KitchenAid KSBP25FKSS00, KSBS25FKBT00, KSCS25FKSS00, KSFS25FKBL00, KSFS25FKBT00 User Manual

...

TECHNICAL EDUCATION

KAR-12

MODELS:

KSBP25FKSS00

KSBS25FKBL00

KSBS25FKBT00

KSBS25FKWH00

KSCS25FKSS00

KSFS25FKBL00

KSFS25FKBT00

KSFS25FKWH00

2001 K MODEL

COUNTER DEPTH

SIDE-BY-SIDE REFRIGERATOR

WITH VARIABLE

CAPACITY COMPRESSOR

JOB AID 4317290A

FORWARD

This Job Aid, “KitchenAid 2001 K Model Counter Depth Side-By-Side Refrigerator With Variable

Capacity Compressor” (Part No. 4317290A), provides the technician with information on the

installation and service of the Side-By-Side Refrigerator. It is to be used as a training Job Aid and

Service Manual. For specific information on the model being serviced, refer to the “Use and Care

Guide,” or “Tech Sheet” provided with the refrigerator.

The Wiring Diagrams and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the Side-By-Side Refrigerator.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the Side-By-Side Refrigerator to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2002, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Safety First......................................................................................................................... 1-1

Electrical Power Supply & Grounding Requirements ................................................... 1-1

Electrostatic Discharge (ESD) Sensitive Electronics.................................................... 1-2

Model & Serial Number Designations ................................................................................ 1-3

Model & Serial Number Label And Tech Sheet Locations................................................. 1-4

Specifications..................................................................................................................... 1-5

Refrigerator Warranty ........................................................................................................ 1-7

INSTALLATION INFORMATION ........................................................................................... 2-1

THEORY OF OPERATION ..................................................................................................... 3-1

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Touch/Display Board, The Insert And Overlay,

& The Motorized Air Door ............................................................................................... 4-2

Removing A Thermistor ..................................................................................................... 4-4

Removing A Door Switch ................................................................................................... 4-5

Removing A Light Socket .................................................................................................. 4-6

Removing The Water Reservoir ........................................................................................ 4-7

Removing The Ice Maker And The Auger Motor & Crush/Cube Solenoid......................... 4-9

Removing The Evaporator Fan Motor, The Bimetal,

The Defrost Heater, & The Evaporator ......................................................................... 4-11

Removing The Condenser Fan Motor ............................................................................. 4-15

Removing The Compressor ............................................................................................. 4-16

Removing The Inverter Assembly.................................................................................... 4-17

Removing The Main Control Board Assembly ................................................................. 4-18

Removing The Water Dispenser Fill Tube ....................................................................... 4-20

Removing The Water Valve ............................................................................................. 4-22

Removing The Freezer Door Handles & Freezer Door ................................................... 4-23

Removing A Roller ........................................................................................................... 4-25

COMPONENT TESTING ........................................................................................................ 5-1

Thermistor.......................................................................................................................... 5-1

Evaporator Fan Motor ........................................................................................................ 5-2

Condenser Fan Motor ........................................................................................................ 5-2

Compressor & Inverter....................................................................................................... 5-3

Motorized Air Door ............................................................................................................. 5-4

Defrost Heater & Bimetal ................................................................................................... 5-4

Main Control Board ............................................................................................................ 5-5

Crush/Cube Solenoid......................................................................................................... 5-6

Ice Maker Auger Motor ...................................................................................................... 5-6

Water Valve Solenoid ........................................................................................................ 5-7

Door Switch ....................................................................................................................... 5-7

- iii -

Page

DIAGNOSIS & TROUBLESHOOTING ................................................................................... 6-1

Diagnosis ........................................................................................................................... 6-1

Pre-Diagnostics Checks ................................................................................................. 6-1

Diagnostics Mode ........................................................................................................... 6-1

Water Filter Input (WFI) Test .......................................................................................... 6-2

Troubleshooting Chart ....................................................................................................... 6-3

WIRING DIAGRAMS & STRIP CIRCUITS ............................................................................. 7-1

Wiring Diagram .................................................................................................................. 7-1

Strip Circuits ...................................................................................................................... 7-2

- iv -

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always

read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

ELECTRICAL POWER SUPPLY &

GROUNDING REQUIREMENTS

Electrical Shock Hazard

Disconnect power before servicing.

Replace all panels before operating.

Failure to do so can result in death or

electrical shock.

Electrical Shock Hazard

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

1-1

Electrical Shock Hazard

ELECTROSTATIC DISCHARGE

(ESD) SENSITIVE ELECTRONICS

ESD problems are present everywhere. ESD

may damage or weaken the electronic control

assembly. The new control assembly may appear to work well after repair is finished, but

failure may occur at a later date due to ESD

stress.

Connect green ground wire to ground

screw.

Failure to do so can result in death or

electrical shock.

• Use an antistatic wrist strap. Connect the

wrist strap to a green ground connection

point or unpainted metal in the appliance; or

touch your finger repeatedly to a green ground

connection point or unpainted metal in the

appliance.

• Before removing the part from its package,

touch the antistatic bag to a green ground

connection point or unpainted metal in the

appliance.

• Avoid touching electronic parts or terminal

contacts. Handle the electronic control assembly by the edges only.

• When repackaging the failed electronic control assembly in an antistatic bag, observe

the above instructions.

1-2

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER K SB S 2 5 F K WH 0 0

PRODUCT GROUP

K = KitchenAid Brand

PRODUCT IDENTIFICATION

BR = Bottom Freezer Reversible Door

SB = Counter Depth Factory Installed Trim

SC = Counter Depth Architect Style

SF = Counter Depth Side By Side

SR = Side By Side Regular

TR = Top Freezer Reversible Door

MERCHANDISING SCHEME/SERIES

CAPACITY/CUBIC FOOT SIZE

MODEL FEATURES

YEAR OF INTRODUCTION

K = 2001

COLOR CODE

WH = White

ENERGY/POWER DESIGNATOR (NUMERIC)

0 = Original, 1 = 1st Change, 2 = 2nd Change, Etc.

ENGINEERING CHANGE (NUMERIC)

0 = Original, 1 = 1st Change, 2 = 2nd Change, Etc.

SERIAL NUMBER

SERIAL NUMBER S L 3 0 10001

MANUFACTURING SITE

S = Fort Smith, AR

YEAR OF PRODUCTION

L = 2001

WEEK OF PRODUCTION

30th WEEK

PRODUCT SEQUENCE NUMBER

1-3

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model/Serial Number Label and Tech Sheet locations are shown below.

Model & Serial Number Location

(Refrigerator Compartment)

Screw

Base Grille

Screw

Tech Sheet

Location

(Behind Base

Grille)

1-4

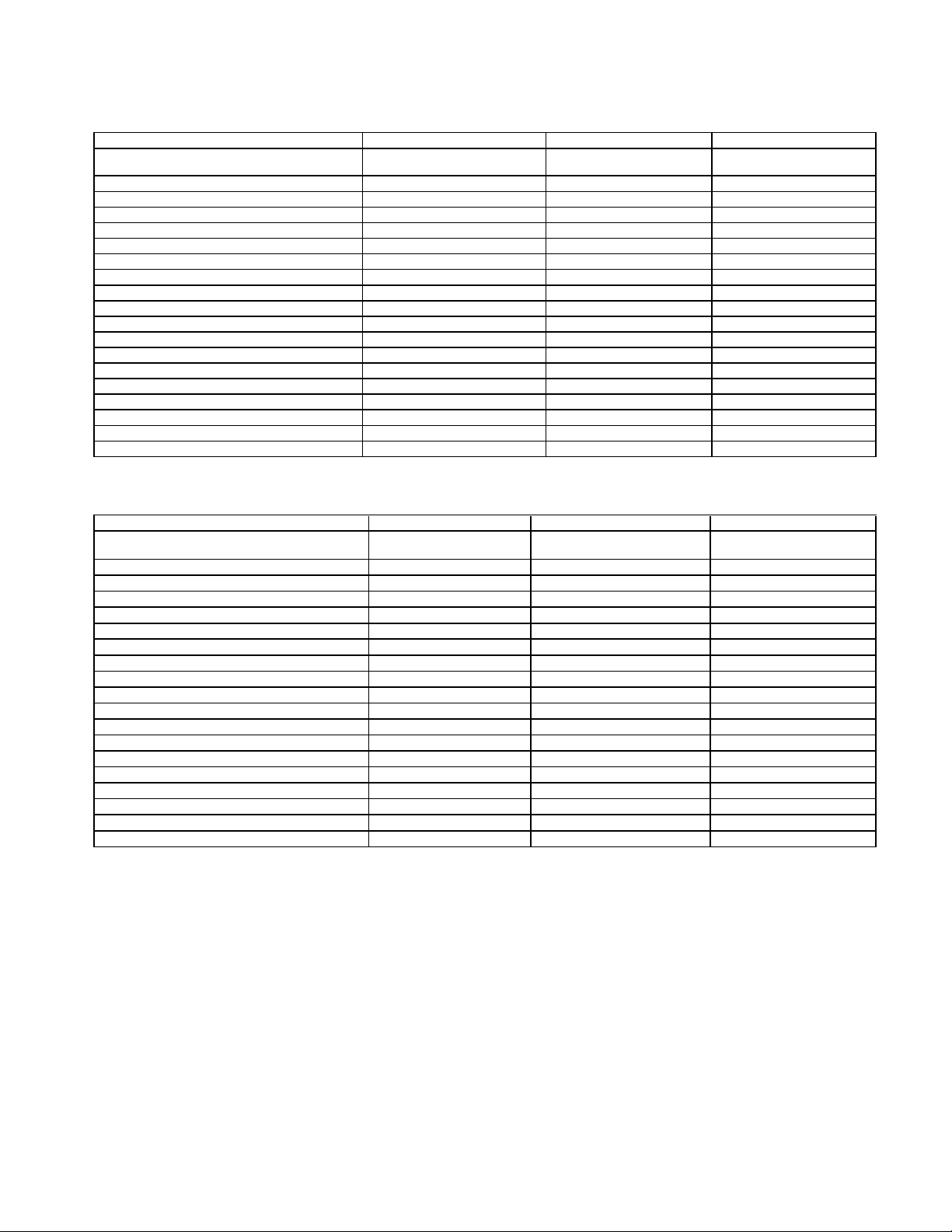

SPECIFICATIONS

KitchenAid C

KitchenAid C

KitchenAid C

KitchenAid C

Whi

KitchenAid C

KitchenAid C

Model Number

Model Description

Size-Configuration

Cabinet Height (Floor To Top Of Cabinet) (in)

Overall Height (Floor To Top Of Hinge Covers) (in)

Cabinet Width (in)

Overall Depth (Including Hardware & Handles) (in)

Depth - Less Doors/Base Grille (Minimum Opening) (in)

Crated Weight (lbs)

Cabinet Color

Cabinet Hinge Cover Color

Cabinet Center Rail Color

Cabinet Deck Rail Color

Cabinet Base Grille/Color

Cabinet Rollers

Refrigerant

Energy Star

Control Type

Standard Warranty (Months)

Full Liner And Sealed System Warranty (Months)

Model Number

Model Description

Size-Configuration

Cabinet Height (Floor To Top Of Cabinet) (in)

Overall Height (Floor To Top Of Hinge Covers) (in)

Cabinet Width (in)

Overall Depth (Including Hardware & Handles) (in)

Depth - Less Doors/Base Grille (Minimum Opening) (in)

Crated Weight (lbs)

Cabinet Color

Cabinet Hinge Cover Color

Cabinet Center Rail Color

Cabinet Deck Rail Color

Cabinet Base Grille/Color

Cabinet Rollers

Refrigerant

Energy Star

Control Type

Standard Warranty (Months)

Full Liner And Sealed System Warranty (Months)

KSBP25FKSS KSBS25FKBL KSBS25FKBT

Installed SS Panel Black Dispenser

ounter Depth Factory

25' Counter Depth 25' Counter Depth 25' Counter Depth

71 1/2 71 1/2 71 1/2

71 7/8 71 7/8 71 7/8

35 1/2 35 1/2 35 1/2

29 3/8 29 3/8 29 3/8

23 5/8 2 4 2 4

360 360 360

Black Black Biscuit

Black Black Biscuit

Black Black Biscuit

Black Black Biscuit

Black Black Biscuit

Front/Rear Adjust Front/Rear Adjust Front/Rear Adjust

R134a R134a R134a

Energy Star Energy Star Energy Star

Electronic ITC Electronic ITC Electronic ITC

12 12 12

60 60 60

KSBS25FKWH KSCS25FKSS KSFS25FKBL

ounter Depth

Dispensing Trim Model

25' Counter Depth 25' Counter Depth 25' Counter Depth

71 1/2 71 1/2 71 1/2

71 7/8 71 3/4 71 3/4

35 1/2 35 1/2 35 1/2

29 3/8 29 1/2 29 3/8

2 4 2 4 23 5/8

360 360 360

White Black Black

White Black Black

White Black Black

White Black Black

White Black Black

Front/Rear Adjust Front/Rear Adjust Front/Rear Adjust

R134a R134a R134a

Energy Star Energy Star Energy Star

Electronic ITC Electronic ITC

12 12 12

60 60 60

te

Series Stainless Wrap Dispenser

ounter Depth Black

Dispensing Trim Model

ounter Depth Architect

Dispensing Trim Model

Freestanding Dispensing

ounter Depth Biscuit

ounter Depth Black

1-5

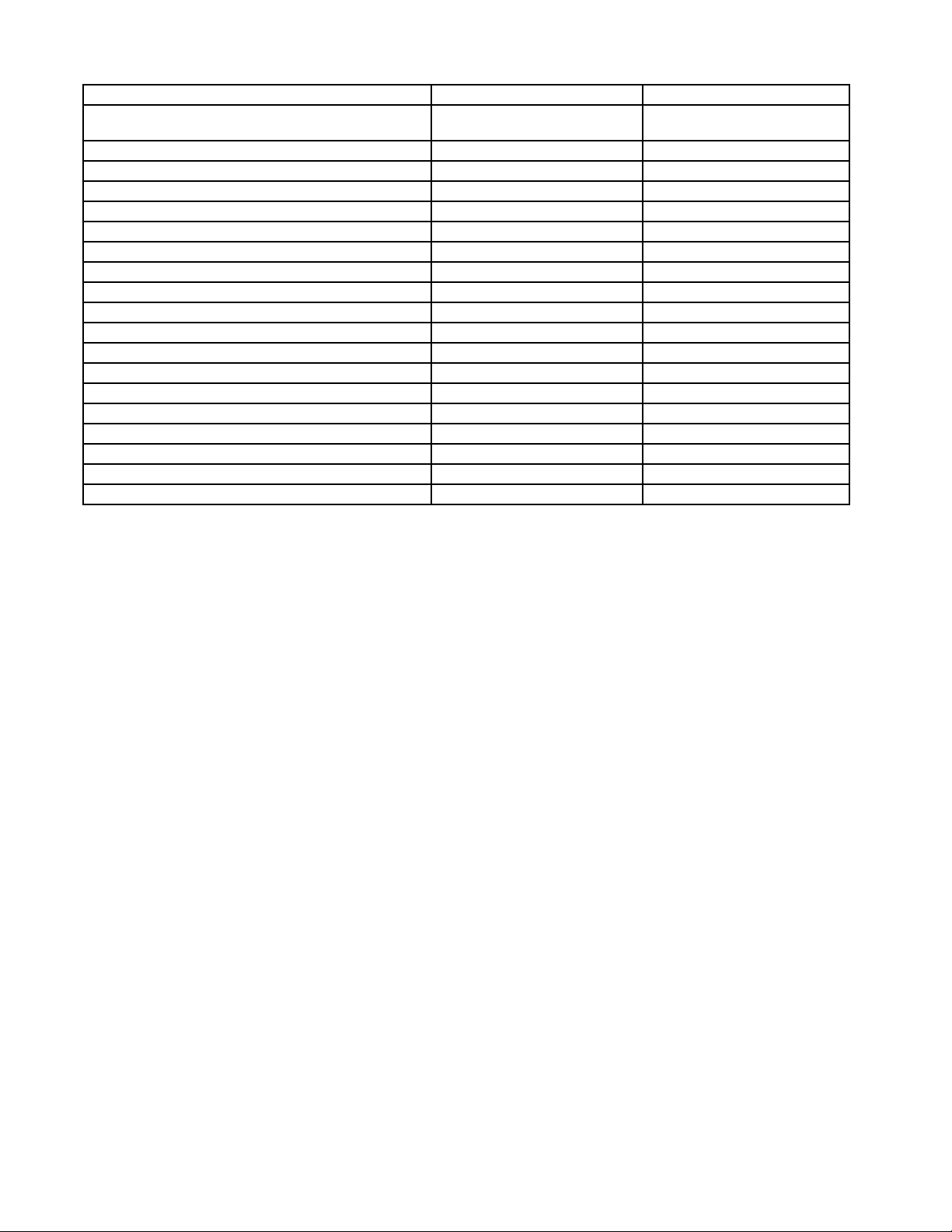

Model Number

KitchenAid C

KitchenAid C

Whi

Model Description

Size-Configuration

Cabinet Height (Floor To Top Of Cabinet) (in)

Overall Height (Floor To Top Of Hinge Covers) (in)

Cabinet Width (in)

Overall Depth (Including Hardware & Handles) (in)

Depth - Less Doors/Base Grille (Minimum Opening) (in)

Crated Weight (lbs)

Cabinet Color

Cabinet Hinge Cover Color

Cabinet Center Rail Color

Cabinet Deck Rail Color

Cabinet Base Grille/Color

Cabinet Rollers

Refrigerant

Energy Star

Control Type

Standard Warranty (Months)

Full Liner And Sealed System Warranty (Months)

KSFS25FKBT KSFS25FKWH

ounter Depth Biscuit

Freestanding Dispensing

25' Counter Depth 25' Counter Depth

71 1/2 71 1/2

71 3/4 71 3/4

35 1/2 35 1/2

29 3/8 29 3/8

23 5/8 23 5/8

360 360

Biscuit White

Biscuit White

Biscuit White

Biscuit White

Biscuit White

Front/Rear Adjust Front/Rear Adjust

R134a R134a

Energy Star Energy Star

Electronic ITC Electronic ITC

12 12

60 60

Freestanding Dispensing

ounter Depth

te

1-6

REFRIGERATOR WARRANTY

ONE-YEAR FULL WARRANTY ON REFRIGERATOR

For one year from the date of purchase, when this refrigerator (excluding the water filter) is operated and maintained according to instructions attached to or furnished with the product, KitchenAid will pay for factory specified

replacement parts and repair labor costs to correct defects in materials or workmanship. Service must be provided by a KitchenAid designated service company. On models with a water filter: 30 day limited warranty on

water filter. For 30 days from the date of purchase, when this filter is operated and maintained according to instructions attached to or furnished with the product, KitchenAid will pay for replacement parts to correct defects

in materials and workmanship.

SECOND THROUGH FIFTH YEAR LIMITED WARRANTY

In second through fifth years from the date of purchase, KitchenAid will pay for replacement or repair of the refrigerator/freezer cavity liner (including labor costs) if the part cracks due to defective materials or workmanship.

Service must be provided by a KitchenAid designated service company. Also, KitchenAid will pay for factory

specified replacement parts and repair labor costs to correct defects in materials or workmanship in the sealed

refrigeration system. These parts are: compressor, evaporator, condenser, dryer, and connecting tubing. Service

must be performed by a KitchenAid designated service company.

SIXTH THROUGH TENTH YEAR LIMITED WARRANTY

In sixth through tenth years from date of purchase, KitchenAid will pay for factory specified replacement parts to

correct defects in materials or workmanship in the sealed refrigeration system. These parts are: compressor,

evaporator, condenser, dryer, and connecting tubing.

LIMITED LIFETIME WARRANTY

In second year through life of product from date of purchase, KitchenAid will pay for replacement of all SLIDE N

LOCKTM Door Bins and SLIDE N LOCKTM Can Racks due to defective materials or workmanship.

KitchenAid will not pay for:

1. Service calls to correct the installation of the refrigerator, to instruct you how to use the refrigerator, to replace house fuses or correct house wiring or plumbing, to replace light bulbs, or replacement water filters

other than as noted above.

2. Repairs when the refrigerator is used in other than normal, single-family household use.

3. Pickup and delivery. The refrigerator is designed to be repaired in the home.

4. Damage resulting from accident, alteration, misuse, abuse, fire, flood, improper installation, acts of God, or

use of products not approved by KitchenAid or KitchenAid Canada.

5. Any food loss due to product failure.

6. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

7. Replacement parts or repair labor costs for units operated outside the United States or Canada.

8. In Canada, travel or transportation expenses for customers who reside in remote areas.

9. Any labor costs during the limited warranty period.

KITCHENAID AND KITCHENAID CANADA SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states or provinces do not allow the exclusion or limitation of incidental or consequential damages, so this

exclusion or limitation may not apply to you. This warranty gives you specific legal rights, and you may also have

other rights which vary from state to state or province to province.

Outside the 50 United States and Canada, this warranty does not apply. Contact the authorized KitchenAid

dealer to determine if another warranty applies.

If you need service, first see the “Troubleshooting” section of the Use and Care Guide. After checking “Troubleshooting,” additional help can be found by checking the “Assistance or Service” section, or by calling the

KitchenAid Customer Interaction Center, 1-800-422-1230 (toll-free), from anywhere in the U.S.A. In Canada,

contact the designated KitchenAid Canada Appliance service company, or call 1-800-807-6777.

1-7

— NOTES —

1-8

INSTALLATION INFORMATION

LEVELING THE REFRIGERATOR

IMPORTANT: All four leveling legs must contact the floor to support and stabilize the full

weight of the refrigerator.

Base Grille Removal

1. Open the refrigerator doors.

NOTE: Do not remove the Tech Sheets fastened behind the grille.

2. Remove the screws from the base grille

and remove the grille.

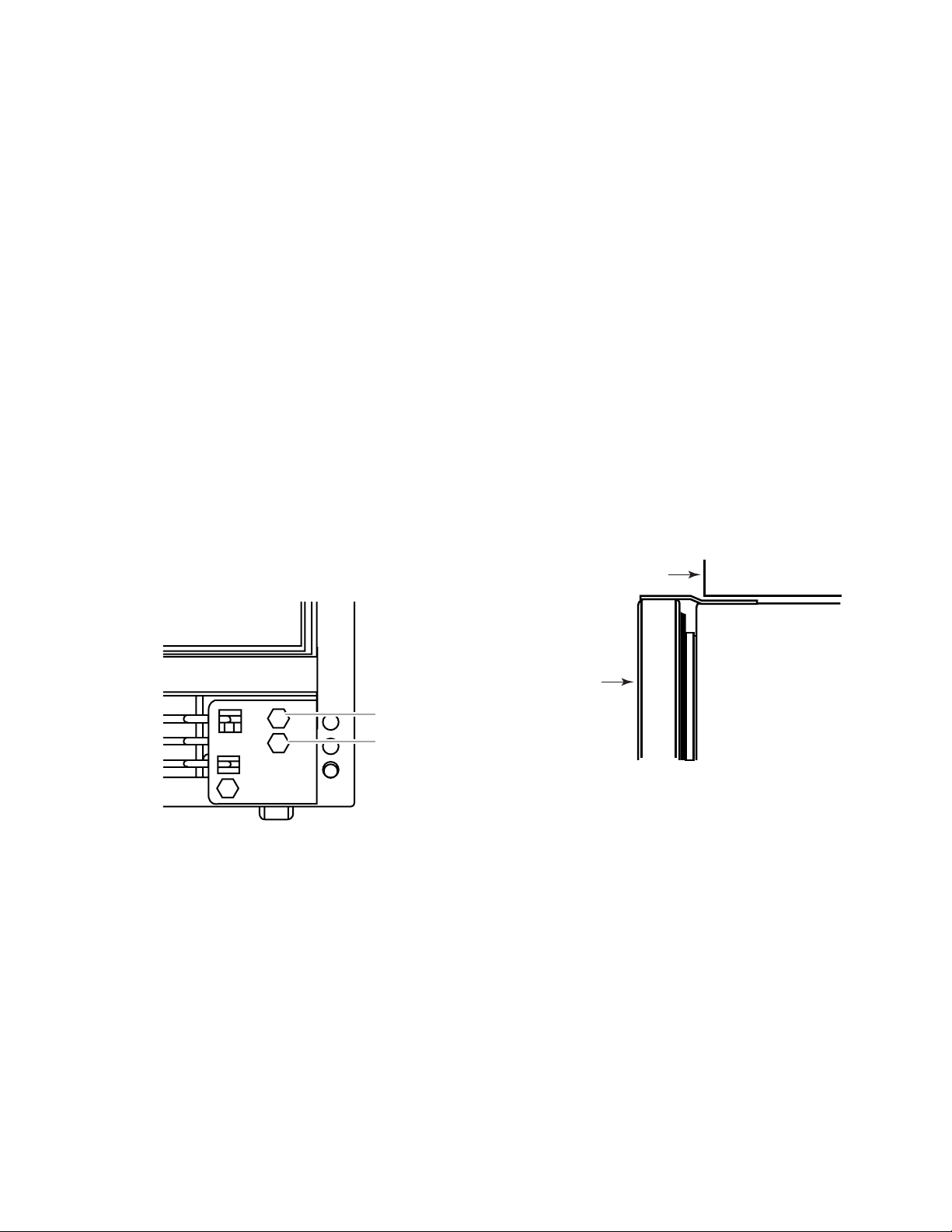

Adjusting The Rollers

The roller adjusting bolts are located behind

the base grille. The refrigerator has four adjustable rollers: two in front, and two in the rear.

There are two sets of roller adjusting bolts

found at the base of the refrigerator on each

side. The rear leveling bolt (1) is yellow, and

the front leveling bolt (2) is silver.

1. Use a 1/2″ (12.70 mm) socket wrench to

adjust the leveling bolts. Turn the leveling

bolt to the right to raise that side of the

refrigerator, or turn the leveling bolt to the

left to lower that side. It may take several

turns of the leveling bolts to adjust the tilt

of the refrigerator.

2. Adjust the front leveling bolt so that the top

of the refrigerator is parallel with the cabinet above the refrigerator.

For standard cabinets, leave approximately

1/8″ (3.18 mm) gap between the top hinges

and the cabinet.

For full-overlay cabinets, leave a 1/4″ (6.35

mm) gap for leveling.

If you do not have a cabinet above the

refrigerator, adjust the refrigerator to make

it level.

Cabinet

1

2

NOTE: Be careful not to unscrew the leveling

bolts too much when lowering the refrigerator.

The bolt head will start to come away from the

refrigerator when it is in the lowest position. If

the bolt comes out of the rear roller bracket, the

compartment access cover on the back of the

refrigerator will have to be removed to reinstall

the bolt.

Front Of

Refrigerator

3. Adjust the rear leveling bolt and level the

refrigerator with the side cabinets, or with

the cabinet end panels.

4. If needed, use the four leveling bolts to

raise the refrigerator to close the gap

between the refrigerator top hinge, and

the cabinet opening. Check to make sure

that all four rollers still touch the floor, and

that the cabinet doors above the refrigerator open all the way.

2-1

— NOTES —

2-2

THEORY OF OPERATION

3.4

Water

Filter

Powe r

On/Off

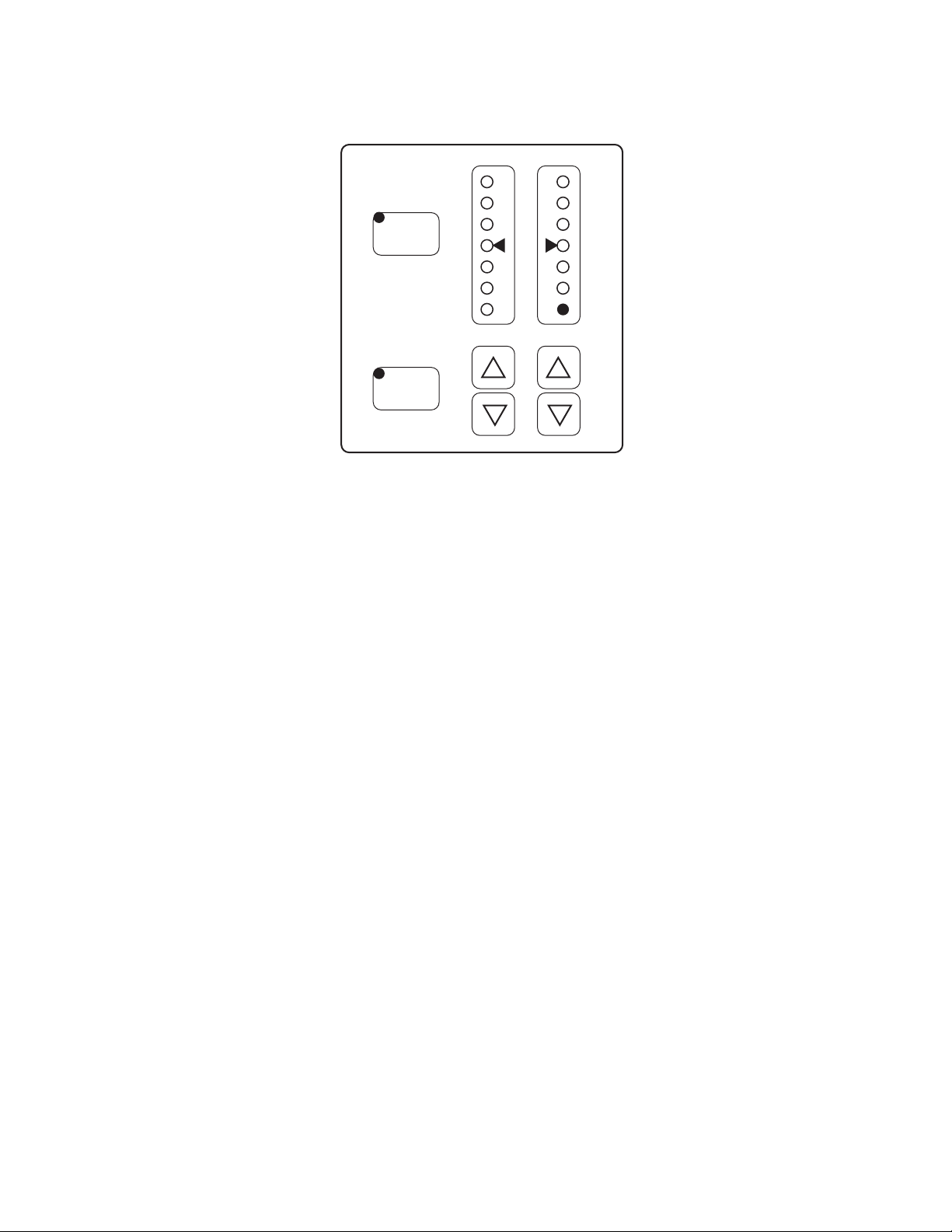

THE ELECTRONIC CONTROL PANEL

1.7

–1.7

–3.4

–5.1

OVERVIEW

The KitchenAid Counter Depth Refrigerator

Constant Flow Temperature Management System uses two thermistors to monitor temperature changes inside the refrigerator and freezer

compartments. The electronic control manages the operation of the variable capacity

compressor (VCC), a variable speed evaporator fan motor, and a variable position air door.

The air door allows independent temperature

control of the refrigerator and freezer compartments.

The electronic control seeks the most efficient

means possible to maintain temperatures as it

controls the operation and speed of the compressor and the evaporator fan motor. Higher

fan speed is used before increasing the compressor speed to minimize power consumption. A nearly constant run time is sought at the

lowest possible fan and compressor speed.

Warmer

8

0

Cooler

Freezer Refrigerator

Warmer

46

40.4

38.7

37

35.3

33.6

31.9

Cooler

NOTE: The illustration above shows the actual

temperature that is associated with each corresponding LED.

Freezer temperatures can be set from 8°F to

–5°F (–13°C to –21°C). Refrigerator temperatures can be set from 46°F to 32°F, (8°C to

0°C).

The Adaptive Defrost Control (ADC) portion of

the electronic control utilizes “pulsed defrost”

technology to perform the defrost function (see

page 3-4).

The electronic control monitors the water valve

for total elapsed time and gallons of water

used. The Water Filter Indicator (WFI) LED

changes color to indicate that the filter needs to

be replaced.

Pressing the Temperature Up or Down adjustment keys will change the refrigerator and

freezer settings. One of seven (7) LEDs light to

display the refrigerator and the freezer settings.

3-1

TEMPERATURE CONTROL

The electronic control checks the resistance of

the thermistors, and compares it to both the

customer temperature settings and the last

thermistor reading taken. This information is

used to determine when to begin a cooling

operation, and if a change is necessary in the

damper setting, or the evaporator fan or compressor speed.

When a warm refrigerator is first put into a

cooling mode, the air door partially opens, and

the compressor and evaporator fan motors

start to run at maximum rpm. The air door will

gradually move to its fully open position.

As the actual temperature in the refrigerator

nears the selected temperature setting, the

electronic control compares the temperatures

in both compartments. The compartment that

has the greatest need for cooling, will control

the speed of the evaporator fan motor.

Freezer Temperature Control —

Temperature Increasing

When the freezer calls for cooling, the compressor begins to run at minimum rpm, (see the

chart on page 3-3), and the evaporator fan

begins to run at 2000 rpm. The compressor

and evaporator speeds are continuously updated. Speed changes are made based on:

• The difference between the actual temperature and the selected temperature settings.

• The rate of temperature change.

If the temperature increases 4°F above the

selected temperature setting, the evaporator

fan speed begins to gradually increase. The

evaporator fan motor reaches the maximum

speed of 3000 rpm at 5°F above the selected

temperature setting, and the compressor speed

begins to gradually increase. A maximum compressor speed of 4500 rpm will be reached at

9°F above the selected temperature setting.

Freezer Temperature Control —

Temperature Decreasing

When the freezer temperature begins to decrease, the process will reverse. The compressor speed decreases, followed by the evaporator fan speed.

Refrigerator Temperature Control —

Temperature Increasing

When the refrigerator calls for cooling while

the freezer is satisfied, the air door begins to

open, and the evaporator fan starts to run at

minimum speed. If the temperature continues

to rise, the air door will continue to open. If the

temperature continues to rise after the air door

is fully open, the evaporator fan speed will

gradually increase to a maximum of 3000 rpm.

If the temperature continues to rise, the compressor starts to run, or if it has already been

running, begins to increase in speed.

Refrigerator Temperature Control —

Temperature Decreasing

As the refrigerator temperature approaches the

selected setting, the control compares the temperatures in both compartments to determine

which compartment will control the fan speed.

If the freezer is further from the selected temperature setting, it controls the fan speed, and

the air door begins to close, thus reducing the

airflow to the refrigerator.

If the freezer is satisfied, the air door remains

open, and the fan speed begins to decrease.

When the selected temperature setting is

reached, the air door closes.

3-2

COMPRESSOR

COMPRESSOR PROTECTION

The main control board supplies a 5 vdc, peakto-peak square wave, at 54 to 150 Hz, to the

inverter board. A standard VOM will read approximately 2.5 vdc. The inverter board supplies the variable capacity compressor with

three-phase 230 vac. Varying the frequency

to the inverter board, and not the voltage,

changes the speed of the compressor. The

compressor can run at speeds of 1620 to 4500

rpm.

NOTE: It is not necessary, nor is it recommended, to test the output of the inverter board.

While the compressor is running, its speed is

continuously updated. Speed is determined

after analyzing two factors:

• The difference between the actual tempera-

ture and the selected temperature settings.

• The rate of temperature change.

Minimum compressor speed is based on the

freezer’s selected temperature setting, as

shown in the following chart.

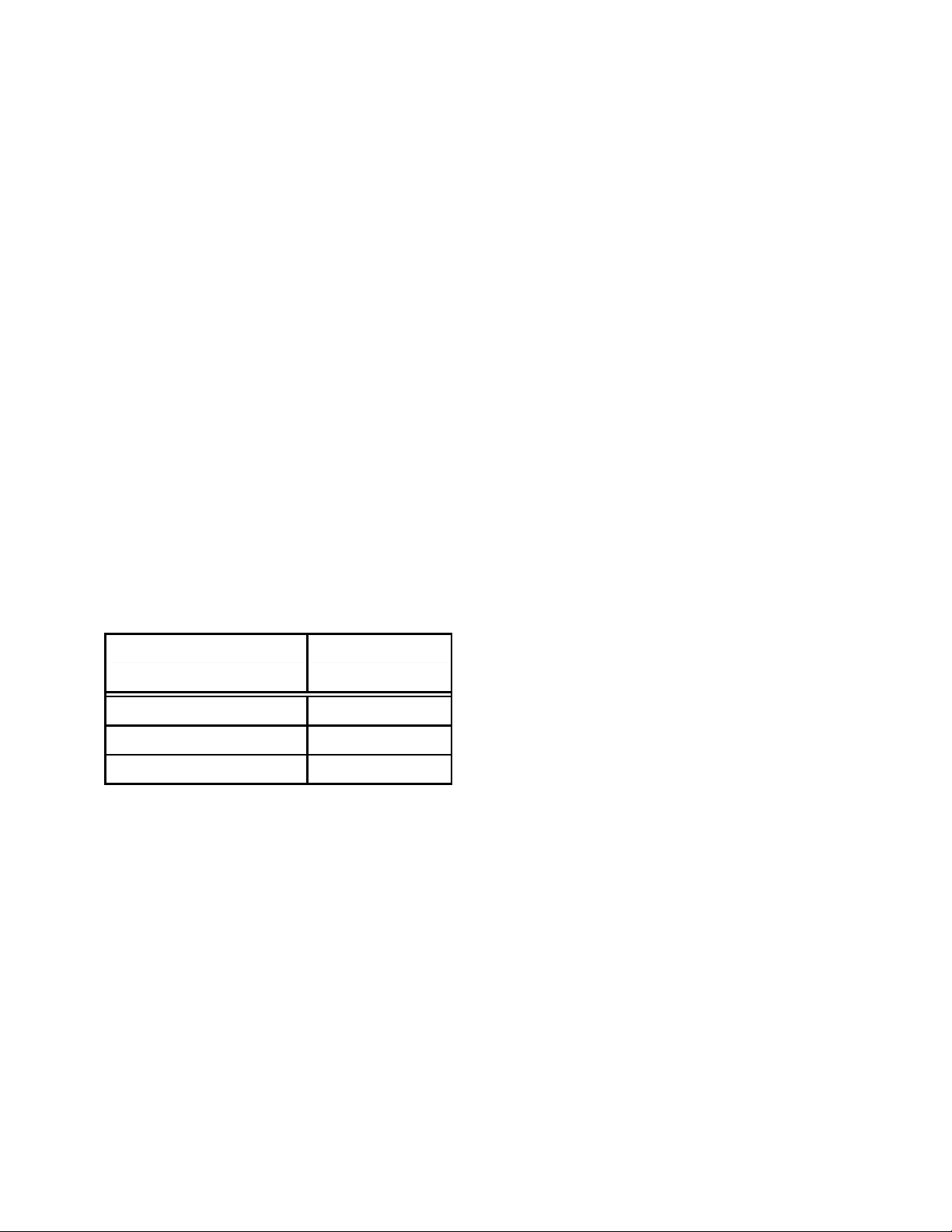

Freezer Temperature Compressor

Setting Minimum Speed

#1 - #5 1620 rpm

# 6 1800 rpm

# 7 2200 rpm

The compressor generally cycles on and off

according to the cut-in and cut-out temperatures of the freezer, however, the refrigerator

can turn on the compressor if the evaporator

fan is at maximum speed and the refrigerator

temperatures are not dropping.

To protect the compressor and maintain efficiency, minimum compressor off time is programmed into the control. When the compressor turns off, a minimum of 7 minutes must

elapse before allowing a restart.

The inverter board utilizes a current limiting

device and thermal protection that eliminates

the need for a compressor mounted thermal

protector.

EVAPORATOR FAN MOTOR

The evaporator fan motor is a 12 vdc, variable

speed motor. The motor has four wires:

• A blue wire provides feedback to monitor the

speed of the motor.

• A red wire provides a constant 12 vdc.

• A yellow wire provides a variable voltage of

between 5 vdc and 17 vdc to control the

motor speed from 2000 to 3000 rpm.

• A white wire provides a common return.

EVAPORATOR FAN &

AIR DOOR DELAY

After defrost, an evaporator fan delay prevents

unnecessary movement of warm, moist air

through the refrigerator, by chilling the evaporator prior to starting the fan. Immediately after defrost drip time, the compressor starts at

4500 rpm, but the evaporator fan is delayed

for 8 minutes. The air door remains closed for

8 minutes following defrost.

AIR DOOR

The air door is driven by a reversible DC

stepper motor. The motor operates on a 12

vdc, peak-to-peak square wave. Voltage is

delivered to the air door in a series of short

pulses. It is not possible to obtain a reliable

voltage reading with a VOM.

Separate windings are used to move the air

door open or closed. The door can be in any

one of 1800 positions from 0 to 90 degrees.

The air door is used to fine-tune the airflow to

the refrigerator.

3-3

The refrigerator temperature determines the

opening of the air door. When the refrigerator

requires cooling, if the evaporator fan motor is

already running for the freezer, the air door

partially opens, and then adjusts, if necessary.

While the refrigerator is cooling, the door will

be adjusting continuously to maintain or recover refrigerator temperature.

ADAPTIVE DEFROST

The adaptive defrost control allows the unit to

enter a defrost mode only when it is needed.

When powered up for the first time, the control

initiates a defrost cycle after 8 hours of compressor run time. By monitoring the duration of

defrost heating time and compressor run time,

the control will continuously adapt the time

between defrosts to optimize efficiency. Time

between defrost periods will vary between 8

and 100+ hours.

Defrost will occur immediately when the compressor has run at 4000 rpm or greater for 1

hour, and 8 hours have elapsed since the last

defrost.

PULSED DEFROST

For the first 7 minutes of defrost, the heater is

on continuously. It will then cycle off for 1

minute, and back on for 2 minutes. The heater

will continue to cycle at this ratio until the

bimetal opens, or until 33 minutes has elapsed.

At this point, heat is discontinued, and a

4-minute “drip time” begins. This allows the

water to drain before the unit returns to a

cooling mode. Maximum defrost time, (pulsed

heat on/off time + drip time) is 37 minutes.

When entering a defrost cycle, if the bimetal is

open, the time to defrost is reset to 8 hours, and

the control will time through the entire 37 minute

defrost period. During diagnostics this will allow a technician time to look for heater operation, and if necessary, bypass the bimetal.

POWER INTERRUPTION

After a power interruption, the following events

will occur:

• The unit returns to the same operating mode

and settings in use prior to the power interruption. If the unit was off, it remains off.

• Initially, the compressor, evaporator fan, and

condenser fan motors will be off.

• The air door will close, and then adjust to the

proper opening. The evaporator fan starts

when the air door opens.

• The adaptive defrost control resets the compressor run time counter to 0, and if the

freezer is above 20°F, the time to defrost is

set to 8 hours.

• If the freezer temperature is below 12°F, the

compressor starts after a delay of 7 minutes.

If the freezer temperature is above 12°F, the

compressor starts immediately.

FAILURE DEFAULTS

In the event of a thermistor, or keypad failure,

the control uses one of the following default

modes, which will continue until the failure is

corrected.

Refrigerator Thermistor

If the control senses an open or a shorted

thermistor, the air door and the evaporator fan

motor will begin to operate on a timed on and

off cycle, based on current selected temperature settings. The evaporator fan motor will run

when the air door is open.

At mid-settings of 37°F / 0°F, the air door will

open for 16 minutes, and close for 30 minutes.

Setting the freezer colder, or the refrigerator

warmer, will reduce the door-open time. Setting the freezer warmer, or the refrigerator

colder, will increase the door-open time.

3-4

Freezer Thermistor

AIR CIRCULATION

If the control senses an open or a shorted

thermistor, the compressor and the evaporator

fan motor will begin to operate on a timed on

and off cycle. The cycle time is based on

current selected temperature settings.

At mid-settings of 37°F / 0°F, the compressor

and the evaporator fan motors will run for 35

minutes, and be off for 25 minutes. Setting the

freezer colder will increase the run time. Setting the freezer warmer will decrease the run

time.

The compressor will run at minimum speed.

The evaporator fan will also run at minimum

speed, unless the refrigerator compartment

requests a higher speed.

Keypad

If the control detects that the keypad is not

working, it reverts to the default temperature

settings of 37°F in the refrigerator, and 0°F in

the freezer.

In order to ensure the proper refrigerator and

freezer compartment temperatures, air must

be able to flow between the two sections.

Air enters the bottom of the freezer compartment and moves up through the evaporator.

Some of the cooled air from the evaporator is

directed back into the freezer, and the rest

goes into the refrigerator through the motorized air door. The refrigerator air then returns to

the freezer through the bottom air return (see

the illustration below).

Evaporator Fan Motor

If the evaporator fan motor malfunctions, the

compressor will run at 4500 rpm for an indefinite period, except during the defrost periods.

ELECTRONIC CONTROL

THERMAL SHUTOFF

The electronic control utilizes an on-board thermistor to shut the compressor off if the temperature rises above 160°F (71°C). When the

temperature drops to 130°F (55°C), the compressor returns to normal operation. This cycle

continues indefinitely until the cause of the high

temperature has been corrected.

It is important not to block any of the vents with

food items. If the vents are blocked, airflow will

be restricted, and the temperature management system will not function properly.

IMPORTANT: Because air circulates between

both sections, any odors formed in one section

will transfer to the other. Keep both sections

clean, and wrap or cover foods tightly to prevent odors from occurring.

3-5

Loading...

Loading...