KitchenAid KGRT607HWH8, KGRT607HWH9, KGRT607HBT8, KGRT607HBT9, KGRT607HBS9 Installation Guide

...Page 1

®

HOME APPLIANCES 9758571

11 " I "

I C111) e

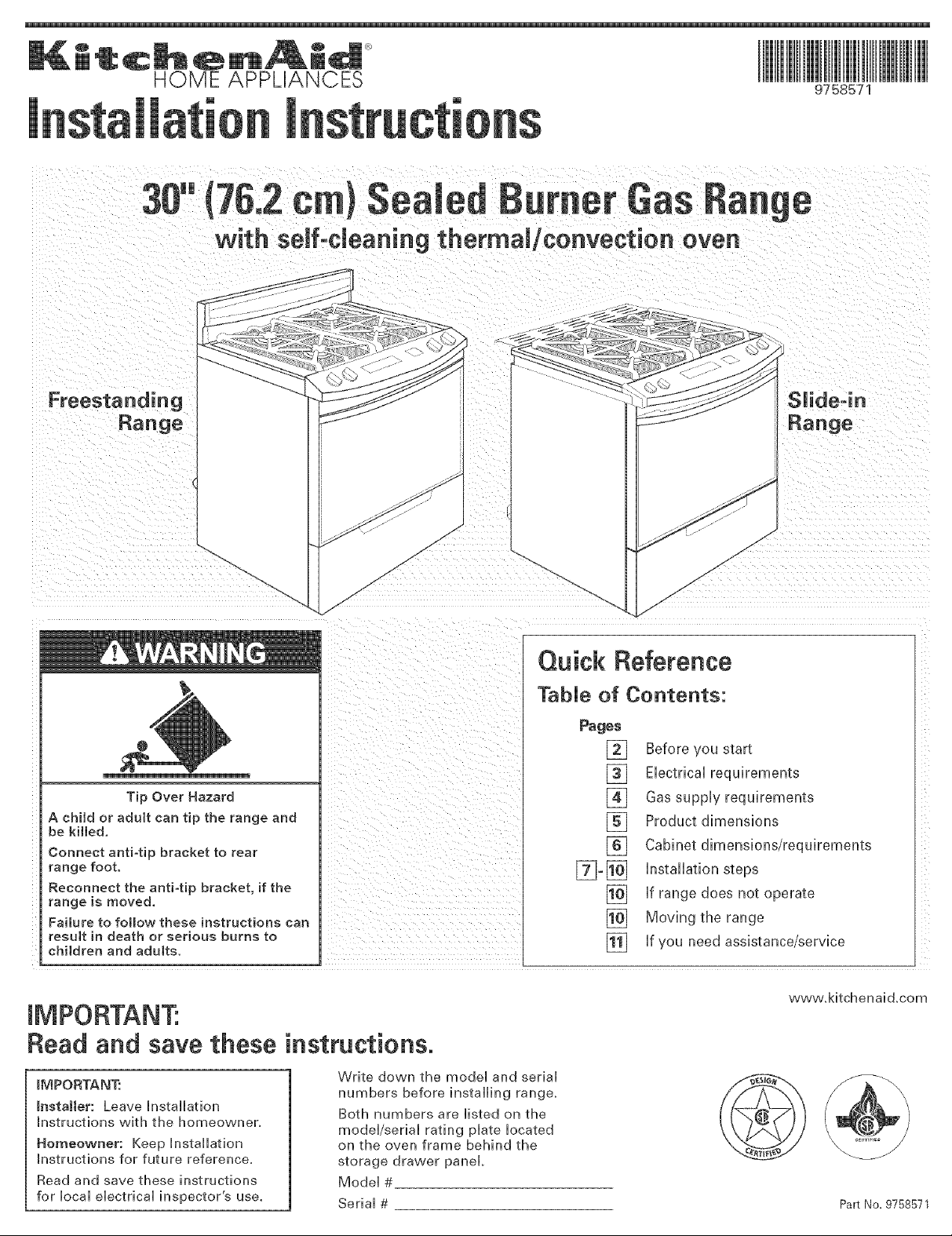

with setf-cJeaning thermal/convection oven

Freestanding Slide=in

Range Range

Quick Reference

TabJe of Contents:

Tip Over Hazard

A child or adult can tip the range and

be killed,

Connect anti=tip bracket to rear

range foot.

Reconnect the anti=tip bracket, if the

range is moved,

Faimure to follow these instructions can

result in death or serious burns to

children and adults. []

Read and save these instructions.

_MPORTANT:

_nstaHer: Leave Installation

Instructions with the homeowner.

Homeowner: Keep Installation

Instructions for future reference,

Read and save these instructions

for local electrical inspector's use.

Write down the model and serial

numbers before installing range,

Both numbers are listed on the

model/serial rating plate located

on the oven frame behind the

storage drawer panel

Model #

Serial # Part No. 9758571

Pages

%-[]

Before ¢ou start

[]

Electrical requirements

[]

[]

Gas supply requirements

Product dimensions

[]

Cabinet dimensions requirements

[]

installation steps

if range does not operate

[]

Moving the range

[]

if you need assistance tservice

www.kitchenaid.com

Page 2

Before you start...

Your safety and the safety of

others are very important.

We have provided many important safety

messages in this manual and on your

appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to

potential hazards that can kill

or hurt you and others.

All safety messages will follow the safety

alert symbol and either the word

'DANGER" or 'WARNING." These

words mean:

You can be killed or seriously injured

if you don't immediately follow

instructions.

You can be kitled or seriously injured

if you don't follow instructions.

All safety messages will tell you what the

potential hazard is, tell you how to

reduce the chance of injury, and tell you

what can happen if the instructions are

not followed.

WARNING: ff the

information in this manua_

is not fommowed exactRy,

a fire or expmosion may

result causing property

damage, persona_ injury

or death.

m Do not store or use

gasoline or other

flammable vapors and

liquids in the vicinity of

this or any other

appliance.

m WHAT TO DO _FYOU

SMELL GAS

o Do not try to right any

appliance.

o Do not touch any

electrical switch.

o Do not use any phone in

your building.

o _mmediatemy caromyour

gas supplier from a

neighbor's phone.

Fo[mow the gas

supp_ier's instructions.

off you cannot reach your

gas supplier, call the fire

department.

_nstam_ation and service

must be performed by a

quamified installer, service

agency or the gas supplier.

IMPORTANT: Observe all governing

codes and ordinances.

Do not obstruct flow of combustion and

ventilation air.

This installation must conform with

all local codes and ordinances. In the

absence of local codes, installation

must conform with American National

Standard, National Fuel Gas Code ANSI

Z223.1 --latest edition x- installation

codes.

It is the customer's responsibility:

• To contact a qualified electrical installer.

• To assure that the electrical installation

is adequate and in conformance with

National Electrical Code, ANSI/NFPA 70

-- latest edition ×-_, and all local codes

and ordinances.

Proper installation is your responsibility.

A qualified technician must install this

range. Make sure you have everything

necessary for correct installation. [t is the

installer's responsibility to comply with

installation clearances specified on the

gas information labekThe gas

information label and model/serial rating

plate are located on the frame behind the

storage drawer.

Check location where range will be

installed.The range should be located for

convenient use in kitchen. Recessed

installations must provide complete

enclosure of the sides and rear of range.

All openings in the wall or floor where

range is to be installed must be sealed.

To eliminate the risk of burns or fire by

reaching over heated surface units,

cabinet storage space located above the

surface units should be avoided. If

cabinet storage is to be provided, the risk

can be reduced by installing a range

hood that proiects horizontally a

minimum of 5 inches beyond the bottom

of the cabinets.

Cabinet opening dimensions that are

shown must be used. Given dimensions

are minimum clearances.

Mobile home installation

The installation of this range must

conform to the Manufactured Home

Construction and Safety Standards, Title

24 CFR, Part 3280 (formerly the Federal

Standard for Mobile Home construction

and Safety, Title 24, HUD, Part 280); or

when such standard is not applicable, the

Standard for Manufactured Homes

Installations (Manufactured Home Sites,

Communities and Setups), ANSI

A225.1/NFPA 501A __, or with local codes.

In Canada, the installation of this range

must conform with the current standards

CAN/CSA-Z240 -- latest edition _, or with

local codes.

When this range is installed in a mobile

home, it must be secured to the floor

during transit. Any method of securing

the range is adequate as long as it

conforms to the standards listed above.

Copies of the standards listed may be obtained

from:

'_CSA International

850! Fast Pleasant Valle',/Rd.

Cleveland, Ohio 44131-5578

_ National Fire Protection Association

One Batterymarch Park

Quincy', Massachusetts, 02269

Page 3

Parts supplied:

Not shown:

• literature pack

• orifice spuds

anti-tip bracket

2 plastic

2 screws

(#10 x 1-I/2")

Bracket must be securely mounted to sub-floor.

Thickness of flooring may require longer screws to

anchor bracket to sub-floor. Longer screws are

available from your local hardware store.

• burner grates and caps

vent cap

• LP conversion orifice spud kit:

1- 0.95 mm cooktop (blue)

2- 0,67 mm cooktop (black)

1- 1.05 mm cooktop (green)

1- #65 broil burner

anchors

Tools needed:

Assemble the required tools and parts

before starting installation. Read and

follow the instructions provided with any

tools listed here.

level

flat-blade screwdriver

Phillips screwdriver

putty knife

pipe wrench

3/8" drive ratchet

3/8" and 5/16" combination wrenches

hand or electric drill

channel lock pliers

measuring tape or ruler

wood floors: 1/8" drill bit

concrete/ceramic floors:

3/16" carbide4ipped masonry drill bit

(Hammer may be needed for anchors.)

Materials needed:

° gas line shutoff valve

• 1/2" male pipe thread nipple for connection

to pressure regulator

• LR gas-resistant pipe-joint compound

• AGA or CSA design-certified flexible metal

appliance connector (4-5 feet) (1.2-1.5 m} or

rigid gas supply line as needed

• Insulated pad or !/4" (6 mm) plywood if

range is installed over carpeting

Electrical requirements

Emectrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

If codes permit and a separate ground

wire is used, it is recommended that a

qualified electrician determine that the

ground path is adequate and that the

outlet is correctly polarized.

Do not ground to a gas pipe.

Check with a qualified electrician if you

are not sure range is properly grounded.

A 120-volt, 60-Hz, AC-only, lO-ampere,

fused electrical supply is required. A

time-delay fuse or circuit breaker is

recommended. It is recommended that a

separate circuit serving only this

appliance be provided.

Electronic ignition systems operate

within wide voltage limits, but proper

grounding and polarity are necessary.

In addition to checking that the outlet is

correctly grounded, the outlet must be

checked by a qualified electrician to see if

it is wired with correct polarity.

IMPORTANT:This range is equipped with

an electronic ignition system that will not

operate if plugged into an outlet that is

not properly polarized.

A wiring diagram is included on the back

of the range.

See "Cabinet dimensions/requirements"

for recommended location of electrical

outlet.

Recommended ground

For personal safety, this range is

equipped with a power supply cord

having a 3 prong ground plug.To

minimize possible shock hazard, the cord

must be plugged into a mating 3 prong,

ground-type outlet, grounded in

accordance with the National Electrical

Code, ANSI/NFPA 70 -- latest edition _, or

CSA Standard C22.1 Canadian Electrical

Code, Part 1 -- latest edition x×-, and aii

local codes and ordinances.

If a mating outlet is not available, it is the

personal responsibility and obligation of

the customer to have a properly

polarized and grounded, 3 prong outlet

installed by a qualified electrician.

3 prong properly polarized

ground-type outlet

3 prong

ground plug

\

power supply

cord

Copies of the standards listed may be obtained

from:

National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts, 02269

_ CSA International

8501 East Pbasant Valley Rd.

Cleveland, Ohio 44131-5575

Page 4

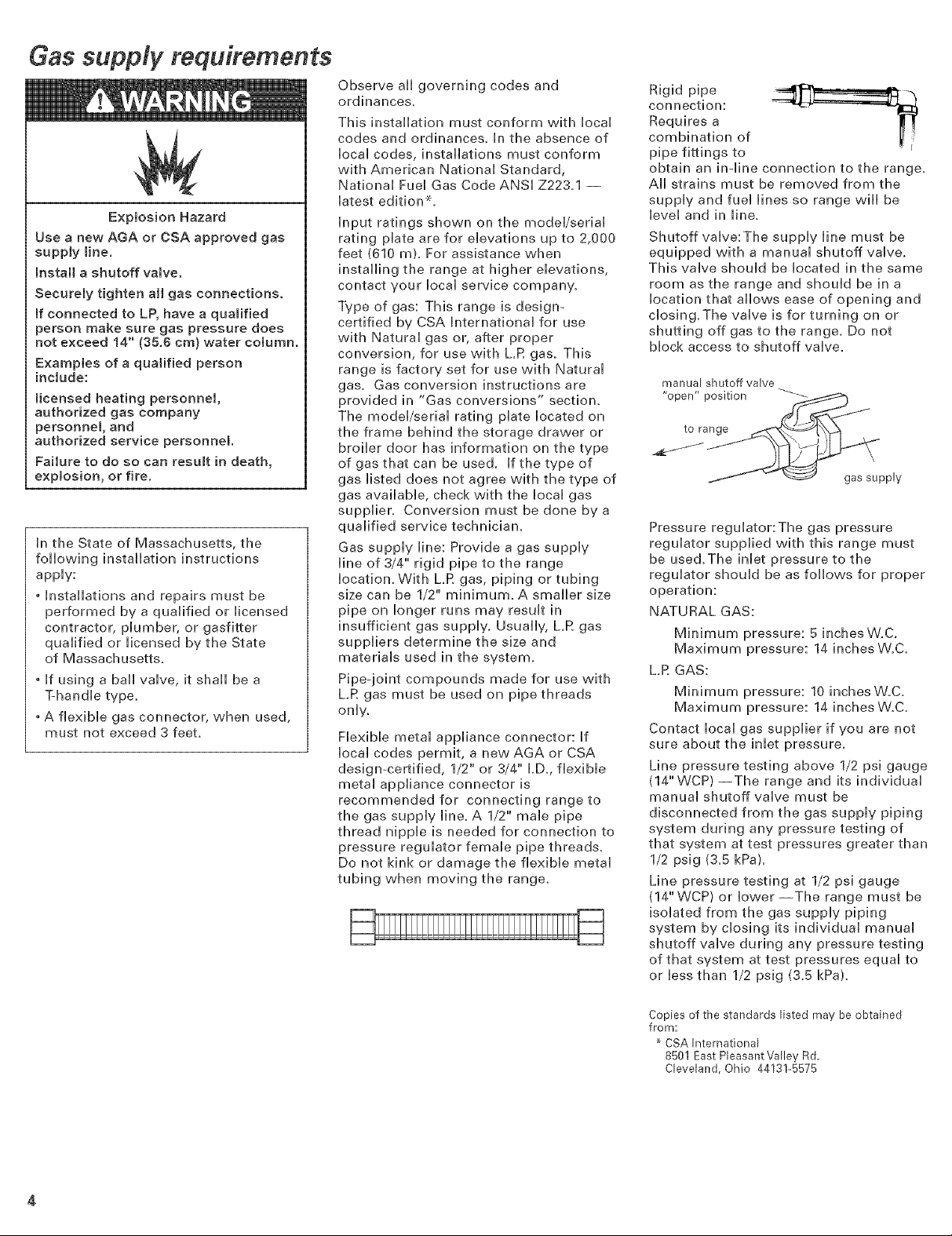

Gas supply requirements

Explosion Hazard

Use a new AGA or CSA approved gas

supply mine.

mnstall a shutoff vaJve.

Securely tighten all gas connections.

ff connected to LP, have a qualified

person make sure gas pressure does

not exceed 14" (35.6 cm) water column.

Examples of a qualified person

include:

licensed heating personnel,

authorized gas company

personne[_ and

authorized service personnel.

Failure to do so can resumt in death,

explosion, or fire.

In the State of Massachusetts, the

following installation instructions

appiy:

installationsand repairs must be

performed by a qualified or licensed

contractor, plumber, or gasfitter

qualified or licensed by the State

of Massachusetts.

• If using a ball valve, it shall be a

T-handle type,

• A flexible gas connector, when used,

must not exceed 3 feet,

Observe aii governing codes and

ordinances.

This installation must conform with local

codes and ordinances, in the absence of

local codes, installations must conform

with American National Standard,

National Fuel Gas Code ANSi Z223.1 --

latest edition _.

input ratings shown on the model/serial

rating plate are for elevations up to 2,000

feet (610 m). For assistance when

installing the range at higher elevations,

contact your local service compan%

Type of gas: This range is design-

certified by CSA International for use

with Natural gas or, after proper

conversion, for use with LR gas. This

range is factory set for use with Natural

gas. Gas conversion instructions are

provided in "Gas conversions" section.

The model/serial rating plate located on

the frame behind the storage drawer or

broiler door has information on the type

of gas that can be used, If the type of

gas listed does not agree with the type of

gas available, check with the local gas

supplier. Conversion must be done bya

qualified service technician.

Gas supply line: Provide a gas supply

line of 3/4" rigid pipe to the range

location. With LR gas, piping or tubing

size can be 1/2" minimum. A smaller size

pipe on longer runs may result in

insufficient gas supply. Usually, LR gas

suppliers determine the size and

materials used in the system.

Pipe-joint compounds made for use with

LR gas must be used on pipe threads

onl%

Flexible metal appliance connector: If

local codes permit, a new AGA or CSA

design-certified, 1/2" or 3/4" I.D., flexible

metal appliance connector is

recommended for connecting range to

the gas supply line. A 1/2" male pipe

thread nipple is needed for connection to

pressure regulator female pipe threads_

Do not kink or damage the flexible metal

tubing when moving the range.

connection:

Requires a

Rigidpipe

combination of

pipe fittings to

obtain an in-line connection to the range.

All strains must be removed from the

supply and fuel lines so range will be

level and in line.

Shutoff valve:The supply line must be

equipped with a manual shutoff valve.

This valve should be located in the same

room as the range and should be in a

location that allows ease of opening and

closing.The valve is for turning on or

shutting off gas to the range. Do not

block access to shutoff valve.

manual shutoff valve

"open" position "-_--

to range

gas supply

Pressure regulator:The gas pressure

regulator supplied with this range must

be used.The inlet pressure to the

regulator should be as follows for proper

operation:

NATURAL GAS:

Minimum pressure: 5 inchesW.C.

Maximum pressure: 14 inches W.C.

LR GAS:

Minimum pressure: 10 inches W.C.

Maximum pressure: 14 inches W.C.

Contact local gas supplier if you are not

sure about the inlet pressure.

Line pressure testing above 1/2 psi gauge

(14" WCP} --The range and its individual

manual shutoff valve must be

disconnected from the gas supply piping

system during any pressure testing of

that system at test pressures greater than

1/2 psig (3.5 kPa).

Line pressure testing at 1/2 psi gauge

(14" WCP} or lower--The range must be

isolated from the gas supply piping

system by closing its individual manual

shutoff valve during any pressure testing

of that system at test pressures equal to

or less than 1/2 psig (3.5 kPa).

Copies of the standards listed may be obtained

from:

CSA International

8501 East Pleasant Valley Rd.

Cbveland, Ohio 44131-5575

Page 5

Product dimensions

Grounded eHectricaH outlet is required. See "EHectricaH requirements['

Proper gas suppH¥ connection must be avaHaMe. See "Gas suppH¥ requirements."

30" (702 cm)jj//_P-

range width

Freestanding Range

8-1/4" (2! cm)

30-1/8"

(91.8 cm)

cooktop

height

44-3/8" (112.7 cm)

SUide4n Range

27-3/4" (70.5 cm)

depth with handle

_MPORTANT: Rear vent must

not be obstructed for proper

ventilation on aH sHideqn

modeHs. See step 6, page 7.

1-1/2" (3.8 cm)

36-1/8" (91.8 cm)

cooktop height

spacer

27-3/4" (70.5 cm)

depth with handle

30" (70.2 cm) width

Page 6

Cabinet dimensions/requirements

Cabk_et opening dimensions shown are for:

25"' (63.5 cm) countertop depth, 24" (61 cm) base

cabinet depth, 36"' (91.4 cm) countertop height

Freestanding or SUide-in Range

4" (10.2 cm) rain. clearance from

both sides of range to side wall

or other combustible material.

Gas line opening

should be located

within this shaded area

Floor gas line

opening if directly

below regulator

3'*17.6

13" (33 cm) max.

upper cabinet depth

e_1_. opening width

30" (76.2 cm)

...... opening width

m

30" (76.2 cm) cabinet

18"

(45.7 cm)

_.I_" For minimum

clearance to

cooktop, see

NOTE*,

(25.4 cm)

18" (45.7 cm)

upper side cabinet

to countertop

Outlet should be

located witNn the

18" x 10"

45.7 x 25.4 cm)

shaded area

IMPORTANT: Some cabinet and building

materials are not designed to withstand

the heat produced by the oven for baking

and self-cleaning. Check with your builder

or cabinet supplier to make sure that the

materials used will not discolor,

delaminate or sustain other damage.

• Do not pinch the power supply cord

between the range and the wall,

• Do not seal the range to the side cabinets.

• Contact a qualified floor covering installer to

check that the floor covering can withstand

at least 200°F (93°C).

• Use an insulated pad or 1/4" (6 mm)

plywood under range if installing range over

carpeting.

IMPORTANT: Rear vent must not be

obstructed for proper ventilation on all

slide-in models. See step 6, page 7.

Anti-tip bracket

The floor-mounted anti-tip bracket

must be installed.To install the

anti-tip bracket supplied, see page 3

and the anti-tip bracket template/

instruction sheet.

NOTE: 24" (61 cm) m[n. when bottom of wood or

metal cabinet is protected by not less than

1/4" (6.4 ram) flame retardant millboard covered

with not less than No. 28 MSG sheet steel, 0.015"

(0.4 ram) stainless steel, 0.024" (0.6 ram)

aluminum or 0.020" (0.5 ram) copper.

30" (76.2 cm) min. clearance between the top of

the cooking platform and the bottom of an

unprotected wood or metal cabinet.

Page 7

Slide@ ranges:

countertop

preparations

The cooktop sides of the slideqn range fit

over the cutout edge of your countertop.

[f you have a square finish (flatt

countertop and the opening width is 30""

(76.2 cm), no countertop preparation is

required.

Formed front-edged countertops:

Must have molded edge shaved fiat

1/2"" (1.3 cm) from each front corner

of opening.

cm)

30-7/8" (78.4 cm)

J

,_ Formed or tiled

countertop trimmed

1/2" (1.3 cm) back at

front corners of

countertop opening.

22-5/8"

(57,5 cm>

Cooktop sides of "f I_

range fit over edges of [

countertop opening. [

New start...

Excessive Weight Hazard

Use two or more people to move and

instal[ range.

Failure to do so can result in back or

other injury.

1[] Remove shipping materials, tape

and protective film from range. Keep

cardboard bottom and shipping base

under range. Remove oven racks and

parts package from inside oven.

NOTE: [f you are installing a slide-in

range, remove back vent package from

range top. See step 6 for vent installation.

m Take four

ca rd boa rd ---__

corners from the

carton. Stack one

cardboard corner

on top of another. Repeat with other two

corners. Place them lengthwise on the

floor behind the range--to support the

range when it is laid on its back, Firmly

grasp the range and gently lay it on its

back on the cardboard corners.

z Puii cardboard shipping base

firmly to remove.

M Use an adjustable wrench to

loosen the leveling legs 1-1/2 turns.

7_ Check that the type of gas supply is

correct for this range. (See model/serial

rating plate.) If connecting to LR gas,

follow directions in Conversion Kit

included in your literature package.

If connecting to Natural gas, continue

with anti4ip bracket installation.

Anti-tip bracket installation

Tip Over Hazard

A child or adult can tip the range and

be killed.

Connect anti-tip bracket to rear

range foot.

Reconnect the anti-tip bracket, if the

range is moved.

Failure to follow these instructions can

result in death or serious burns to

chi[dren and adults.

Contact a qualified floor covering

installer for the best procedure for

drilling mounting holes through your

type floor covering.

Tile countertops may need trim cut back

1/2"" (1.3 cm) from each front corner

and/or rounded edge flattened.

[f countertop opening width is greater

than 30"" (76.2 cm), adjust the 1/2""

(1.3 cm) dimension.

Countertop must be level. Place level on

countertop, first side to side; then front

to back. if countertop is not level, range

will not be level. Oven must be level for

satisfactory baking conditions.

M Piace cardboard or hardboard in

front of range. Stand range back up onto

cardboard or hardboar&

Rear vent installation (slideqn

ranges only): Remove the outside screws

from rear trim on range. Use screws to

attach rear vent to range.

Rear vent must

be installed,

be necessary to anchor the bracket to the

sub-floor. Longer screws are available

from your local hardware store.

Page 8

Operating position

E Move range chose to cabinet

opening.

[] Remove cardboard or

hardboard from under range, Carefully

move range into final position.

[] Pull drawer open to first stop

position. Lift front of drawer to clear

white wheels in drawer guides, Remove

drawer and set it aside on a protected

surface.

[] Make sure the antFtip bracket

is installed:

Look for the anti-tip bracket securely

attached to fioor.

Slide range back so rear range foot

is under anti-tip bracket,

anti-tip

bracket

range foot

[] if installing the range in a

mobile home, you must secure the range

to the floor. Any method of securing the

range is adequate as long as it conforms

to the standards in the "Mobile home

installation" instructions.

[] Place rack in oven. Place level

on rack, first side to side; then front to

back,

If range is not level, pull range forward

until rear leveling leg is removed from

the anti-tip bracket. Use 3/8" drive ratchet

and channel lock pliers to adjust leveling

legs up or down until range is level, Push

range back into position, Check that rear

leveling leg is engaged in antFtip

bracket.

NOTE: Oven must be level for

satisfactory baking conditions,

Gas and electrical connections

-a_ pressure regulator

)i j and valve assembly

"oj _ flexible manual

d"connector

f j connector shutoff valve

g0° elbow \\

1/Z' flare union adapters

[] Assemble the flexible

connector from the gas supply pipe to

the pressure regulator, located in the

lower left side of the storage drawer

area, in this order: shutoff valve, 1/2"

flare union adapter, flexible connector,

1/2" flare union adapter. Seal aii

openings in floor or wail wherever range

is installed.

1

appropriate for use with L,R gas to seal

all gas connections, If flexible connectors

are used, be certain connectors are not

kinked,

gas supply line, Wait a few minutes for

the gas to move through the gas line.

shall be conducted according to the

following instructions:

Test aii connections by brushing on an

approved non-corrosive leak-detection

solution. Bubbles will show a leak,

Correct any leak found.

[] Use pipe-joint compounds

[] Open the shutoff valve in the

[] Test for gas leaks. Leak testing

[] Plug into a grounded 3 prong

outlet. "8888" should appear in clock

display.

Remove vent cap, cooktop

burner caps and grates from parts

package. Align notches in burner caps

with pins in burner base. Burner caps

should be level when properly

positioned. Place burner grates over

burners and caps. Place vent cap over

vent dome.

_ser grate

vent cap

j_J vent dome

Page 9

Check operation

EJeetronie ignition system

Cooktop and oven burners use electronic

ignitors in place of standing pilots. When

a cooktop control knob is turned to the

"LITE" position, the system creates a

spark to light the burner.This sparking

continues until the control knob is turned

to the desired setting.

When the oven control is turned to the

desired setting, a glow bar heats up

bright orange and ignites the gas. No

sparking occurs and the glow bar

remains on while the burners operate.

Cheek operation of eooktop

burners

[] Push in and OFF

turn each control knob "

The flame should light

to the "LITE" position. _ t__,_

within 4 seconds.The

first time a burner is

lighted it maytake _ °*_. j

longer than 4seconds _° '',*'_o

to light because of air _b MeO

in gas line. Lo

[] If burners do not light

properly, turn cooktop control knob to

the "OFF" position. Check that the power

supply cord is plugged in and the circuit

breaker or fuse has not blown. Check that

the gas shutoff valves are set to the

"open" position, Repeat Step 21. ff a

burner does not light at this point,

contact your KitchenAid dealer or

authorized service company for

assistance.

[] Adjust the height of top burner

flames (some models}. Push in and turn

each cooktop control knob from "LJTE"

to "LO" setting quickly.

The cooktop "LO" burner

flame should be a steady blue

flame approximately 1/4"

(0.64 cm} high. It can be

adjusted using the

adjustment screw in the

center of the valve stem.The

valve stern is located directly

underneath the control knob.

if the "LO" flame needs to be adjusted:

a. Remove the control knob.

__J

adiustment screw _ ,__//

b. Hold the knob stem with a pair of

pliers. Use a small flat-blade

screwdriver to turn the screw

located in the center of the control

knob stem until the flame is the

proper size.

c. Replace the control knob.

d.Test the flame by turning the

control from "LO" to "Hi '/checking

the flame at each setting.

low flame

high flame

Top burner flame appearance

Cheek operation of oven

burner

Open oven door.

Remove the oven rack Remove the oven

bottom and place it on a protected

surface.

[] Push the "BAKE" pad and

"350°F '' will appear in the temperature

displa% Press the "START" pad. "LO" will

appear in the display; then "170°E" The

oven burner should light in 50 to 60

seconds.This delay is normaLThe oven

safety valve requires a certain time

before it will open and allow gas to flow.

Electric ignitors are used to light the

oven and broil burners.

Do not insert any object into the opening

of the protective shield that surrounds

the igniton

Do not dean the area_

@

oven rear

oven burner \ ignitor

Check the oven

burner for proper flame.This

flame should have a 1/2"

(1.3 cm) long inner cone of

bluish-green, with an outer

mantle of dark blue, and

should be clean and soft in

character, No yellow tips, blowing or

lifting of flame should occun

[] If the oven flame needsto be

adjusted, locate the air shutter near the

center rear of range. Loosen the locking

screw and rotate the air shutter until the

proper flame appears.Tighten locking

screw.

oven burner air shutter-

air shutter rotate to

location adiust for

locking "" brass orifice

screw hood (nut)

Push "CANCEL/OFF" pad.

Insert oven bottom tabs into slots in oven

burner area. Check that tabs are correctly

placed in slots. If the oven bottom is not

positioned properly, poor baking

performance could occur. Replace oven

racks.

ser flame

oven burner

Page 10

Check operation ef even broil

burner

R Close the oven door. Press the

"BROIL' pad. "500°F '' wiii appear in the

temperature display. Press the "START"

pad.The oven broil burner should light in

50 to 60 seconds, This delay is normal.

The oven safety valve requires a certain

time before it will open and allow gas to

flow.The first time broil burner is lighted,

it may take longer to light because of air

in gas line.The first few times burner is

used sparks may appear.This is normal.

NOTE: Oven door must be shut for broil

burner to operate.

Look through oven window to

check broil burner for proper flame.The

flame should have a uniform, light blue

appearance around the burner surface.

No yellow tips, blowing or lifting of the

flame shouH occur,

NOTE: The first few times the broil

burner is used, yellow sparks may

appear in the flame.This is normal and

will stop after burner has been used a

few times.

[] Press the "CANCEL/OFF" pad, If

the broil burner flame needs adjustment,

contact your KitchenAid dealer or

authorized service company for

assistance.

[] insert storage drawer into slide

rails on sides of drawer opening. Lift

front of drawer slightly and push firmly

to close drawer,

L.R gas conversion

No attempt shall be made to convert the

range from the gas specified on the

model/serial rating plate for use with a

different gas without consulting the

servicing gas supplier. An LR Gas

Conversion Kit is included in your

literature package.

YOu have just finished instaJiing

your new range.To get the

most efficient use from your

range, read your Use & Care

Guide. Keep JnstaJJation

instructions and Guide dose to

range for easy reference. The

instructions wiJJ make instaJJing

the range in another home as

easy as the first instatJation.

Ifrange does not

operate:

[_ Check that the circuit breaker is not

tripped or the house fuse Nown,

[_ Check that the power supply cord is

plugged into the outlet.

[_ Check that gas line is turned on,

[_ See Use and Care Guide for

troubleshooting list,

10

Moving the range

Tip Over Hazard

A child or adult can tip the range and

be killed.

Connect anti-tip bracket to rear

range foot.

Reconnect the anti-tip bracket, if the

range is moved.

Failure to follow these instructions can

result in death or serious burns to

children and adults.

When moving range, slide range onto

cardboard or hardboard to prevent

damaging the floor covering.

If removing the range is necessary for

cleaning or maintenance:

1. Remove the storage drawer.

2_ Shut off gas supply to the range.

3_ Disconnect gas,

4_ Unplug range or disconnect power.

5_ Slide range forward to complete

cleaning or maintenance.

6_ Make sure the anti-tip bracket is

installed:

• Look for the anti-tip bracket securely

attached to floor.

• Slide range back so rear range foot

is under anti-tip bracket.

anti-tip

J'J bracket

range foot

7. Check that range is level.

8_ Reconnect gas line to range and

check for leaks.

9. Plug in range or reconnect power.

10. Reinstall storage drawer.

Page 11

Requesting assistance or service

To avoid unnecessary service caiis, piease check the "Check Operation" section, it may

save you the cost of a service call. if you still need help, follow the instructions below.

Jf Vou need assistance

or service in U.S.A.

Caff the KitchenAid Customer

_nteraation Center toll-free at

1-800-235-0665.

Our consuitants are avaiiabie to assist

you. When caiiing, piease know the

purchase date, and the compiete

modei and seriai number of your

appliance.This information will help

us better respond to your request.

Our consuitants provide assistance

with:

• Features and specifications on

our full line of appiiances

• Instaiiation information

• Use and maintenance procedures

• Accessory and repair parts saies

• Specialized customer assistance

(Spanish speaking, hearing

impaired, iimited vision, etc.)

•Referrais to iocai deaiers, service

companies, and repair parts

distributors

KitchenAid designated service

technicians are trained to fuifiii the

product warranty and provide after-

warranty service, anywhere in the

United States.

To Hecate the designated KitchenAid

service company in your area, you can

aiso Hook in your telephone directory

Yellow Pages.

For further assistance

if you need further assistance, you can

write to KitchenAid with any questions

or concerns at:

KitchenAid Brand Home

Appiiances

Customer interaction Center

c/o Correspondence Dept.

2000 North M-63

Benton Harbor, MI 49022-2692

Piease inciude a daytime phone

number in your correspondence.

Jf Vou need assistance

or service in Canada

When asking for assistance or service,

piease provide a detaiied description of

the probiem, your appiiance's compiete

modei and seriai numbers, and the

purchase date.This information wiii

heip us respond properiy to your

request,

tf the probJem is not due to one of the

items Jisted in "Check Operation":

Contact the deaier from whom you

purchased your appiiance, or caii the

KitchenAid Canada Customer

interaction Center toii-free, 8:30 a.m. -

6:00 p.m. (EST) at 1-800-235-0665.

tf you need service:

Contact your nearest KitchenAid Canada

Appiiance Service branch or authorized

servicing outiet to service your

appiiance. (See list bellow.)

Make sure the service company you

contact is authorized to service your

appiiance during the warranty period.

For further assistance

if you need further assistance, you can

write to KitchenAid Canada with any

questions or concerns at:

Consumer Reiations Department

KitchenAid Canada

1901 Minnesota Court

Mississauga, Ontario L5N 3A7

Piease inciude a daytime phone number

in your correspondence.

KitchenAid Canada AppUiance Service - Consumer Services

Direct service branches:

BRITISH COLUMBIA 1-800-665-6788

ALBERTA 1-800-661-6291

ONTARIO Ottawa area 1-800-267-3456

(except 807 area code) Outside the Ottawa area 1-800-807-6777

MANITOBA, SASKATCHEWAN

and 807 area code in ONTARIO 1-800-665-1683

QUEBEC Montreal (except South Shore) 1-800-361-3032

South Shore Montreal 1-800-361-0950

Quebec City 1-800-463-1523

Sherbrooke 1-800-567-6966

ATLANTIC PROVINCES 1-800-565-1598

11

Page 12

Part No. 9758571

© 2004 KitchenAid

® RegisteredTrademar!< of IqtchenAid.

i :che

HOME APPLIANCES

Prepared by KitchenAid, Benton Harbor, Michigan 49022

Printed in U.S.A.

02/2004

Loading...

Loading...