KitchenAid KGRT607HBL5, YKGST307HW5, YKGST307HS5, YKGST307HB5, YKGRT607HW5 Installation Guide

...Page 1

HOME APPLIANCES

Tip Over Hazard

A child or adult can tip the range and be

killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range

is moved.

Failure to follow these instructions can

result in death or serious burns to children

and adults.

®

Part No. 9753562

I

a

these _n,

iMPORTANT :

Installer: Leave Installation Instructions

with the homeowner.

Homeowner: Keep Installation

instructions and anti-tip bracket

template for future reference.

Save Installation Instructions for local

electrical inspector's use.

O_So

30" (76.2 c

urner

Freestanding and

Slide-in Ranges

with self-cleaning thermal/convection oven

Page 2

Before you start...

Yoursafety and the safety of others is

veryimportant.

Wehaveprovided many important safetymessagesin

this manuaIand on your appliance,Always readand

obeyail safety messages,

This isthe safetyatert symboi. This symboi

alerts you to hazardsthat can kiii or hurt you

and others, Aii safety messageswiii be preceded bythe

safety alert symboI and the word "DANGER"or

"WARNING",Thesewords mean:

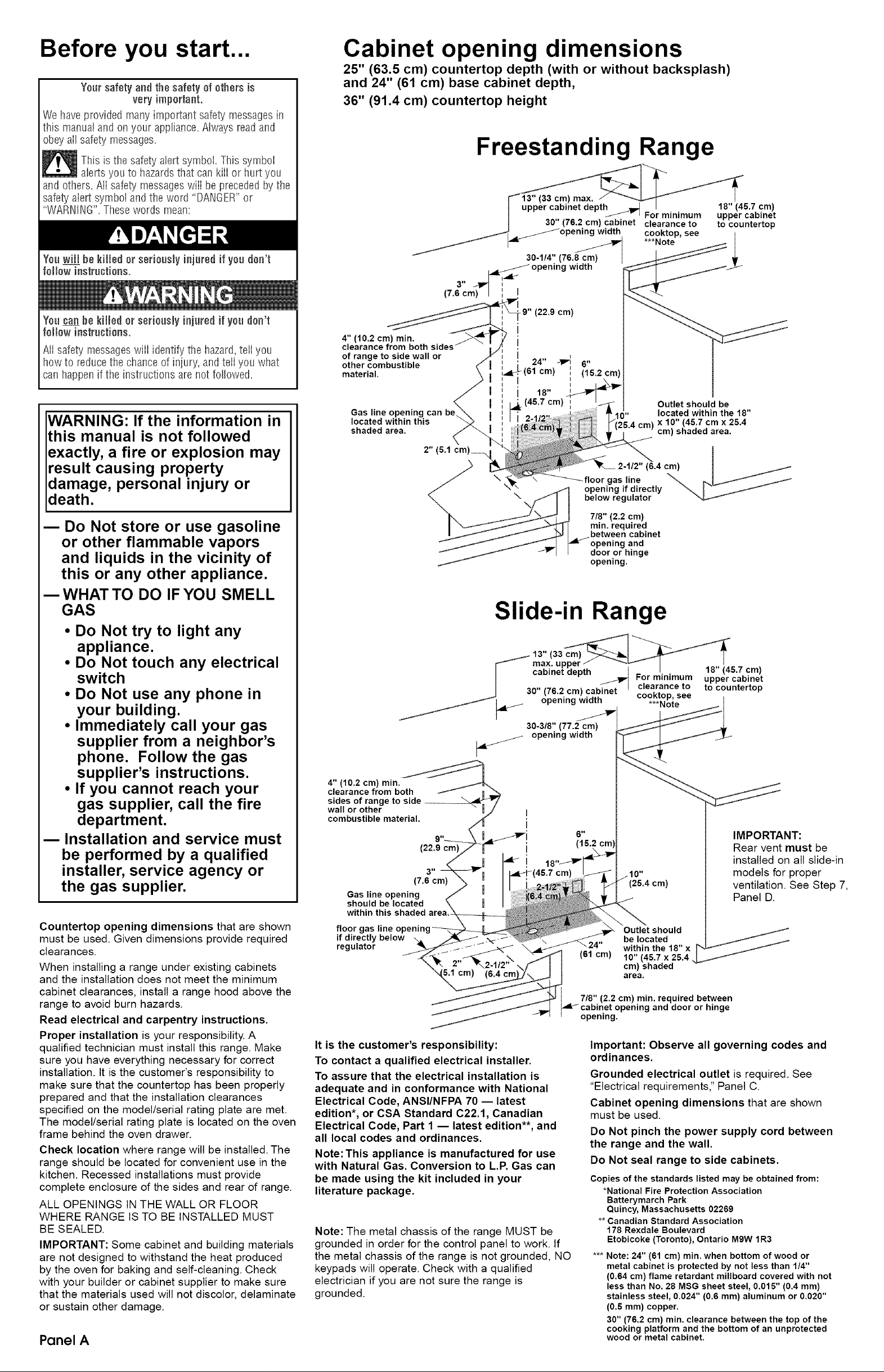

Cabinet opening dimensions

25" (63.5 cm) countertop depth (with or without backsplash)

and 24" (61 cm) base cabinet depth,

36" (91.4 cm) countertop height

Freestanding Range

_6.7 cm)

I 30"_et clearance to to _:ountertop

__g width cooktop, see I

***Note

30-1/4" (76.8 cm)

,_ opening width _ /_

I_ Jf

(7.6cm) I l ! _ 4..

cabinet

You ca_ be killed or seriously injuredif you don't

follow instructions.

AIIsafety messageswilI identify the hazard,teli you

how to reducethe chance of injury, and teti you what

can happenif the instructions arenot followed.

WARNING: If the information in

this manual is not followed

exactly, a fire or explosion may

result causing property

damage, personal injury or

death.

m Do Not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL

GAS

• Do Not try to light any

appliance.

• Do Not touch any electrical

switch

• Do Not use any phone in

your building.

• Immediately call your gas

supplier from a neighbor's

phone. Follow the gas

supplier's instructions.

• If you cannot reach your

gas supplier, call the fire

department.

Installation and service must

be performed by a qualified

installer, service agency or

the gas supplier.

Countertop opening dimensions that are shown

must be used. Given dimensions provide required

clearances.

When installing a range under existing cabinets

and the installation does not meet the minimum

cabinet clearances, install a range hood above the

range to avoid burn hazards.

Read electrical and carpentry instructions.

Proper installation is your responsibility. A

qualified technician must install this range. Make

sure you have everything necessary for correct

installation. It is the customer's responsibility to

make sure that the countertop has been properly

prepared and that the installation clearances

specified on the model/serial rating plate are met.

The model/serial rating plate is located on the oven

frame behind the oven drawer.

Check location where range will be installed. The

range should be located for convenient use in the

kitchen. Recessed installations must provide

complete enclosure of the sides and rear of range.

ALL OPENINGS IN THE WALL OR FLOOR

WHERE RANGE IS TO BE INSTALLED MUST

BE SEALED.

IMPORTANT: Some cabinet and building materials

are not designed to withstand the heat produced

by the oven for baking and self-cleaning. Check

with your builder or cabinet supplier to make sure

that the materials used will not discolor, delaminate

or sustain other damage.

Panel A

I _i-9" (22.9 cm) _

4" (10 2 cm) m n _ __

clearance from both sid _ ! t _

of range to side wall or 'l I ,

other combusbble _ I "61 cm" _ "

material. _ _ ,, (16.2cm)

Gas line located within the 18"

located within this cm_ x 10" (46.7 cm x 26.4

shaded area. " cm) shaded area.

• _ ' 24 _ 6

, I

' 18" '

2-1/2" (6.4 cm) ./

floor gas line _ __/

opening if directly _ I _ /

below regulator

7/6" (2.2 cm)

min, required

between cabinet

opening and

door or hinge

opening.

Slide-in Range

30-3/8" (77.2 cm)

opening width

4" (102cm) min// I

scj!i_oai!ifiim t_°sthde _

combustible material.

6 ,_

(22.9 cm)

3 ,I

(7,6 cm)

Gas line opening

should be located

within this shaded

floor c

if directly below

regulator

It is the customer's responsibility:

To contact a qualified electrical installer.

To assure that the electrical installation is

adequate and in conformance with National

Electrical Code, ANSI/NFPA 70 -- latest

edition*, or CSA Standard C22.1, Canadian

Electrical Code, Part 1 -- latest edition**, and

all local codes and ordinances.

Note: This appliance is manufactured for use

with Natural Gas. Conversion to L.P. Gas can

be made using the kit included in your

literature package.

Note: The metal chassis of the range MUST be

grounded in order for the control panel to work. If

the metal chassis of the range is not grounded, NO

keypads will operate. Check with a qualified

electrician if you are not sure the range is

grounded.

(16.

Outlet should

be located

(61 cm)

7/8" (2,2 cm) min. required between

opening.

within the 18" x

10" (46.7 x 26.4

cm) shaded

area.

opening and door or hinge

Important: Observe all governing codes and

ordinances.

Grounded electrical outlet is required. See

"Electrical requirements," Panel C.

Cabinet opening dimensions that are shown

must be used.

Do Not pinch the power supply cord between

the range and the wall.

Do Not seal range to side cabinets.

Copies of the standards listed may be obtained from:

*National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

** Canadian Standard Association

178 Rexdale Boulevard

Etobicoke (Toronto), Ontario M9W 1R3

*** Note: 24" (61 cm) min. when bottom of wood or

metal cabinet is protected by not less than 1/4"

(0.64 cm) flame retardant millboard covered with not

less than No. 28 MSG sheet steel, 0.016" (0.4 mm)

stainless steel, 0.024" (0.6 mm) aluminum or 0.020"

(0.5 mm) copper.

30" (76.2 cm) min. clearance between the top of the

cooking platform and the bottom of an unprotected

wood or metal cabinet.

Outlet should be

IMPORTANT:

Rear vent must be

installed on all slide-in

models for proper

ventilation. See Step 7,

Panel D.

Page 3

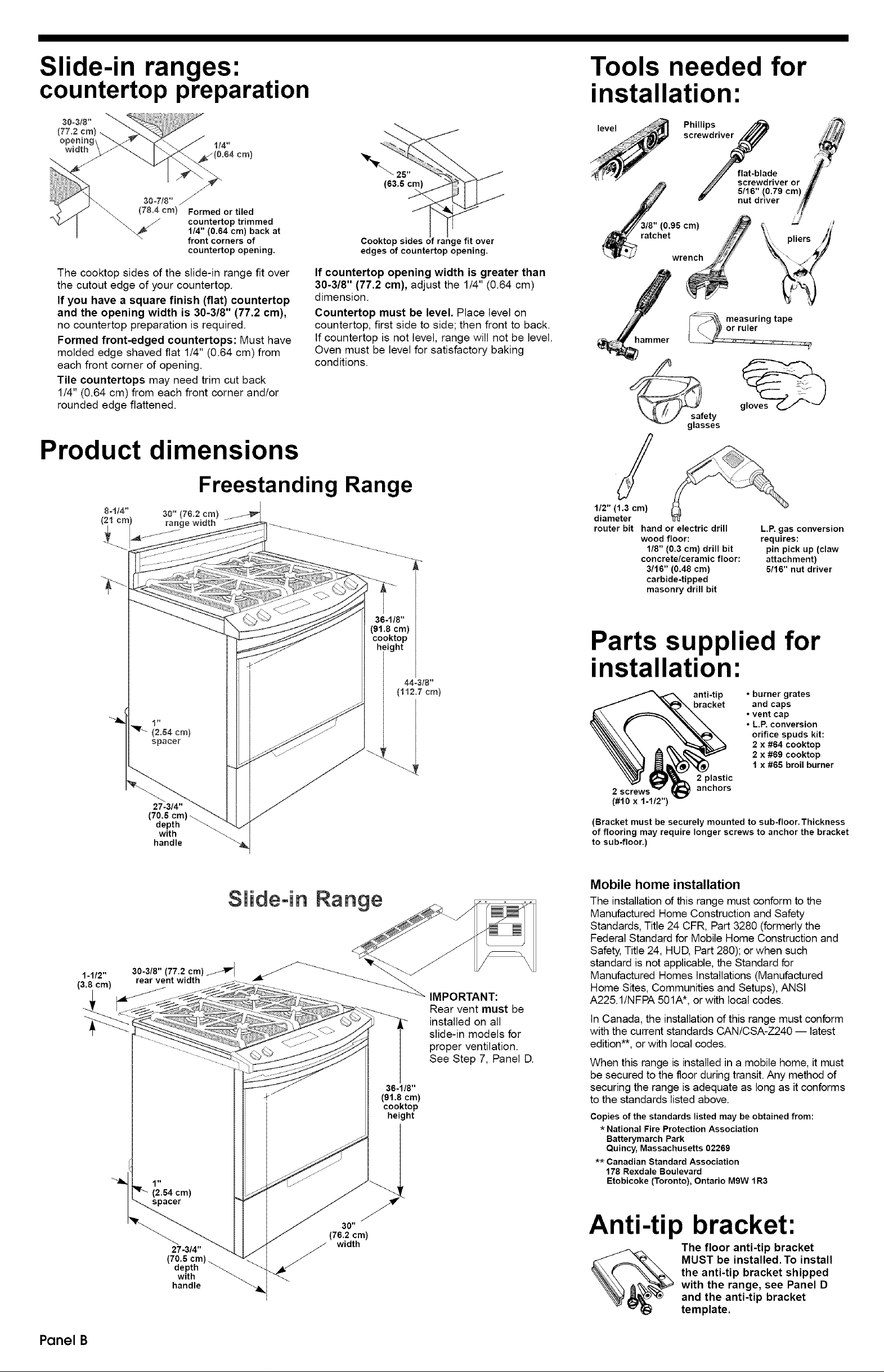

Slide-in ranges:

Tools needed for

countertop preparation

30=3/8"

(77.2 cm)

opening,

width

30-7/8"

(78.4 cm) Formed or tiled

/ countertop trimmed

_,_ 1/4" back at

The cooktop sides of the slide-in range fit over

the cutout edge of your countertop.

If you have a square finish (fiat) countertop

and the opening width is 30-3/8" (77.2 cm),

no countertop preparation is required.

Formed front-edged countertops: Must have

molded edge shaved fiat 1/4" (0.64 cm) from

each front corner of opening.

Tile countertops may need trim cut back

1/4" (0.64 cm) from each front corner and/or

rounded edge flattened.

114"

(0.64 cm)

front corners of

countertop opening.

Cooktop sides of range fit over

edges of countertop opening.

If countertop opening width is greater than

30-3/8" (77.2 cm), adjust the 1/4" (0.64 cm)

dimension.

Countertop must be level. Place level on

countertop, first side to side; then front to back.

If countertop is not level, range will not be level.

Oven must be level for satisfactory baking

conditions.

installation:

Phillips

screwdri_

f/ flat-blade

f/ screwdriver or

_" nut driver

ratchet wrJ _\__pliers //

_-_ measuring tape

hammer ____

_safety

glasses

5/16" (0,79 cm)

Product dimensions

Freestanding Range

8=1/4"

(21 cm

30" (78.2 cm)

range width

27-3/4"

(70,8 cm) -_

depth

with

handle

36-1/8"

(91,8 cm)

cooktop

height

44-318"

(112.7 era)

-4

/

1/2" (1.3 cm)

diameter

router bit hand or electric drill

wood floor:

1/8" (0,3 cm) drill bit

concrete/ceramic floor:

3/16" (0.48 cm)

carbide-tipped

masonry drill bit

Parts supplied for

installation:

anti-tip

bracket

2 plastic

2

(#10 x 1-1/2")

(Bracket must be securely mounted to sub-floor. Thickness

of flooring may require longer screws to anchor the bracket

to sub-floor.)

anchors

L,P, gas conversion

requires:

pin pick up (claw

attachment)

8/16" nut driver

• burner grates

and caps

• vent cap

• L,P, conversion

orifice spuds kit:

2 x #64 cooktop

2 x #69 cooktop

1 x #68 broil burner

1-1/2"

(3.8 cm)

30-3/8" (77,2 cm) _4v I

rear vent width

1 ,I

(2.54 cm)

spacer

Slide-in Range

36-1/8"

(91.8cm)

cooktop

height

IMPORTANT:

Rear vent must be

installed on all

slide-in models for

proper ventilation.

See Step 7, Panel D.

Mobile home installation

The installation of this range must conform to the

Manufactured Home Construction and Safety

Standards, Title 24 CFR, Part 3280 (formerly the

Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD, Part 280); or when such

standard is not applicable, the Standard for

Manufactured Homes Installations (Manufactured

Home Sites, Communities and Setups), ANSI

A225.1/NFPA 501A*, or with local codes.

In Canada, the installation of this range must conform

with the current standards CAN/CSA-Z240 -- latest

edition**, or with local codes.

When this range is installed in a mobile home, it must

be secured to the floor during transit. Any method of

securing the range is adequate as long as it conforms

to the standards listed above.

Copies of the standards listed may be obtained from:

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

** Canadian Standard Association

178 Rexdale Boulevard

Etobicoke (Toronto), Ontario M9W 1R3

Panel B

27-3/4"

(70.5 cm) ._

depth

with

handle

30"

(76.2 cm)

width

Anti-tip bracket:

The floor anti-tip bracket

MUST be installed. To install

the anti-tip bracket shipped

with the range, see Panel D

and the anti-tip bracket

template.

Page 4

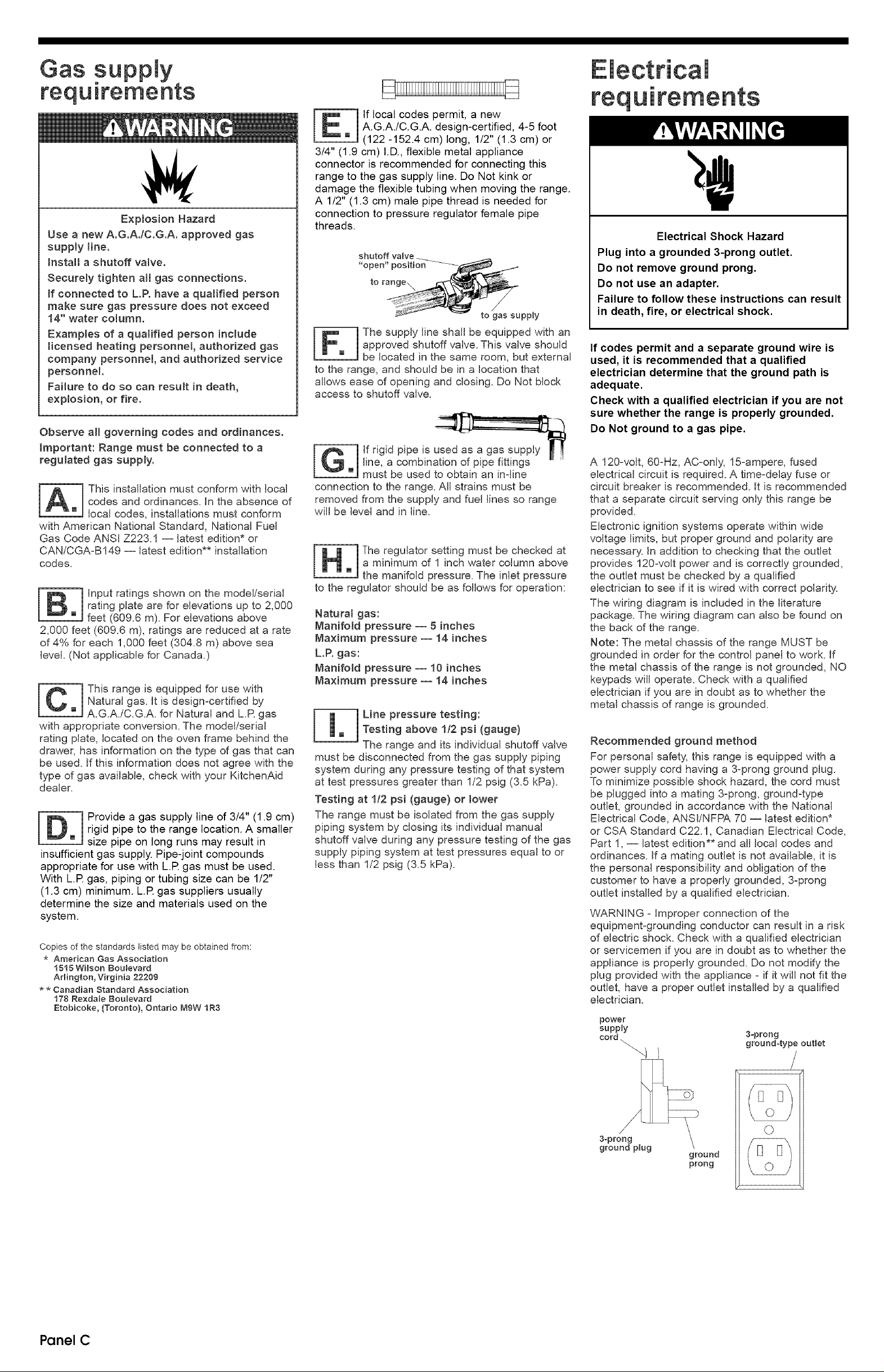

Gas supply

requirements

Explosion Hazard

Use a new A.G.A./C.G.A. approved gas

supply line.

install a shutoff valve.

Securemy tighten all gas connections.

if connected to L.P. have a qualified person

make sure gas pressure does not exceed

14'° water column.

Examples of a qualified person include

licensed heating personnel, authorized gas

company personnel, and authorized service

personnel.

Failure to do so can result in death,

explosion, or fire.

Observe all governing codes and ordinances.

important: Range must be connected to a

regulated gas supply.

This installation must conform with local

codes and ordinances. In the absence of

local codes, installations must conform

with American National Standard, National Fuel

Gas Code ANSI Z223.1 --latest edition* or

CAN/CGA=B149 --latest edition** installation

codes.

Input ratings shown on the modeVseriaJ

rating plate are for elevations up to 2,000

feet (609.6 m). For elevations above

2,000 feet (609.6 m), ratings are reduced at a rate

of 4% for each 1,000 feet (304.8 m) above sea

level. (Not applicable for Canada.)

This range is equipped for use with

Natural gas. It isdesign=certified by

A.G.A./C.G.A. for Natural and LR gas

with appropriate conversion. The model/serial

rating plate, located on the oven frame behind the

drawer, has information on the type of gas that can

be used. If this information does not agree with the

type of gas available, check with your KitchenAid

dealer.

Provide a gas supply line of 3/4" (1.9 cm)

rigid pipe to the range location. A smaller

size pipe on long runs may result in

insufficient gas supply. Pipe-joint compounds

appropriate for use with L.R gas must be used.

With L.R gas, piping or tubing size can be 1/2"

(1.3 cm) minimum. L.R gas suppliers usually

determine the size and materials used on the

system.

Copies of the standards listed may be obtained from:

* American Gas Association

151$ WHson Boulevard

Arlington, Virginia 22209

* * Canadian Standard Association

178 Rexdale Boulevard

Btobicoke, (Toronto), Ontario Mgw 1R3

lf local codes permit, a new

A.G.A./C.G.A. design-certified, 4-5 foot

(122 -152.4 cm) long, 1/2" (1.3 cm) or

3/4" (1.9 cm) I.D., flexible metal appliance

connector is recommended for connecting this

range to the gas supply line. Do Not kink or

damage the flexible tubing when moving the range.

A 1/2" (1.3 cm) male pipe thread is needed for

connection to pressure regulator female pipe

threads.

shutoff va}ve

"open" poeiti__

to range ?_

pply

The supply line shall be equipped with an

approved shutoff valve. This valve should

be located in the same room, but external

to the range, and should be in a location that

allows ease of opening and closing. Do Not block

access to shutoff valve.

,rgdppos glssup

line, a combination of pipe fittings

must be used to obtain an in=line

connection to the range. All strains must be

removed from the supply and fuel lines so range

will be level and in line.

The regulator setting must be checked at

a minimum of 1 inch water column above

the manifold pressure. The inlet pressure

to the regulator should be as follows for operation:

Natural gas:

Manifold pressure -- 5 inches

Maximum pressure -- 14 inches

L.P. gas:

Manifold pressure- 10 inches

Maximum pressure -- 14 inches

Line pressure testing:

Testing above 112 psi (gauge)

The range and its individual shutoff vahie

must be disconnected from the gas supply piping

system during any pressure testing of that system

at test pressures greater than 1/2 psig (3.5 kPa).

Testing at 1f2 psi (gauge) or lower

The range must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 1/2 psig (3.5 kPa).

requ

Electrical Shock Hazard

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Failure to follow these instructions can result

in death, fire, or electrical shock.

If codes permit and a separate ground wire is

used, it is recommended that a qualified

electrician determine that the ground path is

adequate.

Check with a qualified electrician if you are not

sure whether the range is properly grounded.

Do Not ground to a gas pipe.

A 120=volt, 60=Hz, AC=only, 15=ampere, fused

electrical circuit is required. A time=delay fuse or

circuit breaker is recommended. It is recommended

that a separate circuit serving only this range be

provided.

Electronic ignition systems operate within wide

voltage limits, but proper ground and polarity are

necessary. In addition to checking that the outlet

provides 120=volt power and is correctly grounded,

the outlet must be checked by a qualified

electrician to see if it is wired with correct polarity.

The wiring diagram is included in the literature

package. The wiring diagram can also be found on

the back of the range.

Note: The metal chassis of the range MUST be

grounded in order for the control panel to work. If

the metal chassis of the range is not grounded, NO

keypads will operate. Check with a qualified

electrician if you are in doubt as to whether the

metal chassis of range is grounded.

Recommended ground method

For personal safety, this range is equipped with a

power supply cord having a 3=prong ground plug.

To minimize possible shock hazard, the cord must

be plugged intoa mating 3=prong, ground=type

outlet, grounded in accordance with the National

Electrical Code, ANSI/NFPA 70 -- latest edition*

or CSA Standard C22.1, Canadian Electrical Code,

Part 1, -- latest edition** and all local codes and

ordinances. If a mating outlet is not available, it is

the personal responsibility and obligation of the

customer to have a properly grounded, 3=prong

outlet installed by a qualified electrician.

WARNING = improper connection of the

equipment=grounding conductor can result in a risk

of electric shock. Check with a qualified electrician

or servicemen if you are in doubt as to whether the

appliance is properly grounded. Do not modify the

plug provided with the appliance = if it will not fit the

outlet, have a proper outlet installed by a qualified

electrician.

power

supply

cord. 3=prong

"_ ground=type outlet

Panel C

ground plug

O

ground

prong

Page 5

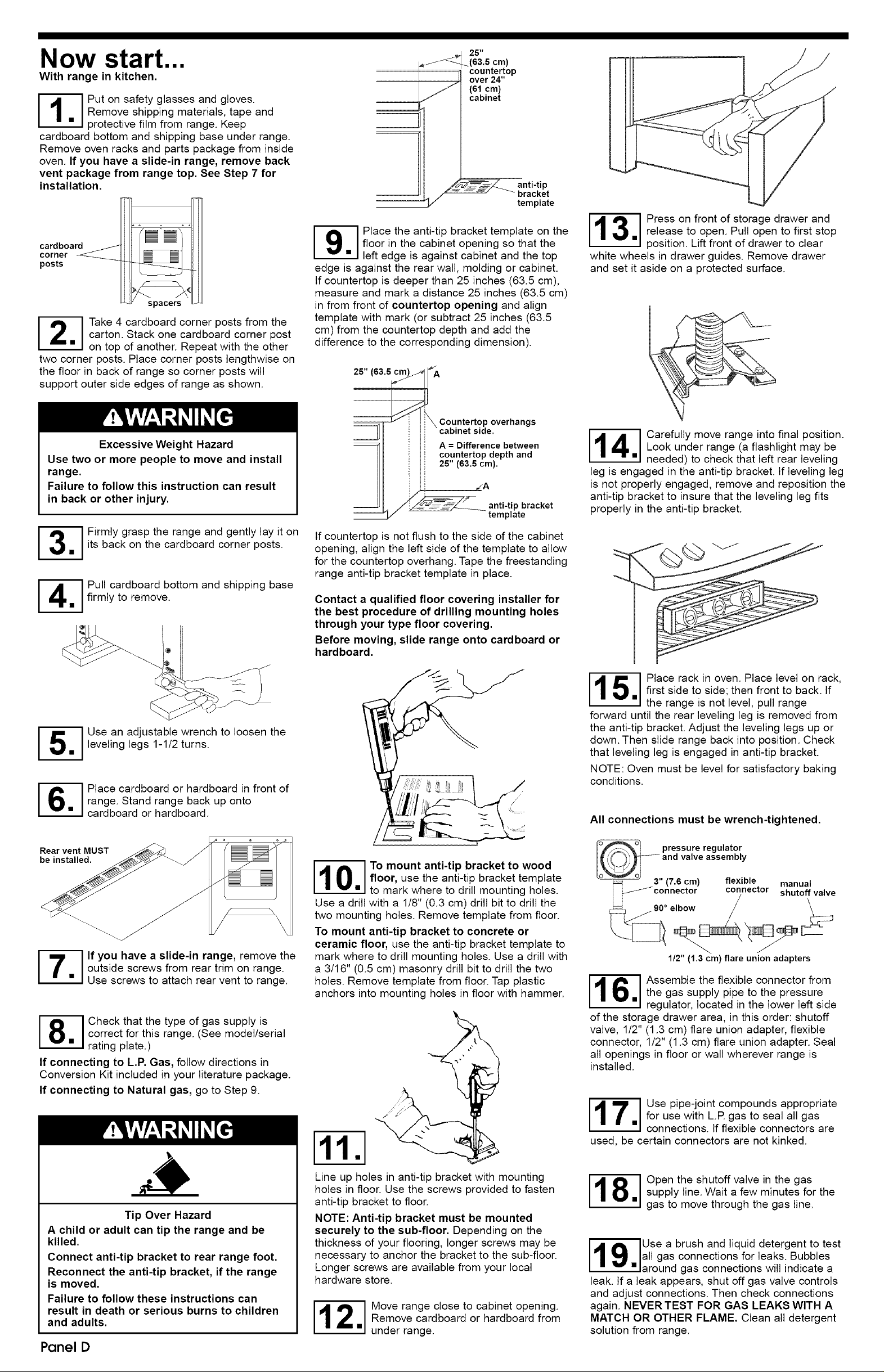

Now start...

With range in kitchen.

Remove shipping materials, tape and

--_ ut on safety glasses and gloves.

protective film from range. Keep

cardboard bottom and shipping base under range.

Remove oven racks and parts package from inside

oven. If you have a slide-in range, remove back

vent package from range top. See Step 7 for

installation.

26"

cm)

countertop

over 24"

(61 cm)

cabinet

anti-tip

bracket

template

cardboar_corner

posts

F_ ake 4 cardboard corner posts from the

two corner posts. Place corner posts lengthwise on

the floor in back of range so corner posts will

support outer side edges of range as shown.

Use two or more people to move and install

range.

Failure to follow this instruction can result

in back or other injury.

F_ irmly grasp the range and gently lay it on

carton. Stack one cardboard corner post

on top of another. Repeat with the other

Excessive Weight Hazard

its back on the cardboard corner posts.

_] lace the anti-tip bracket template on the

floor in the cabinet opening so that the

left edge is against cabinet and the top

edge is against the rear wall, molding or cabinet.

If countertop is deeper than 25 inches (63.5 cm),

measure and mark a distance 25 inches (63.5 cm)

in from front of countertop opening and align

template with mark (or subtract 25 inches (63.5

cm) from the countertop depth and add the

difference to the corresponding dimension).

26" (63.6 cm

Countertop overhangs

X cabinet side.

A = Difference between

countertop depth and

26" (63.6 cm).

_A

anti-tip bracket

template

If countertop is not flush to the side of the cabinet

opening, align the left side of the template to allow

for the countertop overhang. Tape the freestanding

range anti-tip bracket template in place.

I1" Press on front of storage drawer and

white wheels in drawer guides. Remove drawer

and set it aside on a protected surface.

14]Carefully move range into final position.

leg is engaged in the anti-tip bracket. If leveling leg

is not properly engaged, remove and reposition the

anti-tip bracket to insure that the leveling leg fits

properly in the anti-tip bracket.

release to open. Pull open to first stop

• position. Lift front of drawer to clear

Look under range (a flashlight may be

• needed) to check that left rear leveling

firmly to remove.

---_ ull cardboard bottom and shipping base

leveling legs 1-1/2 turns.

-'_ se an adjustable wrench to loosen the

range. Stand range back up onto

-J lace cardboard or hardboard in front of

cardboard or hardboard.

Rear vent MUST

be installed.

outside screws from rear trim on range.

-Jlf you have a slide-in range, remove the

Use screws to attach rear vent to range.

correct for this range. (See model/serial

-_ heck that the type of gas supply is

rating plate.)

If connecting to L.P. Gas, follow directions in

Conversion Kit included in your literature package.

If connecting to Natural gas, go to Step 9.

Contact a qualified floor covering installer for

the best procedure of drilling mounting holes

through your type floor covering.

Before moving, slide range onto cardboard or

hardboard.

I1 Place rack in oven. Place level on rack,

forward until the rear leveling leg is removed from

the anti-tip bracket. Adjust the leveling legs up or

down. Then slide range back into position. Check

that leveling leg is engaged in anti-tip bracket.

NOTE: Oven must be level for satisfactory baking

conditions.

All connections must be wrench-tightened.

[i0]z°m°untan,,-t,pbrack.tt°w°°°

Use a drill with a 1/8" (0.3 cm) drill bit to drill the

two mounting holes. Remove template from floor.

To mount anti-tip bracket to concrete or

ceramic floor, use the anti-tip bracket template to

mark where to drill mounting holes. Use a drill with

a 3/16" (0.5 cm) masonry drill bit to drill the two

holes. Remove template from floor. Tap plastic

anchors into mounting holes in floor with hammer.

floor, use the anti-tip bracket template

• to mark where to drill mounting holes.

I16 Assemble the flexible connector from

of the storage drawer area, in this order: shutoff

valve, 1/2" (1.3 cm) flare union adapter, flexible

connector, 1/2" (1.3 cm) flare union adapter. Seal

all openings in floor or wall wherever range is

installed.

first side to side; then front to back. If

the range is not level, pull range

_ pressure regulator

and valve assembly

3" (7,6 cm) flexible

_connector connector

1/2" (1.3 cm) flare union adapters

the gas supply pipe to the pressure

• regulator, located in the lower left side

manual

shutoff valve

Tip Over Hazard

A child or adult can tip the range and be

killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range

is moved.

Failure to follow these instructions can

result in death or serious burns to children

and adults.

Panel D

Line up holes in anti-tip bracket with mounting

holes in floor. Use the screws provided to fasten

anti-tip bracket to floor.

NOTE: Anti-tip bracket must be mounted

securely to the sub-floor. Depending on the

thickness of your flooring, longer screws may be

necessary to anchor the bracket to the sub-floor.

Longer screws are available from your local

hardware store.

L

I1" Move range close to cabinet opening.

Remove cardboard or hardboard from

• under range.

I17.Use pipe-joint compounds appropriate

used, be certain connectors are not kinked.

I18 ]Open the shutoff valve in the gas

•_ Jailgas connections for leaks. Bubbles

I1" jUse a brush and liquid detergent to test

v • laround gas connections will indicate a

leak. tf a leak appears, shut off gas valve controls

and adjust connections. Then check connections

again. NEVER TEST FOR GAS LEAKS WITH A

MATCH OR OTHER FLAME. Clean all detergent

solution from range.

for use with LP. gas to seal all gas

connections, tf flexible connectors are

supply line. Wait a few minutes for the

• gas to move through the gas line.

Page 6

2 O I Plug power supply cord into

[21 IRem°veventcap'c°°kt°pburnercaps

burner base. Burner caps should be level when

properly positioned. Place burner grates over

burners and caps. Place vent cap over vent dome.

earthed/grounded outlet. "8888" should

• appear in clock display.

• and grates from parts package. Align

notches in burner caps with pins in

burner

5 Remove the oven rack. Remove theoven bottom and place it on a protected

• surface.

6 Check the operation of the ovenburner. Push the "BAKE" pad and

• "350°F'' will appear in the temperature

display. Press the "Start" pad. "LO" will appear in

the display; then "170°F:' The oven burner should

light in 50 to 60 seconds. This delay is normal.

The oven safety valve requires a certain time

before it will open and allow gas to flow.

oven broil burner. Close the oven door.

0 ] Check the operation of the

• Press the "BROttJ' pad. "500°F '' will

appear in the temperature display. Press the "Start"

pad. The oven broil burner should light in 50 to

60 seconds. This delay is normal. The oven

safety valve requires a certain time before it will

open and allow gas to flow. The first time broil

burner is lighted, it may take longer to light

because of air in gas line. The first few times

burner is used sparks may appear. This is normal.

NOTE: Oven door must be shut for broil burner to

operate.

cap' ' vent

vent

i_ dome

Electronic Ignition System m

Initial lighting and gas flame adjustments.

Cooktop and oven burners use electronic ignitors

in place of standing pilots. When the cooktop

control knob is turned to the "LtTE" position, the

system creates a spark to light the burner. This

sparking continues as long as the control knob is

turned to "LITE".

When the oven control is turned to the desired

setting, a glow bar heats up bright orange and

ignites the gas. No sparking occurs and the glow

bar remains on while the burners operate.

[22lCheckthe

turn each control knob

to the "LITE" position. _,

burners. Pushinand _ I(_

The flame should light

within 4 seconds. The

first time a burner is _ _',,_,. /

lighted it may take 4,_,• o_

longer than 4 seconds 4,yo " e _ • _ _o

to light because of air in 4q_D M_o

gas line. LO

operation of OFF

• the cooktop

Electric ignitors are used to light the oven and

broil burners.

Do Not insert any object into the opening of the

protective shield that surrounds the ignitor.

Do Not clean the area.

oven

rear

tor

\

oven burner

7 Check the oven burner for proper flame.

outer mantle of dark blue, and should be clean and

soft in character. No yellow tips, blowing or lifting of

flame should occur.

oven burner

air shutter

location

This flame should have a 1/2" (1.3 cm)

long inner cone of bluish-green, with an

air shutter

-- rotate

locking screw to adjust

for properflame

3" Look through oven window to check

appearance around the burner surface. No yellow

tips, blowing or lifting of the flame should occur.

NOTE: The first few times the broil burner is used,

yellow sparks may appear in the flame. This is

normal and will stop after burner has been used a

few times.

authorized service company for assistance.

close drawer.

should have a uniform, light blue

2 ] Press the "Cancel/Off" pad. If the

3 Insert storage drawer into slide railson sides of drawer opening. Lift front

broil burner flame needs adjustment,

J

• contact your KitchenAid dealer or

• of drawer slightly and push firmly to

broil burner for proper flame. The flame

!

2 3 I If burners do not light properly, turn

cord is plugged in and the circuit breaker or fuse

has not blown. Check that the gas shutoff valves

are set to the "OPEN" position. Repeat Step 22. If

a burner does not light at this point, contact your

KitchenAid dealer or authorized service company

for assistance.

[24 ]Adjusttheheightoftopburner

The cooktop LOW burner flame should be a steady

blue flame approximately 1/4" (0.64 cm) high. It

can be adjusted using the adjustment screw in the

center of the valve stem. The valve stem is located

directly underneath the control knob.

If the LOW flame needs to be adjusted:

a. Remove the control knob.

b. Hold the knob stem with a pair of pliers. Use

a small flat-head screwdriver to

turn the screw located in the

center of the control knob stem

until the flame is the proper

size.

c. Replace the control adjustment

knob. screw

d. Test the flame by

turning the control from

"LO" to "HI", checking the

flame at each setting.

cooktop control knob to the "OFF"

• position. Check that the power supply

[28 ]lfthe°venflameneedst°beadj usted,

and rotate the air shutter until the proper flame

appears. Tighten locking screw.

• flames (some models)

29 ]Push "Cancel/Off" pad. Insert oven

placed in slots. If the oven bottom is not

positioned properly, poor baking performance

could occur. Replace oven racks.

oven burner

locate the air shutter near the center

• rear of range. Loosen the locking screw

bottom tabs into slots in oven burner

• area. Check that tabs are correctly

brass

orifice hood

(nut)

L.P. gas conversion

No attempt shall be made to convert the range

from the gas specified on the model/serial

rating plate for use with a different gas without

consulting the servicing gas supplier. An L.P.

Gas Conversion Kit is included in your

literature package.

To get the most efficient use

from your new range, read your

Use and Care Guide. Keep

Installation Instructions and

Guide close to range for easy

reference.

Top burner flame appearance:

low flame

high flame

Panel E

Page 7

Jfrange does not

operate...

• Check that the circuit breaker is not tripped or the

house fuse blown.

• Check that the power supply cord is plugged into

the wail receptacle.

• Check that the gas supply is on.

• Check that the regulator shutoff valve is in the

"OPEN" position.

For cJeaning and

maintenance...

if removing the range is ever necessary for

cleaning or maintenance, shut off gas supply to

range. Disconnect the gas and electrical supply.

if the gas or electrical supply is inaccessible, lift

the range slightly at the front and pull the range out

away from the wall. Pull the range out only as far

as necessary to disconnect the gas and electrical

supply lines.

Remove the range to complete cleaning or

maintenance.

Move range back into operating position. Remove

drawer. Level the range. Connect gas line to range

and check for leaks. Plug electric power supply

cord into outlet. Make sure that left rear leveling leg

is engaged in the anti-tip bracket.

If you need assistance...

The KitchenAid Consumer Assistance Center will

answer any questions about operating or

maintaining your range not covered in the

Installation Instructions. The KitchenAid Consumer

Assistance Center is open 24 hours a day, 7 days

a week. Just dial 1-800-422-1230 -- the call is free

within the continental United States.

When you call, you will need the range model

number and serial number. Both numbers can be

found on the model/serial rating plate located on

the oven frame behind the oven drawer.

If you need service...

In the event that your KitchenAid appliance should

need service, call the dealer from whom you

purchased the appliance or a KitchenAid-authorized

service company. A KitchenAid-authorized service

company is listed in the Yellow Pages of your

telephone directory under "Appliances -- Household

-- Major -- Service and Repair."

You can also obtain the service company's name

and telephone number by dialing, free, within the

continental United States, the KitchenAid Consumer

Assistance Center telephone number,

1-800-422-1230. A special operator will tell you the

name and number of your nearest KitchenAid-

authorized service company.

Maintain the quality built into your KitchenAid appliance

-- call a KitchenAid-authorized service company.

Moving the range...

Tip Over Hazard

A child or adult can tip the range and be

killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is

moved.

Failure to follow these instructions can result

in death or serious burns to children and

adults.

Kitchen kid ®

HOME APPUANCES

When moving range, slide range onto

cardboard or hardboard to prevent damaging

the floor covering.

If removing the range is necessary for cleaning or

maintenance:

1. Remove the storage drawer.

2. Shut off the gas supply to the range.

3. Slide range forward, away from the wall, just far

enough to disconnect the gas and electric supply

lines.

4. Slide range forward to complete cleaning or

maintenance.

5. Making sure the anti=tip bracket is installed:

• Look for the anti=tip bracket securely attached

to floor.

• Slide range back so rear range foot is under

anti=tip bracket.

6. Check that range is level.

7. Reconnect gas line to range and check for

leaks.

8. Plug power supply cord into outlet. Reinstall

storage drawer.

Part No. 9753562

© 1999 KitchenAid.

® Registered Trademark of KitchenAid, U.S.A. Prepared by KitchenAid, Benton Harbor, Michigan 49022

Printed in U.S.A.

Page 8

APPAREILS MENAGERS

Risque de basculement

Un enfant ou un personne adulte peut faire

basculer la cuisiniere ce qui peut causer un

deces.

Joindre la bride antibasculement au pied

arriere de la cuisiniere.

Joindre de nouveau la bride antibasculement

si la cuisiniere est deplacee,

Le non-respect de ces instructions peut

causer un deces ou des br_lures graves aux

enfants et aux adultes.

®

[] []

Piece n ° 9753562F

I

IMPORTANT :

InstaHateur : Remettre les instructions

d'installation au proprietaire,

Propri_taire : Conserver les instructions

d'installation pour consultation ulterieure,

ainsi que le gabarit de la bride

antibasculement,

Conserver les instructions d'installation pour

consultation par !'inspecteur local des

installations 61ectriques,

Cuisini_re

brQleurs scellds

76,2 cm (30 po)

Modele autonome et module

encastrd

avec four autonettoyant thermique/convection

Page 9

Avant de commencer...

Dimensions de I'ouverture entre les

Vetre e_curit6et ceHe deeautres sent tr_a impertaetes,

rlousdonnons de nombreux messages de s6curit6 irnportants

dansce manuel et au sajet de votre appareil m_nager.Assurez-

vous de touiours lire teas les rnessagesde s_curit_ et de les

respecter.

Ce syrnboled'alerte de sScurit_vous signaleles dangers

susceptibles de causer un dSc_set des blessures

graves. Tousles messagesde sScurit6 seront pr_c6d_s

du symbole d'alerte de s_curit6 et du mot <<DAr/GER>,ou

_<AVERTISSEMENT>,.Ces roots signifient :

Risque peusible de d6c_s oil de blessure grave si veusee

suivez pas Jeuinstruutions.

Touslesrnessagesdes_curit_identifientledangeretvous

indiquentcommentr6duJrele risquedeblessureet cequipeotse

produireuncasdenon-respectdesinstructions.

AVERTISSEMENT : Si les instructions dans

ce manuel ne sent pas strictement

respectees, un incendie ou une explosion

pourrait causer des dommages materiels et

corporels, ou un deces.

m Ne pas remiser d'essence ou d'autres

produits liquides ou volatiles

inflammables, et ne pas utiliser de tels

produits au voisinage de cet appareil ou

de tout autre appareil menager.

QUE FAIRE LORQU'UNE ODEUR DE GAZ

EST PERCEPTIBLE

placards

Profondeur du comptoir de 63,5 cm (25 po) (avec ou sans dosseret) et

profondeur de la base du placard de 61 cm (24 po)

Hauteur du dessus du comptoir : 91,4 cm (36 po)

Cuisini re autonome

33cm(13p°)'_'_ _ I ]_

profondeur max. _ I /

r._ des p!acards _ _ I

superleurs _ '_ .... ,_ 45.7 cm/18 no_

/ _ minimale, compto=r

Degagement de

s_paration de 10,2

(4 po) min. entre la

cuisiniere et un tour ou

des mat_riaux

combustibles, des deux

c6t_s de la cuisinicre.

Positionner la

canalisation d'arriv_e de.

gaz clans la zone grisee.

5,1 cm (2 po)__

/ _,_ Pour la , _ i-"

J largeur de I'ouverture s_paration supeneur

/= . / entre les placards verticale et dessus.de

7,6 cm

(3 po) I I

_1_ I'ouverture

-22,9 cm (9 po)

i

I

- (24 po) ',

I

I 45,7 cm

\

76,2 cm (30 po) _ I distance de entre placard

76,8 cm (30 1/4 po)

largeur de

61 cm

15,2 cm

voir la note***

(6 po)

La prise de

courant

murale devrait

_,4 cm ctre situ_e

(10 po) clans la zone

_-__ouverture de passage de _l _ /

la canalisation de gaz I _ /

clans le plancher, si elle

est directement sous le

d_tendeur.

2,2 cm (7/8 po)

espace min. n_cessaire entre

6,4 cm (2 1/2 po) I /

I'ouverture du placard et la

porte ou les charnieres.

iris_e, de 45,7

cm x 25,4 cm

(18 x 10 po). I

/

[

• Ne pas allumer un appareil menager.

• Ne toucher aucun commutateur

electrique.

• Ne pas utiliser un telephone dans

I'edifice.

• Contacter immediatement le fournisseur

de gaz, du telephone d'un voisin.

Executer les instructions du fournisseur

de gaz.

• S'il n'est pas possible de contacter le

fournisseur de gaz, contacter les

pompiers.

Les operations d'installation et

d'entretien doivent _tre executees par un

installateur qualifie, une entreprise

d'entretien ou le fournisseur de gaz.

Respecter les dimensions indiqu_es pour I'ouverture

dans le dessus de comptoir.

Lors de I'installation d'une cuisiniere sous des placards

existants, si I'installation ne satisfait pas les

degagements minimums, installer une hotte au-dessus

de la cuisiniere pour eviter les risques de brOlures.

Life les instructions concernant I'installation

_lectrique et la menuiserie.

C'est _ I'installateur qu'incombe la responsabilit_ de

r_aliser une installation correcte. L'instalIation de cette

cuisiniere dolt _tre effectuee par un technicien quaIifie. Veiller

avoir tout le materiel necessaire pour une installation correcte.

C'est au proprietaire de I'appareil qu'incombe la responsabiIite

de veiller ace que le dessus du comptoir ait ete

convenablement prepare eta ce que les distances de

separation specifiees sur la plaque signaletique soient

respectees Iors de I'installation. On trouve la plaque

signaletique surle ch&ssis du four, derriere le tiroir.

Inspecter I'emplacement oQ la cuisiniere sera installee. La

cuisiniere devrait normalement 6tre installee dans la cuisine

pour en permettre une utilisation pratique. Pour une installation

dens un encastrement, I'encastrement dolt fermer ies c6tes et

I'arriere de la cuisiniere.

TOUTES LES OUVERTURES DANS LEMUR OU LE

PLANCHER ,_,I_EMPLACEMENT D'INSTALLATION DE LA

CUISlNIERE DOIVENT ETRE SCELLEES.

IMPORTANT : Certains placards et certains materiaux de

construction ne peuvent resister ala chaleur emise par le four

pendant les operations de cuisson au four et d'autonettoyage.

Consulter Ie constructeur ou Ie fournisseur des placards pour

determiner si les materiaux utilises peuvent subir un

changement de couleur, une destratification ou d'autres

dommages.

C'est au client qu'incombe la responsabilit_ :

de contacter un _lectricien qualifi_ pour I'installation.

Panneau A

Cuisini re encastrde

Installation dans un ilot : profondeur de decoupage

de I'ouverture dans le dessus de comptoir 63,5 cm (25 po)

33 cm (13

profondeur max.

F des placards

supeneurs- / 46,7 cm

J 76,2 cm !30 po) distance de entre placard

_/ largeur de I ouverture separation superieur

_ entre les pla_ verticale et dessus de

Degagement de

sdparation de 10,2 cm

(4 po) min. entre la

cuisiniere et un

des mat_riaux

combustibles, des deux

c6t_s de la cuisiniere.

22,9 cm 15,2 cm

(9 po) (6 I:

Positionner la (3 po)

canalisation

d'arriv_e de

dans la zone gris_e.

ouverture de passag

de la canalisation de

gaz dans le plancher,

si elle est directement

sous le detendeur.

de veiller _ ce que I'installation _lectrique soit adequate et

r_alis_e en conformit_ avec les prescriptions du Code

national des installations _lectriques ANSI/NFPA 70 -

derni_re _dition*, ou avec les prescriptions de la derni_re

_dition** du Code canadien des installations _lectriques

ACNOR/CSA C22,1, partie 1 et de tousles codes et

r_glements Iocaux en vigueur,

REMARQUE : Cet appareil est congu pour utilisation avec gaz

naturel. On peut le convertir pour utilisation avec gaz propane

au moyen de I'ensemble de conversion inclus dans votre

trousse de documentation.

Remarque : Le chassis metallique de la cuisiniere DOlT

6tre relie & la terre pour que le tableau de commande

puisse fonctionner. Si le chassis metallique de la

cuisiniere n'est pas relie ala terre, AUCUNE touche du

tableau de commande ne peut fonctionner. En cas de

doute quanta la qualite de liaison & la terre du ch&ssis

metallique de la cuisiniere, consulter un electricien

qualifie.

Important : Respecter les prescriptions de tousles codes

et r_glements en vigueur.

Une prise de courant _lectrique reli_e _ la terre est

necessaire. Voir au panneau C Ies specifications de

i'instatlation electrique.

7,6

45,7 cm _1_"

Pour la (18 po)

minimale, _ comptoir

77,2 cm _

(30 3/8 po)

po) 4 cm

voir la

note***

(10po)

La prise de courant

murale devrait _tre

cm situ_e clans la zone _/

(24 po) grisee, de 48,7 cm x

2,2 cm (7/8 po)

espace min. n_cessaire entre

I'ouverture du placard et la porte ou

les charnicres.

Respecter les dimensions indiqu_es pour I'espace

d'insertion de la cuisini_re entre les placards,

Ne pas coincer le cordon d'alimentation _lectrique entre la

cuisini_re et le tour,

Ne pas sceller I'espace entre la cuisini_re et les placards,

On peut obtenir des exemplaires des normes mentionnees

auprcs de :

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

** Canadian Standard Association/ACNOR

78 Rexdale Boulevard

Etobicoke (Toronto), Ontario M9W 1R3

*** Remarque : distance d'au moins 61 cm (24 po)

Iorsque le fond des placards de bois ou de m_tal est

proteg_ par une planche ignifugee d'au moins 0,64 cm

(1/4 po) recouverte d'une t6le d'acier de calibre MSG

N° 28 au moins, d'acier inoxydable de 0,4 mm

(0,015 po), d'aluminium de 0,6 mm (0,024 po) ou de

cuivre de 0,5 mm (0,020 po),

Distance minimum de 76,2 cm (30 po) entre le sommet

de la table de cuisson et le fond d'un placard de bois

ou de m_tal non protege,

25,4 cm (18 x 10 po).

Page 10

Cuisini res encastrdes,

Outillage ndcessaire

prdparation du comptoir

largeur _-_

d'ouverture

77,2 cm \

(30 3/8 po) _

Le rebord de la cuisiniere encastree recouvre le bord

d6coupe du plan de travail.

Si vous avez un dessus de comptoir _ rebord

plat et que la largeur de I'ouverture est de 77,2

cm (30 3/8 po), aucune preparation du dessus de

comptoir n'est requise.

Dessus de comptoir & rebord avant moul6 : Le

rebord moule dolt 6tre aplani de 0,64 cm (1/4 po) de

chaque coin avant de I'ouverture.

Les dessus de comptoir & carreaux peuvent

necessiter que la garniture soit coupee de 0,64 cm

(1/4 po) de chaque coin avant ou que le rebord

arrondi soit aplani.

0,64 cm

Dessus de comptoir

moul_ ou b carreaux

d_coupe de 0,64 cm

(1/4 po) aux coins avant

de I'ouverture du plan de

travail.

Dimensions du produit

63,5 cm

(2s po)

recouvre les bords de I'ouverture

du plan de travail.

Si la largeur d'ouverture du dessus de comptoir est

sup_rieure & 77,2 cm (30 3/8 po), ajuster la dimension

de 0,64 cm (1/4 po).

Le dessus de comptoir dolt _tre d'aplomb. Placer un

niveau sur le dessus de comptoir, transversalement puis

dans le sens avantiarriere. Si le dessus de comptoir

n'est pas d'aplomb, la cuisiniere ne sera pas d'aplomb.

Pour que la cuisiniere produise de bons resultats de

cuisson, il faut qu'elle soit d'aplomb.

pour I'installation :

tournevis

Phillips _

._Jf tournevis

/j/ lame plate ou

//// tourne-ecrou

_" de 0,79 cm

0,95cm(1/8p°) /_ _\ pince ij

_-_ metre-ruban ou

marteau __

_terSt d e ga_

m_che

bois 1,3 cmi_

(5/16 po)

21 cm cuisiniere

(8 1/4 po) 76,2 cm I

largeur de la

espacement

2_$4cm

(1 po)

70,5 cm

(27 3/4 po)

profondeur

avec poign_e

Cuisini re autonome

hauteur

cuisini_re

91,8 cm

[36 1/8 po)

de la

(44 3/8 po)

112,7 cm

(1/2 po),__

perceuse manueile ou

electrique - plancher de

bois :

foret de 0,3 cm (1/8 po)

plancher de

beton/c_ramique :

foret _ maqonnerie

(pointe de carbure)

0,48 cm (3/16 po)

Pour conversion au

gaz propane :

pince appropri_e

avec dents

tourne-ecrou de

0,49 cm (5/16 po)

Pi ces fournies pour

I'installation :

bride

antibasculement • grilles de brQleur

2 chevilles 2 n° 69 - table de

d'ancrage de cuisson

plastique 1 n° 65 - brBleur

2 vis (n° 10 x 1 1/2 po)

(11faut que la bride antibasculement soit solidement fix_e

au sous-plancher. L'epaisseur du plancher peut n_cessiter

des vis plus Iongues pour qu'elles atteignent le sous-

plancher.)

et chapeaux de

breleur

• chapeau d'event

• gicleurs pour

conversion aM gaz

propane :

2 n° 64 - table de

cuisson

du gril

3.8 cm

(1 1/2 po)

largeur de la

_vent arriere _lv I

77,2 cm (30 3/8 po)

espacement

2,54 cm

po)

Cuisini re encastree

hauteur

de la

cuisini_re

91,8 cm

(36 1/8 po)

IMPORTANT:

I'event arriere dolt _tre

installesur tousles

modeles encastrables

pour une bonne

ventilation. Voir Etape 7,

Panneau D.

Installation dans une residence mobile

Uinstallation de cette cuisiniere dolt satisfaire les criteres

des normes de construction et de securite des

residences prefabriquees, titre 24 CFR, partie 3280

(anciennement Norme federale de construction et de

securite des residences prefabriquees, titre 24 HUD,

partie 280); ou Iorsque ces normes ne sont pas

applicables, I'installation dolt satisfaire les criteres de la

norme d'installation des residences prefabriquees

(residences prefabriquees - sites, communautes et

etablissements) ANSI A225.1/NFPA 501A*, ou des

codes Iocaux en vigueur.

Au Canada, I'installation de cette cuisiniere dolt satisfaire

les criteres de la norme ACNOR/CSA-Z240 en vigueur,

derniere edition**, ou des codes Iocaux en vigueur.

Lorsque cette cuisiniere est installee dans une residence

mobile, elle dolt 6tre bien fixee au plancher Iors d'un

transport. Toute methode de fixation de la cuisiniere au

plancher est adequate Iorsqu'elle satisfait les criteres

des normes mentionnees ci-dessus.

On peut obtenir des exemplaires des normes mentionnees

aupr_s de :

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

** Canadian Standard Association/ACNOR

178 Rexdale Boulevard

Etobicoke (Toronto), Ontario M9W 1R3

Panneau B

profondeur

avec

poignee

70,5 cm

(27 3/4 po)

largeur

76,2 cm

(30 po)

Bride antibasculement :

La bride antibasculement DOlT

_tre fix_e au plancher. Pour

l'installation de la bride

antibasculement fournie avec la

cuisini_re, voir le panneau D et

le gabarit de la bride

antibasculement.

Page 11

Canalisation

d'arriv e de gaz

Risque d'explosion

Utiliser une canalisation de gaz neuve approuvee

par I'A.G.A/C.G.A.

Installer un robinet d'arr_t.

Bien serrer tous les raccords.

Si la cuisiniere est raccordeeau gaz propane,

demander a un technicien qualifie de contr61er

que la pression d'arrivee du gaz ne depasse pas

35,6 cm (14 pc) (colonne d'eau).

Par personne qualifiee, nous entendons, par

exemple, le personnel des services de chauffage

detenant un permis, le personnel autorise de la

compagnie de gaz et le personnel autorise du

service.

Le non-respect de ces instructions peut causer

un deces, une explosion ou un incendie.

Respecter les dispositions de tous les codes et

reglements en vigueur.

Important : La cuisiniere dolt _tre connectee a une

canalisation de gas munie d'un detendeur.

installations doivent _tre conformes aux

En I'absence de codes Iocaux, les

codes ANSI Z223.1 de I'American National

Standard, National Fuel Gas -- la plus recente edition*,

ou CAN/CGA B149 -- la plus recente edition**.

plaque signaletique ont et6 determin6es pour

-_ Les puissances thermiques indiquees sur la

une altitude de 609,6 m (2000 pi). )k une

altitude superieure a 2000 pi, la puissance thermique

diminue a raison de 4 % pour chaque tranche de

304,8 m (1000 pieds) au-dessus du niveau de la mer.

(Ceci n'est pas applicable au Canada.)

I'alimentation au gaz naturel. Sa conception

'_ Cette cuisiniere est 6quipee pour

est homologuee par A.G.A./C.G.A. pour

I'alimentation au gaz naturel ou au gaz propane avec les

accessoires de conversion appropries. La plaque

signaletique situee sur le chassis du four derriere le tiroir

indique le type de gaz & utiliser. Si cette information ne

correspond pas au type de gaz disponible, consulter le

concessionnaire KitchenAid.

cm (314 pc) jusqu'& I'emplacement de la

'_ nstaller une canalisation de gaz rigide de 1,9

cuisiniere. Une canalisation de diametre

inferieur ou de grande Iongueur peut susciter un debit

d'alimentation insuffisant. Utiliser un compose

d'etanch6it6 des joints approprie, compatible avec le gaz

propane. Pour I'alimentation au gaz propane, le diametre

minimum de la canalisation d'alimentation est de 1,3 cm

(1/2 pc). Les fournisseurs de gaz propane determinent

habituellement la taille et les materiaux des

canalisations a utiliser avec le systeme.

On peut obtenir des exemplaires des normes mentionnees

aupr_s de :

*National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

**Canadian Standard Association/ACNOR

178 Rexdale Boulevard

Etobicoke (Toronto), Ontario M9W 1R3

Si le code local le permet, on recommande

I'emploi d'un nouveau raccord metallique

flexible (homologation A.G.A./C.G.A.) -

Iongueur 122-152,4 cm (4-5 pi), diametre interne 1,3 cm

(1/2 pc) ou 1,9 cm (3t4 pc) - pour le raccordement de la

cuisiniere a la canalisation d'arrivee de gaz. Veiller & ne

pas ecraser ou endommager le raccord flexible Iors d'un

deplacement de la cuisiniere. Un filetage m&le de 1,3 cm

(1/2 pc) est necessaire pour la connexion sur le raccord

femelle du detendeur.

robinet d'arr_t,

d'arrivee de gaz

dotee d'un robinet d'arr6t approuve. Ce

'_La canalisation d'arrivee de gaz dolt _tre

robinet devrait 6tre separe de la cuisiniere,

mais situe dans la m6me piece a un endroit oQ on peut

y acceder facilement pour les manoeuvres d'ouverture et

de fermeture. Ne pas entraver I'acces au robinet d'arr6t.

si la cuisiniere d_

une canalisation de gaz rigide, on dolt _

exactement la canalisation avec le raccord de la

cuisiniere. Veiller & ce que la canalisation ne soit

soumise & aucune tension mecanique, pour que la

cuisiniere soit bien alignee et d'aplomb.

de distribution. Lors du fonctionnement, la pression

I'entree du detendeur devrait 6tre comme suit :

utiliser divers raccords pour aligner

detendeur a une pression d'au moins 25 mm

on dolt contr61er le fonctionnement du

(1 pc) (colonne d'eau) au-dessus de la presslon

Gaz naturel :

Pression de distribution - 5 pouces

Pression maximum - 14 pouces

Gaz propane :

Pression de distribution - 10 pouces

Pression maximum - 14 pouces

[_ est de pressurisation de la canalisation :

systeme & une pression relative superieure & 3,5 kPa

(1/2 Ib/po2), il faut que la cuisiniere et sa vanne d'arr6t

individuelle soient deconnectees de la canalisation

d'arrivee de gaz.

Test & 1/2 Ib/po 2 (relative) ou moins

Lors de tout test de pressurisation de la canalisation de

gaz & une pression egale ou inferieure 3,5 kPa

(1/2 Ib/po 2) relative, on dolt fermer le robinet d'arr6t

individuel pour isoler la cuisiniere de la canalisation

d'arrivee de gaz.

Test au-dessus de 1/2 Ib/po 2 (relative)

Lors de tout test de pressurisation du

Exigences dlectriques

Risque de choc electrique

Brancher I'appareil uniquement sur une prise

3 alveoles, reliee a la terre.

Ne pas enlever & broche reliee a la terre.

Ne pas utiliser un adaptateur.

Le non-respect de ces instructions peut

causer un decks, un incendie ou un choc

electrique.

Si les codes le permettent et si un fil separe de liaison b la

terre est utilise, il est recommande qu'un electricien

qualifie determine que la liaison a la terre est adequate.

Ne pas utiliser une canalisation de gaz pour la liaison

electrique b la terre.

En cas de doute en ce qui concerne la liaison b la terre de

I'appareil, contacter un electricien qualifie.

£appareil dolt _tre alimente par un circuit electrique de

120 V (CA seulement), 60 Hz, protege par un fusible de

15 A. On recommande I'emploi d'un fusible temporise ou

d'un disjoncteur. On recommande egalement que

I'appareil soit alimente par un circuit independant.

Le systeme d'allumage electronique fonctionne dans une

grande gamme de tensions, mais il faut que I'appareil

soit convenablement relie a la terre et que la polarite

specifiee soit respectee. En plus de verifier que la prise

de courant electrique est correctement reliee & la terre et

fournit une tension de 120 V, un electricien qualifie dolt

verifier que le c&blage respecte la polarite.

Le schema de c&blage est inclus dans les documents

fournis avec la cuisiniere. On peut egalement trouver le

schema de c&blage a I'arriere de la cuisiniere.

Remarque : Pour que le module de commande

electronique fonctionne, il faut que le chassis metallique

de la cuisiniere soit relie a la terre. Si le chassis

metallique de la cuisiniere n'est pas relie a la terre,

AUCUNE touche du tableau de commande ne

fonctionne. En cas de doute au sujet de la liaison & la

terre du ch&ssis metallique de la cuisiniere, consulter un

electricien qualifie.

Methode recommandee de liaison b la

terre

Pour la securite personnelle des utilisateurs, cet appareil

est muni d'un cordon d'alimentation electrique dote

d'une fiche de branchement a 3 broches, reliee & la

terre. Pour minimiser le risque de choc electrique, le

cordon dolt 6tre branche sur une prise de courant

murale correspondante & 3 alveoles, reliee & la terre,

conformement aux prescriptions du Code national des

installations electriques ANSlINFPA 70 - derniere

edition*, ou normes ACNOR/CSA C22.1 Code canadien

des installations electriques, partie 1, derniere edition**,

eta toutes les prescriptions des codes et reglements

Iocaux en vigueur. Si une prise de courant & 3 alveoles

n'est pas disponible, c'est au proprietaire de I'appareil

qu'incombent la responsabilite et I'obligation personnelle

de faire installer par un electricien qualifie une prise de

courant a 3 alveoles correctement reliee & la terre.

AVERTISSEMENT - La connexion incorrecte du

conducteur pour relier I'appareil a la terre peut causer un

risque de choc electrique. Consulter un electricien ou

technicien qualifie si vous avez des doutes sur la liaison

& la terre correcte de I'appareil. Ne pas modifier la fiche

fournie avec I'appareil - si elle n'entre pas dans la prise,

faire installer une prise appropriee par un electricien

qualifie.

cordon fiche de branchement

, a 3 broches, reliee a la

d alimentation

terre

Panneau C

prise de courant

murale a 3 alveoles,

reliee a la terre

©

broche de

liaison

la terre

Page 12

Commencer maintenant...

avec la cuisini_re dans la cuisine.

Enlever de la cuisiniere les materiaux

---_ orter des gants et des lunettes de securit&

d'emballage, rubans adhesifs et films de

protection. Conserver le fond de I'emballage de carton et

la base utilisee pour I'expedition sous la cuisiniere.

Retirer les grilles du four et le sac de pieces place &

I'interieur du four. Darts le cas d'une cuisini_re

encastr_e, retirer les pi_ces du syst&me d'_vent au

sommet de la cuisini&re. Pour I'installation, voir

I'_tape 7.

dessus de

63,5 cm (25 po)

sur placards de

61 cm (24 po)

abarit de la _ Appuyer sur le tiroir de remisage a ravant,

bride _ pour le degager. Ouvrir le tiroir jusqu'& la

antibasculement premiere butee. Soulever I'avant du tiroir pour

passer par-dessus les roulettes blanches du tiroir.

Enlever completement le tiroir; placer le tiroir de c6te sur

cornieres /

de carton _

entretoises

_7 Empiler les cornieres de carton, par groupes

cuisiniere, pour que les bords externes de la cuisiniere

puissent reposer dessus (voir rillustration).

de deux. Placer les cornieres

Iongitudinalement sur le sol & rarriere de la

Risque de poids excessif

Utiliser deux ou plus de personnes pour d_placer

et installer le cusini&re.

Le non-respect de cette instruction peut causer

une blessure au dos ou d'autres blessures.

F_ Saisir fermement la cuisiniere; placer

doucement la cuisiniere en appui sur la face

arriere, sur les cornieres de carton.

fond de I'emballage de carton pour les enlever.

--'_ Tirer fermement sur la base d'expedition et le

tour les pieds reglables de la cuisiniere.

-'_ vec une cle & molette, desserrer de 1 1/2

_ I Placer le gabarit d'installation de la bride une surface proteg6e.

telle maniere que le bord gauche soit en contact contre

le placard et que le bord superieur soit en contact avec

lemur arriere, la moulure ou le placard. Si la largeur du

dessus de comptoir est superieure & 63,5 cm (25 po),

mesurer et marquer une distance de 63,5 cm (25 po)

depuis le bord avant du dessus de comptoir, et

aligner le gabarit par rapport & cette ligne de reperage

(ou soustraire une distance de 63,5 cm (25 po) de la

largeur du plan de travail, et ajouter la difference & la

dimension correspondante.

63,6 cm(26 po)

Si le dessus de comptoir n'est pas en affleurement avec

le panneau lateral du placard, aligner le bord gauche du

gabarit en tenant compte de la distance de

depassement du dessus de comptoir. Fixer le gabarit de

la bride antibasculement (pour cuisiniere autonome) sur

le plancher avec du ruban adhesif.

Contacter un installateur competent de

recouvrement de plancher pour la meilleure fa_on de

percer des trous de montage selon le type de

plancher. Avant le d_placement, glisser la cuisini&re

sur le carton ou le panneau de bois dur.

antibasculement sur le plancher dans

I

• respace d'insertion entre les placards, de I /'--_2:%_×

position finale. Verifier sous la cuisiniere (il

peut 6tre necessaire d'utiliser une lampe de

niveau sur la grille pour contr61er raplomb de

la cuisiniere, transversalement puis darts le

_ dessus de comptoir en saillie

par rapport au placard

A = Difference entre

63,6 cm (26 po) et la largeur

du dessus de comptoir

_A

gabarit de la bride

antibasculement

[_ ousser prudemment la cuisiniere jusqu'a sa

poche) que le pied reglable arriere gauche est engage

dans la bride antibasculement. Si le pied reglable n'est

pas convenablement engage dans la bride, retirer la

cuisiniere, et modifier si necessaire la position

d'installation de la bride antibasculement pour que le pied

reglable puisse s'engager convenablement dans la bride.

'_ Placer une grille dans le four. Placer un

sens avant/arriere. Si la cuisiniere West pas

correctement d'aplomb, tirer un peu la cuisiniere pour

faire sortir le pied reglable arriere de la bride

antibasculement. Ajuster la position verticale du pied

reglable; reins6rer la cuisiniere. Verifier que le pied

reglable arriere est bien engage dans la bride

antibasculement.

REMARQUE : Pour que la cuisiniere produise de bons

resultats de cuisson, il faut qu'elle soit d'aplomb.

F_7 lacer un morceau de carton ou de bois dur

morceau de carton ou de bois dur.

L'@ventarri_redoit

@treinstalle

ces vis pour fixer I'event arriere a la cusiniere.

arriere sur la cuisiniere.

Verifier que le gaz disponible est celui qui correspond &

la configuration de la cuisiniere (voir la plaque

signaletique). Pour I'alimentation au gaz propane,

executer les instructions qui accompagnent rensemble

de coversion, piece n°9752401, founi par KitchenAid ou

un vendeur autorise de pieces.

Pour I'alimentation au gaz natruel, passer a retape 9.

& I'avant de la cuisiniere. Redresser la

cuisiniere pour la placer en appui sur le

6ter les vis aux deux extremites de la

Si vous avez une cuisini_re encastrable,

garniture a rarriere de la crusiniere. Utiliser

6ter les vis externes de la garniture arriere de

Dans le cas d'une cuisini6re encastr_e,

la cuisiniere. Utiliser ces vis pour fixer revent

Risque de basculement

Un enfant ou un personne adulte peut faire

basculer la cuisiniere ce qui peut causer un

deces.

Joindre la bride antibasculement au pied arriere

de la cuisiniere.

Joindre de nouveau la bride antibasculement si la

cuisiniere est deplacee,

Le non-respect de ces instructions peut causer

un deces ou des br_lures graves aux enfants et

aux adultes.

Ponneou D

0 Pour fixer la

sur un plancher de bois,

utiliser le gabarit de la bride

antibasculement pour

marquer I'emplacement des

trous de montage. Percer les

deux trous de montage avec

un foret de 3 mm (1/8 po). '_

Detacher le gabarit du

plancher.

Pour fixer la bride antibasculement sur un plancher

de b_ton ou de c_ramique, utiliser le gabarit de la

bride antibasculement pour marquer la position des

trous de montage. Percer les deux trous de montage

avec un foret a ma_onnerie de 5 mm (3/16 po). Detacher

du plancher le gabarit de la bride antibasculement.

Inserer les chevilles d'ancrage de plastique dans les

trous de montage du plancher, avec un marteau.

[_ Aligner les trous de la

montage perces dans le plancher.

Utiliser les vis fournies pour fixer

solidement la bride au plancher.

REMARQUE : Les vis de

fixation de la bride

antibasculement doivent _tre

solidement ancr_es dans le

sous-plancher. Selon I'epaisseur du plancher, il peut

6tre necessaire d'utiliser des vis d'ancrage plus Iongues

pour qu'elles prennent prise darts le sous-plancher. On

peut trouver des vis d'ancrage plus Iongues darts tout

magasin de quincaillerie local.

'_ lacer la cuisiniere a proximite de I'espace

de dessous la cuisiniere.

bride

• ant bascu ement

bride antibasculement

avec les trous de "'Z.

d'installation entre les placards. Retirer la

feuille de carton ou le panneau de bois dur

Serrer tousles raccords avec une cir.

/,_ detendeur et vanne

tube de

raccordement raccord robinet d'arr_t

/7,6 cm (3 po) flexible manuel

raccord coude / \

/

.J

raccords droits 1,3 cm (112 po)

'_ onnecter le raccord flexible entre la

tiroir de remisage; executer les raccordements darts

I'ordre suivant : robinet d'arr6t, raccord droit 1,3 cm

(1/2 po), raccord flexible, raccord droit 1,3 mm (112 po).

Assurer I'etancheite de toutes les ouvertures percees

dans le plancher ou lemur Iors de I'installation de la

cuisiniere.

'_ ssurer I'etancheite des connexions de la

gaz propane. Lors de I'utilisation de raccords metalliques

flexibles, veiller ace qu'ils ne soient pas deformes ou

ecrases.

F_ uvrir le robinet d'arr6t de la canalisation de

'_ tiliser un pinceau et un detergent liquide

formation de bulles au niveau des connexions indique la

presence de fuites. En cas de fuite, fermer le robinet

d'arr6t et executer les operations correctives

necessaires. Effectuer de nouveau un test de recherche

des fuites sur les connexions. NE JAMAIS

RECHERCHER DES FUITES DE GAZ A L'AIDE D'UNE

ALLUMETTE OU D'UNE FLAMME QUELCONQUE.

Nettoyer ensuite pour eliminer tout residu de solution de

detergent de la cuisiniere.

canalisation d'arrivee de gaz et le detendeur,

situe sur le c6te gauche dans la zone du

canalisation de gaz avec un compose

d'etancheite approprie, compatible avec le

gaz. Laisser le gaz sortir pendant quelques

minutes pour qu'il expulse Fair residuel des

canalisations.

pour rechercher les fuites sur toutes les

connexions de la canalisation de gaz. La

Page 13

20 I Brancher le cordon d'alimentation electrique

I'horloge.

cuisson et grilles de brt31eur. Aligner les encoches des

chapeaux de brQleur avec les ergots correspondants de

la base de chaque brOleur. Lorsqu'ils sont

convenablement places, les chapeaux de brQleur doivent

6tre d'aplomb. Placer la grille de chaque brQleur par-

dessus le brQleur et le chapeau de brQleur. Placer le

chapeau d'event sur le d6me de I'event.

sur une prise de courant reliee & la terre. On

• volt apparaftre <<8888>>sur I'afficheur de

pieces suivantes : chapeau d'event,

--_ rendre dans le sac de petites pieces les

chapeaux des brQleurs de la table de

grille de

brtileur

Syst me d'allumage lectronique -

Allumage initial et r_glage de la flamme.

Uallumage des brQleurs de la table de cuisson et du four

est r6alise au moyen d'un dispositif d'allumage

electronique, au lieu d'une flamme de veille. Lorsqu'on

place le bouton de commande d'un brQleur de la table

de cuisson a la position <<LITE>>, le systeme gen6re des

etincelles qui allument le brt31eur. La production

d'etincelles se poursuit aussi Iongtemps que le bouton

de commande est tourne a <<LITE>>.

Lorsqu'on place le bouton de commande du brQleur du

four a la position d6siree, une barre d'allumage devient

incandescente (couleur orangee) et provoque

I'inflammation du gaz. II n'y a aucune formation

d'etincelles, et la barre d'allumage demeure

incandescente pendant le fonctionnement du brQleur.

--'_ ContrSler le OFF

cuisson. Appuyer sur le bouton et

le faire touner a la <<LITE>>.

La flamme devrait s'etablir en

moins de 4 secondes. Lors du _ " X/

premier allumage, on peut observer "_-

un delai de plus de 4 secondes, du "_% _ " ' _ _ _o

fait de la presence d'air darts la __o

canalisation de gaz.

fonctionnement des

brOleUrSpositiondela table de _ I f "_t t

25 ] Retirer la grille du four. Enlever le fond du

26 ]Contr61er le fonctionnement du brOleur du

temperature. Appuyer sur la touche START. On volt

apparakre <<LO>>puis <<170°F>>sur l'afficheur. Le brQleur

du four devrait s'allumer apr&s 50 & 60 secondes. Ce

d61ai est normal, l'ouverture de la vanne de securit6 du

four necessite un certain temps.

Des dispositifs d'allumage _lectrique sont utilis6s

pour I'allumage des brt]leurs du four et du gril.

On ne dolt pas ins6rer aucun objet dans I'ouverture

de la gaine protectrice qui entoure chaque dispositif

d'allumage.

N'effectuer aucun nettoyage dans cette zone.

27 ]Verifier qu'une flamme convenable s'etablit

vert de 1,3 cm (1/2 po), et une zone externe bleu

sombre; les petites flammes doivent 6tre nettes et

regulieres. IIne dolt pas y avoir de pointes jaunes ni de

separation entre les petites flammes et le brt31eur.

emplacement de

la virole vis de blocage

d'admission

dd'uairdu brQleur

four; placer le fond du four sur une surface

I

• proteg6e.

four. Appuyer sur la touche BAKE; on volt

I

• apparaftre <<350°F>> sur l'afficheur de

arri_re du four

dispositif

brQleur du four

sur le brQleur du four. Les petites flammes

• devraient comporter un c6ne interne bleu-

virole d'admission

d'air - tourner pour

ajuster pour une

flamme convenable

_3_ _ Contr61er le fonctionnement du brOleur du

sur I'afficheur de temperature. Appuyer sur la touche

START. Le br6leur du four devrait s'allumer apr&s 50

60 secondes. Ce d61ai est normal. IJouverture de la

vanne de securite du four necessite un certain temps.

Lors du premier allumage du brQleur du gril, on peut

observer un delai plus long, du fait de la presence d'air

dans la canalisation de gaz. Lors des premieres

utilisations du brQleur, on peut observer la formation

d'etincelles. Ceci est normal.

REMARQUE : Pour que le brQleur du gril fonctionne, il

faut que la porte du four soit fermee.

_31 _Observer les flammes du brQleur du gril &

uniforme autour de la surface du brQleur. On ne dolt pas

observer de pointes jaunes ou de separation entre les

petites flammes et le brQleur.

REMARQUE : Lors des premieres utilisations du brQleur

du gril, on peut observer des etincelles jaunes darts la

flamme. Ceci est normal; cette formation d'etincelles

disparaft apres quelques utilisations du brQleur.

3_ ppuyer sur la touche Cancel/Off. S'il est

concessionnaire KitchenAid ou un etablissement de

service autoris&

_33 _] Inserer le tiroir de remisage dans les rails de

pousser fermement pour fermer le tiroir.

gril. Fermer la porte du four. Appuyer sur la

touche BROIL; on volt apparaftre <<500°F>>

travers la fen6tre du four. Les petites

flammes doivent avoir une teinte bleu clair

necessaire d'effectuer un reglage de la

flamme du brt31eur du gril, contacter le

coulissement sur les c6tes du Iogement du

tiroir. Soulever legerement I'avant du tiroir;

ramener le bouton de commande & la

"_ i un brQleur ne s'allume pas correctement,

position d'arr6t OFR Verifier que le cordon

d'alimentation electrique est branche et que le fusible

n'est pas grille ou que le disjoncteur n'est pas ouvert.

Verifier que les robinets d'arr6t du gaz sont a la position

d'ouverture. R6peter I'etape 22. Si ace point un brOleur

ne peut s'allumer, contacter le concessionnaire

KitchenAid ou un etablissement de service autoris&

-_ eglage de la, hauteur des

devrait 6tre une flamme stable et bleue haute d'environ

0,64 cm (1/4 po). On peut regler la hauteur de la

flamme & I'aide de la vis de reglage au centre de la tige

du robinet. On trouve la tige de commande du robinet

directement sous le bouton de commande.

S'il est n_cessaire de r_gler la flamme & puissance

minimum :

a. Oter le bouton de commande.

b. Tenir la tige du robinet avec une pince.

Utiliser un petit tournevis a lame plate pour

faire tourner la vis de reglage situee au

centre de la tige du robinet, pour etablir

la taille correcte de la flamme.

c. Reinstaller le bouton de commande.

d. Tester le fonctionnement : faire

tourner le bouton de

commande de <<LO>>

(puissance minimum) a <<HI>>

(puissance maximum);

observer la flamme a chaque

position de reglage.

flammes oes oreleurs

La flamme du brQleur & BASSE puissance

reglage

vis d__ '_

oven burner

28 I s'il est necessaire d'ajuster la flamme du

de blocage et regler la position de la virole jusqu'a

I'etablissement de la flamme convenable. Resserrer la

vis de blocage.

29 ]Appuyer sur la touche Cancel/Off. Inserer les

sont correctement ins6r_s dans les fentes. Si le fond

du four n'est pas correctement positionn_, le

rendement de cuisson au four sera m6diocre.

Reinstaller les grilles du four.

four, identifier la virole d'admission d'air (a

I

• I'arriere du four, au centre). Desserrer la vis

onglets du fond du four dans les fentes pres

I

• du br01eur du four. V6rifier que les onglets

capuchon en

cuivre du gicleur

(ecrou)

Conversion pour

I'alimentation au gaz

propane

On ne dolt jamais entreprendre de convertir la

cuisini6re pour I'alimentation avec un autre gaz que

celui indiqu_ sur la plaque signal_tique sans avoir

d'abord consult_ le fournisseur de gaz. Un

n6cessaire de conversion au gaz propane est inclus

dans votre trousse de documentation.

Pour pouvoir utiliser cette nouvelle