Page 1

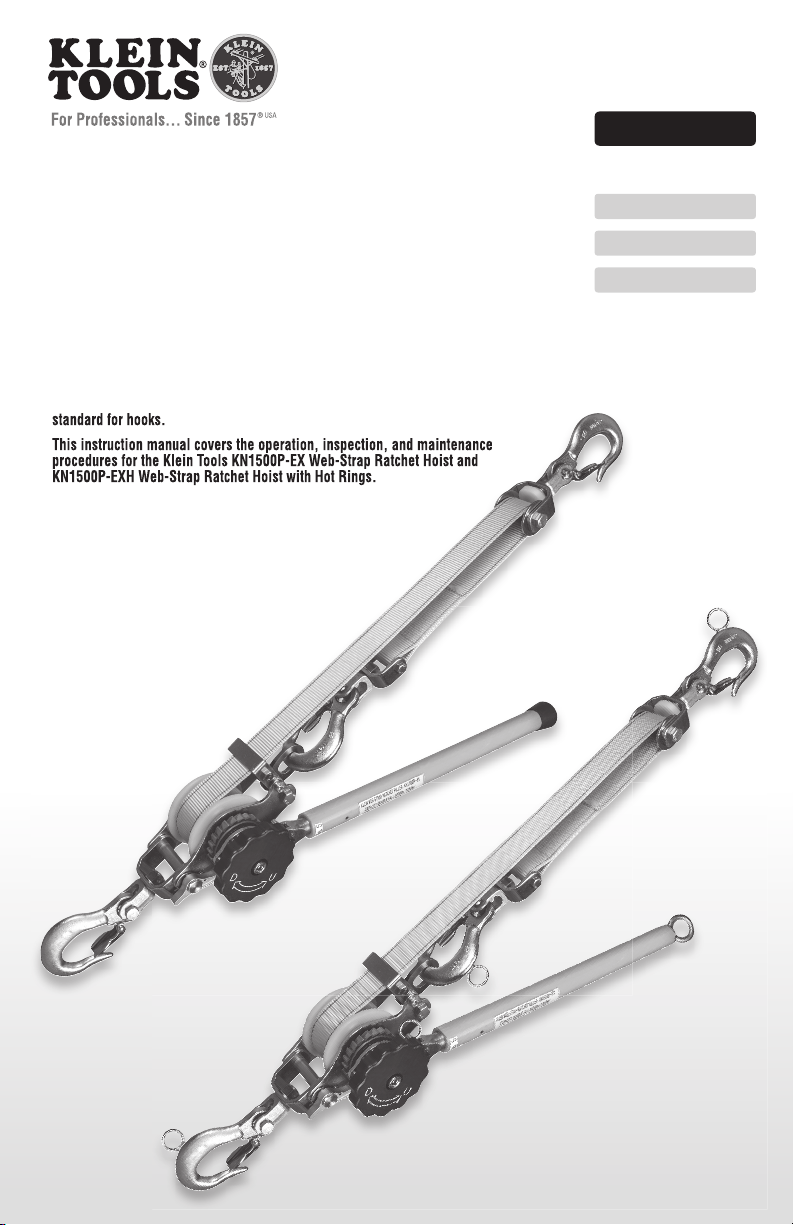

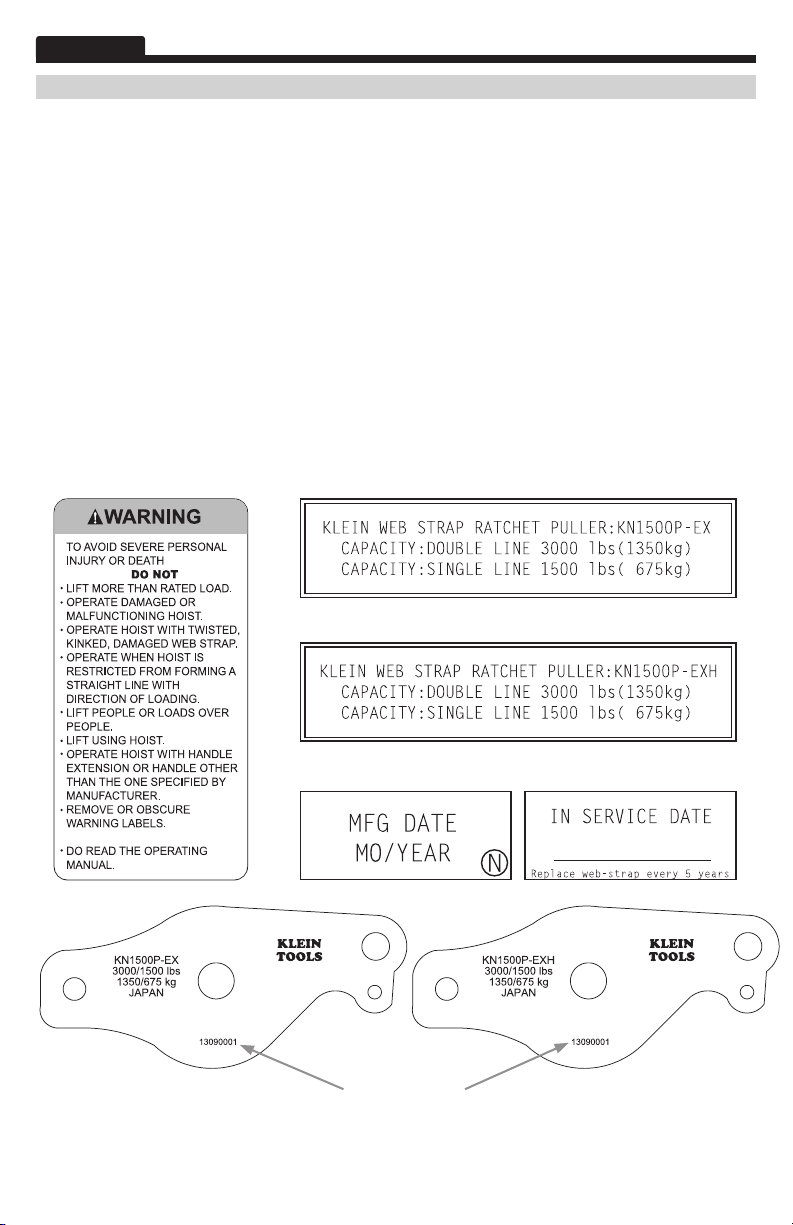

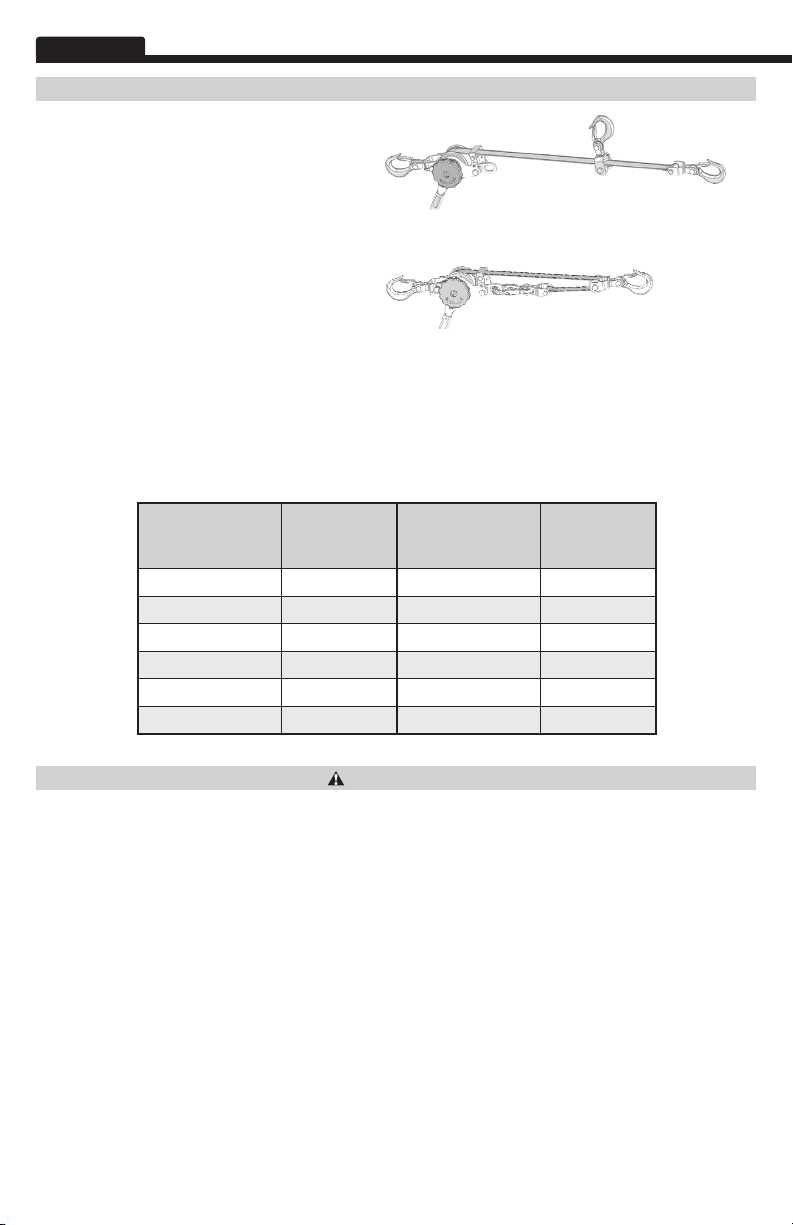

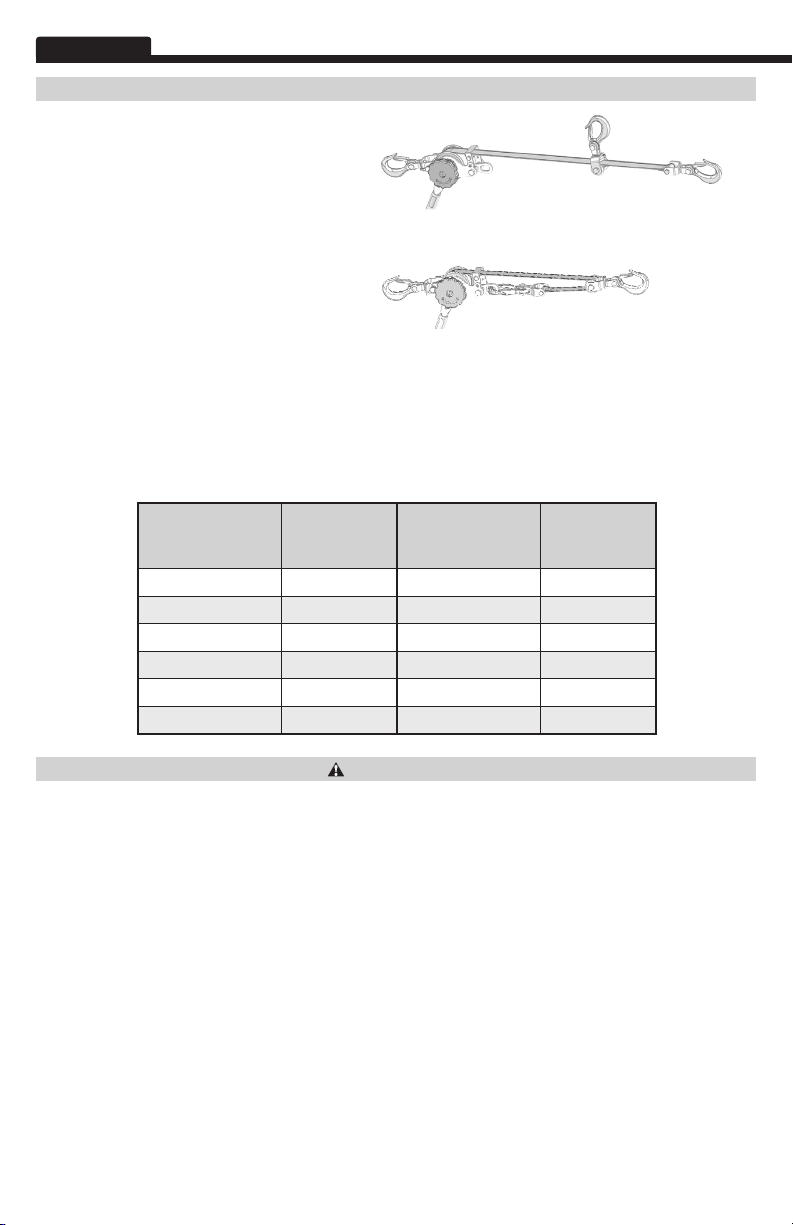

KN1500P-EX

standard for hooks.

This instruction manual covers the operation, inspection, and maintenance

procedures for the Klein Tools KN1500P-EX Web-Strap Ratchet Hoist and

KN1500P-EXH Web-Strap Ratchet Hoist with Hot Rings.

Web-Strap Ratchet Hoist

Instruction Manual

ENGLISH

Español pg. 11

Português pg. 21

KN1500P-EXH

Web-Strap Ratchet Hoist

with Hot Rings

The Klein Tools KN1500P-EX and KN1500P-EXH meet ASME B30.21-2005 standard

for Manually Lever Operated Hoists (Web Strap Type) and ASME B30.10-2009

standard for hooks.

This instruction manual covers the operation, inspection, and maintenance

procedures for the Klein Tools KN1500P-EX Web-Strap Ratchet Hoist and

KN1500P-EXH Web-Strap Ratchet Hoist with Hot Rings.

KN1500P-EX

Français pg. 31

KN1500P-EXH

Page 2

ENGLISH

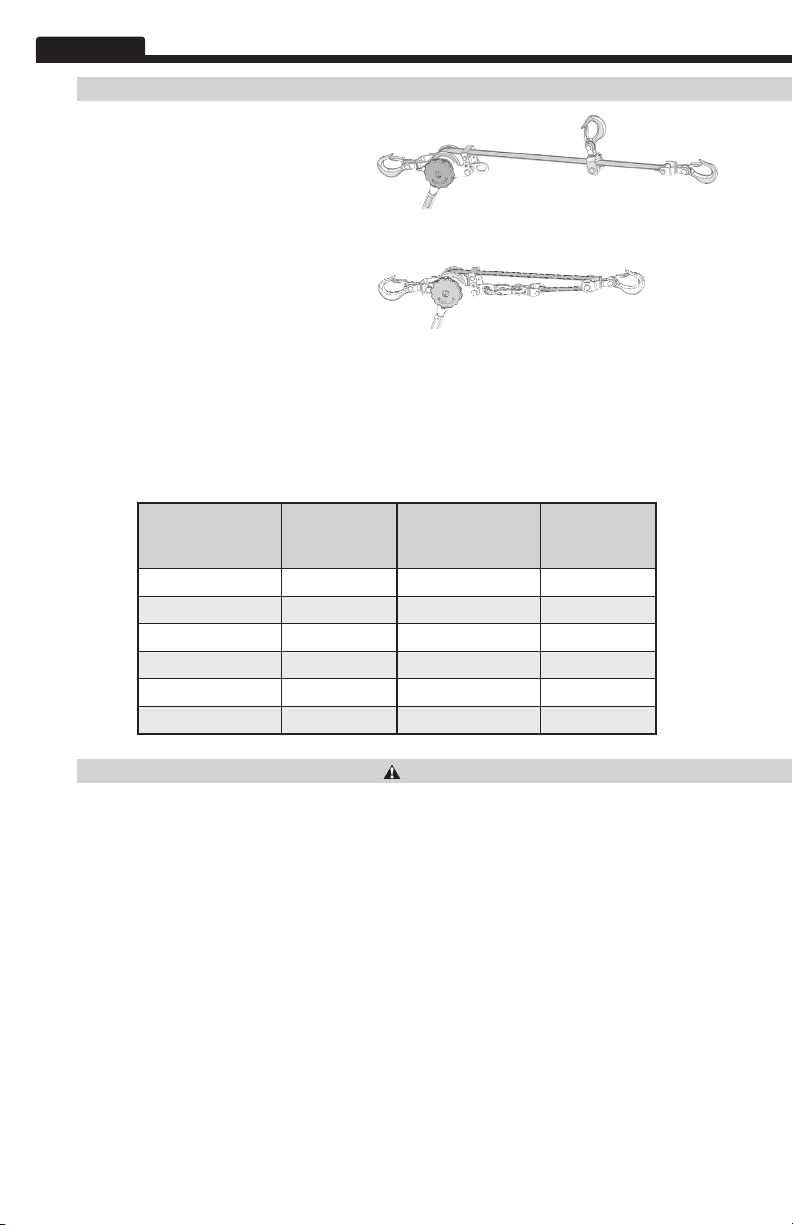

Single Line

Load Rating: 1500 lbs. (675 kg)

Pulling Distance: Max: 138" (3500 mm)

Min: 20" (500 mm)

Double Line

Load Rating: 3000 lbs. (1350 kg)

Pulling Distance: Max: 79" (2000 mm)

Min: 26" (700 mm)

GENERAL SPECIFICATIONS

DANGER:

achieve proper working distances per OSHA Regulation Subpart V, 1926.950 or follow your company’s

work practices.

energized lines than specified by OSHA or your company.

The hoist is NOT an insulating member. Use an appropriate insulating member in series with the hoist to

Use appropriate clothing and gloves for rated voltage if handle must swing closer to

OSHA REGULATION SUBPART V, 1926.950 TABLE V-1

Alternating Current - Minimum Distances

Voltage Range

(Phase to Phase)

Kilovolt

2.1 to 15 2 ft. 0 in. 161 to 169 3 ft. 8 in.

15.1 to 35 2 ft. 4 in. 230 to 242 5 ft. 0 in.

35.1 to 46 2 ft. 6 in. 345 to 362 7 ft. 0 in.

46.1 to 72.5 3 ft. 0 in. 500 to 552 11 ft. 0 in.

72.6 to 121 3 ft. 4 in. 700 to 765 15 ft. 0 in.

138 to 145 3 ft. 6 in.

Minimum

Working

Distance

Voltage Range

(Phase to Phase)

Kilovolt

Minimum

Working

Distance

WARNINGS

For KN1500P-EX and KN1500P-EXH:

• Failure to comply with the following instructions could result in serious injury or death.

• Do not attempt to adjust, repair, or modify any part of the hoist.

• Do not lift more than the rated load.

• Do not operate hoist when it is restricted from forming a straight line with the direction of loading.

• Do not operate hoist with a twisted, kinked, or damaged web strap.

• Do not operate a damaged or malfunctioning hoist.

• Do not lift using hoist.

• Do not use hoist to lift people.

• Do not use hoist to lift loads over people.

• Do not operate hoist with a lever extension.

• Do not remove or obscure warning labels.

Additionally, for KN1500P-EXH:

• Hot rings are NOT load rated for pulling.

• Hot rings will NOT prevent electrical shock and are intended to be used with hot sticks.

2

Page 3

BEFORE OPERATING & HANDLING THE LOAD

Before operating the hoist ensure that:

• The supporting structure or anchoring means have the same or greater load capacity as the hoist.

• The operator has read and understood all information included in this manual, and are familiar with the

operating controls, hoisting practices, and warnings associated with the hoist.

• If any adjustments or repairs to the hoist are needed, report them promptly to a designated person.

• Hoist shall only be used in locations where the operator can be free of the load.

• The operator shall not use a hoist with an out-of-order sign.

• The operator shall not attempt to adjust or repair a hoist, unless qualified to make such adjustments or repairs.

• Hoists shall only be operated by the hand power of one person.

• Hoists shall not be operated with an extension on the handle.

While handling the load, ensure that:

• The hoist web strap is not wrapped around the load.

• The load is attached to the load hook by suitable means.

• The sling or other device is properly seated in the base (bowl) of the hook. The latch shall not be allowed to

support any part of the load.

• The load is not applied to the point of the hook.

• Before applying the load, the operator shall be sure the web strap is not twisted or that multiple parts of the web

strap are not twisted around each other.

• The hoist shall not be operated until the load block, web strap, and hoist body are directly in line with the

direction of loading to avoid sidepull.

• The hoist body or frame is not bearing against any object or the supporting structure.

• The operator shall not apply a load beyond the rated load appearing on the hoist or load block, except during

properly authorized tests.

• Specific attention should be given to balancing of the load and hitching or slinging to prevent slipping of the load.

• The operator shall not release the hoist lever until the ratchet and pawl is engaged and the lever is at rest.

• The operator shall not engage in any activity that will divert the operator’s attention while operating the hoist.

• The operator shall not apply a load to the hoist until the operator and all other personnel are clear of the load.

• The operator shall make sure the load clears any obstacles before moving.

• The load shall not be moved more than a few inches until it is well balanced in the sling or lifting device.

• When starting to lift or pull, the operator should move the load a few inches and then check the hoist for proper

load holding action. The operation shall be continued only after the operator has verified the hoist is operating

properly.

• Hoist shall not be used to lift, support, or otherwise transport people.

• The operator should avoid carrying loads over people.

• The operator should not leave a loaded hoist unattended unless specific precautions have been instituted and

are in place.

• Care shall be exercised when removing a sling from under a landed and blocked load.

3

Page 4

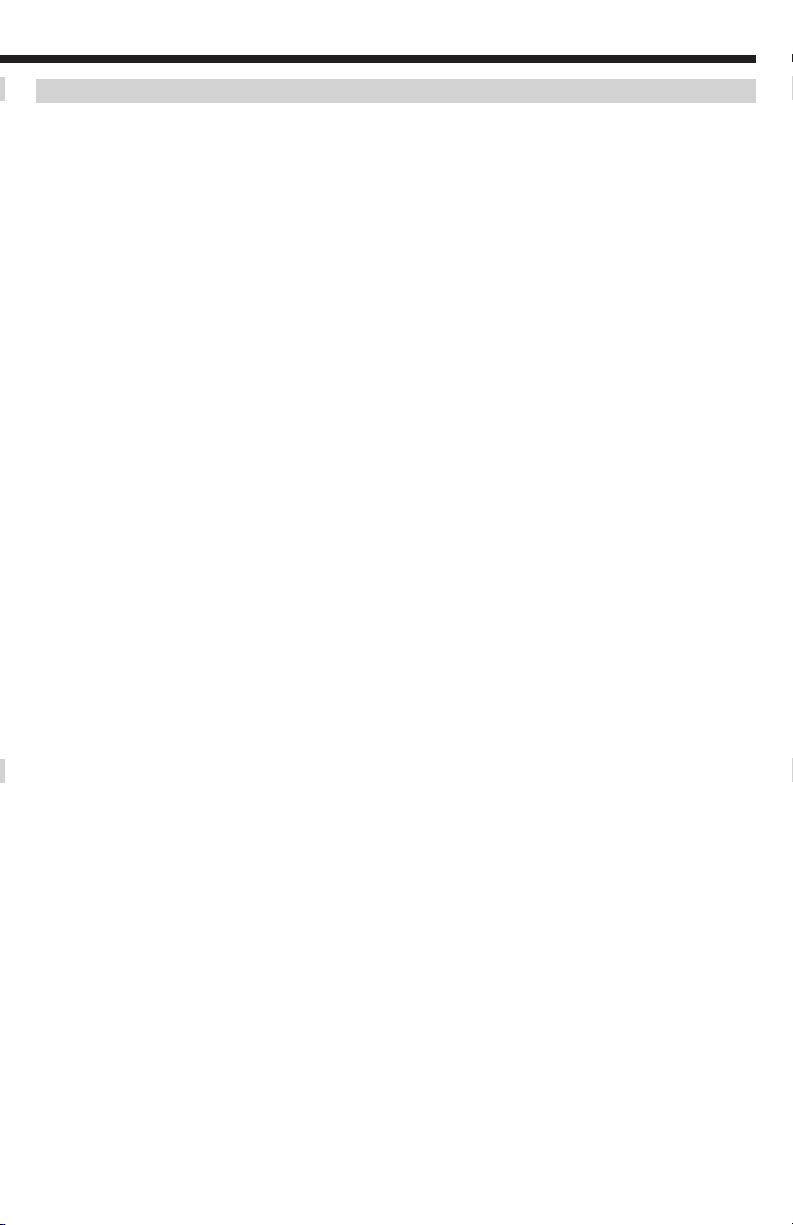

ENGLISH

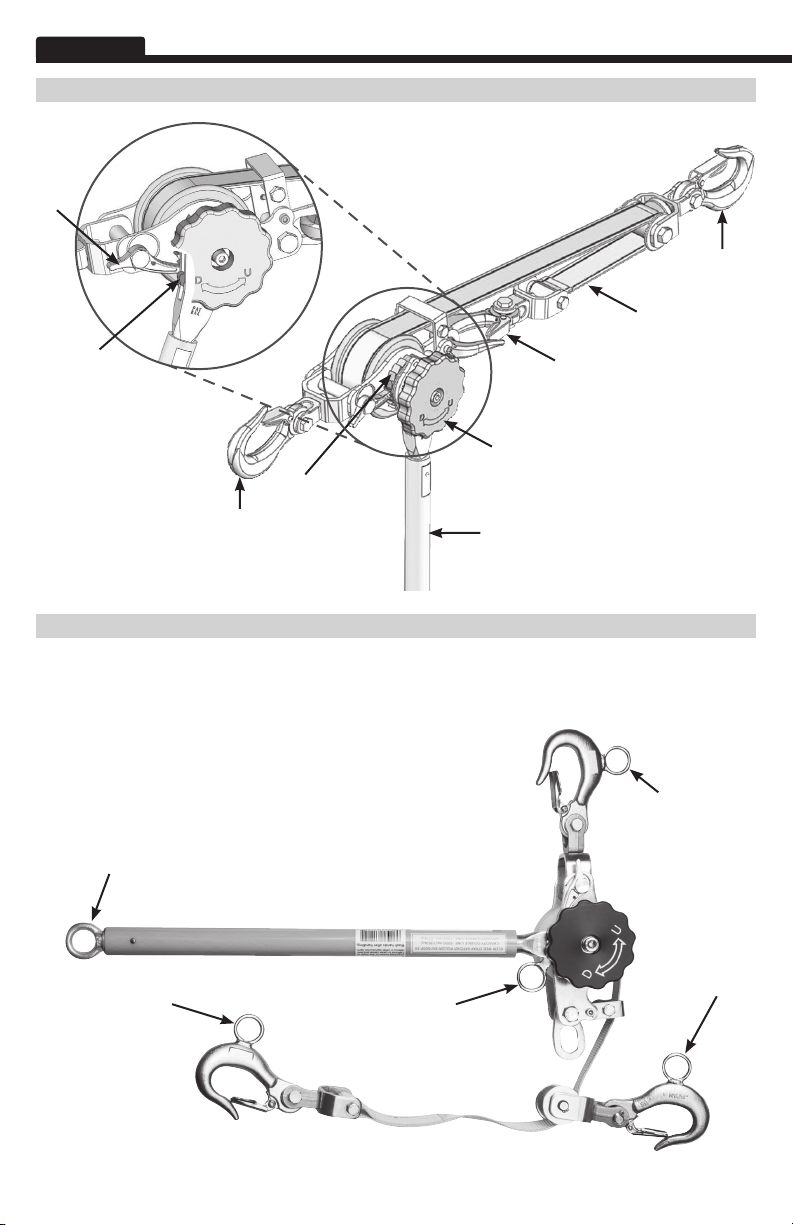

Pawl

FEATURES (KN1500P-EX AND KN1500P-EXH)

Floating Hook

Web Strap

Ratchet

Switch

Drum Knob

Brake Wheel

Hook

Handle

HOT RINGS (KN1500P-EXH ONLY

• All hot rings are intended to support the weight of the hoist (13 lbs 6 oz - 0.623 kg).

• The hook hot rings are designed to aid in positioning and attaching the hooks

onto hardware and grips when used with hot sticks.

• The Ratchet switch hot ring is designed to aid in switching the hoist

from the “D”, “N”, and “U” positions while using a hot stick.

• The handle hot ring is designed to aid in letting out and taking up slack

when used with a hot stick.

Handle Hot Ring

Fixed Hook

)

Hook Hot Ring

Fixed Hook Hot Ring

Floating Hook

Hot Ring

Ratchet Switch Hot Ring

4

Page 5

OPERATING INSTRUCTIONS

Rigging the Hoist for Single or Double Line Pull

1. Single Line – Only the fixed end hook should be attached to the load.

WARNING: Do NOT attach floating hook to a load for a single line pull.

WARNING: Never rig web strap in a choke position by attaching the two hooks to each other.

WARNING: Ensure sling or other device is properly seated in the bowl of the hook, and the

hook latch is securely closed before pulling. Do not use the hook latch to support

any part of the load.

2. Double Line –

attached to the load.

Pulling Out the Web Strap

1. To release tension on the web strap, shift ratchet switch toward the “D” on the handle.

2. Use handle to ratchet the web strap forward or off the drum.

3. For faster payout, switch the ratchet to neutral or the “N” position, disengage the pawl from the brake wheel with

one hand, and pull the web strap with the other hand.

CAUTION: When in use, leave no less than two wraps of the web strap on the drum while pulling.

CAUTION: When web strap is fully paid out, do NOT attempt to further unwind the strap. This could

result in damage to the web strap and/or brake mechanism.

Adding Tension on the Web Strap With a Load Attached:

1. Move ratchet to up or the “U” position.

2. Use the handle to ratchet the web strap upwards, or towards the “U”. Continue to ratchet up until there is no longer

any slack in the strap.

Releasing Tension on the Web Strap With a Load Attached:

1. Switch the ratchet to the down or “D” position.

2. Ratchet down until you feel the tension brake release (typically after one full ratchet).

3. Once the tension brake is released, continue to ratchet down until you can safely unhook the load.

CAUTION: Do NOT unhook the load or otherwise release tension while the ratchet switch is in the up

Fixed end hook should be attached to the eye on the puller body. Floating hook should be

or “U” position. Doing so will cause the brake mechanism to lock. (If locked, put tension

back on the web strap. Switch the ratchet to the down or “D” position and ratchet down

to release the tension brake).

Rewinding the Web Strap

1. To rewind the web strap, shift ratchet switch toward the “U” on the handle.

2. Use handle to ratchet the web strap back onto the drum.

3. For faster return, shift ratchet switch to neutral or the “N” position, and manually rotate the drum knob in the

direction of the “U” or up position.

WARNING: Do NOT attempt to manually unwind the drum if a load is attached.

CAUTION:

Ensure the take-up of the web strap onto the drum is always in the up direction,

or towards the “U”.

5

Page 6

ENGLISH

HOIST INSPECTION

Frequent and Periodic inspections of the web strap hoist must be performed at the intervals described below to ensure

proper operation and safety of the hoist.

Frequent Inspections require a visual examination (records not required) by the operator or other designated person.

If conditions are found during inspection that constitutes a hazard, the designated person shall determine if a more

detailed inspection is required. Frequent inspections should be performed at the following intervals:

• Normal Service – monthly

• Heavy Service – weekly to monthly

• Severe Service – daily to weekly

• Special or infrequent service – as recommended by a qualified person before and after each occurrence.

• Hoists that have been idle for one month or more, but no more than one year shall under-go a frequent inspection

before put back into service.

Periodic Inspections require a visual inspection by a designated person who records the external conditions of

the hoist to provide a basis for continuing inspection. If conditions found during inspection constitute a hazard, a

designated person shall determine if disassembly of the hoist is required. Periodic inspections should be performed at

the following intervals:

• Normal Service – yearly

• Heavy Service – semi-annually

• Severe Service – quarterly

• Special or infrequent service – as recommended by a qualified person before the first such occurrence and as

directed by the qualified person for any subsequent occurrence.

• Hoists that have been out of service for one year or more shall under-go a periodic inspection before put back

into service.

The following charts detail the items that are required to be inspected during Frequent and Periodic inspections. A

seperate chart is included in this instruction manual to record all Periodic Inspections.

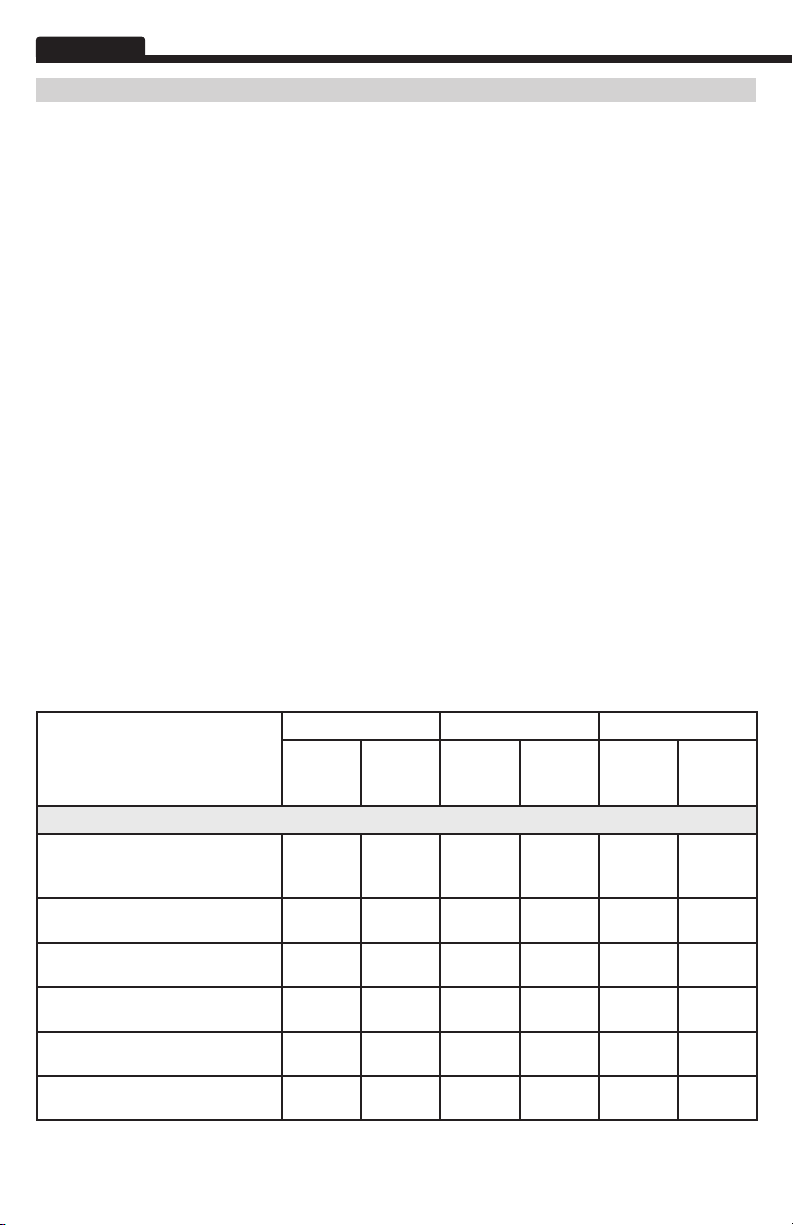

Normal Service Heavy Service Severe Service

Inspection Item

Frequent Inspection

All functional mechanisms for

maladjustment and unusual sounds

Hooks (as designated in this manual)

Hook latch operation, if used

Web strap (as designated in this manual)

Lever for bends, cracks, etc.

Hoist support for damage

Visual

Monthly

Record

Yearly

Visual

Weekly to

Monthly

Record

Semi

Annually

Visual

Daily to

Weekly

• • •

• • •

• • •

• • •

• • •

• • •

6

Record

Quarterly

Page 7

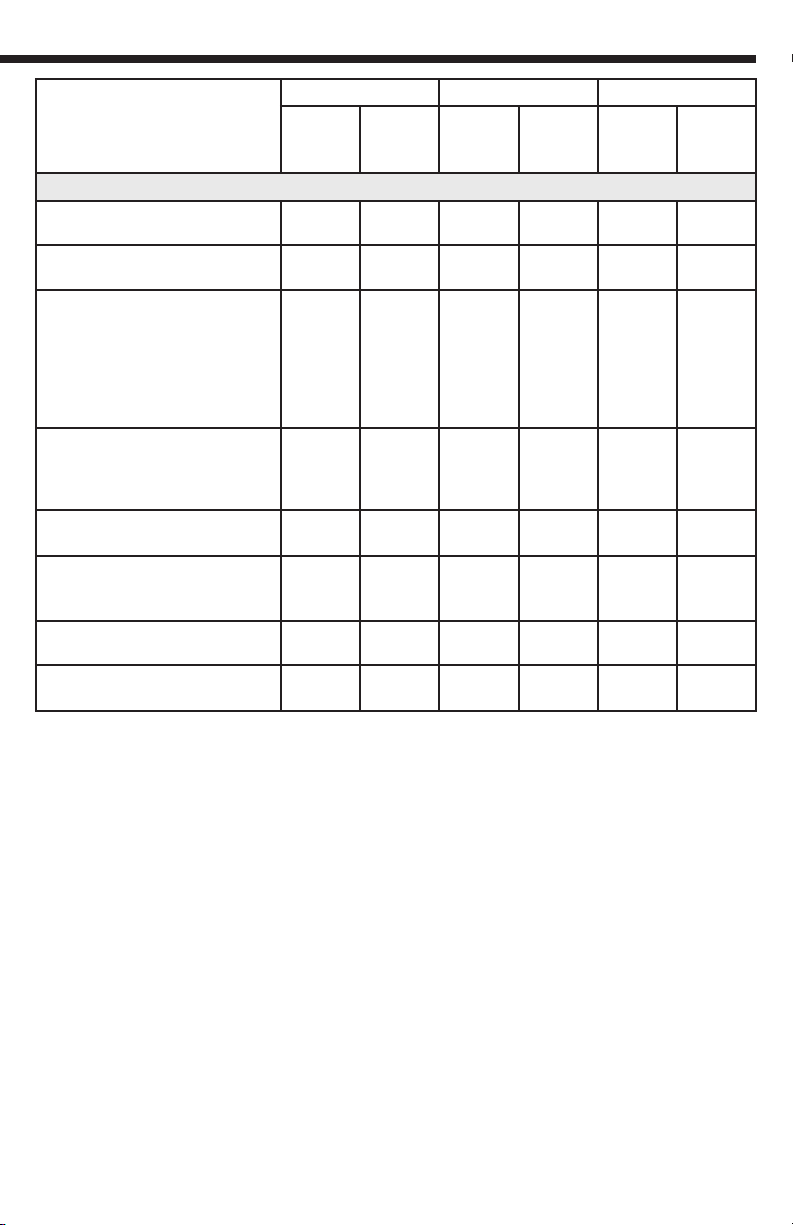

Inspection Item

Periodic Inspection

Normal Service Heavy Service Severe Service

Visual

Monthly

Record

Yearly

Visual

Weekly to

Monthly

Record

Semi

Annually

Visual

Daily to

Weekly

Record

Quarterly

Requirements of frequent inspection

Evidence of loose bolts, nuts, or rivets

Evidence of worn, corroded, cracked,

or distorted parts such as load blocks,

suspension housing, levers, web

strap attachments, clevises, yokes,

suspension bolts, shafts, gears,

bearings, pins, rollers, and locking and

clamping devices

Evidence of damage to hook retaining

nuts or collars, and pins and welds

or rivets used to secure the retaining

members

Evidence of damage or excessive wear

of load sprockets

Evidence of worn pawls, cams, or

ratchets; corroded, stretched, or broken

pawl springs

Label designating load rating

End connections and terminations of

web strap

WARNING: If service becomes necessary on the web strap hoist, all repairs MUST be made by Klein Tools

or an authorized repair center. See Warranty/Repairs section of this manual for more information.

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

7

Page 8

ENGLISH

WEB STRAP INSPECTION

Web straps also require Frequent and Periodic inspections.

Frequent Inspections: Web straps should be visually inspected before each use. The operator or other designated

person should look for signs of:

• Melting or charring

• Acid or caustic burns

• Weld spatter

• Broken stitching

• Cuts or tears

• Damaged eyes or fittings

• Abrasive wear

• Knots

WARNING: If any of the conditions above exist on the web strap, remove from service immediately and contact

Periodic Inspections: The frequency of these inspections should be determined by a qualified person and based on

factors such as usage, environment, and previous experience. Inspections are not required at equal intervals, and

should be more frequent as the web strap approaches the end of its useful life.

CAUTION: We recommend increased frequency of inspections if any of the following conditions are detected:

• Severely worn end connections

• Distortion of the web strap structure

• Evidence of heat damage

WARNING: Web strap should be replaced, regardless of condition, five (5) years after the hoist went into service.

Klein Tools or authorized repair center to replace the web strap.

HOOK INSPECTION

Frequent and Periodic Inspections of the hooks should be performed at the same time those inspections are

performed on the hoist. Hooks should be removed from service, and repaired or replaced, if any of the below

conditions exist:

• Cracks, nicks, and gouges

• Any visibly apparent bend or twist from the plane of the unbent hook

• Any distortion causing an increase in throat opening

• Any damaged latch or malfunctioning latch that does not close the hook’s throat

• Evidence of excessive heat exposure or unauthorized welding

• Evidence of unauthorized alterations such as drilling, machining, grinding, or other modifications

HOIST MAINTENANCE

• Avoid storing web strap hoist in areas that are: high in humidity, dusty, sandy, exposed to direct sunlight.

• If hoist is used in heavy rain or near saltwater, clean all parts of the hoist (except handle and web strap) with a

multi-purpose lubricant.

• Do not allow water to come in contact with the brake area. Water contact could cause the brake to become stiff

or malfunction. If this occurs, the unit may require a factory overhaul before storage or returning to service.

8

Page 9

TESTING

Hoists are tested by Klein Tools before being sold. However, hoists require operational testing if it has been altered,

repaired, or has been out of service for the last 12 months or more. Tests shall be performed by a designated person

and shall include:

• Checking all functions of the hoist while it is suspended in the unloaded state.

• After testing in the unloaded state, a load of at least 100 lbs (single line) and 200 lbs. (double line) shall be applied

to the hoist in order to check proper load control.

A hoist where load-suspension parts have been altered, replaced, or repaired shall be statically or dynamically load tested:

• The need for these tests shall be determined by a qualified person.

• A written report of the test should be prepared and placed on file.

• The test load shall not be less than 100% of the rated load of the hoist or more than 125% of the rated load of the

hoist unless otherwise recommended by the manufacturer or a qualified person.

• The replacement of the web strap is excluded from this load test, but should be tested in accordance with the

operational testing detailed above.

• Test anchorages or suspensions shall be approved by a qualified person.

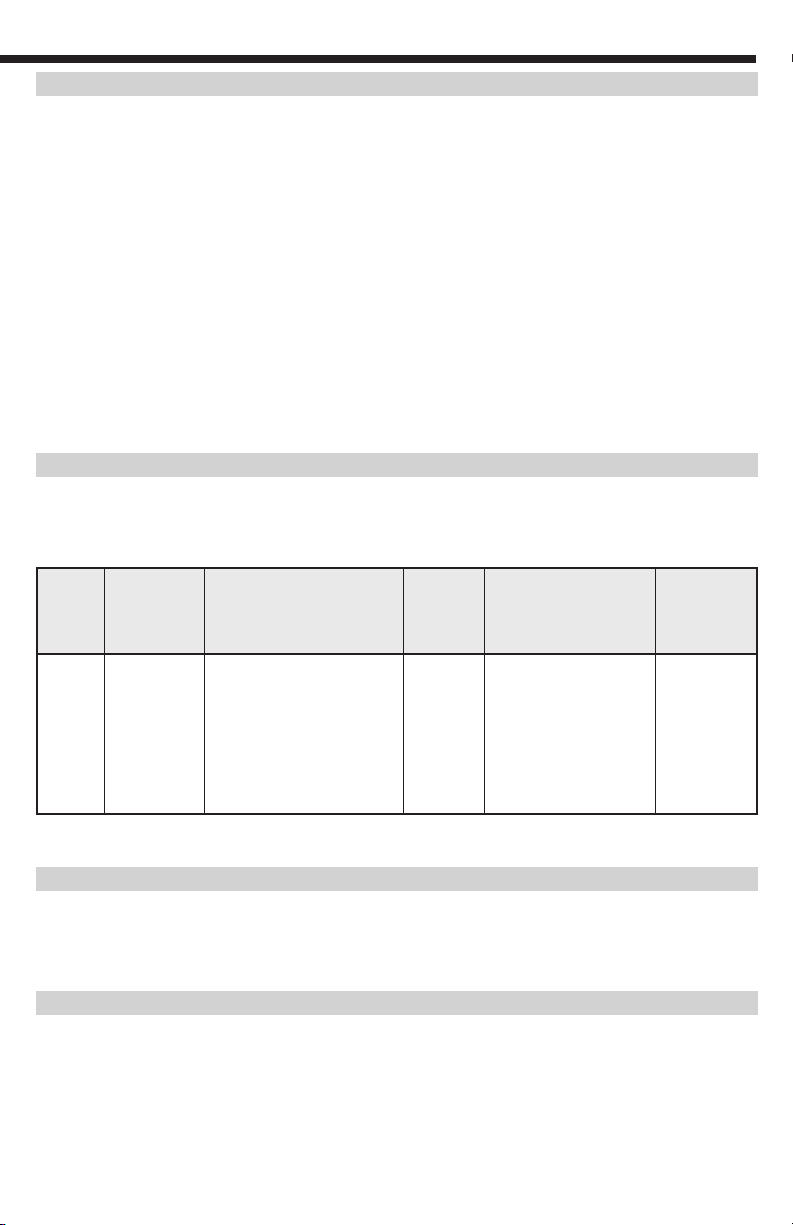

WEB STRAP MAINTENANCE

Store web strap protected from dirt, oil, water, and other foreign materials that could damage the strap or cause deterioration.

Inspect for evidence of exposure to excessive heat, charring, acid burns, chemical contamination or excessive abrasion

as follows:

Type of

Material

Polyester Poor resistance.

Exposure to

Excessive Heat

Fibers become

brittle and will

shrivel, turn

brown in color,

and break when

flexed. Should not

be used above

180°F (82°C).

Exposure to

Chemicals

Good Resistance to most chemicals,

including hydrochloric acid, aqueous

alkalies, and many other solvents.

Exposure to incompatible chemicals

may change fiber color and texture,

similar to a brownish smudge or

smear. Also, fibers will become less

elastic, with transverse cracks caused

by bending.

Exposure

to Molten

Metal or

Flame

Poor

resistance.

Fiber strands

fuse together

and become

hard, brittle,

and shiny.

Exposure to Paints

or Solvents

Generally offers good resistance.

However, paint can penetrate

into the weave and dry. This can

cause webbing to become hard

and brittle and can eventually

break the fibers. Some solvents

may affect fibers (see also

“Exposure to Chemicals”).

Exposure Near

Live Electrical

Lines and

Equipment

Poor protection

(no dielectric

strength).

Provides no

protection to

exposure to live

electrical lines or

equipment.

WARNING: Web strap should be replaced, regardless of condition, five (5) years after the hoist went into service.

HOIST LUBRICATION

Keep the ratchet gear, stopper ball, and turning area operating smoothly by regularly lubricating with a multi-purpose

lubricant. Wipe away any excess.

WARNING: Do NOT apply lubricant to the braking system.

WARRANTY AND REPAIRS

Klein web strap hoists and components, manufactured and sold for commercial or industrial uses, are warranted to

be free from defects in materials and workmanship for one year from the date of purchase. THERE ARE NO IMPLIED

WARRANTIES OF MERCHANTIBILITY OR FITNESS. At its option, Klein will repair or replace, or refund the purchase

price of, any product which fails to conform to this warranty under normal use and service. In no event shall Klein be

liable for incidental or consequential damage.

If your Klein product requires repair or for information on how to exercise your rights under the terms of this warranty,

please contact Klein Tools at 1-800-553-4676.

9

Page 10

ENGLISH

DEFINITIONS

Abnormal operating conditions: Environmental conditions that are unfavorable, harmful, or detrimental to or for the

operation of a hoist, such as excessively high or low ambient temperatures, exposure to weather, corrosive fumes,

dust laden or moisture laden atmospheres, and hazardous locations.

Designated person: A person selected or assigned by the employer or the employer’s representative as being

competent to perform specific duties.

Heavy service: Service that involves operation within the rated load limit, which exceeds normal service.

Normal service: Distributed service that involves operation with randomly distributed loads within the rated load limit,

or uniform loads less than 65% of rated load for not more than 15% of the time.

Quali ed person: A person who, by possession of a recognized degree in an applicable field, or certificate of

professional standing, or who, by extensive knowledge, training, and experience, has successfully demonstrated the

ability to solve or resolve problems relating to the subject matter and work.

Severe service: Service that involves normal or heavy service with abnormal operating conditions.

Serial Number

10

Page 11

Manual de instrucciones

con palanca (tipo correa entretejida) y con la norma ASME B30.10-2009

para ganchos.

Este manual de instrucciones cubre los procedimientos de funcionamiento,

inspección y mantenimiento correspondientes al polipasto de trinquete

con correa entretejida KN1500P-EX y al polipasto de trinquete con

correaentretejida y anillos KN1500P-EXH de Klein Tools.

KN1500P-EX

Polipasto de trinquete

con

correa entretejida

ESPAÑOL

Español pág. 11

Português pág. 21

KN1500P-EXH

Polipasto de trinquete con

correa entretejida y anillos

Los productos KN1500P-EX y KN1500P-EXH de Klein Tools cumplen con

lanorma ASME B30.21-2005 para polipastos accionados manualmente

con palanca (tipo correa entretejida) y con la norma ASME B30.10-2009

para ganchos.

Este manual de instrucciones cubre los procedimientos de funcionamiento,

inspección y mantenimiento correspondientes al polipasto de trinquete

con correa entretejida KN1500P-EX y al polipasto de trinquete con

correaentretejida y anillos KN1500P-EXH de Klein Tools.

Français pág. 31

KN1500P-EX

KN1500P-EXH

Page 12

ESPAÑOL

ESPECIFICACIONES GENERALES

Línea simple

Capacidad de carga: 1500lb (675kg)

Distancia de tracción: Máx.: 138" (3500mm)

Mín.: 20" (500mm)

Doble línea

Capacidad de carga: 3000lb (1350kg)

Distancia de tracción: Máx.: 79" (2000mm)

Mín.: 26" (700mm)

PELIGRO:

El polipasto NO es un instrumento aislante. Utilice una pieza aislante adecuada en serie con el polipasto

para alcanzar distancias de trabajo apropiadas según la regulación de la OSHA subparte V, 1926.950

osigalas prácticas de trabajo de su compañía.

nominal si el mango debe oscilar cerca de líneas energizadas a una distancia menor que la especificada

porla OSHA o su compañía.

REGULACIÓN DE LA OSHA SUBPARTE V, 1926.950 TABLA V-1

Corriente alterna - Distancias mínimas

Rango de voltaje

(entre fases) -

kilovoltio

2,1 a 15 2 pies 0 pulg. 161 a 169 3 pies 8 pulg.

15,1 a 35 2 pies 4 pulg. 230 a 242 5 pies 0 pulg.

35,1 a 46 2 pies 6 pulg. 345 a 362 7 pies 0 pulg.

46,1 a 72,5 3 pies 0 pulg. 500 a 552 11 pies 0 pulg.

72,6 a 121 3 pies 4 pulg. 700 a 765 15 pies 0 pulg.

138 a 145 3 pies 6 pulg.

Distancia

de trabajo

mínima

Utilice vestimenta y guantes apropiados para el voltaje

Rango de voltaje

(entre fases) -

kilovoltio

Distancia

de trabajo

mínima

ADVERTENCIAS

Para KN1500P-EX y KN1500P-EXH:

• El incumplimiento de estas instrucciones puede dar lugar a lesiones graves o mortales.

• No intente ajustar, reparar ni modificar ninguna pieza del polipasto.

• No levante una carga superior a la carga nominal.

• No accione el polipasto si no puede formar una línea recta con la dirección de la carga.

• No accione el polipasto si la correa entretejida está retorcida, enredada o dañada.

• No accione el polipasto si está dañado o no funciona correctamente.

• No levante cargas con el polipasto.

• No utilice el polipasto para levantar personas.

• No utilice el polipasto para levantar cargas cuando haya personas debajo de estas.

• No accione el polipasto utilizando una extensión de la palanca.

• No quite ni tape las etiquetas de advertencia.

Además, para el KN1500P-EXH:

• Los anillos s NO tienen la capacidad de carga para tracción.

• Los anillos NO evitan choques eléctricos y su uso previsto es junto a pértigas de trabajo.

12

Page 13

ANTES DE OPERAR Y MANIOBRAR LA CARGA

Antes de operar el polipasto, asegúrese de que se cumplan las siguientes condiciones:

• La estructura de apoyo o los medios de anclaje tienen la misma capacidad de carga o una capacidad mayor

quela del polipasto.

• El operador ha leído y comprendido toda la información incluida en este manual y está familiarizado con los

controles operativos, las prácticas de elevación y las advertencias asociadas con el polipasto.

• Si es necesario realizar ajustes o reparaciones en el polipasto, infórmelo de inmediato a la persona designada.

• El polipasto solo se debe utilizar en ubicaciones en las que el operador puede estar fuera de la zona donde

pende la carga.

• El operador no debe utilizar un polipasto que tiene un cartel que dice “fuera de servicio”.

• El operador no debe intentar ajustar ni reparar el polipasto a menos que esté calificado para realizar tales

ajusteso reparaciones.

• Los polipastos solo deben ser accionados por la fuerza manual de una persona.

• Los polipastos no deben ser accionados con una extensión del mango.

Al maniobrar la carga, asegúrese de que se cumplan las siguientes condiciones:

• La correa entretejida del polipasto no está enredada alrededor de la carga.

• La carga está sujetada al gancho de carga por medios adecuados.

• La eslinga u otro dispositivo están correctamente colocados en la base (taza) del gancho. El cerrojo no debe

soportar ninguna parte de la carga.

• No se aplica la carga en el punto del gancho.

• Antes de aplicar la carga, el operador se debe asegurar de que la correa entretejida no esté retorcida y de que

sus distintas partes no estén enredadas unas con otras.

• El polipasto no se debe accionar hasta que el bloqueo de carga, la correa entretejida y el cuerpo del polipasto

estén alineados directamente con la dirección de la carga para evitar tracciones laterales.

• El cuerpo o armazón del polipasto no debe ejercer presión contra ningún objeto ni contra la estructura

desoporte.

• El operador no debe aplicar una carga superior a la carga nominal que figura en el polipasto o en el bloqueo

decarga, salvo cuando se trate de pruebas debidamente autorizadas.

• Se debe prestar especial atención al balanceo de la carga y al enganche o la suspensión para evitar que la carga

se deslice.

• El operador no debe liberar la palanca del polipasto hasta que el trinquete y la uña estén enganchados,

ylapalanca esté en reposo.

• El operador no debe realizar ninguna actividad que desvíe su atención mientras opera el polipasto.

• El operador no debe aplicar una carga al polipasto hasta que él mismo y las demás personas no estén fuera

dela zona donde pende la carga.

• El operador debe asegurarse de que la carga pasará sin tocar ningún obstáculo antes de moverla.

• La carga no se debe mover más de unas pocas pulgadas hasta que esté bien balanceada en la eslinga

odispositivo de elevación.

• Al iniciar la elevación o tracción, el operador debe mover la carga unas pocas pulgadas y luego examinar el

polipasto para verificar que la acción de soporte de la carga es la adecuada. La operación solo debe continuar

unavez que el operador haya verificado que el polipasto está funcionando correctamente.

• El polipasto no se debe utilizar para levantar, soportar o transportar personas.

• El operador debe evitar transportar cargas sobre las personas.

• El operador no debe dejar abandonado el polipasto cargado a menos que haya medidas de precaución

específicas y que estas se hayan implementado.

• Se debe tener especial cuidado al quitar una eslinga de la parte inferior de una carga depositada en el piso

ybloqueada.

13

Page 14

ESPAÑOL

Uña

CARACTERÍSTICAS (KN1500P-EX Y KN1500P-EXH)

Gancho flotante

Correa entretejida

Interruptor

deltrinquete

Perilla tipo dial

Rueda de freno

Gancho

Mango

GANCHOS (SOLO KN1500P-EXH

• El uso previsto de todos los ganchos es soportar el peso del polipasto (13lb 6oz - 0,623kg).

• Los anillos del gancho están diseñados para ayudar a posicionar y unir los ganchos

a las piezas metálicas y agarres cuando se usan con anillos.

• El anillo del interruptor del trinquete está diseñado para ayudar a cambiar

la posición del polipasto entre “D”, “N” y “U”, mientras se utiliza una pértiga.

• El anillo del mango está diseñado para ayudar a soltar y tensar el huelgo

cuando se usa con una pértiga.

Anillo del mango

Gancho fijo

)

Anillo del gancho

Anillo del gancho fijo

Anillo del

gancho flotante

Anillo del interruptor

del trinquete

14

Page 15

INSTRUCCIONES DE OPERACIÓN

Instalar el polipasto para una tracción de línea única o doble línea

1. Línea única: solo el extremo del gancho fijo se debe sujetar a la carga.

ADVERTENCIA: NO sujete el gancho flotante a una carga en una tracción de línea única.

ADVERTENCIA: Nunca instale la correa entretejida en una posición de estrangulamiento

ADVERTENCIA: Asegúrese de que la eslinga u otro dispositivo estén correctamente asentados

sujetando los dos ganchos entre sí.

en la taza del gancho y que el cerrojo del gancho esté bien cerrado antes de

comenzar la tracción. No utilice el cerrojo del gancho para soportar ninguna

parte de la carga.

2. Doble línea:

Tirar hacia afuera la correa entretejida

1. Para liberar la tensión sobre la correa entretejida, mueva el interruptor del trinquete hacia la posición “D”

enelmango.

2. Utilice el mango para accionar el trinquete y dirigir la correa entretejida hacia adelante o fuera del tambor.

3. Para soltar con mayor rapidez, coloque el trinquete en la posición neutral o “N”, desenganche la uña de la rueda

defreno con una mano y tire de la correa entretejida con la otra mano.

PRECAUCIÓN: Durante el uso, deje no menos de dos vueltas de la correa entretejida sobre el tambor

PRECAUCIÓN: Cuando la correa entretejida está totalmente suelta, NO intente desenrollarla aun más.

Cómo agregar tensión en la correa entretejida con una carga sujetada:

1. Mueva el trinquete hacia arriba o a la posición “U”.

2. Utilice el mango para accionar el trinquete y dirigir la correa entretejida hacia arriba o hacia la posición “U”.

Continúe accionando el trinquete hasta que la correa esté completamente tensa.

Cómo liberar tensión en la correa entretejida con una carga sujetada:

1. Coloque el trinquete hacia abajo o en la posición “D”.

2. Accione el trinquete hasta que se libere el freno de tensión (en general, después de una acción de trinquete completa).

3. Una vez que el freno de tensión se libera, continúe accionando el trinquete hasta que pueda desenganchar la carga

de manera segura.

PRECAUCIÓN: NO desenganche la carga ni libere la tensión mientras el interruptor del trinquete se

El extremo del gancho fijo se debe sujetar al ojal del cuerpo del extractor. El gancho flotante

se debe unir a la carga.

mientras realiza la tracción.

Podría dañarse la correa entretejida y/o el mecanismo de freno.

encuentra hacia arriba o en la posición “U”. Si lo hace, se bloqueará el mecanismo

defreno. (Si se bloquea, vuelva a tensar la correa entretejida. Coloque el interruptor

haciaabajo o en la posición “D” y accione el trinquete para liberar el freno de tensión).

Enrollar la correa entretejida

1. Para enrollar la correa entretejida, mueva el interruptor del trinquete hacia la posición “U” en el mango.

2. Utilice el mango para accionar el trinquete y colocar la correa entretejida nuevamente sobre el tambor.

3. Para un retorno más rápido, mueva el interruptor del trinquete a la posición neutral o “N” y rote manualmente

laperilla tipo dial en la dirección de la posición “U” o hacia arriba.

ADVERTENCIA: NO intente desenrollar manualmente el tambor si hay una carga sujetada.

PRECAUCIÓN:

Asegúrese de que la toma de la correa entretejida sobre el tambor esté siempre

endirección, hacia arriba o hacia la posición “U”.

15

Page 16

ESPAÑOL

INSPECCIÓN DEL POLIPASTO

Se deben realizar inspecciones frecuentes y periódicas del polipasto de correa entretejida según los intervalos

descritos a continuación para garantizar su correcto funcionamiento y seguridad.

En las inspecciones frecuentes se requiere que el operador u otra persona designada realice un examen visual (no se

requieren registros). Si durante la inspección se hallan condiciones que constituyen un riesgo, la persona designada

debe determinar si es necesario realizar una inspección más minuciosa. Las inspecciones frecuentes se deben realizar

en los siguientes intervalos:

• Servicio normal: mensualmente

• Servicio pesado: semanalmente a mensualmente

• Servicio intensivo: diariamente a semanalmente

• Servicio especial o poco frecuente: según lo recomendado por la persona calificada antes y después de cada instancia.

• Los polipastos que han estado inactivos durante un mes o más, pero no más de un año, deben ser sometidos a una

inspección frecuente antes de volver a ponerlos en servicio.

En las

inspecciones periódicas se requiere que la persona designada realice una inspección visual y registre

lascondiciones externas del polipasto para proporcionar las bases para una inspección continua. Si durante la

inspección se hallan condiciones que constituyen un riesgo, la persona designada debe determinar si es necesario

desarmar el polipasto. Las inspecciones periódicas se deben realizar en los siguientes intervalos:

• Servicio normal: anualmente

• Servicio pesado: semestralmente

• Servicio intensivo: trimestralmente

• Servicio especial o poco frecuente: según lo recomendado por la persona calificada antes de la primera instancia

ysegún lo indicado por la persona calificada para cualquier instancia subsiguiente.

• Los polipastos que han estado fuera de servicio durante un año o más deben ser sometidos a una inspección

periódica antes de volver a ponerlos en servicio.

El siguiente cuadro detalla los elementos que se deben inspeccionar durante las inspecciones frecuentes y periódicas.

En este manual de instrucciones se incluye un cuadro para registrar todas las inspecciones periódicas.

Servicio normal Servicio pesado Servicio intensivo

Elemento de inspección

Inspección frecuente

Todos los mecanismos funcionales para

detectar desajustes y ruidos inusuales

Ganchos (según se indica en este manual)

Funcionamiento del cerrojo del gancho,

si se utiliza

Correa entretejida (según se indica eneste

manual)

Palanca para detectar curvaturas,

grietas, etc.

Soporte del polipasto para detectar daños

Visual

Mensual-

mente

Registro

Anualmente

Visual

Semanal-

mente a

mensual-

mente

Registro

Semestral-

mente

Visual

Diaria-

mente a

semanal-

mente

• • •

• • •

• • •

• • •

• • •

• • •

16

Registro

Trimestral-

mente

Page 17

Elemento de inspección

Inspección periódica

Todos los requisitos de

unainspecciónfrecuente

Evidencia de tornillos,

tuercasoremaches flojos

Evidencia de piezas gastadas,

corroídas, rajadas o deformadas; por

ejemplo, bloqueos de carga, carcasa

de suspensión, palancas, accesorios

de la correa entretejida, horquillas,

yugos, tornillos de suspensión, barras,

engranajes, cojinetes lisos, pernos,

rodillos y dispositivos de traba y apriete

Evidencia de daños en tuercas o

collarines de retención del gancho y

en pernos y soldaduras o remaches

utilizados para sujetar las piezas

deretención

Evidencia de daños o desgaste

excesivo de las ruedas dentadas de

la carga

Evidencia de uñas, levas o trinquetes

gastados o resortes corroídos,

estirados o rotos

Servicio normal Servicio pesado Servicio intensivo

Visual

Mensual-

mente

Registro

Anualmente

Visual

Semanal-

mente a

mensual-

mente

Registro

Semestral-

mente

Visual

Diaria-

mente a

semanal-

mente

Registro

Trimestral-

mente

• • •

• • •

• • •

• • •

• • •

• • •

Etiqueta que indica la capacidad de carga

Conexiones y terminaciones de la

correa entretejida

ADVERTENCIA: Si es necesario reparar el polipasto de correa entretejida, todas las reparaciones DEBEN

serrealizadas por Klein Tools o un centro de reparaciones autorizado. Consulte la sección

Garantía/Reparaciones de este manual para obtener más información.

• • •

• • •

17

Page 18

ESPAÑOL

INSPECCIÓN DE LA CORREA ENTRETEJIDA

Las correas entretejidas también requieren inspecciones frecuentes y periódicas.

Inspecciones frecuentes: Las correas entretejidas deben ser inspeccionadas visualmente antes de cada uso.

Eloperador u otra persona designada debe examinarlas para detectar signos de:

• Pérdida de firmeza o carbonización

• Quemaduras por ácidos o soda cáustica

• Salpicaduras de soldadura

• Costuras rotas

• Cortes o rasgaduras

• Ojales o accesorios dañados

• Desgaste abrasivo

• Nudos

ADVERTENCIA: Si en la correa entretejida se detecta alguna de las condiciones mencionadas, retírela de servicio

Inspecciones periódicas: Una persona calificada debe determinar la frecuencia de estas inspecciones según ciertos

factores como el uso, el entorno y la experiencia previa. No es necesario realizar las inspecciones en intervalos iguales

y deben ser más frecuentes a medida que la correa entretejida se aproxima al final de su vida útil.

PRECAUCIÓN: Recomendamos aumentar la frecuencia de las inspecciones si se detecta alguna de las siguientes

• Conexiones muy gastadas

• Deformación de la estructura de la correa entretejida

• Evidencia de daños ocasionados por el calor

ADVERTENCIA: Independientemente de su estado, la correa entretejida debe ser reemplazada cada cinco (5) años una

inmediatamente y comuníquese con Klein Tools o con un centro de reparaciones autorizado para

sureemplazo.

condiciones:

vez puesto en servicio el polipasto.

INSPECCIÓN DE LOS GANCHOS

Las inspecciones frecuentes y periódicas de los ganchos deben ser realizadas en el mismo momento en que se

realizan las inspecciones del polipasto. Los ganchos se deben retirar del servicio para su reparación o reemplazo

sisedetecta alguna de las siguientes condiciones:

• Rajaduras, melladuras y grietas

• Cualquier signo de doblado o retorcimiento respecto del plano recto del gancho que sea evidente visualmente

• Cualquier distorsión que cause un aumento en la abertura de los ganchos

• Cualquier cerrojo dañado o defectuoso que no cierra la abertura del gancho

• Evidencia de exposición excesiva al calor o signos de soldaduras no autorizadas

• Evidencia de alteraciones no autorizadas como taladrado, maquinado, rectificado u otras modificaciones

MANTENIMIENTO DEL POLIPASTO

• Evite almacenar el polipasto de correa entretejida en áreas que sean muy húmedas, tengan polvo o arena y estén

expuestas a la luz solar directa.

• Si el polipasto se utiliza bajo una lluvia intensa o cerca de agua salada, limpie todas sus piezas (excepto el mango

yla correa entretejida) con un lubricante multiuso.

• No permita que el agua entre en contacto con el área de frenos. Si entrara en contacto con el agua, el freno podría

endurecerse o dañarse. Si esto ocurre, es probable que antes de su almacenamiento o antes de volver a poner la

unidad en servicio, se requiera un reacondicionamiento de fábrica.

18

Page 19

PRUEBAS

Los polipastos son probados por Klein Tools antes de su venta. No obstante, se deben realizar pruebas de funcionamiento

si el polipasto ha sido alterado o reparado o si ha estado fuera de servicio durante 12 meses o más. Las pruebas deben

ser realizadas por una persona designada y deben incluir lo siguiente:

• Se deben verificar todas las funciones del polipasto mientras se mantiene suspendido en el estado descargado.

• Luego de realizar las pruebas en el estado descargado, se debe aplicar una carga de al menos 100lb (línea única)

y200lb (doble línea) para verificar el correcto control de la carga.

En caso de que se hayan alterado, reemplazado o reparado las piezas de suspensión de carga, se deben realizar pruebas

de carga estática o dinámica:

• Una persona calificada debe determinar la necesidad de estas pruebas.

• Se debe preparar y archivar un informe escrito de la prueba.

• La carga de prueba no debe ser inferior al 100% de la carga nominal del polipasto ni superior al 125% de la carga

nominal del polipasto, a menos que lo recomiende el fabricante o una persona calificada.

• El reemplazo de la correa entretejida está excluido de esta prueba de carga, pero se debe probar según las pruebas

de funcionamiento detalladas anteriormente.

• Los anclajes o suspensiones de prueba deben ser aprobados por una persona calificada.

MANTENIMIENTO DE LA CORREA ENTRETEJIDA

Almacene la correa entretejida de modo que quede protegida de la suciedad, el aceite, el agua u otros materiales extraños que

podrían dañarla o deteriorarla.

Examine para detectar evidencias de exposición al calor, carbonización, quemaduras por ácidos, contaminación con

sustancias químicas o una abrasión excesiva:

Tipo de

material

Poliéster Baja resistencia.

Exposición a

calor excesivo

Lasfibras se

vuelven quebradizas

y se resecan,

adoptan un color

marrón y se rompen

cuando se las dobla.

No se debe utilizar

en temperaturas

superiores a

180°F(82°C).

Exposición a

sustancias químicas

Buena resistencia a sustancias químicas,

incluido ácido clorhídrico, álcalis

acuosos y muchos otros solventes.

La exposición a productos químicos

incompatibles puede dar lugar al

cambio de color y de textura de la fibra

adquiriendo un aspecto similar a un

manchado de color parduzco. Además,

las fibras se volverán menos elásticas

y presentarán resquebrajaduras

transversales debido al doblado.

Exposición

a metal

fundido

ollamas

Baja

resistencia.

Las hebras

de las fibras

se fusionan y

se endurecen

volviéndose

frágiles y

brillosas.

Exposición a pinturas

o solventes

Por lo general ofrece buena

resistencia. Sin embargo,

la pintura puede penetrar

en el tejido y secarse. En

consecuencia, las sogas se

endurecen y se vuelven frágiles

hasta que finalmente las fibras

se rompen. Algunos solventes

pueden afectar las fibras

(consulte también “Exposición

asustancias químicas”).

Exposición

cerca de cables

y equipos

eléctricos vivos

Bajo grado de

protección (no

tiene resistencia

dieléctrica).

Noproporciona

ninguna protección

contra líneas

oequipos

eléctricosvivos.

ADVERTENCIA: Independientemente de su estado, la correa entretejida debe ser reemplazada cada cinco (5) años una

vez puesto en servicio el polipasto.

LUBRICACIÓN DEL POLIPASTO

Para que el engranaje del trinquete, la bola de tope y el área giratoria funcionen eficazmente, se deben lubricar

regularmente con lubricante multiuso. Limpie y quite los excesos de lubricante.

ADVERTENCIA: NO aplique lubricante en el sistema de freno.

GARANTÍA Y REPARACIONES

Se garantiza que los polipastos con correa entretejida de Klein y sus componentes, fabricados y vendidos para uso

comercial o industrial, no presentarán defectos en materiales ni de mano de obra durante un año desde la fecha de

compra. EL PRODUCTO NO TIENE NINGUNA GARANTÍA IMPLÍCITA RESPECTO DE COMERCIABILIDAD O APTITUD.

A su criterio, Klein reparará o reemplazará el producto, o reembolsará el precio de compra de cualquier producto que

no cumpla con esta garantía bajo condiciones normales de uso y servicio. En ningún caso, Klein será responsable por

daños incidentales o consecuentes.

Si su producto Klein necesita reparaciones o si desea obtener información sobre cómo ejercer sus derechos conforme

a los términos de esta garantía, comuníquese con Klein Tools al 1-800-553-4676.

19

Page 20

ESPAÑOL

ESPAÑOL

DEFINICIONES

Condiciones de funcionamiento anormales: condiciones del entorno que son desfavorables, dañinas y perjudiciales

para el polipasto o para su funcionamiento, por ejemplo, temperatura ambiente excesivamente alta o extremadamente

baja, exposición a las condiciones climáticas, humos corrosivos, atmósferas cargadas de polvo o humedad y

ubicaciones peligrosas.

Persona designada: una persona seleccionada o designada por el empleador o un representante del empleador como

persona competente para realizar tareas específicas.

Servicio pesado: servicio que implica el funcionamiento dentro del límite de carga nominal y que excede el servicio normal.

Servicio normal: servicio distribuido que implica el funcionamiento con cargas aleatoriamente distribuidas dentro del

límite de carga nominal o cargas uniformes inferiores al 65% de la carga nominal durante no más del 15% del tiempo.

Persona cali cada: una persona que, por poseer un título reconocido en un campo aplicable o un certificado de nivel

profesional o por su amplio conocimiento, capacitación y experiencia, ha demostrado certeramente la capacidad de

resolver o solucionar problemas relacionados con la materia o el trabajo.

Servicio intensivo: servicio que implica un servicio normal o pesado con condiciones de funcionamiento anormales.

Número

deserie

20

Page 21

Manual de instruções

21

(tipocom alça trançada) e à norma ASME B30.10-2009 para ganchos.

Este manual de instrução descreve os procedimentos de operação, inspeção

e manutenção para a Talha de catraca com alça trançada Klein Tools

KN1500P-EX e Talha de catraca com alça trançada e anéis para linhas

e manutenção para a Talha de catraca com alça trançada Klein Tools

e manutenção para a Talha de catraca com alça trançada Klein Tools

energizadas KN1500P-EXH.

KN1500P-EX

Talha de catraca com alça trançada

PORTUGUÊS

Español pág. 11

Português pág. 21

KN1500P-EXH

Talha de catraca com alça trançada

e anel para linhas energizadas

As ferramentas Klein Tools KN1500P-EX e KN1500P-EXH atendem à norma

ASME B30.21-2005 para talhas operadas manualmente com alavanca

(tipocom alça trançada) e à norma ASME B30.10-2009 para ganchos.

Este manual de instrução descreve os procedimentos de operação, inspeção

e manutenção para a Talha de catraca com alça trançada Klein Tools

KN1500P-EX e Talha de catraca com alça trançada e anéis para linhas

energizadas KN1500P-EXH.

Français pág. 31

KN1500P-EX

KN1500P-EXH

21

Page 22

PORTUGUÊS

ESPECIFICAÇÕES GERAIS

Linha única

Classificação da carga: 1500 lb (675 kg)

Distância para puxar: Máx.: 138" (3500 mm)

Mín.: 20" (500 mm)

Linha dupla

Classificação da carga: 3000 lb (1350 kg)

Distância para puxar: Máx.: 79" (2000 mm)

Mín.: 26" (700 mm)

PERIGO:

A talha NÃO é um membro de isolamento. Use um membro de isolamento adequado para a talha alcançar

asdistâncias de funcionamento corretas de acordo com a Regulamentação OSHA Subparte V, 1926.950

ousiga as práticas de trabalho de sua empresa.

omanuseio for mais próximo às linhas energizadas que o especificado pela OSHA ou pela sua empresa.

REGULAMENTAÇÃO OSHA, SUBPARTE V, 1926.950 TABELA V-1

Corrente alternada - distâncias mínimas

Use roupas e luvas apropriadas para a tensão nominal se

Intervalo de tensão

(fase a fase)

quilovolt

2,1 a 15 2’ 0" 161 a 169 3’ 8"

15,1 a 35 2’ 4" 230 a 242 5’ 0"

35,1 a 46 2’ 6" 345 a 362 7’ 0"

46,1 a 72,5 3’ 0" 500 a 552 11’ 0"

72,6 a 121 3’ 4" 700 a 765 15’ 0"

138 a 145 3’ 6"

Distância

mínima de

funcionamento

Intervalo de tensão

(fase a fase)

quilovolt

Distância

mínima de

funcionamento

ADVERTÊNCIAS

Para a KN1500P-EX e a KN1500P-EXH:

• Não seguir estas instruções pode causar sérios ferimentos ou até a morte.

• Não tente ajustar, reparar ou modificar nenhuma peça da talha.

• Não eleve além da carga nominal.

• Não opere a talha quando não puder formar uma linha reta com a direção da carga.

• Não opere a talha com a alça trançada torcida, torta ou danificada.

• Não opere uma talha danificada ou com defeito.

• Não eleve usando a talha.

• Não use a talha para elevar pessoas.

• Não use a talha para elevar cargas sobre as pessoas.

• Não opere a talha com um extensor de alavanca.

• Não remova ou esconda os rótulos de advertência.

Além disso, para a KN1500P-EXH:

• Os anéis para linhas energizadas NÃO possuem carga nominal para puxamento.

• Os anéis para linhas energizadas NÃO evitarão choques elétricos e devem ser usados com bastões

paralinhasenergizadas.

22

Page 23

ANTES DE OPERAR E MANUSEAR A CARGA

Antes de operar a talha, garanta que:

• A estrutura de suporte ou os meios de ancoragem tenham a mesma capacidade de carga que a talha ou maior.

• O operador leu e entendeu todas as informações deste manual e está familiarizado com os controles de

operação, práticas de içamento e advertências associadas à talha.

• Se for necessário fazer qualquer ajuste ou reparo, relate-os imediatamente à pessoa responsável.

• A talha deve ser usada apenas em locais onde o operador possa se livrar da carga.

• O operador não deve usar uma talha que tenha o sinal de “fora de uso”.

• O operador não deve tentar ajustar ou reparar uma talha, a menos que seja qualificado para fazer esses ajustes

ou reparos.

• As talhas devem ser operadas apenas pelo comando de uma pessoa.

• As talhas não devem ser operadas com um extensor da manopla.

Ao manusear a carga, veja se:

• A alça trançada da talha não está enrolada em volta da carga.

• A carga está presa ao gancho pelos meios adequados.

• A eslinga, ou outro dispositivo, está adequadamente assentado na base (bojo) do gancho. Nenhuma parte

dacarga pode apoiar na trava.

• A carga não é aplicada ao ponto do gancho.

• Antes de aplicar a carga, o operador deve ter certeza de que a alça trançada não está torcida ou se várias partes

da alça trançada não estão entrelaçadas.

• A talha não deve ser operada até que o bloco da carga, a alça trançada e o corpo da talha estejam diretamente

alinhados com a direção da carga para evitar deslocamento lateral.

• O corpo ou a estrutura da talha não está sustentado em outro objeto ou na estrutura de suporte.

• O operador não deve aplicar uma carga além da nominal que aparece na talha ou no bloco de carga, exceto

durante os testes autorizados.

• Deve-se prestar bastante atenção ao equilíbrio da carga e amarrar ou prender para evitar que a carga deslize.

• O operador não deve soltar a alavanca da talha até que a catraca e a lingueta se prendam e a alavanca esteja

emrepouso.

• O operador não deve fazer nenhuma atividade que vá distraí-lo durante a operação da talha.

• O operador não deve aplicar uma carga à talha até que o operador e demais pessoas fiquem sem a carga.

• O operador deve assegurar que não há nenhum obstáculo para a carga antes de movê-la.

• A carga não deve ser movida mais que alguns centímetros até que esteja bem equilibrada na eslinga ou

dispositivo de içamento.

• Ao começar a elevar ou puxar, o operador deve mover a carga por alguns centímetros e, depois, verificar se a carga

está presa corretamente na talha. A operação deve continuar apenas depois que o operador confirmar que a talha

está funcionando corretamente.

• A talha não deve ser usada para elevar, apoiar ou transportar pessoas.

• O operador deve evitar carregar as cargas sobre as pessoas.

• O operador não deve deixar uma talha carregada desacompanhada, a menos que as precauções específicas

tenham sido tomadas.

• Deve-se ter cuidado ao remover uma eslinga que está embaixo de uma carga em bloco e no chão.

23

Page 24

PORTUGUÊS

Lingueta

RECURSOS (KN1500P-EX E KN1500P-EXH)

Gancho flutuante

Alça trançada

Interruptor

dacatraca

Botão de tambor

Disco de freio

Gancho

Cabo

ANÉIS PARA LINHAS ENERGIZADAS (SOMENTE KN1500P-EXH

• Todos os anéis para linhas energizadas servem para suportar o peso da talha (13 lb 6 oz - 0,623 kg).

• Os anéis para linhas energizadas do gancho são projetados para auxiliar no

posicionamento e fixação dos ganchos nas ferramentas e empunhaduras

quando forem utilizados com linhas energizadas.

• O anel para linhas energizadas do interruptor da catraca é projetado para

auxiliar na troca das posições “D”, “N” e “U” da talha ao utilizar uma barra

para linha energizada.

• O anel para linhas energizadas do cabo é projetado para auxiliar no aumento

e na diminuição da folga quando utilizado com linhas energizadas.

Anel para linhas energizadas do cabo

Gancho fixo

)

Anel

paralinhas

energizadas

do gancho

Anel para linhas

energizadas

dogancho fixo

Anel para linhas

energizadas do

interruptor da catraca

24

Anel para linhas

energizadas do

gancho flutuante

Page 25

INSTRUÇÕES DE OPERAÇÃO

Montar a talha para linha única ou dupla:

1. Linha única – somente o gancho fixo deve ser preso na carga.

ADVERTÊNCIA: NÃO prenda um gancho flutuante a uma carga para uma linha única.

ADVERTÊNCIA: Nunca coloque uma alça trançada em uma posição de obstrução prendendo

ADVERTÊNCIA: Veja se a linga ou qualquer outro dispositivo está assentado corretamente

osdois ganchos entre eles.

nobojo do gancho e a trava está bem fechada antes de puxar. Não use a

travadoguincho para apoiar nenhuma parte da carga.

2. Linha dupla –

Puxar a alça trançada:

1. Para liberar a tensão da alça trançada, coloque o interruptor da catraca em “D” na manopla.

2. Use a manopla para colocar a alça trançada para frente ou fora do tambor.

3. Para soltar o cabo mais rapidamente, coloque a catraca em neutro ou posição “N”, solte a lingueta do disco de freio

com uma mão, e puxe a alça trançada com a outra.

CUIDADO: Quando estiver em uso, deixe, no mínimo, duas voltas da alça trançada no tambor ao puxar.

CUIDADO: Quando a alça trançada estiver totalmente compensada, NÃO tente soltá-la. Isso pode danificar

Colocar tensão na alça trançada com uma carga presa:

1. Mova a catraca para cima ou para a posição “U”.

2. Use a manopla para colocar a alça trançada para cima ou em “U”. Continue a colocar a catraca para cima, até que

não haja mais nenhuma parte frouxa na alça trançada.

Liberar a tensão na alça trançada com uma carga presa:

1. Coloque a catraca para baixo ou na posição “D”

2. Coloque a catraca para baixo até sentir a liberação do freio de tensão (normalmente depois de uma catraca completa).

3. Quando o freio de tensão for liberado, continue a colocar a catraca para baixo até que solte a carga com segurança.

CUIDADO: NÃO solte a carga, nem libere a tensão, enquanto o interruptor da catraca estiver para cima ou

O gancho fixo deve ser preso ao olhal do corpo do puxador. O gancho flutuante deve ser

preso à carga.

a alça trançada e/ou mecanismo do freio.

na posição “U”. Isso faz o mecanismo do freio travar. (Se travar, coloque a tensão de volta na

alça trançada. Coloque a catraca para baixo ou na posição “D” para liberar o freio de tensão).

Enrolar novamente a alça trançada:

1. Para enrolar novamente a alça trançada, coloque a catraca em “U” na manopla.

2. Use a manopla para colocar a alça trançada de volta ao tambor.

3. Para o retorno mais rápido, coloque a catraca em neutro ou na posição “N” e gire manualmente o botão de tambor

na direção de “U” ou para cima.

ADVERTÊNCIA: NÃO tente desenrolar manualmente o tambor, caso tenha uma carga presa.

CUIDADO:

Verifique se a alça trançada no tambor está sempre virada para cima ou em “U”.

25

Page 26

PORTUGUÊS

INSPEÇÃO DA TALHA

Devem ser realizadas inspeções frequentes e periódicas da alça trançada nos intervalos descritos abaixo para garantir

a operação correta e a segurança da talha.

Inspeções frequentes exigem um exame visual (não é preciso fazer registros) pelo operador ou por outra pessoa

designada. Se, durante a inspeção, forem encontradas condições de perigo, a pessoa designada deve determinar

seépreciso fazer uma inspeção mais detalhada. Devem ser realizadas inspeções frequentes nos seguintes intervalos:

• Serviço normal - mensalmente

• Serviço pesado - semanal a mensalmente

• Serviço severo - diariamente a semanalmente

• Serviço especial ou não frequente - conforme recomendado por uma pessoa qualificada, antes e depois de

cadaocorrência.

• As talhas que ficarem sem funcionar por um mês ou mais, mas por menos de um ano, devem passar por uma

inspeção frequente antes de serem colocados de volta em serviço.

Inspeções periódicas exigem uma inspeção visual por uma pessoa designada que registra as condições externas da

talha para dar uma base para a inspeção contínua. Se, durante a inspeção, forem encontradas condições de perigo,

apessoa designada deve determinar se é preciso desmontar a talha. Devem ser realizadas inspeções periódicas nos

seguintes intervalos:

• Serviço normal - anualmente

• Serviço pesado - semestralmente

• Serviço severo - trimestralmente

• Serviço especial ou não frequente - conforme recomendado por uma pessoa qualificada antes dessa primeira

ocorrência e conforme direcionado pela pessoa qualificada para qualquer ocorrência subsequente.

• As talhas que ficarem fora de serviço por um ano ou mais devem passar por uma inspeção periódica antes de

serem colocadas de volta em serviço.

A tabela a seguir detalha os itens necessários para as inspeções Frequente e Periódica. Há uma tabela separada

incluída neste manual de instrução para registrar todas as Inspeções periódicas.

Serviço normal Serviço pesado Serviço severo

Item para inspeção

Inspeção frequente

Todos os mecanismos funcionais

paradesajustes e sons incomuns

Ganchos (conforme indicado

nestemanual)

Operação da trava do gancho,

se for utilizado

Alça trançada (conforme indicado

nestemanual)

Alavanca para verificar se há dobras,

rachaduras, etc.

Suporte da talha quanto à danificação

Visual

Mensal-

mente

Registro

Anual-

mente

Visual

Semanal

amensal-

mente

Registro

Semestral-

mente

Visual

Diário a

semanal-

mente

• • •

• • •

• • •

• • •

• • •

• • •

26

Registro

Trimestral-

mente

Page 27

Item para inspeção

Inspeção periódica

Serviço normal Serviço pesado Serviço severo

Visual

Mensal-

mente

Registro

Anual-

mente

Visual

Semanal

a mensal-

mente

Registro

Semestral-

mente

Visual

Diário a

semanal-

mente

Trimestral-

Registro

mente

Especificações para inspeção frequente

Evidência de parafusos, porcas ou

rebites soltos

Evidência de peças desgastadas,

corroídas, rachadas ou distorcidas,

como blocos de carga, carcaça de

suspensão, alavancas, fixação das alças

trançadas, fechos, ligações, parafusos

de suspensão, eixos, engrenagens,

rolamentos, pinos e dispositivos de

trava ou fixação

Evidência de danificação nas porcas

deretenção ou anéis do gancho, pinos

e soldas ou rebites usados para prender

os membros de retenção

Evidência de danos ou desgaste

excessivo das rodas dentadas de carga

Evidência de catracas, cames e linguetas

desgastadas; molas de lingueta

corroídas, esticadas ou quebradas

Rótulo indicando a classificação da carga

Conexões de extremidade e

terminações da alça trançada

ADVERTÊNCIA: Se o serviço for necessário na talha de alça trançada, todos os reparos DEVEM ser feitos

pelaKlein Tools ou por um centro autorizado. Para obter mais informações, consulte a

seçãodeGarantia/Reparos deste manual.

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

27

Page 28

PORTUGUÊS

INSPEÇÃO DA ALÇA TRANÇADA

As amarras também exigem inspeções frequentes e periódicas.

Inspeções frequentes: As amarras devem ser visualmente inspecionadas antes de cada uso. O operador, ou outra

pessoa designada, deve procurar sinais de:

• Derretimento ou carbonização

• Queimaduras ácidas ou cáusticas

• Respingo de solda

• Costura quebrada

• Cortes ou rasgos

• Encaixes ou olhais danificados

• Desgaste abrasivo

• Nós

ADVERTÊNCIA: Se houver alguma das condições acima na alça trançada, pare de utilizá-la imediatamente e entre

Inspeções periódicas: A frequência dessas inspeções deve ser determinada por uma pessoa qualificada e com

baseem fatores, como uso, ambiente e experiência prévia. Não é necessário fazer inspeção em intervalos iguais;

elasdevem ser feitas mais frequentemente quando a amarra se aproxima do final de sua vida útil.

CUIDADO: É recomendado aumentar a frequência de inspeções, caso ocorra alguma das condições abaixo:

• Desgaste severo nas conexões da extremidade

• Distorção da estrutura da alça trançada

• Evidência de danos por calor

ADVERTÊNCIA: A alça trançada deve ser substituída, independentemente de sua condição, cinco (5) anos depois

emcontato com a Klein Tools ou com o centro autorizado para substituir a alça trançada.

deser colocada em serviço.

INSPEÇÃO DO GANCHO

As inspeções frequentes e periódicas dos ganchos devem ser feitas ao mesmo tempo em que forem feitas na talha.

Osganchos devem ser retirados de serviço, e reparados ou trocados, caso ocorra alguma das condições abaixo:

• Rachaduras, cortes e sulcos

• Qualquer dobra ou deformação aparente do gancho original

• Qualquer distorção que causar um aumento na abertura da garganta

• Qualquer trava danificada ou com defeito que não feche a entrada do gancho

• Evidência de exposição excessiva ao calor ou solda não autorizada

• Evidência de alteração não autorizada, como perfuração, usinagem, furação ou outras modificações.

MANUTENÇÃO DA TALHA

• Evite armazenar a talha de alça trançada em áreas que tenham: alta umidade, poeira, areia ou que fiquem

diretamente expostas à luz solar.

• Se a talha for usada em chuva pesada ou próximo à água do mar, limpe todas as peças (exceto o cabo e a alça

trançada) com um lubrificante multiuso.

• Não deixe que a água entre em contato com a área do freio. Esse contato pode deixar o freio duro ou com defeito.

Se isso ocorrer, a unidade pode exigir uma revisão de fábrica antes do armazenamento ou de voltar ao serviço.

28

Page 29

TESTE

As talhas são testadas pela Klein Tools antes de serem vendidas. Porém, as talhas precisam de testes operacionais,

caso tenham sido alteradas, reparadas ou tenham ficado fora de serviço por 12 meses ou mais. Os testes devem

serrealizados por uma pessoa indicada e devem incluir:

• Verificação de todas as funções da talha em suspensão e descarregada.

• Depois do teste com a talha descarregada, deve-se aplicar uma carga de, pelo menos, 100 lb (linha única)

e 200 lb (linha dupla) para verificar o controle correto da carga.

Uma talha onde as peças de suspensão de carga foram alteradas, substituídas ou reparadas deve ser testada de modo

estático ou dinâmico:

• A necessidade desses testes deve ser determinada por uma pessoa qualificada.

• Deve ser preparado um relatório por escrito e colocado no arquivo.

• A carga de teste não deve ser menor que 100% ou mais que 125% da carga nominal da talha, a menos que indicado

de outra maneira pelo fabricante ou pessoa qualificada.

• A troca da alça trançada está fora deste teste de carga, mas ela deve ser testada de acordo com o teste operacional

detalhado acima.

• Os testes de ancoragens ou suspensões devem ser aprovados por uma pessoa qualificada.

MANUTENÇÃO DA ALÇA TRANÇADA

Mantenha a alça trançada protegida de sujeira, óleo, água ou outros materiais estranhos que possam danificá-la ou

causardeterioração.

Inspecione para ver se há evidências de exposição ao excesso de calor, carbonização, queimaduras por ácido,

contaminação de produtos químicos ou abrasão em excesso, como segue:

Tipo de

material

Poliéster Resistência fraca.

Exposição à

calor excessivo

As fibras ficam

sensíveis e vão

enrugar, ficar

amarronzadas e

quebrar quando

forem flexionadas.

Não deve ser

usado acima de

180 °F (82 °C).

Exposição a

produtos químicos

Boa resistência à maioria de produtos

químicos, incluindo ácido clorídrico,

álcalis aquosos e muitos outros

solventes. Exposição a produtos

químicos incompatíveis podem

mudar a cor e a textura da fibra,

parecido a uma mancha amarronzada

ou sujeira. As fibras também ficam

menos elásticas, com rachaduras

transversais causadas pelas dobras.

Exposição

a metal

fundido

ouchama

Resistência

fraca. Os

cordões

de fibra se

fundem e

ficam duros,

sensíveis e

brilhantes.

Exposição a tintas

ou solventes

Geralmente oferecem boa

resistência. Porém, a tinta

pode penetrar nos fios e secar.

Isso pode deixar o tecido ficar

mais duro e sensível e pode

até quebrar as fibras. Alguns

solventes podem afetar as fibras

(consulte também “Exposição a

Produtos Químicos”).

Exposição

próxima a

linhas elétricas

e equipamentos

Proteção fraca

(sem força

dielétrica). Não

oferece proteção

à exposição de

fios elétricos ou

equipamentos.

ADVERTÊNCIA: A alça trançada deve ser substituída, independentemente de sua condição, cinco (5) anos depois de

ser colocada em serviço.

LUBRIFICAÇÃO DA TALHA

Mantenha a engrenagem da catraca, a bola de ajuste da extremidade e a área de giro operando suavemente ao

lubrificar regularmente com um lubrificante multiuso. Limpe o excesso.

ADVERTÊNCIA: NÃO aplique lubrificante no sistema de freio.

GARANTIA E REPAROS

As talhas de alça trançada Klein e os componentes fabricados e vendidos para fins comerciais ou industriais têm

garantia contra defeitos no material e mão de obra por um ano, a partir da data da compra. NÃO EXISTEM GARANTIAS

IMPLÍCITAS DE QUALIDADE OU UTILIZAÇÃO. Conforme escolha própria, a Klein irá reparar, substituir ou reembolsar

os produtos que, sob condições normais de uso e serviço, não corresponderem a esta garantia. A Klein está isenta

dequalquer responsabilidade por danos diretos ou indiretos.

Se seu produto Klein precisa de reparo ou informações sobre como exercer seus direitos nos termos desta garantia,

entre em contato com a Klein Tools no telefone 1-800-553-4676.

29

Page 30

PORTUGUÊS

DEFINIÇÕES

Condições de operação anormais: Condições ambientais que são desfavoráveis, perigosas ou causam detrimento

na operação de uma talha, como temperatura ambiente excessivamente alta ou baixa, exposição a intempéries,

vaporcorrosivo, atmosferas com poeira ou umidade e locais perigosos.

Pessoa designada: Pessoa selecionada ou indicada pelo empregador ou seu representante, como sendo competente

para realizar tarefas específicas.

Serviço pesado: Aquele que envolve operação no limite da carga nominal, que excede o serviço normal.

Serviço normal: Serviço distribuído que envolve a operação com cargas distribuídas aleatoriamente dentro do limite

de carga nominal ou cargas uniformes, com menos de 65% da carga nominal por, no máximo, 15% do tempo.

Pessoa quali cada: Uma pessoa que, por ter um grau reconhecido em um campo aplicável, ou certificado

profissional ou que, por conhecimento abrangente, treinamento e experiência, demonstrou, com sucesso,

acapacidade de solucionar ou resolver problemas relacionados ao produto e trabalho.

Serviço severo: Aquele que envolve serviço normal ou pesado com condições de operação anormal.

Número

desérie

30

Page 31

KN1500P-EX

31

manuellement (avec courroie en let) et à la norme ASME B30.10-2009

pour les crochets.

Le présent manuel d’utilisation explique le fonctionnement, l’inspection

et les procédures d’entretien du palan à levier avec courroie en let

KN1500P-EX et du palan à levier avec courroie en let avec anneaux

desuspension KN1500P-EXH de Klein Tools.

Manuel d’utilisation

FRANÇAIS

Palan à levier avec courroie en let

KN1500P-EXH

Dispositif de levage à cliquet

àcourroie en let avec anneaux

desuspension

Les palans à levier KN1500P-EX et KN1500P-EXH de Klein Tools sont

conformes à la norme ASME B30.21-2005 pour les palans actionnés

manuellement (avec courroie en let) et à la norme ASME B30.10-2009

pour les crochets.

Le présent manuel d’utilisation explique le fonctionnement, l’inspection

et les procédures d’entretien du palan à levier avec courroie en let

KN1500P-EX et du palan à levier avec courroie en let avec anneaux

desuspension KN1500P-EXH de Klein Tools.

Español p. 11

Português p. 21

Français p. 31

KN1500P-EX

KN1500P-EXH

31

Page 32

FRANÇAIS

CARACTÉRISTIQUES GÉNÉRALES

Courroie simple

Charge nominale: 675kg (1500lb)

Distance de traction: Max: 3500mm (138po)

Min: 500mm (20po)

Courroie double

Charge nominale: 1350kg (3000lb)

Distance de traction: Max: 2000mm (79po)

Min: 700mm (26po)

DANGER:

pourobtenir la distance de traction appropriée conformément à la règlementation OSHA, sous-partieV, 1926.950

ou selon les meilleures pratiques adoptées par votre entreprise.

latension nominale si la poignée bascule plus près d’une ligne sous tension que la distance minimale indiquée

parOSHA ou par votre entreprise.

Le palan n’est PAS un élément isolant. Utiliser un élément isolant approprié en série avec le palan

Utiliser des vêtements et des gants appropriés à

RÈGLEMENTATION OSHA, SOUS-PARTIEV, 1926.950 TABLEAUV-1

Courant alternatif – Distance minimale

Plage de tension

(entre phases),

kilovolts

2,1 à 15 2pi 0po 161 à 169 3pi 8po

15,1 à 35 2pi 4po 230 à 242 5pi 0po

35,1 à 46 2 pi 6po 345 à 362 7pi 0po

46,1 à 72,5 3pi 0po 500 à 552 11pi 0po

72,6 à 121 3pi 4po 700 à 765 15pi 0po

138 à 145 3pi 6po

Distance

d’utilisation

minimale

Plage de tension

(entre phases),

kilovolts

Distance

d’utilisation

minimale

AVERTISSEMENTS

Pour KN1500P-EX et KN1500P-EXH:

• Le non-respect des directives suivantes pourrait entraîner de graves blessures ou la mort.

• Ne pas tenter d’ajuster, de réparer ou de modifier une quelconque partie du palan.

• Ne pas soulever une charge supérieure à la charge nominale.

• Ne pas utiliser le palan lorsqu’il ne peut pas être orienté en ligne droite avec la charge.

• Ne pas utiliser le palan lorsque la courroie en filet est tordue, déformée ou endommagée.

• Ne pas utiliser un palan endommagé ou défectueux.

• Ne pas utiliser le palan pour soulever des charges.

• Ne pas utiliser le palan pour soulever des personnes.

• Ne pas utiliser le palan pour soulever des charges au-dessus de personnes.

• Ne pas utiliser le palan avec une rallonge fixée à la poignée.

• Ne pas retirer ou masquer les étiquettes d’avertissements.

Autres avertissements pour KN1500P-EXH:

• Les anneaux de suspension ne sont PAS conçus pour tirer des charges.

• Les anneaux de suspension ne protègent PAS contre l’électrocution et sont conçus pour être

utilisés avec une perche isolante.

32

Page 33

AVANT D’UTILISER LE PALAN ET DE MANIPULER LA CHARGE

Avant d’utiliser le palan, s’assurer de remplir les conditions suivantes:

• La structure de soutien ou le dispositif d’ancrage doivent avoir une capacité de charge égale ou supérieure

àcelle du palan.

• L’opérateur a lu et compris toutes les informations comprises dans le présent manuel et est familier avec

l’utilisation de l’appareil, les pratiques de levage et les avertissements associés à l’utilisation du palan.

• S’il est nécessaire d’effectuer des réparations ou d’apporter des ajustements au palan, en informer sans délai

lapersonne désignée.

• Le palan ne doit être utilisé qu’à un emplacement où l’opérateur peut s’éloigner de la charge.

• L’utilisateur ne doit pas utiliser un palan portant une étiquette «Hors service».

• L’opérateur ne devrait pas tenter d’ajuster ou de réparer le palan, sauf s’il est qualifié pour effectuer de

tellesactions.

• Les palans ne devraient être actionnés manuellement que par une seule personne.

• Les palans ne devraient pas être actionnés à l’aide d’une rallonge fixée à la poignée.

Lors de la manipulation de la charge, s’assurer de remplir les conditions suivantes:

• La courroie en filet du palan n’est pas enroulée autour de la charge.

• La charge est fixée au crochet à l’aide d’un dispositif approprié.

• L’élingue ou un autre dispositif est installée de manière adéquate dans la base (creux) du crochet. Le loquet

nedevrait pas supporter, même partiellement, la charge.

• La charge n’est pas appliquée à la pointe du crochet.

• Avant d’appliquer la charge, l’opérateur devrait s’assurer que la courroie du palan n’est pas entortillée ou que

différentes parties de la courroie ne sont pas emmêlées.

• Le palan ne devrait pas être utilisé jusqu’à ce que le patin de chargement, la courroie en filet et le corps du palan

soient parallèles à la direction de traction, pour éviter une traction latérale.

• Le corps ou le cadre du palan n’est pas en contact avec un objet ou avec la structure de soutien.

• L’opérateur ne devrait pas appliquer de charge dépassant la charge nominale indiquée sur le palan ou sur le

patin de chargement, sauf lors de tests dûment autorisés.

• Une attention particulière devrait être portée à l’équilibrage de la charge et à l’attache et à l’élingage, pour prévenir

le glissement de la charge.

• L’opérateur ne devrait pas relâcher le levier de levage jusqu’à ce que le cliquet d’arrêt soit enclenché et le levier

soit immobile.