KitchenAid YKMHC319EBS, YKMHS120EW, MMV4207JK, MMV5227JZ, WMH54521JV Installation Instructions

...Page 1

MICROWAVE HOOD COMBINATION

INSTALLATION INSTRUCTIONS

This product is suitable for use above electric or gas cooking products up to and including 36" (91.4 cm) wide. See the “Installation

Requirements” section for further notes.

These installation instructions cover different models. The appearance of your particular model may differ slightly from the illustration

in these installation instructions.

INSTRUCTIONS D’INSTALLATION

DE L’ENSEMBLE FOUR À MICRO-ONDES/HOTTE

Ce produit est conçu pour l’utilisation au-dessus d’appareils de cuisson électriques ou à gaz de 36" (91,4 cm) de largeur ou moins.

Voir la section “Exigences d’installation” pour d’autres remarques.

Ces instructions d’installation sont valables pour plusieurs modèles. Il se peut que l’apparence de votre propre modèle soit légèrement

différente de celle montrée sur les illustrations dans ce document.

Table of Contents/Table des matières

MICROWAVE HOOD COMBINATION SAFETY ............................ 2

INSTALLATION REQUIREMENTS ................................................. 2

Tools and Parts ..................................................................................2

Remove Cardboard Template ............................................................ 3

Location Requirements ...................................................................... 3

Product Dimensions...........................................................................3

Electrical Requirements ..................................................................... 4

INSTALLATION INSTRUCTIONS ................................................... 5

Remove Mounting Plate ....................................................................5

Rotate Blower Motor ..........................................................................5

Locate Wall Stud(s) ............................................................................ 8

Mark Rear Wall ................................................................................... 9

Drill Holes in Rear Wall ..................................................................... 10

Attach Mounting Plate to Wall .........................................................10

Prepare Upper Cabinet .................................................................... 11

Install Damper Assembly ................................................................. 11

Install the Microwave Oven ..............................................................12

Complete Installation ....................................................................... 13

VENTING DESIGN SPECIFICATIONS .........................................14

ASSISTANCE ................................................................................15

Replacement Parts ..........................................................................15

Accessories. ..................................................................................... 15

SÉCURITÉ DE L’ENSEMBLE FOUR À

MICRO-ONDES/HOTTE...............................................................16

EXIGENCES D’INSTALLATION ...................................................16

Outillage et pièces ...........................................................................16

Dépose du gabarit de carton ........................................................... 17

Exigences d’emplacement ..............................................................17

Dimensions du produit ..................................................................... 18

Spécications électrique ..................................................................18

INSTRUCTIONS D’INSTALLATION .............................................19

Dépose de la plaque de montage ...................................................19

Réorientation du moteur du ventilateur ........................................... 19

Identier la position du/des poteau(x) du colombage mura ...........22

Tracé sur le mur arrière ....................................................................23

Perçage de trous dans le mur arrière ..............................................24

Fixation de la plaque de montage sur le mur .................................. 24

Préparation du placard supérieur .................................................... 25

Installation du module du clapet anti-reu ...................................... 25

Installation du four à micro-ondes ................................................... 26

Achever l’installation ........................................................................ 28

SPÉCIFICATIONS/CONCEPTION DU CIRCUIT

D’ÉVACUATION ............................................................................28

ASSISTANCE ................................................................................30

Pièces de rechange .........................................................................30

Accessoires.. .................................................................................... 30

W11401909A

Page 2

MICROWAVE HOOD COMBINATION SAFETY

INSTALLATION REQUIREMENTS

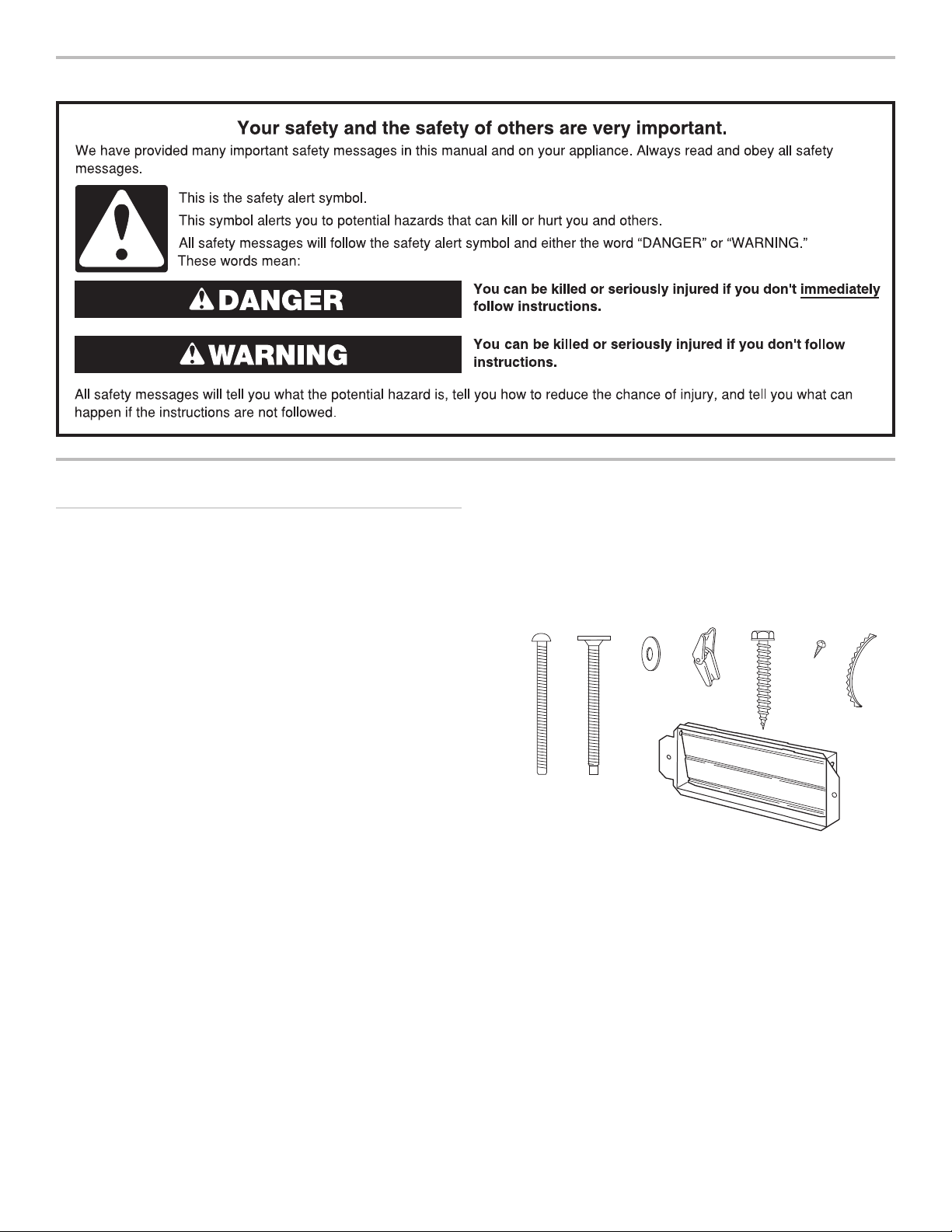

Tools and Parts

Tools Needed

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

■ Measuring tape

■ Pencil

■ Masking tape or thumbtacks

■ Scissors

■ No. 2 Phillips screwdriver

■ No. 3 Phillips screwdriver

for 1/4 - 20 x 3" (7.6 cm)

bolts

■ Drill

■ 3/16" (5 mm), 3/8" (1cm),

5/8" (1.6 cm) drill bits

■ 3/4" (1.9 cm) hole saw

■ Diagonal wire cutting pliers

■ Stud nder

■ 7⁄16" (1.1 cm) socket wrench (or box wrench) for 1/4" x 2"

(6.4 mm x 5.1cm) lag screws

1

■ 1

/2" (3.8 cm) diam. hole drill bit for wood or metal cabinet

■ Keyhole saw

■ Caulking gun and weatherproof caulking compound

■ Duct tape

Parts Needed

For information on reordering, see the “Replacement Parts”

section.

NOTE: The hardware items listed here are for wood studs.

For other types of wall structures, be sure to use appropriate

fasteners.

A

A. 3/16 - 24 x 3" round-head

bolts (2)

B. 1/4 - 20 x 3" at-head bolts (2)

C. Washers (2)

D. 3/16" toggle nuts (2)

E. 1/4" x 2" lag screws (2)

F. #6 x 3/8" Sheet metal screws (2)

G. Power supply cord bushing (1)

H. Damper assembly (for wall or

roof venting)

B

C

DEF

H

Not Shown:

■ Upper cabinet template

■ Mounting plate (attached to

back of microwave oven)

■ Cardboard template (part of

packaging) or wall template

■ Aluminum grease lters

■ Charcoal lters (Depending

on model, charcoal lters may

not be included. See User

Instructions.)

G

NOTE: Depending on model, aluminum grease lter and

charcoal lter may be combined.

Materials Needed

Standard ttings for wall or roof venting. See the “Venting Design

Specications” section.

2

Page 3

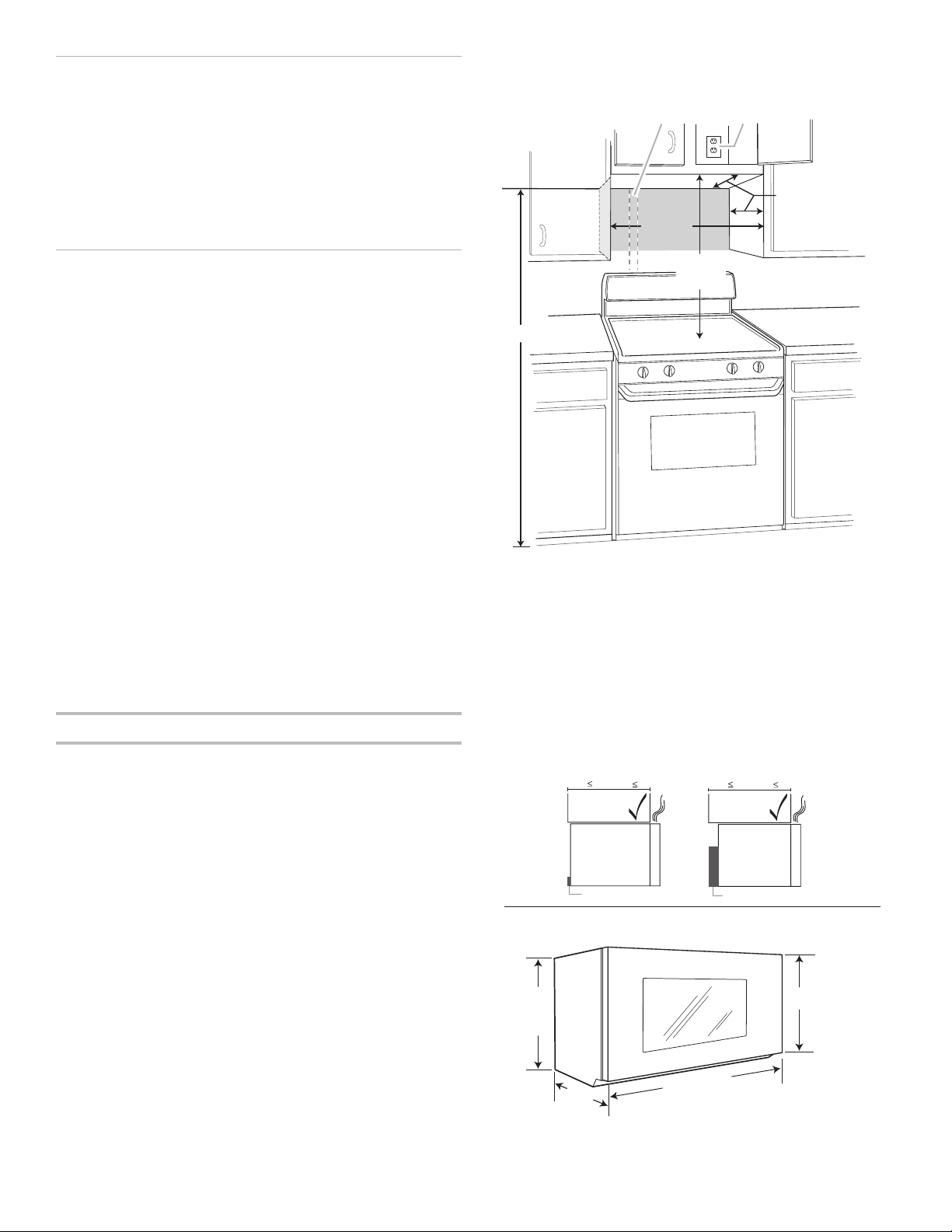

Remove Cardboard Template

12" (30.5 cm) min.

14" (35.6 cm) max.

30"

(76.2 cm)

min.

AB

upper cabinet and

side cabinet depth

30"

(76.2 cm)

typical*

66" (167.6 cm) min.

Product Dimensions

16

¹⁄₄

"

(41.3 cm)

17

¹⁄₈

"

(43.5 cm)

+/-

³⁄₁₆

"

(0.5 cm)

17"

Up to

(43.2 cm)*

cm)

29

⁷⁄₈

" (76.0

I bar mounting plate

Bump out mounting bracket

12"

DEEPER

14"

14"

DEEPER

15"

The cardboard piece from the top of the microwave oven

packaging is perforated. The piece inside the perforation is for

use as a rear wall template.

1. Cut along the perforation to separate the template from the

rest of the cardboard packaging.

2. Set the cardboard template to the side and refer to it during

the “Mark Rear Wall” part of installation.

Depending on your model, skip "Remove Cardboard Template"

steps if full carton box is used for packing. But use the wall

template for "Mark Rear Wall" part of the installation.

Location Requirements

Check the opening where the microwave oven will be installed.

The location must provide:

■ Minimum installation dimensions. See the “Installation

Dimensions” illustration.

■ Minimum one 2" x 4" (5.1 x 10.2 cm) wood wall stud and

minimum 3/8" (1 cm) thickness drywall or plaster/lath within

cabinet opening.

■ Support for weight of 150 lbs (68 kg) which includes

microwave oven and items placed inside the microwave

oven and upper cabinet.

■ Grounded electrical outlet inside upper cabinet. See the

“Electrical Requirements” section.

NOTES:

■ If installing the microwave oven near a left sidewall, make

sure there is at least 6" (15.2 cm) of clearance between the

wall and the microwave oven so that the door can open fully.

■ Some models have a pocket handle. If installing the

microwave near a right side wall, make sure there is at least

3 inches of clearance between wall and microwave oven so

you can grab the handle integrated inside the door.

■ Some cabinet and building materials are not designed to

withstand the heat produced by the microwave oven for

cooking. Check with your builder or cabinet supplier to make

sure that the materials used will not discolor , delaminate, or

sustain other damages.

Special Requirements

For Wall Venting Installation Only:

■ Cutout must be free of any obstructions so that the vent t

properly and the damper blade opens freely and fully.

For Roof Venting Installation Only:

■ If you are using a rectangular-to-round transition piece, the

3" (7.6 cm) clearance needs to exist above the microwave

oven so that the damper blade can open freely and fully.

See “Rectangular to Round Transition” illustration in the

“Venting Design Specications” section.

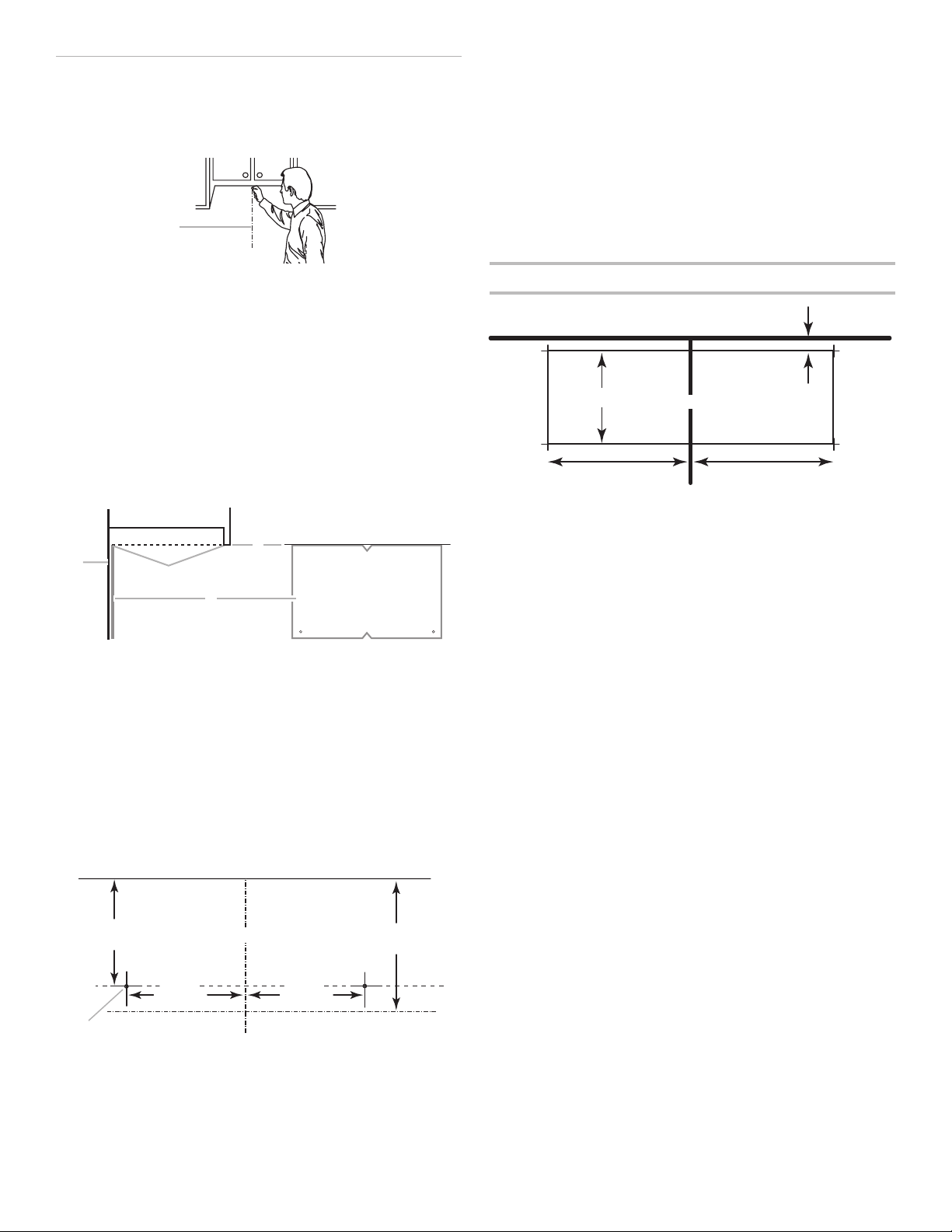

Installation Dimensions

NOTE: The grounded 3 prong outlet must be inside the upper

cabinet. See the “Electrical Requirements” section.

A. 2" x 4" (5.1 x 10.2 cm) wall stud

B. Grounded 3 prong outlet

*30" (76.2 cm) is typical for 66" (167.6 cm) installation height.

Exact dimensions may vary depending on type of range/cooktop

below.

NOTE: To ensure good performance, do not obstruct top vent

airow. If cabinets are deeper than 14" (35.6 cm) but no more

than 15" (38.1 cm), use the bump out mounting kit replacing the

I bar mounting plate fr om the wall. The bump out mounting kit

(part # W11185746) is not provided but can be purchased from

Whirlpool.

*Overall depth of product will vary slightly depending on door

design.

3

Page 4

Electrical Requirements

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Observe all governing codes and ordinances.

Required:

■ A 120 V, 60 Hz, AC only, 15 or 20 A electrical supply with a

fuse or circuit breaker

Recommended:

■ A time-delay fuse or time-delay circuit breaker

■ A separate circuit serving only this microwave oven

GROUNDING INSTRUCTIONS

For all cord connected appliances:

The microwave oven must be grounded. In the event of

an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric

current. The microwave oven is equipped with a cord

having a grounding wire with a grounding plug. The plug

must be plugged into an outlet that is properly installed

and grounded.

WARNING: Improper use of the grounding plug can

result in a risk of electric shock. Consult a qualified

electrician or serviceman if the grounding instructions are

not completely understood, or if doubt exists as to whether

the microwave oven is properly grounded.

Do not use an extension cord. If the power supply cord is

too short, have a qualified electrician or serviceman install

an outlet near the microwave oven.

SAVE THESE INSTRUCTIONS

4

Page 5

INSTALLATION INSTRUCTIONS

A

B

A

A

A

Remove Mounting Plate

Depending on your model, the mounting plate may be in the

foam packaging, or it may be attached to the back of the

microwave oven.

NOTE: To avoid possible damage, cover the work surface.

1. Remove any remaining contents from the microwave oven

cavity.

2. If the mounting plate is attached to the back of the

microwave oven, remove it and set it aside.

3. Tape the microwave oven door closed so that the door does

not swing open while the microwave oven is being handled.

NOTE: To avoid damage to the microwave oven, do not grip or

use the door or door handle while the microwave oven is being

handled.

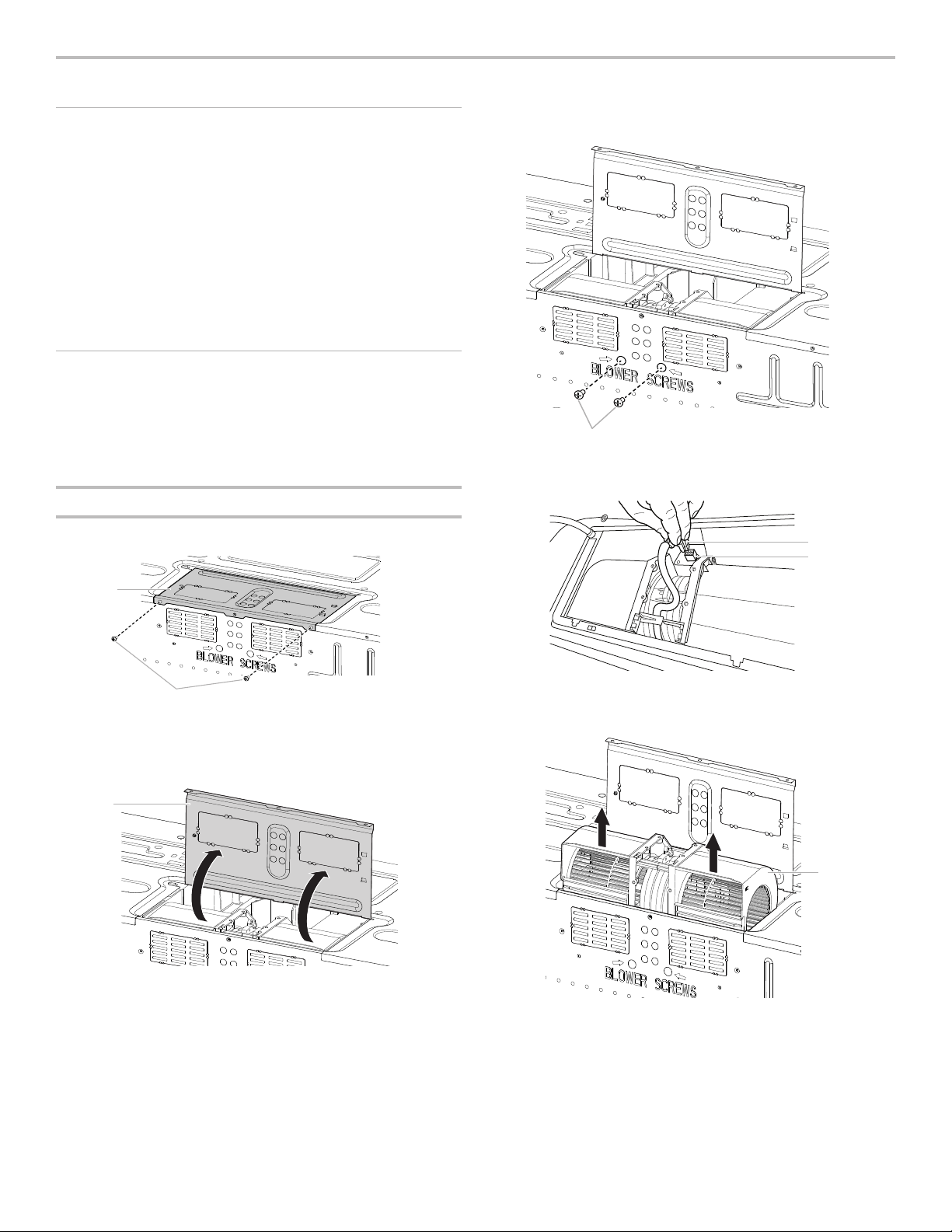

Rotate Blower Motor

The microwave oven is set for recirculation installation. For wall

or roof venting, changes must be made to the venting system.

NOTE: Skip this section if you are using recirculation installation.

Keep the damper assembly in case the venting method is

changed, or the microwave oven is reinstalled in another location

where wall or roof venting may be used.

Wall Venting Installation Only

1. Remove screws attaching damper plate to back of

microwave oven, set the screws aside.

3. Remove 2 blower screws attaching blower motor to the

microwave oven, and set aside.

A. Blower screws (in recessed holes)

4. Disconnect the blower motor wire from the connector.

A

B

A. Blower motor wire

B. Connector

A. Damper plate

B. Screws

2. Turn and hold the damper plate vertically as shown.

A. Damper plate

5. Lift blower motor out of microwave oven, and set aside.

A. Blower Motor

5

Page 6

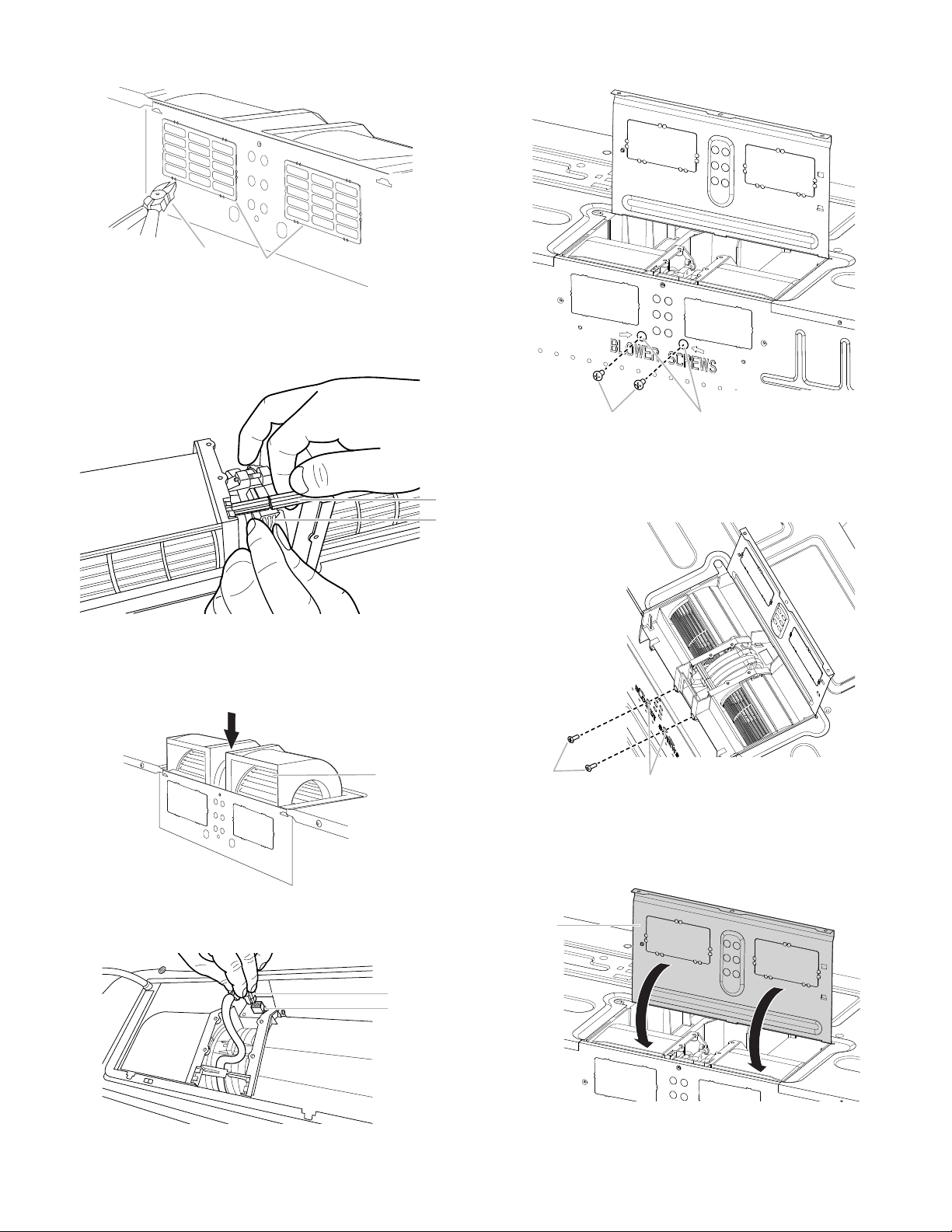

6. Using diagonal wire cutting pliers, gently snip out the

B

A

A

B

A B

A

B

A

rectangular damper vent covers at the perforations.

A. Diagonal wire cutting pliers

B. Rectangular damper vent cover

7. Hold the blower motor wire, put the wire through the blower

motor bridge.

10. Reattach the 2 blower screws into the recessed holes in the

back of the microwave.

A. Screws

B. Recessed holes

A

B

A. Blower motor bridge

B. Blower motor wire

8. Lower blower motor back into the microwave oven. Exhaust

ports face the back of the microwave oven.

A

A. Exhaust Port

9. Reconnect the blower motor wire into the connector.

11. Check to make sure the 2 screws are secured properly in the

blower motor screw holes, so that the motor cannot move.

A. Screws

B. Blower motor screw holes

12. Return the damper plate to its original horizontal position.

A. Blower motor wire

B. Connector

6

A. Damper plate

Page 7

13. Secure damper plate with 2 screws removed in Step 1.

A

B

A. Damper plate

B. Screws

Roof Venting Installation Only

1. Repeat Step 1 from “Wall Venting Installation Only.”

2. Repeat Step 2 from “Wall Venting Installation Only.”

3. Repeat Step 3 from “Wall Venting Installation Only.”

4. Repeat Step 4 from “Wall Venting Installation Only.”

5. Repeat Step 5 from “Wall Venting Installation Only.”

6. Using diagonal wire cutting pliers, gently snip out the

rectangular vent covers on the damper plate at the

perforations.

A

8. Reconnect the blower motor wire into the connector.

9. Reattach the 2 blower screws into the recessed holes in the

back of the microwave.

10. Check to make sure the 2 screws are secured properly in the

blower motor screw holes, so that the motor cannot move.

11. Return the damper plate to its original horizontal position.

A

A. Damper plate

12. Secure damper plate with 2 screws removed in Step 1.

A

B

A. Rectangular vent covers

B. Diagonal wire cutting pliers

7. Lower blower motor back into microwave oven. Exhaust

ports face the top of microwave oven.

A

A. Exhaust port

IMPORTANT: If blower motor is not positioned with at

side facing the back of the microwave oven (as shown),

performance will be poor.

B

A. Damper plate

B. Screws

7

Page 8

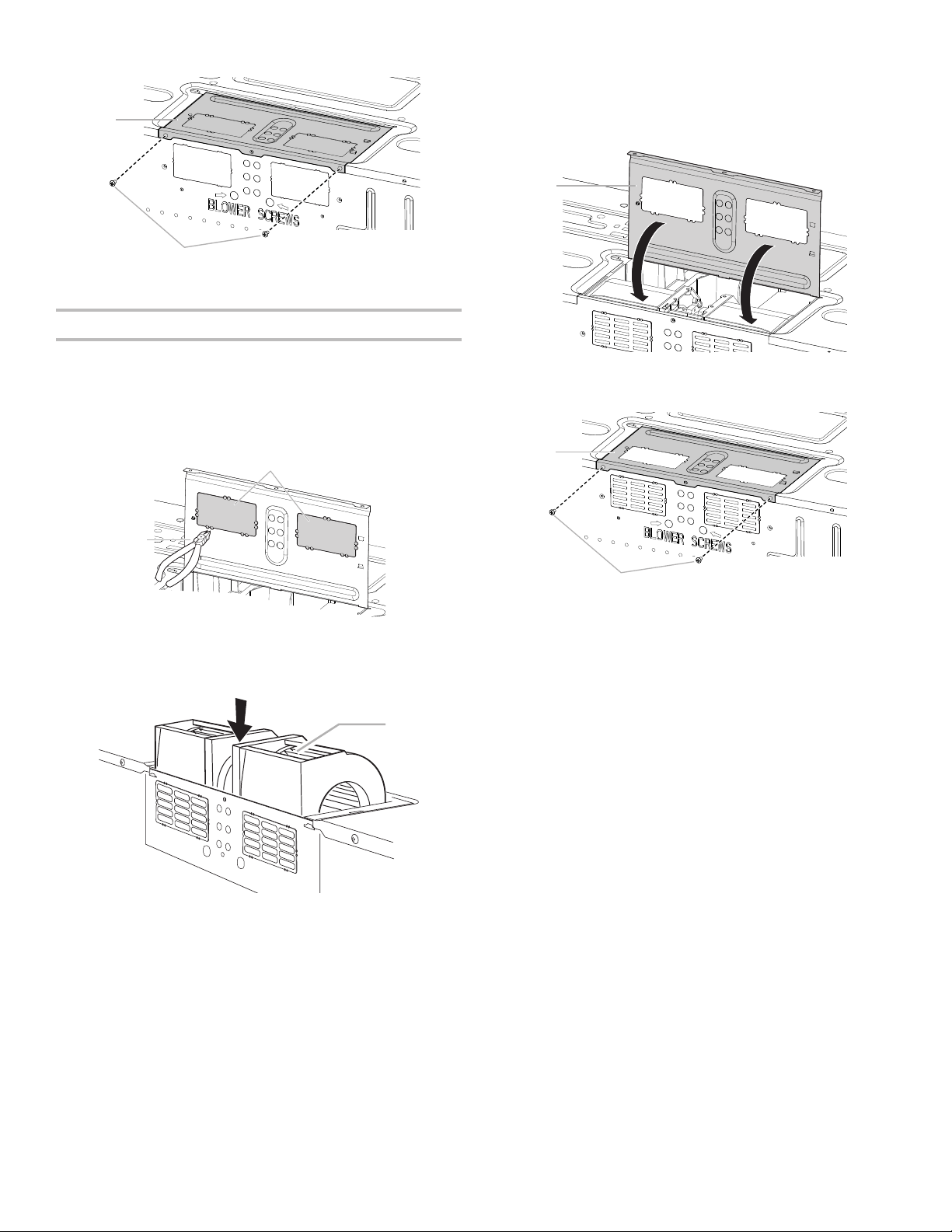

Locate Wall Stud(s)

Figure 1

C

C

D

E

F

Figure 3

D

C

E

Figure 2

B

C

E

F

Figure 4

A,D

D

NOTE: If no wall studs exist within the cabinet opening, do not

install the microwave oven.

See illustrations in “Possible Wall Stud Congurations.”

Possible Wall Stud Congurations

These depictions show examples of preferred installation congurations with the mounting plate.

1. Using a stud nder, locate the edges of the wall stud(s)

within the opening.

2. Mark the center of each stud, and draw a plumb line down

each stud center. See illustrations in “Possible Wall Stud

Congurations.”

No Wall Studs at End Holes

No Wall Studs at End Holes

B

D

A

A

A

A

E

E

NOTE: If wall stud is within 6" (15.2 cm) of the vertical centerline

(see the “Mark Rear Wall” section), only recirculation or roof

venting installation can be done.

Wall Stud at End Hole

B

A

F

D

A,

E

C

B

E

C

F

Wall Studs at End Holes

A,

E

C

A. End holes (on mounting plate)

B. Cabinet opening vertical centerline

C. Wall stud centerlines

D. Holes for lag screws

E. Support tabs

F. Mounting plate center markers

8

Page 9

Mark Rear Wall

A

A

Mounting plate end hole

Upper cabinet bottom

The microwave oven must be installed on a minimum of 1 wall

stud, preferably 2, using a minimum of 1 lag screw, preferably 2.

1. Using measuring tape, nd and clearly mark the vertical

centerline of the opening.

5. With the support tabs facing forward (see illustrations in

the “Locate Wall Stud(s)” section), align the mounting plate

center markers to the centerline on the wall, making sure its

bottom edge is aligned to the horizontal line drawn in Step 3

and that the end holes are properly marked. Make sure the

mounting plate is level.

6. Holding the mounting plate in place, find the wall stud

centerline(s) drawn in Step 2 of “Locate Wall Stud(s)” and

mark at least 1, preferably 2 hole(s) through the mounting

plate, closest to the wall stud centerline(s). See figures 1,

2, and/or 3 in “Possible Wall Stud Congurations” in the

“Locate Wall Stud(s)” section. The blackened holes in the

shaded areas are ideal hole locations.

7. Set the mounting plate aside.

A. Centerline

2. Align the center markers on the cardboard template (carton

top cap) or Wall template, to the centerline on the wall,

making sure it is level, and that the top of the cardboard

template or wall template is butted up against the bottom

edge of the upper cabinet.

NOTES:

■ If the front edge of the upper cabinet is lower than the back

edge, lower the cardboard template or wall template so that

its top is level with the front edge of the cabinet.

■ If the cardboard template or wall template is damaged or

unusable, measure and mark the wall with the dimensions

described in Step 4.

D

C

B

A. Rear wall

B. Cardboard template or Wall template

C. Top of cardboard template or wall template

must align with front edge of cabinet.

D. Front edge of upper cabinet

Wall Venting Installation Only

Upper cabinet bottom

4" (10.2 cm)

6" (15.2 cm)6" (15.2 cm)

Centerline

8. Mark the centerline 3/8" (1 cm) down from the bottom edge

of the upper cabinet.

9. Using measuring tape, measure out 6" (15.2 cm) on both

sides of the centerline, and mark.

10. Measure down 4" (10.2 cm) from the mark made in Step 8

and mark.

11. Using a straightedge, draw the 2 horizontal, level lines

through the marks made in steps 8 and 10.

12. Draw the 2 vertical plumb lines down from the marks made

in Step 9 to complete the 12" x 4" (30.5 x 10.2 cm) rectangle.

This is the venting cutout area.

13. Cut a 3/4" (1.9 cm) hole in one corner of the cutout area.

14. Using a keyhole saw, cut out the venting cutout area.

³⁄₈

" (1 cm)

3. Holding the cardboard template or wall template in place,

mark both holes in the lower corners and draw a horizontal

line across the bottom edge of the cardboard template or

wall template. These represent the mounting plate’s end

holes and bottom edge.

4. Remove the cardboard template or wall template and check

the markings:

15⁵⁄₈"

(39.71 cm)

■ The bottom edge line must be 17

bottom of the upper cabinet and must be level.

■ The end holes must be 15

edge of the upper cabinet and must be on a level line with

each other. They must each be 141⁄8" (35.96 cm) from the

centerline.

14¹⁄₈"

(35.96 cm)

Centerline

14¹⁄₈"

(35.96 cm)

Bottom of mounting plate

5

⁄16" (44.02 cm) from the

5

⁄8" (39.71 cm) from the bottom

17⁵⁄₁₆"

(44.02 cm)

9

Page 10

Drill Holes in Rear Wall

C

A

A

B

In addition to being installed on at least 1 wall stud, the

mounting plate must attach to the wall at both end holes. If the

end holes are not over wall studs, use two 3/16-24 x 3"

round-head bolts with toggle nuts; if 1 end hole is over a wall

stud, use 1 lag screw and one 3/16-24 x 3" round-head bolt with

toggle nut; or if both end holes are over wall studs, use 2 lag

screws. Following are 3 installation congurations.

Installation for No Wall Studs at End Holes

(Figures 1 and 2)

1. Drill 5/8" (1.6 cm) holes through the wall at both end holes

marked in Step 3 of the “Mark Rear Wall.”

2. Drill 3/16" (5 mm) hole(s) into the wall stud(s) at the hole(s)

marked in Step 6 of the “Mark Rear Wall.” Refer to gures 1

and 2 in “Possible Wall Stud Congurations” in the “Locate

Wall Stud(s)” section.

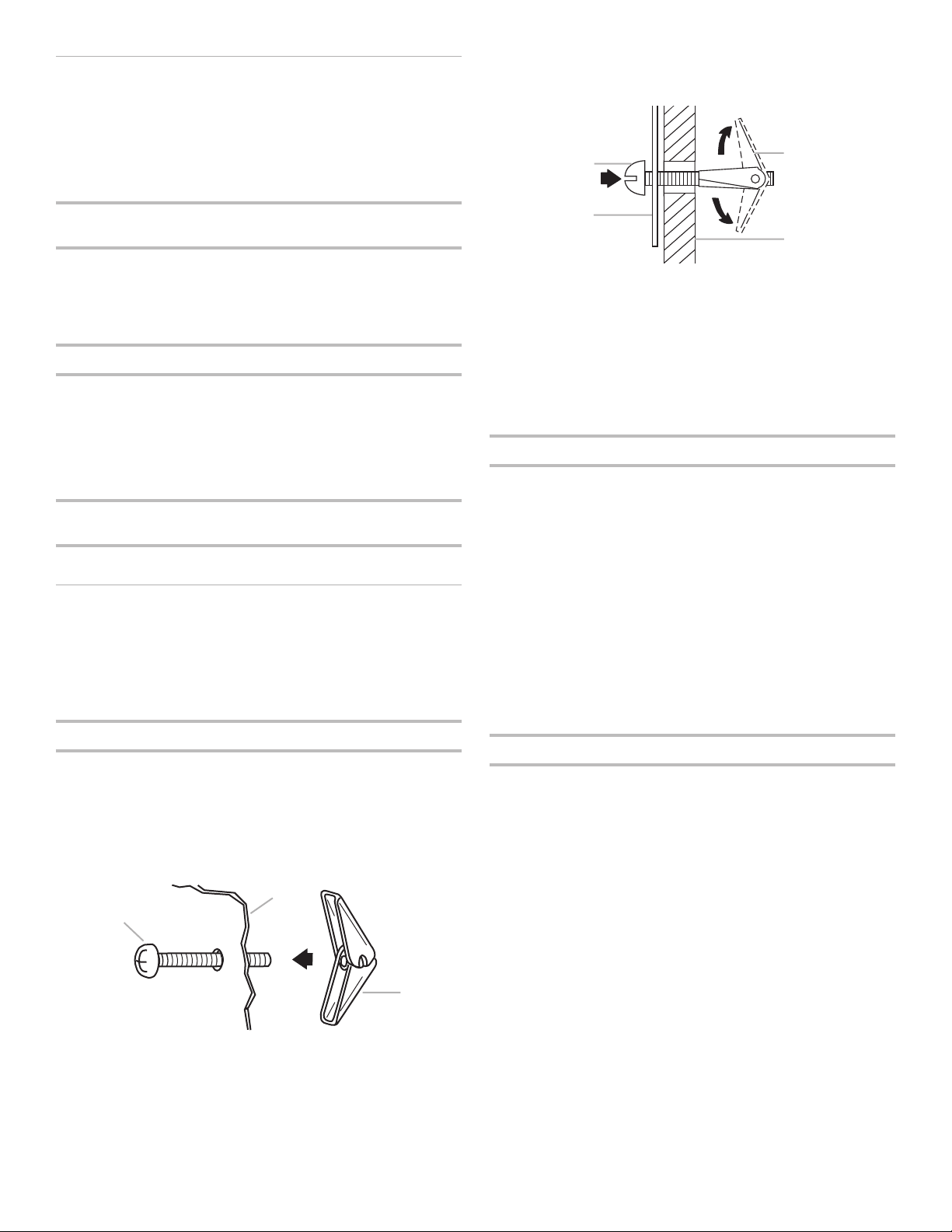

4. Push the 2 bolts with toggle nuts through the drywall, and

nger tighten the bolts to make sure toggle nuts have

opened against drywall.

C

D

A. 3/16-24 x 3" round-head bolt

B. Mounting plate

C. Spring toggle nut

D. Drywall

Installation for Wall Stud at One End Hole (Figure 3)

1. Drill a 3/16" (5 mm) hole into the wall stud at the end hole

marked in Step 3 of the “Mark Rear Wall.”

2. If installing on a second wall stud, drill a 3/16" (5 mm) hole

into the wall stud at the other hole marked in Step 6 of the

“Mark Rear Wall.” Refer to Figure 3 in “Possible Wall Stud

Congurations” in the “Locate all Stud(s)” section.

3. Drill a 5/8" (1.6 cm) hole through the wall at the other end

hole.

Installation for Wall Studs at Both End Holes

(Figure 4)

1. Drill 3/16" (5 mm) holes into the studs at the end holes

marked in Step 3 of the “Mark Rear Wall.”

Attach Mounting Plate to Wall

NOTE: Secure the mounting plate to the wall at both end holes

drilled into the wall studs and/or drywall using either 3/16-24 x

3" (7.6 cm) round-head bolts and toggle nuts or 1/4 x 2" (5.1 cm)

lag screws.

Refer to illustrations in “Possible Wall Stud Congurations” in the

“Locate Wall Stud(s)” section.

No Wall Studs at End Holes (Figures 1 and 2)

NOTE: The mounting plate must be secured to the wall on at

least 1 wall stud as well as at both ends.

1. With the support tabs of the mounting plate facing forward,

insert 3/16-24 x 3" round-head bolts through both end holes

of mounting plate.

2. Start toggle nuts on bolts from the back of the mounting

plate. Leave enough space for the toggle nuts to go through

the wall and to open.

5. Insert lag screw(s) into the hole(s) drilled into wall stud(s) in

Step 2 of “Installation for No Wall Studs at End Holes” in the

“Drill Holes in Rear Wall” section.

6. Check alignment of mounting plate, making sure it is level.

7. Securely tighten all lag screws and bolts.

Wall Stud at One End Hole (Figure 3)

1. With the support tabs of the mounting plate facing forward,

insert a 3/16-24 x 3" round-head bolt through the end

hole that ts over the 5/8" (16 mm) hole drilled in Step 3 of

“Installation for Wall Stud at One End Hole” in the “Drill Holes

in Rear Wall” section.

2. Start a toggle nut on the bolt from the back of the mounting

plate. Leave enough space for the toggle nut to go through

the wall and to open.

3. Position mounting plate on the wall.

4. Push the bolt with toggle nut through the drywall, and nger

tighten the bolt to make sure toggle nut has opened against

drywall.

5. Insert a lag screw into the remaining end hole.

6. If installing on a second wall stud, insert a lag screw into the

other hole drilled in Step 2 of “Installation for Wall Stud at

One End Hole” in the “Drill Holes in Rear Wall” section.

7. Check alignment of mounting plate, making sure it is level.

8. Securely tighten the lag screw(s) and bolt.

Wall Studs at Both End Holes (Figure 4)

1. Position mounting plate on the wall.

2. Insert lag screws into both end holes.

3. Check alignment of mounting plate, making sure it is level.

4. Securely tighten the lag screws.

B

A. 3/16-24 x 3" round-head bolt

B. Mounting plate

C. Spring toggle nut

3. Position mounting plate on the wall.

10

Page 11

Prepare Upper Cabinet

A

B

AB CD

1. Disconnect power to outlet.

2. Remove all contents from upper cabinet.

3. Place Upper Cabinet Template against the bottom of the

upper cabinet, and attach with tape or thumbtacks. Make

sure the template centerline aligns with the vertical centerline

on the rear wall.

The “rear wall” arrows must be against the rear wall so that

the holes cut into the upper cabinet align with the holes in

the top of the microwave oven.

NOTES:

■ If the upper cabinet has a frame around it, trim the template

edges so that it ts inside the frame, against the upper

cabinet bottom. The template has trim lines to use as guides.

■ If the wall behind the microwave oven (as installed) has a

partial wall covering (for example, tile backsplash), be sure

the “Rear Wall” arrows align to the thickest part of t he rear

wall (for example, the thickness of the tiles rather than the

drywall).

4. Make sure the 10" (25.4 cm) dimension from the rear wall to

points “D” and “E” on the template is maintained.

D

10"

(25.4 cm)

c

r

-

e

p

U

p

F

p

b

inet

a

t

e

m

l

t

e

a

E

10"

G

(25.4 cm)

Install Damper Assembly

(for wall venting only)

1. Check that damper blade moves freely and opens fully.

2. Position the damper assembly on the back of the microwave

oven so that the damper blade hinge is at the top, and the

damper blade opens away from the microwave oven.

A. Back of microwave oven

B. Damper assembly

C. Damper blade

D. #6 x 3/8" Sheet metal screws

3. Secure damper assembly with 2 #6 x 3/8" sheet metal

screws.

5. Cut the 11⁄2" (3.8 cm) diameter hole at the circular shaded

area “G” on the template. This hole is for the power supply

cord.

NOTE: If upper cabinet is metal, the supply cord bushing

needs to be installed around the supply cord hole as shown.

A. Metal cabinet

B. Power supply cord bushing

6. Drill 3/8" (10 mm) holes at points “D” and “E” on the

template. These are for two 1/4-20 x 3" bolts and washers

used to secure the microwave oven to the upper cabinet.

For Roof Venting Installation Only:

7. Cut 3/4" (1.9 cm) hole at one corner of the shaded

rectangular area “F” on Upper Cabinet Template.

8. Using a keyhole saw, cut out the rectangular area.

11

Page 12

Install the Microwave Oven

A

A

WARNING

Excessive Weight Hazard

Use two or more people to move and install

microwave oven.

Failure to do so can result in back or other injury.

IMPORTANT: The control side of the microwave oven is the

heavy side. Handle the microwave oven gently.

1. Remove the 2 packing spacers from the top of the vent grille

before using the microwave oven.

A

A. Packing spacers (2)

NOTE: Depending on your model, it may not have packing

spacers. If it does not have packing spacers, begin with step 2.

2. Place a washer on each 1/4-20 x 3" at-head bolt and place

inside upper cabinet near the 3/8" (10 mm) holes.

3. Make sure the microwave oven door is closed and taped

shut.

5. With front of microwave oven still tilted, thread power supply

cord through the power supply cord hole in the bottom of the

upper cabinet.

6. Rotate microwave oven up toward upper cabinet.

NOTE: If venting through the wall, make sure the damper

assembly ts easily into the vent in the wall cutout.

7. Push microwave oven against mounting plate and hold in

place.

NOTE: If microwave oven does not need to be adjusted, skip

steps 7 through 9.

8. If adjustment is required, rotate microwave oven downward.

Using 2 or more people, lift microwave oven off of mounting

plate, and set aside on a covered surface.

9. Loosen mounting plate screws. Adjust mounting plate and

retighten screws.

10. Repeat steps 3 through 6.

11. With the microwave oven centered, and with at least one

person holding it in place, insert bolts through upper cabinet

into microwave oven. Tighten bolts until there is no gap

between upper cabinet and microwave oven.

NOTES:

■ Some upper cabinets may require bolts longer or shorter

than 3" (7.6 cm). Longer or shorter bolts are available at

most hardware stores.

■ Overtightening bolts may warp the top of the microwave

oven. To avoid warping, wood ller blocks (installer to

provide) may be added. The blocks must be the same

thickness as the space between the upper cabinet

bottom and the microwave oven.

4. Using 2 or more people, lift microwave oven and hang it on

support tabs at the bottom of mounting plate.

NOTE: To avoid damage to the microwave oven, do not grip

or use the door or door handle while the microwave oven is

being handled.

A. Bolts

B

A. Mounting plate

B. Support tabs

12

Page 13

NOTE: Avoid damage to the mounting nut, screw the bolts into

AB C

DE F

the mounting nut holes around 15-20 mm by hand rst, make

sure the bolts thread in properly. Then tighten with tools.

A

15-20 mm

B

A. Bolt

B. Mounting Nut

For Roof Venting Installation Only

1. Insert damper assembly through the cabinet cutout so that

the long tab of the damper assembly slides under the raised

tabs of the damper plate. Then secure with #6 x 3/8" sheet

metal screw.

NOTE: The screw cannot be installed if the damper assembly is

not positioned as shown.

A. Raised tabs

B. Damper assembly

C. #6 x 3/8" Sheet metal screw

D. Upper cabinet cutout

E. Long tab

F. Damper plate

Complete Installation

1. Install lters. Refer to the User Instructions for lter

placement.

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

2. Plug microwave oven into grounded 3 prong outlet.

3. Reconnect power.

4. Check the operation of microwave oven by placing 1 cup

(250mL) of water on the turntable and programming a cook

time of 1 minute at 100% power. Test vent fan and exhaust

by operating the vent fan.

5. If the microwave oven does not operate:

■ Check that a household fuse has not blown, or that a

circuit breaker has not tripped. Replace the fuse or reset

the circuit breaker. If the problem continues, call an

electrician.

■ Check that the power supply cord is plugged into a

grounded 3 prong outlet.

■ See the User Instructions for troubleshooting information.

The installation is now complete.

Save Installation Instructions for future use.

2. Connect vent to damper assembly.

A. Vent

B. Damper assembly (under vent)

AB

13

Page 14

VENTING DESIGN SPECIFICATIONS

A

B

C

E

F

D

3" (7.6 cm)

AB C

DE FG

This section is intended for architectural designer and builder/

contractor reference only.

NOTES:

■ Vent materials needed for installation are not provided

with microwave hood combination.

■ We do not recommend using a exible metal vent.

■ To avoid possible product damage, be sure to vent air

outside, unless using recirculation installation. Do not

vent exhaust air into concealed spaces, such as spaces

within walls or ceilings, attics, crawl spaces or garages.

For optimal venting installation, we recommend:

■ Using roof or wall caps that have backdraft dampers.

■ Using a rigid metal vent.

■ Using the most direct route by minimizing the length

of the vent and number of elbows to provide efcient

performance.

■ Using uniformly sized vents.

■ Using duct tape to seal all joints in the vent system.

■ Using caulking compound to seal exterior wall or roof

opening around cap.

■ Not installing 2 elbows together, for optimal hood

performance.

If venting through the wall, be sure that there is proper clearance

within the wall for the damper to open fully.

If venting through the roof, and rectangular-to-round transition is

used, be sure there are at least 3" (7.6 cm) of clearance between

the top of the microwave oven and the transition piece. See

“Rectangular-to-Round Transition” illustration.

Rectangular-to-Round Transition

NOTE: The minimum 3" (7.6 cm) clearance must exist between

the top of the microwave oven and the rectangular-to-round

transition piece so that the damper can open freely and fully.

A. Roof cap

B. 6" (15.2 cm) min. diameter round vent

C. Elbow (for wall venting only)

D. Wall cap

1

E. 3

⁄4" x 10" to 6" (8.3 x 25.4 cm to 15.2cm)

rectangular-to-round transition piece

F. Vent extension piece, at least 3" (7.6 cm) high

Recommended Standard Fittings

The following length equivalents are for use when guring vent

length. See the examples in “Recommended Vent Length.”

Roof venting

Wall venting Wall cap

Roof cap

A. Rectangular-to-round transition piece: 31⁄4" x 10" to 6" = 5ft

(8.3 x 25.4 cm to 15.2 cm = 1.5 m)

B. Roof cap: 31⁄4" x 10" = 24 ft (8.3 x 25.4 cm = 7.3 m)

C. 90° elbow: 31⁄4" x 10" = 25 ft (8.3 x 25.4 cm = 7.6 m)

D. 90° elbow: 6" = 10 ft (15.2 cm = 3 m)

E. Wall cap: 31⁄4" x 10" = 40 ft (8.3 x 25.4 cm = 12.2 m)

F. 45° elbow: 6" = 5 ft (15.2 cm = 1.5 m)

G. 90° at elbow: 31⁄4" x 10" = 10 ft (8.3 x 25.4 cm = 3 m)

14

Page 15

Recommended Vent Length

A B

C

6 pi (1.8 m)

2 pi

(0.6 m)

A B

C D

6 pi (1.8 m)

2 pi

(0.6 m)

A

A 31⁄4" x 10" (8.3 x 25.4 cm) rectangular or 6" (15.2 cm) round

vent should be used.

The total length of the vent system including straight vent,

elbow(s), transitions and wall or roof caps must not exceed

the equivalent of 140 ft (42.7 m) for either type of vent. See

the “Recommended Standard Fittings” section for equivalent

lengths.

For best performance, use no more than three 90° elbows.

To calculate the length of the system you need, add the

equivalent lengths of each vent piece used in the system.

See the following examples:

6" (15.2 cm) vent system = 73 ft (22.2 m) total

31⁄4" x 10" (8.3 x 25.4 cm) vent system = 73 ft (22.2 m)

total

A. One 3

B. 1 wall cap = 40 ft (12.2 m)

C. 2 ft (0.6 m) + 6 ft (1.8 m) straight = 8 ft (2.4 m)

1

⁄4" x 10" (8.3 x 25.4 cm) 90° elbow = 25 ft (7.6 m)

ASSISTANCE

Call your authorized dealer or service center. When you call, you

will need the microwave oven model number and serial number.

Both numbers can be found on the model and serial number

plate, which is located behind the microwave oven door on the

front frame of the microwave oven.

If you need additional assistance, call us at our toll-free number

or visit our website listed in the User Guide.

A. Two 90° elbows = 20 ft (6.1 m)

B. 1 wall cap = 40 ft (12.2 m)

C. 1 rectangular-to-round transition piece = 5 ft (1.5 m)

D. 2 ft (0.6 m) + 6 ft (1.8 m) straight = 8 ft (2.4 m)

If the existing vent is round, a rectangular to round transition

piece must be used. In addition, a rectangular 3" (7.6 cm)

extension vent between the damper assembly and rectangular to

round transition piece must be installed to keep the damper from

sticking.

Accessories

Filler Panel Kits are available from your dealer to use when

installing this microwave oven in a 36" (91.4 cm) or

42"(106.7cm) wide opening. The ller panels come in pairs.

Each panel is 3" (7.6 cm) wide.

Replacement Parts

If any of the installation hardware needs to be replaced, call us at

our toll-free number listed in the User Guide.

Following is a list of available replacement parts. You will need

your model and serial numbers located on the front facing of the

microwave oven opening, behind the door.

■ Damper Assembly

■ Mounting Plate

■ Upper Cabinet Template

■ Mounting Screw Kit (includes parts A-G in “Parts

Supplied” in the “Tools and Parts” section)

A. Filler panels

Filler Panel Kits: 8171336 White

8171337 Black

8171338 Biscuit

8171339 Stainless Steel

99403 Almond

See your authorized dealer or service center for details.

15

Page 16

SÉCURITÉ DE L’ENSEMBLE FOUR À MICRO-ONDES/HOTTE

A

B

C

DEF

G

H

EXIGENCES D’INSTALLATION

Outillage et pièces

Outillage nécessaire

Rassembler les outils et pièces nécessaires avant de

commencer l’installation. Lire et suivre les instructions fournies

avec les outils mentionnés ici.

■ Mètre ruban

■ Crayon

■ Ruban de masquage ou

■ Ciseaux

■ Tournevis Phillips n° 2

■ Tournevis Phillips n° 3 pour vis de 1/4-20 x 3" (7,6 cm)

■ Perceuse

■ Mèches de 3/16" (5 mm), 3/8" (1 cm) et 5/8" (1,6 cm)

■ Scie-cloche de 3/4" (1,9 cm)

■ Pince à coupe diagonale

■ Détecteur magnétique (des poteaux de colombage)

■ Clé à douille de 7⁄16" (11,11 mm) (ou clé polygonale) pour vis

d’ancrage de 1/4" x 2" (6,4 mm x 5,1 cm)

■ Foret de 1

métallique

■ Scie à guichet

■ Pistolet à calfeutrage et composé de calfeutrage résistant

aux intempéries

■ Ruban adhésif pour conduit

Pièces fournies

Pour la commande de pièces, voir la section “Pièces de

rechange”.

16

1

/2" (3,8 cm) de diamètre pour placard de bois ou

REMARQUE: Les articles de quincaillerie présentés ci-dessous

sont destinés à l’utilisation sur un colombage de bois. En

présence d’une structure de mur différente, utiliser les organes

de xation app opriés.

A. Vis à tête ronde de 3/16-24 x 3" (2)

B. Vis à tête plate de 1/4-20 x 3" (2)

C. Rondelles (2)

D. Écrous articulés de 3/16" (2)

E. Vis d’ancrage de 1/4" x 2" (2)

F. Vis à tôle de 6 x 3/8" (2)

G. Garniture pour trou de passage du

cordon d’alimentation (1)

H. Module de clapet anti-reux

(pour décharge à travers le mur ou

le toit)

Composants non illustrés :

■ Gabarit pour placard

supérieur (mural)

■ Plaque de montage

(xation à l’arriè e du four

à microondes)

■ Gabarit de carton

(partie de l’emballage)

ou gabarit mural

■ Filtres à graisse en

aluminium

■ Filtres à charbon (selon

le modèle, les lt es à

charbon peuvent ne

pas être inclus. Voir les

Instructions d’utilisation.)

REMARQUE: Selon le modèle de l’appareil, le lt e à graisse en

aluminium et le lt e à charbon peuvent être combinés.

Matériaux nécessaires

Composants standard pour décharge à travers le mur ou à

travers le toit. Voir la section “Spécications/conception d circuit

d’évacuation”.

Page 17

Dépose du gabarit de carton

AB

12 ≤ PLUS

PROFOND

14 ≤ PLUS

Support de montage

Le morceau de carton du dessus de l’emballage du four à

microondes est perforé. La partie à l’intérieur des trous de

perforation est à utiliser comme gabarit de mur arrière.

1. Découper le long des trous perforés pour détacher le gabarit

du reste de l’emballage de carton.

2. Mettre le gabarit de carton de côté et s’y référer lors de

l’étape d’installation “Tracé sur le mur arrière”.

Selon le modèle, passer les étapes "Ôter le gabarit de carton"

si une boîte en carton complète est utilisée comme emballage.

Utilisercependant le gabarit mural pour effectuer la section

"Tracé sur le murarrière" de l’installation.

Exigences d’emplacement

Inspecter l’espace où le four à micro-ondes sera installé.

L’emplacement d’installation doit disposer de :

■ Dimensions minimales à respecter lors de l’installation. Voir

l’ illustration “Dimensions à respecter lors de l’installation”.

■ Au moins un poteau de colombage en bois 2" x 4" (5,1

x 10,2 cm), et parement de plâtre ou panneau de gypse

d’épaisseur 3/8" (1 cm) ou plus, dans l’ouverture du placard.

■ Capacité de support de charge de 150 lbs (68 kg), ceci

incluant le four à micro-ondes et les articles placés à

l’intérieur du four à micro-ondes et du placard supérieur.

■ Prise de courant électrique reliée à la terre à l’intérieur du

placard supérieur. Voir la section “Spécications électriques".

REMARQUES:

■ Dans le cas de l’installation du four à micro-ondes à

proximité d’une paroi latérale sur le côté gauche, veiller

à laisser un espace libre de 6" (15,2 cm) ou plus entre le

mur et le four à micro-ondes, pour permettre la manoeuvre

d’ouverture complète de la porte.

■ Certains modèles sontmunisd’unepoignéedissimulée. Dans

le cas de l’installation du four à micro-ondes près d’une paroi

latérale sur le côté droit, laisser un espace libre de 3 po ou

plus entre le mur et le four à micro-ondes pour permettre

d’agripper la poignée intégrée à la porte.

■ Les matériaux de certains placards et certains matériaux de

construction ne sont pas conçus pour résister à la chaleur

émise par le four à micro-ondes lors des opérations de

cuisson. Consulter le constructeur de la maison ou

le fabricant des placards pour déterminer si les matériaux

utilisés pourraient subir un changement de couleur,

une déstratication ou d’aut es dommages.

Exigences spéciales

Pour une installation avec décharge murale seulement:

■ L’ouverture découpée doit être exempte d’obstruction pour

l’ajustement adéquat du conduit, et pour que le clapet

antireux puisse manoeuv er complètement et librement.

Pour une installation avec décharge à l’extérieur à travers le

toit seulement:

■ Si l’on utilise un raccord de transition rectangulaire/rond, on

doit disposer d’un espace libre de 3" (7,6 cm) au-dessus

du four à micro-ondes pour que la lame du clapet antireux puisse manoeuver complètement et librement. Voir

l’illustration “Raccord de transition rectangulaire/rond” à

la section “Spécications/conception du ci cuit

d’évacuation”.

Dimensions à respecter lors de l’installation

REMARQUE : La prise de courant à 3 alvéoles reliée à la terre

doit être située à l’intérieur du placard supérieur. Voir la section

“Spécications électriques”.

12" (30,5 cm) min.

14" (35,6 cm) max.

30"

(76,2 cm)

min.

30"

(76,2 cm)

typique*

66" (167,6 cm) min.

A. Poteau du colombage mural de 2" x 4"

B. Prise à 3 alvéoles reliée à la terre

*30" (76,2 cm) est typique pour une hauteur d’installation de 66"

(167,6 cm). Les dimensions exactes peuvent varier en fonction

du type de cuisinière/table de cuisson se trouvant en-dessous.

REMARQUE: Pour garantir de bons résultats, ne pas obstruer

l’ouverture d’évacuation supérieure. Si la profondeur des

armoires est de plus de 14 po (35,6 cm), mais pas plus de 15

po (38,1 cm), utiliser l’ensemble de montage de bourrelet pour

remplacer la plaque de montage sur le mur. L’ensemble de

montage de bourrelet (numéro de pièce W11185746) n’est pas

fourni, mais peut être acheté de Whirlpool.

≤ 14

PROFOND ≤ 15

de bourrelet

profondeur du

placard supérieur et

du placard latéral

17

Page 18

Dimensions du produit

(41,3 cm)

(43,2 cm)*

(43,5 cm)

"

¹⁄₈

17

"

³⁄₁₆

+/(0,5 cm)

"

¹⁄₄

16

J

usqu'à

17"

⁷⁄₈

" (76,0

cm)29

*La profondeur totale du produit varie légèrement selon

la conception de la porte.

Spécications électriques

AVERTISSEMENT

Risque de choc électrique

Brancher sur une prise à 3 alvéoles reliée à la terre.

Ne pas enlever la broche de liaison à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Le non-respect de ces instructions peut causer

un décès, un incendie ou un choc électrique.

Observer les dispositions de tous les codes et règlements en

vigueur.

Nécessaire :

■ Une alimentation électrique de 120 V, 60 Hz, CA

seulement, 15 ou 20 A, protégée par un fusible

ou un disjoncteur.

Recommandé :

■ Un fusible temporisé ou un disjoncteur temporisé.

■ Un circuit distinct exclusif à ce four à micro-ondes.

INSTRUCTIONS DE LIAISON

À LA TERRE

■

Pour tout appareil ménager connecté par un cordon

de courant électrique :

Il faut que le four à micro-ondes soit relié à la terre. En

cas de court-circuit électrique, la liaison à la terre réduit le

risque de choc électrique car le courant électrique

dispose d’un itinéraire direct d’acheminement à la terre.

Le four à micro-ondes est doté d’un cordon de courant

électrique qui comporte un fil de liaison à la terre, avec

broche de liaison à la terre. On doit brancher la fiche sur

une prise de courant convenablement installée et reliée à

la terre.

AVERTISSEMENT : L’utilisation incorrecte du

dispositif de liaison à la terre peut susciter un risque de choc

électrique. L’utilisateur qui ne comprend pas bien les

instructions de liaison à la terre, ou qui n’est pas certain que

le four à micro-ondes soit convenablement relié à la terre,

devrait consulter un électricien ou un technicien qualifié.

Ne pas utiliser un câble de rallonge. Si le cordon de

courant électrique est trop court, demander à un électricien

ou un technicien qualifié d’installer une prise de courant à

proximité du four à micro-ondes.

CONSERVEZ CES

INSTRUCTIONS

18

Page 19

INSTRUCTIONS D’INSTALLATION

A

B

A

A

A

Dépose de la plaque de montage

Selon votre modèle, la plaque de montage peut se trouver soit

dans l’emballage en mousse, soit xée à l’arrièe du four à

micro-ondes.

REMARQUE : Couvrir la surface de travail pour éviter de

l’endommager.

1. Retirer de la cavité du four à micro-ondes tous les articles

qui peuvent s’y trouver.

2. Si la plaque de montage est xée sur la partie arrièe du four

à micro-ondes, la retirer et la mettre de côté.

3. Utiliser du ruban adhésif pour immobiliser la porte fermée du

four à micro-ondes an qu’elle ne puisse pas s’ouvrir duran

la manipulation du four.

REMARQUE : Pour éviter d’endommager le four à micro-ondes,

ne pas prendre prise sur la porte ou la poignée de la porte

durant la manipulation du four à micro-ondes.

Réorientation du moteur du ventilateur

Le four à micro-ondes a été conguré à l’usine pou une

installation avec recyclage de l’air. Pour la décharge de l’air

aspiré à travers le mur ou à travers le toit, on doit modier le

système de ventilation du fou.

REMARQUE : Si le produit est destiné à être utilisé avec

recyclage de l’air, ne pas tenir compte de cette section.

Conserver le module du clapet pour le cas où une autre méthode

d’évacuation serait utilisée ultérieurement ou dans le cas où le

four à micro-ondes serait réinstallé ultérieurement en un autre

endroit, avec décharge à l’extérieur à travers le mur ou à travers

le toit.

3. Retirer 2 vis de ventilateur xant le moteur du ventilateur au

four à micro-ondes et les garder pour plus tard.

A. Vis du ventilateur (dans des trous encastrés)

4. Débrancher le l du moteur de ventilateur du connecteur.

A

B

Pour une installation avec décharge murale

seulement

1. Ôter les vis xant la plaque de support du clapet à la partie

arrière du four à micro-ondes et les garder pour plus tard.

A. Plaque de support du clapet anti-reu

B. Vis

2. Tourner et maintenir la plaque de support du clapet à la

verticale, comme illustré.

A. Fil du moteur de ventilateur

B. Connecteur

5. Sortir le moteur du four à micro-ondes et le garder pour plus

tard.

A. Plaque de support du clapet

A. Moteur du ventilateur

19

Page 20

6. Utiliser une pince coupante pour découper doucement les

B

A

A

B

A B

A

B

A

points de xation rectangulaires des couvercles de

fermeture.

A. Pince coupante diagonale

B. Couvercles de fermeture rectangulaire du clapet

7. Tenir le l du moteur, placer le l à travers le pont du moteur

de ventilateur.

10. Fixer de nouveau les 2 vis du ventilateur dans les trous

encastrés situés à l’arrière du four à micro-ondes.

A. Vis

B. Trous encastrés

A

B

A. Pont du moteur de ventilateur

B. Fil du moteur de ventilateur

8. Abaisser le moteur de ventilateur pour le réinsérer dans le

four à micro-ondes. L’orice de sortie fait face vers l’arrière

du four à micro-ondes.

A

A. Orice de sortie

9. Rebrancher le l du moteur de ventilateur dans le

connecteur.

11. S’assurer que les 2 vis sont bien xées dans les trous de vis

du moteur de ventilateur pour que le moteur ne puisse pas

bouger.

A. Vis

B. Trous de vis du moteur de ventilateur

12. Remettre la plaque de support du clapet à sa position

horizontale d’origine.

A. Fil du moteur de ventilateur

B. Connecteur

20

A. Plaque de support du clapet

Page 21

13. Fixer la plaque de support du clapet à l’aide des 2 vis qui ont

A

B

été retirées à l’étape 1.

A. Plaque de support du clapet

B. Vis

Pour une installation avec décharge à l’extérieur à

travers le toit seulement

1. Répéter l’étape 1 de “Pour une installation avec décharge

murale seulement”.

2. Répéter l’étape 2 de “Pour une installation avec décharge

murale seulement”.

3. Répéter l’étape 3 de “Pour une installation avec décharge

murale seulement”.

4. Répéter l’étape 4 de “Pour une installation avec décharge

murale seulement”.

5. Répéter l’étape 5 de “Pour une installation avec décharge

murale seulement”

6. Utiliser une pince coupante diagonale pour découper

doucement les couvercles du conduit rectangulaire aux

perforations du clapet antiretour

A

8. Rebrancher le l du moteur de ventilateur dans le

connecteur.

9. Fixer de nouveau les 2 vis du ventilateur dans les trous

encastrés situés à l’arrière du four à micro-ondes.

10. S’assurer que les 2 vis sont bien xées dans les trous de vis

du moteur de ventilateur pour que le moteur ne puisse pas

bouger.

11. Remettre la plaque de support du clapet à sa position

horizontale d’origine.

A

A. Plaque de support du clapet

12. Fixer la plaque de support du clapet à l’aide des 2 vis qui ont

été retirées à l’étape 1.

A

B

B

A. Couvercles de fermeture rectangulaire

B. Pince coupante diagonale

A. Plaque de support du clapet

B. Vis

7. Abaisser le moteur de ventilateur pour le réinsérer dans le

four à micro-ondes. Les orices de sortie font face vers le

haut du four à micro-ondes.

A

IMPORTANT: Si le moteur du ventilateur n’est pas positionné

avec le côté plat orienté vers l’arrière du four à micro-ondes

(comme illustré), le rendement sera médiocre.

A. Orice de sorti

21

Page 22

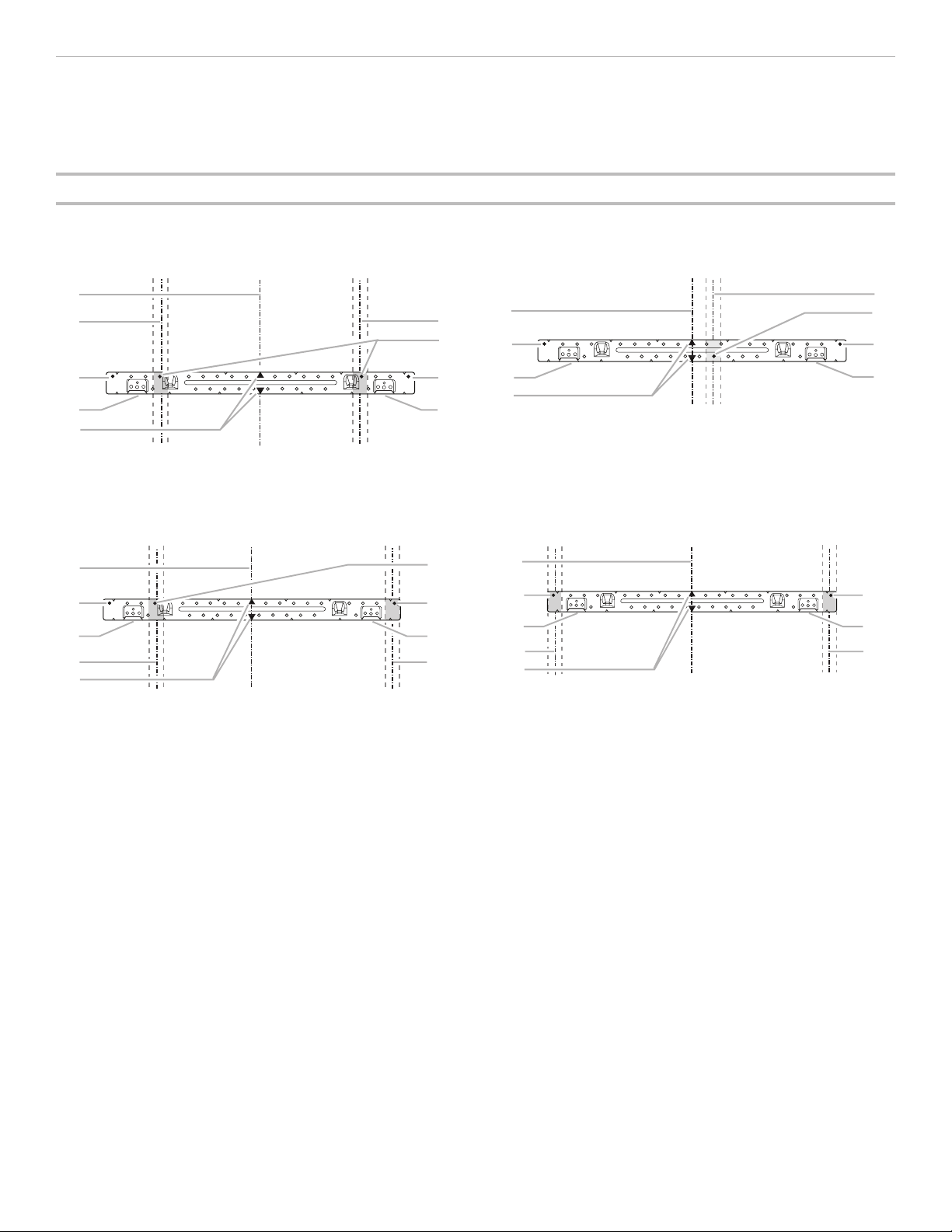

Identier la position du/des poteau(x) du colombage mural

Figure 1

C

C

D

E

F

Figure 3

D

C

E

F

Figure 2

B

C

E

F

Figure 4

A,D

D

REMARQUE : S’il n’y a aucun poteau du colombage mural dans

la zone délimitée par l’ouverture dans le placard supérieur, ne

pas installer le four à micro-ondes.

Voir les illustrations à la section “Congurations possibles d

colombage mural”.

Congurations possibles du colombage mural

Les illustrations ci-dessous présentent des exemples de congurations préférées d’installation avec la plaque de montage.

1. Utiliser un détecteur magnétique pour localiser dans

l’ouverture les rives du/des poteau(x) du colombage mural.

2. Marquer la position du centre de chaque poteau du

colombage, et tracer l’axe de chaque poteau à l’aide d’un

l à plomb. oir les illustrations à la section “Congurations

possibles du colombage mural”

Aucun poteau du colombage à la position des trous

d’angle

B

A

A

E

Un trou d’angle face à un poteau du colombage mural

B

A

D

A,

E

C

Aucun poteau du colombage à la position des trous

d’angle

D

A

A

E

REMARQUE :

Si le poteau de colombage mural se trouve à 6" (15,2 cm) ou

moins de l’axe central vertical (voir la section “Tracé sur le

mur arrière”), seule une installation sans décharge à l’extérieur

(recyclage) ou une installation avec décharge par le toit peut être

réalisée.

Deux trous d’angle face à des poteaux du colombage

mural

B

A,

E

C

F

E

C

22

A. Trous d’angle (sur la plaque de montage)

B. Axe vertical central de l’ouverture dans le placard

C. Axes centraux de poteau du colombage

D. Trous pour vis d’ancrage

E. Pattes de support

F. Repères centraux sur la plaque de montage

Page 23

Tracé sur le mur arrière

A

A

Fond du placard supérieur

e

Trou d'angle de la plaque de montage

Le four à micro-ondes doit être xé sur au moins un poteau d

colombage mural, et de préférence sur 2 poteaux; on utilise pour

cela au moins 1 vis d’ancrage, et de préférence 2 vis.

1. Utiliser un mètre ruban; déterminer et marquer clairement la

position de l’axe central vertical de l’ouverture.

A. Axe central

2. Aligner le marquage central du gabarit de carton (partie

supérieure du carton) ou le gabarit mural avec l’axe central

sur le mur, en faisant attention qu’il soit bien de niveau et

que le haut du gabarit de carton soit bien positionné bout à

bout avec le bas de l’armoire.

REMARQUES :

■ Si le bord avant de l’armoire supérieure est plus bas que le

bord arrière, abaisser le gabarit de carton ou le gabarit mural

de manière à ce que son sommet soit au même niveau que

le bord avant de l’armoire.

■ Si le gabarit de carton ou gabarit mural est endommagé ou

inutilisable, mesurer et inscrire les dimensions sur le mur,

comme décrit à l’étape 4.

■ Les trous d’angle doivent être situés à 15

5

⁄8" (39,71 cm) de

la rive inférieure du placard supérieur et doivent être alignés

les uns avec les autres. Chacun doit être situé à 141⁄8"

(35,96cm) de l’axe central.

5. Une fois les brides de support orientées vers l’avant (voir

les illustrations de la section “Iden n de la positio du/des

poteau(x) du colombage mural”), aligner le tracé du centre

de la plaque de montage avec l’axe central sur le mur,

en s’assurant que sa rive inférieure est alignée avec l’axe

horizontal tracé à l’étape 3 et que les trous d’angle sont

correctement indiqués. S’assurer que la plaque de montage

est d’aplomb.

6. Tout en maintenant la plaque de montage en place, trouver

l’axe central/les axes centraux des poteaux du colombage

marqué(s) à l’étape 2 de la section “Iden n d la position du/

des poteau(x) du colombage mural”, et marquer la position

d’au moins 1, et de préférence 2, trou(s) à travers la plaque

de montage - le plus près possible de l’axe central/des

axes centraux de chaque poteau du colombage. Voir les

u es 1, 2et/ou 3 de la section “Conguration possibles du

colombage mural” à la section “Iden n d la position du/

des poteau(x) du colombage mural”. Les trous à utiliser de

préférence sont ceux qui sont marqués en noir dans les

zones grisées.

7. Conserver la plaque de montage à part.

Pour une installation avec décharge murale

seulement

Fond du placard supérieur

³⁄₈" (1 cm)

D

C

B

A. Mur arriére

B. Gabarit de carton ou gabarit mural

C. Le sommet du gabarit de carton ou gabarit

mural doit être aligné avec le bord avant

de l’armoire.

D. Rive avant du placard supérieur

3. Tout en maintenant le gabarit de carton ou gabarit mural

en place, marquer l’emplacement des deux trous dans les

coins inférieurs et tracer une ligne horizontale en travers

du bord inférieur du gabarit de carton ou gabarit mural.

Ils correspondent aux trous d’extrémités de la plaque de

montage ainsi qu’au bord inférieur.

4. Ôter le gabarit de carton ou gabarit mural et vérier les

points de marquage:

15⁵⁄₈"

(39,71 cm)

Axe central

17⁵⁄₁₆"

(44,02 cm)

4" (10,2 cm)

Axe central

8. Marquer un point sur l’axe central à 3/8" (1 cm) au-dessous

de la rive inférieure du placard supérieur.

9. Utiliser un mètre ruban; marquer un point à 6" (15,2 cm) de

chaque côté de l’axe central.

10. Marquer un point à 4" (10,2 cm) au-dessous de la marque

tracée à l’étape 8.

11. Utiliser une règle; tracer 2 lignes horizontales entre les

marques tracées aux étapes 8 et 10.

12. Tracer 2 lignes verticales à partir des marques faites à l’étape

9 à l’aide d’un l à plomb pour obtenir un ectangle complet

de 12" x 4" (30,5 x 10,2 cm). Ce rectangle délimite la zone à

découper pour le passage du conduit d’évacuation.

13. Découper un trou de 3/4" (19 mm) dans un coin de la zone à

découper.

14. À l’aide d’une scie à guichet, découper la zone à découper

pour le passage du conduit d’évacuation.

14¹⁄₈"

■ L’axe de la rive inférieure doit être situé à 17

(35,96 cm)

de la partie inférieure du placard supérieur et doit être

d’aplomb.

14¹⁄₈"

(35,96 cm)

Partie inférieure de

la plaque de montag

5

⁄16" (44,02cm)

23

Page 24

Perçage de trous dans le mur arrière

C

A

B

A

B

En plus de la xation sur au moins un poteau du colombage,

o doit également xer la plaque de montage sur le mur au

nivea des deux trous d’angle. Si la position des trous d’angle

ne coïncide pas avec celle des poteaux du colombage mural,

utiliser deux vis à tête ronde de 3/16-24 x 3" avec écrou

articulé; s’il y a un trou d’angle en coïncidence avec le poteau

de colombage, utiliser une vis d’ancrage et une vis à tête ronde

de 3/16-24 x 3" avec écrou articulé; si les deux trous coïncident

avec les poteaux de colombage mural, utiliser deux vis

d’ancrage. On présente cidessous 3 congurations d’installation.

Aucun poteau du colombage à la position des trous

d’angle (Figures 1 et 2)

1. Percer des trous de 5/8" (16 mm) à travers le mur à

l’emplacement des deux trous d’angle marqués à l’étape 3

de la section “Tracé sur le mur arrière”

2. Percer un ou plusieurs trous de 3/16" (5 mm) dans le(s)

poteau(x) de colombage mural à l’emplacement du/des

trou(s) d’angle marqué(s) à l’étape 6 de la section “Tracé

sur le mur arrière”. Voir les gures 1 et 2 du paragraphe

“Congurations possibles d u colombage mural” à la sectio

“Identication de la position du/des poteau(x) du colombag

mural”.

Poteau du colombage mural à un trou d’angle

(Figure 3)

1. Percer un trou de 3/16" (5 mm) à travers le poteau de

colombage mural à l’emplacement du trou d’angle marqué

à l’étape 3 dans “Tracé sur le mur arrière”.

2. Si l’on souhaite xer l’appareil sur un second poteau du

colombage mural, percer un trou de 3/16" (5 mm) dans

le poteau du colombage mural à l’emplacement de l’autre

trou marqué à l’étape 6 dans “Tracé sur le mur arrière”. Voir

la gure 3 dans le paragraphe “Congurations possibles d

colombage mural” à la section “Identication de la positio

du/des poteau(x) du colombage mural”

3. Percer un trou de 5/8" (16 mm) à travers le mur au niveau de

l’autre trou d’angle.

2. Engager un écrou articulé sur chaque vis par l’arrière de la

plaque de montage. Veiller à disposer de sufsammen

d’espace pour que les écrous articulés puissent traverser

le panneau de gypse et se déployer à l’intérieur de la cavité

murale.

A. Vis à tête ronde de 3/16-24 x 3"

B. Plaque de montage

C. Écrou articulé à ressort

3. Positionner la plaque de montage sur le mur.

4. Pousser les deux vis avec écrou articulé à travers le panneau

de gypse; visser les vis à la main pour vérier que chaqu

écrou articulé s’est déployé et prend appui contre le

panneau de gypse.

C

D

A. Vis à tête ronde de 3/16-24 x 3"

B. Plaque de montage

C. Écrou articulé à ressort

D. Panneau de gypse

Poteaux du colombage mural aux deux trous d’angle

(Figure 4)

1. Percer des trous de 3/16" (5 mm) à travers les poteaux

ducolombage mural à l’emplacement des trous d’angle

marqués à l’étape 3 dans “Tracé sur le mur arrière”.

Fixation de la plaque de montage

sur le mur

REMARQUE : Fixer la plaque de montage sur le mur, dans les

deux trous d’angle percés dans les poteaux du colombage et/

ou à travers le panneau de gypse à l’aide de vis à tête ronde de

3/16-24 x 3" avec écrou articulé ou vis d’ancrage de 1/4 x 2".

Voir les illustrations du paragraphe “Congurations possible du

colombage mural” à la section “Identication de la positio

du/des poteau(x) du colombage mural”.

Aucun poteau du colombage à la position des trous

d’angle (Figures 1 et 2)

REMARQUE : La plaque de montage doit être xée sur le mur

e sur au moins un poteau de colombage, ainsi qu’aux deux

angles.

1. Alors que les pattes de support de la plaque de montage

sont orientées vers l’avant, insérer des vis à tête rondede

3/16-24 x 3" dans les deux trous d’angle de la plaque de

montage.

24

5. Insérer la/les vis d’ancrage dans le/les trou(s) percé(s)

dans le(s) poteau(x) de colombage mural à l’étape 2 du

paragraphe “Aucun poteau du colombage à la position des

trous d’angle” de la section “Perçage des trous dans le mur

arrière”.

6. Contrôler l’alignement de la plaque de montage; veiller à

établir un bon aplomb.

7. Serrer solidement toutes les pièces d’ancrage (vis et

boulons).

Poteau du colombage mural à un trou d’angle

(Figure 3)

1. Alors que les pattes de support de la plaque de montage

sont orientées vers l’avant, insérer une vis à tête ronde

de 3/16-24 x 3" dans le trou d’angle coïncidant avec le trou

de 5/8" (16 mm) percé à l’étape 3 du paragraphe “Poteau du

colombage mural à un trou d’angle” de la section “Perçage

des trous dans le mur arrière”.

2. Engager un écrou articulé sur la vis par l’arrière de la plaque

de montage. Veiller à disposer de sufsamment d’espac

pour que l’écrou articulé puisse traverser le panneau de

gypse et se déployer à l’intérieur de la cavité murale.

3. Positionner la plaque de montage sur le mur.

4. Pousser la vis avec écrou articulé à travers le panneau de

gypse; visser la vis à la main pour vérier que chaqu écrou

articulé s’est déployé et prend appui contre le panneau de

gypse.

5. Insérer une vis d’ancrage dans le trou d’angle restant.

6. Si l’on souhaite xer également l’appareil sur un second

poteau du colombage mural, insérer une vis d’ancrage dans

l’autre trou percé à l’étape 2 du paragraphe “Poteau du

colombage mural à un trou d’angle” de la section “Perçage

des trous dans le mur arrière”.

Page 25

7. Contrôler l’alignement de la plaque de montage; veiller à

A

B

AB CD

établir un bon aplomb.

8. Serrer solidement la/les vis d’ancrage et le boulon.

Poteaux du colombage mural aux deux trous d’angle

(Figure 4)

1. Positionner la plaque de montage sur le mur.

2. Insérer les vis d’ancrage dans les deux trous d’angle.

3. Contrôler l’alignement de la plaque de montage; veiller à

établir un bon aplomb.

4. Serrer solidement les vis d’ancrage.

Préparation du placard supérieur

1. Interrompre l’alimentation électrique.

2. Retirer tout le contenu du placard supérieur.

3. Placer le gabarit du placard supérieur contre le fond du

placard supérieur, et le xer avec du ruban adhésif ou de

punaises. Veiller à aligner l’axe central du gabarit avec l’axe

vertical central tracé sur le mur arrière.

Les èches cor espondant au mur arrière doivent être contre

le mur arrière, pour qu’on puisse obtenir l’alignement des

trous découpés dans le placard supérieur avec les trous

situés au sommet du four à micro-ondes.

REMARQUES :

■ Si le placard supérieur comporte un cadre périmétrique,

tailler les bords du gabarit de telle manière qu’il puisse

s’ajuster dans le cadre, contre le fond du placard supérieur.

Le gabarit comporte des lignes de découpe qu’on peut

utiliser comme guides.

■ Si le mur situé derrière le micro-ondes comporte un

revêtement mural partiel (par exemple, un dosseret à

carreaux), s’assurer que les èches cor espondant au mur

arrière s’alignent avec la partie la plus épaisse du mur arrière

(par exemple, l’épaisseur des carreaux plutôt que le panneau

de gypse).

4. Veiller à laisser un espace de 10" (25,4 cm) entre le mur

arrière et les points “D” et “E” sur le gabarit.

REMARQUE : Si le placard supérieur est métallique, la bague de

cordon d’alimentation nécessite d’être installée autour du trou

de passage du cordon d’alimentation – voir l’illustration.

A. Placard métallique

B. Garniture du trou de passage du

cordon d’alimentation

6. Percer des trous de 3/8" (10 mm) aux points “D” et “E” du

gabarit. Ces trous sont utilisés pour le passage de deux vis

de 1/4-20 x 3" avec rondelle, utilisées pour la xation du fou

à micro-ondes contre le placard supérieur.

Pour une installation avec décharge à l’extérieur à

travers le toit seulement :

7. Découper un trou de 3/4" (19 mm) dans un coin de la zone

ombrée rectangulaire “F” sur le gabarit du placard supérieur.

8. À l’aide d’une scie à guichet, découper la zone rectangulaire.

Installation du module du clapet

anti-reux

(pour décharge à travers le mur uniquement)

1. Vérier que la lame du clapet anti- eux manoeuv e librement

et s’ouvre complètement.

2. Positionner le module du clapet anti-reux sur la face arriè e

du four à micro-ondes an que la cha nière de la lame du

clapet anti-reux soit positionnée dans la partie supérieu e,

et que la lame du clapet anti-reux s’ouv e sans toucher le

four à micro-ondes.

D

(25,4 cm)

5. Percer le trou de diamètre 11⁄2" (3.8 cm) dans la zone

circulaire grisée “G” du gabarit. Ce trou est utilisé pour le

passage du cordon d’alimentation.

10"

Ga

ba

rit

F

duplacar

d m

ur

al

G

E

10"

(25,4 cm)

A. Face arriére du four à micro-ondes

B. Module du clapet anti-reu

C. Lamp du clapet anti-reu

D. Vis à tôle de 6 x 3/8" (2)

3. Fixer le clapet antiretour à l’aide de 2 vis à tôle de 6 x 3/8".

25

Page 26

Installation du four à micro-ondes

AVERTISSEMENT

A

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer et

installer le four à micro-ondes.

Le non-respect de cette instruction peut causer

une blessure au dos ou d'autre blessure.

IMPORTANT: Le côté du four à micro-ondes où se trouve le

module de commande est le plus lourd. Manipuler le four à

microondes délicatement.

1. Retirer les 2 cales d’espacement xées au-dessus de la grill

de ventilation avant d'utiliser le four à micro-ondes.

A

REMARQUE : Pour éviter d’endommager le four à micro-ondes,

ne pas prendre prise sur la porte ou la poignée de la porte

durant les manutentions du four à micro-ondes.

B

A. Plaque de montage

B. Pattes de support

5. Alors que l’avant du four à micro-ondes est encore incliné,

enler le co don d’alimentation à travers le trou de passage

percé dans le fond du placard supérieur.

A. Cales d’espacement (2)

REMARQUE: Selon le modèle, il pourrait ne pas y avoir de

cales d’espacement. S’il n’y a pas de cales d’espacement,

commencer à l’étape 2.

2. Placer une rondelle sur chaque vis à tête plate de 1/4-

20 x 3"; placer les vis à l’intérieur du placard supérieur, à

proximité des trous de 3/8" (10 mm).

3. Vérier que la porte du four à mic o-ondes est fermée, et

qu’elle est immobilisée par du ruban adhésif.

4. Faire intervenir 2 personnes ou plus pour soulever le four à

micro-ondes et le suspendre aux pattes de support situées

en bas de la plaque de montage.

6. Redresser le four à micro-ondes vers le placard supérieur.

REMARQUE : En cas d’évacuation à travers le mur, veiller à ce

que le clapet anti-reux s’insè e facilement dans le conduit dans

l’ouverture du mur.

7. Pousser le four à micro-ondes contre la plaque de montage;

maintenir le four en place.

REMARQUE : Si aucun autre ajustement de la position du four à

micro-ondes n’est nécessaire, omettre les étapes 7-9.

8. Si un ajustement est nécessaire, faire pivoter le four à

microondes vers le bas. Faire intervenir 2 personnes ou

plus pour soulever le four à micro-ondes et le dégager de

la plaque de montage; placer le four à part sur une surface

couverte.

9. Desserrer les vis de la plaque de montage. Ajuster la plaque

de montage et resserrer les vis.

10. Répéter les étapes 3-6.

11. Alors que le four à micro-ondes est centré, et tandis qu’au

moins une personne le maintient en place, insérer les vis à

travers le placard supérieur et dans le four à micro-ondes.

Serrer les vis jusqu’à ce qu’il ne reste aucun espace entre le

placard supérieur et le four à micro-ondes.

REMARQUES:

■ Certaines congurations du placa d supérieur

nécessitent l’emploi de vis plus longues ou plus courtes

que 3" (7,6 cm). Acheter les vis nécessaires plus longues

ou plus courtes dans une quincaillerie locale.

26

Page 27

■ Un serrage excessif des vis peut provoquer une

A

AB C

DE F

AB

déformation (gauchissement) du sommet du four à

micro-ondes. Pour éviter un gauchissement, on peut

ajouter des cales d’appui en bois (fournies par

l’installateur). L’épaisseur des cales doit correspondre à

l’épaisseur de l’espace résiduel entre le fond du placard

supérieur et le four à micro-ondes.

A. Bolts

REMARQUE : An d’éviter d’endommager l’écrou de montage,

visser d’abord les boulons dans les trous d’écrou de montage à

la main jusqu’en profondeur de 15 à 20 mm en veillant à ce que

les boulons s’enlent correctement. Serrer ensuite les boulons à

l’aide d’un outil.

Pour une installation avec décharge à l’extérieur à

travers le toit seulement

1. Insérer le module du clapet anti-reux à travers l’ouvertu e

découpée dans le placard supérieur, de telle manière que la

patte longue du module du clapet anti-reux puisse glisse

sous les pattes d’arrimage relevées de la plaque de support

du clapet. Fixer ensuite à l’aide d’une vis à tôle de 6 x 3/8".

REMARQUE : Il n’est pas possible d’installer la vis si le module

du clapet anti-reux n’est pas positionné comme on le voit su

l’illustration.

A. Pattes d’arrimage relevées

B. Module du clapet anti-reu

C. Vis à tôle de 6 x 3/8"

D. Ouverture découpée dans le

placard supérieur

E. Patte longue

F. Plaque de support du clapet

A

B

A. Boulon

B. Écrou de montage

2. Connecter le conduit d’évacuation au module du clapet

anti-reux.

15-20 mm

A. Conduit d’évacuation

B. Module du clapet anti-reux

(sous le conduit d’évacuation)

27

Page 28

Achever l’installation

1. Installer les lt es. Voir les Instructions d’utilisation pour la

mise en place des lt es.

AVERTISSEMENT

Risque de choc électrique

Brancher sur une prise à 3 alvéoles reliée à la terre.

Ne pas enlever la broche de liaison à la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un câble de rallonge.

Le non-respect de ces instructions peut causer

un décès, un incendie ou un choc électrique.

2. Brancher le four à micro-ondes sur une prise à trois alvéoles

reliée à la terre.

3. Reconnecter la source de courant électrique.

4. Contrôler le fonctionnement du four à micro-ondes : placer

sur le plateau rotatif 1 tasse (250 mL) d’eau, et programmer

une période de cuisson de 1 minute à la puissance maximale

(100 %). Faire fonctionner le ventilateur d’extraction pour

tester son fonctionnement.

5. Si le four à micro-ondes ne fonctionne pas :

■ Déterminer si un fusible est grillé ou si un disjoncteur

s’est déclenché. Remplacer le fusible ou réenclencher le

disjoncteur. Si le problème persiste, appeler