Kitchenaid KFDD500ESS Installation

INSTALLATION INSTRUCTIONS

IMPORTANT:

Save for local electrical inspector's use.

IMPORTANT :

À conserver pour consultation par l'inspecteur local des installations électriques.

W10694070B

30" (76.2 CM) DOUBLE OVEN DUAL FUEL RANGES

INSTRUCTIONS POUR L’INSTALLATION DES CUISINIÈRES

À BI-COMBUSTIBLE ET FOUR DOUBLE DE 30" (76,2 CM)

Table of Contents Table des matières

RANGE SAFETY............................................................................. 2

INSTALLATION REQUIREMENTS ............................................... 4

Tools and Parts............................................................................ 4

Location Requirements ............................................................... 4

Electrical Requirements - U.S.A. Only ........................................ 6

Electrical Requirements - Canada Only...................................... 7

Gas Supply Requirements .......................................................... 7

INSTALLATION INSTRUCTIONS ................................................. 9

Unpack Range............................................................................. 9

Adjust Leveling Legs ................................................................... 9

Install Anti-Tip Bracket ................................................................ 9

Make Gas Connection............................................................... 10

Verify Anti-Tip Bracket Is Installed and Engaged ..................... 11

Level Range............................................................................... 11

Electronic Ignition System......................................................... 11

Complete Installation................................................................. 12

GAS CONVERSIONS ................................................................... 13

LP Gas Conversion.................................................................... 13

Natural Gas Conversion ............................................................ 15

Moving the Range ..................................................................... 16

SÉCURITÉ DE LA CUISINIÈRE................................................... 17

EXIGENCES D’INSTALLATION .................................................. 18

Outils et composants................................................................. 18

Exigences d'emplacement ........................................................ 19

Spécifications électriques.......................................................... 20

Spécifications de l’alimentation en gaz..................................... 21

INSTRUCTIONS D'INSTALLATION............................................ 22

Déballage de la cuisinière.......................................................... 22

Réglage des pieds de nivellement ............................................ 22

Installation de la bride antibasculement.................................... 23

Raccordement au gaz ............................................................... 23

Vérifier que la bride antibasculement est

bien installée et engagée........................................................... 24

Réglage de l'aplomb de la cuisinière ........................................ 25

Système d'allumage électronique............................................. 25

Achever l'installation.................................................................. 26

CONVERSIONS DE GAZ ............................................................. 27

Conversion pour l'alimentation au gaz propane ....................... 27

Conversion pour l'alimentation au gaz naturel.......................... 29

Déplacement de la cuisinière .................................................... 31

RANGE SAFETY

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

– Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch.

•

Do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

•

If you cannot reach your gas supplier, call the fire department.

– Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell gas” instructions.

IMPORTANT: Do not install a ventilation system that blows air downward toward this gas cooking appliance. This type of

ventilation system may cause ignition and combustion problems with this gas cooking appliance resulting in personal injury or

unintended operation.

2

In the State of Massachusetts, the following installation instructions apply:

■

Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

■

If using a ball valve, it shall be a T-handle type.

■

A flexible gas connector, when used, must not exceed 3 feet.

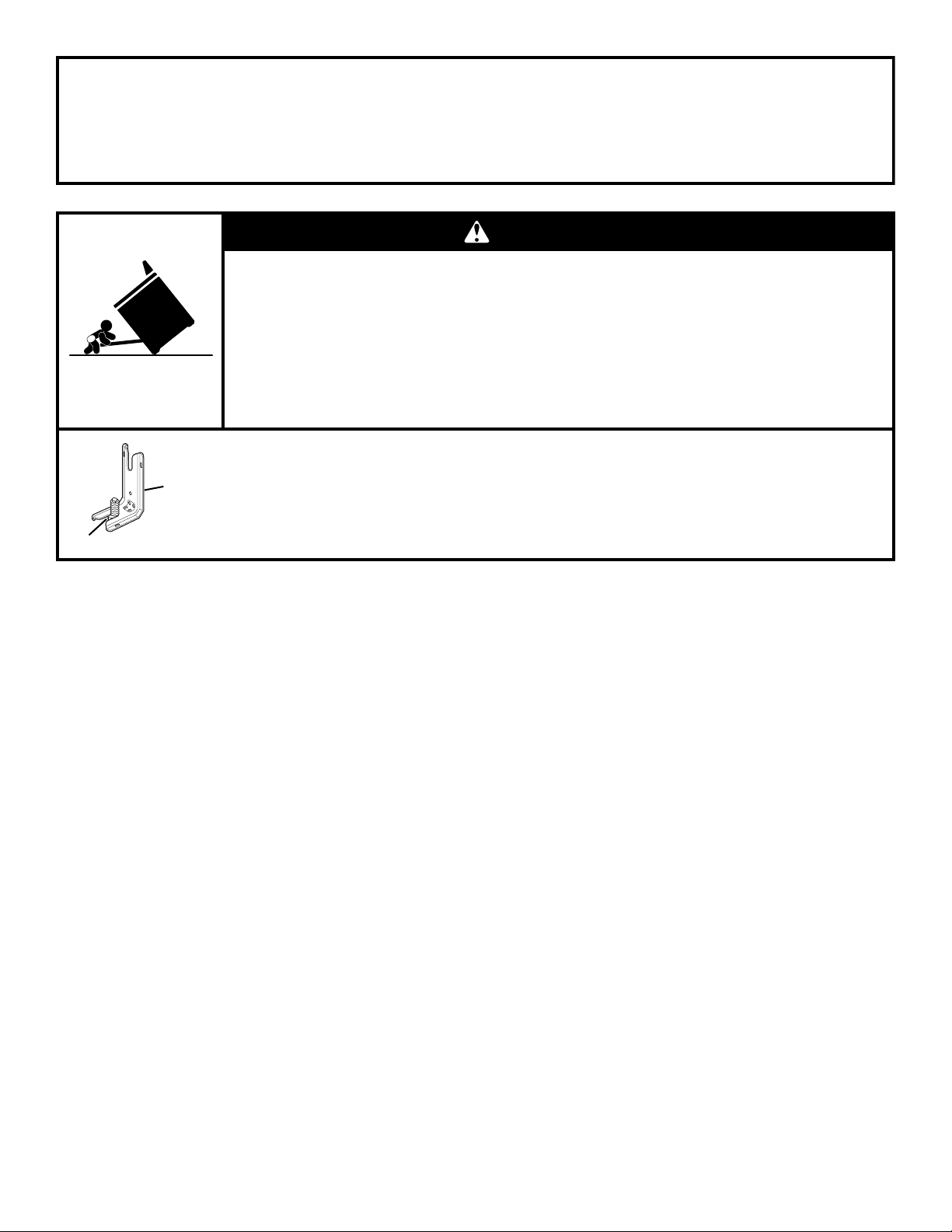

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation instructions.

Slide range back so rear range foot is engaged in the slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed and engaged.

Failure to follow these instructions can result in death or serious burns to children and adults.

To verify the anti-tip bracket is installed and engaged:

• Slide range forward.

• Look for the anti-tip bracket securely attached to floor or wall.

• Slide range back so rear range foot is under anti-tip bracket.

• See installation instructions for details.

WARNING

Anti-Tip

Bracket

Range Foot

3

INSTALLATION REQUIREMENTS

†®TORX and T20 are registered trademarks of Acument Intellectual Properties, LLC.

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools Needed

■ Tap e me as ure

■ Phillips screwdriver

®

■ T20

■ Flat-blade screwdriver

■ ¹⁄₈" (3.2 mm) flat-blade

Tor x

®†

screwdriver

screwdriver

■ Level

■ Hand or electric drill

■ Wrench or pliers

■ Pipe wrench

■ ¹⁵⁄₁₆" (2.4 cm) combination

wrench

■ ¹⁄₈" (3.2 mm) drill bit

Parts Supplied

Check that all parts are included.

■ LP/Natural Gas Conversion Kit (located on back of range near

lower side)

■ Burner grates

■ Burner caps

■ Oven racks

■ #12 x 1⁵⁄₈" (4.1 cm) screws (for mounting anti-tip bracket) (2)

■ Anti-tip bracket (taped inside upper oven with literature

package)

Anti-tip bracket must be securely mounted to the back wall or

floor. Thickness of flooring may require longer screws to

anchor bracket to subfloor. Longer screws are available from

your local hardware store.

Location Requirements

IMPORTANT: Observe all governing codes and ordinances. Do

not obstruct flow of combustion and ventilation air.

■ It is the installer’s responsibility to comply with installation

clearances specified on the model/serial/rating plate. The

model/serial/rating plate is located behind the control panel

and may be rotated up from behind the control panel for

viewing from the front of the range.

■ The range should be located for convenient use in the

kitchen.

■ Recessed installations must provide complete enclosure of

the sides and rear of the range.

■ ³⁄₈" (1 cm) nut driver

■ Marker or pencil

■ Pipe-joint compound

resistant to LP gas

■ Noncorrosive leak-detection

solution

For LP/Natural Gas

Conversions

■ ½" (1.3 cm) combination

wrench

■ ⁹⁄₃₂" (7.0 mm) nut driver

■ Masking tape

■ To eliminate the risk of burns or fire by reaching over heated

surface units, cabinet storage space located above the

surface units should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing a range hood

or microwave hood combination that projects horizontally a

minimum of 5" (12.7 cm) beyond the bottom of the cabinets.

■ All openings in the wall or floor where range is to be installed

must be sealed.

■ Do not seal the range to the side cabinets.

■ Cabinet opening dimensions that are shown must be used.

Given dimensions are minimum clearances.

■ The anti-tip bracket must be installed. To install the anti-tip

bracket shipped with the range, see “Install Anti-Tip Bracket”

section.

■ Grounded electrical supply is required. See the appropriate

“Electrical Requirements” section.

■ Proper gas supply connection must be available. See “Gas

Supply Requirements” section.

■ Contact a qualified floor covering installer to check that the

floor covering can withstand at least 200°F (93°C).

■ Use an insulated pad or ¼" (0.64 cm) plywood under range if

installing range over carpeting.

IMPORTANT: To avoid damage to your cabinets, check with your

builder or cabinet supplier to make sure that the materials used

will not discolor, delaminate or sustain other damage. This oven

has been designed in accordance with the requirements of UL

and CSA International and complies with the maximum allowable

wood cabinet temperatures of 194°F (90°C).

Mobile Home - Additional Installation Requirements

The installation of this range must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280). When such standard is not

applicable, use the Standard for Manufactured Home

Installations, ANSI A225.1/NFPA 501A or with local codes.

In Canada, the installation of this range must conform with the

current standards CAN/CSA-A240-latest edition, or with local

codes.

Mobile Home Installations Require:

■ When this range is installed in a mobile home, it must be

secured to the floor during transit. Any method of securing

the range is adequate as long as it conforms to the standards

listed above.

■ Four-wire power supply cord or cable must be used in a

mobile home installation.

4

Product Dimensions

C**

E***

D

F

A**

B*

B

D

C

E

A

F

G

H

I

J

K

L

8½"

(21.6 cm)

14"

(35.6 cm)

8½" (21.6 cm)**

gas line location

1½"

(3.8 cm)

1¼"*

(3.1 cm)

2¼" (5.7 cm)

***

L

A.

35³⁄₄

" ±

¹⁄₈

cooktop height (minimum)

with leveling legs screwed all

the way in**

B. Model/serial/rating plates

(located behind the control

panel)*

" (90.8 ± 0.3 cm)

*Model/serial/rating plates may be rotated up from behind the

control panel for viewing from the front of the range.

C.

47³⁄₈

" ±

¹⁄₈

overall height (minimum) with

leveling legs screwed all the

way in**

D.

28¹⁄₂

depth with handle

E.

26¹⁄₈

F.

29¹⁵⁄₁₆

width

" (120.3 ± 0.3 cm)

" ±

¹⁄₄

" (72.4 ± 0.6 cm)

" ±

¹⁄₈

" (66.4 ± 0.3 cm)***

" ±

¹⁄₁₆

" (76.0 ± 0.2 cm)

**Range can be raised approximately 1" (2.5 cm) by adjusting

the leveling legs.

***Excludes handle. Dimension given is from wall to front of oven

door and will vary based on electric outlet receptacle

installation.

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and 36"

(91.4 cm) countertop height.

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

Range may be installed with zero clearance to combustible

construction at the rear and on the sides below the cooktop.

A. 18" (45.7 cm) upper cabinet to countertop

B. 13" (33.0 cm) upper cabinet depth

C. 30" (76.2 cm) min. opening width

D. For minimum clearance to the top of the cooktop, see NOTE.

E. in U.S.A.: 30" (76.2 cm) min. opening width

in Canada: 31" (78.7 cm) min. opening width

F. 3" (7.6 cm) min. clearance from both sides of the range to the side

wall or other combustible material.

G. Cabinet door or hinges should not extend into the cutout.

H. 3" (7.6 cm) distance from wall

I. 1

¹⁄₂

" (3.8 cm) min. from right side cabinet

J. 8" (20.3 cm) width

K. 7" (17.8 cm) min. from floor

L. 2" (5.1 cm) min. from floor

*Drill on centerline 1¼" (3.1 cm) from rear wall for gas supply

line.

**Gas lines must be installed within the shaded area to ensure

proper alignment of this oven with cabinets.

***Recessed electrical plugs must be installed within the shaded

area to ensure proper alignment of this oven with cabinets.

NOTE: 24" (61.0 cm) minimum when bottom of wood or metal

cabinet is covered by not less than ¹⁄₄" (0.64 cm) flame retardant

millboard covered with not less than No. 28 MSG sheet steel,

0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the cooking

platform and the bottom of an uncovered wood or metal cabinet.

5

Electrical Requirements - U.S.A. Only

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

■ This range is manufactured with a 4-wire power supply cord

rated at 240 volts, 40 amps, rated at 194°F (90°C) and

investigated for use with this range.

Range Rating* Specified Rating of Power

120/240 Volts 120/208 Volts Amps Temp Rating

Supply Cord Kit and

Circuit Protection

Be sure that the electrical connection and wire size are adequate

and in conformance with the National Electrical Code, ANSI/

NFPA 70-latest edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

WARNING: Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a

qualified electrician or service technician if you are in doubt as to

whether the appliance is properly grounded. Do not modify the

power supply cord plug. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Electrical Connection

Check local codes and consult gas supplier. Check existing

electrical supply and gas supply. See “Gas Supply

Requirements” sections.

It is recommended that all electrical connections be made by a

licensed, qualified electrical installer.

■ Range must be connected to the proper electrical voltage

and frequency as specified on the model/serial/rating plate.

The model/serial/rating plate is located on the right vertical

surface of the oven door frame. Refer to the illustrations in the

“Product Dimensions” section of the “Location

Requirements” section.

8.8 - 16.5 kW

16.6 - 22.5 kW

*The NEC calculated load is less than the total connected load

listed on the model/serial rating plate.

■ When a 4-wire, single phase 240 volt, 60 Hz., AC only

electrical supply is available, a 40-amp minimum circuit

protection is required on 30" (76.2 cm) ranges, fused on both

sides of the line.

■ A time-delay fuse or circuit breaker is recommended.

■ This range is equipped with a UL or CSA International

Certified Power Cord intended to be plugged into a standard

14-50R wall receptacle. Be sure the wall receptacle is within

reach of range’s final location.

■ Do not use an extension cord.

■ The wiring diagram is located on the back of the range or in a

clear plastic bag.

7.8 - 12.5 kW

12.6 - 18.5 kW

40 or 5050194°F (90°C)

194°F (90°C)

6

Electrical Requirements - Canada Only

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Be sure that the electrical connection and wire size are adequate

and in conformance with the CSA Standard C22.1, Canadian

Electrical Code, Part 1 - latest edition, and all local codes and

ordinances.

A copy of the above code standards can be obtained from:

Canadian Standards Association

178 Rexdale Blvd.

Toronto, ON M9W 1R3 CANADA

■ Check with a qualified electrical installer if you are not sure

the range is properly grounded.

Range Rating* Specified Rating of Power

Supply Cord Kit and

Circuit Protection

120/240 Volts 120/208 Volts Amps Temp Rating

8.8 - 16.5 kW

16.6 - 22.5 kW

*The NEC calculated load is less than the total connected load

listed on the model/serial/rating plate.

■ When a 4-wire, single phase 250 volt, 60 Hz., AC only

electrical supply is available, a 40-amp minimum circuit

protection is required on 30" (76.2 cm) ranges, fused on both

sides of the line.

■ A time-delay fuse or circuit breaker is recommended.

■ This range is equipped with a UL or CSA International

Certified Power Cord intended to be plugged into a standard

14-50R wall receptacle. Be sure the wall receptacle is within

reach of range’s final location.

7.8 - 12.5 kW

12.6 - 18.5 kW

40 or 5050194°F (90°C)

194°F (90°C)

Gas Supply Requirements

Observe all governing codes and ordinances.

IMPORTANT: This installation must conform with all local codes

and ordinances. In the absence of local codes, installation must

conform with American National Standard, National Fuel Gas

Code ANSI Z223.1 - latest edition or CAN/CGA B149 - latest

edition.

IMPORTANT: Leak testing of the range must be conducted

according to the manufacturer’s instructions.

Type of Gas

Natural Gas:

■ This range is factory set for use with Natural gas. See “Gas

Conversions” section. The model/serial/rating plate located

behind the control panel has information on the types of gas

that can be used. If the types of gas listed do not include the

type of gas available, check with the local gas supplier.

LP Gas Conversion:

Conversion must be done by a qualified service technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial/rating plate for use with a different

gas without consulting the serving gas supplier. See “Gas

Conversions” section.

■ Do not use an extension cord.

■ The wiring diagram is located on the back of the range or in a

clear plastic bag.

7

Gas Supply Line

†®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

A

B

C

Gas Pressure Regulator

■ Provide a gas supply line of ¾" (1.9 cm) rigid pipe to the

range location. A smaller size pipe on longer runs may result

in insufficient gas supply. With LP gas, piping or tubing size

can be ½" (1.3 cm) minimum. Usually, LP gas suppliers

determine the size and materials used in the system.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON®† tape.

Flexible Metal Appliance Connector:

■ If local codes permit, a new CSA design-certified, 4 to 5 ft

(122 to 152.4 cm) long, ½" or ¾" (1.3 or 1.9 cm) I.D.

(inside diameter), flexible metal appliance connector may

be used for connecting range to the gas supply line.

■ A ½" (1.3 cm) male pipe thread is needed for connection

to the female pipe threads of the inlet to the appliance

pressure regulator.

■ Do not kink or damage the flexible metal tubing when

moving the range.

■ Must include a shutoff valve:

The supply line must be equipped with a manual shutoff

valve. This valve should be located in the same room but

external to the range, such as an adjacent cabinet. It should

be in a location that allows ease of opening and closing. Do

not block access to shutoff valve. The valve is for turning on

or shutting off gas to the range.

A. Gas supply line

B. Shutoff valve “open” position

C. To range

The gas pressure regulator supplied with this range must be

used. The inlet pressure to the regulator should be as follows for

proper operation:

Natural Gas:

Minimum pressure: 5" WCP

Maximum pressure: 14" WCP

LP Gas:

Minimum pressure: 11" WCP

Maximum pressure: 14" WCP

Contact local gas supplier if you are not sure about the inlet

pressure.

Burner Input Requirements

Input ratings shown on the model/serial/rating plate are for

elevations up to 2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced at a

rate of 4% for each 1,000 ft (304.8 m) above sea level (not

applicable for Canada).

Gas Supply Pressure Testing

Gas supply pressure for testing regulator must be at least

1" water column pressure above the manifold pressure shown on

the model/serial rating plate.

Line Pressure Testing above ½ psi Gauge (14" WCP)

The range and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of ½ psi (3.5 kPa).

Line Pressure Testing at ½ psi Gauge (14" WCP) or Lower

The range must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to

or less than ½ psi (3.5 kPa).

8

INSTALLATION INSTRUCTIONS

WARNING

Excessive Weight Hazard

Use two or more people to move and install range.

Failure to do so can result in back or other injury.

WARNING

Tip Over Hazard

A child or adult can tip the range and be killed.

Install anti-tip bracket to floor or wall per installation

instructions.

Slide range back so rear range foot is engaged in the

slot of the anti-tip bracket.

Re-engage anti-tip bracket if range is moved.

Do not operate range without anti-tip bracket installed

and engaged.

Failure to follow these instructions can result in death

or serious burns to children and adults.

A

B

C

Unpack Range

1. Remove shipping materials, tape and film from the range.

Keep cardboard bottom under range.

2. Remove oven racks and parts package from inside oven.

3. To place range on its back, take 4 cardboard corners from the

carton. Stack one cardboard corner on top of another.

Repeat with the other 2 corners. Place them lengthwise on

the floor behind the range to support the range when it is laid

on its back.

4. Using 2 or more people, firmly grasp the range and gently lay

it on its back on the cardboard corners.

5. Pull cardboard bottom firmly to remove.

6. Use an adjustable wrench to loosen the leveling legs.

7. Place cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto cardboard or

hardboard.

Adjust Leveling Legs

1. If range height adjustment is necessary, use a wrench or

pliers to loosen the 4 leveling legs.

This may be done with the range on its back or with the range

supported on 2 legs after the range has been placed back to

a standing position.

NOTE: To place range back up into a standing position, put a

sheet of cardboard or hardboard in front of range. Using 2 or

more people, stand range back up onto the cardboard or

hardboard.

2. Adjust the leveling legs to the correct height. Leveling legs

can be loosened to add up to a maximum of 1" (2.5 cm). A

minimum of ³⁄₁₆" (5.0 mm) is needed to engage the anti-tip

bracket.

NOTE: If height adjustment is made when range is standing,

tilt the range back to adjust the front legs, then tilt forward to

adjust the rear legs.

3. When the range is at the correct height, check that there is

adequate clearance under the range for the anti-tip bracket.

Before sliding range into its final location, check that the antitip bracket will slide under the range and onto the rear

leveling leg prior to anti-tip bracket installation.

Install Anti-Tip Bracket

1. Remove the anti-tip bracket that is taped inside the upper

oven with the package containing literature.

2. Determine which mounting method to use: floor or wall.

If you have a stone or masonry floor, you can use the wall

mounting method.

3. Determine and mark edge of range in the cutout space. The

mounting bracket can be installed on either the left side or

right side of the cutout. Position mounting bracket in cutout

so that right (or left) edge of the bracket is ¹⁵⁄₁₆" (2.4 cm) from

the marked edge of the range, as shown.

A. Anti-tip bracket

B. Mark edge of range.

C.

¹⁵⁄₁₆

" (2.4 cm)

9

4. Drill two ¹⁄₈" (3.0 mm) holes that correspond to the bracket

A

B

A

B

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

A

B

C

D

E

F

G

H

A

B

holes of the determined mounting method. See the following

illustrations.

Floor Mounting Wall Mounting

3. Use a ¹⁵⁄₁₆" combination wrench and an adjustable wrench to

attach the flexible connector to the adapters.

IMPORTANT: All connections must be wrench-tightened. Do

not make connections to the gas regulator too tight. Making

the connections too tight may crack the regulator and cause

a gas leak. Do not allow the regulator to turn when tightening

fittings.

A. #12 x 1

B. Anti-tip bracket

5. Using the two #12 x 1⁵⁄₈" (4.1 cm) Phillips-head screws

provided, mount anti-tip bracket to the wall or floor.

⁵⁄₈

" screws (4.1 cm)

A. #12 x 1

B. Anti-tip bracket

⁵⁄₈

Make Gas Connection

Typical Flexible Connection

1. Apply pipe-joint compound made for use with LP gas to the

smaller thread ends of the flexible connector adapters (see B

and G in the following illustration).

2. Attach one adapter to the gas pressure regulator and the

other adapter to the gas shutoff valve. Tighten both adapters,

being certain not to move or turn the gas pressure regulator.

10

" screws (4.1 cm)

A. Gas pressure regulator

B. Use pipe-joint compound.

C. Adapter (must have ½" male

pipe thread)

D. Flexible connector

4. Gas supply pipe must be located within clearance area as

shown in the “Cabinet Dimensions” illustration in “Location

Requirements” section.

5. Plug in range to a grounded outlet. See the appropriate

“Electrical Requirements” section.

6. Slide range into place so that the rear range foot is inserted

into the slot of the anti-tip bracket.

E. Manual gas shutoff valve

F. ½" or ¾" gas pipe

G. Use pipe-joint compound.

H. Adapter

Complete Connection

1. Open the manual shutoff valve in the gas supply line. The

valve is open when the handle is parallel to the gas pipe.

A. Closed valve

B. Open valve

2. Test all connections by brushing on an approved

noncorrosive leak-detection solution. If bubbles appear, a

leak is indicated. Correct any leak found.

3. Remove cooktop burner caps and grates from parts

package. Align recess in burner caps with pins in burner

base. Burner caps should be level when properly positioned.

If burner caps are not properly positioned, surface burners

will not light. Place burner grates over burners and caps.

Loading...

Loading...