Input, light switches on 1st floor

I2 Input, light switches on 2nd floor

I3 Input, light switches on 3rd floor

I4 Input, light switches on 4th floor

I5 Input, central ON switch

I6 Input, central OFF switch

I7 Input, contact in fire alarm system

M1 Marker relay, buffer memory light on 1st floor ON/OFF

M2 Marker relay, buffer memory light on 2nd floor ON/OFF

M3 Marker relay, buffer memory light on 3rd floor ON/OFF

M4 Marker relay, buffer memory light on 4th floor ON/OFF

M5 Marker relay, buffer memory light ON/OFF at central switch

M6 Marker relay, buffer memory light ON/OFF at central switch

or via fire alarm system

Q1 Output relay, lights on 1st floor

Q2 Output relay, lights on 2nd floor

Q3 Output relay, lights on 3rd floor

Q4 Output relay, lights on 4th floor

T1 Timing relay, control pulse, central light OFF switch

1 Contact switch, Time 1 Current switch,

Mon–Fri 6:30 p.m./Sat 2:30 p.m.

4

EATON CORPORATION

Page 5

easyRelay applications

Product Application AP05013001E

Effective February 2013

Benefits

t

Implemented functions:

t 1 x single-channel time switch with weekly and daily programs

t 4 x impulse changeover relays with central circuit

t

Less wiring required

t

Takes up less space than conventional systems

t

Increased flexibility facilitates modification and extension

t

Password function protects against unauthorized access

Examples

I

1

I2

I3

I4

I5

Floor Lighting

1/4/13

M1

M2

M3

M

4

M5S

Customer: Program:

Date: Page:

Example 2

1

Comment:

Turn on 1st floor—press (51–53)

Turn on 2nd floor—press (54–56)

Turn on 3rd floor—press (57–59)

Turn on 4th floor—press (510–512)

Central corridor lighting ON switch S13

M

4

M6

1

T1

M5

TI1

6

Floor Lighting

1/4/13

Comment:

Q4

Lights on 4th floor ON (H4)

central switch or in the event of a fire

TT1

Press to turn off all lights together

MR

1

1st floor lights OFF from central switch

M2R

2nd floor lights OFF from central switch

MR3

3rd floor lights OFF from central switch

MR4

4th floor lights OFF from central switch

MR5

Reset from central ON switch

Central corridor lighting OFF switch S14

Customer: Program:

Date: Page:

Example 2

2

MI5

7

M1

6

MM2

MM6

3

M6

M6

Central lighting ON switch (S13) or

in the event of a fire (K1)

Q1

Lights on 1st floor ON (HI)

central switch or in the event of a fire

Q2

Lights on 2nd floor ON (H2)

central switch or in the event of a fire

Q3

Lights on 3rd floor ON (H3)

central switch or in the event of a fire

Figure 7. easyRelay Display Diagram

Figure 8. easyRelay Display Diagram

MO F R

18 30

ON

OFF

18 31

Floor Lighting

1/4/13

01S

00

TRG T

RES

-

:

:

::::::

ON

OFF

S

14 30

14 31

TRG T

RES

A

-

:

:

1

+

I

A

+

Customer: Program:

Date: Page:

Timing relays

Time switches

Example 2

3

I

B

+

ON

OFF

TRG T

RES

-

:

:

Figure 9. easyRelay Display Parameters

EATON CORPORATION

5

Page 6

Product Application AP05013001E

Effective February 2013

easyRelay applications

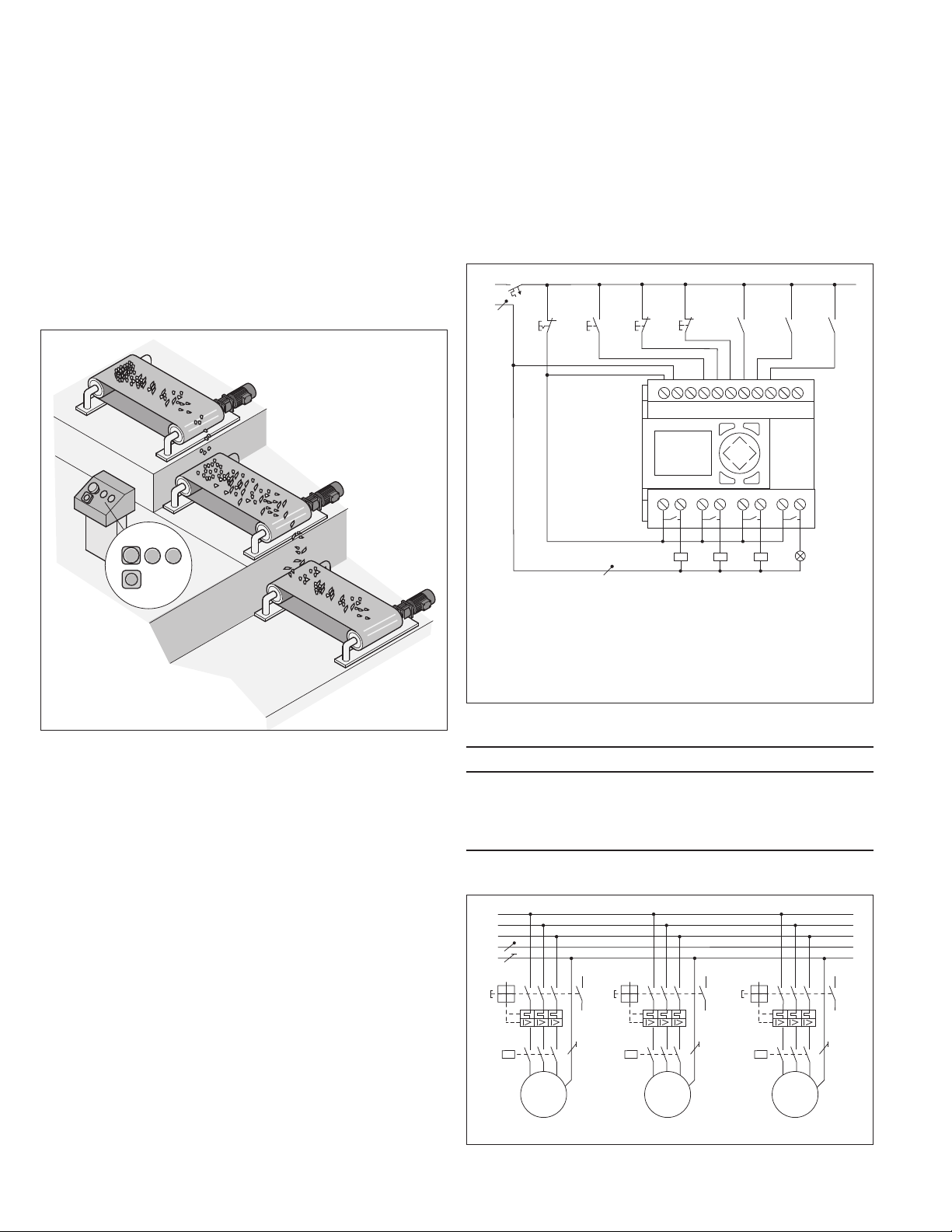

Belt sequence control for three conveyor

belts with motor monitoring

Task

To start up and shut down three conveyor belts at different times.

There are to be three operating modes “Staggered start-up”,

“Staggered shut-down”, and “Fast stop”. The motor-protective circuit

breakers in the belt drives should be monitored; if a circuit breaker

trips, the conveyor system should stop in a controlled manner.

Thefault should also be signaled by a flashing light.

Overview drawing

Belt 1

Belt 2

10

Motor failure

If a drive motor fails, the trip-indicating auxiliary contact (PKZ) opens.

The fault is signaled via the flashing light and automatically triggers

the STOP function. This means that in the event of a fault, any belts

downstream of the defective drive run at no-load for 5 seconds

before they are turned off. Any belts upstream of the defective drive

are turned off immediately.

Control circuit

F1

L1

N

S0

S1

S2

S3

I1 I2 I3 I4 I5 I6 I7 I8

L

NN

DEL

EASY512-AC-R

12 12 12 12

Q1 Q2 Q3 Q4

K1

ESC

K2

Q1

ALT

OK

K3

Q3

Q2

H1

Belt 3

Figure 10. Overview

Operating description

The three conveyor belts in a bulk material handling installation have

to be started up and shut down at different times in order to ensure

that the materials are transported safely and without interruption.

Startup

When START button S1 is pressed, the belts start up at 5-second

intervals (this interval is permanently programmed and cannot be

changed). Belt 3 starts up first.

Shutdown

When STOP button S2 is pressed, the belts stop in reverse order,

i.e., starting from belt 1. This guarantees that the belts are running

at no-load when they are restarted, thus avoiding heavy starting with

a loaded belt.

When the button is pressed, 5 seconds elapse before belt 1 is shut

down. The subsequent belts turn off again after a 5-second delay. It

must be possible to change the time via the easyRelay. To do this,

the “+” must be set when the function block is programmed.

“Fast stop” button S3 turns off all three belts without a timedelay.

S0 Emergency stop

S1 START button

S2 STOP button

S3 Fast stop button

Q1–Q3 Trip-indicating auxiliary contact for motor 1–3

K1–K3 Motor, belt 1–3

H1 Indicator light

F1 16 A, char B miniature circuit breaker

Figure 11. Control Wiring Diagram

CAUTION

THE SAFETY REQUIREMENTS OF THE APPLICABLE VDE, IEC, UL, AND CSA

STANDARDS REQUIRE THE PHASE THAT IS USED FOR THE POWER SUPPLY

TO BE USED FOR THE INPUTS AS WELL. IF THIS IS NOT THE CASE, THE

easyRELAYS WILL NOT DETECT THE CONNECTION LEVEL AND CAN BE

DAMAGED BYOVERVOLTAGES.

Load circuit

L1

L2

L3

N

PE

Q1

K1

3 ~

M1

4.43

Q2

4.44

K2

M

3 ~

M2

4.43

Q3

4.44

K3

M

3 ~

M3

4.43

4.44

M

Figure 12. Load Circuit Diagram

6

EATON CORPORATION

Page 7

easyRelay applications

Product Application AP05013001E

Effective February 2013

List of operands

I1 Input, START button

I2 Input, STOP button

I3 Input, Fast stop button

I4 Input, trip-indicating auxiliary contact for motor 1

I5 Input, trip-indicating auxiliary contact for motor 2

I6 Input, trip-indicating auxiliary contact for motor 3

M1 Marker relay, buffer memory, trip-indicating auxiliary

contact, motor 1, 2, 3

M2 Marker relay, buffer memory, STOP

M3 Marker relay, buffer memory, START

Q1 Output, contactor in motor for belt 1

Q2 Output, contactor in motor for belt 2

Q3 Output, contactor in motor for belt 3

Q4 Output, indicator light

T1 Timing relay with 5-second ON delay —> Start belt 2

T2 Timing relay with 5-second ON delay —> Start belt 1

T3 Timing relay with 5-second OFF delay —> Stop belt 1

T4 Timing relay with 5-second OFF delay —> Stop belt 2

T5 Timing relay with 5-second OFF delay —> Stop belt 3

T6 Timing relay flashing for 1 second to indicate fault

Benefits

t

Implemented functions:

t 2 x ON-delayed timing relays

t 2 x OFF-delayed timing relays

t 1 x flash/blink relay

t 2 x auxiliary contactors

t

Less wiring required

t

Takes up less space than conventional systems

t

Password function protects against unauthorized access

Examples

Customer: Program:

Date: Page:

Belt control

1/4/13

I

4I5I6

I1 M1

Q3

T1 M1

Q2

2

MT1

I2

2

TM3

M3

1

M

3

I

Q1

Comment:

M1

Motor-protective circuit breaker 1, 2, 3 not tripped

Q3S

START button-> motor for belt 3 on

M3S

START button pressed

T1T

ON-delay for belt 2

Q2S

Motor for belt 2 on

TT2

ON-delay for belt 1

Q1

S

Motor for belt 1 on

M2

S

STOP button pressed

TT3

OFF-delay for belt 1

QR1

Motor for belt 1 off

Q3

TT4

OFF-delay for belt 2

Figure 13. easyRelay Display Diagram

Example 3

1

EATON CORPORATION

7

Page 8

Product Application AP05013001E

Effective February 2013

easyRelay applications

Customer: Program:

Date: Page:

Belt control

1/4/13

T

43

M

5

I

6I

I

3

2

Q

M3

T5

6

I

I3

I4

I

5

I

6

6

T

Q2

R

T5T

QR3

TT6

Q4

Comment:

Motor for belt 2 off

OFF-delay for belt 3

Motor for belt 3 off

A motor has failed

Indicator light

Example 3

2

Customer: Program:

Date: Page:

Belt control

1/4/13

T

53

M

1

M

3I

I

2

1

M

3I

R

R

Comment:

M2

Reset buffer memory for STOP

M3

Reset buffer memory for START

Example 3

3

Figure 14. easyRelay Display Diagram

Figure 15. easyRelay Display Diagram

X

X

Belt control

1/4/13

X

05S

00 05 00 05 00

TRG T

RES

05S

00 05 00 01 00

TRG T

RES

S

::::::

1

+

4

+

TRG T

RES

X

SS

::::::

TRG T

RES

Customer: Program:

Date: Page:

Timing relays

Timing relays

Figure 16. easyRelay Display Parameters

Example 3

4

2

+

5

+

X

S

TRG T

RES

TRG T

RES

3

+

6

+

8

EATON CORPORATION

Page 9

easyRelay applications

Product Application AP05013001E

Effective February 2013

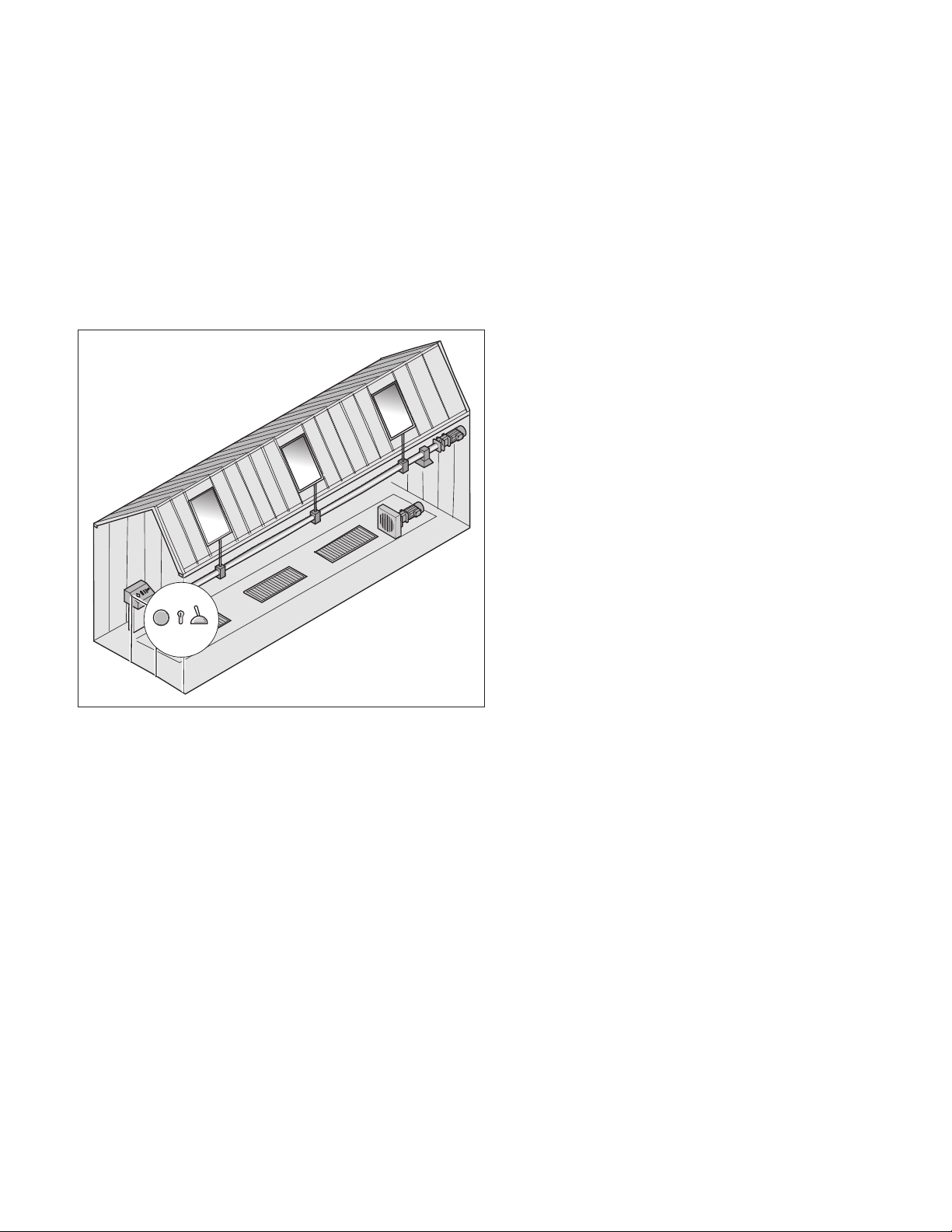

Greenhouse temperature and

ventilationcontrol

Task

To automatically open and close the roof lights of a greenhouse in

order to adjust the ventilation and temperature. Warm air should

beblown in via the heating system when the temperature drops

below a certain level. The drive motors for the fans and the roof

lights must be monitored for faults, which should also be signaled

bya flashing light.

Overview drawing

Warm air supply

When the temperature in the greenhouse falls below a certain level,

the fan motor M2 is automatically activated to blow in warm air. The

motor is switched off again when the temperature returns to the

desired level.

Motor failure

If M1 or M2 fails, the contact of the corresponding trip-indicating

auxiliary contact Q1 or Q2 opens. The fault is signaled via the

flashing light H1 for both motors.

Continuous ventilation

Key switch S1 is used to turn off the automatic temperature control

and select “Continuous ventilation”. It may be necessary to first

close the roof lights and then open them again in order to use

thisfunction.

It should be possible to enter the motor run time T2, which

determines how far the roof light is opened, directly on the

easyRelay.

The roof lights can be opened as far as the end position. The default

for T2 is 4 seconds.

Manual operation

For maintenance and repairs, the windows can be opened via the

P2button (Up arrow) and closed via the P4 button (Down arrow).

ote:N The P buttons are activated in the Special menu. Press ALT and DEL

simultaneously to change to the Special menu. See also the User Manual

MN05013003E.

Figure 17. Overview

Operating description

The greenhouse is also used as a display and sales area. The roof

lights are opened for ventilation and are closed again depending

on the temperature. The “Open window” and “Close window”

switching points are programmed via the easyRelay. The voltage

output of temperature sensor B1 supplies the necessary comparison

value. The following example demonstrates how the switching points

are determined or calculated.

Ventilation control

All the roof lights are activated by a three-phase AC motor M1 with

a reversing contactor circuit. The end positions are detected by limit

switch S2 (open) and S3 (closed). The motor switches off when the

limit switch is reached.

EATON CORPORATION

9

Page 10

Product Application AP05013001E

Effective February 2013

easyRelay applications

Control circuit

L1

N

PE

F1

G1

~

S0

+24V

B1 Temperature sensor

F1 16 A char. B miniature circuit breaker

F2 Miniature circuit breaker (optional)

G1 Power supply unit 230 Vac/24 Vdc

H1 Motor fault indicator light

K1 Contactor for Open window drive motor

K2 Contactor for Close window drive motor

K3 Contactor for fan motor

Q1 Window drive motor tripping indicator

Q2 Fan motor tripping indicator

S0 Emergency stop

S1 Key switch

S2 Open limit switch

S3 Closed limit switch

F2

-

0V

S2

S1

24V

0V 0V

EASY512-DC-R

12 12 12 12

Q2 Q3 Q4

Q1

K2

K1

K2

K1

S3

I1 I2 I3 I4 I5 I6 I7 I8

DEL

ESC

K3

Q2

Q1

ALT

OK

H1

Figure 18. Control Wiring Diagram

ote:N The electrical interlock may be omitted when using a reversing

contactor combination with a mechanical interlock.

Load circuit

L1

L2

L3

N

PE

Q1

K1

M

3 ~

M1

4.43

4.44

Q2

K2

K3

M

3 ~

M2

Figure 19. Load Circuit Diagram

T

0-10V

4.43

4.44

Sample switching points

t

Temperature sensor measuring range: –35°C to +55°C

t

Output signal from temperature sensor: 0 to 10 Vdc

t

Selected switching point—Open: 25°C

t

Selected switching point—Close: 23°C

t

B1

Selected switching point—Heat: 20°C

General formula for the comparison value:

10V

×=

UL + LL

(Switchpoint + LL)

UL = Upper limit of measured value

LL = Lower limit of measured value

Set point value for Open comparator:

10V

55ºC + 35ºC

×=(25ºC + 35ºC) 6, 4V

Set point value for Close comparator:

10V

55ºC + 35ºC

×=(23ºC + 35ºC) 6, 4V

Set point value for Heat comparator:

10V

55ºC + 35ºC

×=(20ºC + 35ºC) 6, 1V

A switching range (± 0.1V) must be defined for each comparison

value to avoid having to repeatedly turn ON and OFF when the

comparison value is reached.

t

This gives the following switching points

in the comparator blocks:

t Open window

ON = 6.8V

OFF = 6.6V

t Close window

ON = 6.3V

OFF = 6.5V

t Heat

ON = 6.0V

OFF = 6.2V

List of operands

A1 Comparator, Open window ON

A2 Comparator, Open window OFF

A3 Comparator, Close window ON

A4 Comparator, Close window OFF

A5 Comparator, Heat ON

A6 Comparator, Heat OFF

I1 Input, key switch for continuous ventilation

I2 Input, Open limit switch

I3 Input, Closed limit switch

I4 Input, window drive motor trip-indicating auxiliary contact.

Input, fan motor trip-indicating auxiliary contact

I8 Input, comparative voltage of temperature sensor

10

EATON CORPORATION

Page 11

easyRelay applications

Product Application AP05013001E

Effective February 2013

M1 Marker relay, buffer memory, Open window

M2 Marker relay, buffer memory, Close window

M3 Marker relay, buffer memory, Open window comparator

M4 Marker relay, buffer memory, Close window comparator

M5 Marker relay, buffer memory, Heat comparator

M6 Open marker via T2

P2 Up arrow cursor button = Open window

P4 Down arrow cursor button = Close window

Q1 Output, contactor for Open window drive motor

Q2 Output, contactor for Close window drive motor

Q3 Output, contactor for fan motor

Q4 Output, motor fault indicator light

T1 Timing relay, flashing, for fault message

T2 Timing relay, single-pulse, 4 seconds = opening time

for continuous ventilation

Benefits

t

Implemented:

t 1 x ON-delayed timing relay

t 1 x flash/blink relay

t

Temperature values can be processed (analog values)

t

Less wiring required

t

More flexible if modifications are required

Customer: Program:

Date: Page:

Greenhouse

1/4/13

M

5I5

I1 I3

4

I

I5

T1

1

I

R

Q3

T2T

M6S

T1T

Q

4

M6

Comment:

20C, motor 2, ->warm air

degree of opening via T2

Marker Open via T2

Motor 1 or 2 defective

Indicator light H1 flashes

Reset marker Open via T2

Example 4

2

Examples

A

1

A2

A3

A4

A5

A6

M

3

1

M

P

2

T2

MM4

2

P4

I1

Greenhouse

1/4/13

2

I

12I

Q

I2

I2

I3

Q

I1

I3

I3 M6

I4

1

MS3

MR3

MS4

M4R

M5S

MR5

MI4 1

Q1

M2

Q2

Customer: Program:

Date: Page:

Example 4

1

Comment:

Open window ON

Open window OFF

Close window ON

Close window OFF

Heat ON

Heat OFF

25C, do not open window, motor 1

Motor 1 opens

23C, do not close window, motor 1

Motor 1 closes

Figure 21. easyRelay Display Diagram

Customer: Program:

Date: Page:

Timing relays

Analog comparators

Analog comparators

Greenhouse

1/4/13

01S

00

TRG T

RES

ANALOG ANALOG ANALOG

I8

68

.

ANALOG ANALOG ANALOG

I8

65

.

1

+

A A

1

+

A A

4

+

S

:::

I8

66

.

I8

60

.

04 00

:::

TRG T

RES

Example 4

3

2

+

2

+

5

+

I8

63

.

I8

62

.

TRG T

RES

A

3

+

A

6

+

Figure 20. easyRelay Display Diagram

Figure 22. easyRelay Display Parameters

EATON CORPORATION

11

Page 12

Product Application AP05013001E

Effective February 2013

easyRelay applications

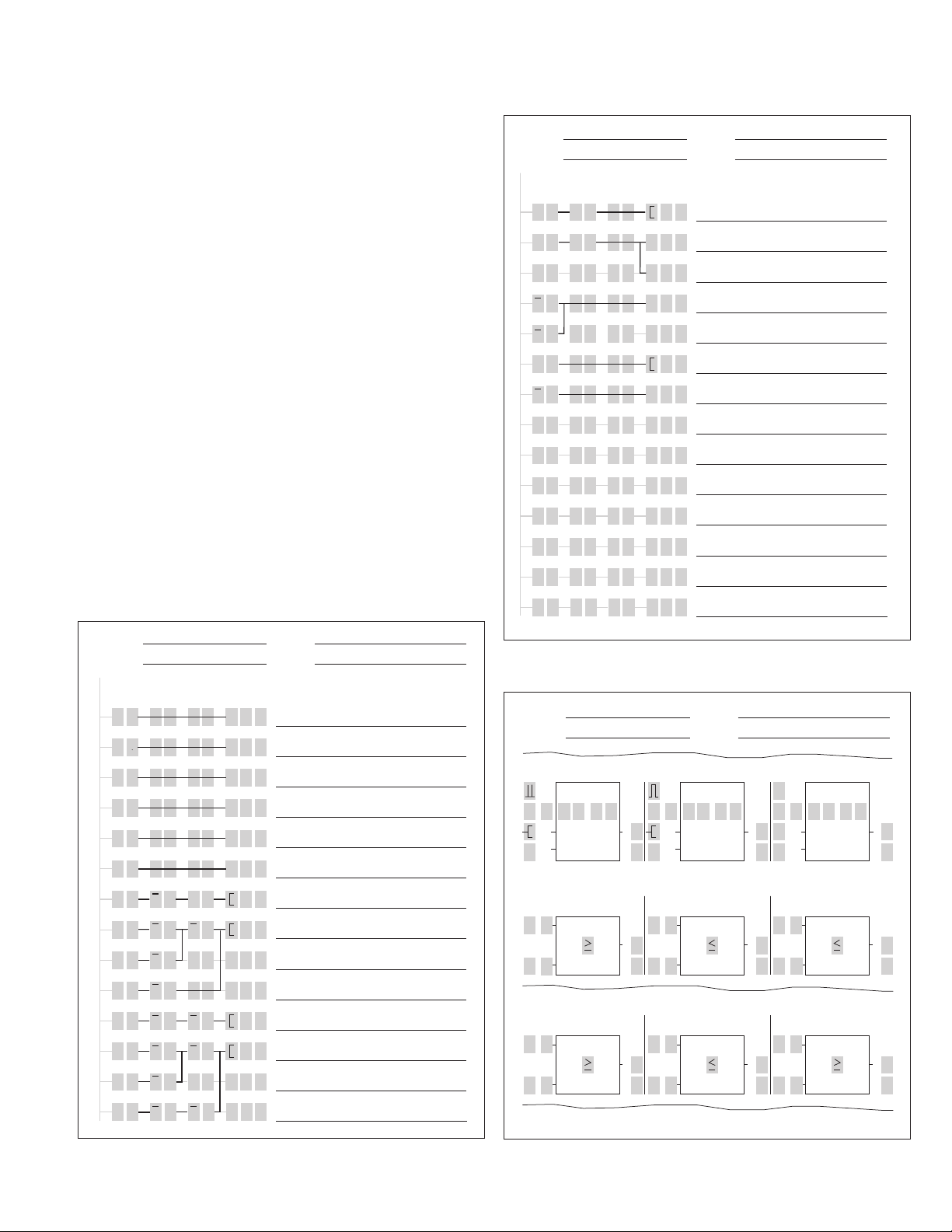

Lighting control in a production room

Task

To automatically turn on the lighting fixtures in a production room

during production hours. The lights should turn on and off gradually

in response to changes in the daylight level. It must be possible to

turn the switch for the individual lighting stages on and off manually

at any time. Faults in the lighting system should be signaled by a

flashing light.

Overview drawing

Connection to the busbar system

Phase 1:

Every 1st, 4th, 7th, and 10th neon light.

Activated via contactor K1.

Enabled via daylight control switch B1.

Phase 2:

Every 2nd, 5th, 8th, and 11th neon light.

Activated via contactor K2.

Enabled via daylight control switch B2.

Phase 3:

Every 3rd, 6th, 9th, and 12th neon light.

Activated via contactor K3.

Enabled via daylight control switch B3.

Lighting stages

Stage 0:

All the lights are off.

Stage 1:

Every third light is on. Contact B1 is closed.

Stage 2:

Every third light is off. Contacts B1 and B2 are closed.

Stage 3:

All the lights are on. Contacts B1, B2, and B3 are closed.

Manual operation

It must be possible to switch the individual lighting stages

atlightswitches S1 through S3.

Use of the manual function is signaled by indicator lights

H1throughH3.

Figure 23. Overview

Operating description

Three light fixtures, each with 12 fluorescent lights, are suspended

from a busbar system. The lighting is on from 6:00 a.m. to 5:30 p.m.

Monday through Friday and is varied according to the daylight level.

The switch-on times and the ON duration must be variable to suit

requirements.

Lighting stages

The use of three different switching stages guarantees the

necessary brightness, saves energy, and places a uniform load

onthe mains supply.

Failure of a busbar

The busbars are protected via miniature circuit breakers Q1 through

Q3 and are monitored by trip indicating auxiliary contacts. Faults are

signaled in the form of a group alarm via flashing indicator lightH4.

ote:N If the daylight control switches already have an ON-delay or OFF-delay,

these times should be set as low as possible (of the order of 1 second).

Alternatively, the ON-delayed timers T1 through T6 programmed in the

easyRelay (default value 60 seconds) can be changed to obtain the required

overall delay.

12

EATON CORPORATION

Page 13

easyRelay applications

Product Application AP05013001E

Effective February 2013

Control circuit

F1

L1

N

B1

S1

S2

S3

L

NN

EASY512-AC-RC

12 12 12 12

Q1 Q2 Q3 Q4

K1

B2

I1 I2 I3 I4 I5 I6 I7 I8

DEL

ESC

K2

K3

Q1

B3

ALT

OK

S1

S2

S3

Q2

Q3

H3

H2

H1

H4

B1–B3 Contact, daylight control switch 1–3

F1 16 A, char B miniature circuit breaker

H1–H3 Indicator light, stage 1–3

H4 Fault indicator light

K1–K3 Cont actor, lighting stage 1–3

Q1–Q3 Miniature circuit breaker 1–3

S1–S3 Light switch, stage 1–3

Figure 24. Control Wiring Diagram

CAUTION

THE SAFETY REQUIREMENTS OF THE APPLICABLE VDE, IEC, UL, AND CSA

STANDARDS REQUIRE THE PHASE THAT IS USED FOR THE POWER SUPPLY

TO BE USED FOR THE INPUTS AS WELL. IF THIS IS NOT THE CASE, THE

easyRELAYS WILL NOT DETECT THE CONNECTION LEVEL AND CAN BE

DAMAGED BYOVERVOLTAGES.

Load circuit

Switching points of the daylight control switch

On <- B2-> Off

LightDark

On <- B3-> Off

On <- B1-> Off

Figure 26. Switching Points of the Daylight Programmable

Switch

List of operands

I1 Input, light switch, stage 1

I2 Input, light switch, stage 2

I3 Input, light switch, stage 3

I4 Input, contact of daylight control switch 1

I5 Input, contact of daylight control switch 2

I6 Input, contact of daylight control switch 3

I7 Input, circuit breaker messages

M1 Marker relay, buffer memory, stage 1

M2 Marker relay, buffer memory, stage 2

M3 Marker relay, buffer memory, stage 3

Q1 Output, contactor for stage 1

Q2 Output, contactor for stage 2

Q3 Output, contactor for stage 3

Q4 Output, fault indicator light

T1 Timing relay with 60-second ON delay —> Stage 1 ON

T2 Timing relay with 60-second ON delay —> Stage 1 OFF

T3 Timing relay with 60-second ON delay —> Stage 2 ON

T4 Timing relay with 60-second ON delay —> Stage 2 OFF

T5 Timing relay with 60-second ON delay —> Stage 3 ON

T6 Timing relay with 60-second ON delay —> Stage OFF

T7 Timing relay, flashing for 1 second to indicate fault

L1

L2

L3

N

PE

Q1

K1

4.43

4.44

Q2

K2

Figure 25. Load Circuit Diagram

4.43

4.44

Benefits

t

Implemented functions:

t 1 x flash/blink relay

Q3

K3

4.43

4.44

1L1

1L2

1L3

N

PE

2L1

2L2

2L3

N

PE

3L1

3L2

3L3

N

PE

t 1 x single-channel time switch with weekly and daily programs

t

Functional overall solution

t

Less wiring required

t

Takes up less space than conventional systems

EATON CORPORATION

13

Page 14

Product Application AP05013001E

Effective February 2013

Examples

I

4

T1

I

4

T2

I5

TI3

I

5

T4

6

Light fixtures

1/4/13

TT1

MS1

TT2

M1R

T3T

S

M2

T

T4

R

M2

T

T5

Customer: Program:

Date: Page:

Example 5

1

Comment:

Daytime control switch 1 ON, B1

Stage 1 ON

Daytime control switch 1 OFF, B1

Stage 1 OFF

Daytime control switch 2 ON, B2

Stage 2 ON

Daytime control switch 2 OFF, B2

Stage 2 OFF

Daytime control switch 3 ON, B3

I

1

M1

I

2

M2

I3

M3

Light fixtures

1/4/13

Comment:

Q1

Stage 1 ON (B1)

Q2

Stage 2 ON (B1 + B2)

Q3

Stage 3 ON (B1 + B2 + B3)

Customer: Program:

Date: Page:

easyRelay applications

Example 5

2

S

T

R

T

M3

Stage 3 ON

T6

Daytime control switch 3 OFF, B3

M3

Stage 3 OFF

T7

Fault in busbar 1, 2 or 3

Q4

Fault indicator light, Is,

TT5

6

I

6

I

7

T7

Figure 27. easyRelay Display Diagram

Figure 28. easyRelay Display Diagram

X

Light fixtures

1/4/13

60S

00

TRG T

RES

60S

00

TRG T

RES

X

60 00 60 00

S

:::

1

+

X

S

:::

4

+

:::

TRG T

RES

60 00 60 00

:::

TRG T

RES

Customer: Program:

Date: Page:

Timing relays

Timing relays

Example 5

3

2

+

5

+

X

S

XX

S

TRG T

RES

TRG T

RES

3

+

6

+

14

EATON CORPORATION

Timing relays

01S

00

TRG T

RES

:::

7

+

:::

TRG T

RES

Figure 29. easyRelay Display Parameters

TRG T

RES

Page 15

easyRelay applications

Product Application AP05013001E

Effective February 2013

Booster pumps

Task

Two pumps provide the water supply for an installation. Their

operation is to be monitored. The two pumps are to be operated

alternately to prevent excessive wear. The operating status and

the faults within the installation are to be signaled by two indicator

lights. It must be possible to select the pressure-related switching

points for activating the pumps as required.

Overview drawing

Faults

Electrical failure of a pump motor is detected by the trip-indicating

auxiliary contacts for the motor-protective circuit breaker Q1 and Q2.

The pump that is still in working order will be activated. If one of

the pumps is mechanically defective, the resulting drop in pressure

will be detected, and the other pump will be activated after time T4

has elapsed. Both fault types are signaled by the flashing indicator

light H1 or H2. When both pumps are electrically defective, indicator

lights H1 and H2 will flash simultaneously.

Low pressure

The system is monitored for low pressure, which is signaled

by indicator lights H1 and H2 that flash alternately after time T5

has elapsed. It must be possible to set the low pressure limit on

the easyRelay.

Acknowledgement

All fault messages are retained until they have been acknowledged

by pressing the S3 button.

Maintenance

It must be possible to directly switch pump P1 using key switch S1

and pump P2 using key switch S2.

Figure 30. Overview

Operating description

Pumping operation

The pumping station provides the water supply for an installation. It

must also ensure that the pressure does not fall below a specified

minimum level. There are two booster pumps—P1 and P2. If the

pressure is too low, one of the pumps is activated via pressure

sensor B1. To ensure that the two pumps are subject to equal use

and wear, they are run alternately for 48-hour periods. Two indicator

lights, H1 and H2, signal which of the two pumps is in use. If the

easyRelay is disconnected from the power supply, the operating

hours count will start again, and pump 1 will be activated first.

To enable the pumps to change over after a shorter or longer

operating period, counters C1 and C2 should be set to new

comparison values using the following formula:

Desired changeover time in hours x 60 = comparison value.

Default: 48 hours x 60 = 2880.

EATON CORPORATION

15

Page 16

Product Application AP05013001E

Effective February 2013

easyRelay applications

Control circuit

L1

N

PE

F1

G1

~

S0

+24V

B1 Pressure sensor

F1 16 A char. B miniature circuit breaker

F2 Miniature circuit breaker (optional)

G1 Power supply unit 230 Vac/24 Vdc

H1 Indicator light for pump 1

H2 Indicator light for pump 2

K1 Contactor for pump P1

K2 Contactor for pump P2

Q1 Trip-indicating auxiliary contact for pump 1

Q2 Trip-indicating auxiliary contact for pump 2

S0 Emergency stop

S1 Key switch for pump 1

S2 Key switch for pump 2

S3 Acknowledgement button

F2

-

0V

S1

0V

+24V

EASY512-DC-R

12 12 12 12

Q1

K1

Figure 31. Control Wiring Diagram

Load circuit

L1

L2

L3

N

PE

Q1

K1

M

3 ~

M1

4.43

4.44

Figure 32. Load Circuit Diagram

Q2

Q1

S2

I1 I2 I3 I4 I5 I6 I7 I8

0V

Q2 Q3

K2

ALT

DEL

OK

ESC

H1

Q2

K2

Pressure diagram

S3

P

0-10V

B1

0 bar

Figure 33. Pressure Diagram

A1A2 A3

Pressure

Switching points

A1 Pump 1 or pump 2 is activated; H1 or H2 lights up

A2 Low pressure After time T4 (10 sec), changeover to the

inactive pump, the fault is indicated by flashing signal

at H1 or H2. After time T5, a total failure is signaled by

H1 and H2 flashing alternately

Q4

A3 Pump 1 or pump 2 is switched off; H1 or H2 goes out

See example 4 for determining the pressure switching points.

H2

List of operands

A1 Comparator for minimum pressure monitoring, lower threshold

A2 Comparator for low pressure monitoring due to electrical or

mechanical fault

A3 Comparator for minimum pressure monitoring, upper threshold

C1 Counter with 30-second pulse for operating hours of pump 1

C2 Counter with 30-second pulse for operating hours of pump 2

I1 Input, key switch for directly activating pump 1

I2 Input, key switch for directly activating pump 2

I3 Input, motor-protective circuit breaker for pump 1

I4 Input, motor-protective circuit breaker for pump 2

I5 Input, fault message acknowledgement button

M1 Pump changeover marker relay M1 = Off: pump 1;

M1 = On: pump 2

M2 Marker relay for low pressure/mechanical fault, pump 1

M3 Marker relay for low pressure/mechanical fault, pump 2

M4 Marker relay for electrical fault, pump 1

M5 Marker relay for electrical fault, pump 2

M6 Marker relay for total failure of pumping system

4.43

M7 Marker relay for minimum pressure switching point,

switch pump on/off

4.44

M8 Marker relay, buffer memory, indicator light for pump 1

M9 Marker relay, buffer memory, indicator light for pump 2

Q1 Output, contactor for pump 1

Q2 Output, contactor for pump 2

M

3 ~

M2

Q3 Output, indicator light for pump 1

Q4 Output, indicator light for pump 2

T1 30-second cycle for recording operating time, pump 1

T2 30-second cycle for recording operating time, pump 2

T3 1-second cycle for flashing signal from indicator light

T4 Time delay for low pressure message/mechanical fault,

pump 1, 2

T5 Time delay for low pressure message, total failure

16

EATON CORPORATION

Page 17

easyRelay applications

Product Application AP05013001E

Effective February 2013

Benefits

t

Implemented functions:

t 1 x flash/blink relay

t 2 x ON-delayed timing relays

t 1 x operating hour counters

t

Processing of pressure values (analog values)

t

Variable switching points and operating hour changeover

t

Less wiring required

t

Takes up less space than conventional systems

Examples

Pumping station

Customer: Program:

1/4/13

Date: Page:

A

1

A3

I1

M7 M1 I 3

M1 I 4

I2

1Q

T

1

C1

Q2

T2

C2

M

S7

MR7

M8

Q1

Q2

M9

TT1

CRC2

C1

S

M1

TTR2

C1

C

C2

R

M1

Example 6

1

Comment:

Lower threshold for minimum pressure

Upper threshold for minimum pressure

Pump 1 ON indicator light

Pump 1 active

Pump 2 active

Pump 2 ON indicator light

Pump 1 run time clock

Reset counter 2

Pulse counter 1-48 hours

Change over to pump 2

Pump 2 run time clock

Reset counter 1

Pulse counter 2-48 hours

Change over to pump 1

Figure 34. easyRelay Display Diagram

Pumping station

Customer: Program:

1/4/13

Date: Page:

Comment:

T

I3

I4

A2

I5

5T

T

Q

4

I

M2

T

M2

M4

M8

M6 T3

T3

S

R

S

T

M

3

1

4

36

S

M

Clock for flashing signal from indicator light

1

MS

Electrical fault in pump 1

M4

Active pump 2

M1

Electrical fault in pump 2

M5

Active pump 1

T4

Low pressure monitoring

TT5

MSS6

Low pressure signal, total failure

M2

Mechanical fault in pump 1

M1

Active pump 2

Q3

Fault in pump 1 -> Indicator light

H1 flashes

Pump 1 in use

Total failure ->Lights flash alternately

Figure 35. easyRelay Display Diagram

Pumping station

Customer: Program:

1/4/13

Date: Page:

Comment:

M

S22Q4T3

M3 I 3

M5

M9

M6

T3

5I

M

M

6

Mechanical fault in pump 2

MR

1

Active pump 1

Q4T3M3

Fault in pump 2 -> Indicator light

H2 flashes

Pump 2 in use

Total failure -> Lights flash alternately

MR2

Acknowledge fault messages

MRR3

Example 6

2

Example 6

3

M4

R

M5

M6

R

Figure 36. easyRelay Display Diagram

EATON CORPORATION

17

Page 18

Product Application AP05013001E

Effective February 2013

easyRelay applications

Customer: Program:

Date: Page:

Timing relays

Timing relays

Analog comparators

Up and down counters

Pumping station

1/4/13

30S

00

TRG T

RES

X

10S

00

TRG T

RES

ANALOG ANALOG ANALOG

I8

29

.

28 80 28 80

DIR

CNT

RES

S S

30 00 01 00

:::

1

+

X

S

:::

4

+

I8

A A

1

+

20

.

C

1

+

:::

TRG T

RES

25 00

:::

TRG T

RES

DIR

CNT

RES

Figure 37. easyRelay Display Parameters

Example 6

4

2

+

5

+

2

+

C

2

+

I8

31

.

TRG T

RES

TRG T

RES

DIR

CNT

RES

Tank installation level indicator

Task

To monitor the fill level of three tanks. When the maximum level is

reached, this should be indicated by a visual and audible signal.

Overview drawing

3

+

A

3

+

Figure 38. Overview

Operating description

The fill level of three fat tanks in an animal feed plant is monitored.

If one tank is full, the corresponding indicator light H1, H2, or H3

C

flashes in the control room to signal that a “new value” is being

formed. After a set time has elapsed (default 3 seconds), an alarm

starts as well. Acknowledgement button S4 can be used for all

three tanks; it acknowledges the audible signal from the alarm and

changes the flashing light to a continuous light.

18

EATON CORPORATION

Page 19

easyRelay applications

Product Application AP05013001E

Effective February 2013

Control circuit

F1

L1

N

S1

S2

L

EASY512-AC-R

12 12 12 12

Q1 Q2 Q3 Q4

H1

F1 16 A, char. B miniature circuit breaker

H1 Indicator light for tank 1

H2 Indicator light for tank 2

H3 Indicator light for tank 3

H4 Alarm

S1 Level indicator for tank 1

S2 Level indicator for tank 2

S3 Level indicator for tank 3

S4 Acknowledgement button

Figure 39. Control Wiring Diagram

S3

NN

S4

I1 I2 I3 I4 I5 I6 I7 I8

DEL

ESC

H2

List of operands

I1 Input, float switch for tank 1

I2 Input, float switch for tank 2

I3 Input, float switch for tank 3

I4 Input, acknowledgement button

M1 Marker relay, acknowledged full message from tank 1

M2 Marker relay, acknowledged full message from tank 2

M3 Marker relay, acknowledged full message from tank 3

Q1 Output, indicator light for tank 1

Q2 Output, indicator light for tank 2

ALT

Q3 Output, indicator light for tank 3

Q4 Output, Alarm

T1 Timing relay with 3-second ON delay —> delay after tank 1

OK

full message

T2 Timing relay with 3-second ON delay —> delay after tank 2

full message

T3 Timing relay with 3-second ON delay —> delay after tank 3

full message

H4

H3

T4 Single-pulse timing relay —> Alarm ON set pulse

T5 Single-pulse timing relay —> Alarm ON set pulse

T6 Single-pulse timing relay —> Alarm ON set pulse

T7 Timing relay flashing for 0.5 second —> New value signal

Benefits

t

Implemented functions:

t 3 x ON-delayed timing relays

t 1 x flash/blink relay

t 3 x auxiliary contactors

t

Less wiring required

t

Takes up less space than conventional systems

CAUTION

THE SAFETY REQUIREMENTS OF THE APPLICABLE VDE, IEC, UL, AND CSA

STANDARDS REQUIRE THE PHASE THAT IS USED FOR THE POWER SUPPLY

TO BE USED FOR THE INPUTS AS WELL. IF THIS IS NOT THE CASE, THE

easyRELAYS WILL NOT DETECT THE CONNECTION LEVEL AND CAN BE

DAMAGED BYOVERVOLTAGES.

EATON CORPORATION

19

Page 20

Product Application AP05013001E

Effective February 2013

easyRelay applications

Examples

Customer: Program:

Date: Page:

Tank installation

1/4/13

M

I

11

M

1

M

1

I4

M

I2 2

M

2

M2

I4

T

7

Q1

M1

T1T

T

7

Q2

M2

T2T

Example 7

1

Comment:

Tank 1 full (S1), H1 flashes

H1 maintained light

by acknowledgement button

Timing relay for alarm

Tank 2 full (S2), H2 flashes

H2 maintained light

by acknowledgement button

Timing relay for alarm

Tank installation

Customer: Program:

1/4/13

Date: Page:

Comment:

M3

I

3

1

T

T

2

T3

T

4

T5

T6

4

I

T7

M3

M3

I4

Q3

Tank 3 full (S3), H3 flashes

M3

H3 maintained light

by acknowledgement button

T3T

Timing relay for hooter

T4T

Pulse for alarm from tank 1

T5T

Pulse for alarm from tank 2

T6T

Pulse for alarm from tank 3

QSR4

Alarm ON for tank 1 after 3 seconds

Alarm ON for tank 2 after 3 seconds

Alarm ON for tank 3 after 3 seconds

Q4

Alarm OFF with acknowledgement button S4

T7T

Clock for flashing signal

Example 7

2

Figure 40. easyRelay Display Diagram

Figure 41. easyRelay Display Diagram

Tank installation

Customer: Program:

1/4/13

Date: Page:

Timing relays

XX X

03S

TRG T

RES

Timing relays

00S

TRG T

RES

Timing relays

00S

TRG T

RES

00

1

+

00

4

+

50

7

+

03 00 03 00

S S

:::

TRG T

RES

S S

00 00 00 00

:::

TRG T

RES

:::

TRG T

RES

Example 7

3

:::

TRG T

2

RES

+

:::

TRG T

5

RES

+

:::

TRG T

RES

3

+

6

+

20

Figure 42. easyRelay Display Parameters

ote:N The specified time of 0 seconds in the timing relay produces a pulsing

signal of the same length as one easyRelay cycle time.

EATON CORPORATION

Page 21

easyRelay applications

Product Application AP05013001E

Effective February 2013

Access monitoring for a parking garage

Task

To monitor the occupancy of a company parking garage. Cars can

enter the garage provided that there are still some spaces available.

Access is controlled by a barrier system. The occupancy of the

garage is signaled by a “Full/Empty” display.

Overview drawing

Faults

A fault in the barrier system, which is signaled via make contact S1,

is displayed by flashing indicator light H1 in the garage attendant’s

booth.

Maintenance

The barrier can be opened by pressing the P2 function button

(Uparrow) on the easyRelay.

Control circuit

F1

L1

N

S1

S2

S3

S4

S5

I1 I2 I3 I4 I5 I6 I7 I8

L

NN

ALT

DEL

OK

EASY512-AC-R

12 12 12 12

Q1 Q2 Q3 Q4

ESC

Figure 43. Overview

Operating description

Entry and exit

Access to the garage is monitored by a swipe card reader. If the

card is valid, contact S3 is closed briefly. When a vehicle leaves

the garage, contact S2 is closed via an induction loop embedded

in the ground. A display panel with the message “Full” or “Spaces

free” at the point of entry should indicate whether there are still

parking spaces available. If voltage is present at signal input K2, the

display panel should read “Full”, otherwise it should read “Spaces

free”. The barrier opens when a voltage pulse is applied to K1 for

2 seconds, and it closes automatically when a vehicle has passed

through or after a set time has elapsed.

Counting the vehicles

Incoming and outgoing vehicles should be counted by the easyRelay.

The maximum number of vehicles that can be parked can be set

on the easyRelay. Vehicles may enter if there are parking spaces

available. The counter can be reset to zero via the key switch S5 in

order to establish a baseline.

K1

F1 16 A, char. B miniature circuit breaker

H1 Fault flashing indicator light

K1 Barrier driving circuit

K2 Display panel driving circuit

S1 Barrier fault indicator

S2 Contact for induction loop

S3 Contact for swipe card reader

S4 Open barrier button

S5 Reset counter key switch

K2

H1

Figure 44. Control Wiring Diagram

CAUTION

THE SAFETY REQUIREMENTS OF THE APPLICABLE VDE, IEC, UL, AND CSA

STANDARDS REQUIRE THE PHASE THAT IS USED FOR THE POWER SUPPLY

TO BE USED FOR THE INPUTS AS WELL. IF THIS IS NOT THE CASE, THE

easyRELAYS WILL NOT DETECT THE CONNECTION LEVEL AND CAN BE

DAMAGED BYOVERVOLTAGES.

Manual operation

The garage attendant should be able to open the barrier at any time

using button S4, regardless of whether the garage is full or not.

EATON CORPORATION

21

Page 22

Product Application AP05013001E

Effective February 2013

easyRelay applications

List of operands

C1 Vehicle counter

I1 Input, fault barrier

I2 Input, contact for induction loop

I3 Input, contact for swipe card reader

I4 Input, open barrier button

I5 Input, reset counter key switch

P2 Up arrow cursor button = open barrier

Q1 Output, open barrier

Q2 Output, display panel

Q3 Output, fault indicator light

T1 Single 2-second single-pulse timing relay =

open barrier pulse

T2 Timing relay with 1-second flashing cycle =

barrier fault flashing message

Benefits

t

Implemented functions:

t 1 x flash/blink relay

t 1 x up/down counter with reset function

t 1 x ON-delayed timing relay

t

Compact system

t

Easy program duplication with program transfer

Examples

I

3

I2

I4

P2

T1

5

I

I

2

I2

I

3

C1

I1

2

T

Parking garage

1/4/13

C1

C1

T

T1

Q1

C1R

C1D

CC1

Q2

T2T

Q3

Customer: Program:

Date: Page:

Example 8

1

Comment:

Open pulse from swipe card reader

Induction loop

Attendant

Maintenance

Barrier opens

Counter reset by S5

Counting direction DOWN

Car exiting = Counter - 1

Car entering = Counter + 1

Full

Fault at barrier

Flashing signal in attendant’s booth

Figure 45. easyRelay Display Diagram

Customer: Program:

Date: Page:

Timing relays

Up and down counters

Parking garage

1/4/13

02S

00

TRG T

RES

00 30

DIR

CNT

RES

S

01 00

:::

1

+

C

1

+

:::

TRG T

RES

DIR

CNT

RES

Figure 46. easyRelay Display Parameters

Example 8

2

2

+

C

TRG T

RES

DIR

CNT

RES

C

22

EATON CORPORATION

Page 23

easyRelay applications

Product Application AP05013001E

Effective February 2013

Time-controlled lighting system

Task

To activate the lighting in rarely visited rooms in a library only

whenturned on by the user in order to save energy. The user

mayselect how long he/she wants the lights to remain on. It should

alsobe possible to switch the lights on and off permanently at a

central switch.

Overview drawing

Figure 47. Overview

Operating description

The four groups of lights (H1 through H4) in a library should only

beswitched on at a reader’s request. Two flush-mounted buttons

(S1through S8) are provided for this purpose at the end of a

shelving area. Ifthe reader presses the button briefly, the light will

come on for just 5 minutes. More pressure on the button will light

the area for a half-hour period. All the lights can be turned on and off

for cleaning via the central flush-mounted S9 button.

Control circuit

F1

L1

N

S3

S2

S1

F1 16 A, char. B miniature circuit breaker

H1 Lights in area A

H2 Lights in area B

H3 Lights in area C

H4 Lights in area D

S1–S2 Light switch in area A

S3–S4 Light switch in area B

S5–S6 Light switch in area C

S7–S8 Light switch in area D

S9 Central ON/OFF light switch

S4

L

NN

EASY512-AC-R

12 12 12 12

Q1 Q2 Q3 Q4

H1

S5

S6

I1 I2 I3 I4 I5 I6 I7 I8

DEL

ESC

H2

H3

S8

S7

ALT

OK

S9

H4

Figure 48. Control Wiring Diagram

CAUTION

THE SAFETY REQUIREMENTS OF THE APPLICABLE VDE, IEC, UL, AND CSA

STANDARDS REQUIRE THE PHASE THAT IS USED FOR THE POWER SUPPLY

TO BE USED FOR THE INPUTS AS WELL. IF THIS IS NOT THE CASE, THE

easyRELAYS WILL NOT DETECT THE CONNECTION LEVEL AND CAN BE

DAMAGED BYOVERVOLTAGES.

EATON CORPORATION

23

Page 24

Product Application AP05013001E

Effective February 2013

easyRelay applications

List of operands

C1 Counter, ON duration 5 min., area A

C2 Counter, ON duration 30 min., area A

C3 Counter, ON duration 5 min., area B

C4 Counter, ON duration 30 min., area B

C5 Counter, ON duration 5 min., area C

C6 Counter, ON duration 30 min., area C

C7 Counter, ON duration 5 min., area D

C8 Counter, ON duration 30 min., area D

I1 Input, light switch S1/S2, area A

I2 Input, light switch S3/S4, area B

I3 Input, light switch S5/S6, area C

I4 Input, light switch S7/S8, area D

I5 Input, central ON/OFF light switch

M1 Marker relay, buffer memory, light in area A ON for 5 min.

M2 Marker relay, buffer memory, light in area A ON for 30 min.

M3 Marker relay, buffer memory, light in area B ON for 5 min.

M4 Marker relay, buffer memory, light in area B ON for 30 min.

M5 Marker relay, buffer memory, light in area C ON for 5 min.

M6 Marker relay, buffer memory, light in area C ON for 30 min.

M7 Marker relay, buffer memory, light in area D ON for 5 min.

M8 Marker relay, buffer memory, light in area D ON for 30 min.

M9 Marker relay, buffer memory, light ON/OFF at central switch

Q1 Output relay, light area A

Q2 Output relay, light area B

Q3 Output relay, light area C

Q4 Output relay, light area D

T1 Timing relay with 2-second ON delay = short/long

ON duration, area A

T2 Timing relay with 2-second ON delay = short/long

ON duration, area B

T3 Timing relay with 2-second ON delay = short/long

ON duration, area C

T4 Timing relay with 2-second ON delay = short/long

ON duration, area D

T8 Flashing 20-second cycle for short/long ON duration

Benefits

t

Implemented functions:

t 12 x ON-delayed timing relays

t 1 x impulse changeover relay

t

Less wiring required

t

Takes up less space than conventional systems

Examples

Library lighting

Customer: Program:

1/4/13

Date: Page:

Comment:

T8

R

M9

Central light ON/OFF switch

TTT1

M1

Switch S1/S2 short pressure

M2

Switch S1/S2 long pressure

C1C

Counter 1 Duration: 5 minutes

C2C

Counter 2 Duration: 30 minutes

5 min.

Q1

Light at output 1 ON 30 min.

C1R

via central ON switch

C2

Reset counter 1 and 2

I5

I1

M1

I1

M

M

M2

C

C2

M9

I

Q1

T1

Q1

2

T8

1

T8

M1

1

M2

1

Figure 49. easyRelay Display Diagram

Library lighting

Customer: Program:

1/4/13

Date: Page:

Comment:

T

R

T2

M3

Switch S3/S4 short pressure

M4

Switch S3/S4 long pressure

C3C

Counter 3 Duration: 5 minutes

C4C

Counter 4 Duration: 30 minutes

5 min.

Q2

Light at output 2 ON 30 min.

C3R

via central ON switch

C4

Reset counter 3 and 4

T3T

I2

M3

I2

M4

M3

M

C

C4

M

I2

I3

Q2

T2

Q2

T8

T8

4

M3

3

M4

9

Example 9

1

Example 9

2

24

EATON CORPORATION

5

M

Q3

M5

Switch S5/S6 short pressure

Figure 50. easyRelay Display Diagram

Page 25

easyRelay applications

Product Application AP05013001E

Effective February 2013

Library lighting

Customer: Program:

1/4/13

Date: Page:

Comment:

I3 T3

Q3

M6

M5

M6

C

5

C

6

M

9

I3

I

4

M7

I4

8

M

7

M

T8

T8

M5

M6

Q4

T4

Q4

T8

M6

Switch S5/S6 long pressure

C5C

Counter 5 Duration: 5 minutes

C6C

Counter 6 Duration: 30 minutes

5 min.

Q3

Light at output 3 ON 30 min.

C5R

via central ON switch

C6R

Reset counter 5 and 6

T4T

M7

Switch S7/S8 short pressure

M8

Switch S7/S8 long pressure

CC7

Counter 7 Duration: 5 minutes

Figure 51. easyRelay Display Diagram

Example 9

3

Customer: Program:

Date: Page:

Timing relays

Timing relays

Library lighting

1/4/13

XX X

02S

X

00

TRG T

RES

02S

00

TRG T

RES

1

+

4

+

02 00 02 00

S S

:::

TRG T

RES

30 00

S

:::

TRG T

RES

Example 9

5

:::

2

+

:::

8

+

TRG T

RES

TRG T

RES

Figure 53. easyRelay Display Parameters

Customer: Program:

Date: Page:

Up and down counters

Library lighting

1/4/13

00 05

DIR

CNT

RES

00 30 00 05

DIR

C

1

+

CNT

RES

Example 9

6

C

2

+

DIR

CNT

RES

3

+

C

3

+

Library lighting

Customer: Program:

1/4/13

Date: Page:

Comment:

C

M8 T8

M7

C

7

M8

C

8

I4

C8

Counter 8 Duration: 30 minutes

Q4

5 min.

C7R

Light at output 4 ON 30 min.

C8R

Reset counter 7 and 8

Example 9

4

Up and down counters

00 30 00 05 00 30

DIR

C

CNT

RES

Up and down counters

00 05 00 30

DIR

CNT

RES

4

+

C

7

+

DIR

CNT

RES

DIR

CNT

RES

Figure 54. easyRelay Display Parameters

DIR

C

5

+

C

8

+

CNT

RES

DIR

CNT

RES

C

6

+

C

Figure 52. easyRelay Display Diagram

EATON CORPORATION

25

Page 26

Product Application AP05013001E

Effective February 2013

easyRelay applications

Refrigeration control system

Task

To turn the compressors of the refrigeration system in a hotel on

and off in response to the system pressure. The system pressure

is supplied by the easyRelay via analog input I8. The value at I8 is

compared with set point values and the switching points are derived

from the comparison value.

Overview drawing

Control circuit

L1

N

PE

F1

G1

~

F2

+24V

-

0V

S0

B1 Pressure sensor

F1 16 A, char. B miniature circuit breaker

F2 Miniature circuit breaker (optional)

G1 Power supply unit 230 Vac/24 Vdc

K1–K4 Compressor 1–4

S0 Emergency stop

S1 ON/OFF key switch

S1

I1 I2 I3 I4 I5 I6 I7 I8

24V

0V 0V

EASY512-DC-R

12 12 12 12

Q1 Q2 Q3 Q4

K1

ALT

DEL

OK

ESC

K2

K4

K3

P

0-10V

B1

Figure 55. Overview

Operating description

The pressure of the refrigeration system is compared with set

point values. Timers are connected upstream of the outputs so that

pressure fluctuations in the system do not cause the compressors

to turn on immediately.

Set point values

Output Q1:

Set: A1 ≥ 1.8 bar

Time T1 = 5 sec

Reset: A5 ≤ 1.7 bar

Output Q2:

Set: A2 ≥ 2.0 bar

Time T2 = 20 sec

Reset: A6 ≤ 1.9 bar

Output Q3:

Set: A3 ≥ 2.2 bar

Time T3 = 20 sec

Reset: A7 ≤ 2.1 bar

Output Q4:

Set: A4 ≥ 2.4 bar

Time T4 = 20 sec

Reset: A8 ≤ 2.3 bar

Figure 56. Control Wiring Diagram

Load circuit

L1

L2

L3

N

PE

Q1

K1

4.43

Q2

4.44

K2

M

3 ~

M1

4.43

Q3

4.44

K3

M

3 ~

M2

4.43

Q4

4.44

K4

M

3 ~

M3

Figure 57. Load Circuit Diagram

List of operands

A1 Comparator, motor 1 ON after T1 has elapsed

A2 Comparator, motor 2 ON after T2 has elapsed

A3 Comparator, motor 3 ON after T3 has elapsed

A4 Comparator, motor 4 ON after T4 has elapsed

A5 Comparator, motor 1 OFF

A6 Comparator, motor 2 OFF

A7 Comparator, motor 3 OFF

A8 Comparator, motor 4 OFFI1 Input, system ON/OFF

I8 Input, comparison voltage from pressure sensor

4.43

4.44

M

3 ~

M4

26

EATON CORPORATION

Page 27

easyRelay applications

Product Application AP05013001E

Effective February 2013

Q1 Output, motor 1

Q2 Output, motor 2

Q3 Output, motor 3

Q4 Output, motor 4

T1 Timing relay, ON delay, motor 1

T2 Timing relay, ON delay, motor 2

T3 Timing relay, ON delay, motor 3

T4 Timing relay, ON delay, motor 4

Benefits

t

Implemented functions:

t 4 x ON-delayed timing relays

t

Processing of pressure values (analog values)

t

Password function protects against unauthorized access

Examples

Customer: Program:

Date: Page:

Refrigeration system

1/4/13

I

1

T

1

T

2

T3

T

4

A

5

A6

A7

8

A

A1

A2

A3

A4

T1

T

T2T

T3T

T4T

Q1S

Q2S

Q3S

Q4S

QRR1

QR2

QR3

Q4

Example 10

1

Comment:

System switched on and pressure > 1.8 bar

Pressure > 2.0 bar

Pressure > 2.2 bar

Pressure > 2.4 bar

Compressor 1 (M1) ON after 5 sec.

Compressor 2 (M2) ON after 20 sec.

Compressor 3 (M3) ON after 20 sec.

Compressor 4 (M4) ON after 20 sec.

Pressure < 1.7 bar, compressor 1 OFF

Pressure < 1.9 bar, compressor 2 OFF

Pressure < 2.1 bar, compressor 3 OFF

Pressure < 2.3 bar, compressor 4 OFF

Customer: Program:

Date: Page:

Timing relays

Timing relays

Refrigeration system

1/4/13

XX X

05S

X

00

TRG T

RES

20S

00

TRG T

RES

1

+

4

+

20 00 20 00

S S

:::

TRG T

RES

:::

TRG T

RES

Example 10

2

:::

2

+

:::

TRG T

RES

TRG T

RES

Figure 59. easyRelay Display Parameters

Customer: Program:

Date: Page:

Analog comparators

Analog comparators

Analog comparators

Refrigeration system

1/4/13 3

ANALOG ANALOG ANALOG

I8

18

.

ANALOG ANALOG ANALOG

I8

24

.

ANALOG ANALOG ANALOG

I8

21

.

I8

A A

12

20

.

I8

A A

45

17

.

I8

A A

78

23

.

Example 10

I8

22

.

I8

19

.

3

+

A

3

A

6

A

Figure 58. easyRelay Display Diagram

Figure 60. easyRelay Display Parameters

EATON CORPORATION

27

Page 28

Product Application AP05013001E

Effective February 2013

easyRelay applications

Perimeter advertising in a stadium

Task

The time-dependent control of four advertising panels, each with

three sides. Each side is to be visible for 30 seconds, after which

thenext side is to be turned to the front.

Overview drawing

Figure 61. Overview

Operating description

Start

Start/Stop button S5 is used to start the procedure for all four panel

fixture electrical strips. The visible advertising panel is on view for a

variable time (controlled via T1 through T4). It should be possible to

stop the entire procedure by pressing the S5 button again.

Rotation

Once the set time has elapsed, the motor (M1 through M4)

associated with the strip must start automatically. The strip rotates

to display the next advertising panel. Once the advertising panel

is in the correct position, this is signaled via the corresponding

limit switch (S1 through S4) and the motor is turned off. To enable

the strip to leave the limit switch position, disconnection must be

bypassed, again fora variable time (controlled via T5 through T8),

when the rotation procedure starts.

Testing and maintenance

It must be possible to activate the rotation procedure manually in