Page 1

Welcome to the Klipsch line of Professional Theater Speaker Systems!

Since the earliest days of amplified sound systems, Klipsch has utilized the

latest concepts in loudspeaker design, surpassing the expectations of

concurrent fidelity. Today, by combining our design excellence with a solid

tradition of sonic reproduction quality, Klipsch provides a comprehensive

family of professional theater speakers, ranging from compact systems perfect

for small auditoriums, mixing suites and viewing rooms, to large four-way

horn-loaded systems applicable for installation in the largest cinema venues.

In Klipsch designs, you will find technical updates on traditional high quality

cinema sound systems, taking into consideration the digital sound sources of

today. Thanks to the Klipsch Tractrix® Horns used on high frequency and

mid-bass components, the Klipsch Professional Theater Speaker Systems offer

wider dynamics, controlled coverage, smoother power transfer functions, lower

distortion and superior efficiency, all in a broad range of available systems.

Included in the following pages are installation instructions for the Klipsch

family of professional theater sound products. If you have any questions or

need more information, please contact Klipsch directly at 1-800-KLIPSCH.

Our technical support staff will be happy to assist you.

Sincerely

Page 2

Table of Contents

General Introduction Pg. 2-5

Safety

Amplification

Wire Gauge

Crossovers Pg 5-6

General Aiming Goals

Behind-The-Screen and Stage Systems Pg 6

Placement Considerations

Vertical

Horizontal

Mechanical Installation for KPT-MCM-4 Grand Pg 7

Mechanical Installation for KPT-MCM-3 Grand Pg 7

Mechanical Installation for KPT-Jubilee™ Pg 8

Mechanical Installation for KPT-941-T Pg 8

Mechanical Installation for KPT-941 Pg 9

Mechanical Installation for KPT-904 Pg 9

Mechanical Installation for KPT-535 Pg 10

Mechanical Installation for KPT-325 Pg 10

Mechanical Installation for KPT-684 Pg 11

Mechanical Installation for KPT-484 Pg 11

Mechanical Installation for KPT-250, KPT-200, KPT-100 Pg 11

Mechanical Installation for KPT-110 Pg 11

Surround Sound System Installation Pg 11

Screen Sound System Setup and Alignment Pg 12

Wiring Detail Example Pg 13

System Specifications Pg 13

Delay Settings Pg 13

Crossover Frequencies Pg 13

Contact and Service Info Pg 14

Page 3

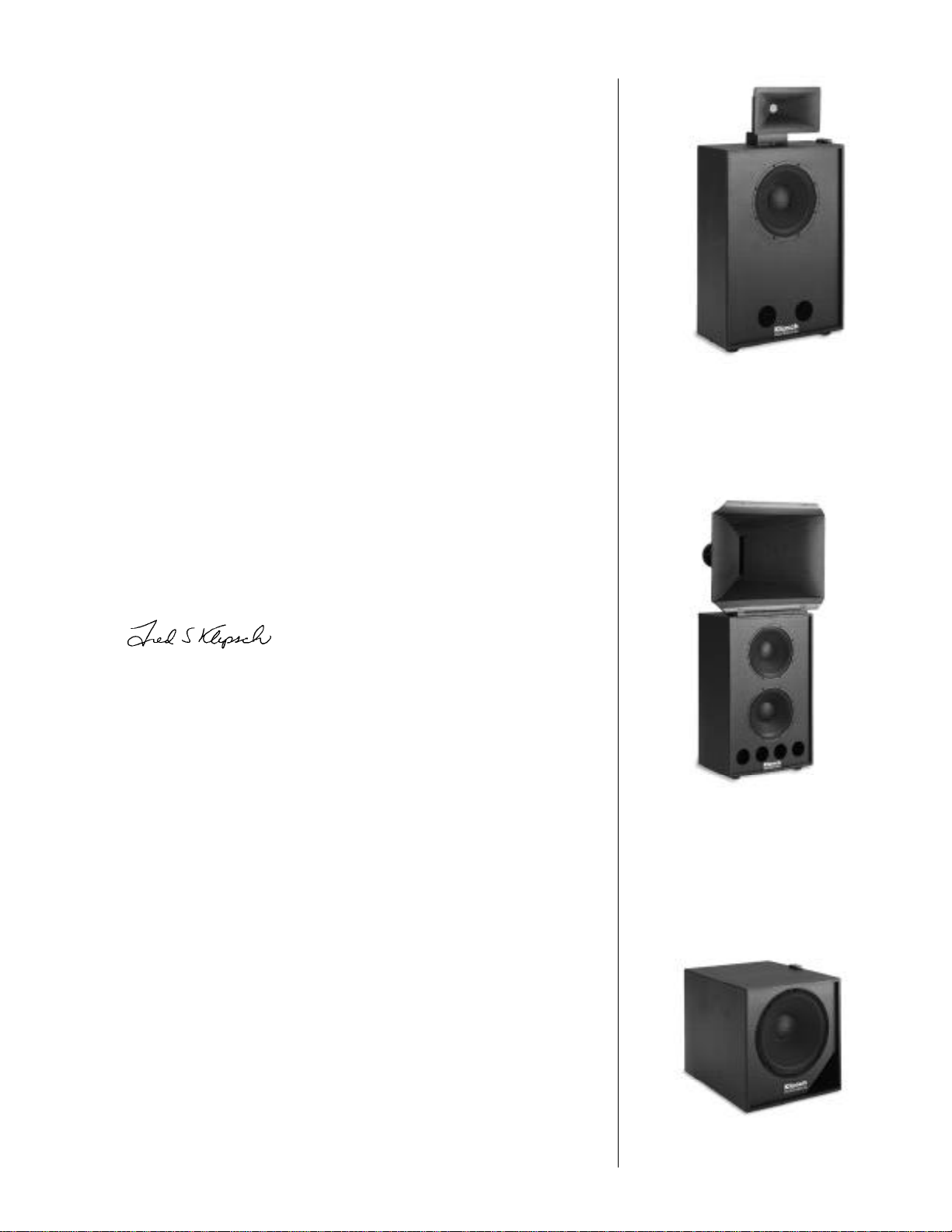

Fig. 22

Fig. 23

Mechanical Installation Drawings for KPT-484

and KPT-684

Please refer to figures. 22 and 23. These figures provide dimensions

required for creating baffles or for proper placement behind the screen.

Connectors can be made to the system by using the terminator panel

located on top of the unit.

KPT-484

Screen Sound System Setup and Alignment

After assembling the speakers, but prior to operation, be sure that wiring

connections are correct and that the installed systems are free from

problems, utilizing the following steps:

KPT-684

1) At the loudspeaker component end of the cable run, "short" the

positive and negative connections for each frequency section together,

and verify that your resistance meter reads the short when measured from

the amplifier end.

2) Verify that all amplifier channels and speaker components have been

wired correctly and are in proper polarity.

3) Set the electronic crossover and amplifier channels as per manufacturer

recommended settings. Refer to the speaker component specifications for

each system.

4) With a low level pink noise or frequency generator signal source, verify

that the low frequency amplifier and processor outputs for each of the

systems is feeding the proper speaker component(s). Do the same for all

of the amplifier and speaker sections, across all of the installed systems.

5) After pre-testing the system as indicated above, verifying operation and

completing a basic gain staging setup, to check for rattles, buzzes or

vibrations from the hardware, use a variable frequency oscillator or pink

noise source to "sweep" the system between 20Hz and 1000Hz at LOW,

MEDIUM, and then HIGH volume.

6) Complete a preliminary gain staging of the entire system per applicable

processor specifications, then verify that component aiming properly

addresses listening requirements throughout the house.

7) Complete proper final gain staging per processor recommendations.

Page 4

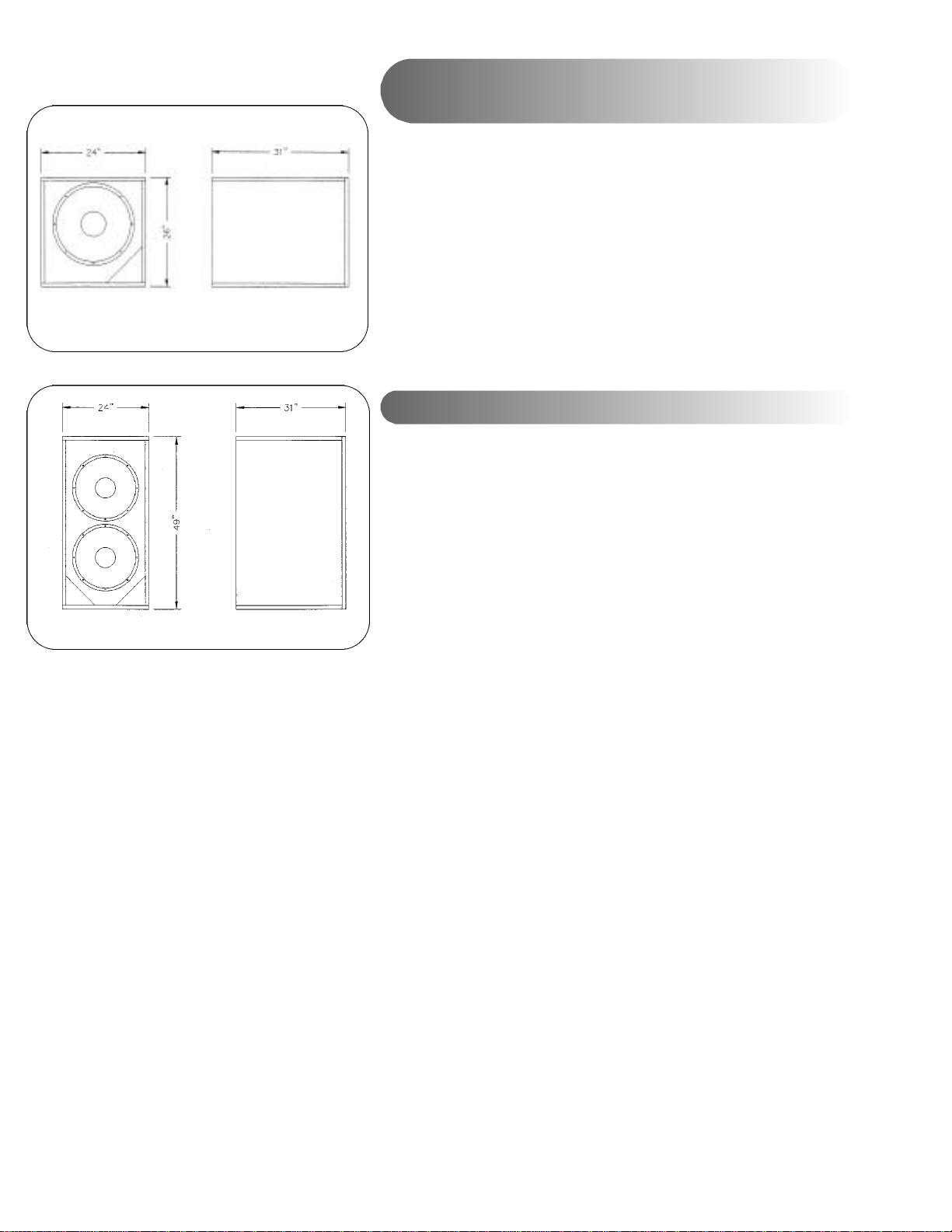

Mechanical Installation Drawings for KPT-250,

KPT-200 and KPT-100 Surround Sound Speakers

Please refer to the following drawings for installation details: Figures

17, 18, 19 and 20.

The bolt locations shown in "A" on Fig. 17 are common to models

KPT-250, KPT-200 and KPT-100 surround sound speakers, and are

used when mounting the speakers using a Goldberg bracket. The bolt

hole locations shown at "B" in Fig. 17 are used when mounting the

speakers using either an APC or OmniMount bracket.

Mechanical Installation Drawing for KPT-110

Surround Sound Speaker

Figure 21 shows the basic dimensions for the KPT-110. Location "A"

bolts and washers are to be used when mounting the speaker with a

Goldberg bracket.

Fig. 17

Fig. 18

Fig. 19

Surround Sound System Installation

Installation drawings for the surround sound speaker systems are

located in the following section. All of the systems are pre-assembled

for installation on-site, and include passive frequency dividing

networks. Please refer to the specification page for power and

impedance information.

Connections to the internal passive frequency dividing networks are

made on the termination panel located in the top of the units. Note

that models KPT-200 and KPT-100 include internal SMPTE/ISO 2696

X-curve de-emphasis.

Klipsch surround speaker mounting hardware is designed for readily

available Goldberg, APC and OmniMount brackets.

Fig. 20

Fig. 21

Page 5

Klipsch Professional Theater Speaker Systems

The hardware required to mount the component modules is included with the speaker

components on all Klipsch behind-the-screen and stage speaker systems. Hardware

primarily consists of brackets, yokes, bolts, nuts and washers for mounting and properly

aiming the mid-bass and high frequency horns and drivers above the low frequency

enclosures. The surround sound speakers, intended for wall mounting, are pre-drilled for

use with industry standard Goldberg, APC and OmniMount® brackets. Please refer to the

loudspeaker model installation diagrams in the following sections for specific assembly

details.

S a f e t y

After assembling the components on each speaker system, but before operation, all bolts

and nuts should be double-checked for proper seating and tightness. Due to the weight

and size of the components, damage could occur if the devices were to become

unattached.

A m p l i f i c a t i o n

For B-chain amplifier power matching, please refer to the specifications for each

component module. Amplifiers should be overrated to ensure available dynamic

headroom and freedom from distortion on loud signal passages. Level capabilities in the

house should meet or exceed your specific processor system standards when speaker

component specifications are factored in. Note that nominal dialogue levels in modern

theaters are typically 85dB or greater, with effect and music levels at a 105dB average.

When using passive crossovers (as opposed to actively dividing signals for the low,

mid-bass, high frequency and optional extended high frequency sections), Klipsch

recommends designing the system with 6dB of amplifier headroom.

Wire Gauge

The choice of gauge for speaker interconnect wire plays a major role in the power transfer

efficiency between amplifiers and speakers. Signal loss per distance charts for the various

gauges of speaker wire and loudspeaker impedances indicate that the largest gauge of wire

should be used, whenever possible, to minimize insertion loss, amplifier loading and

frequency response non-linearities.

C r o s s o v e r s

Although passive crossovers are available for a number of the Klipsch screen and stage

systems, there are advantages to using active crossovers. By actively dividing the frequency

sections for the systems, less power is lost to heat in the passive crossover, and device

control (damping factor) is greatly improved. In virtually every case, the speaker system

performance is improved through bi- or tri-amplification. Of course, the performance

improvements must be weighed against the cost of additional amplifier channels.

Page 6

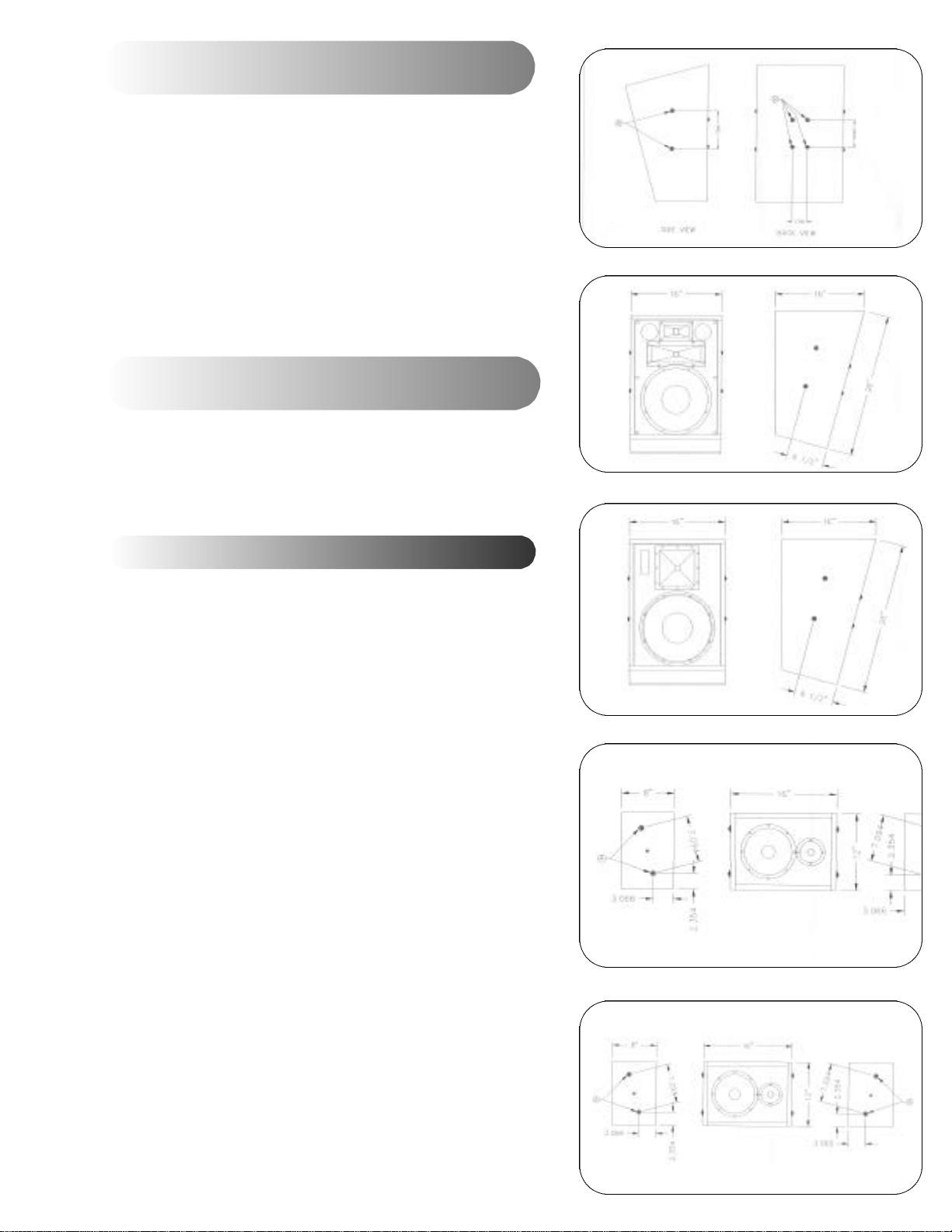

Fig. 13

Fig. 14

Mechanical Installation Drawings for KPT-535

Please refer to the following drawings for assembly details:

Figures 13 and 14.

After unpacking all components, locate the KPT-402 compression driver

and horn. Attach the driver to the horn using supplied hardware.

Locate the two1/4"-20 screws on top of the KPT-904/940-LF. Remove the

two screws and washers. Place the KPT-402-MF unit on top of the KPT904/940-LF, making sure that the hole/slot as indicated by "A" in Fig. 13

lines up with the holes in the KPT-904/940-LF. Reinstall the screws and

washers. Adjust the horizontal angle as desired and tighten the screws.

Locate the KPT-Grand-HF. Locate the two1/4"-20 on the KPT-Grand-HF.

Remove the two screws and washers. Place the KPT-Grand-HF on top of

the KPT-402-MF and align the holes. Reinstall the screws and washers

and tighten screws as shown at "C" on Fig. 13.

Locate the 1/4"-20 nuts as shown at "D" in Fig. 13. To adjust the vertical

angle, loosen the nuts and adjust the horns until the desired vertical

angle is achieved. Tighten the nuts.

Fig. 15

Fig. 16

Mechanical Installation Drawings for KPT-325

Please refer to the following drawings for assembly details:

Figures 15 and 16.

After unpacking all the components, locate the two1/4"-20 screws on top

of the KPT-315-LF. Remove the two screws and washers. Place the KPT904-HF unit on top of the KPT-315-LF, making sure that the hole/slot as

indicated by "A" in Fig. 15 lines up with the holes in the KPT-315-LF.

Reinstall the screws and washers. Adjust the horizontal angle as desired

and tighten the screws.

Locate the 1/4"-20 bolts/nuts on both sides of the bracket as shown at "B"

in Fig. 15. To adjust the vertical angle, loosen the bolts and nuts and

adjust the horn until the desired vertical angle is achieved. Tighten the

bolts and nuts.

Page 7

Mechanical Installation Drawings for KPT-941

Please refer to the following drawings for assembly details:

Figures 9 and 10.

After unpacking all components, locate the KPT-941 HF

compression driver and horn. Attach the driver to the horn using

supplied hardware.

Locate the two1/4"-20 screws on top of the KPT-904/940-LF.

Remove the two screws and washers. Place the KPT-941-HF unit

on top of the KPT-904/940-LF, making sure that the hole/slot as

indicated by "A" in Fig. 9 lines up with the holes in the KPT904/940-LF. Reinstall the screws and washers. Adjust the

horizontal angle as desired and tighten the screws.

Locate the 1/4"-20 nuts as shown at "C" in Fig. 10. To adjust the

vertical angle, loosen the nuts and adjust the horn until the

desired vertical angle is achieved. Tighten the nuts.

Fig. 9

Fig. 10

Mechanical Installation Drawings for KPT-904

Please refer to the following drawings for assembly details:

Figures 11 and 12:

After unpacking all the components, locate the two1/4"-20 screws

on top of the KPT-904/940-LF. Remove the two screws and

washers. Place the KPT-904-HF unit on top of the KPT-904/940LF, making sure that the hole/slot as indicated by "A" in Fig. 11

lines up with the holes in the KPT-904/940-LF. Reinstall the

screws and washers. Adjust the horizontal angle desired and

tighten the screws.

Locate the 1/4"-20 bolts and nuts on both sides of the bracket as

shown at "B" in Fig. 11. To adjust the vertical angle, loosen the

bolts and nuts, and adjust the horn until the desired vertical angle

is achieved. Tighten the bolts and nuts.

Fig. 11

Fig. 12

Page 8

Optional passive crossovers are available for the following systems

KPT-941

KPT-535 (Mid-bass to high frequency only)

KPT-904

KPT-325

Recommended crossover frequencies for the various components can be found in the system specification section.

GE N E R A L AI M I N G GO A L S

Klipsch theater audio products utilize Tractrix® Horns in the screen and stage systems' mid-bass and high-frequency devices

for precise coverage and projection. By making the appropriate tilt-down adjustments on the supplied installation hardware,

and, if required, toeing-in the left and right outside speakers, you can achieve proper and precise vertical and horizontal aiming

of the system. The degree of toe-in will be determined by the depth and width of the auditorium, and the height and distance

of the screen from the seating area.

For localization to be effective, audience seating must fall inside the horizontal and vertical coverage patterns of the outside

high frequency horns. All Klipsch theater speaker systems utilize consistent coverage angles of 80 degrees or higher, with the

larger auditorium-appropriate systems providing nominal 90 degree coverage angles. Refer to the specification page for

component section coverage data.

BE H I N D- TH E- SC R E E N A N D STA G E SY S T E M S

Installation assembly drawings for the behind-the-screen and stage systems are located in the following section. All of the

systems are designed for assembly on-site and only require a few tools to complete. Electronic crossover frequency dividing

network specifications and delay settings are provided in the delay and crossover frequency section. Several of the systems have

optional passive crossovers available. Refer to the previous page for systems with available passive crossovers.

PL A C E M E N T CO N S I D E R AT I O N S

VE RT I C A L P O S I T I O N I N G

Behind-the-screen speaker systems should generally be located with the highest frequency horn section positioned at

approximately two-thirds the height of the perforated screen. The front edge of the high frequency horns, after tilt-down and

aiming, should be as close to the back of the screen as possible, without actually touching it. This will help ensure that a

minimal amount of back-reflection from the screen is created, minimizing "comb filter" frequency response anomalies.

HO R I Z O N TA L P O S I T I O N I N G

For proper localization, seating areas should fall inside the horizontal and vertical coverage patterns of the high frequency horn

devices. In L-C-R, three-channel, behind-the-screen systems, the speakers should be spaced an equal distance apart, with the

outside left and right speakers immediately inside of the unmasked screen area of the widest format projected (typically 2.35:1).

When the screen is masked to smaller formats (such as 1.85:1), acoustically transparent masking should be used to avoid

blocking of the high frequencies. In five-channel behind-the-screen systems, the speakers should be positioned equidistant

from each other across the stage.

The exact amount of toe-in and tilt will be determined by the depth and width of the auditorium, and the height and distance

of the screen from the seating area. The outside speakers' patterns (on axis) should cross two-thirds of the way to the rear. In

doing this, the audience members seated closer to the screen will be slightly off-axis when the speakers are aimed toward the

back wall, with levels balancing evenly owing to the inverse square distance law, front to rear. The Klipsch Tractrix® Horns in

the high-frequency and mid-bass sections will provide linear frequency response, although at reduced levels, as the listening

angle off-axis is increased, up to the pattern limits of the horn components.

Page 9

Mechanical Installation Drawings for KPT-MCM-4 Grand.

Please refer to the following drawings for assembly details:

Figures 1 and 2.

After unpacking all components, locate the KPT-941 HF compression

driver and horn. Attach the driver to the horn using supplied hardware.

Locate the two1/4"-20 screws on top of the KPT-XII. Remove the two

screws and washers. Place the KPT-941-HF unit on top of the KPT-XII,

making sure that the hole/slot as indicated by "B" in Fig. 1 lines up with

holes in the KPT-XII. Reinstall the screws and washers. Adjust the

horizontal angle as desired and tighten screws.

Locate the KPT-Grand-HF. Locate the two1/4"-20 screws on the KPTGrand-HF. Remove the two screws and washers. Place the KPT-GrandHF on top of the KPT-941-HF and align the holes. Reinstall the screws

and washers and tighten screws as shown at "D" in Fig. 1.

Locate the 1/4"-20 nuts as shown at "A" in Fig. 1. To adjust the

vertical angle, loosen the nuts and adjust horns until desired vertical

angle is achieved. Tighten nuts.

Fig. 1

Fig. 2

Mechanical Installation Drawings for KPT-MCM-3 Grand

Please refer to the following drawings for assembly details:

Figures 3 and 4.

After unpacking all components, locate the KPT-941 HF compression

driver and horn. Attach the driver to the horn using supplied hardware.

Locate the two1/4"-20 screws on top of the KPT-XII. Remove the two

screws and washers. Place the KPT-941-HF unit on top of the KPT-XII,

making sure that the hole/slot as indicated by "B" in Fig. 3 lines up

with the holes in the KPT-XII. Reinstall the screws and washers. Adjust

the horizontal angle as desired and tighten screws.

Locate the 1/4"-20 nuts as shown at "A" in Fig. 3. To adjust the vertical

angle, loosen the nuts and adjust the horn until the desired vertical

angle is achieved. Tighten the nuts.

Fig. 3

Fig. 4

Page 10

Fig. 5

Mechanical Installation Drawings for KPT-Jubilee™

Please refer to the following drawings for assembly details:

Figures 5 and 6:

After unpacking all the components, locate the two1/4"-20 screws on

top of the KPT-XII. Remove the two screws and washers. Place the KPT904-HF unit on top of the KPT-XII, making sure that the hole/slot as

indicated by "A" in Fig. 5 lines up with the holes in the KPT-XII.

Reinstall the screws and washers. Adjust the horizontal angle as desired

and tighten screws.

Fig. 6

Fig. 7

Locate the 1/4"-20 bolts/nuts on both sides of the bracket as shown at

"B" in Fig. 5. To adjust the vertical angle, loosen the bolts and nuts, and

adjust the horn until the desired vertical angle is achieved. Tighten

bolts and nuts.

Mechanical Installation Drawings for KPT-941-T

Please refer to the following drawings for assembly details:

Figures 7 and 8.

After unpacking all components, locate the KPT-941-T compression

driver and horn. Attach the driver to the horn using supplied hardware.

Locate the two1/4"-20 screws on top of the KPT-904/940-LF. Remove

the two screws and washers. Place the KPT-941-T-HF unit on top of the

KPT-904/940-LF, making sure that the hole/slot as indicated by "A" in

Fig. 7 lines up with the holes in the KPT-904/940-LF. Reinstall the

screws and washers. Adjust the horizontal angle as desired and tighten

the screws.

Fig. 8

Locate the 1/4"-20 nuts as shown at "C" in Fig. 7. To adjust the vertical

angle, loosen the nuts and adjust the horn until the desired vertical

angle is achieved. Tighten the nuts.

Page 11

Fig. 24

Page 12

Klipsch Professional Theater Speaker Systems

Installation Manual

Applicable for the Installation and assembly of the following products:

Screen Systems

KPT-MCM Grand

KPT-Jubilee® Stage System

KPT-941-T (THX® – Approved)

KPT-941

KPT-535

KPT-904

KPT-325

Surround Systems

KPT-250

KPT-200 (THX® – Approved)

KPT-100 (THX® – Approved)

KPT-110

SU B W O O F E R S

KPT-684 (THX® – Approved)

KPT-484

Loading...

Loading...