Page 1

Installation

Instructions

Kl+chenAtd

l

FOR THE WAY IT’S MADE:

changing the Bin Door

and lower Panels . . . . . . . . . . . . . . . 2

Thermostat

callbratlons . . . . . .-......,.., 3

Shipboard operation ., . . . 3

General Information . . . . . .,,,, 4

Unpack

Utllltles I.............,........,.,,,,,

Locate unit

Level unlt ......I.I...I ,,......,,,, 5

For the Plumber . . . . . . . . . . . . . . . . . . 6

Connect to water . . . . . . . . . . 6

Connect to draln . . . . . . . . . . . 7

Connect draln pump . . . . 7

For the Electrician . . . . . . . . . . . . . . . 8

Electrical requirements . . 8

Groundlng method . . . . . . . 8

Operating Instructions . ..., ,, 9

How the Ice

Maker Works...... IIIIIIII...I.II 10

Things to Remember . . . . . . . . 10

Unit Wiring Diagrams . . . . . .,, 11

Check Operation . I I ,. . I I ., ., . 1 1

I.II..II..,,,,..,..I.,.,,,,

. . . . . ..,.. I . . . . . . . . . . 5

4

4

118004224230

Call our Consumer Assistance Center

wlth questlons or comments.

KITCHENAID” Automatic Ice Maker

Model: KUlSl85

Page 2

Changing the Bin Door and

Lower Panels

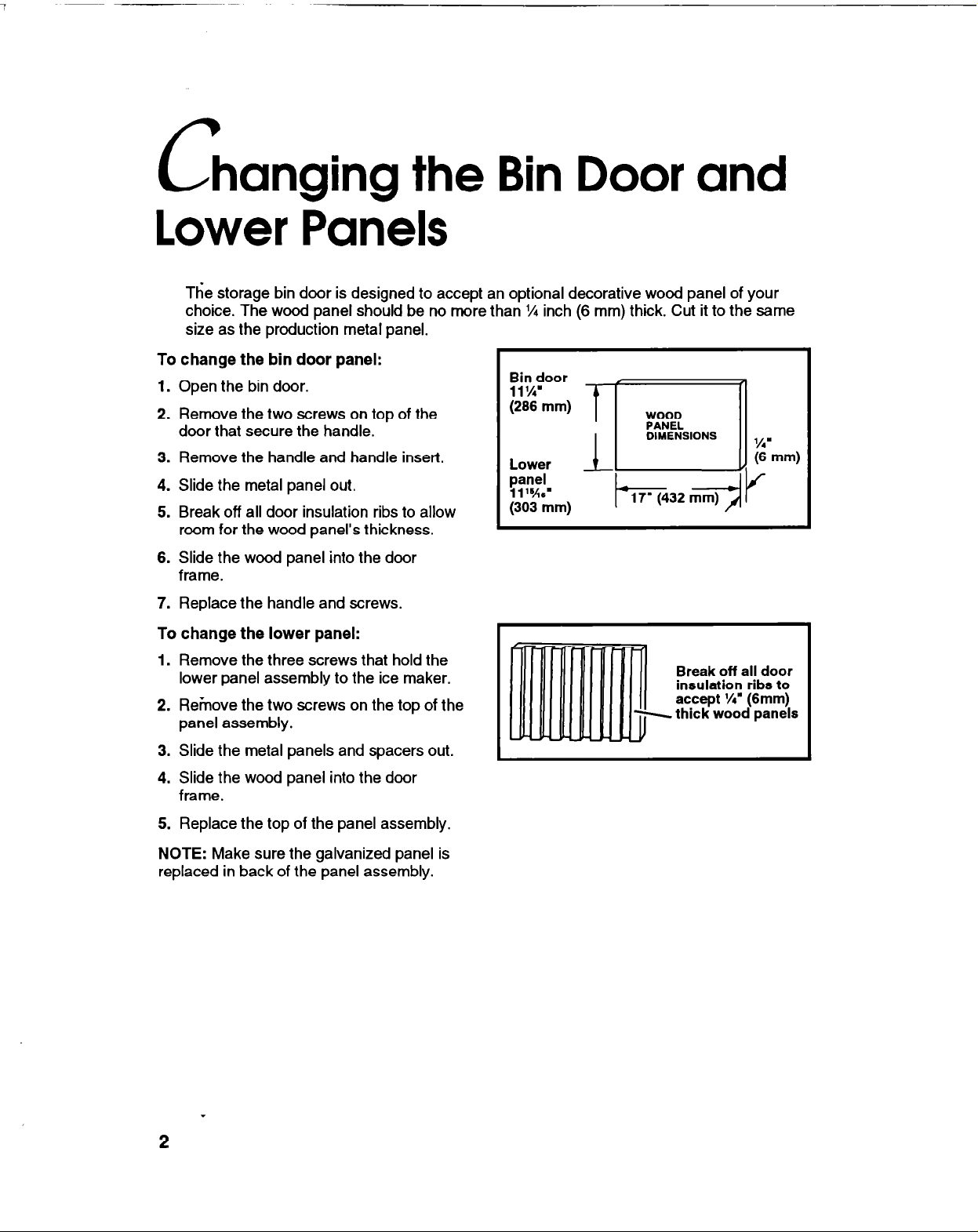

The storage bin door is designed to accept an optional decorative wood panel of your

choice. The wood panel should be no more than l/4 inch (6 mm) thick. Cut it to the same

size as the production metal panel.

To change the bin door panel:

1.

Open the bin door.

2.

Remove the two screws on top of the

door that secure the handle.

3. Remove the handle and handle insert.

4. Slide the metal panel out.

5. Break off all door insulation ribs to allow

room for the wood panel’s thickness.

6. Slide the wood panel into the door

frame.

7. Replace the handle and screws.

To change the lower panel:

Ktoor

(26; mm)

DIMENSIONS

Lower

1.

Remove the three screws that hold the

lower panel assembly to the ice maker.

2.

Remove the two screws on the top of the

panel assembly.

3. Slide the metal panels and spacers out.

4. Slide the wood panel into the door

frame.

5. Replace the top of the panel assembly.

NOTE:

replaced in back of the panel assembly.

Make sure the galvanized panel is

-

Break off all door

insulation ribs to

accept Yi” (6mm)

thick wood panels

2

Page 3

hanging the Bin Door and Lower Panels

c

Thermostat calibrations

If ice maker is installed more than 2,000 feet

(600 m) above sea level, the Bin and Ice

Thickness Thermostats must be adjusted

to a warmer setting. Disconnect electricity,

remove thermostat, and follow the directions

for turning the altitude adjustment screw as

shown in the label on each thermostat.

Shipboard operation

When this ice maker is installed aboard a

ship, it may be necessary to purchase and

install a water deflector. The deflector hangs the storage bin area. Order the necessary

between the lower edge of the evaporator

and the cutter grid. It keeps the water

flowing over the evaporator from spilling into

parts from your local ice maker dealer.

3

Page 4

eneral Information

G

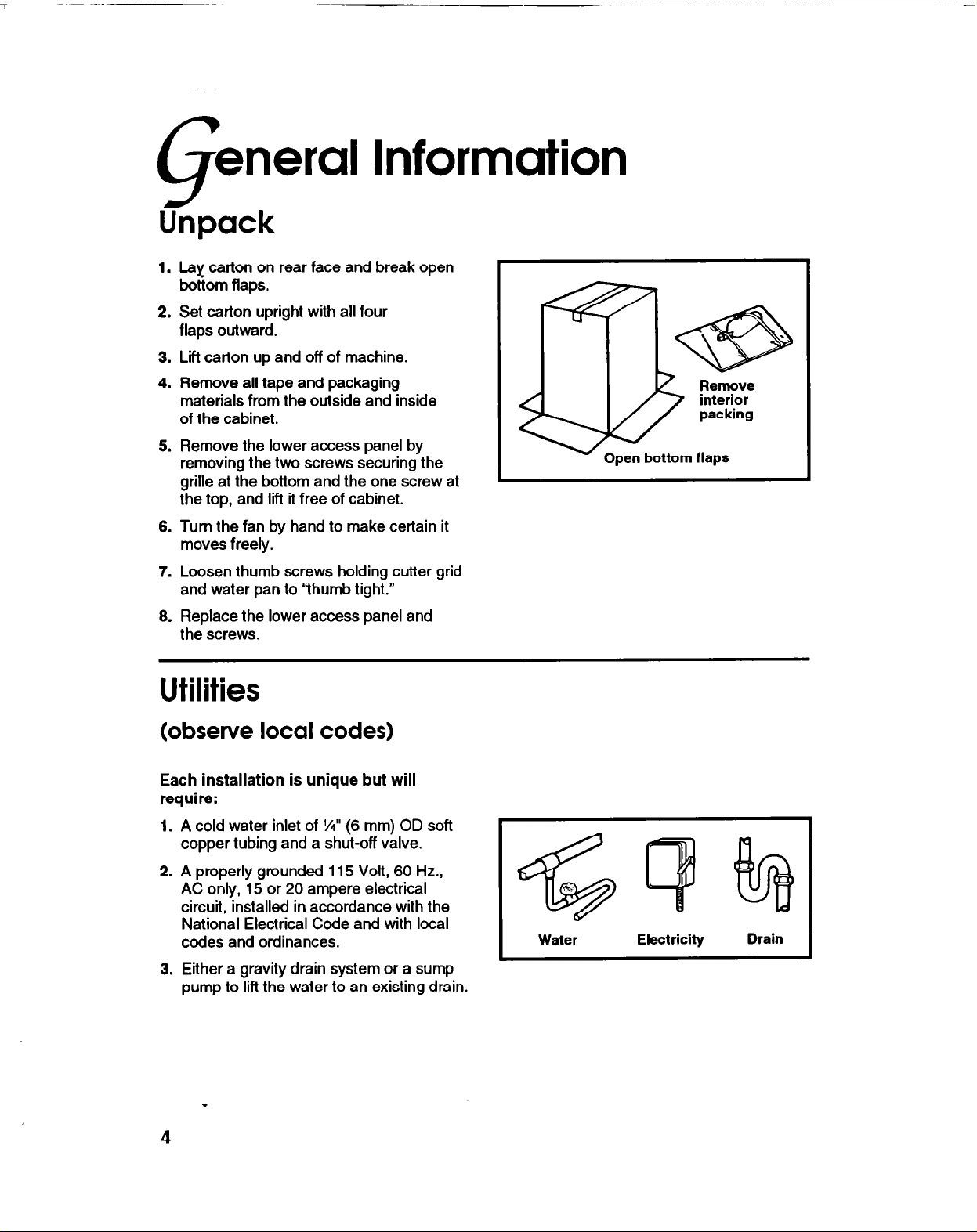

1. Lay carton on rear face and break open

bottom flaps.

2. Set carton upright with all four

flaps outward.

3. Lii carton up and off of machine.

4. Remove all tape and packaging

materials from the outside and inside

of the cabinet.

5. Remove the lower access panel by

removing the two screws securing the

grille at the bottom and the one screw at

the top, and lift it free of cabinet.

6. Turn the fan by hand to make certain it

moves freely.

7. Loosen thumb screws holding cutter grid

and water pan to “thumb tight.”

8. Replace the lower access panel and

the screws.

Utilities

(observe local codes)

Each installation is unique but will

require:

1.

A cold water inlet of W (6 mm) OD soft

copper tubing and a shut-off valve.

2. A properly grounded 115 Volt, 60 Hz.,

AC only, 15 or 20 ampere electrical

circuit, installed in accordance with the

National Electrical Code and with local

codes and ordinances.

- Open bottom flaps

Electricity

Drain

3. Either a gravity drain system or a sump

pump to lift the water to an existing drain.

4

Page 5

locate unit

1.

Place unit so the front side will be completely unobstructed to provide proper

airflow.

eneral Information HEI

G

2. Area should be well ventilated with

temperature above 55°F (13°C) and below

119°F (43°C). Best results are obtained

between 70°F (21 “C) and 90°F (32°C).

3. Provisions for electricity, water, and drain

connections should be determined.

4. The unit may be closed in on the top and

three sides, but the front

unobstructed for air circulation and proper

operation. Installation should be such that

the cabinet can be moved forward for

servicing, if necessary.

MUST BE

level unit

1.

After placing unit in position, check to

make certain the unit is level side-to-side

and front-to-back.

2. Accurate leveling is essential for proper

operation.

3. Unit should be shimmed so that it is solid

as well as level. The shims should be of

hard permanent type material such as

Masonite.

This unit

MUST be

installed in

an area

rotected

rom the

P

elements,

such as

wind, rain,

and water

spray or

drip.

4. If you are installing this ice maker in a

commercial setting that requires National

Sanitation Foundation (NSF) installation

procedures, NSF requires that the ice

maker be sealed to the floor at the

bottom rail. For compliance with this NSF

sealing procedure, we recommend a

silicone-type sealer.

90°F

(32°C)

70°F

(21°C)

BEST

RANGE

1

5

Page 6

or the Plumber

F

Connect to water

(observe local codes)

1. Use W (6 mm) OD soft copper tubing for

the cold water supply.

2. Provide a convenient manual shut-off

valve in the water line.

3. Position the tubing so it can enter the

access hole located in the right hand rear

of the cabinet. The tubing should extend

beyond the cabinet front when the

cabinet is pushed back into position.

NOTES:

Always purge the water line before making

the final connection to the inlet of the water

valve to prevent possible water valve

malfunction.

After the cabinet is in place, bend the tubing

to meet the connection at the water valve.

The garden hose threaded compression

fitting is found in the parts bag. This joint

provides a convenient disconnect for

service. Be sure the tubing is clear of

compressor to prevent rattle.

Hole for

fieldsupplied

water line

RIGHT END VlEW

W (19 mm)

BACK VIEW BACK VIEW

17%’ 17%’

I.

(yY$&L2;~

Water

inlet

solenoid

valve

run to open

6

v-+$yT standpipe

. ,ra ml

(a mm)

Lm ‘-- - m)

Page 7

Connect to drain

(observe local codes)

1.

The unit is provided with a gravity drain.

2.

The ideal installation has a standpipe

[32

mm] minimum) installed directly below

the outlet of the drain tube. Refer to

figures for the proper location of the

standpipe.

3. It may be desirable to insulate drain line

thoroughly up to drain inlet.

(1 Vi"

Connect drain pump

.~

sr the Plumber m

When drain connection below the level of

the unit is not available, a drain pump may

be used to lift the water to an available

drain.

1.

Install drain pump in rear compartment

are%. Run bin drain directly into pump as

shown. Attach pump in level position.

2. Plug power cord of ice maker into receptacle on drain pump.

3. Plug power cord of drain pump into wall

receptacle.

NOTE:

include a DRAIN PUMP. If your ice maker

model does not include a DRAIN PUMP,

one can be ordered from your dealer.

Your ice maker may or may not

LINE

ADD HOSE FROM BIN DRAIN

DIRECTLY TO PUMP

/

warn ID TUBE

ICE MAKER

POWER CORD

TO DRAIN

PUMP

RECEPTACLE

DRAIN PUMP

POWER

CORD TO

WALL

RECEPTACLE

7

Page 8

or the Electrician

F

Electrical requirements

A 115 Volt, 60 Hz., AC only, 15 or 20

ampere electrical supply circuit, properly

grounded in accordance with the National

Electrical Code and local codes and ordinances is required.

Grounding method

DO NOT, UNDER ANY CIRCUMSTANCES,

REMOVE THE POWER SUPPLY CORD

GROUND PRONG.

For your personal safety, this appliance

must be grounded. This appliance is

equipped with a power supply cord which

has a 3-prong grounding plug. To minimize

possible shock hazard, the cord must be

plugged into a mating 3-prong grounding

type wall receptacle, grounded in accordance with the National Electrical Code and

local codes and ordinances. If a mating wall

receptacle is not available, it is the personal

responsibility and obligation of the customer

to have a properly grounded 3-prong wall

receptacle installed by a qualified electriiian.

3-prong grounding-type

wall receptacle ,

It is recommended that a separate circuit,

serving only this appliance, be provided.

Use a receptacle which cannot be turned off

with a switch or pull chain. DO NOT use an

extension cord.

Electrical Shock Hazard

. Electrical ground Is requlred on this

appliance.

. Do Not ground to a gas pipe.

. Do Not modify the power supply cord

plug. If It does not fit the outlet, have

a proper outlet installed by a quali-

fied electrician.

l

Do Not have a fuse in the neutral or

grounding circuit. A fuse in the

neutral or grounding circuit could

result in an electrical shock.

l

Do Not use an extension cord with

this appliance.

l

Check with a qualified electrician if

you are in doubt as to whether the

appliance is properly grounded.

Failure to follow these instructions could

result in death, electrical shock, or

serious injury.

8

PO

su

co

grounarng plug

Page 9

0

l

For complete operation information, refer to

the Use and Care Guide.

l

Before starting, wash out interior of cabinet

with a Baking Soda solution (2 tablespoons

[26

water). Rinse thoroughly.

l

Make certain the water is turned on.

l

Turn switch to the “ON” position.

perating Instructions

grams] soda to 1 quart [l liter] of warm

CUllER GRID

Vi” x?h” (19 mm x 19 mm)

IMPORTANT:

before expecting ice and for 24 hours before

trying to set the thickness control.

If installed more than 2,000 feet (600 m)

above sea level, see page 3 for thermostat

adjustments.

Allow unit to run for 3 hours

9

Page 10

H

ow the Ice Maker Works

l Compressor runs

l Condenser fan runs

l Water pump runs (circulates water)

l Cutter grid is warm to touch

WHEN THE DESIRED ICE SLAB THICKNESS IS REACHED, THE HARVEST

CYCLE BEGINS AND THE FOLLOWING

HAPPENS:

l Evaporator thermostat is satisfied

l Compressor keeps running

l Condenser fan stops or turns very slowly

l Water pump stops

l Hot gas solenoid opens

5

l Water enters only during the defrost cycle.

Therefore the first cycle will be completed

without water in the system.

l As the room and water temperatures vary,

so will the amount of ice produced. This

means that higher operating temperatures

will result in reduced ice production.

l The unit will shut off when ice in the

storage bin touches the bin thermostat

well and will automatically cycle to keep

the bin full.

ings to Remember

l Water inlet valve opens

l Excess water is flushed out of the

drain pan

l Cutter grid is warm to the touch

NOTE:

2 minutes.

MACHINE RESUMES FREEZING AFTER

SLAB IS RELEASED FROM EVAPORATOR AND THE CUTTING PROCESS

BEGINS.

WHEN THE STORAGE BIN IS FILLED, BIN

THERMOSTAT OPENS.

l Cutter grid remains on

l The storage bin is not refrigerated and

l The unit needs good air circulation to

l The water system, including filter screen in

Normal harvest cycle takes 1 to

some melting will occur. This also varies

with the room temperature.

perform efficiently. Keep the front grille and

the condenser clean.

the water inlet solenoid valve, needs to be

cleaned periodically for good circulation.

Instructions are located on the inner

door panel.

10

Page 11

21

This model operates at 115 volts except for

the cutter grid circuit which operates at 8.5

volts at 1 amp.

The compressor runs at all times except

when the Bin Thermostat becomes satisfied

and opens the circuit. This de-energizes the

system except for the transformer and cutter

grid.

Under normal operating conditions, when

the evaporator reaches the preset temperature (+lO” to -3°F [-12” to -1 9”C], depending

on thickness of ice) the evaporator thermostat opens, terminating operation of the fan

motor and pump motor. The hot gas solenoid and the water valve solenoid are

energized at this time and remain so until the

evaporator reaches 38” + 2°F (3” + 1%).

Disconnect power before servicing unit.

Failure to do so could result in electrical

shock.

nit Wiring Diagrams

Electrical Shock Hazard

NOTE:

Maximum fuse size: 15 amps.

Check Operation

Start the unit by turning the service

a0

switch to “ON” and opening the line

water valve.

NOTE:

tH

Right is “CLEAN.” In ‘CLEAN” position,

only the pump operates.

Check condenser fan to make sure it is

d

revolving. Check for airflow. Do not

insert hand into fan area.

Water will not enter pump pan until

d

freezing plate gets cold and machine

goes into a harvest cycle.

Left is “OFF’ - Middle is “ON” -

Check for even water flow over freez-

d

ing plate. Unit must be level for proper

operation.

Check for desired cube thickness and

d

after 24 hours adjust if necessary.

Maximum ice yield will be obtained

with ice thickness at l/i’ (13 mm) to %”

(16 mm).

Replace grille.

d

11

Page 12

Part No. 2175675

cb 1994 KlkhenAld

QD RegIstered Trademark /TM Trademark 01 KItchenAM.

Printed in U.S.A.

Loading...

Loading...