KitchenAid KSSC36FKB00, KSSC36FKS00, KSSC36QKS00, KSSC42FKB00, KSSC42FKS00 Service Manual

...

TECHNICAL EDUCATION

www.Appliantology.org

JOB AID 4317326A

JOB AID 4317326A

MODELS:

KAR-11

KSSC36FKB00

KSSC36FKS00

KSSC36QKS00

KSSC42FKB00

KSSC42FKS00

KSSC42QKS00

KSSC48FKB00

KSSC48FKS00

KSSC48QKS00

KSSP36QKS00

KSSP42QKS00

KSSP48QKS00

KSSS36FKB00

KSSS36FKT00

KSSS36FKW00

KSSS36FKX00

KSSS36QKB00

KSSS36QKT00

KSSS36QKW00

KSSS36QKX00

2001 K MODEL

KSSS42FKB00

KSSS42FKT00

KSSS42FKW00

KSSS42FKX00

KSSS42QKB00

KSSS42QKT00

KSSS42QKW00

KSSS42QKX00

KSSS48FKB00

KSSS48FKT00

KSSS48FKW00

KSSS48FKX00

KSSS48QKB00

KSSS48QKT00

KSSS48QKW00

KSSS48QKX00

BUILT-IN SIDE-BY-SIDE

REFRIGERATOR WITH VARIABLE

CAPACITY COMPRESSOR

JOB AID 4317326A

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

This KitchenAid Job Aid, 2001 K Model Built-In Side-By-Side Refrigerator With Variable Capacity

Compressor (Part No. 4317326A), provides the technician with information on the installation and

service of the Built-In Side-By-Side Refrigerator. It is to be used as a training Job Aid and Service

or “Tech Sheet” provided with the refrigerator.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

The goal of this Job Aid is to provide detailed information that will enable the service technician to

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the refrigerator to its proper operational status.

Copyright © 2002, Whirlpool Corporation, Benton Harbor, MI 49022

www.Appliantology.org

- ii -

- ii -

TABLE OF CONTENTS

GENERAL

Safety First...................................................................................................................

Anti-Tip Requirements.................................................................................................. 1-2

Specifications.................................................................................................................

THEORY OF OPERATION

COMPONENT ACCESS

Component Locations ........................................................................................................ 4-1

And The Main Control Board Assembly.......................................................................... 4-4

The Defrost Heater, And The Evaporator ..................................................................... 4-10

COMPONENT TESTING

Thermistor.....................................................................................................................

Condenser Fan Motor ........................................................................................................ 5-2

Compressor & Inverter....................................................................................................... 5-3

5-4

-5

Crush/Cube Solenoid......................................................................................................... 5-6

Water Valve Solenoid ........................................................................................................ 5-7

www.Appliantology.org

- iii -

- iii -

Pre-Diagnostics Checks ................................................................................................. 6-1

Diagnostics Mode ........................................................................................................... 6

-1

Water Filter Input (WFI) Test .......................................................................................... 6-2

Troubleshooting Chart ....................................................................................................... 6-3

WIRING DIAGRAMS & STRIP CIRCUITS

Wiring Diagram—Bottom Mount ........................................................................................ 7-1

Wiring Diagram—Side-By-Side Models ............................................................................. 7-2

Strip Circuits .................................................................................................................

www.Appliantology.org

- iv -

- iv -

electrical shock.

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

You can be killed or seriously injured if you don’t

diately follow instructions.

diately follow instructions.

You can be killed or seriously injured if you don’t follow

www.Appliantology.org

assembly. The new control assembly may ap-

failure may occur at a later date due to ESD

stress.

• Use an antistatic wrist strap. Connect the

wrist strap to a green ground connection

touch your finger repeatedly to a green ground

connection point or unpainted metal in the

appliance.

• Before removing the part from its package,

touch the antistatic bag to a green ground

connection point or unpainted metal in the

appliance.

• Avoid touching electronic parts or terminal

contacts. Handle the electronic control as-

sembly by the edges only.

• When repackaging the failed electronic con-

trol assembly in an antistatic bag, observe

the above instructions.

Connect green ground wire to ground

screw.

electrical shock.

Tip Over Hazard

when not completely installed.

tor is completely installed.

serious injury.

www.Appliantology.org

SERIAL NUMBER

MODEL NUMBER K SS S 42 Q K X 0 0

www.Appliantology.org

PRODUCT GROUP

K = KitchenAid Brand

PRODUCT IDENTIFICATION

BR = Bottom Mount Right Hand Hinge

BL = Bottom Mount Left Hand Hinge

SS = Side-By-Side Built-In

MERCHANDISING SCHEME/SERIES

C = Wrap Around Stainless Steel

P = Factory Installed Panel Kit

S = Framed Trim Kit (Panels Not Included)

CAPACITY/ SIZE

36 = 36″ Width

42 = 42″ Width

48 = 48″ Width

FEATURES

D = Ice & Water Dispensing

F = Factory Installed Ice Maker w/Filter

M = Factory Installed Ice Maker wo/Filter

Q = Ice/Crushed Ice & Water Dispensing w/Filter

YEAR OF INTRODUCTION

K = 2001

COLOR CODE

X = No Color Used

ENERGY POWER CONSUMPTION CHANGE

0 = Original, 1 = 1st Change, 2 = 2nd Change, Etc.

ENGINEERING CHANGE (NUMERIC)

0 = Original, 1 = 1st Change, 2 = 2nd Change, Etc.

SERIAL NUMBER Q L 30 10003

MANUFACTURING SITE

Q = LaVergne, TN

YEAR OF PRODUCTION

L = 2001

WEEK OF PRODUCTION

30th WEEK

PRODUCT SEQUENCE NUMBER

AND TECH SHEET LOCATIONS

The Model/Serial Number Label and Tech Sheet locations are shown below.

(Freezer Compartment)

Tech Sheet Location

(On Unit Compartment Cover)

(On Unit Compartment Cover)

www.Appliantology.org

SPECIFICATIONS

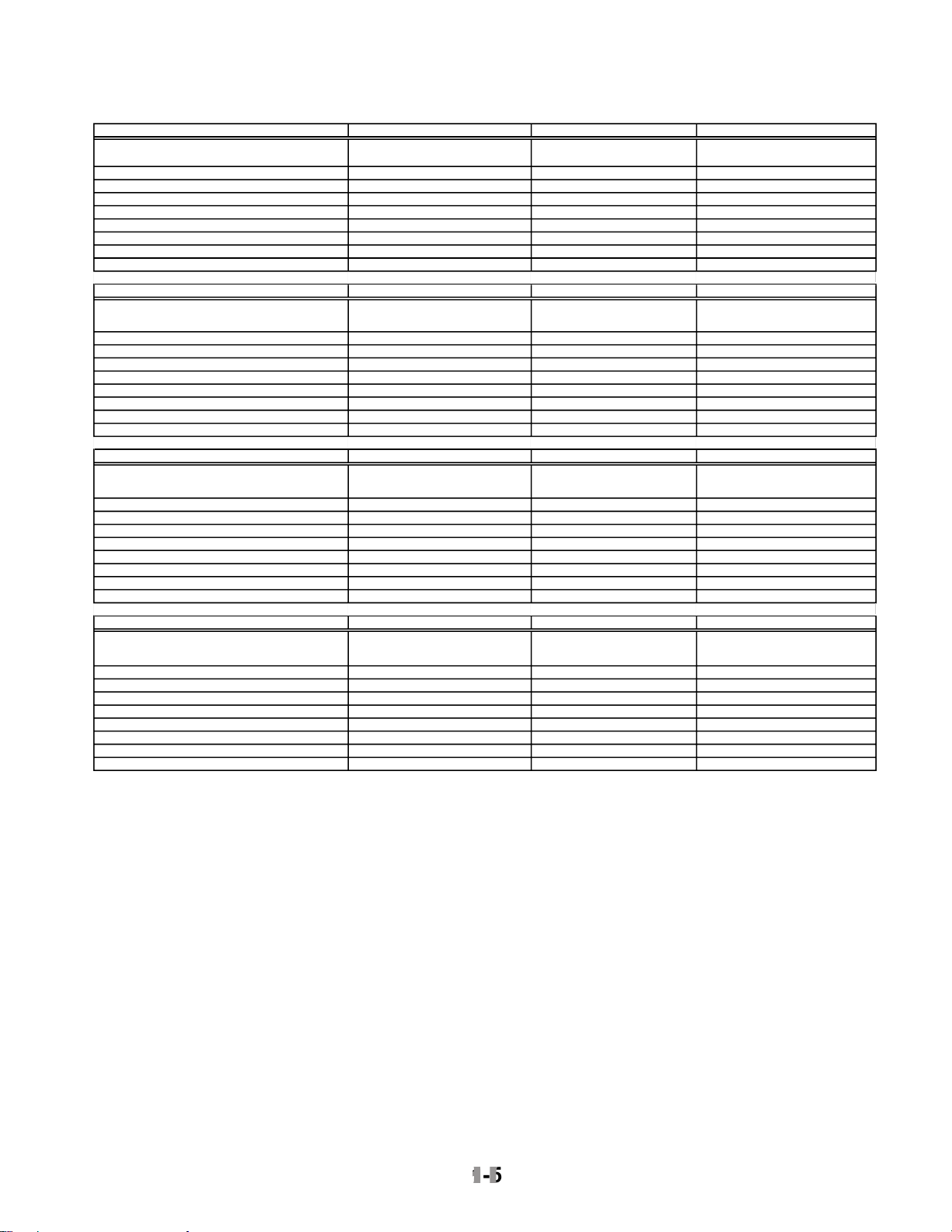

Model Number KSSC36FKB KSSC36FKS KSSC36QKS

www.Appliantology.org

Model Description

Size-Configuration 36" 36" 36"

Refrigerator Volume (Cu Ft) 13 13 13

Freezer Volume (Cu Ft) 7.5 7.5 7.4

Crated Weight (lbs) 500 500 500

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 72 72

Sealed System Warranty (Months) 144 144 144

Model Number KSSC42FKB KSSC42FKS KSSC42QKS

Model Description

Size-Configuration 42" 42" 42"

Refrigerator Volume (Cu Ft) 13 15.6 15.7

Freezer Volume (Cu Ft) 9.1 9.1 8.9

Crated Weight (lbs) 552 552 552

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 72 72

Sealed System Warranty (Months) 144 144 144

Model Number KSSC48FKB KSSC48FKS KSSC48QKS

Model Description

Size-Configuration 48" 48" 48"

Refrigerator Volume (Cu Ft) 18.3 18.3 18.4

Freezer Volume (Cu Ft) 10.7 10.7 10.5

Crated Weight (lbs) 579 579 579

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 72 72

Sealed System Warranty (Months) 144 144 144

Model Number KSSP36QKS KSSP42QKS KSSP48QKS

Model Description

Size-Configuration 36" 42" 48"

Refrigerator Volume (Cu Ft) 13 15.7 18.4

Freezer Volume (Cu Ft) 7.4 8.9 10.5

Crated Weight (lbs) 500 552 579

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 72 72

Sealed System Warranty (Months) 144 144 144

Black Architect Series - Non-Disp.

with water filter

Black Architect Series - Non-Dispenser

Black Architect Series - Non-Dispenser

with water filter

with water filter

Stainless Steel - Dispenser - Factory

Installed Panels with water filter

Architect Series - Non-Dispenser with

Architect Series - Non-Dispenser with

Stainless Steel - Dispenser - Factory

water filter

Architect Series - Non-Dispenser

with water filter

water filter

Installed Panels with water filter

Stainless Steel Architect Series -

Disp. - with water filter

Stainless Steel Architect -

Dispenser with water filter

Stainless Steel Architect Series

with Dispenser with Water Filter

Stainless Steel - Dispenser - Factory

Installed Panels with Water Filter

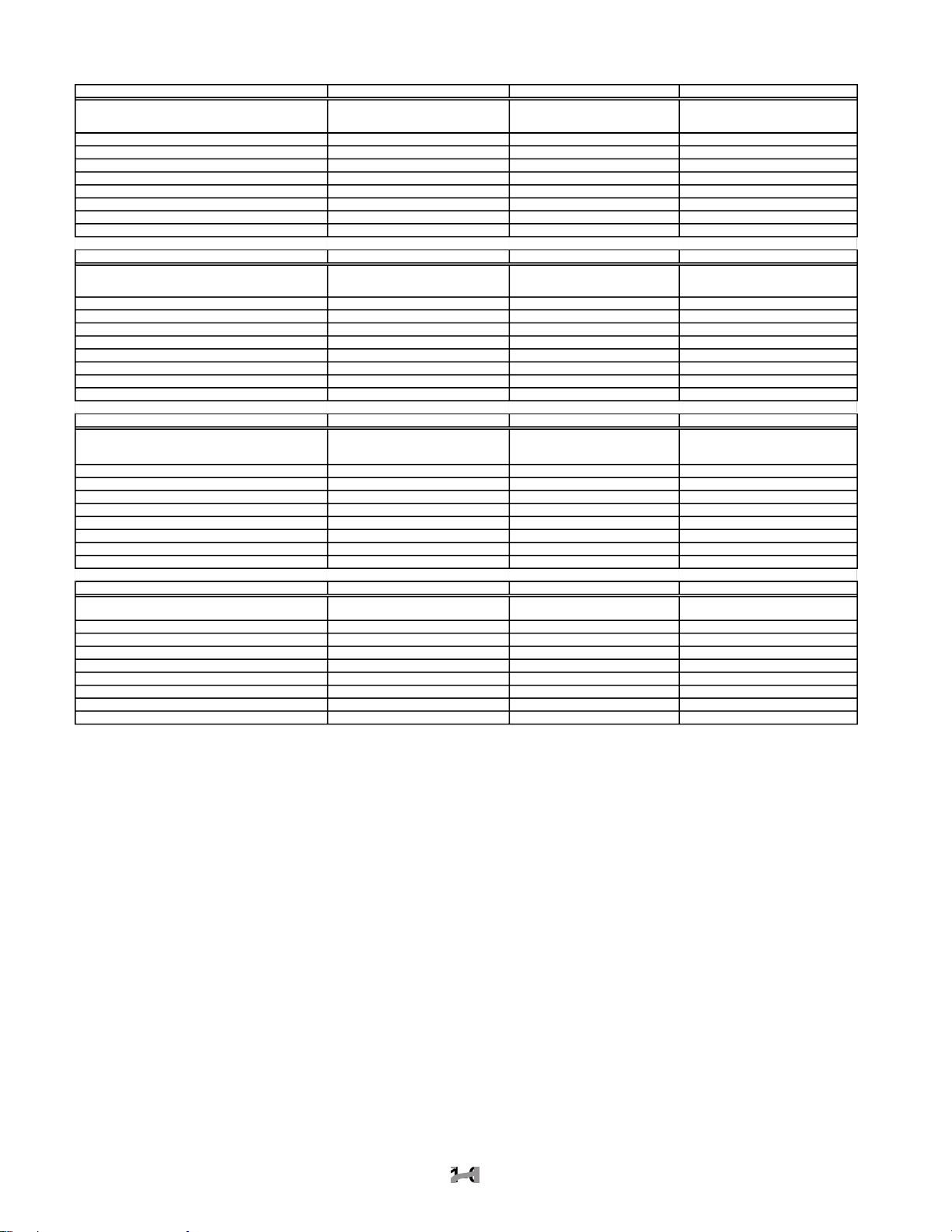

Model Number KSSS36FKB KSSS36FKT KSSS36FKW

www.Appliantology.org

Model Description

Size-Configuration 36" 36" 36"

Refrigerator Volume (Cu Ft) 13 13 13

Freezer Volume (Cu Ft) 7.5 7.5 7.5

Crated Weight (lbs) 500 500 500

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 72 72

Sealed System Warranty (Months) 144 144 144

Model Number KSSS36FKX KSSS36QKB KSSS36QKT

Model Description

Size-Configuration 36" 36" Side By Side 36" Side by Side

Refrigerator Volume (Cu Ft) 13 13 13

Freezer Volume (Cu Ft) 7.5 7.4 7.4

Crated Weight (lbs) 500 500 500

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 60 60

Sealed System Warranty (Months) 144 144 144

Model Number KSSS36QKW KSSS36QKX KSSS42FKB

Model Description

Size-Configuration 36" Side By Side 36" Side By Side 42"

Refrigerator Volume (Cu Ft) 13 13 15.6

Freezer Volume (Cu Ft) 7.4 7.4 9.1

Crated Weight (lbs) 500 500 552

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 60 60 72

Sealed System Warranty (Months) 144 144 144

Model Number KSSS42FKT KSSS42FKW KSSS42FKX

Model Description

Size-Configuration 42" 42" 42"

Refrigerator Volume (Cu Ft) 15.6 15.6 15.6

Freezer Volume (Cu Ft) 9.1 9.1 9.1

Crated Weight (lbs) 552 552 552

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 72 72

Sealed System Warranty (Months) 144 144 144

Black Trim -Custom Panels Required-

Non-Dispenser with water filter

Brushed Aluminum Trim -Custom Panels

Required-Non-Dispenser with water filter

KitchenAid White Dispenser

with Water Filter

Biscuit Trim - Non-Dispenser with water

filter- Custom Panels Required

Biscuit Trim -Custom Panels Required-

Non-Dispenser with water filter

KitchenAid Black

Dispenser Water Filter

KitchenAid Black Dispenser

with Water Filter

White Trim - Non-Dispenser with water

filter- Custom Panels Required

White Trim-Non-Dispenser-Custom

Panels Required with water filter

KitchenAid Biscuit

Dispenser Water Filter

Black Trim - Non-Dispenser with water

filter- Custom Panels Required

Brushed Aluminum Trim - Non-Dispenser

with water filter- Custom Panels Required

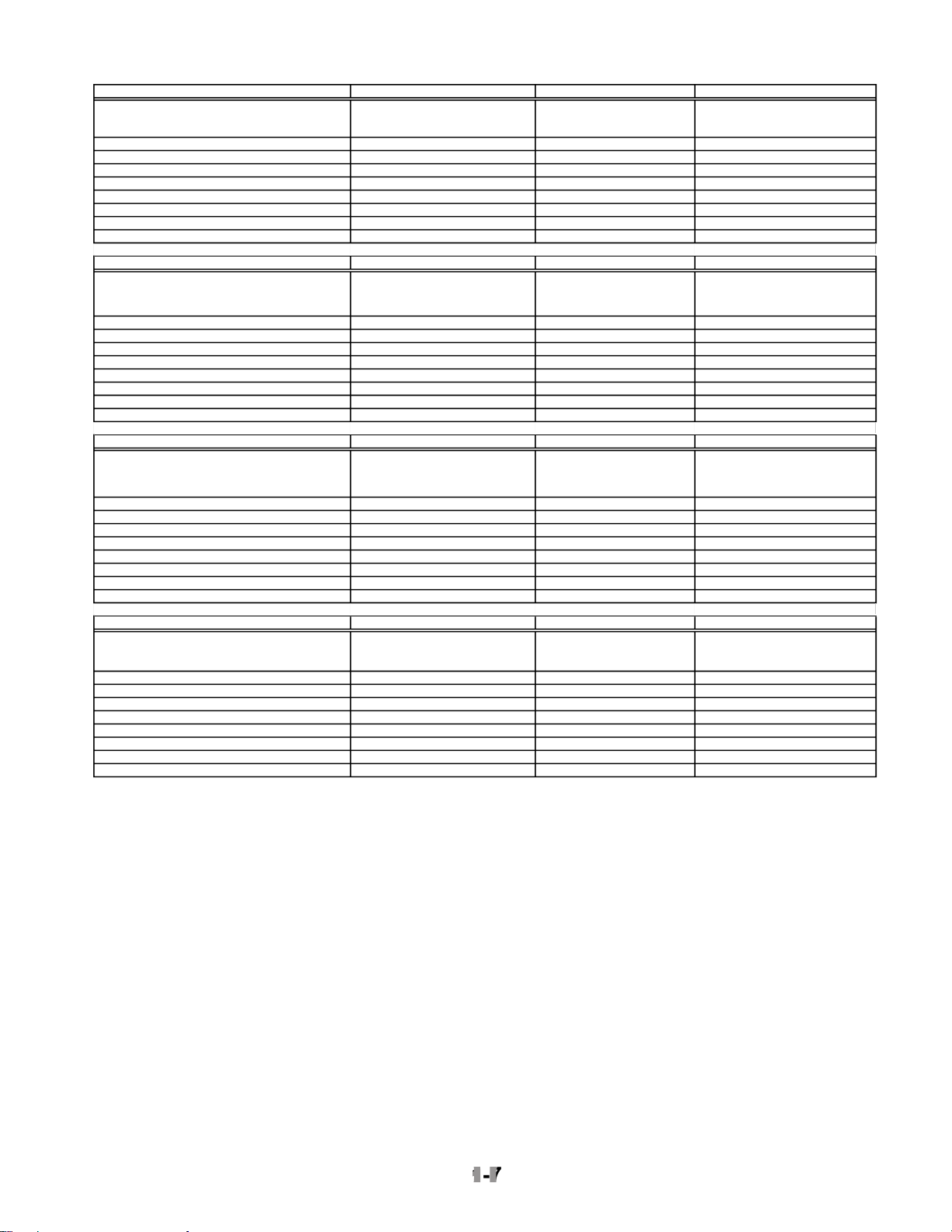

Model Number KSSS42QKB KSSS42QKT KSSS42QKW

www.Appliantology.org

Model Description

Size-Configuration 42" Side by Side 42" Side by Side 42" Side by Side

Refrigerator Volume (Cu Ft) 15.7 15.7 15.7

Freezer Volume (Cu Ft) 8.9 8.9 8.9

Crated Weight (lbs) 552 552 552

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 72 72

Sealed System Warranty (Months) 144 144 144

Model Number KSSS42QKX KSSS48FKB KSSS48FKT

Model Description

Size-Configuration 42" 48" 48"

Refrigerator Volume (Cu Ft) 15.7 18.3 18.3

Freezer Volume (Cu Ft) 8.9 10.7 10.7

Crated Weight (lbs) 552 579 579

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 72 72

Sealed System Warranty (Months) 144 144 144

Model Number KSSS48FKW KSSS48FKX KSSS48QKB

Model Description

Size-Configuration 48" 48" 48" Side by Side

Refrigerator Volume (Cu Ft) 18.3 18.3 18.4

Freezer Volume (Cu Ft) 10.7 10.7 10.5

Crated Weight (lbs) 579 579 579

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 72 72

Sealed System Warranty (Months) 144 144 144

Model Number KSSS48QKT KSSS48QKW KSSS48QKX

Model Description

Size-Configuration 48" Side by Side 48" Side by Side 48" Side by Side

Refrigerator Volume (Cu Ft) 18.4 18.4 18.4

Freezer Volume (Cu Ft) 10.5 10.5 10.5

Crated Weight (lbs) 579 579 579

Refrigerant 134a 134a 134a

Standard Warranty (Months) 24 24 24

Full Liner And Sealed System Warranty (Months) 72 72 72

Sealed System Warranty (Months) 144 144 144

KitchenAid Black Dispenser

Water with Filter

Black Dispenser-Brushed Aluminum

Trim-Custom Panels Required

White Trim Model-Custom Panels Required-

Non-Dispenser with water filter

KitchenAid Biscuit Dispenser

with Water Filter

KitchenAid Biscuit

with Water Filter

Black Trim Model-Custom

Panels Required-Non-Dispenser

with water filter

Brushed Aluminum Trim Model-

Custom Panels Required-Non-

Dispenser with water filter

KitchenAid White Dispenser

Water with Filter

KitchenAid White Water Filter

Biscuit Trim Model-Custom Panels

Required-Non-Dispenser with water filter

KitchenAid Black Dispenser

Water with Filter

KitchenAid Water Filter Black Dispenser-

Brushed Aluminum Trim-

®

BUILT-IN REFRIGERATOR WARRANTY

TWO-YEAR FULL WARRANTY ON REFRIGERATOR

and maintained according to instructions attached to or furnished with the product, KitchenAid will pay for factory

specified replacement parts and repair labor costs to correct defects in materials or workmanship. Replacement parts

and labor costs to correct defects in light bulbs, one year. Service must be provided by a KitchenAid designated

service company.

Water filter cartridge: 30 day limited warranty on water filter. For 30 days from the date of purchase, when this filter

for replacement parts to correct defects in materials and workmanship.

THIRD THROUGH SIXTH YEAR LIMITED WARRANTY

to instructions attached to or furnished with the product, KitchenAid will pay for factory specified replacement parts

and repair labor costs to correct defects in materials or workmanship in the sealed refrigeration system. These parts

are: compressor, evaporator, condenser, dryer, and connecting tubing. Service must be performed by a KitchenAid

designated service company.

SEVENTH THROUGH TWELFTH YEAR LIMITED WARRANTY

to instructions attached to or furnished with the product, KitchenAid will pay for factory specified replacement parts

to correct defects in materials or workmanship in the sealed refrigeration system. These parts are: compressor,

evaporator, condenser, dryer, and connecting tubing.

furnished with the product, KitchenAid will replace all Door Bins due to defective materials or workmanship.

2. Repairs when the refrigerator is used in other than normal, single-family household use.

3. Pickup and delivery. The refrigerator is designed to be repaired in the home.

4. Damage resulting from accident, alteration, misuse, abuse, fire, flood, improper installation, acts of God, or use

of products not approved by KitchenAid or KitchenAid Canada.

5. Any food or medicine loss due to product failure.

6. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

7. Removal and replacement of trim or decorative panels that interfere with servicing the product.

8. Labor or parts installed by any non-designated service company during the full warranty period, unless approved

by KitchenAid before service is performed.

9. In Canada, travel or transportation expenses for customers who reside in remote areas.

TIAL DAMAGES.

Some states or provinces do not allow the exclusion or limitation of incidental or consequential damages, so this

exclusion or limitation may not apply to you. This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state or province to province.

Outside the 50 United States and Canada, a different warranty may apply. Contact your authorized KitchenAid

dealer to determine if another warranty applies.

shooting,” additional help can be found by checking the “Assistance or Service” section or by calling the

(toll-free), from anywhere in the U.S.A. In Canada,

contact your designated KitchenAid Canada Appliance service company or call:

www.Appliantology.org

INSTALLATION INFORMATION

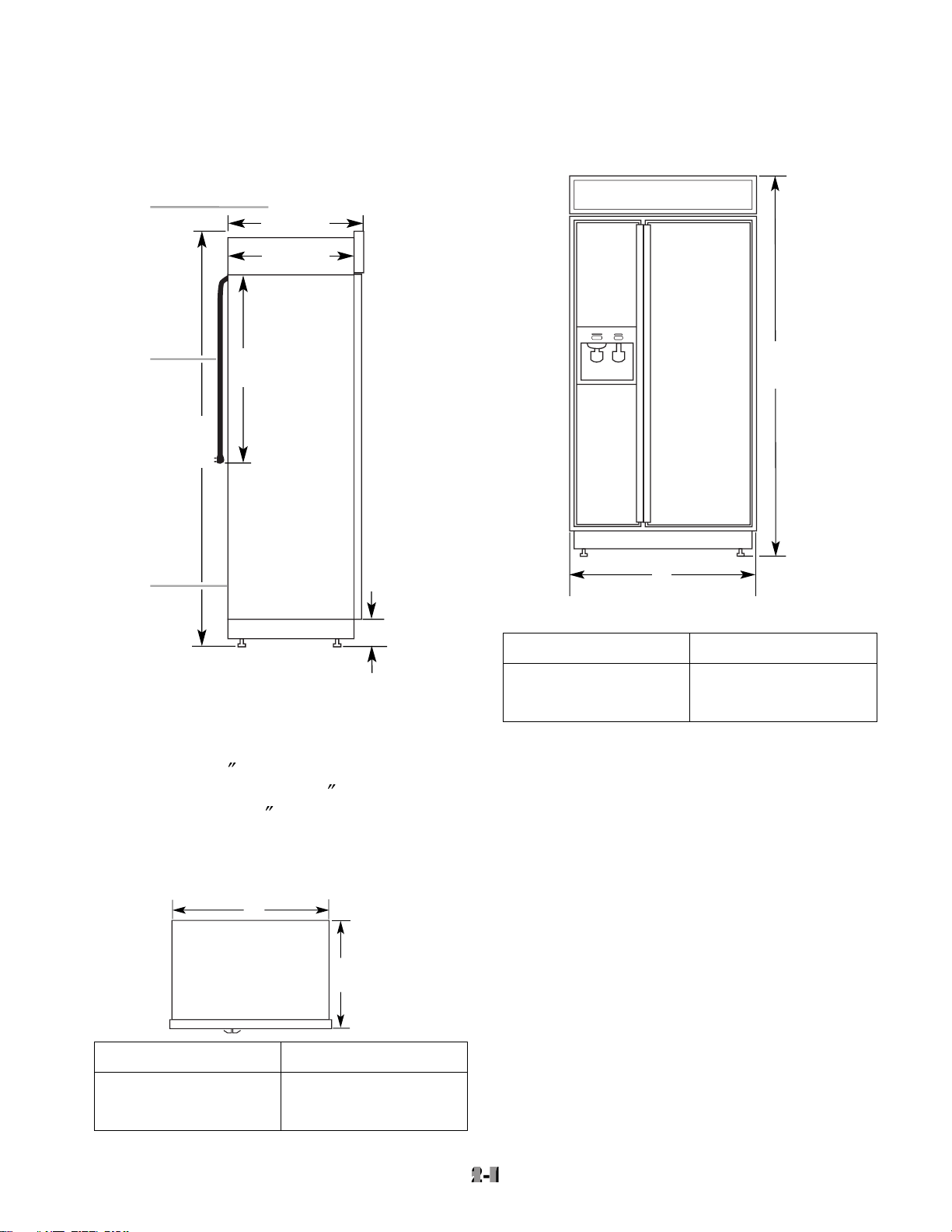

Side View

ers extended 1/8

(3 mm) below the rollers. For

(32 mm) below

the rollers, add 1-1/8

(29 mm) to this dimen-

sion.

Top View

831/

8

"

(211 cm)

A

(see chart following)

Width of Refrigerator

36" (91 cm)

42

"

(106 cm)

48

"

(122 cm)

36-1/4

"

(92 cm)

42-1/4

"

(107 cm)

48-1/4

"

(123 cm)

Model Width A (as shown above)

the distance from outside trim to outside trim.

www.Appliantology.org

2-1

2-1

1

2

831/8"

(211 cm)*

3

251/8"

(64 cm)

231/2"

(60 cm)

24"

(61 cm)

1

/2" (9 cm)*

3

Model Width A

36" (91 cm)

42

"

(106 cm)

"

(122 cm)

48

1. 25-1/8" (64 cm) dimension is to front of top grille

2. Power cord (24") (61 cm)

3. 5 ft. (1.5 m) water line tubing taped to back

A

25-1/8"

(64 cm)

35

"

(89 cm)

41

"

(104 cm)

"

(119 cm)

47

1

d

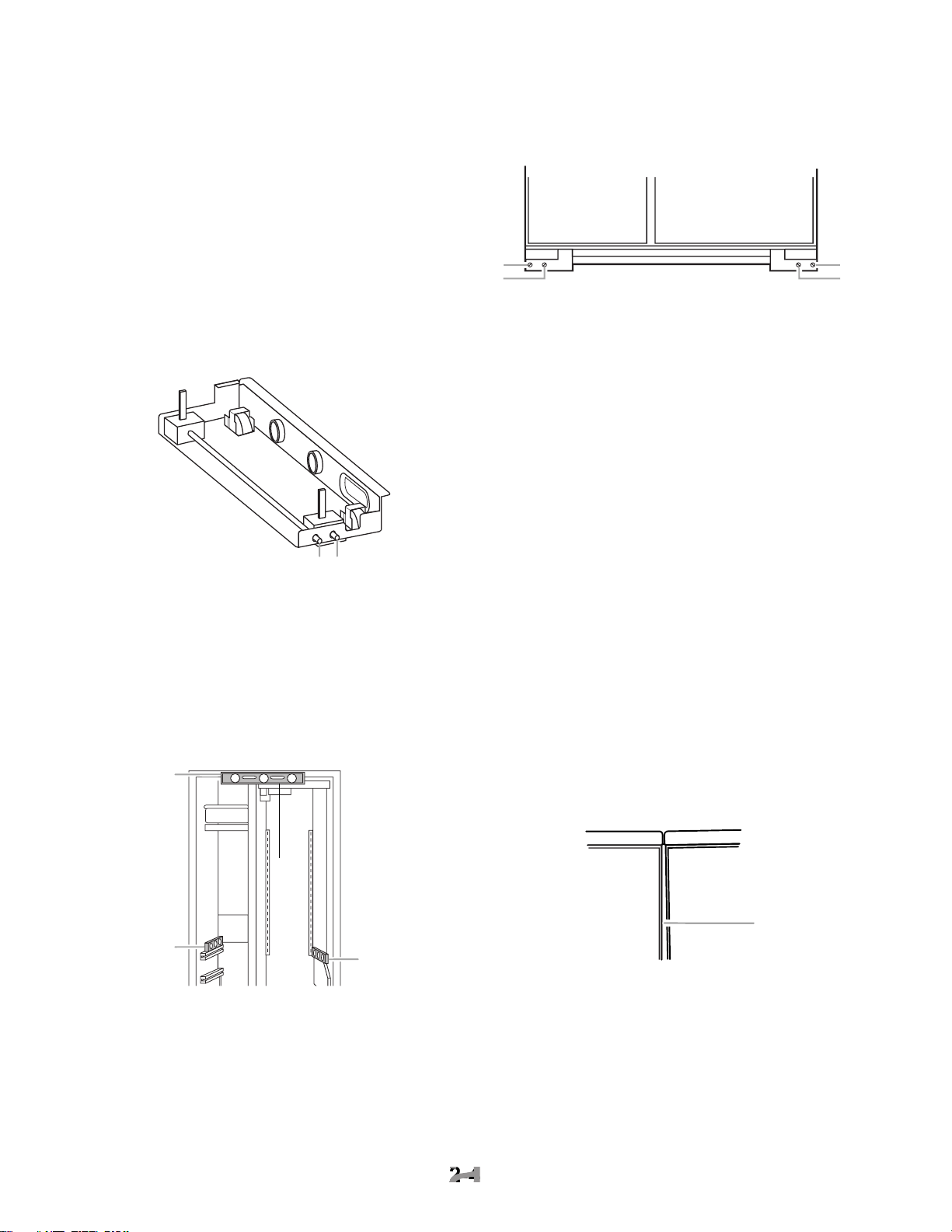

Openings

The built-in refrigerator can be installed into a

of cabinets using a side panel to enclose the

(12.7 mm) clearance to remove the top

grille and for proper air flow.

Wall studs must be located on the rear wall 80

to 90

(203 - 229 cm) above the floor.

The solid soffit must be within 1

(2.5 cm)

soffit is higher than 1

(2.5 cm), or one is not

available, then the refrigerator must be braced

to prevent tipping during use. See “Anti-Tip

A grounded electrical outlet should be placed

(10.2 cm) from the

The water shutoff should be located in the base

cabinet on either side of the refrigerator. The

through the right cabinet must be within 1/2

A 1/2

(12.7 mm) hole for plumbing should be

within the bottom shaded area. The water line

can be through the floor or wall. If the recom-

tional plumbing is necessary.

80" - 90"

(203-229 cm)

4"

(10.2 cm)

6"

(15.2 cm)

3" (7.6 cm)

83-1/4" (211.5 cm) min.

84-3/4" (215 cm) max.

to bottom of solid soffit.

(60 cm) min.

11"

(28 cm)

77"

(196 cm)

A

Width

(see chart following)

1

2

4

6"

(15.2 cm)

6"

(15.2 cm)

3

1. Stud location

2. Grounded electrical outlet location

3. Recommended water shutoff valve location

4. Plumbing hole and water line location (wall or floor)

36" (91.4 cm)

42

"

(106.7 cm)

48

"

(121.9 cm)

35-1/2

"

(90.2 cm)

41-1/2

"

(105.4 cm)

47-1/2

"

(120.7 cm)

Model Width A (as shown above)

Width of Opening:

23-1/2"

www.Appliantology.org

2-2

2-2

1. A 1/2" (12.7 mm) space is require

WATER SUPPLY REQUIREMENTS

• If you turn the refrigerator on before the

water line is connected, turn the ice maker

off.

• All installations must meet local plumbing

code requirements.

• Use copper tubing and check for leaks. In-

stall copper tubing only in areas where tem-

A kit is available with a 1/4

(6.35 mm) saddle-

type shutoff valve, a union, and copper tubing.

saddle-type valve complies with local plumb-

water flow and clog easily.

Connect the ice maker to a cold water line with

water pressure between 15 and 100 psi (103 -

690 kPa). If you have questions about water

ANTI-TIP BOARDS

• The solid soffit must be within 1

″

soffit is higher than 1

available, prevent the refrigerator from tip-

• It is recommended that the boards be in-

stalled before the refrigerator is installed.

• Boards must be long enough to fully cover

the width of the compressor cover.

21

r

To Install The Anti-Tip Boards:

80

to 90

(203 - 229 cm) above the floor.

2. Securely attach one or two 2

x 4

x 32

wall studs behind the refrigerator. Use six

#8 x 3

″

The wood screws must be screwed into

the studs at least 1-1/2

(3.8 cm). The

• Locate the boards so the bottom surface of

the boards are 84

″

• During installation, raise the refrigerator up

so there is 1/4

″

the top of the refrigerator and the bottom of

the anti-tip boards. Do not crush the con-

denser cover when raising the rear leveling

www.Appliantology.org

2-3

2-3

3

2" (5 cm)

4

1. Center board 1/4" (6 mm) max. above refrigerato

2. Two 2" x 4" x 32" (5 cm x 10 cm x 81 cm) boards

3. Attach to studs with 6-#8 x 3" (7.6 cm) screws

4. Compressor cover

All four leveling legs must contact the floor to

support and stabilize the full weight of the

erator, and not for permanent support.

wise) until the refrigerator weight is supported

To avoid cabinet damage, do not apply more

than 50 in/lbs (58 cm/kg) of torque to the

1. Rear leveling legs

the refrigerator frame. Check to see if the

2. Use the leveling bolts to adjust the leveling

to right.

3. Place a level on the shelves and check to

see if the refrigerator is level from front to

4. Use the leveling bolts to adjust the leveling

to back.

5. Make sure that all four leveling legs con-

tact the floor and support the full weight of

the refrigerator.

6. Make a final check to see that the refrig-

erator is level.

ADJUSTING THE DOORS

alignment to the left, right, in, or out.

the freezer and refrigerator doors. Make

sure that the spacing between the doors is

the same distance at the top and bottom.

2. If the door gap is uneven, the side trim

entire door gasket liner. Remove the six

www.Appliantology.org

2-4

2-4

2. Front leveling legs

1 2

1

2

1. Rear leveling bolt

2. Front leveling bolt

1

2

1

2

1. Level to check left to right leveling

2. Level to check front to back leveling

2

1. Uneven door gap

1

3. Loosen the four 3/8

″

top of both door hinges.

1. Mounting screws

4. Adjust the hinges so that the door gap is

the same distance at the top and bottom.

5. Check the side door gasket gap. Make

sure that the distance is the same at the

top and bottom. Adjust the hinges, as

6. Recheck the front door gap spacing to

even.

7. Tighten the top hinge screws securely.

8. Reinstall the side door trim.

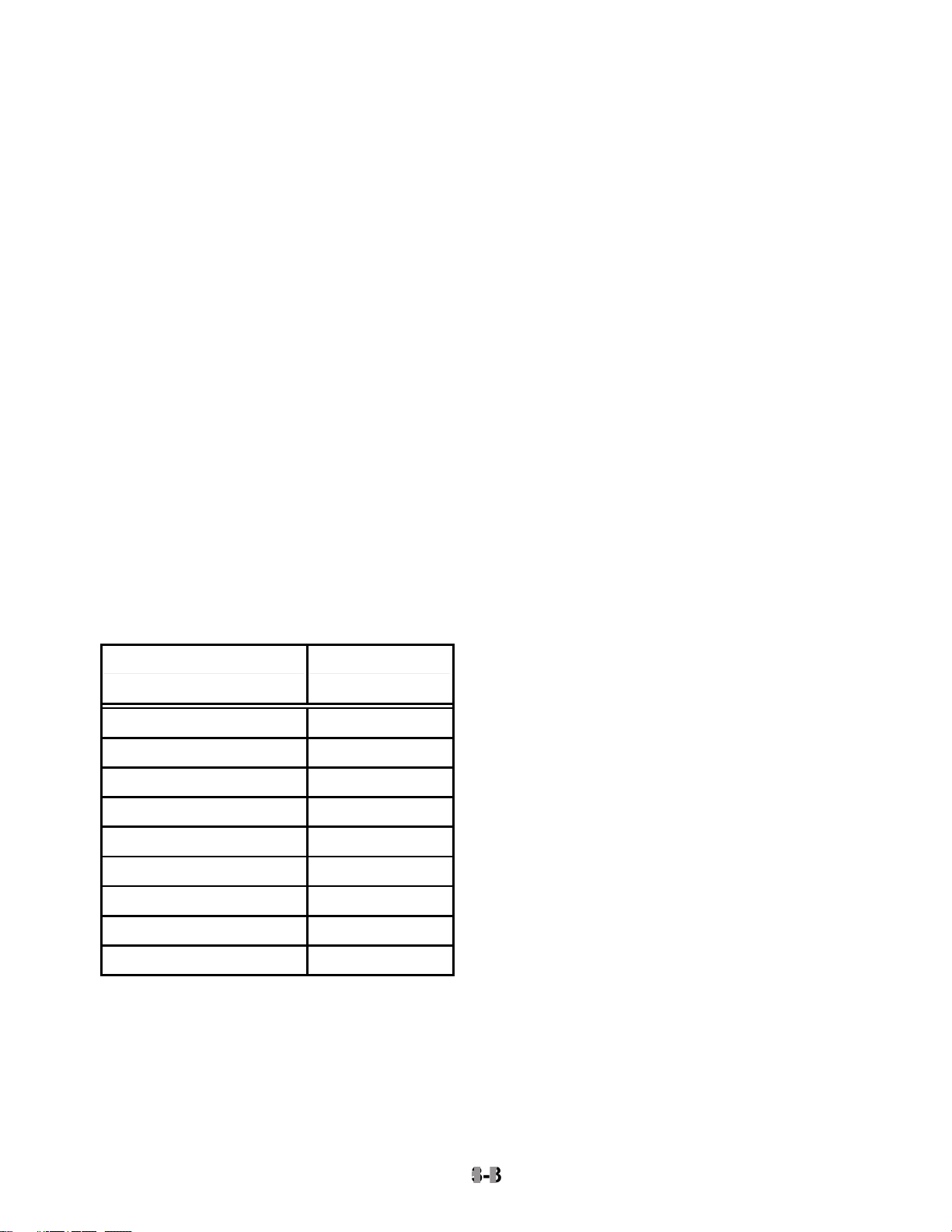

the door.

2. Use an allen wrench and remove the door

stop screw and locking plate from the

3. Use an open-end wrench and turn the

4. Replace the locking plate and door stop

screw. Turn the bushing slightly to align

the hinge and locking plate screw holes.

www.Appliantology.org

2-5

2-5

1

1. Locking plate

2. Door stop screw

3. Bushing

and make sure that they open freely. If a

door opens too wide, remove the door

stop screw from the bottom hinge.

12 3

2. Move the door to the desired open posi-

tion, and then reinstall the door stop screw

at one of the three holes that is closest to

the desired position.

www.Appliantology.org

2-6

2-6

1. Door stoop setscrew (130° position)

°

position.

2. 110

°

position.

3. 90

THEORY OF OPERATION

OVERVIEW

The KitchenAid Built-In Refrigerator Constant

two thermistors to monitor temperature changes

operation of the variable capacity compressor

and a variable position air door. The air door

allows independent temperature control of the

The electronic control seeks the most efficient

controls the operation and speed of the com-

fan speed is used before increasing the com-

tion. A nearly constant run time is sought at the

–9

C to –23

C). Refrigerator tempera-

tures can be set from 46

C to

0

C).

The Adaptive Defrost Control (ADC) portion of

the electronic control utilizes “pulsed defrost”

technology to perform the defrost function (see

THE ELECTRONIC TEMPERATURE CONTROL PANEL

The electronic control monitors the water valve

for total elapsed time and gallons of water

The numeric display can be set for Fahrenheit

or Celsius and displays the actual tempera-

tures. The display range for the refrigerator is

from 27

above or below these limits will be displayed at

the corresponding temperature limit. During

and the refrigerator will read 32

The display will show the temperature setting

any time the actual temperature is within

±

6

of the customer setting. This will prevent con-

cern over temperature fluctuations when the

doors are opened. Press the temperature ad-

justment key to view the current temperature

setting, or to change the setting. When the

temperature adjustment key is used to change

the temperature setting, the display will brighten

for 5 seconds.

Available features include:

• Water Filter Indicator

• Max Cool

• Over-Temperature Alarm

• Holiday Mode

www.Appliantology.org

3-1

3-1

Power

On/Off

Warmer

Colder

FREEZER REFRIGERATOR

°C

SELECT

Warmer

WATER FILTER

RESET

PERCENT LEFT

Colder

Temperature Decreasing

When the freezer temperature begins to de-

crease, the process will reverse. The compres-

sor speed decreases, followed by the evapo-

Temperature Increasing

When the refrigerator calls for cooling while

the freezer is satisfied, the air door begins to

open, and the evaporator fan starts to run at

to rise, the air door will continue to open. If the

temperature continues to rise after the air door

gradually increase to a maximum of 3000 rpm.

Temperature Decreasing

As the refrigerator temperature approaches the

selected setting, the control compares the tem-

which compartment will control the fan speed.

the air door begins to close, thus reducing the

airflow to the refrigerator.

open, and the fan speed begins to decrease.

When the selected temperature setting is

TEMPERATURE CONTROL

The electronic control checks the resistance of

the thermistors, and compares it to both the

customer temperature settings and the last

thermistor reading taken. This information is

operation, and if a change is necessary in the

damper setting, or the evaporator fan or com-

When a warm refrigerator is first put into a

cooling mode, the air door partially opens, and

the compressor and evaporator fan motors

start to run at maximum rpm. The air door will

gradually move to its fully open position.

As the actual temperature in the refrigerator

electronic control compares the temperatures

the speed of the evaporator fan motor.

Temperature Increasing

When the freezer calls for cooling, the com-

chart on page 3-3), and the evaporator fan

and evaporator speeds are continuously up-

dated. Speed changes are made based on:

• The difference between the actual tempera-

ture and the selected temperature settings.

• The rate of temperature change.

selected temperature setting, the evaporator

fan speed begins to gradually increase. The

evaporator fan motor reaches the maximum

speed of 3000 rpm at 5

temperature setting, and the compressor speed

9

www.Appliantology.org

3-2

3-2

The main control board supplies a 5 vdc, peak-

to-peak square wave, at 54 to 150 Hz, to the

three-phase 230 vac. Varying the frequency

to the inverter board, and not the voltage,

changes the speed of the compressor. The

compressor can run at speeds of 1620 to 4500

While the compressor is running, its speed is

continuously updated. Speed is determined

after analyzing two factors:

• The difference between the actual tempera-

ture and the selected temperature settings.

• The rate of temperature change.

freezer’s selected temperature setting, as

shown in the following chart.

The compressor generally cycles on and off

according to the cut-in and cut-out tempera-

tures of the freezer, however, the refrigerator

can turn on the compressor if the evaporator

fan is at maximum speed and the refrigerator

temperatures are not dropping.

To protect the compressor and maintain effi-

ciency, minimum compressor off time is pro-

grammed into the control. When the compres-

sor turns off, a minimum of 7 minutes must

elapse before allowing a restart.

The inverter board utilizes a current limiting

device and thermal protection that eliminates

the need for a compressor mounted thermal

The evaporator fan motor is a 12 vdc, variable

speed motor. The motor has four wires:

• A blue wire provides feedback to monitor the

speed of the motor.

• A red wire provides a constant 12 vdc.

• A yellow wire provides a variable voltage of

• A white wire provides a common return.

AIR DOOR DELAY

After defrost, an evaporator fan delay prevents

through the refrigerator, by chilling the evapo-

ter defrost drip time, the compressor starts at

4500 rpm, but the evaporator fan is delayed

for 8 minutes. The air door remains closed for

8 minutes following defrost.

AIR DOOR

The air door is driven by a reversible DC

stepper motor. The motor operates on a 12

vdc, peak-to-peak square wave. Voltage is

delivered to the air door in a series of short

voltage reading with a VOM.

Separate windings are used to move the air

door open or closed. The door can be in any

one of 1800 positions from 0 to 90 degrees.

The air door is used to fine-tune the airflow to

the refrigerator.

Freezer Temperature Compressor

www.Appliantology.org

3-3

3-3

Setting (°°°°F)

Minimum Speed

9 to –2 1620 rpm

–3 1800 rpm

– 4 2000 rpm

–5 2200 rpm

–6 2400 rpm

–7 2600 rpm

–8 2800 rpm

–9 3000 rpm

–10 3200 rpm

The refrigerator temperature determines the

opening of the air door. When the refrigerator

already running for the freezer, the air door

While the refrigerator is cooling, the door will

cover refrigerator temperature.

ADAPTIVE DEFROST

The adaptive defrost control allows the unit to

enter a defrost mode only when it is needed.

When powered up for the first time, the control

defrost heating time and compressor run time,

the control will continuously adapt the time

and 100+ hours.

defrost.

on continuously. It will then cycle off for 1

will continue to cycle at this ratio until the

At this point, heat is discontinued, and a

4-minute “drip time” begins. This allows the

water to drain before the unit returns to a

cooling mode. Maximum defrost time, (pulsed

When entering a defrost cycle, if the bimetal is

open, the time to defrost is reset to 8 hours, and

the control will time through the entire 37 minute

defrost period. During diagnostics this will al-

tion, and if necessary, bypass the bimetal.

After a power interruption, the following events

will occur:

• The unit returns to the same operating mode

and settings in use prior to the power inter-

• Initially, the compressor, evaporator fan, and

condenser fan motors will be off.

• The air door will close, and then adjust to the

when the air door opens.

• The adaptive defrost control resets the com-

freezer is above 20

set to 8 hours.

• If the freezer temperature is below 12

compressor starts after a delay of 7 minutes.

compressor starts immediately.

the control uses one of the following default

corrected.

thermistor, the air door and the evaporator fan

off cycle, based on current selected tempera-

ture settings. The evaporator fan motor will run

when the air door is open.

At mid-settings of 37

open for 16 minutes, and close for 30 minutes.

Setting the freezer colder, or the refrigerator

warmer, will reduce the door-open time. Set-

ting the freezer warmer, or the refrigerator

colder, will increase the door-open time.

www.Appliantology.org

3-4

3-4

off cycle. The cycle time is based on current

selected temperature settings.

At mid-settings of 37

C, the compressor

and the evaporator fan motors will run for 35

freezer colder will increase the run time. Set-

ting the freezer warmer will decrease the run

time.

The compressor will run at minimum speed.

The evaporator fan will also run at minimum

speed, unless the refrigerator compartment

working, it reverts to the default temperature

settings of 37

the freezer.

compressor will run at 4500 rpm for an indefi-

The “Call Service Alarm” will sound until the

failure has been corrected.

THERMAL SHUTOFF

The electronic control utilizes an on-board ther-

C). When the

temperature drops to 130

C), the com-

continues indefinitely until the cause of the high

temperature has been corrected.

the alarm sounds.

ture setting to 32

C) and the freezer to

–10

C) for 24 hours. During Max Cool,

the freezer and refrigerator temperature dis-

the actual temperatures.

than 1 hour. The control returns to the previous

temperature settings are changed.

AUTOMATIC MAX ICE

Automatic Max Ice operates any time the ice

of Automatic Max Ice is 1-1/2 hours. During

Automatic Max Ice the following occurs:

• The freezer display shows the user tempera-

ture settings and not the actual temperature.

• The freezer temperature setting changes to

–9

C).

• The evaporator fan runs at 3000 rpm.

• The compressor runs the entire 1-1/2 hour

ence between actual freezer temperature

and -9

C).

The Holiday Mode may be used for the follow-

• On vacation.

• Religious observance (Sabbath Mode).

When the Holiday Mode is selected, the corre-

sponding green LED flashes for 2 seconds,

and then remains on, to indicate that the fea-

ture is activated.

www.Appliantology.org

3-5

3-5

Loading...

Loading...