KitchenAid KIVD800TOB, KIVD860TOB, KPID850T, KPED890T Installation Instructions,Use And Care Information

KIVDEIOOTOB

30” Plenum

KIVD860TOB

36” Plenum

KPED890T

External Power

KPID850T

Internal Power

30” and 36”

Downdraft

Vent Systems

IMPORTANT:

Read and save these instructions.

Installer: Leave Installation Instructions with the

Homeowner.

Homeowner: Keep Installation Instructions for

luture reference.

Save Installation Instructions for local electrical

inspector’s use

SPECIAL NOTE:

Dimensions and

o:her

Information given are lor

Installations with any KItchenAid cooktop. If installIng

the downdraft venl system with a different brand of

cooktop, consult that manufacturer’s cutout dlmenslons

and lnstailatlon methods and the Information in this

guide

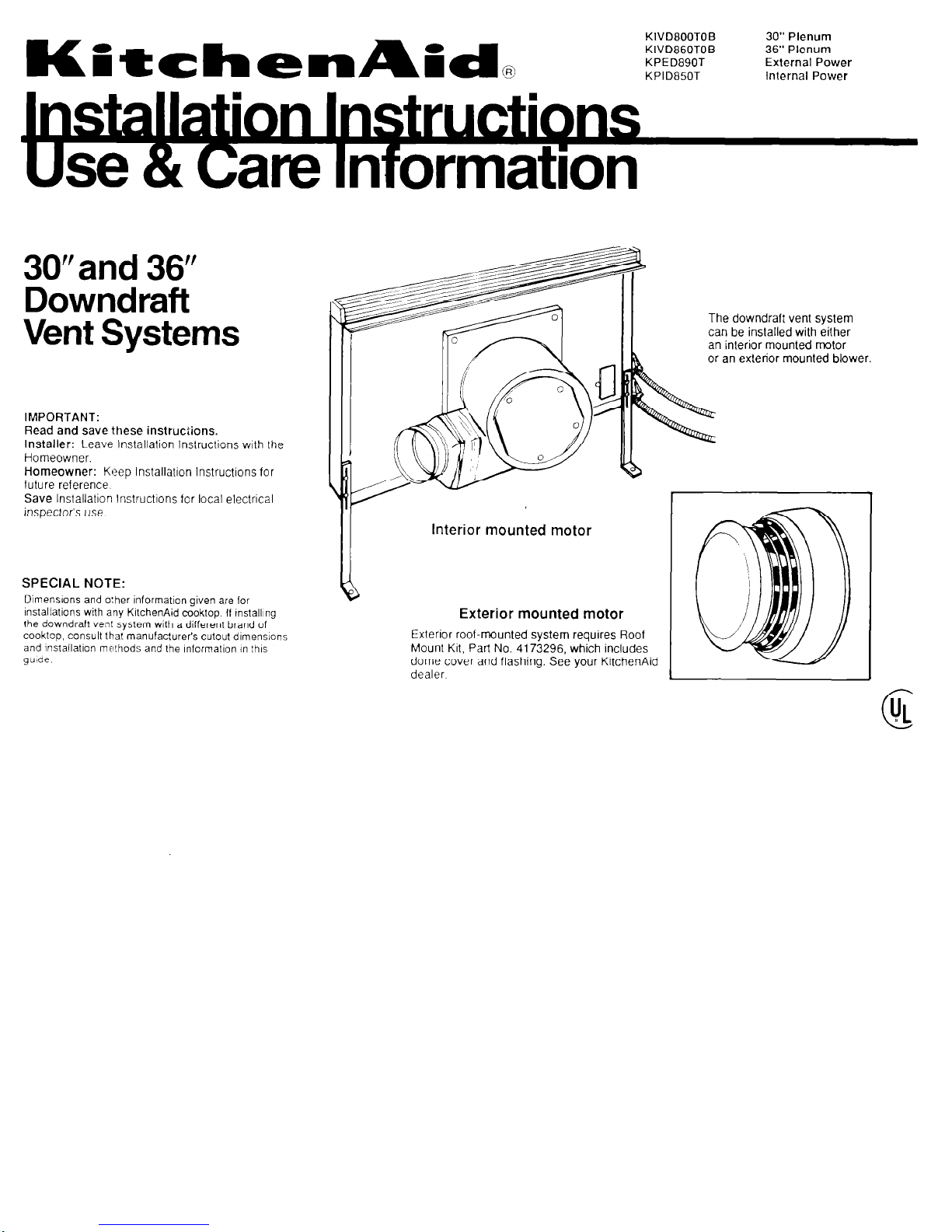

Interior mounted motor

a

Exterior mounted motor

Exterior roof-mounted system requires Roof

Mount Kit, Part No. 4173296, which includes

dome cover and flashing. See your KItchenAid

dealer

The downdraft vent system

can be installed with either

an interior mounted motor

or an exterior mounted blower

C

UL

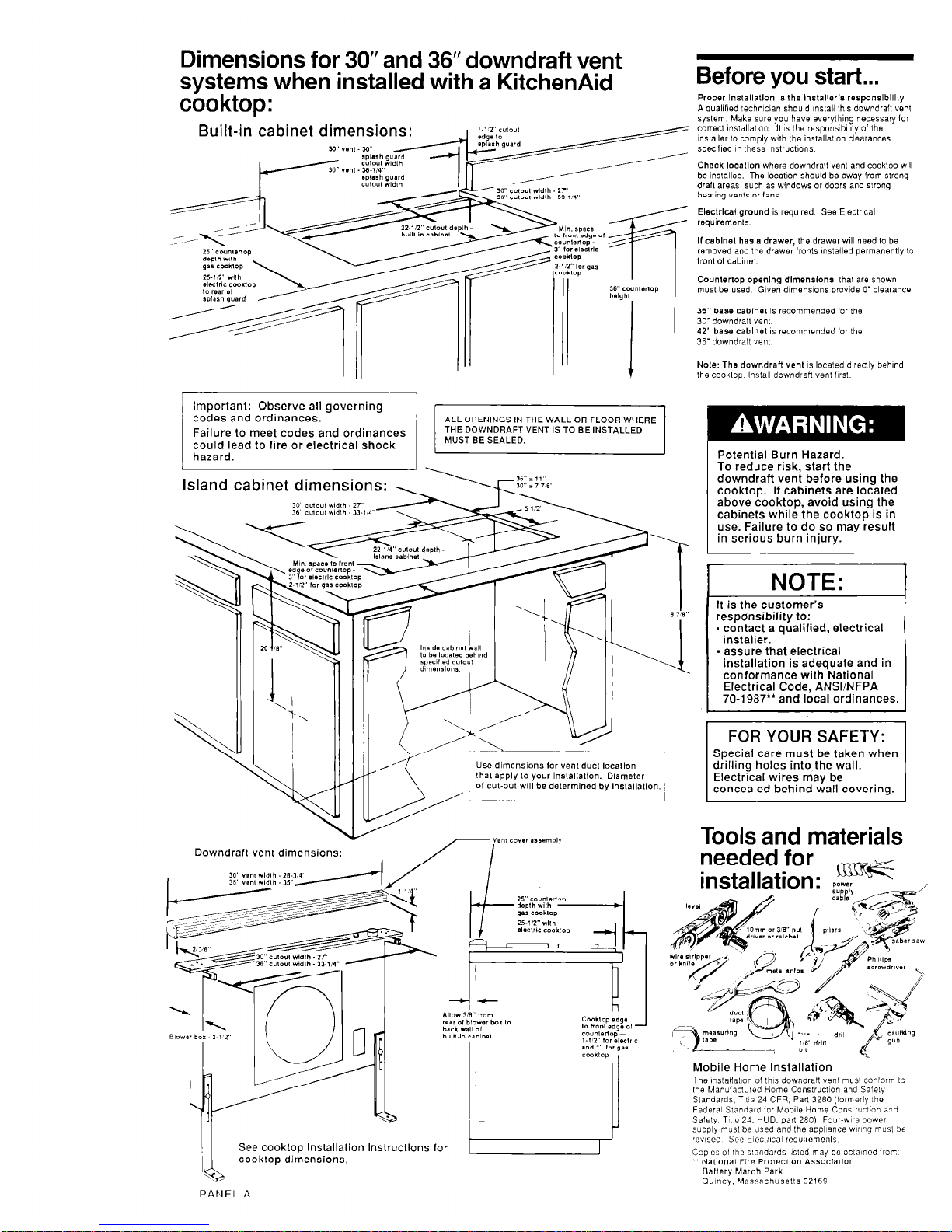

Dimensions for 30” and 36” downdraft vent

systems when installed with a KitchenAid

cooktop:

Before you start...

Proper lnslallatlon IS the Installer’s responslblllly.

A quaIlfled technician should ~nslall Ihis downdraft “en!

system Make sura you have everything necessary lor

corred ~nslallal~on II IS Ihe responslblllly 01 Ihe

mstaller lo comply with Ihe installallon clearances

specllled ,n these ~nslrucl~ons.

Check locatlon where downdrall venl and cooklop WIII

be inslalled. The local~on should be away from slrong

drall areas, such as windows or doors and strong

healing ven,s or lans.

Eleclrlcal ground is requred See Eleclr~cal

requiremenls

If cablnel hss a drawer, Ihe drawer WIII need lo be

removed and Ihe drawer lronls lnslalled permanently lo

lronl of cabfnel

Counlerlop openlna dlmenslons lhal are shown

Built-in cabinet dimensions:

y1” *sn, YI” -

36” base cablnel IS recommended lor Ihe

30’downdrafl “en,.

42” be% cablnel IS recommended lor Ihe

36- downdrafl “en,

Note: The downdraft “en, IS located dlrealy behmd

the cookiop lnslall downdraH “en, hrsl

Important: Observe all governing

1 ;;;,I; Ordinances’

ALL OPENINGS IN THE WALL OR FLOOR WHERE

Failure to meet codes and ordinances

THE DOWNDRAFT VENT IS TO BE INSTALLED

e

could lead to fire or electrical shock

1 \l

downdraft vend before using the

Island cabinet dimensions:

30’ CtiO”! Widlh ZT

NOTE:

It is the customer’s

responsibility to:

- contact a qualified, electrical

installer.

- assure that electrical

installation is adequate and in

conformance with National

Electrical Code, ANSVNFPA

70-1987” and local ordinances.

8 7,v

----------I

FOR YOUR SAFETY:

Special care must be taken when

drilling holes into the wall.

Electrical wires may be

concealed behind wall covering.

Use dimensions lor vent duct locatlon

lhal apply lo your Inslallatlon. Diameler

of cut-out will be delermlned by Inslallallon.

J

I

I

Tools and materials

Downdraft vent dimensions:

Mobile Home Installation

The mslaHa11on of IhIs downdraH vanI mus! conlorm lo

Ihe Manufactured Home Conslrucl~on and Salely

Slandarda. TII!B 24 CFR. Parl 3280 (formerly the

Federal Standard for MoblIe Home Conslruct~on a-d

Salely T~!le 24. HUD, parI 280) Four-wre power

supply musl be Jsed and Ihe appliance Waring mu51 Se

,evlsed See E~eclr~cal reqwemenls

Capes 01 ,hs standards l,sled may be ablalned :‘o-,

** National Fire Proleclion Associalion

II,

See cooktop Installation

lnstructlons for

I

cooktop dimensions,

PANEI- A

I

Ballery March Park

O”,ncy. hlassachusells 02169

Electrical

requirements

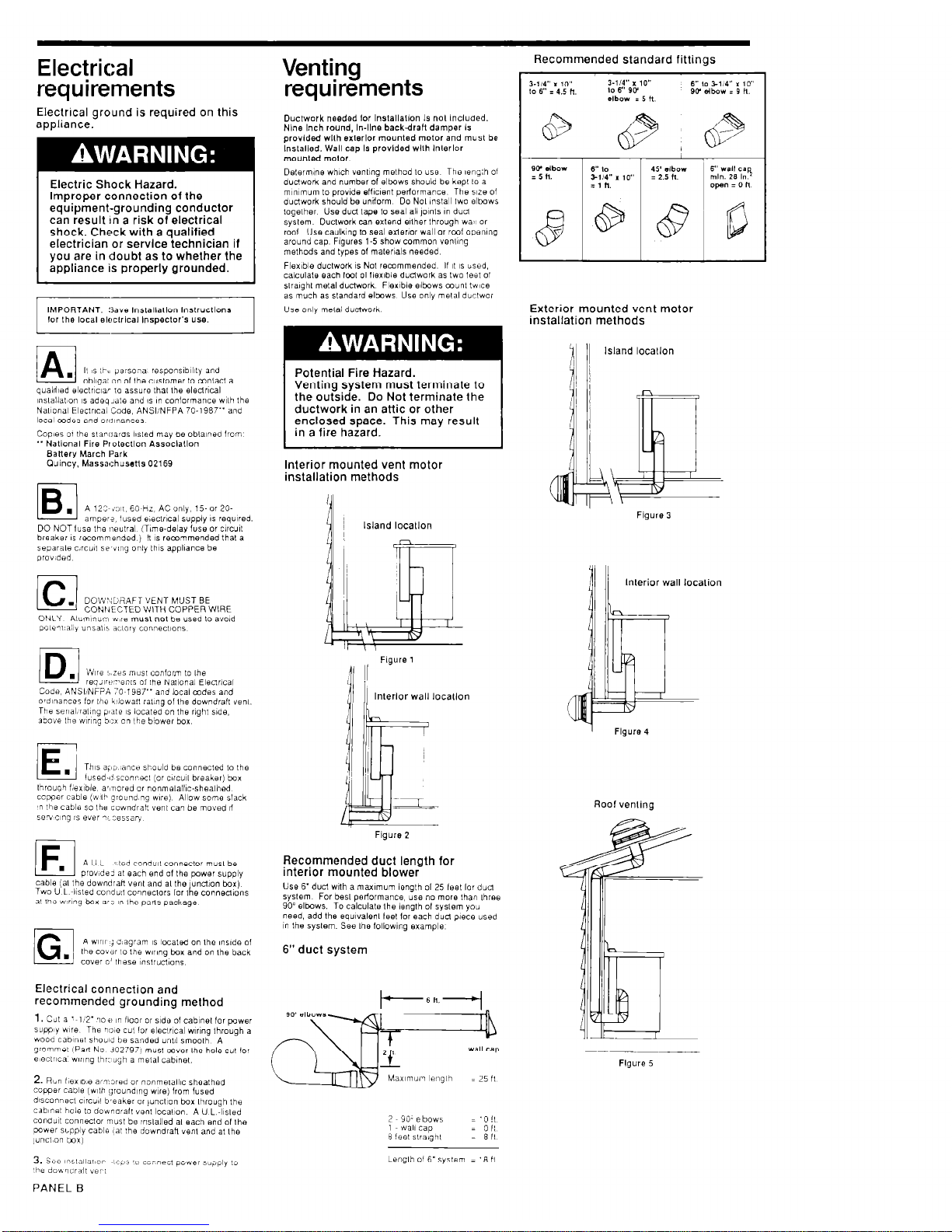

Venting

requirements

Electrical ground is required on this

appliance.

Recommended standard fittings

Ouchvork needed lor lnslallallon Is nol Included.

Nine Inch round, In-line backdraft damper Is

provided wllh exlerlor mounted motor and must be

Inslalled. Wall cap Is provided wllh lnlerlor

mounled motor.

Delermine which venl~ng melhod lo usa Thu leng:h 01

duclwork and number of elbows should be kept 10 a

mmmum lo provide efllcent perlormance The we of

duclwork should be undorm Do Nol inslall Iwo elbows

loqelher Use dud lake lo seal all ,o1n1s or. duel

Electric Shock Hazard.

Improper connection of the

equipment-grounding conductor

can result In a risk of electrical

shock. Check with a qualified

electrician or service technician if

you are in doubt as to whether the

appliance is properly grounded.

sykm Ductwork can extend elth& through wa’~ or

rod Use caulking to seal exierior wall or rcrot open\ng

around cap FIguris l-5 show common wwng

melhods and types of

malerials

needed

Flexible ductwork 1s Not recommended If I( 1s used,

calculale each fool 01 llexlble dudwork as Lwo feet of

slralghl metal ductwork. Flerlble elbows c~unl twce

as much as slandard elbows Use only melal dbclwor

Use onlv melal ductwork

IMPORTANT: !;a,. lnstallallon lnsirucllons

Exterior mounted vent motor

installation methods

11 II

Island locallon

Potential Fire Hazard.

Venting system must terminate to

the outside. Do Not terminate the

ductwork in an attic or other

enclosed space. This may result

in a fire hazard.

Interior mounted vent motor

installation methods

Island locallon

Figure 3

~nslallat~on IS adoq~ate and 1s in conformance wllh the

Nal~onal Eleclrlca, ‘Code. ANSIINFPA 70-1987” and

local mdes and or~!,nances

BaHery March Park

Cluincy, Massachussns 02169

IB

.

A 123 in,, 60 Hz, AC only, 15. or 20.

amper?. iused evxlr1c.3 supply 1s required.

DO NOT IUSB the ~leutral (Time-delay fuse or c1rcu0

breaker 1s recommended, II IS recommended thal a

separale c,rcui, se’v,ng oniy ,h,s appliance be

prov,ded

/c1

. DOW:;bHAFT VENT MUST BE

CONNECTED WITH COPPER WIRE

Code, ANSI/NFPA 70 ,987” and local codes and

o’dlwrces for Ihe k’lowa!, ral,ng 01 Ihe downdrall ye,,,.

The ser~al~ral~no o,aIe 1s located on Ihe riaht side.

lnlerior wall location

1

Flgure 4

1E

.

This +i, lance should be connecled lo the

lused-i! sconrecl (or circu,, breaker] box

Ibroug’l f;ex~ble, ar,nored or nonmelalllc-shealhed.

ccpper cable (wlb grouna ng we) Allow some slack

T Ihs cable so Ihe cowndrah vent can be moved II

sevclng is e”el nL:essar,

Roof venling

Figure 2

1F

A U L . ited cond”,, conneclor mus, be

prov,de> al each end 01 Ihs power supply

cable (al the downdran “en, and a, Ihe unct,on box)

Two U L ~+sled condu:! co,,,,eclors lor 1 e connenions

b

a’ I’le w~r,ng box ari in Ihe parls package

Recommended duct length for

interior mounted blower

Use 6’duct with a maximum lenglh 01 25 feet lo, dud

syslem For besl perlormance, use no more lhan three

90’ elbows. To calculale Ihe length 01 syslem you

need, add the eqwalenl Ieel for each duel piece used

in Ihe syslem. See Ihe lollowlng example

6” duct system

/G

A WIIII j d,agram ,s located on Ihe ,ns,de of

.

Ihe co”dr lo Ihe w,r,ng box and on Ihe back

cover o’ these ~mslrucl~ons

Electrical connection and

recommended grounding method

2. Rbn I~BXID,~ armored or nonme,allIc sheathed

copper cable (wllh grounding we) from fused

dlsconnecl c,rcu~l b,eaker or ,uncl,on box lhrauqh Ihe

cabInsI hole lo dounarall “en, local~on

A U L &led

cond”,t conr,eclor musl be ;nslalled a, each end of Ihe

cower supply cable ,a, :he downdraH venl and a, Ihe

,unc,.on tmxj

Figure 5

2 90. elbows

1 wali cap

8 !eel slra,gh,

Length o’ 6’syslem = ‘8 ,I

PANEL

B

Loading...

Loading...