Page 1

INSTRUCTION MANUAL

ENGLISH

FRANÇAIS pg. 37

ESPAÑOL pg. 19

HVAC Clamp Meter

1000V

Ω

True RMS

Measurement

Technology

• MICROAMPS DC

• DIFFERENTIAL

TEMPERATURE

• DIGITAL

TEMPERATURE

CALIBRATION

• INRUSH CURRENT

• LOW IMPEDANCE

CL450

Page 2

2

GENERAL SPECIFICATIONS

The Klein Tools CL450 is an automatically ranging true root mean

square (TRMS) digital clamp meter that measures AC current

and Inrush current via the clamp, AC/DC voltage, Microamps DC,

resistance, continuity, frequency, capacitance, and test diodes via test

leads, and differential temperature via K-Type thermocouple probes.

• Environment: Indoor and oudoor

• Operating Altitude: 6562 ft. (2000m)

• Relative Humidity: <80% non-condensing

• Operating Temp: 32° to 122°F (0° to 50°C)

• Storage Temp: 14° to 122°F (-10° to 50°C)

• Accuracy: Values stated at 65° to 83°F (18° to 28°C)

• Temp Coefcient: 0.1 x (Quoted Accuracy) per °C above

28°C or below 18°C, corrections are required when ambient

working temp is outside of Accuracy Temp range

• Batteries: 3 x 1.5V AAA

• Dimensions: 10.04" x 3.77" x 1.59" (255 x 96 x 40 mm)

• Weight: 13.6 oz. (386 g) including batteries

• Calibration: Accurate for one year

• Standards: Conforms to UL STD 61010-1, 61010-2-032,

61010-2-033.

Certified to CSA STD C22.2 No. 61010-1,

61010-2-032, 61010-2-033.

IEC/EN 61010-1, 61010-2-032,

61010-2-033, 61326-1.

• Pollution degree: 2

• Accuracy: ± (% of reading + # of least significant digits)

• Drop Protection: 6.6 ft. (2m)

• Safety Rating: CAT IV 600V, Double insulation

CAT IV: Measurement category IV is applicable to test and

measuring circuits connected at the source of the building’s

low-voltage MAINS installation.

• Electromagnetic Environment: IEC/EN 61326-1. This

equipment meets requirements for use in basic and controlled

electromagnetic environments like residential properties,

business premises, and light-industrial locations.

Specifications subject to change.

ENGLISH

Page 3

3

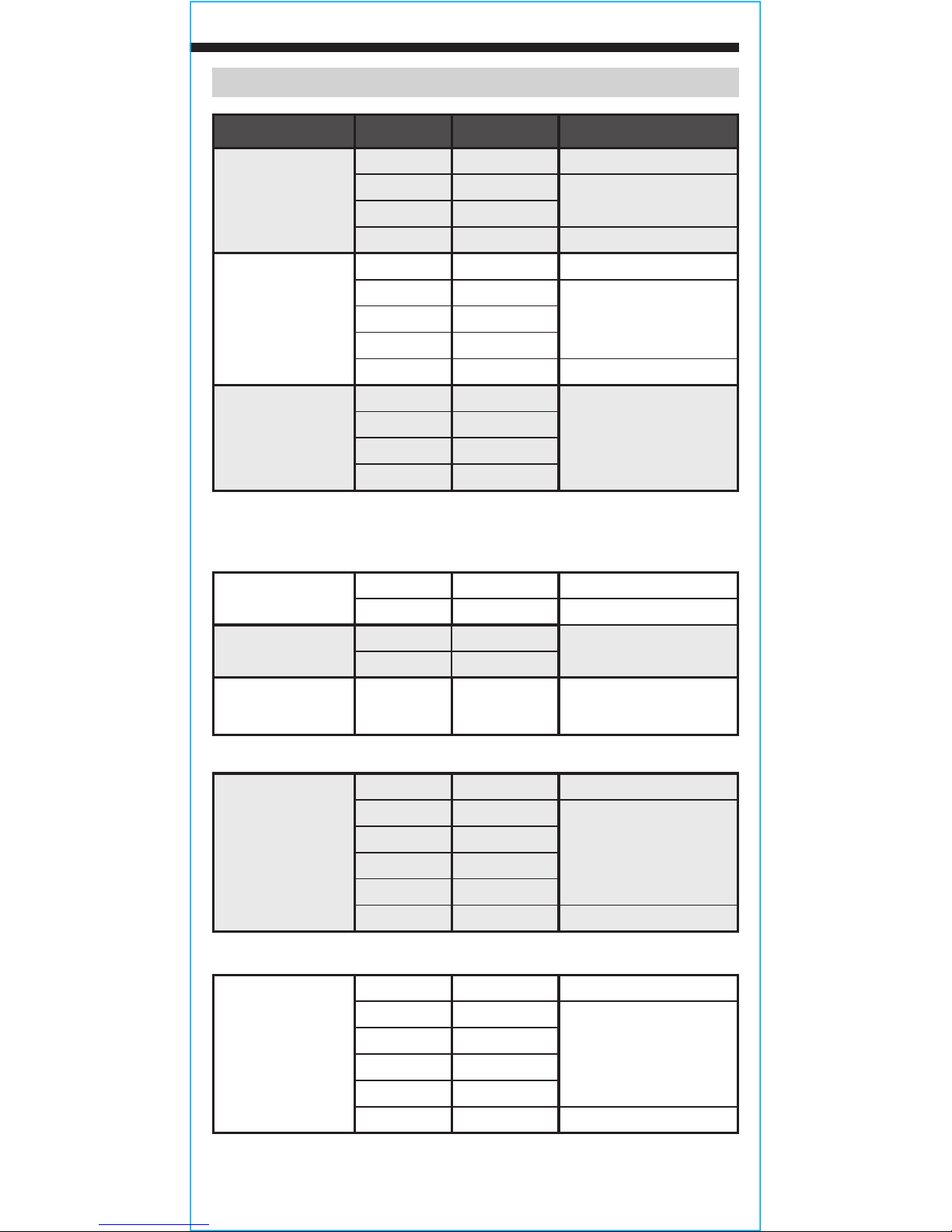

ELECTRICAL SPECIFICATIONS

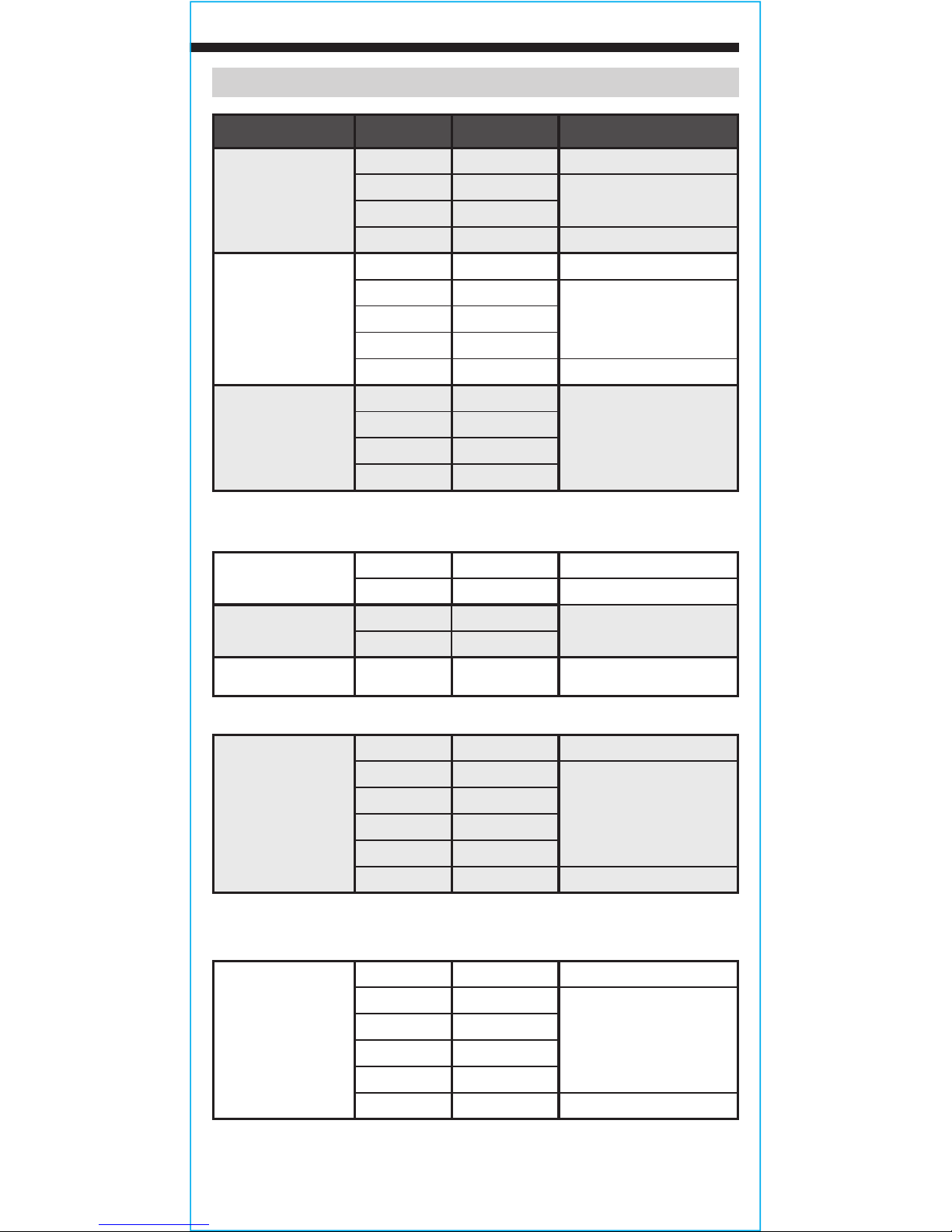

Function Range Resolution Accuracy (50/60 Hz)

AC Voltage

(V AC)

6.000V 1mV ±(1.5% + 5 digits)

60.00V 10mV

±(1.2% + 5 digits)

600.0V 100mV

1000V 1V ±(1.7% + 5 digits)

DC Voltage

(V DC)

600mV 0.1mV ±(1.0% + 8 digits)

6.000V 1mV

±(0.8% + 3 digits)60.00V 10mV

600.0V 100mV

1000V 1V ±(1.2% + 3 digits)

AC + DC

Voltage

(V)

6.000V 1mV

±(2% + 6 digits)

60.00V 10mV

600.0V 100mV

1000V 1V

Input Impedance: ≥

10MΩ

Frequency Range:

45 to 400Hz (AC only)

Maximum Input: 1000V AC RMS or 1000V DC

AC Current

(A AC)

60.00A 10mA ±(2.5% + 10 digits)

600.0A 100mA ±(2.0% + 10 digits)

AC Current (A)

Inrush

60.00A 10mA

±(10.0% + 10 digits)

600.0A 100mA

DC Current (µA) 200µA 1µA ±(0.9% + 6 digits)

Frequency Range: 50 to 60Hz (AC only)

Resistance

600.0Ω 0.1Ω ±(1.2% + 5 digits)

6.000KΩ 1Ω

±(1.2% + 3 digits)

60.00kΩ 10Ω

600.0kΩ 100Ω

6.000MΩ 1kΩ

60.00MΩ 10kΩ ±(2.0% + 5 digits)

Maximum Input: 600V AC RMS or 600V DC

Capacitance

60.00nF 0.010nF ±(4.0% + 25 digits)

600.0nF 0.1nF

±(4.0% + 8 digits)

6.000µF 0.001µF

60.00µF 0.01µF

600.0µF 0.1µF

6000µF 1µF ±(10.0% + 9 digits)

Maximum Input: 600V AC RMS or 600V DC

Page 4

4

ENGLISH

WARNINGS

To ensure safe operation and service of the meter, follow these instructions.

Failure to observe these warnings can result in severe injury or death.

• Before each use verify meter operation by measuring a known voltage

or current.

• Never use the meter on a circuit with voltages that exceed the

category based rating of this meter.

• Do not use the meter during electrical storms or in wet weather.

• Do not use the meter or test leads if they appear to be damaged.

• Use only with CAT IV rated test leads.

• Ensure meter leads are fully seated, and keep fingers away from the

metal probe contacts when making measurements.

ELECTRICAL SPECIFICATIONS

Function Range Resolution Accuracy

Temperature

(Fahrenheit)

-40° to 32°F

0.1

°F

±(2.0% + 6°F)

33° to 932°F

±(1.0% + 2°F)

933° to 1832°F

1

°F

±(1.5% + 6°F)

Temperature

(Celsius)

-40° to 0°C

0.1

°C

±(2.0% + 3°C)

1° to 500°C

±(1.0% + 1°C)

501° to 1000°C

1

°C

±(1.5% + 3°C)

FREQUENCY (AUTO-RANGING)

99.99Hz 0.01Hz

±(1.0% + 5 digits)

999.9Hz 0.1Hz

9.999kHz 1Hz

99.99kHz 10Hz

999.9kHz 100Hz

Measurement Range: 10Hz – 1MHz

≤100kHz – 250mV rms ≤Input amplitude ≤20V rms

>100kHz – 1MHz: 600mV rms ≤Input amplitude ≤20V rms

DUTY CYCLE

0.1% to 99.9%

0.1% Reference only

Frequency width: ≤100kHz

OTHER MEASUREMENT APPLICATIONS

• Diode Test: Max. 1.0mA, open circuit voltage ~ 2.5V DC

• Continuity Check: Test current 0.5mA

• Low Impedance (Low Z): Input impedance: >3kΩ

Max input: 1000V RMS

• Auto Power off: After ~10 minutes of inactivity

• Overload:

"OL" indicated on display, overload protection

1000V in Voltage setting, 600V RMS in all other settings

• Polarity: "-" on display indicates negative polarity

• Display: 3-5/6 digit, 6000 Count LCD

Page 5

5

SYMBOLS ON METER

Alternating Current (AC) Direct Current (DC)

A

Amperage

V

Voltage

µA

Micro Amps

Hz

Frequency

°

F

Degrees Fahrenheit

°

C

Degrees Celsius

Audible Continuity

%

Duty-Cycle

Diode Test Low Impedance

Capacitance Resistance (Ohms)

+ Positive – Negative

COM

Common Ground

Double Insulated Class II

Warning or Caution:

To ensure safe operation and service of this meter,

follow all warnings and instructions detailed in this manual.

Risk of Electrical Shock:

I

mproper use of this meter can lead to risk of

electrical shock. Follow all warnings and instructions detailed in this manual.

Risk of Electrical Shock:

Application around and removal from

UNINSULATED HAZARDOUS LIVE conductors is permitted.

SYMBOLS ON LCD

AC

AC Measurement DC DC Measurement

Negative Reading Data Hold

Auto Ranging

MAX

Maximum Value Hold

MIN

Minimum Value Hold Low Battery

Auto Power Off Audible Continuity

Diode Test High Voltage

k

kilo (value x 103)

m

mili (value x 10-3)

M

Mega (value x 106)

n

nano (value x 10-9)

μ

micro (value x 10-6)

V

Volts

Ohms

F

Farads

A

Amps Relative Mode

LoZ

Low Impedance

%

Duty Cycle

Hz

Frequency (Hertz)

°

C

Degrees (Celsius)

°

F

Degrees (Fahrenheit)

INRUSH

Inrush Current

LPF

Low-Pass Filter

T1

T1 Temperature

T2

T2 Temperature

T-CAL

Temperature Calibration

T1-T2

Differential Temperature

AVG

Average

AC+DC

AC Voltage + DC Voltage

WARNINGS

• Use caution when working with voltages above 25V AC RMS or

60V DC. Such voltages pose a shock hazard.

• To avoid false readings that can lead to electrical shock, replace

batteries when a low battery indicator appears.

• Do not attempt to measure resistance or continuity on a live circuit.

• Always adhere to local and national safety codes. Use personal

protective equipment to prevent shock and arc blast injury where

hazardous live conductors are exposed.

• Do not attempt to measure voltages greater than 600V in LoZ setting.

• To avoid risk of electric shock, disconnect leads from any voltage

source before removing battery door.

• To avoid risk of electric shock, do not operate meter while battery

door is removed.

Page 6

6

ENGLISH

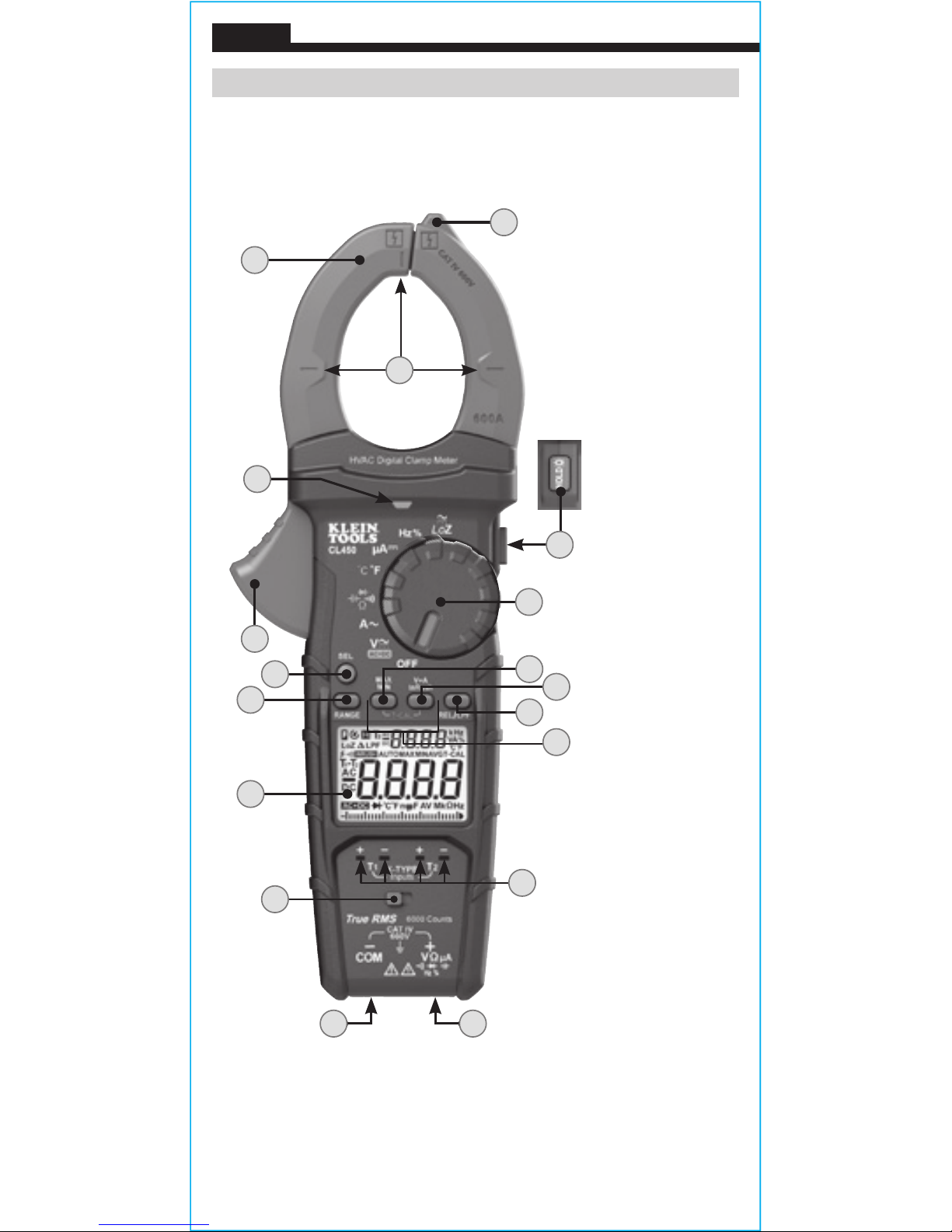

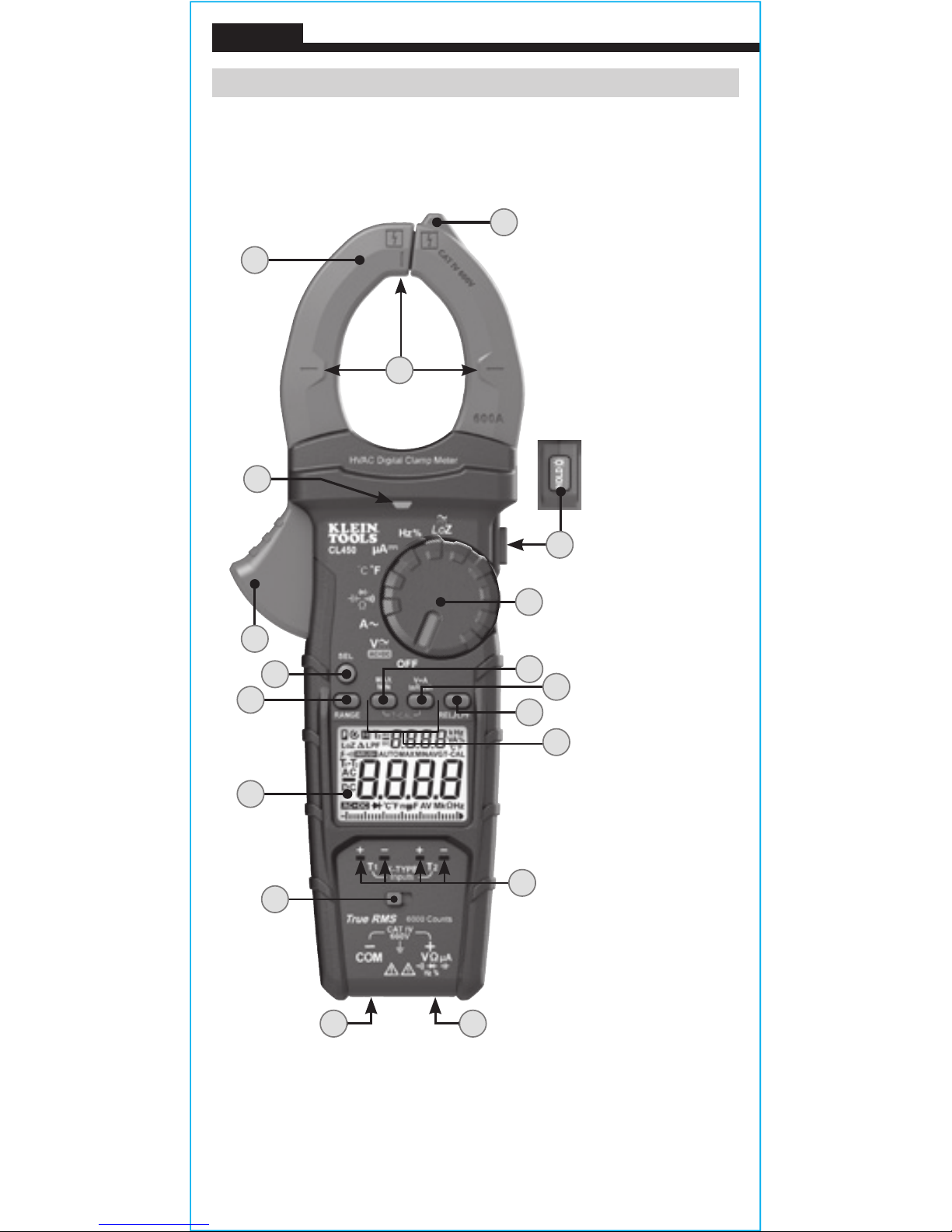

FEATURE DETAILS

NOTE: There are no user-serviceable

parts inside meter.

1.

6000 count

LCD display

2.

Function

selector

switch

3.

Clamp

4.

"COM" jack

5.

"VΩ" jack

6.

Data Hold /

Backlight

button

7.

"RANGE"

button

8.

"MAX/MIN"

button

9.

SEL (select)

button

10.

V+A /

Inrush Current

button

11.

Relative /

Low-Pass Filter

button

12.

Temperature

Calibration

buttons

13.

Clamp trigger

(press to open

clamp)

14.

Arrow markings

15.

N

on-contact

Voltage Testing

Indicator

16.

Non-Contact

Voltage Testing

Sensor

17.

K-Type

temperature

probe inputs

18.

Temperature

probe input

switch

1

9

7

3

13

10

16

15

54

8

11

6

14

12

17

18

2

Page 7

7

FUNCTION BUTTONS

ON/OFF

To power ON the meter, rotate the Function Selector switch

2

from

the OFF setting to any measurement setting. To power OFF the meter,

rotate the Function Selector switch 2 to the OFF setting. By default,

the meter will automatically power OFF after 10 minutes of inactivity.

To deactivate the power OFF functionality press and hold the SEL

button 9 before powering ON from the OFF setting. When auto

power OFF is deactivated, the Auto Power Off icon will not be

visible in the display.

SEL (SELECT) BUTTON (FOR SECONDARY FUNCTIONS)

The SEL button 9 activates the secondary function for each

application accessible by the function selector switch 2:

• In Voltage

V /

and Low Impedance modes, it toggles

between AC and DC measurements.

• In Temperature

mode, it toggles between

°F (Fahrenheit) and

°C (Celsius) measurements.

• In Continuity/Resistance/Capacitance/Diode-Test

mode, it

toggles through these measurements in order

.

The default function for each application is printed on the meter in

white, the secondary functions in orange. An icon on the LCD display

will indicate which function is active.

DATA HOLD

Press the Data Hold / Backlight button

6

to hold the measurement

on the display. Press again to release the display to return to live

measuring.

BACKLIGHT

Press and hold the Data Hold / Backlight button 6 for more than 2

seconds to turn ON the backlight. Repeat process to turn OFF.

RANGE

The meter defaults to auto-ranging mode . This mode

automatically determines the most appropriate measurement range

for the testing that is being conducted. To manually force the meter to

measure in a different range, use the Range button 7.

1. Press the "RANGE" button 7 to manually select measurement

range ( is deactivated on the LCD). Repeatedly press the

"RANGE" button 7 to cycle through the available ranges, stopping

once the desired range is reached.

2. To return to auto-ranging mode, press and hold the "RANGE"

button 7 for more than one second ( is reactivated).

Page 8

8

ENGLISH

FUNCTION BUTTONS

MAX/MIN

When the "MAX/MIN" button 8 is pressed, the meter keeps track of

the Maximum, Minimum and Average values as the meter continues

to take samples.

1. When measuring, press "MAX/MIN" button 8 to toggle between

the Maximum value (MAX), Minimum value (MIN) and Average

value (AVG). If a new Maximum, Minimum or Average occurs, the

display will update with the new value.

2. Press "MAX/MIN" button 8 for more than one second to return to

normal measuring mode.

RELATIVE MODE

When the REL/LPF button

11

is pressed, the meter will show the

relative value on the main display and real time measurement on the

secondary display. Press the REL/LPF button

11

to return to normal

measuring mode.

LOW-PASS FREQUENCY MODE

For voltage readings of high frequency motors, long press the REL/

LPF button

11

and meter will apply a low pass filter to ensure a more

accurate reading. Long press the REL/LPF button

11

to return to

normal measuring mode.

NON-CONTACT VOLTAGE TESTING

Approach the conductor under test leading with the non-contact

voltage sensor

16

. The meter delivers visual warning signals 15

when AC voltage is detected by the non-contact voltage sensor.

OPERATING INSTRUCTIONS

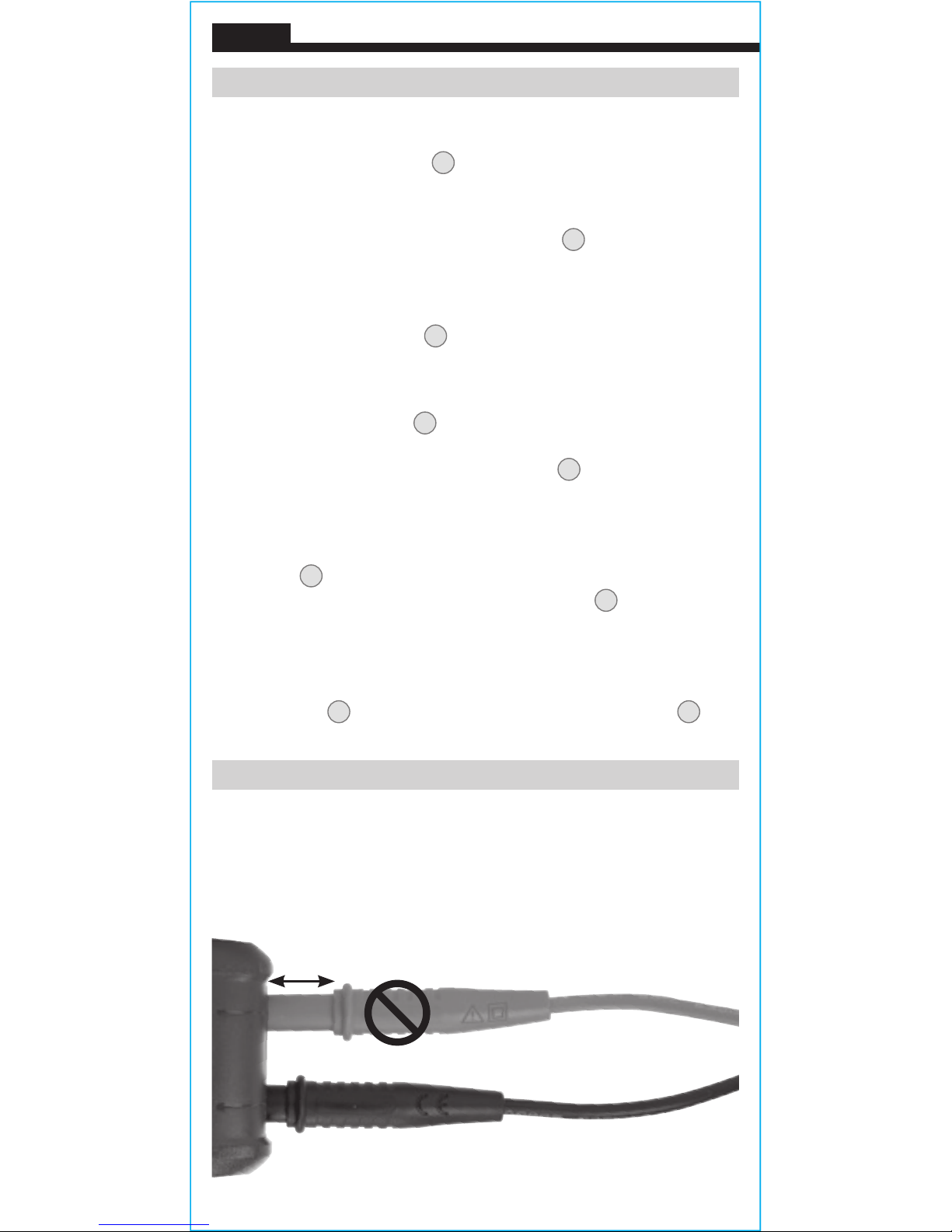

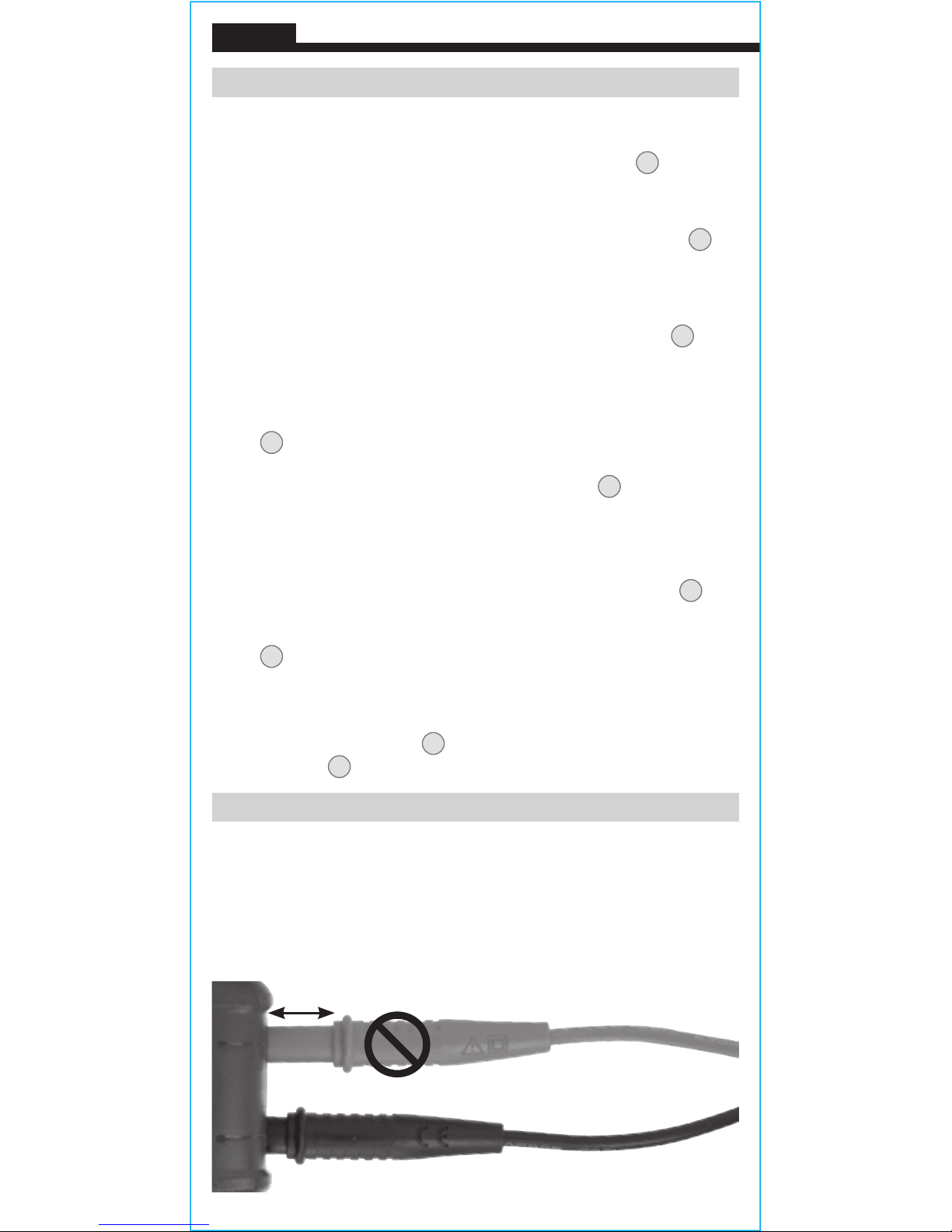

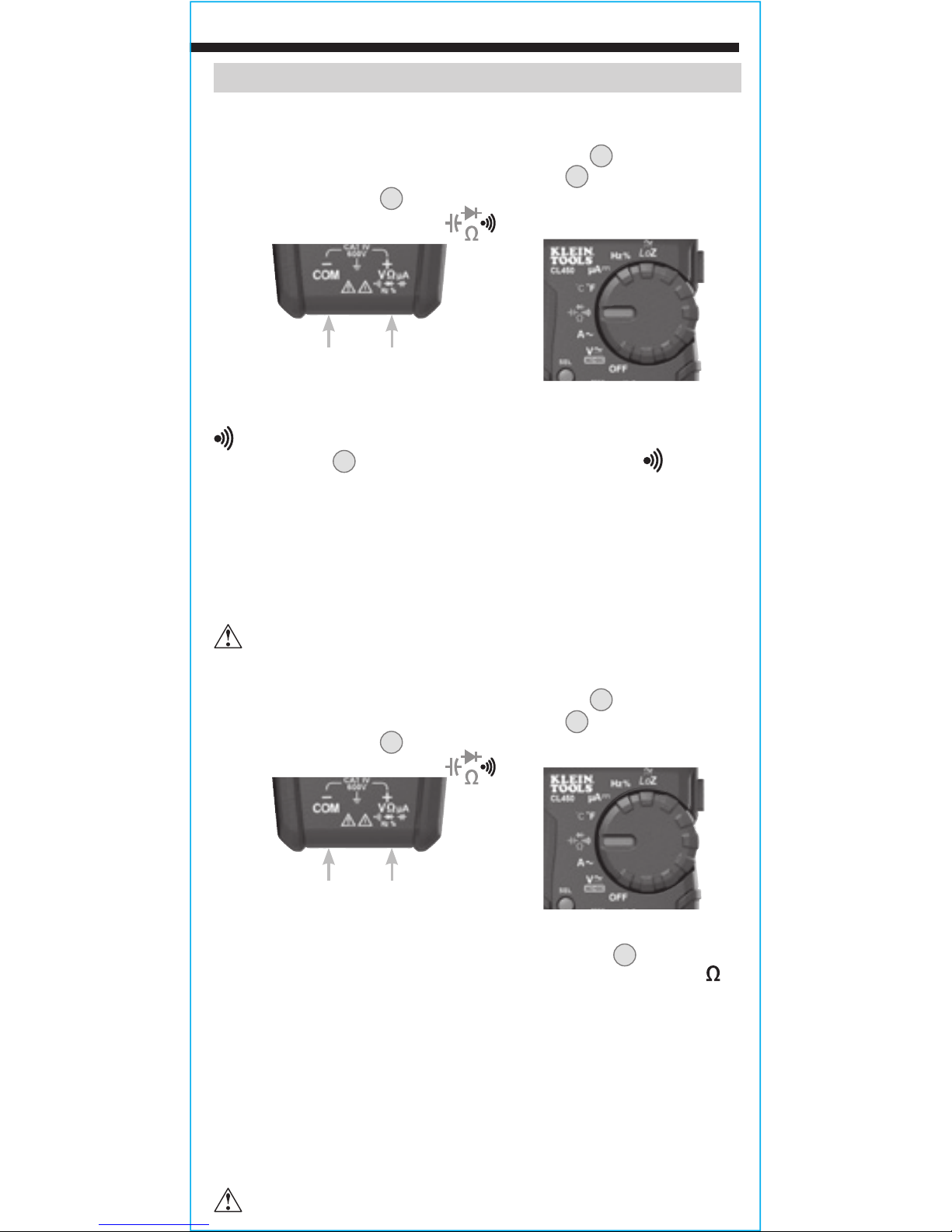

CONNECTING TEST LEADS

Do not test if leads are improperly seated. Results could cause

intermittent display readings. To ensure proper connection, firmly

press leads into the input jack completely.

INCORRECT

CORRECT

Page 9

9

OPERATING INSTRUCTIONS

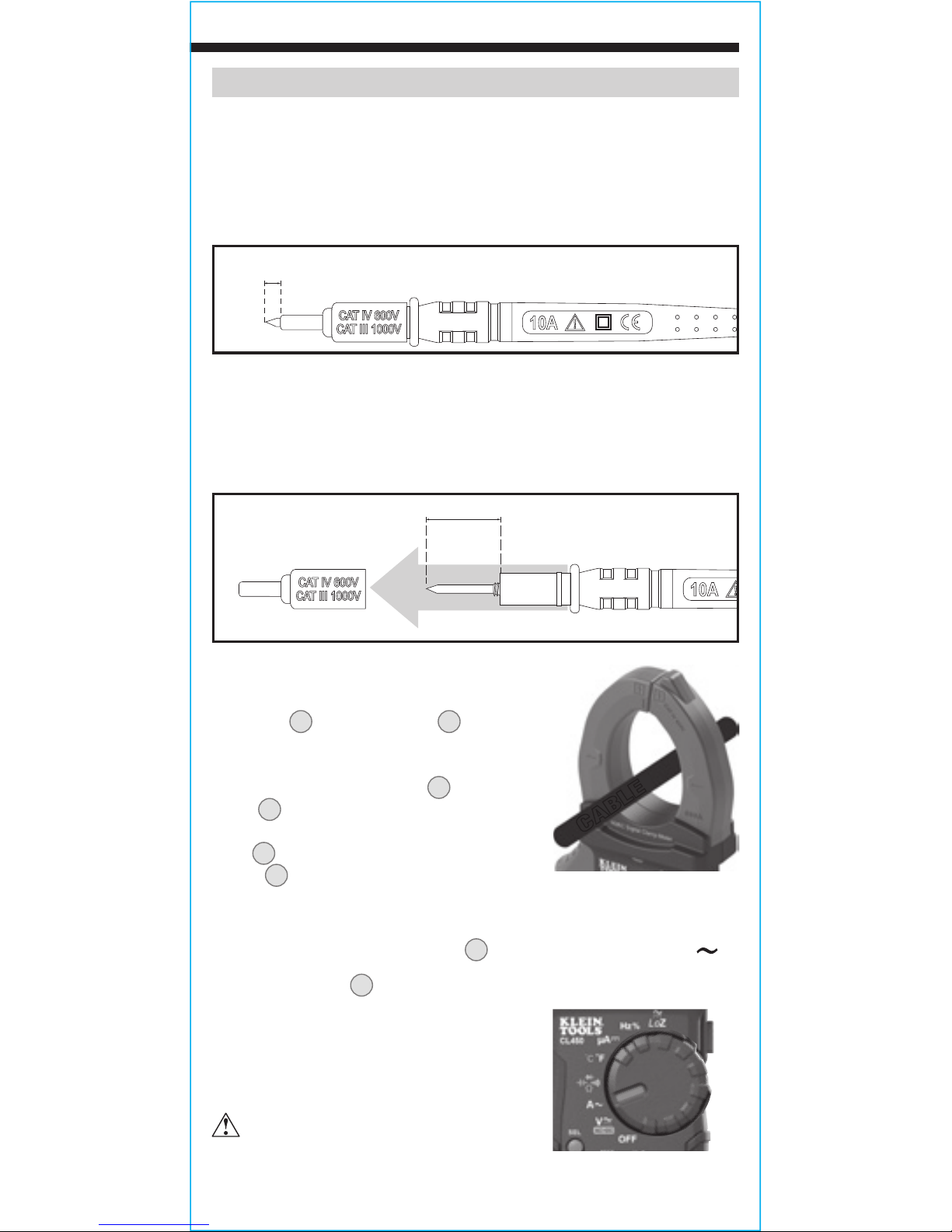

TESTING IN CAT III / CAT IV MEASUREMENT LOCATIONS

Ensure the test lead shield is pressed firmly in place. Failure to use

the CATIII / CATIV shield increases arc-flash risk.

TESTING IN CAT II MEASUREMENT LOCATIONS

CAT III / CAT IV shields may be removed for CAT II locations. This

will allow testing on recessed conductors such as standard wall

outlets. Take care not to lose the shields.

AC CURRENT (LESS THAN 600A)

AC Current is measured by pressing the

clamp trigger

13

to open the clamp 3 and

placing it around a current-carrying wire.

When measuring, care should be taken to

ensure that the clamp 3 is completely

closed with trigger 13 fully released, and

that the wire passes perpendicularly through

the center of the clamp 3 in line with the

arrow markings 14.

To measure current:

1. Rotate the Function Selector switch 2 to the AC current A setting.

2. Place clamp

3

around wire. The current measurement will be

shown in the display.

The meter will auto-range to display the

measurement in the most appropriate

range.

Disconnect test leads when

measuring with the clamp.

5/32"

(4 mm)

.7" (18 mm)

WIRE

Page 10

10

ENGLISH

OPERATING INSTRUCTIONS

INRUSH CURRENT

The Inrush feature captures starting current of a compressor motor.

Starting current can assist in diagnosing a motor before it fails.

To measure inrush current:

1. Rotate the Function Selector switch 2 to

the AC current A setting.

2. Place clamp

3

around wire. The

current measurement will be shown in

the display.

3. Long press the V+A/Inrush button

10

for 2 seconds to enter the Inrush mode and manually select 60A

or 600A range by pressing the RANGE button

7. Place the clamp

around the compressor start wire and turn motor on. The starting

current will hold on the main display. The Inrush measurement

period is 100-miliseconds.

4. Long press V+A/Inrush button

10 for 2 seconds to exit.

MICROAMPS DC CURRENT

Microamps DC is applied to a flame rectifier diode test on a heater

control.

1. Rotate the Function Selector switch 2

to the µA setting.

2. Connect the leads between flame sensor

probe and control module and turn on

heating unit.

3. The current measurement will be

shown in the main display.

NOTE: When the flame is on, there should be a measureable µA

DC signal, typically under 10 μA DC. Compare measurement to

manufacturer’s specifications.

Page 11

11

OPERATING INSTRUCTIONS

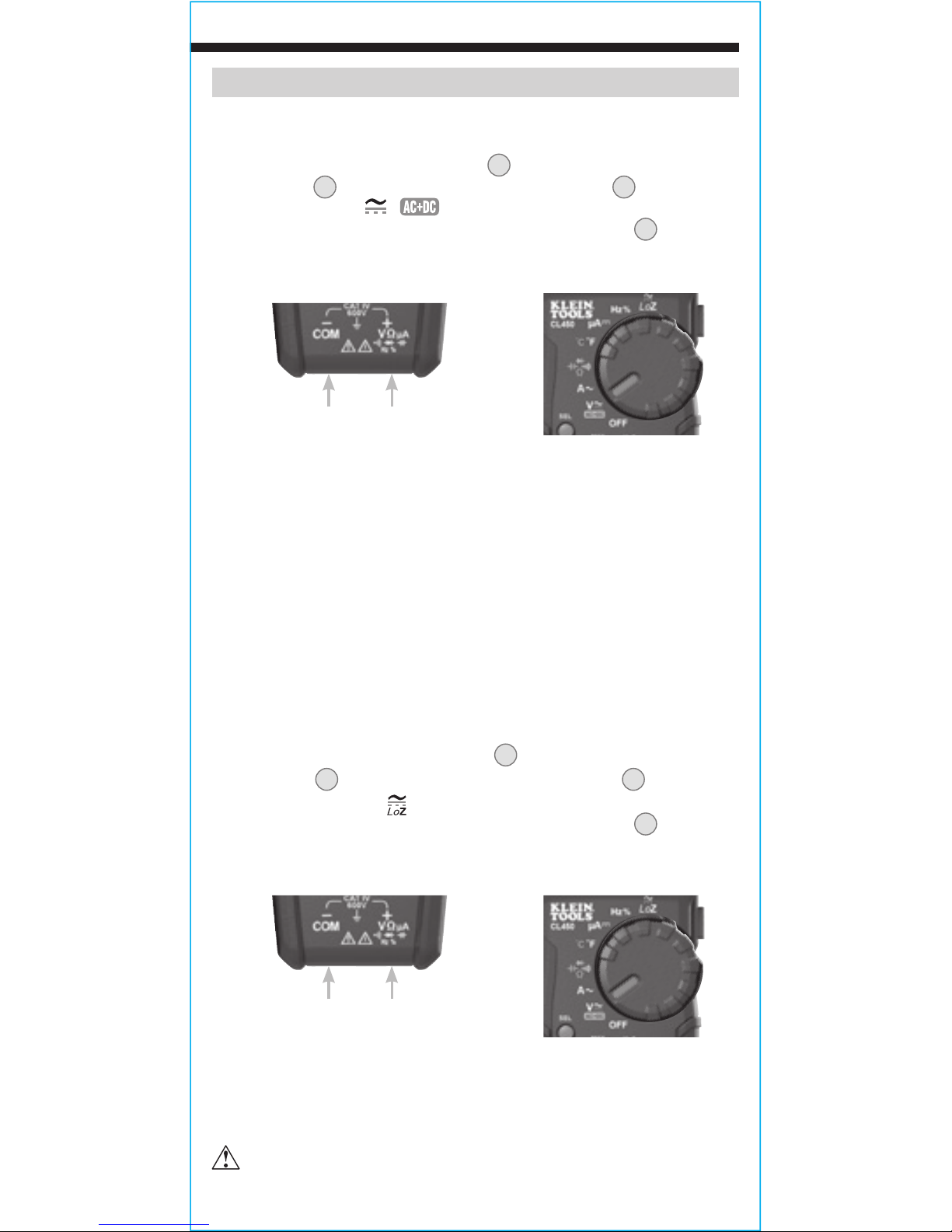

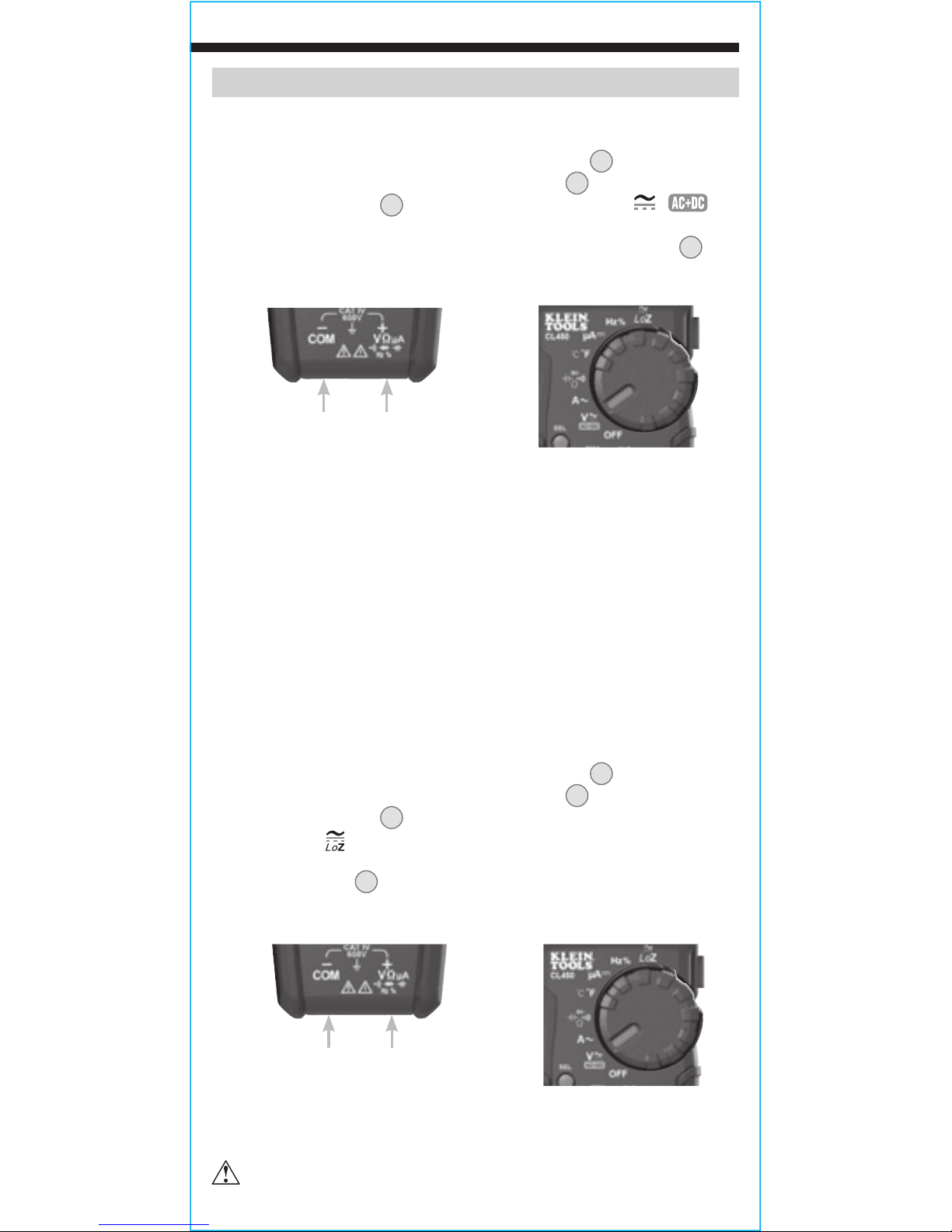

AC/DC VOLTAGE (LESS THAN 1000V)

1. Insert RED test lead into VΩ jack 5, and BLACK test lead into

COM jack 4, and rotate function selector switch 2 to the

AC/DC voltage

V

/

setting.

The meter defaults to AC

measurement.

To measure DC, press the SEL button 9 to toggle

between AC and DC modes. The AC or DC icon on the LCD

indicates which mode is selected.

2. Apply test leads to the circuit to be tested to measure voltage.

The meter will auto-range to display the measurement in the

most appropriate range.

NOTE: If "–" appears on the LCD, the test leads are being applied to

the circuit in reverse. Swap the position of the leads to correct this.

NOTE: When in a voltage setting and the test leads are open,

readings of order mV may appear on the display. This is noise and

is normal. By touching the test leads together to close the circuit

the meter will measure zero volts.

AC/DC LoZ VOLTAGE (LESS THAN 600V)

1. Insert RED test lead into VΩ jack

5

, and BLACK test lead into

COM jack

4

, and rotate function selector switch 2 to the

AC/DC LoZ voltage setting.

The meter defaults to AC

measurement.

To measure DC, press the SEL button 9 to toggle

between AC and DC modes. The AC or DC icon on the LCD

indicates which mode is selected. Note "AC" or "DC" on the display.

2. Apply test leads to the circuit to be tested to measure voltage.

The meter will auto-range to display the measurement in the

most appropriate range.

Do not attempt to measure voltages greater than 600V

in LoZ setting.

Black lead Red lead

Black lead Red lead

Page 12

12

OPERATING INSTRUCTIONS

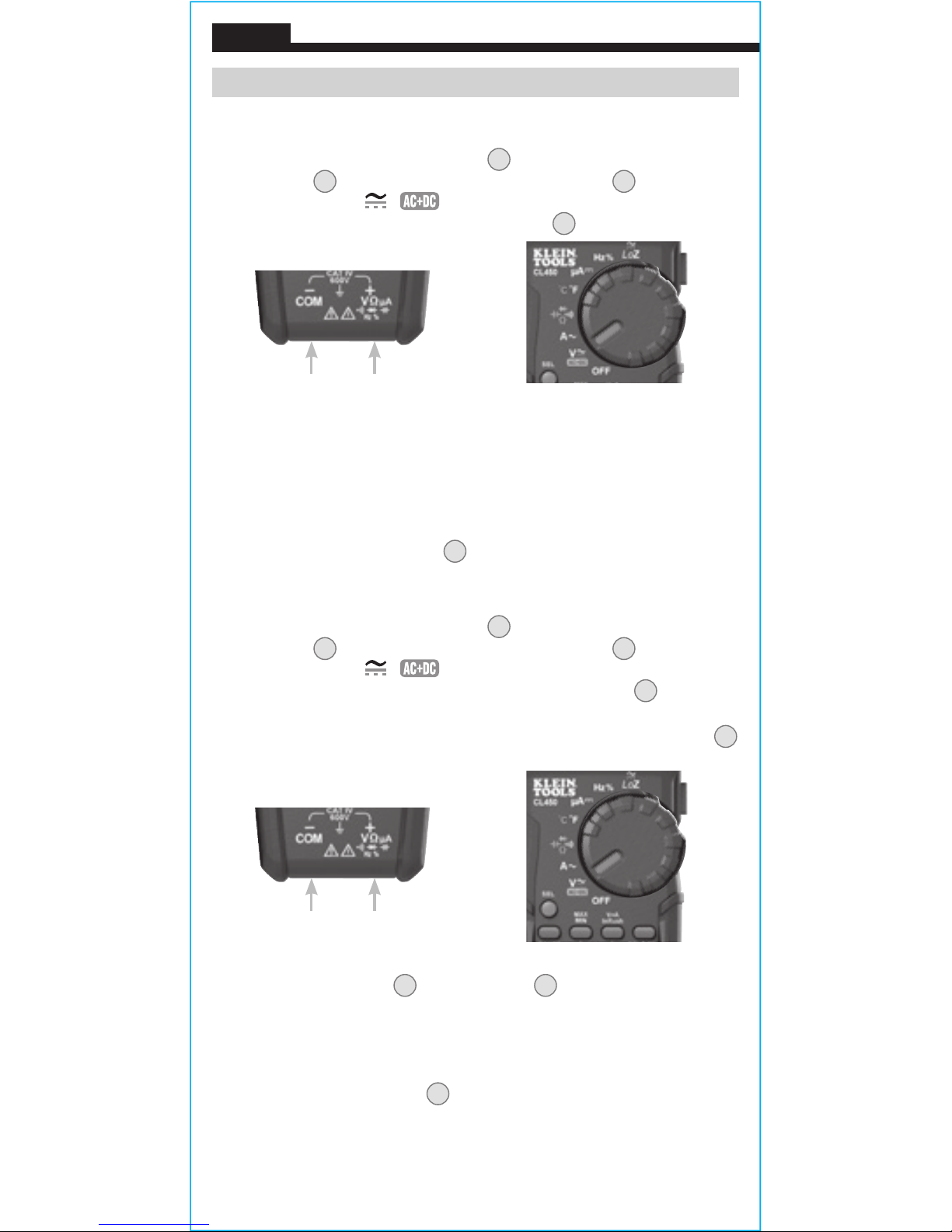

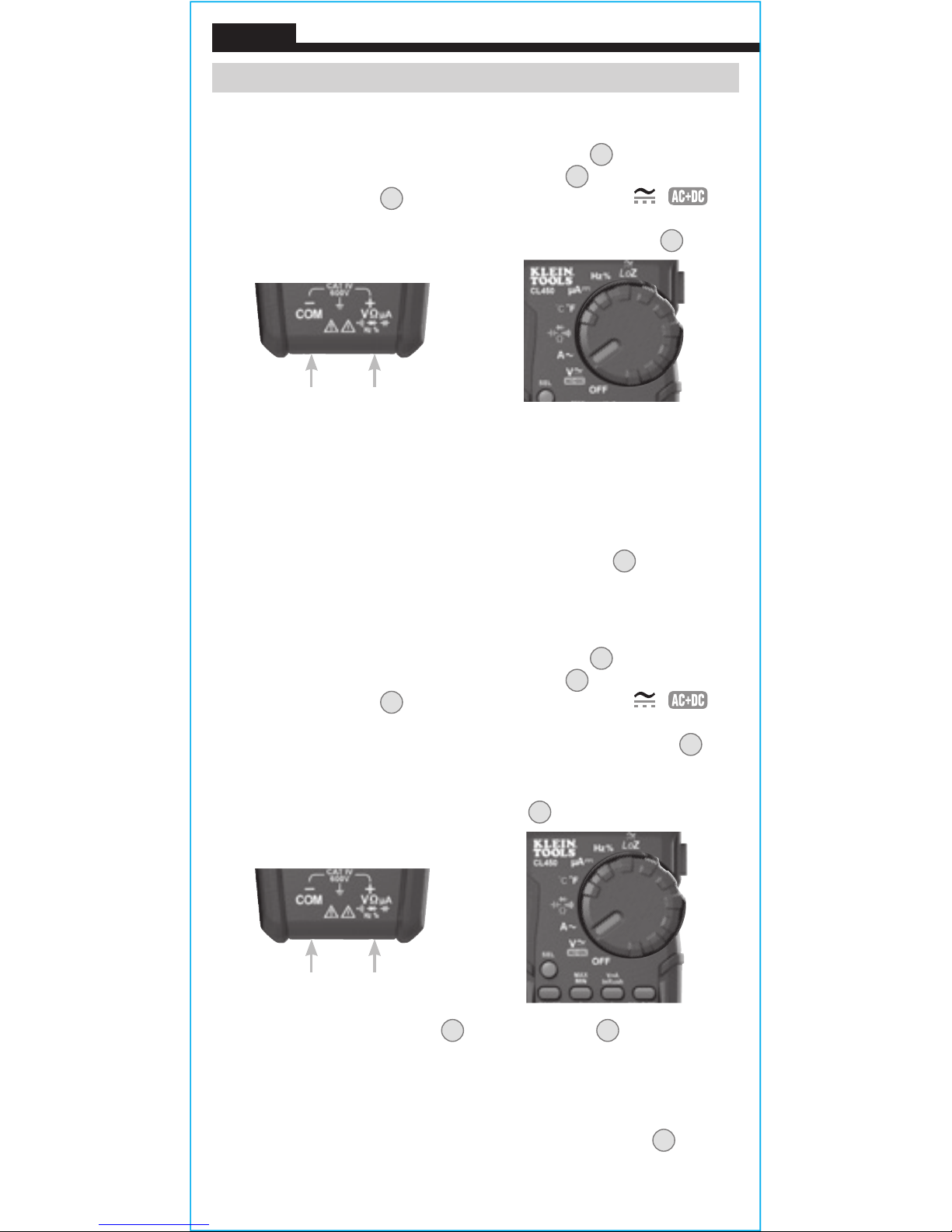

AC VOLTAGE + DC VOLTAGE FUNCTION

1. Insert RED test lead into VΩ jack 5, and BLACK test lead into

COM jack 4, and rotate function selector switch 2 to the

AC/DC voltage

V

/

setting.

The meter defaults to AC

measurement.

Long press the SEL button 9 to enter the

ACV + DCV mode.

2. Apply test leads to the circuit to be tested to measure voltage.

The meter will auto-range to display the measurement in the

most appropriate range. The ACV + DCV measurement will

be in the main display, and the secondary display will have the

individual voltages that toggle between the AC and DC voltages.

3. Long press the SEL button 9 to exit the mode.

AC VOLTAGE + AC AMPERAGE FUNCTION

1. Insert RED test lead into VΩ jack

5

, and BLACK test lead into

COM jack 4, and rotate function selector switch 2 to the

AC/DC voltage

V

/

setting.

The meter defaults to AC

measurement.

To measure DC, press the SEL button 9 to toggle

between AC and DC modes. The AC or DC icon on the LCD

indicates which mode is selected. Press the

V+A/Inrush button

10

to enter the ACV + ACA mode.

2. Press clamp trigger

13

to open clamp 3 and place around

current-carrying wire.

3. The main display will show AC Voltage and the secondary

display will show AC Amperage.

4. Press V+A/Inrush button

10 to exit.

ENGLISH

Black lead Red lead

Black lead Red lead

Page 13

13

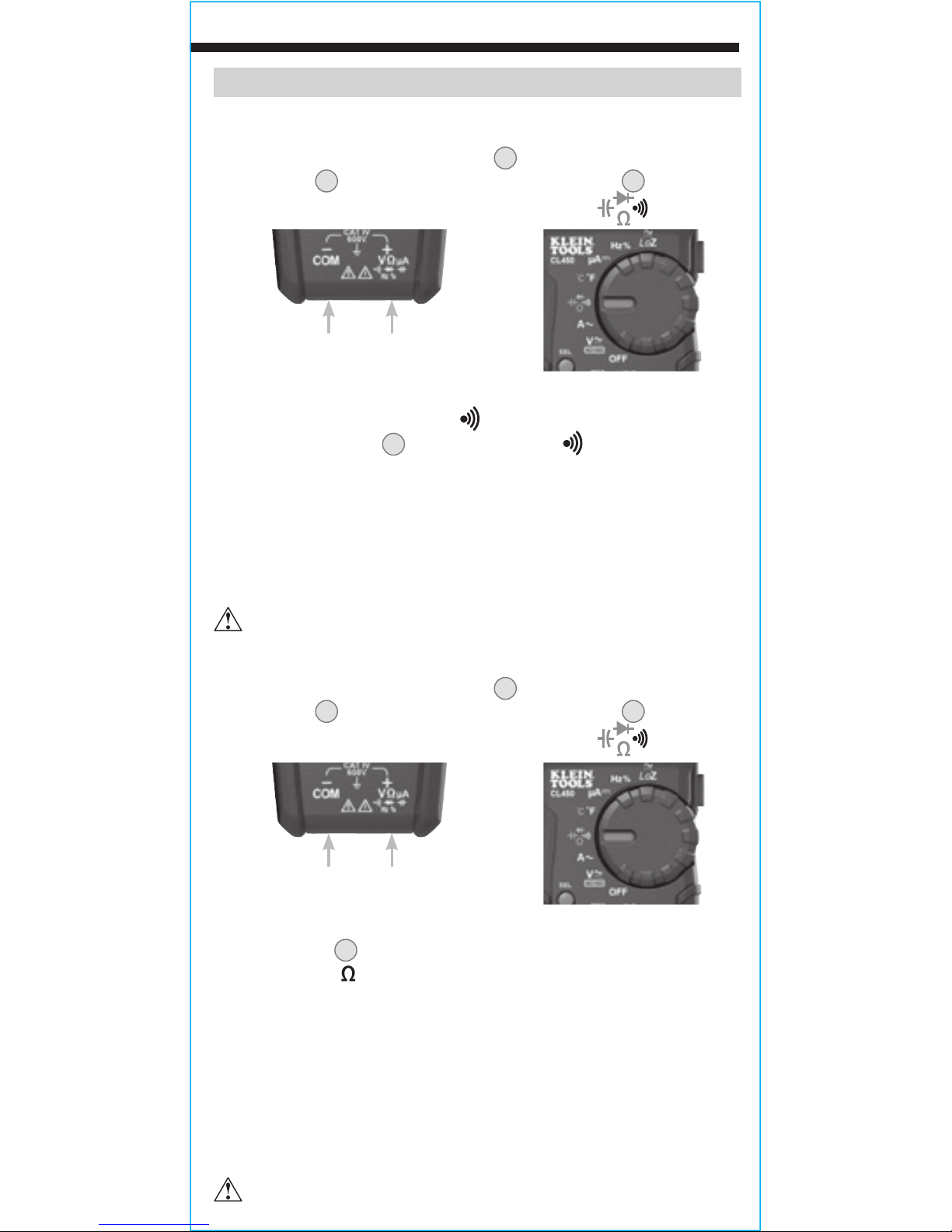

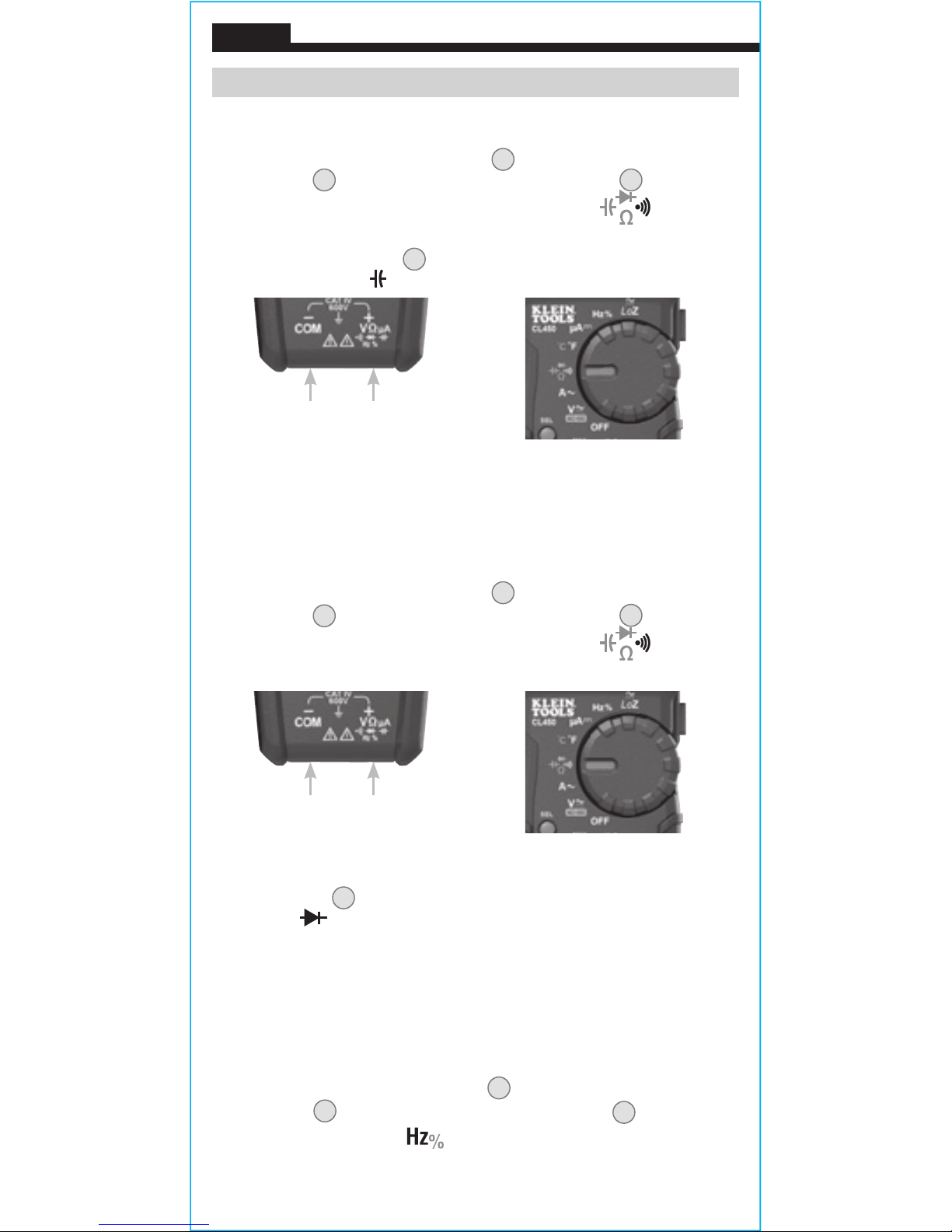

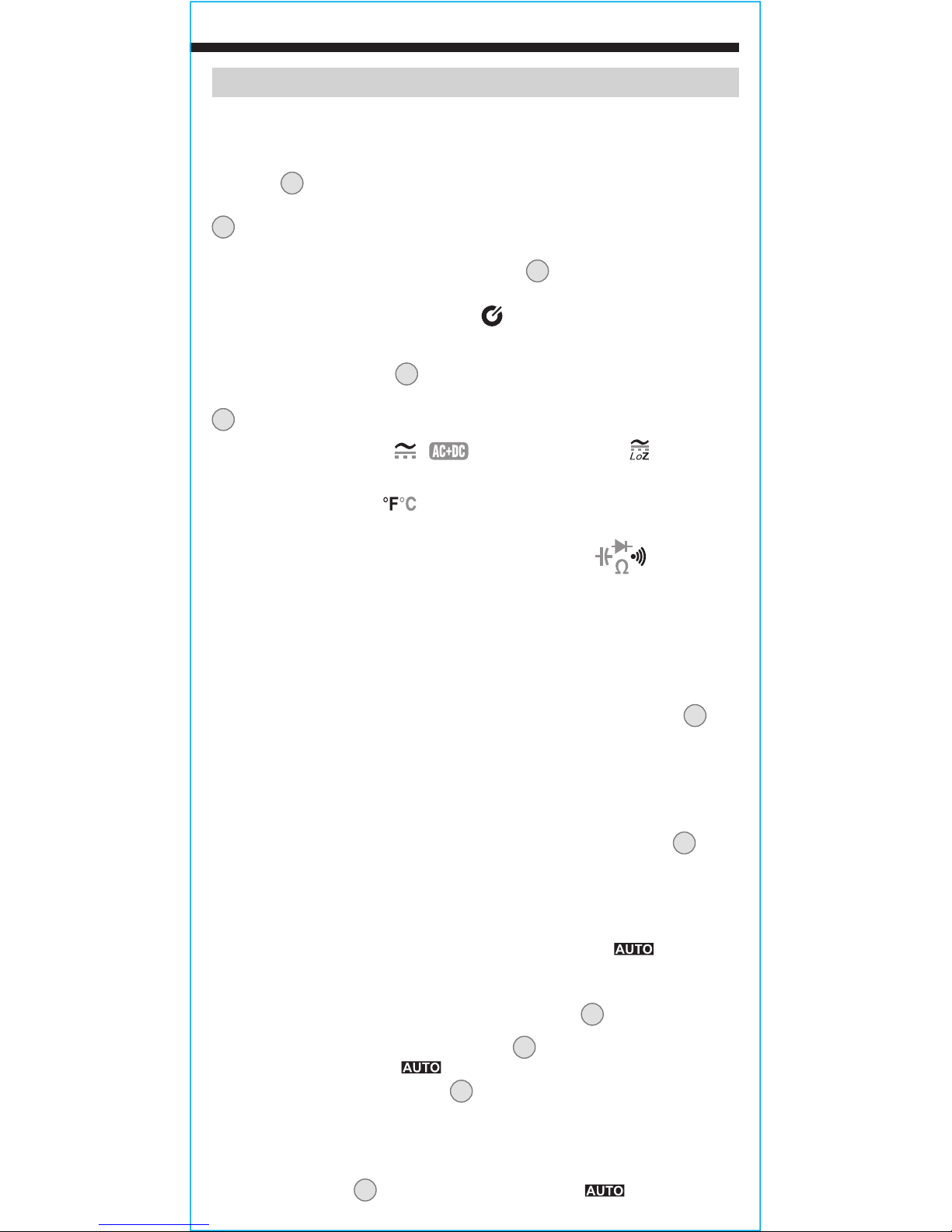

RESISTANCE MEASUREMENTS

1. Insert RED test lead into VΩ jack

5

, and BLACK test lead into

COM jack

4

, and rotate function selector switch 2 to the

Continuity/Resistance/Capacitance/Diode-Test

setting.

NOTE: The meter defaults to Continuity testing in this mode. Press

the SEL button

9

once to enter Resistance testing mode. The

Resistance icon

will appear on the display.

2. Remove power from circuit.

3. Measure resistance by connecting test leads to circuit. The

meter will auto-range to display the measurement in the most

appropriate range.

NOTE: When in a Resistance setting and the test leads are open

(not connected across a resistor), or when a failed resistor is under

test, the display will indicate O.L. This is normal.

DO NOT attempt to measure resistance on a live circuit.

CONTINUITY

1. Insert RED test lead into VΩ jack

5

, and BLACK test lead into

COM jack

4

, and rotate function selector switch 2 to the

Continuity/Resistance/Capacitance/Diode-Test

setting.

NOTE: The meter defaults to Continuity testing in this mode. Ensure

that the Continuity Testing icon

is visible on the display. If not,

press the SEL button

9

repeatedly until the icon is shown.

2. Remove power from circuit.

3. Test for continuity by connecting conductor or circuit with test

leads. If resistance is measured less than 10Ω, an audible signal

will sound and display will show a resistance value indicating

continuity. If circuit is open, display will show "OL".

DO NOT attempt to measure continuity on a live circuit.

OPERATING INSTRUCTIONS

Black lead Red lead

Black lead Red lead

Page 14

14

ENGLISH

OPERATING INSTRUCTIONS

CAPACITANCE

1. Insert RED test lead into VΩ jack 5, and BLACK test lead into

COM jack 4, and rotate function selector switch 2 to the

Continuity/Resistance/ Capacitance/Diode-Test

setting.

2.

NOTE: The meter defaults to Continuity testing in this mode.

Press the SEL button 9 twice to enter capacitance mode. The

Capacitance icon will appear on the display.

3. Remove power from circuit.

4. Measure capacitance by connecting test leads across the capacitor.

The meter will auto-range to display the measurement in the most

appropriate range.

DIODE TEST

1. Insert RED test lead into VΩ jack

5

, and BLACK test lead into

COM jack

4

, and rotate function selector switch 2 to the

Continuity/Resistance/ Capacitance/Diode-Test

setting.

NOTE: The meter defaults to Continuity testing in this mode. Press

the SEL button 9 three times to enter Diode testing mode. The

Diode icon will appear on the display.

2. Touch test leads to diode. A reading of 200-800mV on display

indicates forward bias, "OL" indicates reverse bias. An open

device will show "OL" in both polarities. A shorted device will

show approximately 0mV.

FREQUENCY / DUTY-CYCLE

1. Insert RED test lead into VΩ jack

5

and BLACK test lead into

COM jack

4

, and rotate function selector switch 2 to the

Frequency/Duty-Cycle

setting.

Black lead Red lead

Black lead Red lead

Page 15

15

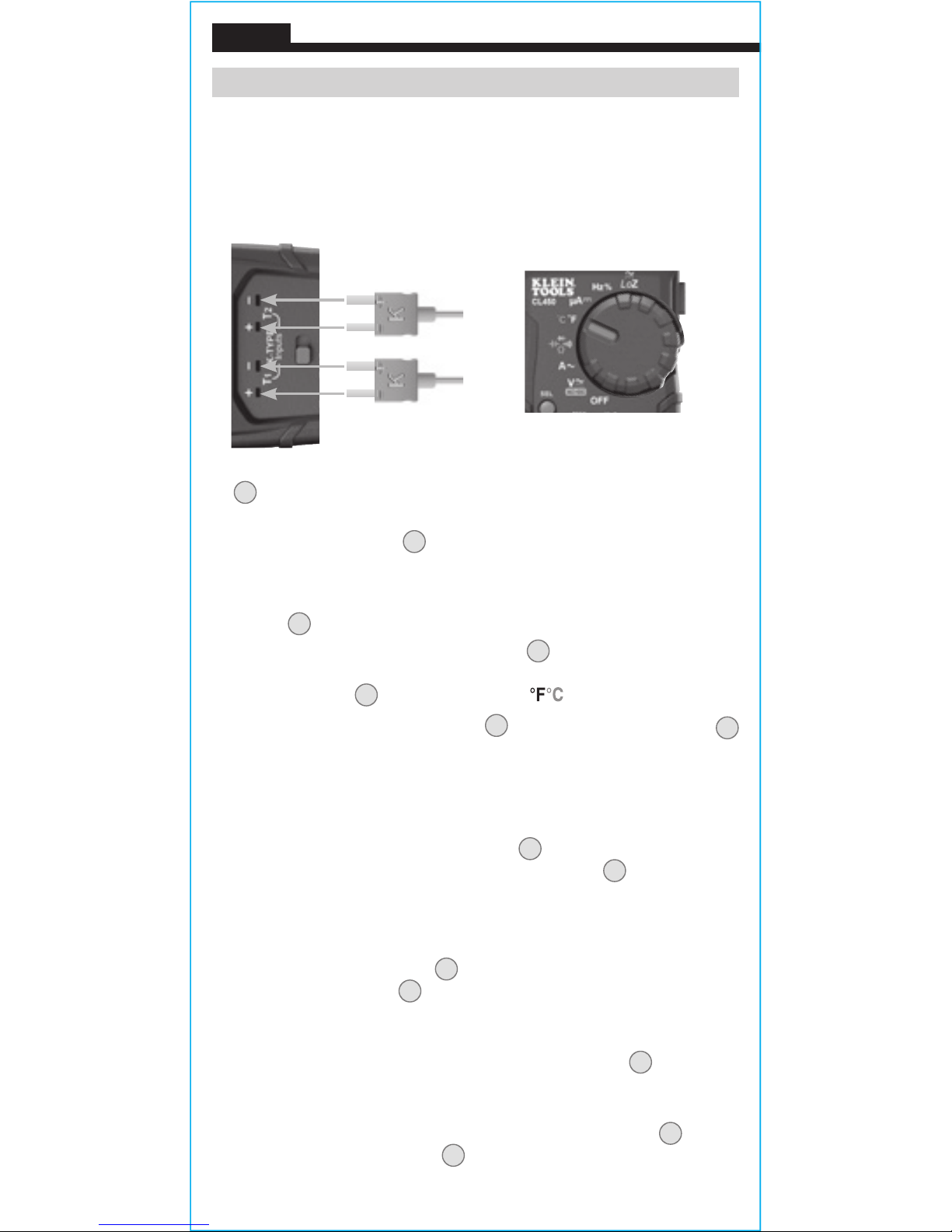

TEMPERATURE

1. Remove leads from meter and slide the temperature probe input

switch 18 to close jacks and expose the K-Type thermocouple

ports.

2. Insert K-type thermocouple into port T1 17 (observe polarity

markings on thermocouple and meter), and rotate function

selector switch 2 to the Temperature setting.

NOTE: The meter defaults to Fahrenheit scale in this mode. To

enter Celsius scale, long-press the SEL button 9. Ensure that the

appropriate icon (either °F or °C) appears on the display.

NOTE: The meter may be set to default to the Celsius scale by

powering-ON the meter from the OFF position with the Data Hold

& Backlight button

6

depressed. To re-set the default to the

Fahrenheit scale repeat the power-ON sequence.

3. To measure temperature, make contact between the

thermocouple tip and the object being measured. When

thermocouple tip and object are in thermal equilibrium, the

measurement on the display will stabilize. The meter will autorange to display the measurement in the most appropriate range.

Remove thermocouple before switching meter to other

measurement functions.

T

he thermocouple included with the original purchase

is suitable for temperatures below 356°F / 180°C only.

To measure higher temperatures, a K-type thermocouple

with the appropriate measurement range should be used.

NOTE: The main display shows Frequency and the secondary display

shows Duty-Cycle.

2. Measure by connecting test leads across the circuit.

OPERATING INSTRUCTIONS

Black lead Red lead

K-Type Thermocouple

Page 16

16

OPERATING INSTRUCTIONS

DIFFERENTIAL TEMPERATURE

1. When two K-Type thermocouples are attached to the meter,

the main display will show T1 temperature and the secondary

display will show T2 temperature. Insert one K-type thermo

couple into port T1 and another into port T2.

2. To measure the differential temperature press the "SEL" button

9

and the T1-T2 icon will be displayed. The main display will

show the differential temperature value.

3. Press the SEL button

9

again to exit differential temperature.

TEMPERATURE CALIBRATION

1. Remove leads from meter and slide the temperature probe input

switch 18 to close jacks and expose the K-Type thermocouple ports.

2. Insert K-type thermocouple into ports 17 (observe polarity

markings on thermocouple and meter), and rotate function

selector switch

2

to the Temperature setting.

3. Long press the MAX/MIN button 8 and the V+A/Inrush button

10

at the same time. The meter will beep, and the CAL icon will

appear on the secondary display and the main display will have the

temperature measurement.

NOTE: In T-CAL mode, the T1 and T2 channels can be selected for

calibration by pressing the SEL button 9, and the °F and °C units

can be changed by a long press to the SEL button 9.

4. Place the K-Type thermocouple in a known temperature system

(eg. ice water, boiling water, or other standard temperature

source) and allow to stabilize.

5. Utilize the RANGE button

7

to increase the measured value and

the REL/LPF button

11 to decrease the value. Once adjusted to

the correct value, the T-CAL icon will appear on the display and

it will remain on the screen to designate a user calibration.

NOTE: To clear calibration data, long-press the HOLD 6 button to

default to factory temperature calibration. The T-CAL icon will be

removed from the display.

6. To exit the calibration mode, long-press the MAX/MIN

8

button

and the

V+A/Inrush button 10

at the same time.

ENGLISH

K-Type Thermocouples

Page 17

17

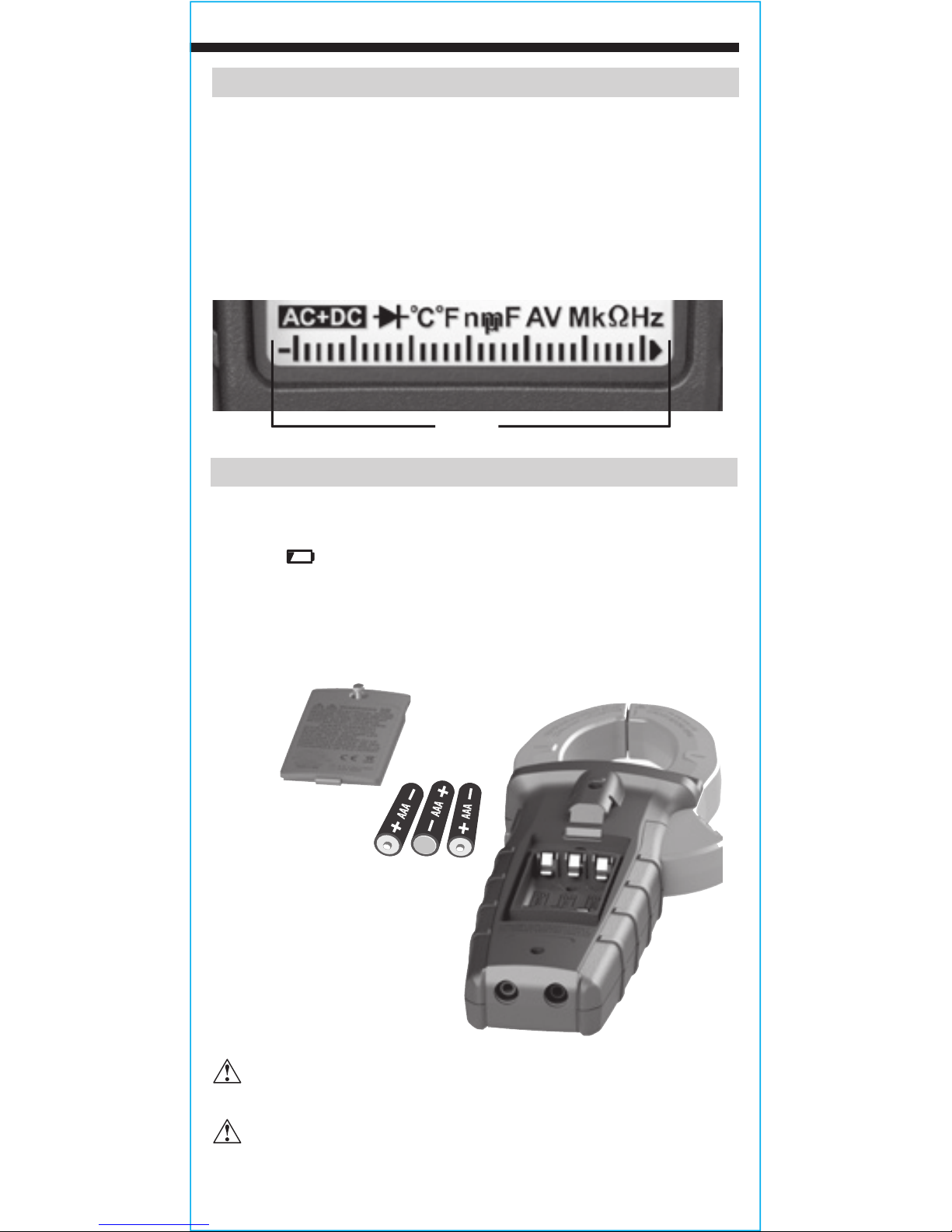

MAINTENANCE

BATTERY REPLACEMENT

When the indicator is displayed, batteries must be replaced.

1. Loosen screw on battery door.

2. Replace 3 x AAA batteries (note proper polarity).

3. Replace battery door and fasten securely with screw.

T

o avoid risk of electric shock, disconnect leads from any voltage

source before removing battery door.

To avoid risk of electric shock, do not operate meter while

battery door is removed.

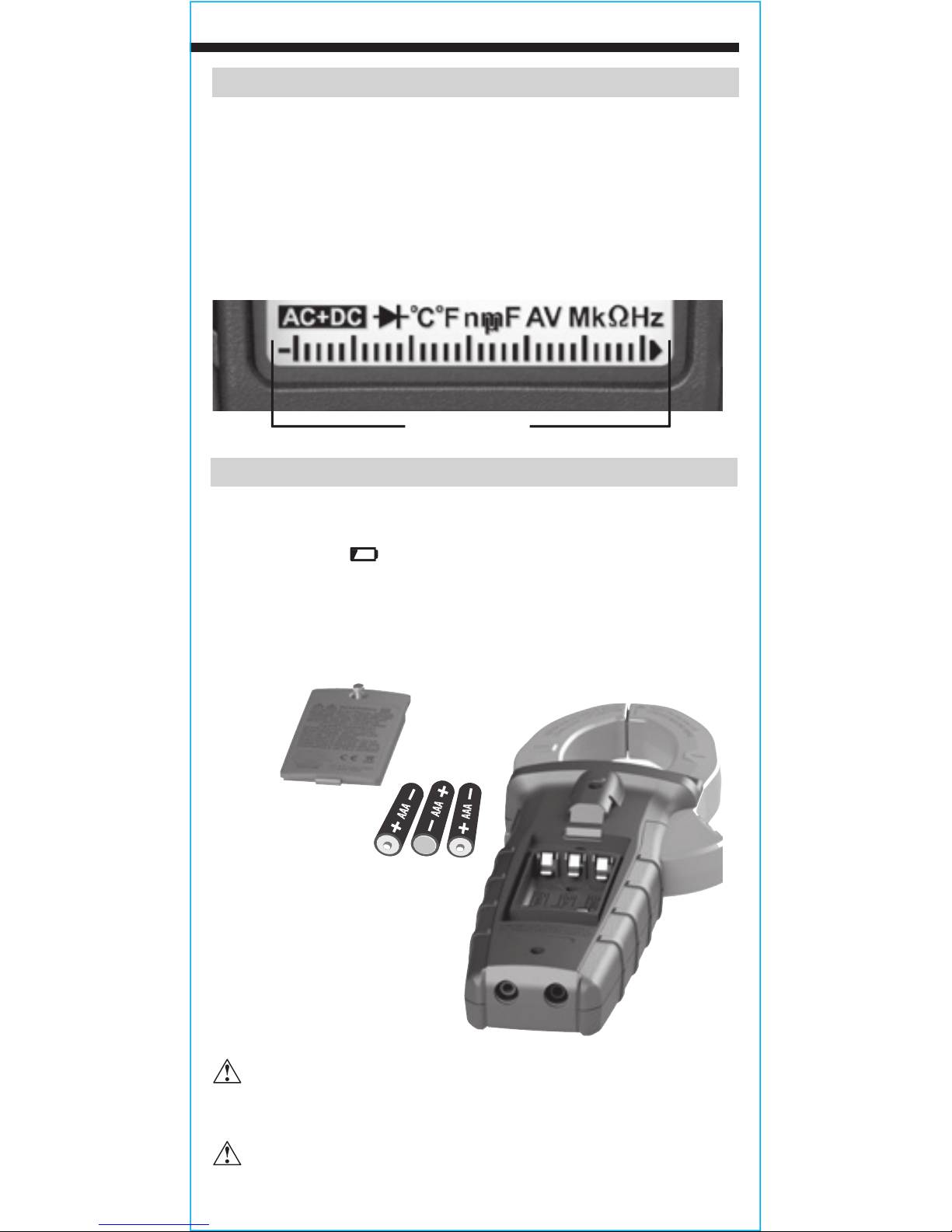

BAR GRAPH

The Bar Graph is an analog representation of the measurement. It responds

to the measurement approximately 3-5 times faster than the digits in the

digital display which, in certain circumstances, may allow the user to have

a clearer view of quick changes in the property being measured. In any

given range, the bar graph scales from zero on the left hand side to the

maximum value of the range on the right hand side of the display.

Bar graph

OPERATING INSTRUCTIONS

Page 18

ENGLISH

CLEANING

Be sure meter is turned off and wipe with a clean, dry lint-free

cloth.

Do not use abrasive cleaners or solvents.

STORAGE

Remove the batteries when meter is not in use for a prolonged

period of time. Do not expose to high temperatures or

humidity. After a period of storage in extreme conditions

exceeding the limits mentioned in the General Specifications

section, allow the meter to return to normal operating

conditions before using.

WARRANTY

www.kleintools.com/warranty

DISPOSAL / RECYCLE

Do not place equipment and its accessories in the trash.

Items must be properly disposed of in accordance with local

regulations. Please see www.epa.gov or www.erecycle.org

for additional information.

CUSTOMER SERVICE

KLEIN TOOLS, INC.

450 Bond Street

Lincolnshire, IL 60069

1-877-775-5346

customerservice@kleintools.com

www.kleintools.com

Page 19

ESPAÑOL

CL450

MANUAL DE INSTRUCCIONES

Multímetro de gancho

para HVAC

Ω

True RMS

Tecnología de

medición

• MICROAMPERIOS CD

• TEMPERATURA

DIFERENCIAL

• CALIBRACIÓN DE

TEMPERATURA

DIGITAL

• CORRIENTE DE

INSERCIÓN

• BAJA IMPEDANCIA

Page 20

20

ESPAÑOL

ESPECIFICACIONES GENERALES

Klein Tools CL450 es un multímetro digital de gancho de rango automático

con media cuadrática real (TRMS) que mide corriente CA y corriente de

inserción con la pinza, mide voltaje CA/CD, microamperios CD, resistencia,

continuidad, frecuencia y capacitancia, prueba diodos con cables de prueba

y mide temperatura diferencial con sondas de termopar tipo K.

• Entorno: Interiores y exteriores

• Altitud de funcionamiento: 6562pies (2000m)

• Humedad relativa: <80% sin condensación

• Temperatura de operación: 32°F a 122°F (0°C a 50°C)

• Temperatura de almacenamiento: 14°F a 122°F (-10°C a 50°C)

• Precisión: Valores establecidos según una temperatura ambiente de

65°F a 83°F (18°C a 28°C)

• Coeciente de temperatura: 0,1 × (precisión indicada) por cada

°C por encima de los 28°C o por debajo de los 18°C, es necesario

realizar correcciones si la temperatura del ambiente de trabajo se

encuentra fuera del rango de precisión de temperatura

• Baterías: 3 AAA de 1,5V

• Dimensiones: 10,04" × 3,77" × 1,59" (255mm × 96mm × 40mm)

• Peso: 13,6 oz (386 g) incluidas las baterías

• Calibración: Precisa durante un año

• Normas: Cumple con las normas UL 61010-1, 61010-2-032

y 61010-2-033.

Certificado según las normas CSA STD C22.2 No. 61010-1,

61010-2-032 y 61010-2-033.

IEC/EN 61010-1, 61010-2-032,

61010-2-033, 61326-1.

• Grado de contaminación: 2

• Precisión: ± (% de lectura + cantidad de dígitos menos significativos)

• Protección ante caídas: 6,6pies (2m)

• Clasicación de seguridad: CATIV 600V, doble aislamiento

CATIV: La categoría IV de medición es aplicable a los circuitos de

medición y prueba conectados a la fuente de la instalación de red de

bajo voltaje de un edificio.

• Entorno electromagnético: IEC/EN 61326-1. Este equipo cumple con

los requisitos apropiados para su uso en entornos electromagnéticos

básicos y controlados, como propiedades residenciales,

establecimientos comerciales e instalaciones de industria ligera.

Especificaciones sujetas a cambios.

Page 21

21

ESPECIFICACIONES ELÉCTRICAS

Función Rango Resolución Precisión

(50Hz/60Hz)

Voltaje CA

(V CA)

6,000V 1mV ± (1,5% + 5 dígitos)

60,00V 10mV

± (1,2% + 5 dígitos)

600,0V 100mV

1000V 1V ± (1,7% + 5 dígitos)

Voltaje CD

(V CD)

600mV 0,1mV ± (1,0% + 8 dígitos)

6,000V 1mV

± (0,8% + 3 dígitos)60,00V 10mV

600,0V 100mV

1000V 1V ± (1,2% + 3 dígitos)

Voltaje CA + CD

(V)

6,000V 1mV

± (2% + 6 dígitos)

60,00V 10mV

600,0V 100mV

1000V 1V

Impedancia de entrada: ≥

10MΩ

Rango de frecuencia:

45Hz a 400Hz (solo CA)

Entrada máxima: 1000 V CA RMS o 1000 V CD

Corriente CA

(A CA)

60,00A 10mA ± (2,5% + 10 dígitos)

600,0A 100mA ± (2,0% + 10 dígitos)

Corriente de

inserción (A)

de CA

60,00A 10mA

± (10,0% + 10 dígitos)

600,0A 100mA

Corriente CD (µA)

200µA 1µA ± (0,9 % + 6 dígitos)

Intervalo de frecuencia: 50Hz a 60Hz (solo CA)

Resistencia

600,0Ω 0,1Ω ± (1,2% + 5 dígitos)

6,000kΩ 1Ω

± (1,2% + 3 dígitos)

60,00kΩ 10Ω

600,0kΩ 100Ω

6,000MΩ 1kΩ

60,00MΩ 10kΩ ± (2,0% + 5 dígitos)

Entrada máxima: 600V CA RMS o 600V CD

Capacitancia

60,00nF 0,010nF ± (4,0% + 25 dígitos)

600,0nF 0,1nF

± (4,0% + 8 dígitos)

6,000µF 0,001µF

60,00µF 0,01µF

600,0µF 0,1µF

6000µF 1µF ± (10,0% + 9 dígitos)

Entrada máxima: 600V CA RMS o 600V CD

Page 22

22

ESPAÑOL

ADVERTENCIAS

Para garantizar un funcionamiento y servicio seguros del medidor, siga

estas instrucciones. El incumplimiento de estas advertencias puede

provocar lesiones graves o la muerte.

• Antes de cada uso, verifique el funcionamiento del multímetro midiendo

un voltaje o corriente conocidos.

• Nunca debe utilizar este multímetro en un circuito con voltajes que

excedan la clasificación correspondiente a la categoría del multímetro.

• No utilice el multímetro durante tormentas eléctricas o en clima húmedo.

• No utilice el multímetro o los cables de prueba si en apariencia están dañados.

• Utilice el probador con cables de prueba con clasificación CAT IV únicamente.

• Asegúrese de que los cables del multímetro estén correctamente colocados y mantenga

los dedos lejos de los contactos de la sonda de metal al realizar las mediciones.

ESPECIFICACIONES ELÉCTRICAS

Función Rango Resolución Precisión

Temperatura

(Fahrenheit)

-40°F a 32°F

0,1

°F

± (2,0% + 6°F)

33°F a 932°F

± (1,0% + 2°F)

933°F a 1832°F

1

°F

± (1,5% + 6°F)

Temperatura

(Celsius)

-40°C a 0°C

0,1

°C

± (2,0% + 3°C)

1°C a 500°C

± (1,0% + 1°C)

501°C a 1000°C

1

°C

±(1,5% + 3°C)

FRECUENCIA (RANGO AUTOMÁTICO)

99,99Hz 0,01Hz

± (1,0% + 5dígitos)

999,9Hz 0,1Hz

9,999kHz 1Hz

99,99kHz 10Hz

999,9kHz 100Hz

Rango de medición: 10Hz a 1MHz

≤100kHz – 250mV RMS ≤amplitud de entrada ≤20V RMS

>100kHz – 1MHz: 600mV RMS ≤amplitud de entrada ≤20V RMS

CICLO DE SERVICIO

0,1% a 99,9%

0,1% Solo como referencia

Ancho de frecuencia: ≤100kHz

OTRAS APLICACIONES DE MEDICIÓN

• Prueba de diodo:

1,0mA máx., 2,5V CD de voltaje de circuito abierto aprox.

• Vericación de continuidad: 0,5mA de corriente de prueba

• Baja impedancia (Low Z): Impedancia de entrada: >3kΩ

Entrada máx.: 1000VRMS

• Apagado automático: Después de aprox. 10minutos de inactividad

• Sobrecarga:

Se indica "OL" en pantalla, protección contra sobrecarga de

1000V en posición de voltaje, 600V RMS en las demás

posiciones

• Polaridad: "-" en pantalla indica polaridad negativa

• Pantalla: LCD de 3-5/6dígitos con recuento de 6000

Page 23

23

SÍMBOLOS DEL MULTÍMETRO

Corriente alterna (CA) Corriente directa (CD)

A

Amperaje

V

Voltaje

µA

Microamperios

Hz

Frecuencia

°

F

Grados Fahrenheit

°

C

Grados Celsius

Continuidad por indicador audible

%

Ciclo de servicio

Prueba de diodo Baja impedancia

Capacitancia Resistencia (ohmios)

+ Positivo – Negativo

COM

Común

Conexión a tierra

Doble aislamiento Clase II

Advertencia o precaución:

Para garantizar un funcionamiento y servicio

seguros del multímetro, respete todas las advertencias y siga las instrucciones

descritas en este manual.

Riesgo de choque eléctrico:

El

uso incorrecto de este multímetro puede dar lugar

a riesgos de choque eléctrico. Respete todas las advertencias y siga las instrucciones

descritas en este manual.

Riesgo de choque eléctrico:

Se permite su uso alrededor de entornos de

CONDUCTORES ACTIVOS PELIGROSOS SIN AISLAMIENTO, como para el

retiro de estos.

SÍMBOLOS DE LA PANTALLA LCD

AC

Medición de CA DC Medición de CD

Lectura negativa Retención de datos

Rango automático

MAX

Retención del valor máximo

MIN

Retención del valor mínimo

Batería baja

Apagado automático

Continuidad por indicador audible

Prueba de diodo Alto voltaje

k

kilo (valor × 103)

m

mili (valor × 10-3)

M

Mega (valor × 106)

n

nano (valor × 10-9)

μ

micro (valor × 10-6)

V

Voltios

Ohmios

F

Faradios

A

Amperios Modo relativo

LoZ

Baja impedancia

%

Ciclo de servicio

Hz

Frecuencia (Hertz)

°

C

Grados (Celsius)

°

F

Grados (Fahrenheit)

INRUSH

Corriente de inserción

LPF

Filtro de paso bajo

T1

Temperatura T1

T2

Temperatura T2

T-CAL

Calibración de temperatura

T1-T2

Temperatura diferencial

AVG

Promedio

AC+DC

Voltaje CA + Voltaje CD

ADVERTENCIAS

• Proceda con precaución cuando trabaje con voltajes superiores a 25V CA RMS

o 60V CD. Esos voltajes implican un riesgo de choque eléctrico.

• Para evitar lecturas falsas que puedan provocar choque eléctrico, reemplace las

baterías cuando aparezca el indicador de batería baja.

• No intente medir resistencia o continuidad en un circuito activo.

• Cumpla siempre con los códigos de seguridad locales y nacionales. Utilice

equipo de protección personal para prevenir lesiones por choque eléctrico y arco

eléctrico en los lugares donde haya conductores activos peligrosos expuestos.

• No intente medir voltajes mayores de 600V en la posición "LoZ" (Baja impedancia).

• Para evitar el riesgo de choque eléctrico, desconecte los cables de toda fuente

de voltaje antes de retirar la tapa del compartimento de baterías.

• Para evitar riesgo de choque eléctrico, no haga funcionar el multímetro sin

colocar la tapa del compartimento de baterías.

Page 24

24

ESPAÑOL

DETALLES DE LAS CARACTERÍSTICAS

NOTA: El medidor no contiene en su interior

piezas que el usuario pueda reparar.

1.

Pantalla LCD con

recuento de 6000

2.

Perilla selectora

de función

3.

Pinza

4.

Conector "COM"

(COMÚN)

5.

Conector "VΩ"

6.

Botón de retención

de datos/

retroiluminación

7.

Botón "RANGE"

(RANGO)

8.

Botón

"MAX/MIN"

(MÁXIMO/MÍNIMO)

9.

Botón

"SEL"

(SELECCIONAR)

10.

Botón "V+A/Inrush"

(V+A/Corriente de

inserción)

11.

Botón "REL/LPF"

(Relativo/Filtro de

paso bajo)

12.

Botones de

calibración de

temperatura

13.

Gatillo de la pinza

(presionar para abrir

la pinza)

14.

Marcas de flechas

15.

Indicador

de

prueba de voltaje

con contacto

16.

Sensor de prueba

de voltaje sin

contacto

17.

Entradas de sonda

de temperatura

tipo K

18.

Interruptor de

entrada de sonda

de temperatura

1

9

7

3

13

10

16

15

54

8

11

6

14

12

17

18

2

Page 25

25

BOTONES DE FUNCIONES

ENCENDIDO/APAGADO

Para encender el multímetro, gire la perilla selectora de función 2 de

la posición "OFF" (APAGADO) a cualquier parámetro de medición. Para

apagar el multímetro, gire la perilla selectora de función 2 a la posición

"OFF" (APAGADO). De forma predeterminada, el multímetro se apagará

automáticamente después de 10minutos de inactividad. Para desactivar

la función de apagado automático, mantenga presionado el botón "SEL"

(SELECCIONAR) 9 antes de encender la unidad desde la posición "OFF"

(APAGADO). Al desactivar la función de apagado automático, el icono

correspondiente no se visualiza en la pantalla.

BOTÓN "SEL" (SELECCIONAR) (PARA FUNCIONES SECUNDARIAS)

El botón "SEL" 9 (SELECCIONAR) sirve para activar la función secundaria

de cada aplicación a la que se accede con la perilla selectora de función

2

:

• En los modos Voltaje

V /

y Baja Impedancia , alterna entre

mediciones de CA y CD.

• En el modo Temperatura

, alterna entre mediciones en

°F

(Fahrenheit) y °C (Celsius).

• En el modo Continuidad/Resistencia/Capacitancia/Prueba de diodo

, alterna entre estas mediciones en ese orden

.

La función predeterminada de cada aplicación está impresa en el multímetro

en color blanco, y las funciones secundarias, en color naranja. Un icono en

la pantalla LCD indicará qué función está activa.

RETENCIÓN DE DATOS

Presione el botón de retención de datos/retroiluminación 6 para retener la

medición en la pantalla. Vuelva a presionar "HOLD" (RETENER) para que la

pantalla regrese a la medición en curso.

RETROILUMINACIÓN

Mantenga presionado el botón de retención de datos/retroiluminación 6

durante más de 2segundos para encender la retroiluminación. Repita el

procedimiento para apagarla.

RANGE (RANGO)

El modo predeterminado del multímetro es el de rango automático .

Este modo determina automáticamente el rango de medición más adecuado

para la prueba que se está realizando. Para que el multímetro mida en un

rango diferente, utilice el botón "Range" (Rango) 7.

1. Presione el botón "RANGE" (RANGO) 7 para seleccionar manualmente

el rango de medición ( desaparece de la pantalla LCD). Presione

el botón "RANGE" (RANGO) 7 varias veces para recorrer los rangos

disponibles y deténgase en el rango deseado.

2. Para volver al modo de rango automático, mantenga presionado el botón

"RANGE" (RANGO)

7

durante más de un segundo ( vuelve a

aparecer en la pantalla).

Page 26

26

ESPAÑOL

BOTONES DE FUNCIONES

MAX/MIN (MÁXIMO/MÍNIMO)

Cuando se presiona el botón "MAX/MIN" (MÁXIMO/MÍNIMO) 8, el

multímetro registra los valores máximo, mínimo y promedio a medida que

toma las muestras.

1. Mientras mide, presione el botón "MAX/MIN" (MÁXIMO/MÍNIMO)

8

para alternar entre el valor máximo (MAX), el valor mínimo (MIN) y

el valor promedio (AVG). Si se detecta un valor máximo, mínimo o

promedio nuevo, la pantalla se actualiza con el valor nuevo.

2. Mantenga presionado el botón "MAX/MIN" (MÁXIMO/MÍNIMO)

8

durante más de un segundo para volver al modo de medición normal.

MODO RELATIVO

Cuando se presiona el botón "REL/LPF" (RELATIVO/FILTRO DE PASO

BAJO) 11, el multímetro muestra el valor relativo en la pantalla principal

y la medición en tiempo real en la pantalla secundaria. Presione de nuevo

el botón "REL/LPF" (RELATIVO/FILTRO DE PASO BAJO) 11 para volver al

modo de medición normal.

MODO DE FRECUENCIA DE FILTRO DE PASO BAJO

Para las lecturas de voltaje en motores de alta frecuencia, mantenga

presionado el botón "REL/LPF" (RELATIVO/FILTRO DE PASO BAJO) 11 y el

multímetro aplicará un filtro de paso bajo para garantizar una lectura más

precisa. Mantenga presionado el botón "REL/LPF" (RELATIVO/FILTRO PASO

BAJO) 11 para volver al modo de medición normal.

PRUEBA DE VOLTAJE SIN CONTACTO

Acerque el sensor de voltaje sin contacto al conductor ubicado

debajo del cable de prueba

16

. El multímetro emite señales visuales

de advertencia

15

cuando este sensor detecta un voltaje CA.

INSTRUCCIONES DE OPERACIÓN

CONEXIÓN DE LOS CABLES DE PRUEBA

No realice pruebas si los cables no están bien conectados. Los

resultados podrían generar lecturas intermitentes en pantalla. Para

garantizar una buena conexión, presione los cables firmemente en

el conector de entrada hasta el final.

INCORRECTO

CORRECTO

Page 27

27

INSTRUCCIONES DE OPERACIÓN

PRUEBAS EN PUNTOS DE MEDICIÓN CON CLASIFICACIÓN

CAT III/CAT IV

Asegúrese de que el blindaje del cable de prueba esté firmemente colocado

en su lugar. No utilizar el blindaje CATIII/CATIV aumenta el riesgo de que

se produzca un arco eléctrico.

PRUEBAS EN PUNTOS DE MEDICIÓN CON CLASIFICACIÓN CATII

Es posible retirar blindajes CATIII/CATIV para realizar mediciones en

los puntos con clasificación CATII. Esto permite efectuar pruebas en

conductores empotrados, como tomacorrientes de pared estándar.

Procure no perder los blindajes.

CORRIENTE CA (MENOS DE 600A)

La corriente CA se mide presionando el gatillo

de la pinza 13 para que la pinza 3 se abra

y se la pueda colocar alrededor del cable que

conduce la corriente. Al medir, se debe tener

cuidado de cerrar bien la pinza 3 soltando el

gatillo 13 por completo, y de que el cable pase

perpendicularmente a través del centro de la

pinza 3 y quede alineado con las marcas de

flechas 14.

Para medir la corriente realice lo siguiente:

1. Gire la perilla selectora de función 2 a la posición de corrienteCA A .

2. Coloque la pinza

3

alrededor del cable. La medición de corriente

aparecerá en la pantalla.

El multímetro

seleccionará automáticamente un rango

para mostrar la medición en el rango más

adecuado.

Desconecte los cables de prueba

cuando mida con la pinza.

5/32"

(4 mm)

.7" (18 mm)

CABLE

5/32"

(4 mm)

0,7" (18 mm)

CABLE

Page 28

28

ESPAÑOL

INSTRUCCIONES DE OPERACIÓN

CORRIENTE DE INSERCIÓN

La función de corriente de inserción captura la corriente de arranque de un

motor de compresor. Esta corriente de arranque puede servir de ayuda para

diagnosticar problemas en un motor antes de que falle.

Para medir la corriente de inserción realice lo siguiente:

1. Gire la perilla selectora de función 2 a la

posición de corrienteCA A .

2. Coloque la pinza

3

alrededor del cable.

La medición de corriente aparecerá en la

pantalla.

3. Mantenga presionado el botón "V+A/Inrush"

(V+A/Corriente de inserción)

10 durante

2segundos para ingresar al modo de

corriente de inserción y seleccionar manualmente el rango 60A o 600A

presionando el botón "RANGE" (RANGO)

7. Coloque la pinza alrededor

del cable de arranque del compresor y encienda el motor. En la pantalla

principal, se mostrará el valor de corriente de arranque. El período de

medición de la corriente de inserción es de 100milisegundos.

4. Mantenga presionado el botón "V+A/Inrush" (V+A/Corriente de inserción)

10

durante 2segundos para salir de esta función.

MICROAMPERIOS DE CD

La función microamperios de CD se utiliza para la prueba de diodo

rectificador detector de llama en el control de un calefactor.

1. Gire la perilla selectora de función 2 a la

posición µA .

2. Conecte los cables de prueba entre la sonda

sensora de llama y el módulo de control, y

encienda la unidad calefactora.

3. La medición de corriente aparecerá en la

pantalla principal.

NOTA: Cuando la llama está encendida, debe detectarse una señal medible

de µA de CD, generalmente por debajo de los 10μA de CD. Compare los

valores medidos con las especificaciones del fabricante.

Page 29

29

INSTRUCCIONES DE OPERACIÓN

VOLTAJE CA/CD (MENOS DE 1000 V)

1. Inserte el cable de prueba ROJO en el conector VΩ 5 y el cable de

prueba NEGRO en el conector "COM" (COMÚN) 4, y gire la perilla

selectora de función 2 a la posición de voltaje CA/CD

V /

.

El

valor predeterminado de la función de medición de voltaje del multímetro

es CA.

Para medir CD, presione el botón "SEL" (SELECCIONAR) 9 para

alternar entre los modos CA y CD. El icono de CA o de CD que aparece

en la pantalla indica el modo seleccionado.

2. Aplique los cables de prueba al circuito que se probará para medir el

voltaje. El multímetro seleccionará automáticamente un rango para

mostrar la medición en el rango más adecuado.

NOTA: Si en la pantalla LCD se visualiza "–", los cables de prueba se están

aplicando invertidos al circuito. Invierta la posición de los cables para

solucionar el problema.

NOTA: Cuando el multímetro está en la posición de medir voltaje y los

cables de prueba están en circuito abierto, es posible que se visualicen

lecturas del tipo mV en la pantalla. Esto es ruido y es normal. Al juntar los

cables de prueba para cerrar el circuito, la lectura del multímetro será de

cero voltios.

VOLTAJE

CA/CD LOZ (BAJA IMPEDANCIA) (MENOS DE 600V)

1. Inserte el cable de prueba ROJO en el conector VΩ 5 y el cable de

prueba NEGRO en el conector "COM" (COMÚN) 4, y gire la perilla

selectora de función 2 a la posición de voltaje CA/CD "LoZ" (Baja

impedancia) .

El valor predeterminado de la función de medición de

voltaje del multímetro es CA.

Para medir CD, presione el botón "SEL"

(SELECCIONAR) 9 para alternar entre los modos CA y CD. El icono de

CA o de CD que aparece en la pantalla indica el modo seleccionado. En

la pantalla se visualizará "AC" o "DC".

2. Aplique los cables de prueba al circuito que se probará para medir el

voltaje. El multímetro seleccionará automáticamente un rango para

mostrar la medición en el rango más adecuado.

No intente medir voltajes mayores de 600V en la posición

"LoZ" (Baja impedancia).

Cable

negro

Cable

rojo

Cable

negro

Cable

rojo

Page 30

30

ESPAÑOL

INSTRUCCIONES DE OPERACIÓN

FUNCIÓN

VOLTAJE CA + VOLTAJE CD

1. Inserte el cable de prueba ROJO en el conector VΩ 5 y el cable de

prueba NEGRO en el conector "COM" (COMÚN) 4, y gire la perilla

selectora de función 2 a la posición de voltaje CA/CD

V /

.

El

valor predeterminado de la función de medición de voltaje del multímetro

es CA.

Mantenga presionado el botón "SEL" (SELECCIONAR) 9 para

ingresar al modo VCA + VCD.

2. Aplique los cables de prueba al circuito que se probará para medir el

voltaje. El multímetro seleccionará automáticamente un rango para

mostrar la medición en el rango más adecuado. La medición de VCA +

VCD aparecerá en la pantalla principal y la pantalla secundaria mostrará

los voltajes individuales en alternancia entre voltajes de CA y CD.

3. Mantenga presionado el botón "SEL" (SELECCIONAR) 9 para salir de

este modo.

FUNCIÓN

VOLTAJE CA + AMPERAJE CA

1. Inserte el cable de prueba ROJO en el conector VΩ 5 y el cable de

prueba NEGRO en el conector "COM" (COMÚN) 4, y gire la perilla

selectora de función 2 a la posición de voltaje CA/CD

V /

.

El

valor predeterminado de la función de medición de voltaje del multímetro

es CA.

Para medir CD, presione el botón "SEL" (SELECCIONAR) 9 para

alternar entre los modos CA y CD. El icono de CA o de CD que aparece

en la pantalla indica el modo seleccionado. Presione el botón

"V+A/Inrush" (V+A/Corriente de inserción)

10 para ingresar al modo

VCA + ACA.

2. Presione el gatillo de la pinza

13

para abrir la pinza 3 y colocarla

alrededor del cable que conduce la corriente.

3. El voltaje de CA se mostrará en la pantalla principal y el amperaje

de CA, en la pantalla secundaria.

4. Presione el botón "V+A/Inrush" (V+A/Corriente de inserción)

10 para

salir de este modo.

Cable

negro

Cable

rojo

Cable

negro

Cable

rojo

Page 31

31

MEDICIÓN DE RESISTENCIA

1. Inserte el cable de prueba ROJO en el conector VΩ 5 y el cable de

prueba NEGRO en el conector "COM" (COMÚN) 4, y gire la perilla

selectora de función 2 a la posición de Continuidad/Resistencia/

Capacitancia/Prueba de diodo .

NOTA: La función predeterminada del multímetro en este modo es la prueba

de continuidad. Presione el Botón "SEL" (SELECCIONAR) 9 una vez

para ingresar al modo de prueba de resistencia. El icono de resistencia

aparecerá en la pantalla.

2. Desconecte la energía del circuito.

3. Mida la resistencia conectando los cables de prueba al circuito. El

multímetro seleccionará automáticamente un rango para mostrar la

medición en el rango más adecuado.

NOTA: Cuando el multímetro está en la posición de medir resistencia y los

cables de prueba están en circuito abierto (no conectados a través de un

resistor), o cuando se está probando un resistor averiado, aparecerá en la

pantalla la leyenda OL. Esto es normal.

NO intente medir resistencia en un circuito activo.

CONTINUIDAD

1. Inserte el cable de prueba ROJO en el conector VΩ 5 y el cable de

prueba NEGRO en el conector "COM" (COMÚN) 4, y gire la perilla

selectora de función 2 a la posición de Continuidad/Resistencia/

Capacitancia/Prueba de diodo .

NOTA: La función predeterminada del multímetro en este modo es la

prueba de continuidad. Asegúrese de que el icono de prueba de continuidad

se visualice en la pantalla. De lo contrario, presione el botón "SEL"

(SELECCIONAR) 9 varias veces hasta que aparezca el icono .

2. Desconecte la energía del circuito.

3. Pruebe la continuidad conectando el conductor o el circuito con los

cables de prueba. Si la lectura de la medición de resistencia es inferior

a 10Ω, se oirá una señal audible y en la pantalla se visualizará un valor

de resistencia que indicará la continuidad. Si el circuito está abierto,

aparecerá "OL" en la pantalla.

NO intente medir continuidad en un circuito activo.

INSTRUCCIONES DE OPERACIÓN

Cable

negro

Cable

rojo

Cable

negro

Cable

rojo

Page 32

32

ESPAÑOL

INSTRUCCIONES DE OPERACIÓN

CAPACITANCIA

1. Inserte el cable de prueba ROJO en el conector VΩ 5 y el cable de

prueba NEGRO en el conector "COM" (COMÚN) 4, y gire la perilla

selectora de función 2 a la posición de Continuidad/Resistencia/

Capacitancia/Prueba de diodo .

2.

NOTA: La función predeterminada del multímetro en este modo es la

prueba de continuidad. Presione el botón "SEL" (SELECCIONAR) 9

dos veces para ingresar al modo de prueba de capacitancia. El icono de

capacitancia aparecerá en la pantalla.

3. Desconecte la energía del circuito.

4. Mida la capacitancia conectando los cables de prueba al capacitor. El

multímetro seleccionará automáticamente un rango para mostrar la

medición en el rango más adecuado.

PRUEBA DE DIODO

1. Inserte el cable de prueba ROJO en el conector VΩ 5 y el cable de

prueba NEGRO en el conector "COM" (COMÚN) 4, y gire la perilla

selectora de función 2 a la posición de Continuidad/Resistencia/

Capacitancia/Prueba de diodo .

NOTA: La función predeterminada del multímetro en este modo es la prueba

de continuidad. Presione el botón "SEL" (SELECCIONAR) 9 tres veces

para ingresar al modo de prueba de diodo. El icono de diodo aparecerá

en la pantalla.

2. Haga que los cables de prueba toquen el diodo. Si en la pantalla se

visualiza una lectura de 200mV-800mV, hay polarización directa, y si se

visualiza "OL", hay polarización inversa. Si un dispositivo está en circuito

abierto, se indicará "OL" en ambas polaridades. Si un dispositivo está en

cortocircuito, se indicará 0mV aproximadamente.

FRECUENCIA/CICLO DE SERVICIO

1. Inserte el cable de prueba ROJO en el conector VΩ 5 y el cable de prueba

NEGRO en el conector "COM" (COMÚN) 4, y gire la perilla selectora de

función 2 a la posición de frecuencia/ciclo de servicio .

Cable

negro

Cable

rojo

Cable

negro

Cable

rojo

Page 33

33

TEMPERATURA

1. Retire los cables de prueba del multímetro y deslice el interruptor de

entrada de sonda de temperatura 18 para que se cierren los conectores

y queden expuestos los puertos del termopar tipo K.

2. Inserte el termopar tipo K en el puerto T1 17 (observe las marcas de

polaridad en el termopar y en el multímetro), y gire la perilla selectora

de función 2 a la posición de temperatura .

NOTA: La escala de temperatura predeterminada del multímetro en este

modo es Fahrenheit. Para ingresar a la escala en grados Celsius, mantenga

presionado el botón "SEL" (SELECCIONAR) 9. Asegúrese de que aparezca

en pantalla el icono correspondiente ( °F o °C).

NOTA: Se puede establecer la escala en grados Celsius como

predeterminada encendiendo el multímetro desde la posición "OFF"

(APAGADO) con el botón de retención de datos/retroiluminación

6

presionado. Para volver a la configuración de escala en grados Fahrenheit

predeterminada, repita la secuencia de encendido.

3. Para medir la temperatura, haga que la punta del termopar y el objeto

que se medirá entren en contacto. Cuando la temperatura de la punta del

termopar y la del objeto se hayan equilibrado, se estabilizará la lectura en

la pantalla. El multímetro seleccionará automáticamente un rango para

mostrar la medición en el rango más adecuado.

Retire el termopar antes de con gurar el multímetro en otras

funciones de medición.

El

termopar que viene con el paquete original es apto para

temperaturas inferiores a 356°F/180°C únicamente. Para medir

temperaturas más elevadas, se debe utilizar un termopar tipo K

con el rango de medición adecuado.

NOTA: La frecuencia se mostrará en la pantalla principal y el ciclo de

servicio, en la pantalla secundaria.

2. Realice la medición conectando los cables de prueba al circuito.

INSTRUCCIONES DE OPERACIÓN

Cable

negro

Cable

rojo

Termopar tipo K

Page 34

34

ESPAÑOL

INSTRUCCIONES DE OPERACIÓN

TEMPERATURA DIFERENCIAL

1. Cuando se conectan dos termopares tipo K al multímetro, la pantalla

principal mostrará la temperatura T1 y la secundaria, la temperatura T2.

Inserte un termopar tipo K en el puerto T1 y el otro en el puerto T2.

2. Para medir la temperatura diferencial, presione el botón "SEL"

(SELECCIONAR) 9 y se visualizará el icono T1-T2. La pantalla principal

mostrará el valor de temperatura diferencial.

3. Presione el botón "SEL" (SELECCIONAR) 9 nuevamente para salir de la

función de temperatura diferencial.

CALIBRACIÓN DE TEMPERATURA

1. Retire los cables de prueba del multímetro y deslice el interruptor de

entrada de sonda de temperatura 18 para que se cierren los conectores

y queden expuestos los puertos del termopar tipo K.

2. Inserte el termopar tipo K en los puertos

17

(observe las marcas de

polaridad en el termopar y en el multímetro), y gire la perilla selectora de

función 2 a la posición de temperatura .

3. Mantenga presionados los botones "MAX/MIN" (MÁXIMO/MÍNIMO) 8

y "V+A/Inrush" (V+A/Corriente de inserción) 10 al mismo tiempo. El

multímetro emitirá un pitido y se visualizará el icono CAL en la pantalla

secundaria, mientras la medición de temperatura aparecerá en la

pantalla principal.

NOTA: En el modo T-CAL, se pueden seleccionar los canales T1 y T2 para la

calibración presionando el botón "SEL" (SELECCIONAR) 9; también, se

pueden cambiar entre las unidades °F y °C manteniendo presionado el botón

"SEL" (SELECCIONAR) 9.

4. Coloque el termopar tipo K en un sistema de temperatura conocido

(como por ejemplo, agua helada, agua hirviendo u otra fuente de

temperatura estándar) y deje que se estabilice.

5. Utilice el botón "RANGE" (RANGO) 7 para aumentar el valor medido y el

botón "REL/LPF" (RELATIVO/FILTRO DE PASO BAJO) 11 para disminuir el

valor. Una vez ajustado el valor correcto, se visualizará el icono T-CAL en la

pantalla y permanecerá para designar una calibración hecha por el usuario.

NOTA: Para borrar los datos de calibración, mantenga presionado el botón

"HOLD" (RETENER) 6 para restaurar la calibración de temperatura

predeterminada de fábrica. El icono T-CAL desaparecerá de la pantalla.

6. Para salir del modo de calibración, mantenga presionados los botones

"MAX/MIN"

(MÁXIMO/MÍNIMO)

8

y "V+A/Inrush" (V+A/Corriente de

inserción) 10 al mismo tiempo.

Termopares tipo K

Page 35

35

MANTENIMIENTO

REEMPLAZO DE LAS BATERÍAS

Cuando aparece el indicador , se deben reemplazar las baterías.

1. Afloje el tornillo de la tapa del compartimento de baterías.

2. Reemplace las 3 baterías AAA (observe la polaridad correcta).

3. Vuelva a colocar la puerta del compartimento de baterías y apriete el

tornillo firmemente.

P

ara evitar el riesgo de choque eléctrico, desconecte los cables de

toda fuente de voltaje antes de retirar la tapa del compartimento de

baterías.

Para evitar riesgo de choque eléctrico, no haga funcionar el

multímetro sin colocar la tapa del compartimento de baterías.

GRÁFICO DE BARRAS

El gráfico de barras es una representación analógica de la medición. Responde

a la medición aproximadamente de 3 a 5 veces más rápido que los dígitos de

la pantalla digital y, en determinadas circunstancias, puede ofrecer al usuario

una visión más clara de los cambios rápidos que ocurren en la propiedad que

se está midiendo. En cualquier intervalo dado, los valores del gráfico de barras

aumentan desde cero en el lado izquierdo hasta el valor máximo en el lado

derecho de la pantalla.

Gráfico de barras

INSTRUCCIONES DE OPERACIÓN

Page 36

ESPAÑOL

LIMPIEZA

Asegúrese de que el medidor esté apagado y límpielo con un

paño limpio, seco, que no deje pelusas.

No utilice solventes ni

limpiadores abrasivos.

ALMACENAMIENTO

Retire las baterías si no va a utilizar el medidor durante un

tiempo prolongado. No lo exponga a la humedad ni a altas

temperaturas. Luego de un período de almacenamiento

en condiciones extremas que sobrepasen los límites

mencionados en la sección Especificaciones generales, deje

que el medidor vuelva a las condiciones de funcionamiento

normales antes de utilizarlo.

GARANTÍA

www.kleintools.com/warranty

ELIMINACIÓN/RECICLAJE

No arroje el equipo ni sus accesorios a la basura. Los

elementos se deben desechar correctamente de acuerdo

con las regulaciones locales. Visite www.epa.gov o

www.erecycle.org para obtener más información.

SERVICIO AL CLIENTE

KLEIN TOOLS, INC.

450 Bond Street

Lincolnshire, IL 60069

1-877-775-5346

customerservice@kleintools.com

www.kleintools.com

Page 37

FRANÇAIS

CL450

MANUEL D’UTILISATION

Multimètre à pince CVC

• MICROAMPÈRES C.C.

• TEMPÉRATURE

DIFFÉRENTIELLE

• RÉGLAGE

NUMÉRIQUE DE LA

TEMPÉRATURE

• COURANT D’APPEL

• FAIBLE IMPÉDANCE

Technologie de

mesure réelle

de RMS (valeur effi cace)

Ω

Page 38

38

FRANÇAIS

CARACTÉRISTIQUES GÉNÉRALES

Le CL450 de KleinTools est un multimètre numérique à pince à échelle

automatique et à mesure réelle de RMS qui mesure le courant c.a. et le

courant d’appel à l’aide d’une pince, la tension c.a./c.c., les microampères

c.c., la résistance, la continuité, la fréquence, la capacité ainsi que les

diodes d’essai à l’aide de fils de test, et la température différentielle à l’aide

de sondes thermocouples de typeK.

• Environnement: À l’intérieur et à l’extérieur

• Altitude de fonctionnement: 2000m (6562pi)

• Humidité relative: <80%, sans condensation

• Température de fonctionnement: 0°C à 50°C (32°F à 122°F)

• Température d’entreposage: -10°C à 50°C (14°F à 122°F)

• Précision: Valeurs définies entre 18°C et 28°C (65°F et 83°F)

• Coefcient de température: 0,1 x (précision indiquée) par °C

au-dessus de 28°C ou en dessous de 18°C; des corrections sont

nécessaires lorsque la température ambiante de travail n’est pas dans

la plage de Température de précision

• Piles: 3piles alcalines AAA de 1,5V

• Dimensions:

255mm x 96mm x 40mm (10,04po x 3,77po x 1,59po)

• Poids: 386g (13,6oz) en tenant compte des piles

• Étalonnage: Précis pendant un an

• Normes: Conforme aux normes UL 61010-1, 61010-2-032 et

61010-2-033.

Certifié conforme aux normes CSA C22.2 n°61010-1, 61010-2-032

et 61010-2-033.

IEC/EN 61010-1, 61010-2-032,

61010-2-033 et 61326-1.

• Niveau de pollution: 2

• Précision: ± (% de la lecture + nombre de chiffres les moins significatifs)

• Protection contre les chutes: 2 m (6,6pi)

• Cote de sécurité: CAT.IV 600V, double isolation

CAT.IV: La catégorie de mesureIV est applicable aux circuits de test

et de mesure connectés à la source de l’installation du RÉSEAU basse

tension du bâtiment.

• Environnement électromagnétique: IEC/EN61326-1. Cet équipement

répond aux exigences pour une utilisation dans des environnements

électromagnétiques ordinaires et contrôlés comme les zones

résidentielles, les locaux commerciaux et les sites industriels légers.

Les caractéristiques techniques peuvent faire l’objet de modifications.

Page 39

39

SPÉCIFICATIONS ÉLECTRIQUES

Fonction Plage Résolution Précision (50/60Hz)

Tension c.a.

(Vc.a.)

6,000V 1mV ±(1,5% + 5chiffres)

60,00V 10 mV

±(1,2% + 5chiffres)

600,0V 100mV

1000V 1V ±(1,7% + 5chiffres)

Tension c.c.

(Vc.c.)

600mV 0,1mV ±(1,0% + 8chiffres)

6,000V 1mV

±(0,8% + 3chiffres)60,00V 10mV

600,0V 100mV

1000V 1V ±(1,2% + 3chiffres)

Tension c.a. + c.c.

(V)

6,000V 1mV

±(2% + 6chiffres)

60,00V 10mV

600,0V 100mV

1000V 1V

Impédance en entrée: ≥10MΩ

Plage de fréquences: 45Hz à 400Hz (c.a. seulement)

Courant d’entrée maximal: 1000Vc.a. (valeur efficace) ou 1000Vc.c.

Courant c.a.

(Ac.a.)

60,00A 10mA ±(2,5% + 10chiffres)

600,0A 100mA ±(2,0% + 10chiffres)

Courant d’appel

c.a. (A)

60,00A 10mA

±(10,0% + 10chiffres)

600,0A 100mA

Courant continu

(µA)

200µA 1µA ±(0,9% + 6chiffres)

Plage de fréquences: 50Hz à 60Hz (c.a. seulement)

Résistance

600,0Ω 0,1Ω ±(1,2% + 5chiffres)

6,000kΩ 1Ω

±(1,2% + 3chiffres)

60,00kΩ 10Ω

600,0kΩ 100Ω

6,000MΩ 1kΩ

60,00MΩ 10kΩ ±(2,0% + 5chiffres)

Courant d’entrée maximal: 600Vc.a. (valeur efficace) ou 600Vc.c.

Capacité

60,00nF 0,010nF ±(4,0% + 25chiffres)

600,0nF 0,1nF

±(4,0% + 8chiffres)

6,000µF 0,001µF

60,00µF 0,01µF

600,0µF 0,1µF

6000µF 1µF

±(10,0% + 9chiffres)

Courant d’entrée maximal: 600Vc.a. (valeur efficace) ou 600Vc.c.

Page 40

40

FRANÇAIS

AVERTISSEMENTS

Pour garantir une utilisation et un entretien du multimètre sécuritaires,

suivez ces instructions. Le non-respect de ces avertissements peut

entraîner des blessures graves, voire la mort.

• Avant chaque utilisation, vérifiez le fonctionnement du multimètre en

mesurant une tension ou un courant de valeur connue.

• N’utilisez jamais le multimètre sur un circuit dont la tension dépasse la

tension correspondant à la cote de sécurité de l’appareil.

• N’utilisez pas le multimètre lors d’orages électriques ou par temps humide.

• N’utilisez pas le multimètre ou les fils d’essai s’ils semblent avoir été

endommagés.

• Utilisez uniquement des fils de test conformes à la norme CAT.IV.

• Assurez-vous que les fils de test sont bien installés et évitez de toucher les

contacts métalliques des sondes lors de la mesure.

• Faites preuve de prudence lors de mesures sur des circuits de plus de 25Vc.a. (valeur

efficace) ou de 60Vc.c. De telles tensions constituent un risque de choc électrique.

SPÉCIFICATIONS ÉLECTRIQUES

Fonction Plage Résolution Précision

Température

(degrés Fahrenheit)

-40°F à 32°F

0,1

°F

±(2,0% + 6°F)

33°F à 932°F

±(1,0% + 2°F)

933°F à 1832°F

1

°F

±(1,5% + 6°F)

Température

(degrés Celsius)

-40°C à 0°C

0,1

°C

±(2,0% + 3°C)

1°C à 500°C

±(1,0% + 1°C)

501°C à 1000°C

1

°C

±(1,5% + 3°C)

FRÉQUENCE (ÉCHELLE AUTOMATIQUE)

99,99Hz 0,01Hz

±(1,0% + 5chiffres)

999,9Hz 0,1Hz

9,999kHz 1Hz

99,99kHz 10Hz

999,9kHz 100Hz

Plage de mesure: 10Hz à 1MHz

≤100kHz à 250mV (valeur efficace) ≤amplitude d’entrée ≤20V (valeur efficace)

>100kHz à 1MHz: 600mV (valeur efficace) ≤amplitude d’entrée ≤20V (valeur efficace)

CYCLE DE SERVICE

0,1 à 99,9%

0,1%

À des fins de référence seulement

Plage de fréquences: ≤100kHz

AUTRES APPLICATIONS DE MESURE

• Test de diode: Maximum 1,0mA, tension à circuit ouvert d’environ 2,5 Vc.c.

• Vérication de continuité: Courant de test de 0,5mA

• Faible impédance: Impédance en entrée: >3kΩ

Courant maximal: 1000V (valeur efficace)

• Arrêt automatique: Après environ 10minutes d’inactivité

• Surcharge:

«OL» indiqué sur l’affichage, protection contre la surcharge

1000V dans le réglage de mesure de tension, 600V (valeur

efficace) dans tous les autres réglages

• Polarité: «-» sur l’affichage indique une polarité négative

• Afchage: ACL de 35/6chiffres avec 6000lectures

Page 41

41

SYMBOLES SUR LE MULTIMÈTRE

Courant alternatif (c.a.) Courant continu (c.c.)

A

Intensité

V

Tension

µA

Micro-ampérage

Hz

Fréquence

°

F

Degrés Fahrenheit

°

C

Degrés Celsius

Indicateur sonore de continuité

%

Cycle de service

Test de diode Faible impédance

Capacité Résistance (ohms)

+ Positif – Négatif

COM

Commun

Mise à la terre

Double isolation, classeII

Avertissement ou mise en garde:

Pour garantir une utilisation et un entretien

sécuritaires du multimètre, suivre les avertissements et les instructions

présents dans ce manuel.

Risque de choc électrique:

Une utilisation inappropriée

de ce multimètre peut

provoquer un risque de choc électrique. Suivez les avertissements et instructions

présents dans ce manuel.

Risque de choc électrique:

L’enserrement ou le retrait de conducteurs NON

ISOLÉS, SOUS TENSION et potentiellement DANGEREUX est autorisé.

SYMBOLES À L’ÉCRANACL

AC

Mesure de tension c.a. DC Mesure de tension c.c.

Lecture négative Maintien des données

Évaluation automatique de la

sensibilité

MAX

Maintien de la valeur

maximale

MIN

Maintien de la valeur minimale

Pile faible

Arrêt automatique

Indicateur sonore de continuité

Test de diode Haute tension

k

kilo (valeur x 103)

m

milli (valeur x 10-3)

M

Méga (valeur x 106)

n

nano (valeur x 10-9)

μ

micro (valeur x 10-6)

V

Volts

Ohms

F

Farads

A

Ampères Mode relatif

LoZ

Faible impédance

%

Cycle de service

Hz

Fréquence (Hertz)

°

C

Degrés (Celsius)

°

F

Degrés (Fahrenheit)

INRUSH

Courant d’appel

LPF

Filtre passe-bas

T1

Température1

T2

Température2

T-CAL

Réglage de la température

T1-T2

Température différentielle

AVG

Moyenne

AC+DC

Tension c.a. + tension c.c.

AVERTISSEMENTS

• Pour éviter le

s lectures faussées pouvant provoquer un choc électrique,

remplacez les piles lorsque l’indicateur de piles faibles apparaît.

• Ne tentez pas de mesurer la résistance ou la continuité sur un circuit alimenté

en électricité.

• Assurez-vous de respecter en tout temps les codes de sécurité locaux et

nationaux. Utilisez de l’équipement de protection individuelle pour prévenir des

blessures causées par les chocs électriques et les arcs électriques lorsque des

conducteurs nus alimentés dangereux sont présents.

• Ne tentez pas de mesurer des valeurs supérieures à 600V en réglage LoZ (de

faible impédance).

• Pour éviter le risque de choc électrique, débranchez les fils de test de toute

source de tension avant de retirer la porte du compartiment à piles.

• Pour éviter tout risque de choc électrique, n’utilisez pas le multimètre lorsque la

porte du compartiment à piles est retirée.

Page 42

42

1

9

7

3

13

10

16

15

54

8

11

6

14

12

17

18

2

FRANÇAIS

CARACTÉRISTIQUES DÉTAILLÉES

REMARQUE: Ce multimètre ne contient

aucune pièce réparable par l’utilisateur.

1.

ÉcranACL jusqu’à

6000lectures

2.

Commutateur

de sélection de

fonctions

3.

Pince

4.

PriseCOM

5.

PriseVΩ

6.

Bouton HOLD

(Maintien des

données)/

rétroéclairage

7.

Bouton RANGE

(Échelle)

8.

Bouton MAX/MIN

9.

Bouton SEL

(Sélection)

10.

Bouton V+A/ INRUSH

(Courant d’appel)

11.

Bouton REL/LPF

(relatif/filtre passebas)

12.

Boutons de réglage

de la température

13.

Gâchette de pince

(appuyer pour ouvrir

la pince)

14.

Marquages de

flèche

15.

Indicateur

de test

de tension sans

contact

16.

Capteur de test

de tension sans

contact

17.

Entrées des

sondes de

température de

typeK

18.

Interrupteur

d’entrée de

la sonde de

température

Page 43

43

BOUTONS DE FONCTION

MARCHE/ARRÊT

Pour allumer le multimètre, tournez le commutateur de sélection de

fonctions 2 du réglage OFF (Arrêt) à tout autre réglage de mesure. Pour

éteindre le multimètre, tournez le commutateur de sélection de fonctions

2

au réglage OFF (Arrêt). Par défaut, l’appareil s’éteint automatiquement

après 10minutes d’inactivité. Pour désactiver cette fonctionnalité,

maintenez enfoncé le bouton SEL (Sélection) 9 avant d’allumer l’appareil,

depuis le réglage OFF (Arrêt). Lorsque la fonction d’arrêt automatique est

désactivée, l’icône d’arrêt automatique ne sera pas visible à l’écran.

BOUTON SEL (SÉLECTION) [POUR LES FONCTIONS SECONDAIRES]

Le bouton SEL (Sélection) 9 active les fonctions secondaires pour chaque

application accessible à l’aide du commutateur de sélection de fonctions

2

:

• En modes de tension

V /

et de faible impédance , il bascule

entre les mesures c.a. et c.c.

• En mode température

, il bascule entre les mesures

°C (degrés

Celsius) et °F (degrés Fahrenheit).

• En mode continuité/résistance/capacité/test de diode

, il alterne

entre ces mesures, dans cet ordre

.

La fonction par défaut pour chaque application est imprimée en blanc sur le

multimètre; les fonctions secondaires sont indiquées en orange. Une icône

sur l’écranACL indiquera quelle fonction est active.

MAINTIEN DES DONNÉES

Appuyez sur le bouton HOLD (Maintien des données)/Rétroéclairage6

pour que la lecture actuelle demeure affichée. Appuyez de nouveau sur

ce bouton pour effacer l’affichage afin de recommencer à effectuer des

mesures en temps réel.