CONDUIT BENDER AND ANGLE SETTER™ GUIDE

Offset Bend Steps

1.

Measure distance X to obstruction and height Y to clear obstruction.

2. Multiply height Y by shrink/inch. Add this to distance to obstruction X.

This is first bend line.

Multiply height Y by constant multiplier. This is distance between bends.

3.

Mark second bend line at this distance.

4. Bend first bend using first bend line. Spin conduit 180° and perform

second bend using second bend line.

Saddle Bend Steps

Measure distance X to center of obstruction and height Y to

1.

clear obstruction.

Add distance X to center of obstruction to shrink value from Saddle

2.

Bend table. Make center bend mark at this distance.

Multiply height Y by constant multiplier. This is distance between bends.

3.

Mark second bend line at this distance.

4.

Bend first bend using first bend line. Spin conduit 180° and perform

second bend using second bend line.

ZIP

GUIDETM

FOR

OFFSETS

A

2"

3"

4"

5"

6"

7"

Offset Depth

8"

9"

10"

ZIP

GUIDETM

FOR

SADDLES

A

1" 2-1/2" 3/16" 2" 1/4"

2" 5" 3/8" 4" 1/2"

3" 7-1/2" 9/16" 6" 3/4"

4" 10" 3/4" 8" 1"

5"

Obstruction Height

6" 15" 1-1/8" 12" 1-1/2"

22-1/2º 30º 45º 60º

CB

Distance

Between

5-1/4" 3/8" —

7-3/4" 9/16" 6" 3/4" — — — —

10-1/2" 3/4" 8" 1" — — — —

15-1/2" 1-1/8" 12" 1-1/2" 8-1/2" 2-1/4" 7-1/4" 3"

18-1/4" 1-5/16" 14" 1-3/4" 9-3/4" 2-5/8" 8-1/2" 3-1/2"

20-3/4" 1-1/2" 16" 2" 11-1/4" 3" 9-5/8" 4"

23-1/2" 1-3/4" 18" 2-1/4" 12-1/2" 3-3/8" 10-3/4" 4-1/2"

B B

Distance

Center

Amount

Bends

13" 15/16" 10" 1-1/4" 7" 1-7/8" — —

26" 1-7/8" 20" 2-1/2" 14" 3-3/4" 12" 5"

45º 60º

22.5º

Return Bends

DC

From

Amount

Mark

12-

15/16" 10" 1-1/4"

1/2"

Shrink

Shrink

Distance

Between

Bends

Return Bends

Distance

From

Center

Mark

CB CB CB

Distance

Shrink

Amount

30º

DC

Amount

Between

— — — — —

Shrink

Bends

Amount

Shrink

Distance

Between

Bends

Shrink

Amount

A

BENDER

TAKE UP

TABLE

1/2" Ridgid

3/4" Ridgid

KLEIN TOOLS, INC

© 2020

Find Quality Products Online at: sales@GlobalTestSupply.com

MKT200815 Rev. 09/20 A

www.GlobalTestSupply.com

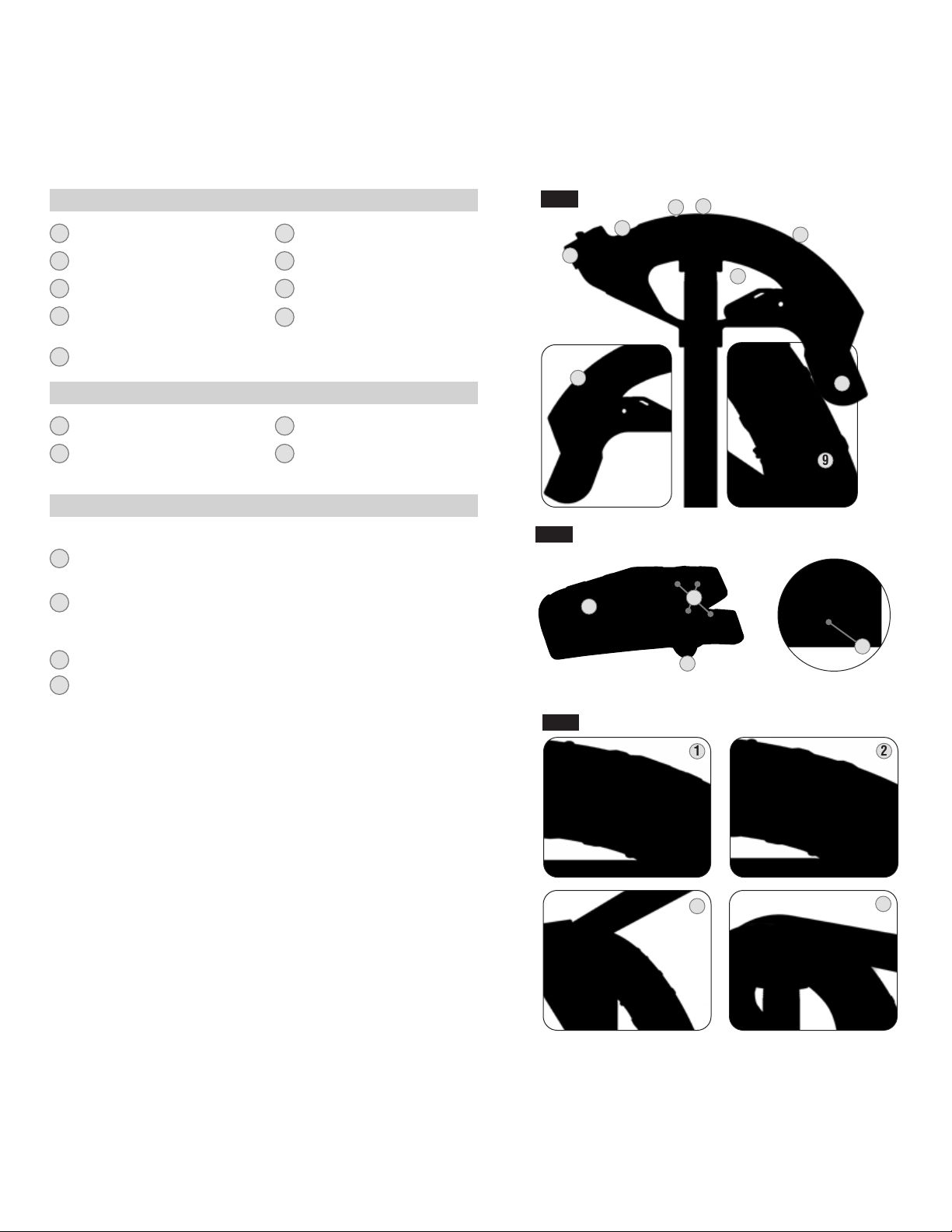

90º

Stub-Up Bend

CB

Conduit

Size

1/2" EMT 5"

3/4" EMT

1" EMT

Stub

Height

6"

8"

1

Hook

2

Alignment Arrow

3

45° Center-of-Bend

90° Back-of-Bend &

4

60° Center-of-Bend

5

Bend Angle Lines

CONDUIT BENDER — FIG. 1

6

Foot Pedal

7

Angle Setter™ Storage

8

Bend Angle Multipliers

Alignment Notches

9

(use with Angle Setter™)

ANGLE SETTER™* — FIG 2

FIG. 1

4

3

2

1

7

8

5

6

1

Conduit Stop Track

2

Angle Alignment Grooves

* For use with EMT Conduit

3

Alignment Tabs

4

Lanyard Hole

ANGLE SETTER™ INSTRUCTIONS — FIG 3

Use markings for desired bend angle (10°, 22.5°, 30°, 45°)

Align the Angle Setter™ alignment groove with end of bender head

1

angle line (30º shown).

Using your palm, press Angle Setter™ firmly into place, until

2

it is flush with the sides of the bender channel - ensure

alignment tabs are fully seated into alignment notches.

Insert conduit into bender head and prepare to bend as usual.

3

Bend conduit until contact with the Angle Setter™ is felt.

4

Will work for floor and air bends.

Caution: Bending past Angle Setter™ can result in kinks in conduit

FIG. 2

FIG.3

9

1

2

4

3

1

2

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

4

Loading...

Loading...