KitchenAid KFGU766VSS00 Installation Guide

LPGAS AND HIGH ALTITUDECONVERSION INSTRUCTIONS

Conversion KitW10136725 forKFGUand KFGSModel Series

may result causing property damage, personal injury or death.

I WARNING: If the information in this manual is not followed exactly, a fire or explosion I

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

I

I

Gather the required tools and parts necessary for correct LP gas

conversion.

Tools needed

• Flat-blade screwdriver

• T20TORX _t screwdriver

• %2" (#0 [2 mm]) flat blade screwdriver (screwdriver shaft must

be a minimum of 11/8"[28.0 mm] long)

• Phillips screwdriver

• Adjustable wrench

• 7 mm nut driver

• 10 mm wrench

• 15 mm wrench

• 17 mm wrench

Parts supplied

• LP orifice package(8287082)

• Conversion instructions (8287002A)

• Conversion label (8287070)

High Altitude Conversion

To convert the cooktop for elevations above 6,560ft (1999.5 m),

order a High Altitude Conversion Kit.

• Part Number W10163349 - LP high altitude

• Part Number W10163727 - Natural gas high altitude

To order, see the "Assistance or Service" section of the Use and

Care Guide.

1-®TORX is a registered trademark of Textron Innovations Inc.

8287002A

IMPORTANT: Gas conversions from Natural gas to LP gas must

be done by a qualified installer. Before proceeding with

conversion, shut off the gas supply to the cooktop prior to

disconnecting the electrical power.

WARNING

This conversion kit shall be installed by a

qualified service agency in accordance

with the manufacturer's instructions and

all applicable codes and requirements of

the authority having jurisdiction. If the

information in these instructions is not

followed exactly, a fire, explosion or

production of carbon monoxide may

result causing property damage, personal

injury or loss of life. The qualified service

agency is responsible for the proper

installation of this kit. The installation is

not proper and complete until the

operation of the converted appliance is

checked as specified in the

manufacturer's instructions supplied with

this kit.

In the State of Massachusetts, the following installation

instructions apply:

[] Installations and repairs must be performed by a qualified

or licensed contractor, plumber, or gasfitter qualified or

licensed by the State of Massachusetts.

[] If using a ball valve, it shall be a T-handle type.

[] A flexible gas connector, when used, must not exceed

3 feet.

Explosion Hazard

Use a new CSA international approved gas supply line.

install a shut-off valve,

Securely tighten all gas connections.

if connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

1=

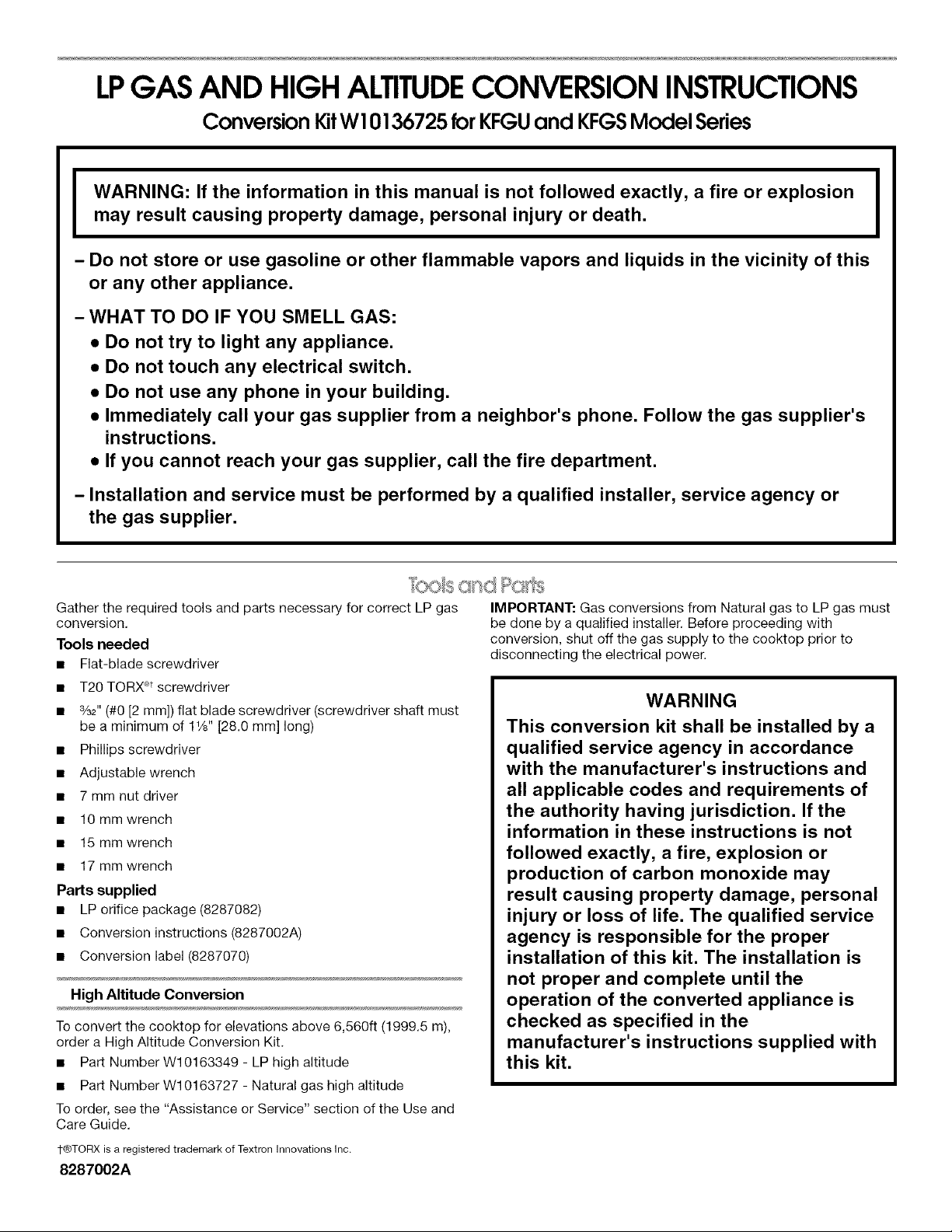

Turn manual shutoff valve to the closed position.

2.

Unplug cooktop or disconnect power.

To Convert Gas Pressure Regulator

A

C

D

A. Access cap

B. Rear of cooktop

C. Gas pressure regulator

D. Gas flow

3=

Determine the type of regulator you have:

Style 1: The cap has a slot and "NAT" printed on it.

Remove access cap by using a flat-blade screwdriver or

quarter, turning the access cap counterclockwise.

The gas pressure regulator has 2 settings that are stamped

on either side of the cap. Turn the cap and reinstall into

regulator with the stamp "LP" visible from the outside of the

regulator.

+1

Style 2: The cap does not have a slot and requires a wrench

to be removed.

Remove the access cap by using a wrench, turning the

access cap counterclockwise.

Remove spring retainer from the cap by pushing against the

flat side of the spring retainer. Look at the spring retainer to

locate the "NAT" or "LP" position. Turn over the spring

retainer so the "LP" is showing on the bottom. Snap the

spring retainer back into the cap. Reinstall the cap onto the

regulator.

.................................................................B

A

"__ ....................C

A. Tocooktop

B.Shutoff valve(closedposition)

C.Gassupply line

J

E D C

A. Access cap D. LP position

B. Gasket E. NAT position

C. Gas pressure regulator

4,

Test the gas pressure regulator and gas supply line.

The regulator must be checked at a minimum 1" (2.5 cm)

water column above the set pressure. The inlet pressure to

the regulator should be as follows for operation and checking

the regulator setting:

LP Gas:

Minimum pressure 10" (25.4 cm)W.C.R

Supply pressure 14" (35.5 cm) W.C.R

Gas Supply Pressure Testing

Line pressure testing above 1/2psi gauge (14" WCP)

The cooktop and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2psi (3.5 kPa).

Line pressure testing at 1/2psi gauge (14" WCP) or lower

The cooktop must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2psi (3.5 kPa).

5. If installed, remove the burner grates.

Use the following charts to match the correct gas orifice spud

with the burner location and model being converted.

LP Gas Orifice Spud Chart

Burner Stamp Size Inner Burner Stamp (A)and Size

Rating (A) (Center burners only)

5,000 BTU 066 0.66 mm

8,000 BTU 083 0.83 mm A

High Altitude Conversions

IMPORTANT: You must convert LP gas with LP gas high altitude

or Natural gas with Natural gas high altitude. If you need to

convert LP gas to Natural gas high altitude or Natural gas to LP

gas high altitude you must convert the pressure regulator, for this

you must follow steps 1, 2, and 3 of the respective conversion

that you need.

LP Gas Orifice Spud Chart for High Altitude Conversion

Burner Stamp Size Inner Burner Stamp (A)and Size

Rating (A) (Center burnersonly)

5,000 BTU 062 0.62 mrn

8,000 BTU 079 0.79 mm A

11,000BTU 092 0.92 mm ['-'_'_q

12,000BTU 093 0.93 mm 6 0.5*0.5 mm

14,000BTU 100 1.00mm 6 0.5*0.5 mm

16,000BTU 107 1.07 mm 6 0.5*0.5 mm A. Size stamp

Burner Models

Model Right Right Center Center Left Left

No. front rear (outer) (inner) front rear

KFGS106 079 092 093 6 079 062

KFGS166 092 079 100 6 092 062

KFGU7O6 079 092 093 6 079 092

KFGU766 092 079 107 6 092 062

11,000BTU 097 0.97 mm r,--_ _]

12,000BTU 099 0.99 mm 6 0.5*0.5 mm

14,000BTU 108 1.08mm 6 0.5*0.5 mm

16,000BTU

115 1.15 mm 6 0.5*0.5 mm A. Sizestamp

Burner Models

Model Right Right Center Center Left Left

No. front rear (outer) (inner) front rear

KFGS106 083 097 099 6 083 066

KFGS166 097 083 108 6 097 066

KFGU7O6 083 097 0949 6 083 066

KFGU766 097 083 115 6 097 066

Burner locations

B

A. Left front

B. Left rear

C. Center

D

D. Right rear

E. Right front

6. Remove all burner caps and burner bases. If necessary,

remove the burner ring.

A

B D

......................._O

8.

On KFGU models only, lift the front part of the cooktop and

unhook the wire harness to detach it from the glass control

panel of the metal cooktop.

On all models, remove the metal cooktop and the sheet of

insulation from the cooktop base.

C E

A. Burner cap

B. Igniter electrode

C. Burner base

D. Gas tube opening

E. Burner ring

7.

Using a T20 TORX®screwdriver, remove the orifice holder

screws (C).

A

\

C A B

C

A. Igniter electrode

B. Orifice holder

C. Orifice holder screws

D. Orifice spud

CC_ 0

A. Metal cooktop

B. Sheet of insulation

C. Cooktop base

<Cb

9. To Convert Right or Left Burners:

• Press 7 mm nut driver down onto the gas orifice spud and

remove by turning it counterclockwise and lifting out.

• Set gas orifice spud aside.

• Replace with correct LP gas orifice spud. See the LP Gas

Orifice Spud Charts.

10. To Convert Center Burners:

• Use 10 mm wrench to loosen and remove the orifice.

• Replace with correct LP gas orifice spud. See the LP Gas

Orifice Spud Charts.

• Use Phillips screwdriver to loosen the venturi screw. Slide

the brass venturi into the injector, stop at the first groove

(C). Securely tighten the venturi screw.

A. Orifice

B. Venturi

C. First Groove (16 mm LP gas

setting)

D. Second groove (12 mm Natural

gas setting)

E. Venturi screw

Use 15 mm wrench to loosen the nut securing the tube to

the adapter nut. Remove the tube from the adapter nut.

A

B C D

A. Tube

B. Attachment nut (15 mm)

• Use 17 mm wrench to loosen and remove the adapter

nut.

• Replace with correct LP gas orifice spud. See the LP Gas

Orifice Spud Charts.

• Replace adapter nut and secure with 17 mm nut.

Reattach tube and secure with 15 mm nut.

11. Place Natural gas orifice spuds in plastic parts bag for future

use and keep with literature package.

12. Replace sheet of insulation.

13. On KFGU models only, reattach wire harness to the control

panel on the cooktop glass.

14. Replace the metal cooktop and tighten all the screws to

secure cooktop to base.

15. Replace burner bases and tighten all the orifice screws.

Replace burner caps. If necessary, replace burner ring.

IMPORTANT: The igniter electrode is ceramic and could

break during conversion. Be sure that the electrode comes

through the hole in the burner head smoothly while tightening

screws.

i

C. Adapter nut (17 mm)

D. Orifice spud

A B

/

[

/

The gas pressure regulator has 2 settings which are stamped

on either side of the cap. Turn the cap and reinstall into

regulator with the stamp "NAT" visible from the outside of the

regulator.

÷1

Style 2: The cap does not have a slot and requires a wrench

to be removed.

Remove the access cap by using a wrench, turning the

access cap counterclockwise.

Remove spring retainer from the cap by pushing against the

flat side of the spring retainer. Look at the spring retainer to

locate the "LP" or "NAT" position. Turn over the spring

retainer so the "NAT" is showing on the bottom. Snap the

spring retainer back into the cap. Reinstall the cap onto the

regulator.

A

T B

E D C

A. Access cap D. NAT position

B. Gasket E.LP position

C. Gas pressure regulator

I

A. Burner cap

B. Electrode

C. Burner base

16. Open shutoff valve in the gas supply line. The valve is open

when the handle is parallel to the gas pipe.

17. Plug in cooktop or reconnect power.

REMEMBER: Once you have completed converting all the

cooktop burners, test the cooktop for leaks by brushing on

an approved noncorrosive leak-detection solution. Bubbles

will show, indicating a leak. Correct any leaks found.

1.

Turn manual shutoff valve to the closed position.

2.

Unplug cooktop or disconnect power.

3.

Determine the type of regulator you have:

Style 1: The cap has a slot and "LP" printed on it.

Remove access cap by using a flat-blade screwdriver or

quarter, turning the access cap counterclockwise.

......... _

'C

4. If they are installed, remove the burner grates.

Use the following charts to match the correct gas orifice spud

with the burner location and model being converted.

Natural Gas Orifice Spud Chart

Burner Stamp Size Inner BurnerStamp (A)and Size

Rating (A) (Center burners only)

6,000 BTU 110 1.10 mm

9,100 BTU 134 1.34 mm A

12,000BTU 155 1.55mm r_-_-]

15,000BTU 168 1.68mm 10 0.5*0.82 mm

18,000BTU 184 1.84mm 10 0.5"0.82mm

20,000 BTU

Burner Models

Model Right Right Center Center Left Left

No. front rear (outer) (inner) front rear

KFGS106 134 155 168 10 134 110

KFGS166 155 134 184 10 155 110

KFGU706 110 155 168 10 134 110

KFGU766 155 134 193 10 155 110

193 1.93 mm 10 0.5*0.82 mm A. Size stamp

High Altitude Conversions

6,

Using a T20 TORX ®screwdriver, remove the orifice holder

screws (C),

IMPORTANT: You must convert LP gas with LP gas high altitude

or Natural gas with Natural gas high altitude. If you need to

convert LP gas to Natural gas high altitude or Natural gas to LP

gas high altitude you must convert the pressure regulator, for this

you must follow steps 1, 2, and 3 of the respective conversion

that you need.

Natural Gas Orifice Spud Chart for High Altitude Conversion

Burner Stamp Size Inner Burner Stamp (A) and Size

Rating (A) (Center burners only)

6,000 BTU 105 1.05 mm

9,100 BTU 128 1.28 mm A

12,000BTU 148 1.48 mm r--.,_×-,1

15,000BTU 153 1.53 mm 10 0.5*0.82 mm*

18,000BTU 173 1.73 mm 10 0.5*0.82 mm*

20,000 BTU 183 1.83 mm 10 0.5*0.82 mm* A. Sizestamp

Burner Models

Model Right Right Center Center Left Left

No. front rear (outer) (inner) front rear

KFGSlO6 128 148 153 10 128 105

KFGS166 148 128 173 10 148 105

KFGU706 128 148 153 10 128 105

KFGU766 148 128 183 10 148 105

A C A B

A. Igniter electrode

B. Orifice spud

C. Orifice holder screws

D. Orifice holder

7,

On KFGU models only, lift the front part of the cooktop and

unhook the wire harness to detach it from the glass control

panel of the metal cooktop.

On all models, remove the metal cooktop and the sheet of

insulation from the cooktop base.

5. Remove all burner caps and burner bases. If necessary,

remove the burner ring.

A

A. Burner cap

B. Igniter electrode

C. Burner base

D. Gas tube opening

E. Burner ring

A

dCib

C ...................................

A. Metal cooktop

B.Sheet of insulation

C. Cooktop base

8. To Convert Right or Left Burners:

• Press 7 mm nut driver down onto the gas orifice spud and

remove by turning it counterclockwise and lifting out,

• Set gas orifice spud aside.

• Replace with correct Natural gas orifice spud. See the

Natural Gas Orifice Spud Charts.

9. To Convert Center Burners:

• Use 10 mm wrench to loosen and remove the orifice.

• Replace with correct Natural gas orifice spud. See the

Natural Gas Orifice Spud Charts.

Loading...

Loading...