Page 1

SP2300

Output power

9 W (3 x 3W)

Resistance

24 Ohm

Dimensions

110 x 80 mm

Weight

360 g

Omnidirectional speaker for white noise generator

White noise generators are widely used for protecting premises against acoustic leakage eavesdropping. The SP2300

omnidirectional speaker is an important component for such system. While the transducers inject the generated noise

into the surfaces and structures stopping distributing of sound through them, the role of the speaker is to fill voids,

cavities and ventilation shafts with the audio interference to prevent leakage of sound through the air.

Creating of audio noise in the voids/cavities increases the general level of protection by preventing such kinds of

listening as:

Listening with the help of a wall stethoscope placed behind the construction adjacent to cavity (typically from a

top floor behind the drop ceiling)

Leakage of sound outside the target room through the void/cavities (for example, through the ventilation or

common holes for the pipes of heating system)

Bringing a wired microphone to a void or cavity

Hiding a covert surveillance device in a void or cavity

The SP2300 speaker, when connected to a white noise generator, will create efficient interference to all mentioned

kinds of eavesdropping. The DNG-2300 is the recommended white noise generator for the SP2300. It has a separate

SPEAKERS output with adjustable volume and can feed up to 12 speakers simultaneously.

Specification

Usage

Ventilation shafts and other voids leading outside the protected room

Ventilation makes it possible to carry out eavesdropping without penetrating into the target zone. Sound from the

target room propagates through the shafts/voids and can be picked up remotely. In the case of sufficient distance a

wired microphone can be run within the shaft. In order to prevent leakage of speech information the SP2300 can be

positioned inside a void/shaft. If the void is not large enough to accommodate the speaker, the speaker can be

disassembled and placed without the holders.

Since the SP2300 is assembled from 3 speakers, each of them can be used separately for smaller voids. Disassemble the

SP2300 by removing the triangle holders, cut the cables, place the separate speakers where necessary and then connect

again in series.

Page 2

Use 1 x SP2300 for a big shaft or a disassembled "1/3" speaker for a smaller void

Space behind the drop ceiling

Sound distributes in all directions; therefore, all conversations inside the target area can be easily picked up under the

drop ceiling. The most popular methods of eavesdropping are:

1) Drilling a hole from the top floor in order to place a wired microphone or its tube extender behind the drop ceiling.

This method is preferred over direct drilling into the room as the drop ceiling hides signs of work.

2) Placement a bugging device in the space under the drop ceiling.

The SP2300 can be placed behind the drop ceiling in order to protect from the mentioned listening methods. If there

are no partitions behind the drop ceiling, the quantity of speakers can be selected in correspondence with the following

suggestions:

1 x SP2300 speaker per each 9-10 square meters

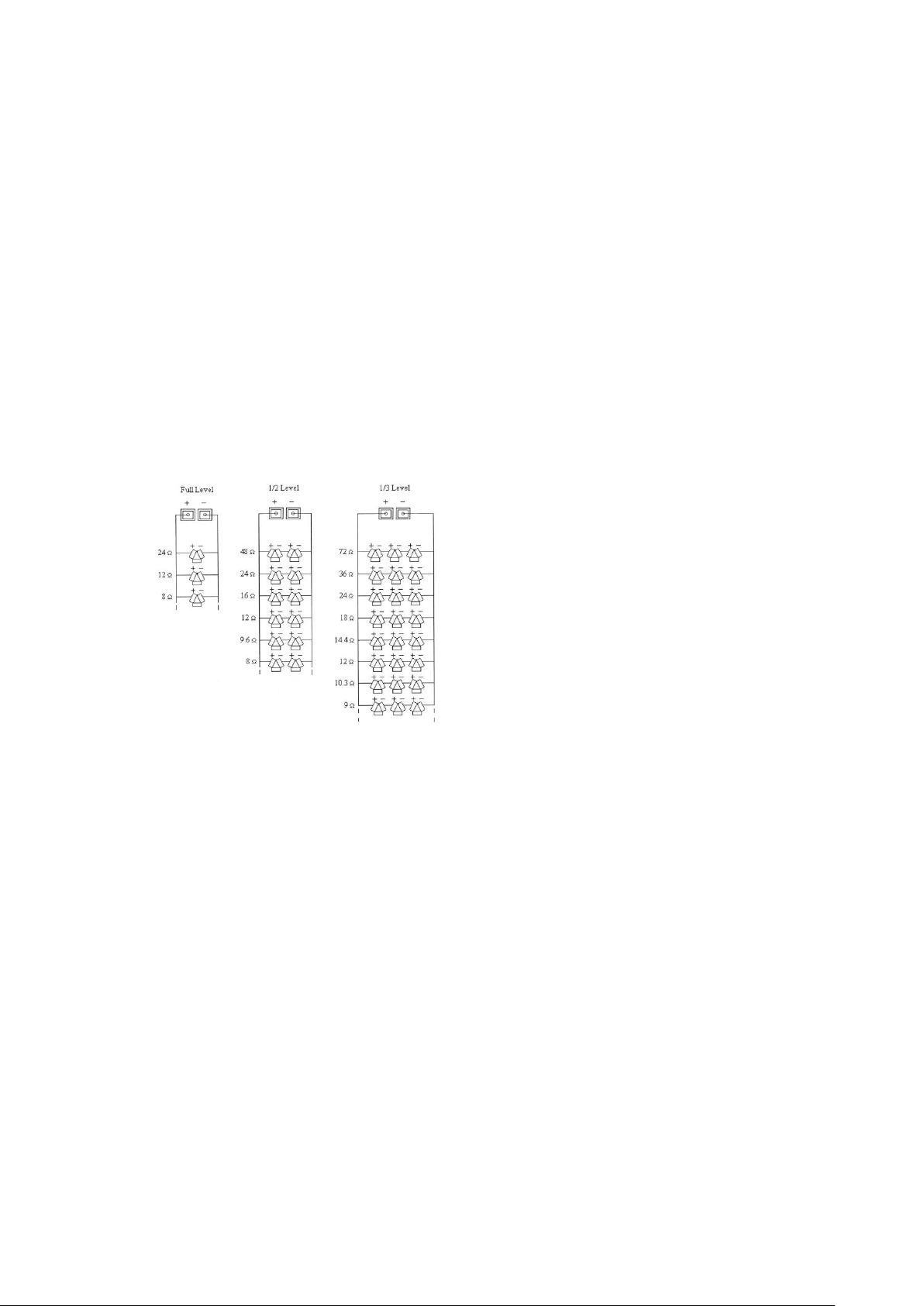

Connection

Depending on the selected number of speaker, choose a wiring diagram from the below picture. Consider the

generator's minimum load for the SPEAKERS channel (8 Ohm for the DNG2300)

The output power is divided between the speakers, so when there are more speakers, each separate unit will receive

less power. The percentage shows the relative power produced by a speaker, comparing to the variant with a parallel

connection of 3 speakers.

"100% level" speakers are recommended for large ventilation shafts

"50% level" – for regular voids/cavities

"33% level" – for small voids/cavities

Combining levels can be done, but care should be taken to verify the load for the generator and correct output volume

out of each speaker.

The percentage reflects the relative power, while the real output will also depend on the generator's volume control.

Typically, when there are more speakers the volume should be set higher. To determine the sufficient level for the

output channel it is necessary to conduct some tests with the help of an acoustic leakage probe. By creating a test

sound in the room with the generator active it is possible to adjust the noise to such a level that the external probing

does not capture any sound within or near the void/cavity.

In fact there is not some additional describes.

1. Device supplied with the manual only

2. There is not any braket in supplier set

Page 3

3. The power cord that installed in SP2300 is around 1 m. Lenght of cable from SP2300 to generator depends

from square of wires, for exmple, if you will be use the cable with square 0.22 m2 the lenght from SP2300 to

generator is up to 30 m, for square 0.75 m2 the lenght will be up to 60 m.

Loading...

Loading...