Page 1

These

instructions

e

xplain

ho

to

operate,

inspect,

and

maintain

the

Wire

TE:

this

y

wa

tags

which

to

fo

vices

tags

to

the

vice

full

t

v

To

the

three

wear

vic

Wire

Anchorage

to

vide

the

vice

the

f

The

Wire

When

y

y

the

the

y

the

job

that

the

type

vice fthe

job

to

wa

to

with

tools

vices

y

typical

Wire

Anchorage

This

vice

vides

y

types

transmission

to

wers

The

Wire

Anchorage

to

The

function

the Klein identifying symbol shown belo

This

wa

tags

the

®

Anchorage

Wire

Anchorage

y

with

W

y

ve

these

T

y

who

f

wed

the

warnings,

this

to

thes

warnings,

to

T

vie

w

the

ye

Page 2

Wire

that

yl

vides

xcellent

to

flame

the

vin

yl

y

Aircraft

the

flame

torch.

f

with

finish

to

The

the

the

ylon

webbing

which

to

fr

xcessiv

wear

with

x

fo

to

the

we

Throat

The

finish

xceeds

Although

wo

to

f

when

xposed

to

f

f

we

f

when

wor

y

w

the

the

types

the

job

y

to

the

taining

to

their

y

to

vide

wor

free

from

that

vides

free

to ywho

training

y

ve

y

y

to

what

y

to

y

what

y

y

this

with

vices

wa

ys

to

to

T

ype

to

to

fuse

xcept

together

fo

y

fibers

y

when

fl

which

f

Will

t r

W

to

Aircraft

yl

y

ysical

ties

The

wing

t

ws

the

ties

the

that

y

with

Wire

to

the

wide

va

the

wor

this

OSHA, should

the

to

which

the

xposed.

the

T

tment

Page 3

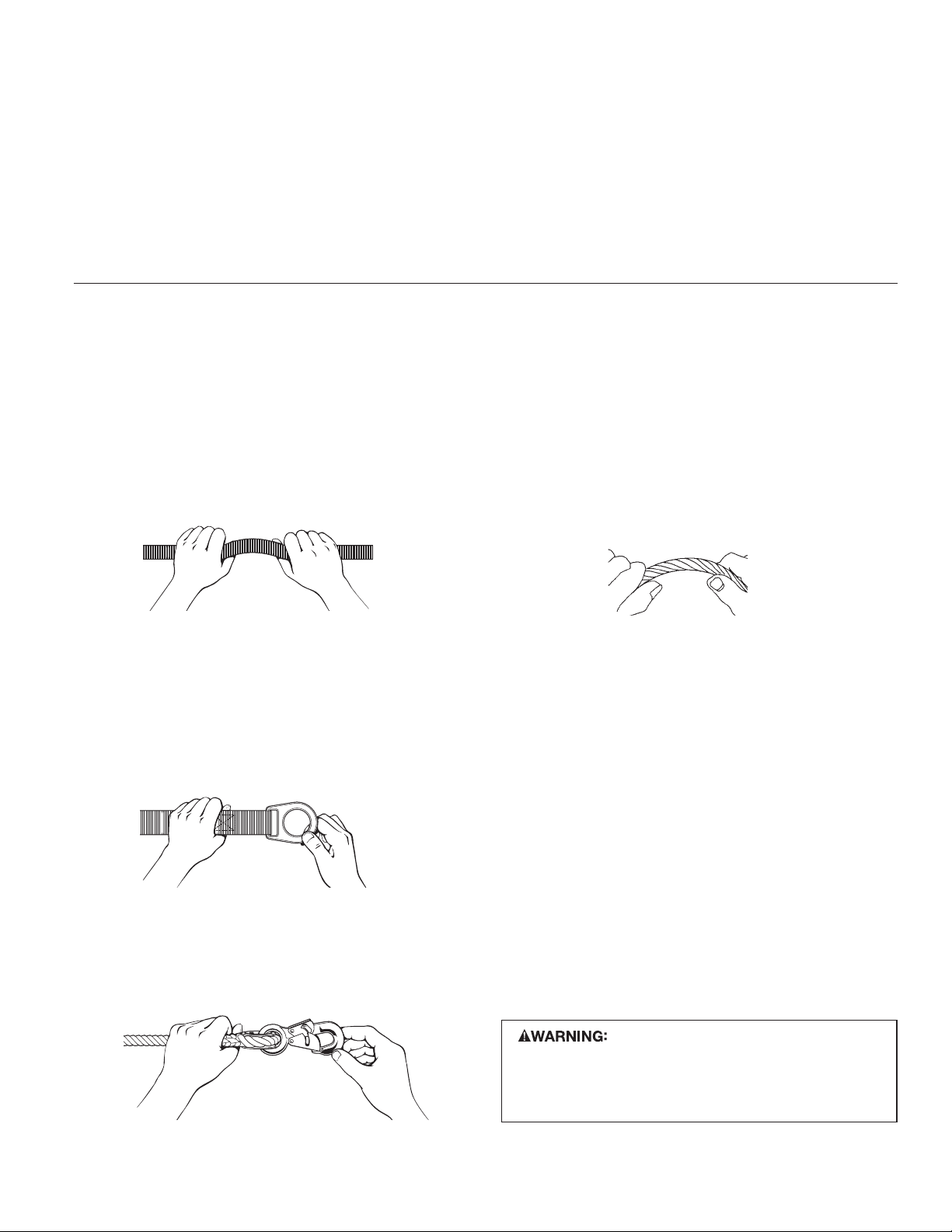

General Inspection Procedures

Remove from service and replace all worn,

1. Check for wear and deterioration.

Bef

ore each use, carefully inspect your anchorage connector

for signs of wear, deterioration, or evidence of impact loading.

Visually inspect for loose threads, pulled rivets, burns, cuts,

distor

tions, abrasions, or other evidence of chemical or

physical deterioration that may have weakened the material

or assemb

2.

Check all snap-hooks, buckles, and D-rings.

ly.

Inspect hardware for malfunctions and cracks.

altered, or damaged equipment.

3.

If the unit does not pass inspection, immediately remove it

from ser

vice and destroy it.

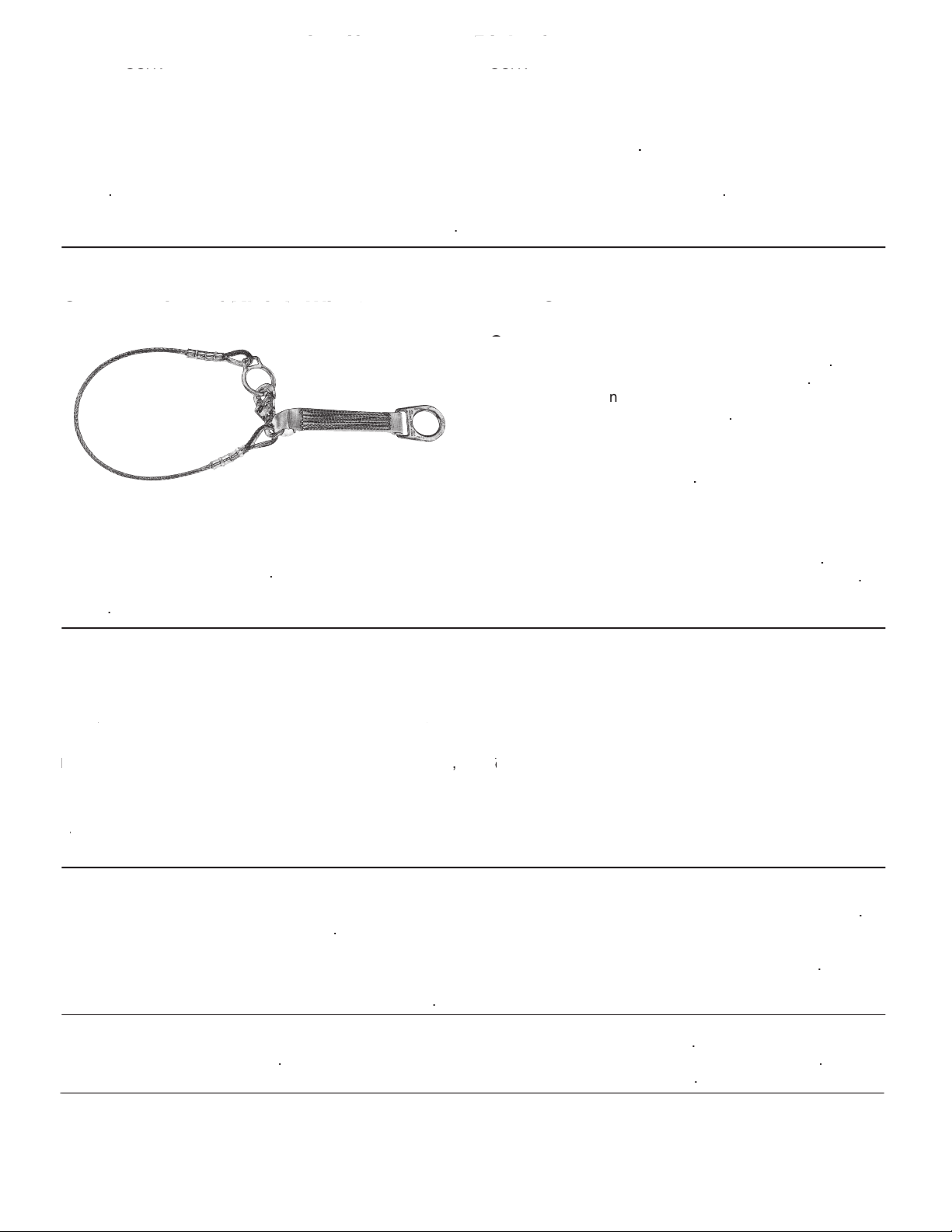

Wire Rope Anchorage Connector Inspection Procedures

1.Inspect the stitching and webbing.

Check stitching for broken, burned, cut, or pulled stitches.

Broken strands appear as tufts on the surface. To inspect,

hold the webbing with your hands six to eight inches apart.

Bend the webbing in an inverted “U” to cause surface tension,

exposing problem areas. Inspect all web areas. Damage from

cuts, abrasion, corrosives, heat, or chemicals should be

apparent.

2. Inspect the D-rings.

Check the D-rings for distortion or cracks. The D-ring on the

end of the nylon webbing should rotate freely in the roller.

Distortion of the roller may indicate impact loading. Check all

D-ring attachment points for unusual wear, distortion, or

damage. Badly pitted D-rings indicate chemical corrosion. If

any of these conditions are found, the equipment should be

destroyed immediately.

D

4. Inspect the wire rope cable.

Inspect entire length of vinyl-coated aircraft cable for cut,

broken, welded, or otherwise damaged cable strands. Nicks,

tears, scrapes in vinyl coating are to be expected and are not

in themselves damaging to the unit. However, further

examine cable beneath that area of vinyl to see if damage

has extended into the cable.Damaged cable requires that the

unit fail inspection. Check cable eyes for excess distortion

which may indicate impact loading.

Destroy and replace all worn, altered, or damaged

OPE equipment.

5.

If evidence of excessive wear, deterioration, alteration,

or mechanical malfunction is observed, the anchorage

connector should be destroyed. Never work with worn or

damaged equipment. Using damaged, altered, or worn

equipment can cause serious injury or death.

The inspector is the most important part of any

inspection procedure.

6.

Check all equipment thoroughly and follow all safety

procedures and guidelines. Do not take any shortcuts.

3. Inspect the snap-hook.

Check that the snap-hook is not distorted or cracked and that

the keepers are free of burrs, functioning properly, clean, and

not bent.

Important Note: OSHA specifies that all employers covered

by the Occupational Safety and Health Act are responsible for

inspection and maintenance of all tools and equipment used

by the employees – whether owned by the employees or by

the company. Personal-protective equipment should be

inspected before each use, and immediately removed from

service if any sign of wear or damage is found.

Should any unusual conditions be

noted during inspection which are not specified

here, do not use the equipment until a competent

person, as defined by OSHA, has determined its

usability.

Page 3

Page 4

w

to

wa

tags

vided

with

the

Wire

Anchorage

They vide

tant

tags

future

TE:

wa

tags

to

Wire

Anchorage

y

these

tags

the

T

tment

toll-free

f

w

to

ve

them

the

the

f

which

the

job

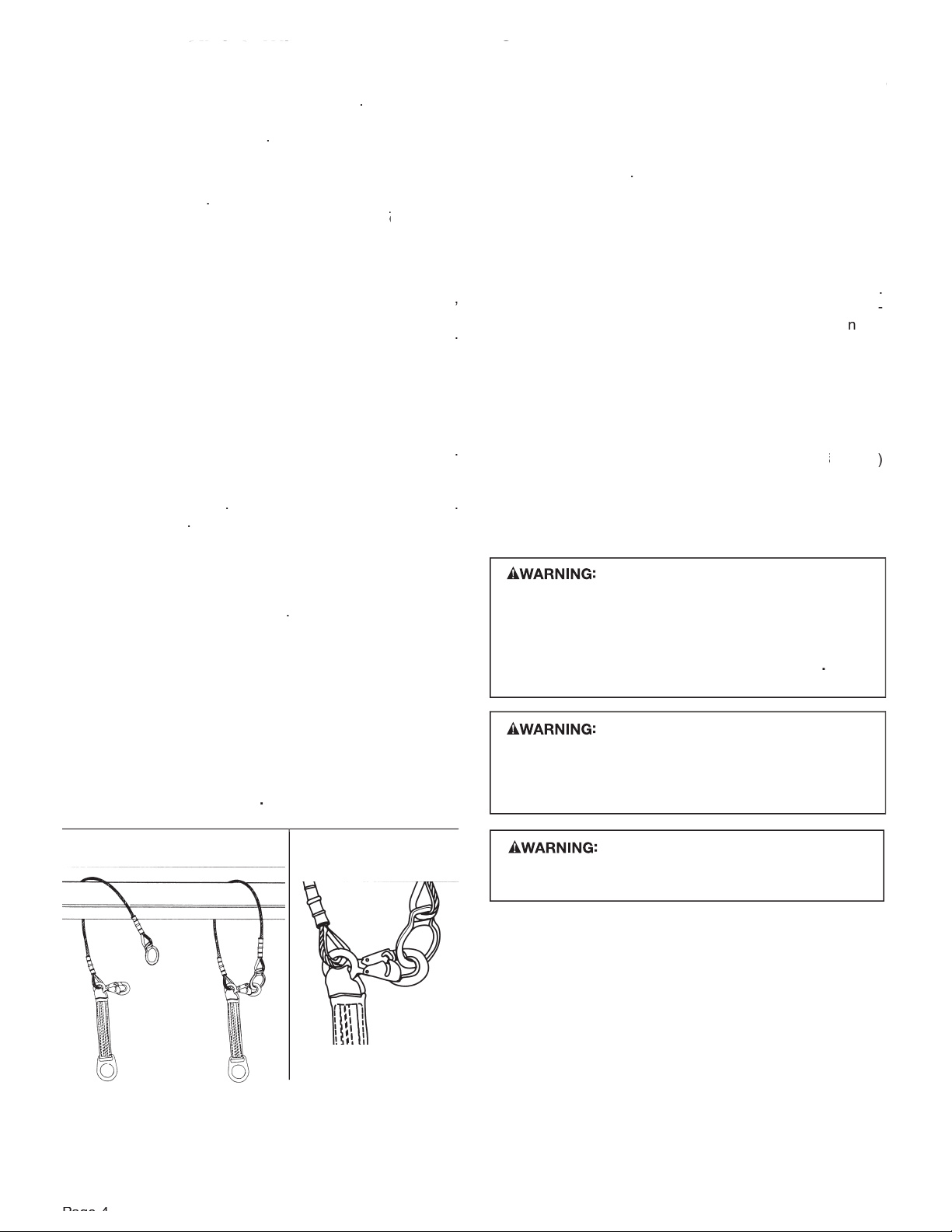

The

fall-arrest

t

w

w

t.

the

Wire

Anchorage

which

wrap

the

freely

the

two

Wire

Anchorage

The

the

two

the

the

tion.

The

f

the

v

to

the

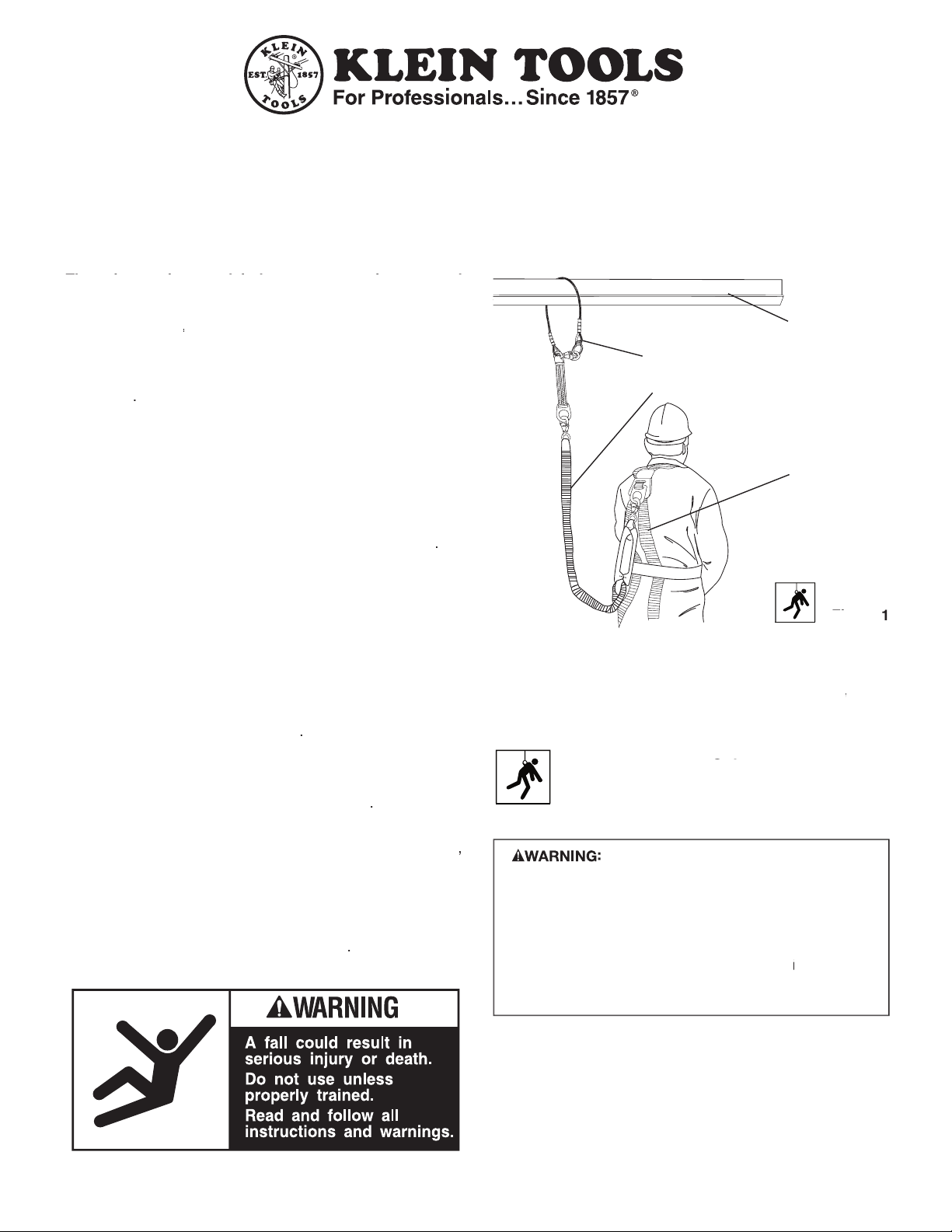

y manner other than as sho

wn in Figure 1 (see page 1),

to

Wire

Anchorage

y

To

the

Wire

Anchorage

to

the

f

fa

the

the

the

the

ve

the

to

that

visual

that

the

freel

y

the

that

the

y

ver

The D-r

ylon webbing of the

Wire

Anchorage

y

wa

ys

ve

the

y

to

f

When

the

Wire

Anchorage

fa

ystem,

vice

ve

f

f

y

y

ting

the

job

the

the

vice

to

the

fa

y

Attach

the

the

free yfa

vice

to

the

the

the

ylon

webbing

the Wire

Anchorage

visual

that

the

vice

freel

y

that

y

to

with

the

vent

fall.

The

free-f

xceed

to

the

to

tension.

the

tug

to

Whene

ver

there

fall,

Theref

when

wo

wa

ys

the

fall-arrest

th

the

to

with

ya

vice

When

fall

ver

to

y

t

this

Wire

y

that

O

to

fit

the

job

®

Page 5

A

wr

vicing

f

this

vice

the

y

with

ylon

wa

w

tur

thinner

Allo

ylon objects to dr

y naturally

the

to

the

y

Page 6

For F

all Arrest Use Only

DO NOT REMOVE THIS LABEL

Model: Size: Date:

READ BEFORE USE

READ BEFORE USE

QUESTIONS?

Call TOLL-FREE 1-800-553-4676

Klein Tools, Inc.

OSHA 1910, 1915 & 1926

ANSI A10.14 Made in U.S.A.

Klein-Lite®, Klein-Lok®, Klein-Kord®,

Softee™, Ultra-Hyde™

T-

125

207

■ Read, understand and follow all instructions, cautions and warnings attached to and/or packed with

this and all occupational protective equipment before each use.

■ For use by properly trained professionals only

.

■ Employer – Before

allowing the use of this equipment, instruct your employees as to its proper

use

and alert them to these warnings.

■ Do NOT use units with steel cable near electrical lines or equipment.

■ Never work without independent fall-arrest protection if there is danger of a fall.

■ To attach this device to the fall-arrest anchorage, pass the cable over the fall-arrest anchorage (such

as an aerial boom, I-beam or similar structural member approved by a qualified person, as defined by

OSHA) and attach the ring on the end of the cable back onto the Klein-Lok

® snap hook. Never wrap a

rope lanyard around a beam or other structural member; it could be cut or damaged. Instead, use

connecting devices specifically designed for these purposes.

■ Fall-arrest anchorage must support a minimum of 5,000 lbs. (22.2kN) per attached worker and be

independent of worker support.

■ Rig to avoid contact with structures below in a fall. If using a deceleration unit, add 3-1/2 ft. (1m)

to the potential fall distance to allow for unit extension.

■ Always work directly under the fall-arrest anchorage to reduce the possibility of swing-fall injuries

(pendulum effect).

■ Free-fall distance must NOT exceed 6 ft. (1.8m). Always keep anchorage at or above shoulder height

to minimize fall distance.

■ OSHA requires that impact force in a fall NOT exceed an 1,800 lb. (8kN) limit with a harness.

Therefore, minimize slack in fall-arrest connecting devices or use deceleration unit to stay under 1,800

lbs. (8kN).

■ Unit must be destroyed if subjected to impact loading.

■ Always visually check that: 1) each snap hook freely engages the intended D-ring or attachment

point, and 2) the snap-hook keeper (gate) is completely closed with each use. Have a co-worker visually

check to make sure that the snap hook attached to the fall-arrest D-ring (centered in the back of the

harness) is properly secured. Never rely solely on feel or sound in attempting to determine that a snap

hook is engaged.

■ Before each use check that: 1) unit is free of burns, cuts, abrasions, broken strands or stitches,

kinks, knots or excessive wear

, 2) locking snap hooks, D-rings, and thimbles (if any) are not distorted

or cracked, and 3) hook keepers are free of burrs, functioning properly, clean and not bent. If the unit

does not pass the inspection, it should be removed from service immediately and destroyed or

reinspected by a competent person as defined by OSHA to determine its usability.

■ Make sure each snap hook is positioned so that its keeper (gate) is never load bearing.

■ Only use locking snap hooks.

■ Occupational Protective Equipment (OPE) must only be used for the specific purpose for which it is

designed and intended.

■ Only use this unit with harnesses and connecting devices meeting OSHA fall-arrest standards.

■ Never allow non-metallic rope or webbing to come in contact with high-temperature surfaces,

welding sparks, or other heat sources.

■ Never attach a lanyard back onto itself or attach multiple lanyards together.

■ Never tie knots in lanyards. Knots can reduce the strength of the lanyard by up to 50%.

■ Never attach multiple snap hooks onto a D-ring.

■ Never disable locking keeper (latch) on snap hook or alter a connecting device in any way.

■ Never join two snap hooks together. They are NOT intended to be used that way, and could twist

apart.

■ Snap hooks attached onto D-rings must have less than 3/4” (19mm) throat opening. Never attach

ladder or rebar hooks onto D-rings.

■ For personal fall-arrest use only. NOT for towing, hoisting, recreational or sporting use. Only use as

an anchorage connector in a personal fall-arrest system

.

■ Assume the responsibility for determining that your OPE equipment is in excellent condition at all

times.

■ Store your OPE equipment out of direct sunlight and in a clean, dry area.

■ Klein strongly recommends that Klein components NOT be interchanged with other components

made by other manufacturers because Klein cannot guarantee that other manufacturers’ components

are free of defects in materials or workmanship.

139192

wa

tags

to

y

these

tags

the

T

tment,

toll-free

f

w

to

ve

the

tags

free

©

©

Para uso solamente en detención de caidas

NO QUITE ESTA ETIQUET

A

Modelo: Tamaño: Fecha

:

LEER ANTES DE USAR

LEER ANTES DE USAR

¿PREGUNTAS?

Llame GRATIS al 1-800-553-4676

Klein Tools, Inc.

OSHA 1910, 1915 y 1926

ANSI A10.14

Fabricado en los EE.UU.

Klein-Lite®, Klein-Lok®, Klein-Kord

®, Softee™, Ultra-Hyde™

ST-125

207

■ Lea, entienda y siga todas las instrucciones, precauciones y advertencias colocadas y/o embaladas

con

éste y con todos los equipos de protecci

ón laboral antes de cada uso.

■ Para uso sólo por profesionales

con capacitaci

ón apropiada.

■ Empleador: Antes de permitir

el uso de este equipo, instruya a sus empleados en cuanto a su uso

apropiado

y al

értelos de estas advertencias.

■ NO utilice unidades con cable de acero

cer

ca de cables o equipos el

éctricos.

■ Nunca trabaje sin protección de detención de caídas independiente si hay peligro

de ca

ída.

■ Para sujetar este dispositivo al anclaje de detención de caídas, pase el cable sobre el anclaje de

detecci

ón de caídas (como un pescante aéreo,

una viga en I o un miembro estructural similar aprobado

por una persona calificada, de acuerdo

con la definici

ón de OSHA) y acople el anillo que está en el

extremo del cable de vuelta en el gancho de presi

ón Klein-Lok®

. Nunca enrolle

un acollador de cuerda

alrededor

de una viga u otro

miembro estructural; el acollador podr

ía resultar

cortado o da

ñado. En

lugar de ello, utilice dispositivos de conexión diseñados específicamente para estos prop

ósitos.

■ El anclaje de detención de caídas debe soportar un mínimo de 5,000 lb (22.2 kN) por trabajador

sujeto y debe ser independiente del soporte del trabajador

.

■ Realice el montaje de manera que se evite el contacto con las estructuras

que est

én debajo en

caso de ca

ída. Si utiliza una unidad de desaceleración, añada 3.5 pies (1 m) a la distancia de caída

potencial para tener en cuenta la extensi

ón de la unidad.

■ T

rabaje

siempre directamente

debajo del anclaje de detecci

ón de caídas para reducir

la posibilidad de

lesiones por ca

ídas con columpiamiento (efecto de péndulo).

■ La distancia de caída libre NO debe sobrepasar 6 pies (1.8 m). Mantengasiempre el anclaje a la altura

de los hombros o por encima de

éstos para minimizar la distancia de caída.

■ OSHA requiere

que la fuer

za de impacto en una ca

ída

NO sobrepase

el

límite de 1,800 lb (8 kN) con

un ar

nés. Por lo tanto, debe minimizar la flojedad en los dispositivos de conexión de detención de caídas

o utilizar una unidad de desaceleraci

ón para permanecer

por debajo de 1,800 lb (8 kN).

■ La unidad debe destruirse si resulta

sometida a carga por impactos.

■ Asegúrese siempre visualmente de que: 1) cada gancho de presión se acople libremente en el anillo

en D o en el punto de sujeci

ón previsto, y 2) el fijador (compuerta) del gancho de presión esté

completamente cerrado

con cada uso. Haga que un compa

ñero

de trabajo se asegure visualmente de

que el gancho de presi

ón sujeto al anillo en D de detención de caídas (centrado en la parte

trasera de

l

ar

nés) esté sujeto apropiadamente.

Nunca dependa solamente de la sensaci

ón o del sonido al intentar

determinar

si un gancho de presi

ón está acoplado.

■ Antes de cada uso, asegúrese de que: 1) la unidad no tenga quemaduras, cortes, abrasiones,

hebras o costuras rotas, enredos, nudos ni desgaste excesivo, 2)

los ganchos de presión de fijación,

los anillos en D y los dedales (en caso de que los haya) no est

én distorsionados ni agrietados, y 3) los

fijadores de los ganchos est

én libres de rebabas, funcionen apropiadamente, estén limpios y no estén

doblados. Si la unidad no pasa la inspecci

ón, debe retirarse de servicio inmediatamente y

destruirse o volver a inspeccionarse por una persona competente, de acuerdo con la definici

ón de

OSHA, para determinar su utilizabilidad.

■ Asegúrese de que cada gancho de presión esté posicionado de manera que su fijador (compuerta)

nunca soporte cargas.

■ Utilice únicamente ganchos de presión de fijación.

■ El equipo de protección laboral (EPL) debe utilizarse solamente para el propósito específico para el

que est

á diseñado y previsto.

■ Utilice esta unidad únicamente con arneses y dispositivos de conexión que cumplan con las normas

de OSHA para detenci

ón de caídas.

■ Nunca deje que cuerda o malla no metálica entre en contacto con superficies que estén a alta

temperatura, chispas de soldadura u otras fuentes de calor

.

■ Nunca sujete un acollador de vuelta en sí mismo ni sujete juntos varios acolladores.

■ Nunca haga nudos en los acolladores. Los nudos pueden reducir la resistencia del acollador hasta

en un 50 %.

■ Nunca sujete varios ganchos de presión a un anillo en D.

■ Nunca inutilice el fijador (compuerta) de cierre de un gancho de presión ni altere un dispositivo de

conexi

ón de ninguna forma.

■ Nunca acople entre sí dos ganchos de presión. Estos ganchos NO están diseñados para utilizarse de

esta manera y podr

ían torcerse hasta separarse.

■ Los ganchos de presión acoplados a anillos en D deben tener una abertura de garganta de menos de

3/4" (19 mm). Nunca acople ganchos de escalera de mano o de barra de refuerzo a anillos en D.

■ Para uso personal de detención de caídas solamente. La unidad NO está diseñada para remolcar o

izar, ni para uso recreativo o deportivo. Utilice la unidad solamente como conector de anclaje en un

sistema personal de detenci

ón de caídas.

■ Asuma la responsabilidad de determinar si su equipo de EPL está en excelentes condiciones en todo

momento.

■ Guarde su equipo de EPL fuera de la luz solar directa y en un área limpia y seca.

■ Klein recomienda enfáticamente que los componentes Klein NO se intercambien con otros

componentes hechos por otros fabricantes, ya que Klein no puede garantizar que los componentes de

otros fabricantes est

én libres de defectos de materiales o de fabricación.

139198

Page 7

xplican

y

yo

f

tencia

tencia

xión

y/o

fo

te

tres

A) anclaje

y

xión.

y

v

xión

y

viga

todo

Asegúrese

y

xión

y

trabajo

Asegúrese

y

todas

y

tencias

y/o

todas

y

típico

xión

y

tipos

y

torres

transmisión.

función

también

y

tencia

y

®

Anclaje

Acollador

Para profesionales... desde 1857

®

ya

y

todas

ver

tencias,

y

f

ver

tencias,

y

ves

te

y

va

y

visi

ADVERTENCIA

Una caída podría causar lesiones

graves o la muerte.

No utilice este dispositivo a menos que

haya recibido capacitación adecuada.

Lea y siga todas las instrucciones y

advertencias.

!

Page 8

vinilo

xcelente

y

T

fundido

y

to

vinilo

viación

f

y

Ambos

xtremo

ylon

tiene

yuda

y

xcesiv

ylon

y

®

®

temente

y

tura

tiene

T

tinentes

A

trabajadores

xpuestos

trabaje

Aprenda

tipos

y

trabajo

y

y

trabajo

yuda

tienen

y

xión

Tipo

fundido

xcesiv

vuelv

y

Algunos

tiene

xcepto

funden

y

fo

fibras

fibras

fuer

tes

y

f

y

vuelv

viación

xcelente

xcelente

xcelente

vinilo)

físicas

va

xistentes

trabajo

y

y

xpondrá

tamento

T

Page 9

y

tadas

fo

ve

tida

tensi

to

todas

tes

videntes

tengan gr

en el e

xtremo de la malla

ylon

todos

v

ve

de estas situaciones, se debe destruir el equipo inmediatamente.

Aseg

y

fijadores

tengan

funcionen

y

toda

viaci

v

vinilo

tiene

tadas

ya

y

v

vinilo

y

e

xamine

vinilo

xtendido

xige

v

tienen

xceso

y

todo

va

e

videncia

xcesiv

funcionamiento

trabaje

te

tante

todo

y

todos

y

tante:

todos

tos

y

y

y

todas

y

todos

tanto

tenecen

tenecen

y

vicio

y

y

Antes

videncia

visualmente

y

flojos

tes

videncia

funcionen

y

tengan

todos

y

y

todo

tado,

vicio

y

y

D

va

c

ya

!

ADVER

Page 10

tencia y todas las instr

vistas

fo

tante

y

todas

futura.

y/o

tencia e instr

tamento

tamente

viga

tubería

ya

tar

trabajador

y

trabajador

tamaño

y

fijación.

tamaños

tamaños

viación.

y

yo

viación.

y

y

y

xtremo

vuelta

Klein-Lok

visual

y

fijador

t

c

p

fijador

t

tando

xtremo

ylon

vier

te

y

xión

Antes

trabajo

fijación

xión debe sujetarse al anillo en D de detención de

trasero

fijación

xtremo

xión

xtremo

ylon

visual

xi

y

fijadores

tener

xtensión

tirón

todo

xión.

xista

tanto,

trabajando

te

va

ficar

te

ficos

trabajo.

ves

te

!

!

ADVER

!

ADVER

®

Page 11

jef

todas

f

vicio

y

ve

ylon

templada

y

ve.

fuer

tes

trementina,

y

ylon

y

todos

funcionan

y

Page 12

For F

all Arrest Use Only

DO NOT REMOVE THIS LABEL

Model: Size: Date:

READ BEFORE USE

READ BEFORE USE

QUESTIONS?

Call TOLL-FREE 1-800-553-4676

Klein Tools, Inc.

OSHA 1910, 1915 & 1926

ANSI A10.14 Made in U.S.A.

Klein-Lite®, Klein-Lok®, Klein-Kord®,

Softee™, Ultra-Hyde™

T-

125

207

■ Read, understand and follow all instructions, cautions and warnings attached to and/or packed with

this and all occupational protective equipment before each use.

■ For use by properly trained professionals only

.

■ Employer – Before

allowing the use of this equipment, instruct your employees as to its proper

use

and alert them to these warnings.

■ Do NOT use units with steel cable near electrical lines or equipment.

■ Never work without independent fall-arrest protection if there is danger of a fall.

■ To attach this device to the fall-arrest anchorage, pass the cable over the fall-arrest anchorage (such

as an aerial boom, I-beam or similar structural member approved by a qualified person, as defined by

OSHA) and attach the ring on the end of the cable back onto the Klein-Lok

® snap hook. Never wrap a

rope lanyard around a beam or other structural member; it could be cut or damaged. Instead, use

connecting devices specifically designed for these purposes.

■ Fall-arrest anchorage must support a minimum of 5,000 lbs. (22.2kN) per attached worker and be

independent of worker support.

■ Rig to avoid contact with structures below in a fall. If using a deceleration unit, add 3-1/2 ft. (1m)

to the potential fall distance to allow for unit extension.

■ Always work directly under the fall-arrest anchorage to reduce the possibility of swing-fall injuries

(pendulum effect).

■ Free-fall distance must NOT exceed 6 ft. (1.8m).Always keep anchorage at or above shoulder height

to minimize fall distance.

■ OSHA requires that impact force in a fall NOT exceed an 1,800 lb. (8kN) limit with a harness.

Therefore, minimize slack in fall-arrest connecting devices or use deceleration unit to stay under 1,800

lbs. (8kN).

■ Unit must be destroyed if subjected to impact loading.

■ Always visually check that: 1) each snap hook freely engages the intended D-ring or attachment

point, and 2) the snap-hook keeper (gate) is completely closed with each use. Have a co-worker visually

check to make sure that the snap hook attached to the fall-arrest D-ring (centered in the back of the

harness) is properly secured. Never rely solely on feel or sound in attempting to determine that a snap

hook is engaged.

■ Before each use check that: 1) unit is free of burns, cuts, abrasions, broken strands or stitches,

kinks, knots or excessive wear

, 2) locking snap hooks, D-rings, and thimbles (if any) are not distorted

or cracked, and 3) hook keepers are free of burrs, functioning properly, clean and not bent. If the unit

does not pass the inspection, it should be removed from service immediately and destroyed or

reinspected by a competent person as defined by OSHA to determine its usability.

■ Make sure each snap hook is positioned so that its keeper (gate) is never load bearing.

■ Only use locking snap hooks.

■ Occupational Protective Equipment (OPE) must only be used for the specific purpose for which it is

designed and intended.

■ Only use this unit with harnesses and connecting devices meeting OSHA fall-arrest standards.

■ Never allow non-metallic rope or webbing to come in contact with high-temperature surfaces,

welding sparks, or other heat sources.

■ Never attach a lanyard back onto itself or attach multiple lanyards together.

■ Never tie knots in lanyards. Knots can reduce the strength of the lanyard by up to 50%.

■ Never attach multiple snap hooks onto a D-ring.

■ Never disable locking keeper (latch) on snap hook or alter a connecting device in any way.

■ Never join two snap hooks together. They are NOT intended to be used that way, and could twist

apart.

■ Snap hooks attached onto D-rings must have less than 3/4” (19mm) throat opening. Never attach

ladder or rebar hooks onto D-rings.

■ For personal fall-arrest use only. NOT for towing, hoisting, recreational or sporting use. Only use as

an anchorage connector in a personal fall-arrest system

.

■ Assume the responsibility for determining that your OPE equipment is in excellent condition at all

times.

■ Store your OPE equipment out of direct sunlight and in a clean, dry area.

■ Klein strongly recommends that Klein components NOT be interchanged with other components

made by other manufacturers because Klein cannot guarantee that other manufacturers’ components

are free of defects in materials or workmanship.

139192

Para uso solamente en detención de caidas

NO QUITE ESTA ETIQUET

A

Modelo: Tamaño: Fecha

:

LEER ANTES DE USAR

LEER ANTES DE USAR

¿PREGUNTAS?

Llame GRATIS al 1-800-553-4676

Klein Tools, Inc.

OSHA 1910, 1915 y 1926

ANSI A10.14 Fabricado en los EE.UU.

Klein-Lite®, Klein-Lok®, Klein-Kord

®, Softee™, Ultra-Hyde™

ST-125

207

■ Lea, entienda y siga todas las instrucciones, precauciones y advertencias colocadas y/o embaladas

con

éste y con todos los equipos de protecci

ón laboral antes de cada uso.

■ Para uso sólo por profesionales

con capacitaci

ón apropiada.

■ Empleador: Antes de permitir

el uso de este equipo, instruya a sus empleados en cuanto a su uso

apropiado

y al

értelos de estas advertencias.

■ NO utilice unidades con cable de acero

cer

ca de cables o equipos el

éctricos.

■ Nunca trabaje sin protección de detención de caídas independiente si hay peligro

de ca

ída.

■ Para sujetar este dispositivo al anclaje de detención de caídas, pase el cable sobre el anclaje de

detecci

ón de caídas (como un pescante aéreo,

una viga en I o un miembro estructural similar aprobado

por una persona calificada, de acuerdo

con la definici

ón de OSHA) y acople el anillo que está en el

extremo del cable de vuelta en el gancho de presi

ón Klein-Lok®

. Nunca enrolle

un acollador de cuerda

alrededor

de una viga u otro

miembro estructural; el acollador podr

ía resultar

cortado o da

ñado. En

lugar de ello, utilice dispositivos de conexión diseñados específicamente para estos prop

ósitos.

■ El anclaje de detención de caídas debe soportar un mínimo de 5,000 lb (22.2 kN) por trabajador

sujeto y debe ser independiente del soporte del trabajador

.

■ Realice el montaje de manera que se evite el contacto con las estructuras

que est

én debajo en

caso de ca

ída. Si utiliza una unidad de desaceleración, añada 3.5 pies (1 m) a la distancia de caída

potencial para tener en cuenta la extensi

ón de la unidad.

■ T

rabaje

siempre directamente

debajo del anclaje de detecci

ón de caídas para reducir

la posibilidad de

lesiones por ca

ídas con columpiamiento (efecto de péndulo).

■ La distancia de caída libre NO debe sobrepasar 6 pies (1.8 m). Mantenga siempre el anclaje a la altura

de los hombros o por encima de

éstos para minimizar la distancia de caída.

■ OSHA requiere

que la fuer

za de impacto en una ca

ída

NO sobrepase

el

límite de 1,800 lb (8 kN) con

un ar

nés. Por lo tanto, debe minimizar la flojedad en los dispositivos de conexión de detención de caídas

o utilizar una unidad de desaceleraci

ón para permanecer

por debajo de 1,800 lb (8 kN).

■ La unidad debe destruirse si resulta

sometida a carga por impactos.

■ Asegúrese siempre visualmente de que: 1) cada gancho de presión se acople libremente en el anillo

en D o en el punto de sujeci

ón previsto, y 2) el fijador (compuerta) del gancho de presión esté

completamente cerrado

con cada uso. Haga que un compa

ñero

de trabajo se asegure visualmente de

que el gancho de presi

ón sujeto al anillo en D de detención de caídas (centrado en la parte

trasera de

l

ar

nés) esté sujeto apropiadamente.

Nunca dependa solamente de la sensaci

ón o del sonido al intentar

determinar

si un gancho de presi

ón está acoplado.

■ Antes de cada uso, asegúrese de que: 1) la unidad no tenga quemaduras, cortes, abrasiones,

hebras o costuras rotas, enredos, nudos ni desgaste excesivo, 2)

los ganchos de presión de fijación,

los anillos en D y los dedales (en caso de que los haya) no est

én distorsionados ni agrietados, y 3) los

fijadores de los ganchos est

én libres de rebabas, funcionen apropiadamente, estén limpios y no estén

doblados. Si la unidad no pasa la inspecci

ón, debe retirarse de servicio inmediatamente y

destruirse o volver a inspeccionarse por una persona competente, de acuerdo con la definici

ón de

OSHA, para determinar su utilizabilidad.

■ Asegúrese de que cada gancho de presión esté posicionado de manera que su fijador (compuerta)

nunca soporte cargas.

■ Utilice únicamente ganchos de presión de fijación.

■ El equipo de protección laboral (EPL) debe utilizarse solamente para el propósito específico para el

que est

á diseñado y previsto.

■ Utilice esta unidad únicamente con arneses y dispositivos de conexión que cumplan con las normas

de OSHA para detenci

ón de caídas.

■ Nunca deje que cuerda o malla no metálica entre en contacto con superficies que estén a alta

temperatura, chispas de soldadura u otras fuentes de calor

.

■ Nunca sujete un acollador de vuelta en sí mismo ni sujete juntos varios acolladores.

■ Nunca haga nudos en los acolladores. Los nudos pueden reducir la resistencia del acollador hasta

en un 50 %.

■ Nunca sujete varios ganchos de presión a un anillo en D.

■ Nunca inutilice el fijador (compuerta) de cierre de un gancho de presión ni altere un dispositivo de

conexi

ón de ninguna forma.

■ Nunca acople entre sí dos ganchos de presión. Estos ganchos NO están diseñados para utilizarse de

esta manera y podr

ían torcerse hasta separarse.

■ Los ganchos de presión acoplados a anillos en D deben tener una abertura de garganta de menos de

3/4" (19 mm). Nunca acople ganchos de escalera de mano o de barra de refuerzo a anillos en D.

■ Para uso personal de detención de caídas solamente. La unidad NO está diseñada para remolcar o

izar, ni para uso recreativo o deportivo. Utilice la unidad solamente como conector de anclaje en un

sistema personal de detenci

ón de caídas.

■ Asuma la responsabilidad de determinar si su equipo de EPL está en excelentes condiciones en todo

momento.

■ Guarde su equipo de EPL fuera de la luz solar directa y en un área limpia y seca.

■ Klein recomienda enfáticamente que los componentes Klein NO se intercambien con otros

componentes hechos por otros fabricantes, ya que Klein no puede garantizar que los componentes de

otros fabricantes est

én libres de defectos de materiales o de fabricación.

139198

y/o

tencia

tección

y/o

tamento

T

y/o

tener

tencia

©

©

Para profesionales... desde 1857

®

Loading...

Loading...