Page 1

KAC-34

TECHNICAL EDUCATION

SELF-CLEANING

SLIDE-IN ELECTRIC

RANGE

Models KESC300H, KESC307H, KESH307H

JOB AID 4317335

Page 2

FORWARD

This KitchenAid Job Aid, “Self-Cleaning Slide-In Electric Range,” (Part No. 4317335), provides the

technician with information on the installation, operation, and service of the Self-Cleaning SlideIn Electric Range. It is to be used as a training Job Aid and Service Manual. For specific information

on the model being serviced, refer to the “Use and Care Guide,” or “Wiring Diagram” provided with

the electric range.

The Wiring Diagram and Strip Circuits used in this Job Aid are typical and should be used for

training purposes only. Always use the Wiring Diagram supplied with the product when servicing

the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the KitchenAid Self-Cleaning Slide-In Electric Range.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the range to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made

on our products by anyone other than Authorized Service Technicians.

Copyright © 2002, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

Page 3

TABLE OF CONTENTS

Page

GENERAL............................................................................................................................... 1-1

Safety First......................................................................................................................... 1-1

KitchenAid Model & Serial Number Designations.............................................................. 1-3

Model & Serial Number Label Location ............................................................................. 1-4

Specifications..................................................................................................................... 1-5

KitchenAid Electric Range Warranty.................................................................................. 1-7

INSTALLATION INFORMATION ........................................................................................... 2-1

Electrical Supply Requirements ......................................................................................... 2-1

Moving The Range ............................................................................................................ 2-8

THEORY OF OPERATION ..................................................................................................... 3-1

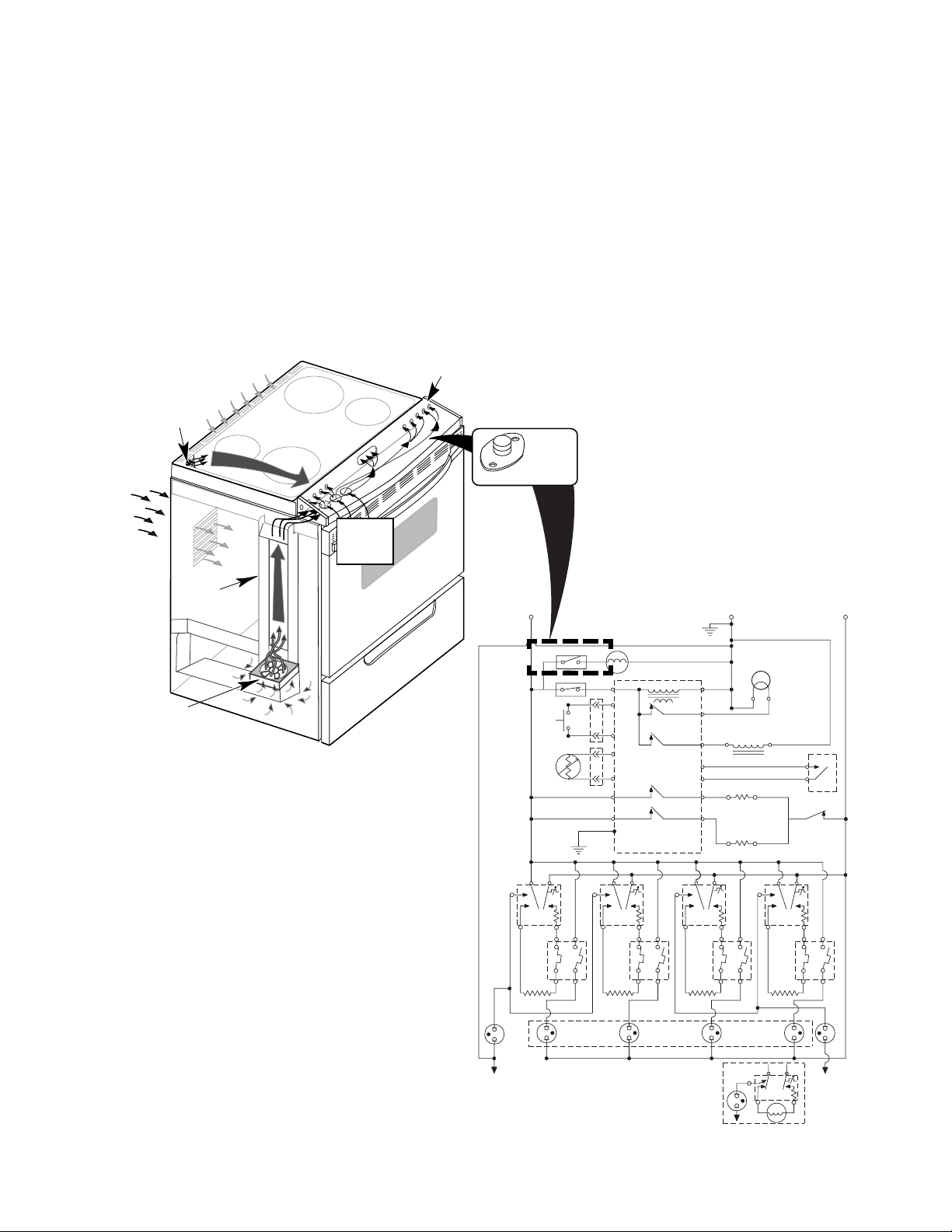

Air Flow—Rear Panel ........................................................................................................ 3-1

Cooling Fan Air Flow ......................................................................................................... 3-2

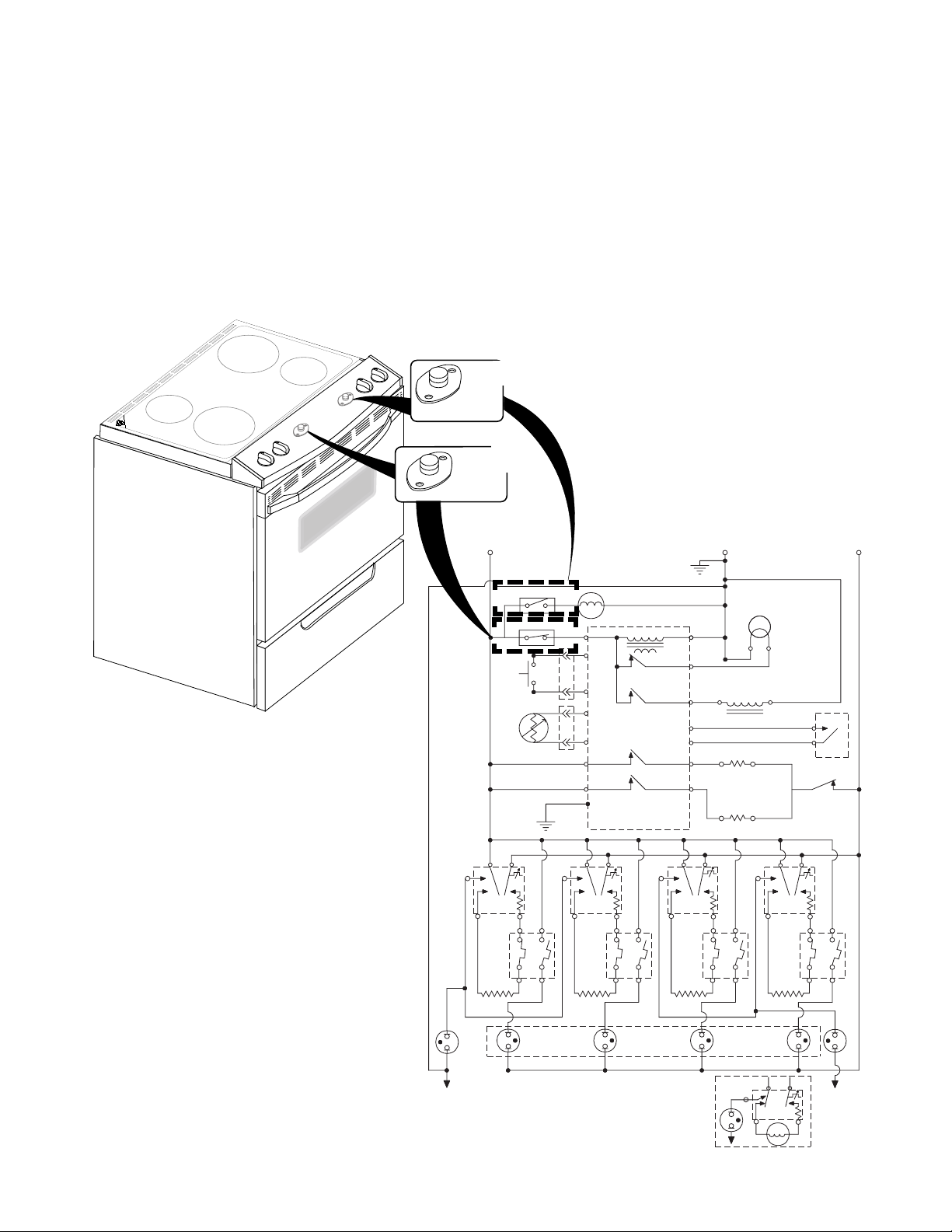

The Bimetal Switches ........................................................................................................ 3-3

The Surface Element Limiter ............................................................................................. 3-4

The Door Lock Solenoid & Door Latch Switch................................................................... 3-5

How The Self-Clean Cycle Works ..................................................................................... 3-6

COMPONENT ACCESS ......................................................................................................... 4-1

Component Locations ........................................................................................................ 4-1

Removing The Control Panel, An Infinite Switch & Bimetal Switch ................................... 4-2

Removing The Electronic Oven Control And An Indicator Light ........................................ 4-4

Removing An Element & Limiter And The Hot Surface Indicator Assembly ...................... 4-5

Removing The Cooktop Glass ........................................................................................... 4-7

Removing The Door Latch Assembly & The Door Switch ............................................... 4-10

Removing The Dual Broil Element And The Hidden Bake Element ................................ 4-12

Removing The Convection Bake Element & Fan Motor .................................................. 4-14

Removing An Oven Light Socket Assembly .................................................................... 4-16

Removing The Meat Probe Jack ..................................................................................... 4-17

Removing The Oven Temperature Sensor ...................................................................... 4-18

Removing A Side Panel ................................................................................................... 4-19

Removing The Double Line Break (DLB) Relay And The Cooling Fan Motor ................ 4-20

Removing The Oven Door ............................................................................................... 4-22

Removing The Decorative Glass, The Oven Door Handle, The Hinges,

And The Oven Door Glass........................................................................................... 4-23

Removing The Oven Door Gasket................................................................................... 4-25

- iii -

Page 4

Page

COMPONENT TESTING ........................................................................................................ 5-1

Bimetal Switch ................................................................................................................... 5-1

Single Element Infinite Switches........................................................................................ 5-2

Dual Element Infinite Switch (Optional) ............................................................................. 5-3

Surface Elements & Limiters ............................................................................................. 5-4

Door Switch ....................................................................................................................... 5-6

Door Latch Assembly......................................................................................................... 5-6

Hidden Bake Element ........................................................................................................ 5-7

Dual Broil Element ............................................................................................................. 5-7

Convection Bake Element ................................................................................................. 5-8

Convection Fan Motor ....................................................................................................... 5-8

Oven Temperature Sensor ................................................................................................ 5-9

Cooling Fan Motor ............................................................................................................. 5-9

Double Line Break (DLB) Relay....................................................................................... 5-10

DIAGNOSIS & TROUBLESHOOTING ................................................................................... 6-1

Diagnosis ........................................................................................................................... 6-1

Failure / Error Display Codes—Tech Sheet #9753028, Rev. B ..................................... 6-1

Fault Error Code Charts................................................................................................ 6-2

Troubleshooting Charts ..................................................................................................... 6-3

Oven Temperature Calibration .......................................................................................... 6-6

WIRING DIAGRAM & STRIP CIRCUITS ............................................................................... 7-1

Wiring Diagram— #9753028, Rev. B................................................................................. 7-1

Strip Circuits ...................................................................................................................... 7-3

- iv -

Page 5

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always

read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance

of injury, and tell you what can happen if the instructions are not followed.

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

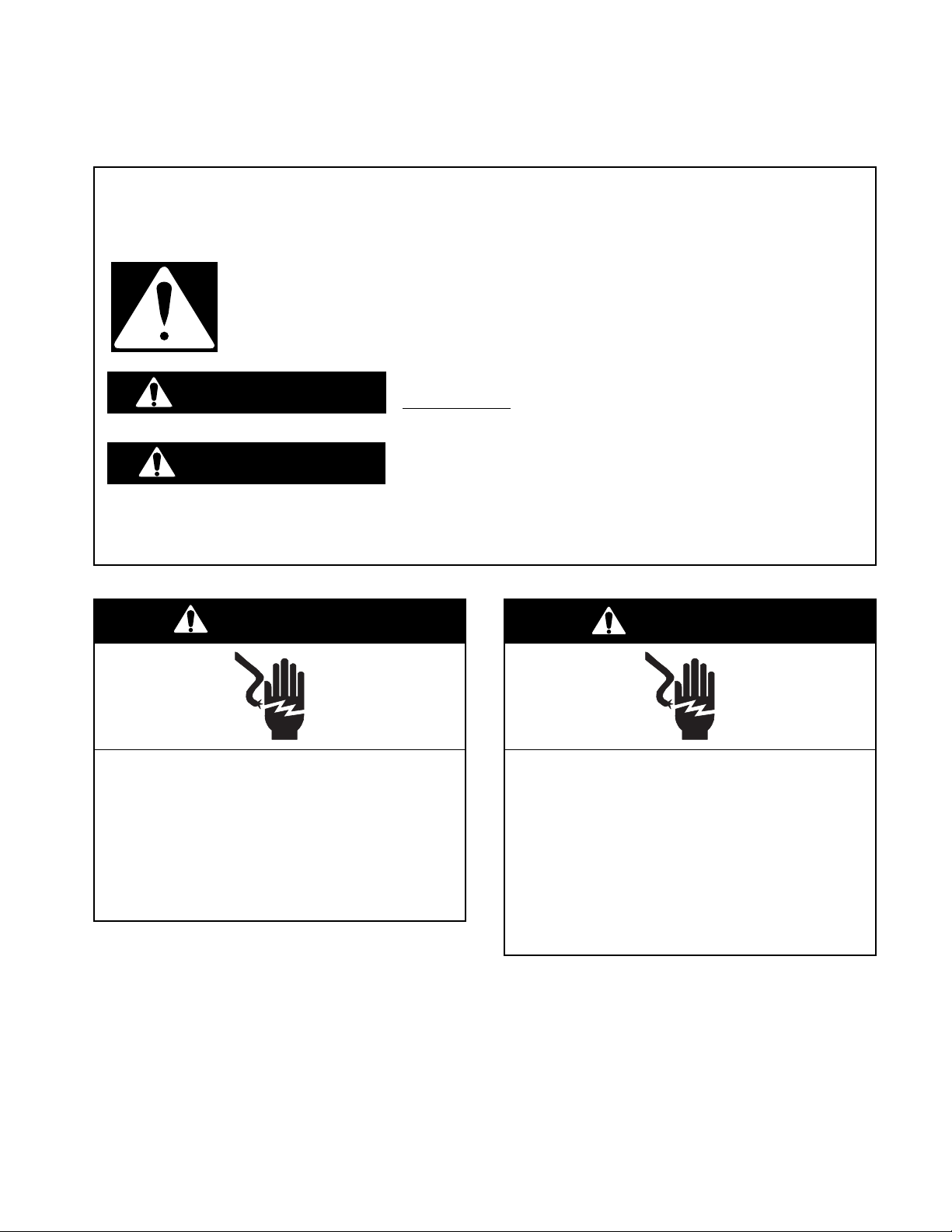

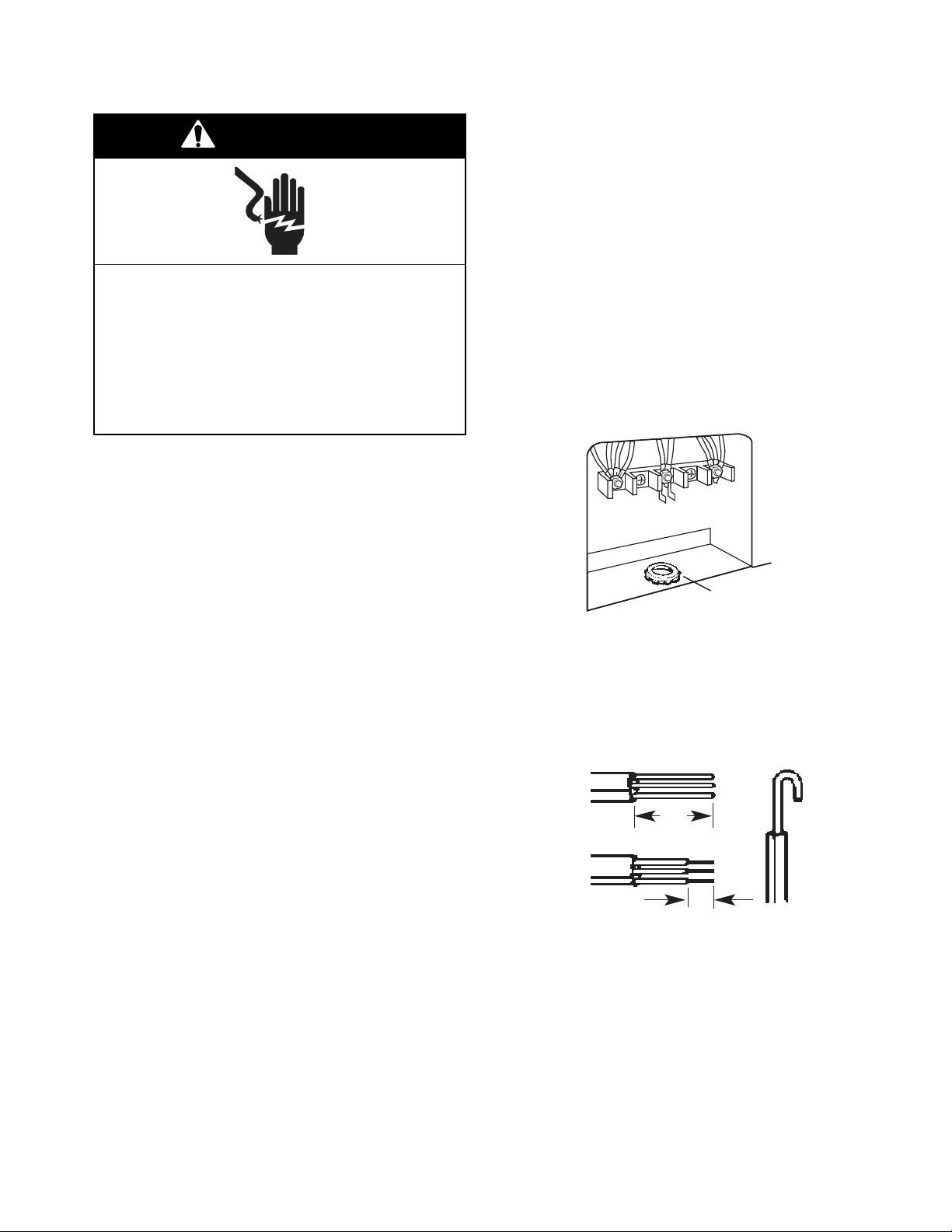

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

WARNING

Electrical Shock Hazard

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

1-1

Page 6

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere.

ESD may damage or weaken the electronic control assembly. The new control

assembly may appear to work well after

repair is finished, but failure may occur at

a later date due to ESD stress.

• Use an antistatic wrist strap. Connect the

wrist strap to the green ground connection point, or to an unpainted metal surface in the appliance.

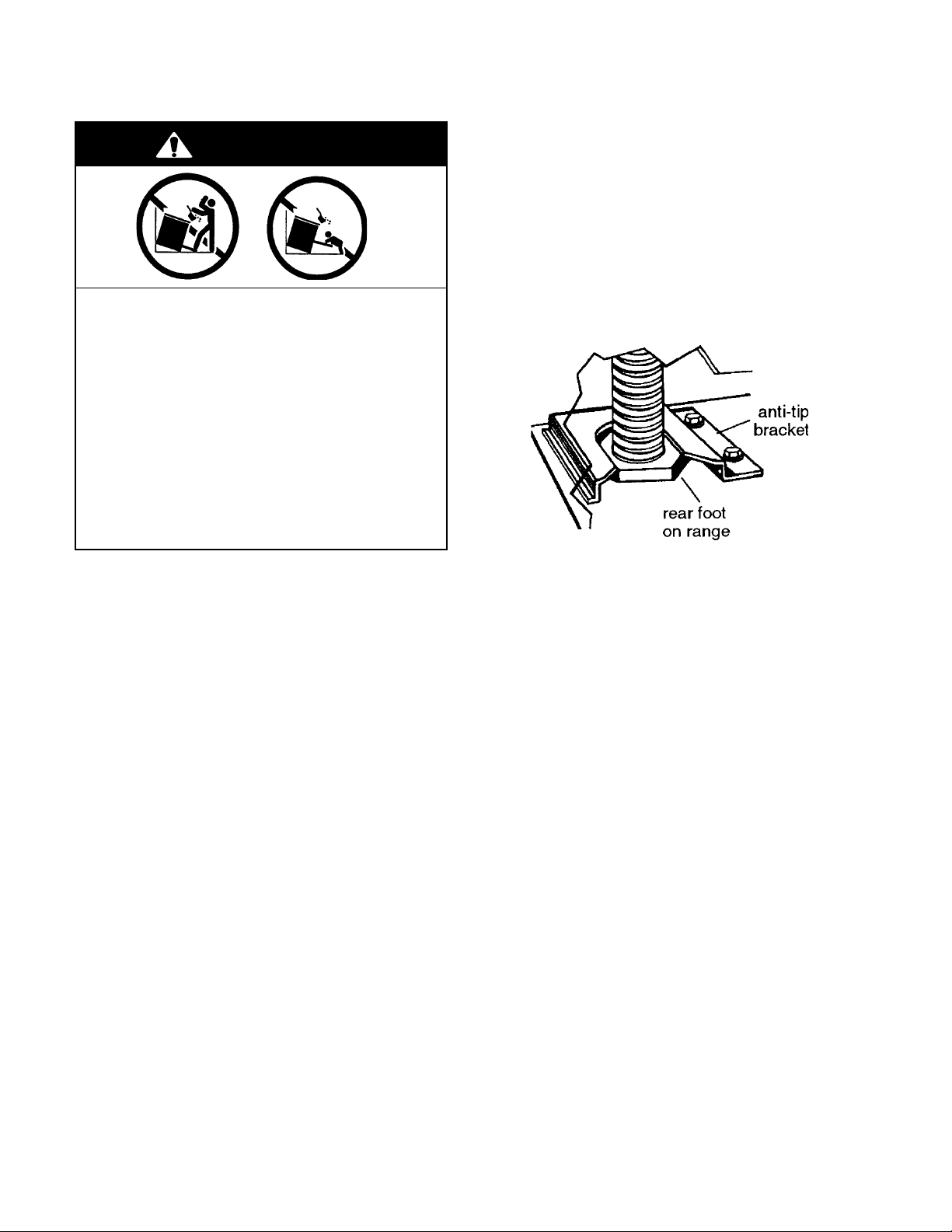

WARNING

Tip-Over Hazard

A child or adult can tip the range

and be killed.

Connect anti-tip bracket to rear

range foot.

Reconnect the anti-tip bracket, if the

range is moved.

Failure to follow these instructions

can result in death or serious burns

to children and adults.

- OR -

• Touch your finger repeatedly to a green

ground connection point, or to an unpainted metal surface in the appliance.

• Before removing the part from its package, touch the antistatic bag to a green

ground connection point, or to an unpainted metal surface in the appliance.

• Avoid touching electronic parts, or terminal contacts. Handle the electronic control assembly by the edges only.

• When repackaging the failed electronic

control assembly in an antistatic bag,

observe the previous instructions.

1-2

Page 7

KITCHENAID MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER K ES C 30 0 H BL 4

INTERNATIONAL SALES IND.

OR MARKETING CHANNEL

IF PRESENT

PRODUCT GROUP

K = KITCHENAID

PRODUCT IDENTIFICATION

DD = DUAL FUEL DROP-IN / SLIDE-IN

DR = DUAL FUEL RANGE

ED = ELECTRIC DROP-IN RANGE

EE = ELECTRIC EYE-LEVEL RANGE

ER = ELECTRIC STANDARD RANGE

ES = ELECTRIC SLIDE-IN RANGE

GD = GAS DROP-IN RANGE

GE = GAS EYE-LEVEL RANGE

GR = GAS STANDARD RANGE

GS = GAS SLIDE-IN RANGE

MERCHANDISING SCHEME

C = CERAMIC GLASS TOP

H = CERAMIC W/HALOGEN

I = IMPERIAL

P = PROFESSIONAL / COMMERCIAL

S = STANDARD

T = TEMPERED GLASS TOP

CAPACITY / SIZE / SERIES / CONFIGURATION

1ST POSITION 2ND POSITION

1 = DROP-IN 0 = 30″ WIDE

2 = DROP-IN / SLIDE-IN COMBO 6 = 36″ WIDE

3 = SLIDE-IN

4 = COMMERCIAL

5 = STANDARD

7 = EYE-LEVEL

8 = 48″

9 = 60″

FEATURES

0 = STANDARD FEATURES

2 = PLUS FEATURES OR SEALED BURNERS

W / GRILL / CONVECTION OVEN

3 = SEALED BURNERS W / GRIDDLE / CONVECTION OVEN

4 = SEALED BURNERS W / GRILL & GRIDDLE / CONVECTION OVEN

5 = DELUXE FEATURES

7 = DELUXE FEATURES / CONVECTION OR

SEALED BURNERS / CONVECTION OVEN

YEAR OF INTRODUCTION

H = 1999, J = 2000, K= 2001, L - 2002

COLOR CODE

BL = BLACK, WH = WHITE, BT = BISCUIT

BS = BLACK ON STAINLESS

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER

SERIAL NUMBER IM K 3 1 73981

MANUFACTURING SITE

IM = MONTMAGNY

YEAR OF PRODUCTION

K = 2000, L = 2001, M = 2002

WEEK OF PRODUCTION

31 = 31ST WEEK

PRODUCT SEQUENCE NUMBER

1-3

Page 8

MODEL & SERIAL NUMBER LABEL LOCATION

The Model/Serial Number label location is shown below.

Model & Serial Number Location

(Located Behind Storage Drawer)

1-4

Page 9

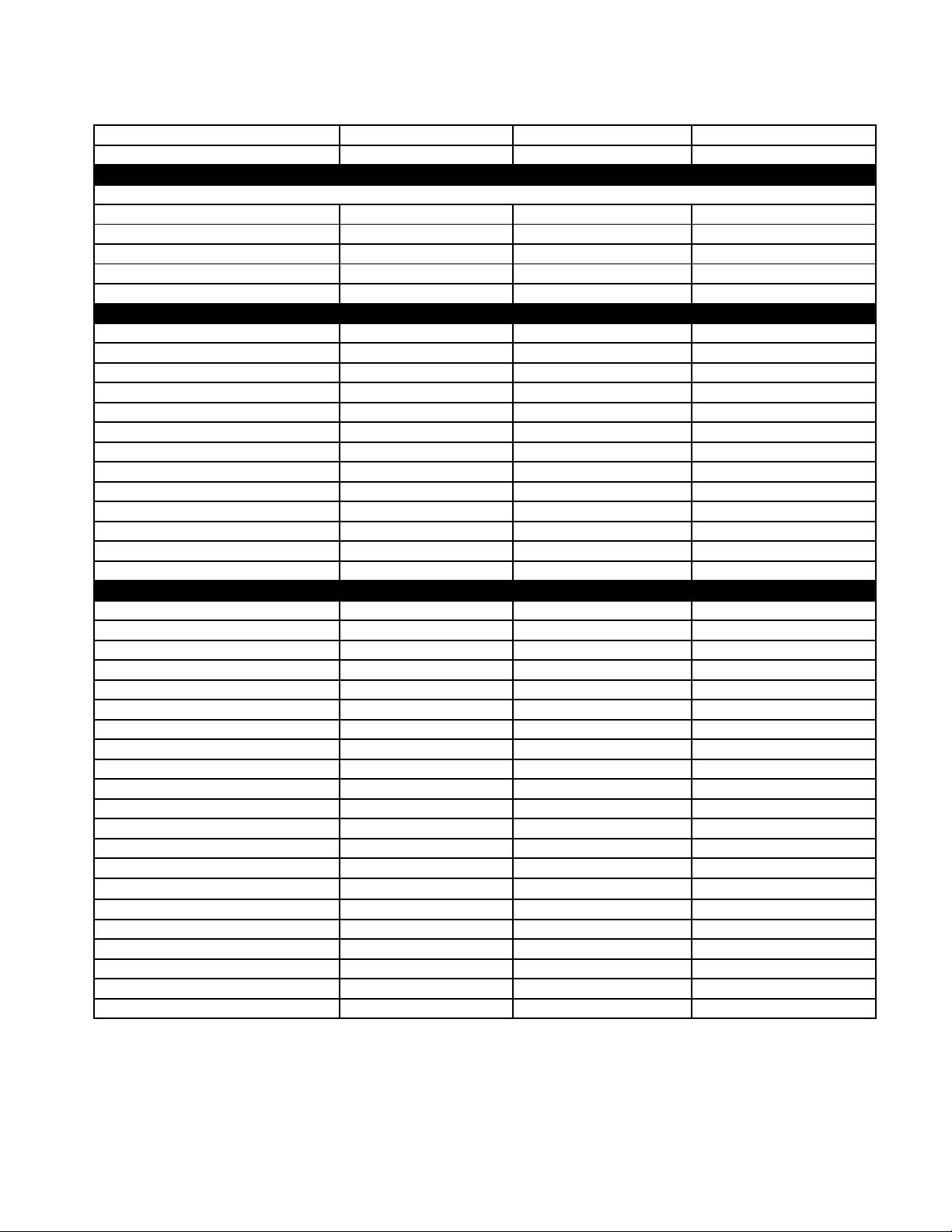

SPECIFICATIONS

Model

Model Description

Dimensions/Specifications

Exterior Dimensions

Height To Maintop (in)

Overall Depth Inc Hrdwr/Hndl (in)

Depth Without Handle (in)

Door Swing (in)

Shipping Weight (lbs)

Exterior

Cabinet Finish

Front Frame

Leveling Legs

Oven Window Size and Type

Removable Door and Hinges

Door Liner Finish

Door Type

Control Panel Location

Control Panel Color

Control Panel Construction

Control Knob Type, #, Fcn

Simmer Specialty Switch

Keep Warm Switch

Cooktop Features

Cooktop Material

Hot Surface Indicator

Burner Box Finish

Cooktop Support Rods

Electric Cooktop Element

Electric Element Configuration

Electric Element Type

Electric Right Front Size

Electric RF Output (w@240/208v)

Electric Left Front Size

Electric LF Output (w@240/208v)

Electric Right Rear Size

Electric RR Output (w@240/208v)

Electric Left Rear Size

Electric LR Output (w@240/208v)

Oven Controls

Oven Control Type

Oven Control Location

Control Lock Out

Delayed Cooking Option

Timer

KESC300H WH/BL/BT KESC307H WH/BT/BS KESH307H WH/BL/BS

Slide-In Slide-In Slide-In Radiant/Halogen

36" 36" 36"

26.75" 26.75" 26.75"

24.5" 24.5" 24.5"

21.75" 21.75" 21.75"

160 160 160

Painted Painted Painted

Porcelain Porcelain Porcelain

Yes Yes Yes

Large/Glass Large/Glass Large/Glass

Yes Yes Yes

Porcelain Porcelain Porcelain

Glass Glass Glass

Front Front Front

White White White

Glass Glass Glass

Infinite Switch Single Blade Infinite Switch Single Blade Infinite Switch Single Blade

Yes Yes Yes

Yes Yes Yes

Ceran Top Ceran Top Ceran Top

4 Neon Cluster 4 Neon Cluster 4 Neon Cluster

Galvanized Galvanized Galvanized

No No No

Yes Yes Yes

6", 7", 8", 9.5" 6", 7", 8", 9.5" 6", 7", 8", 9.5"

Radiant Radiant Radiant

7" 7" 7"

1800W 1800W 1800W/Halogen

9.5" 9.5" 9.5"

2500W/1500W 2500W/1500W 2500W/1500W

8" 8" 8"

2200W 2200W 2200W

6" 6" 6"

1500" 1500" 1500"

EOC EOC EOC

Glass Capacitive Glass Capacitive Glass Capacitive

Front Front Front

Yes Yes Yes

Yes Yes Yes

in EOC in EOC in EOC

1-5

Page 10

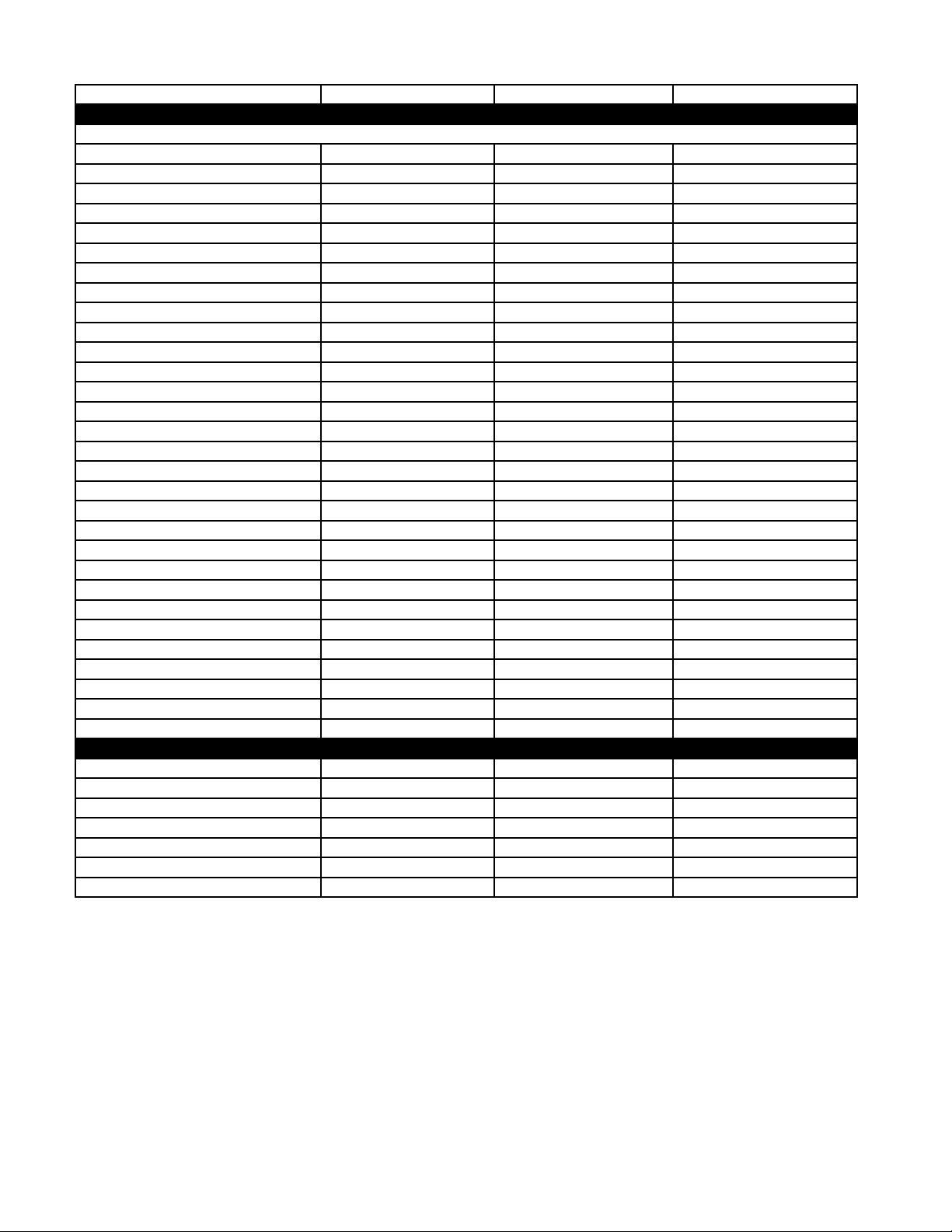

Model

Interior

Main Oven

Cooking System

Cleaning System

Auto Self Clean Latch

Oven Liner Finish

Oven Volume (cu ft)

Oven Height (in)

Oven Width (in)

Oven Depth (in)

Rack Guides #

Oven Racks #

Oven Rack Type & # Each

Oven Rack

Broiler Pan

Broiler Pan Finish

Broiler Pan Grid Finish

Oven Light Number

Main Electric Oven

Hidden Bake Element

Bake (W@240/208v)

Broil Inner Elem (W@240/208v)

Broil Outer Elem (W@240/208v)

Oven Lower Panel/ Door

Drawer/Panel Front

Storage Drawer Liner

Drawer/Panel Height (in)

Drawer/Panel Width (in)

Drawer/Panel Depth (in)

Glides

Lower Drawer Handle Type/Material

Lower Drawer Handle Color

Product Literature

Cookbook

Installation Instructions

Tech Sheet

Use & Care Guide

Other

Agency Approvals

Anti-tip Device With Unit

KESC300H WH/BL/BT KESC307H WH/BT/BS KESH307H WH/BL/BS

Conventional Fan Convection Fan Convection

Self Cleaning Self Cleaning Self Cleaning

Yes Yes Yes

Porcelain Porcelain Porcelain

3.62 cu ft 3.28 3.28

15.75" 15.75" 15.75"

23 1/16" 23 1/16" 23 1/16"

18.25" 16 5/16" 16 5/16"

55 5

23 3

2 Flat

Yes Yes Yes

Yes Yes Yes

Porcelain Porcelain Porcelain

Porcelain Porcelain Porcelain

1 Incandescent 2 Incandescent 2 Incandescent

Yes Yes Yes

No Yes Yes

2500W

1665W 1665W 1665W

1000W 1000W 1000W

Yes Yes Yes

Painted Painted Painted

Yes Yes Yes

5.1" 5.1" 5.1"

23.3" 23.3" 23.3"

20" 20" 20"

Nylon Rollers Nylon Rollers Nylon Rollers

Formed at Top Formed at Top Formed at Top

White White White

No Yes Yes

9752043 B 9752043 B 9752043 B

9753027 9753027 9753027

Yes Yes Yes

Ceran Polish Incl Ceran Polish Incl Ceran Polish Incl

UL,CSA UL,CSA UL,CSA

Floor Floor Floor

1-6

Page 11

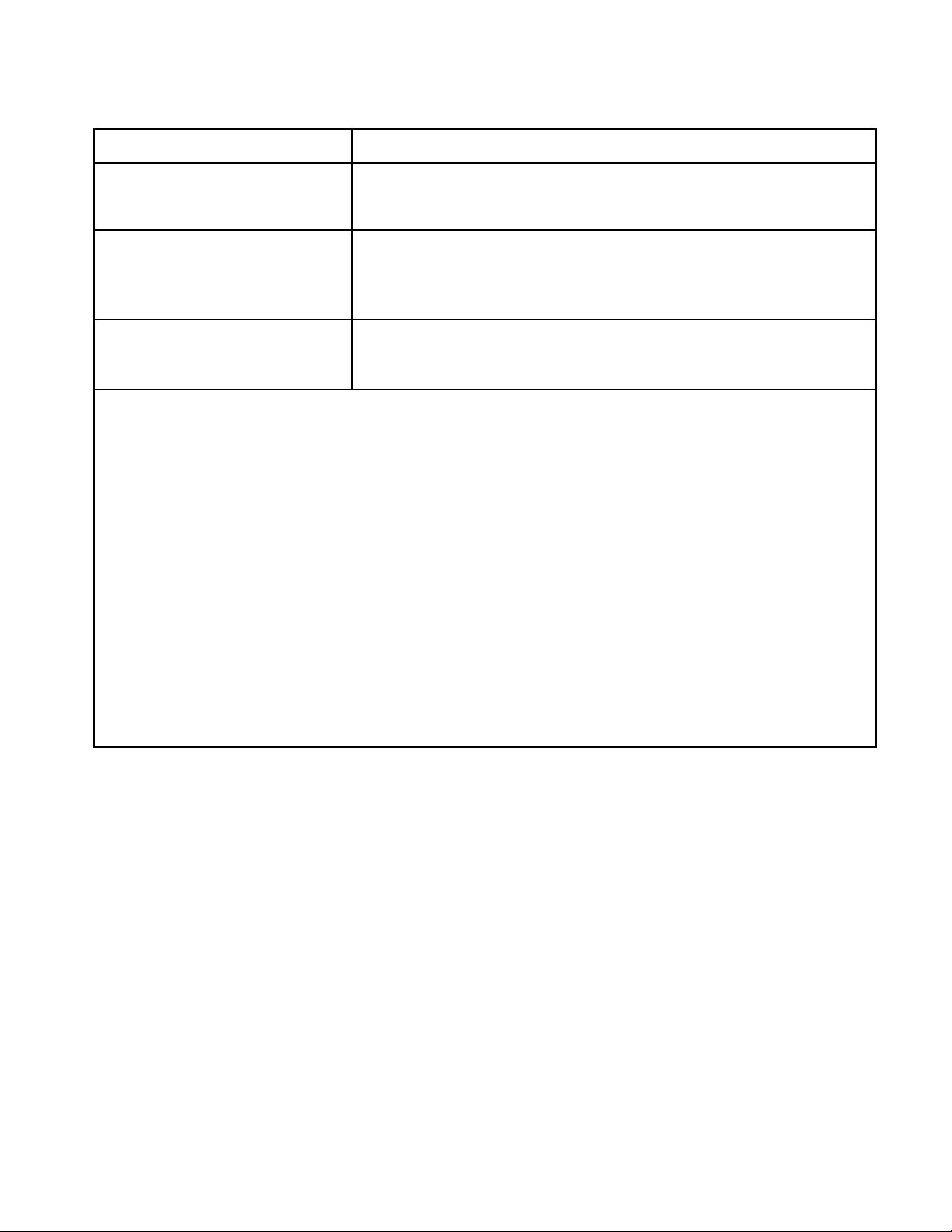

KITCHENAID ELECTRIC RANGE WARRANTY

LENGTH OF WARRANTY

FULL ONE YEAR WARRANTY

From Date of Purchase.

SECOND THROUGH FIFTH YEAR

LIMITED WARRANTY

From Date of Purchase.

SECOND THROUGH TENTH

YEAR LIMITED WARRANTY

From Date of Purchase.

KITCHENAID WILL NOT PAY FOR:

A. Service calls to:

1. Correct the installation of the range.

2. Instruct you how to use the range.

3. Replace house fuses or correct house wiring.

B. Repairs when range is used in other than normal, single family household use.

C. Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation, or

installation not in accordance with local electrical codes.

D. Any labor costs during the limited warranties.

E. Replacement parts or repair labor costs for units operated outside the United States and Canada.

F. Pickup and delivery. Your range is designed to be repaired in the home.

G. Repairs to ceramic glass cooktop if it has not been cared for as recommended in the Use and Care Guide.

H. Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

I. In Canada, travel or transportation expenses to customers who reside in remote areas.

KITCHENAID WILL PAY FOR:

Replacement parts and repair labor costs to correct defects in materials

or workmanship. Service must be provided by a KitchenAid designated

servicing outlet.

Replacement parts for any electric element to correct defects in materials or workmanship. Replacement ceramic glass if breakage is due to

defects in materials or workmanship. Replacement parts for solid state

touch control system to correct defects in materials or workmanship.

Replacement parts for the porcelain oven cavity / inner door if the part

rusts through due to defects in materials or workmanship.

KITCHENAID OR KITCHENAID CANADA DO NOT ASSUME ANY RESPONSIBILITY FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES. Some states or provinces do not allow the exclusion or limitation of incidental or

consequential damages, so this exclusion or limitation may not apply to you. This warranty gives you special legal

rights, and you may also have other rights which vary from state-to-state or province-to-province.

Outside the United States and Canada, a different warranty may apply. For details, please contact your

authorized KitchenAid dealer.

If you need service first see the “Troubleshooting” section of the Use and Care Guide. After checking ”Troubleshooting,” additional help can be found by checking the “Requesting Assistance or Service” section, or by calling

our Customer Interaction Center telephone numbers, listed below, from anywhere in the U.S.A. or Canada.

KitchenAid: 1-800-422-1230

Canadian Residents call: 1-800-807-6777

1-7

Page 12

— NOTES —

1-8

Page 13

INSTALLATION INFORMATION

ELECTRICAL SUPPLY REQUIREMENTS

2. Wire sizes and connections must conform

WARNING

to the requirements of the National Electrical Code, ANSI/NFPA 70—latest edition*,

or CSA Standard C22.1, Canadian Electrical Code, Part 1—latest edition**, and

all local codes and ordinances for the

kilowatt rating of the range.

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

GENERAL

If codes permit, and a separate grounding wire

is used, it is recommended that a qualified

electrician determine that the grounding path is

adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you are not

sure that the range is grounded.

Do not have a fuse in the neutral or ground

circuit.

1. When a 4-wire or 3-wire, single-phase,

120/240-volt, 60-Hz, AC-only electrical

supply is available, a 50-ampere maximum circuit protection is required, (or, if

specified on the model/serial plate, when

a 4-wire, or 3-wire, single-phase, 120/

208-volt, 60 Hz, AC-only electrical supply

is available, a 40-ampere maximum circuit

protection is required), fused on both sides

of the line. A time-delay fuse, or circuit

breaker is recommended. The model/serial rating plate is located behind the storage drawer (see page 1-4).

Copies of the standards listed may be obtained

from:

* National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

** CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

3. This range can be connected directly to

the fused disconnect, or circuit breaker

box, through flexible, armored, or nonmetallic sheathed, copper cable (with ground

wire). Locate the junction box to allow two

to three feet of slack in the line so that the

range can be moved, if servicing is ever

necessary. Do not cut the conduit.

A U.L.-listed conduit connector must be

provided at each end of the power supply

cable, at the range, and at the junction

box. Wire sizes, (copper wire only), and

connections, must conform with the rating

of the range.

2-1

Page 14

ELECTRICAL CONNECTIONS

(Not used for Canadian

Installations)

This range can be connected directly to the

fused disconnect, or circuit breaker box, through

flexible, armored, or nonmetallic sheathed,

copper cable with a grounding wire. Allow two

to three feet of slack in the line so that it can be

moved if servicing is ever necessary.

A U.L.-listed conduit connector must be provided at each end of the power supply cable at

the range, and at the junction box.

brass

terminal

nuts

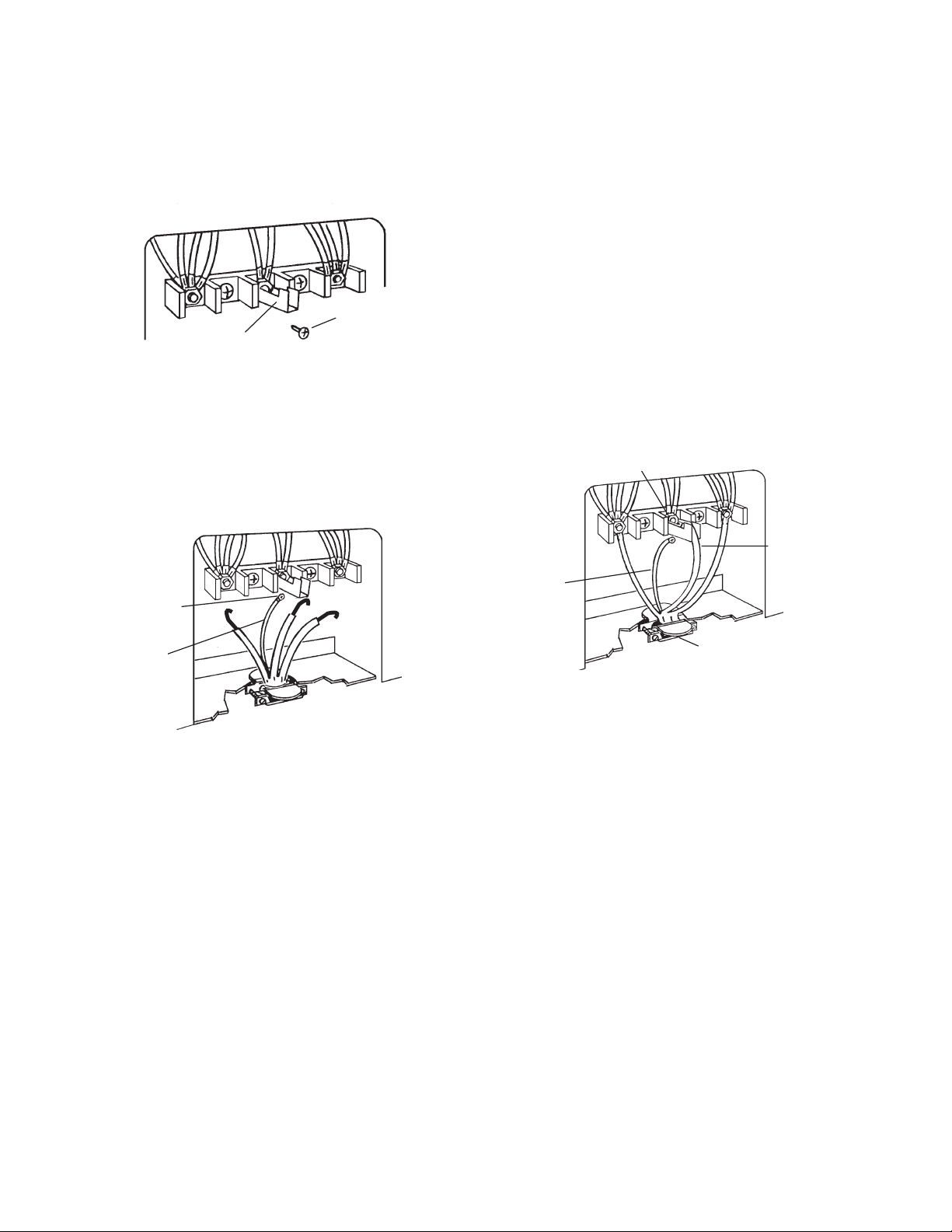

Remove the terminal block cover located on

the back of the range.

terminal

block cover

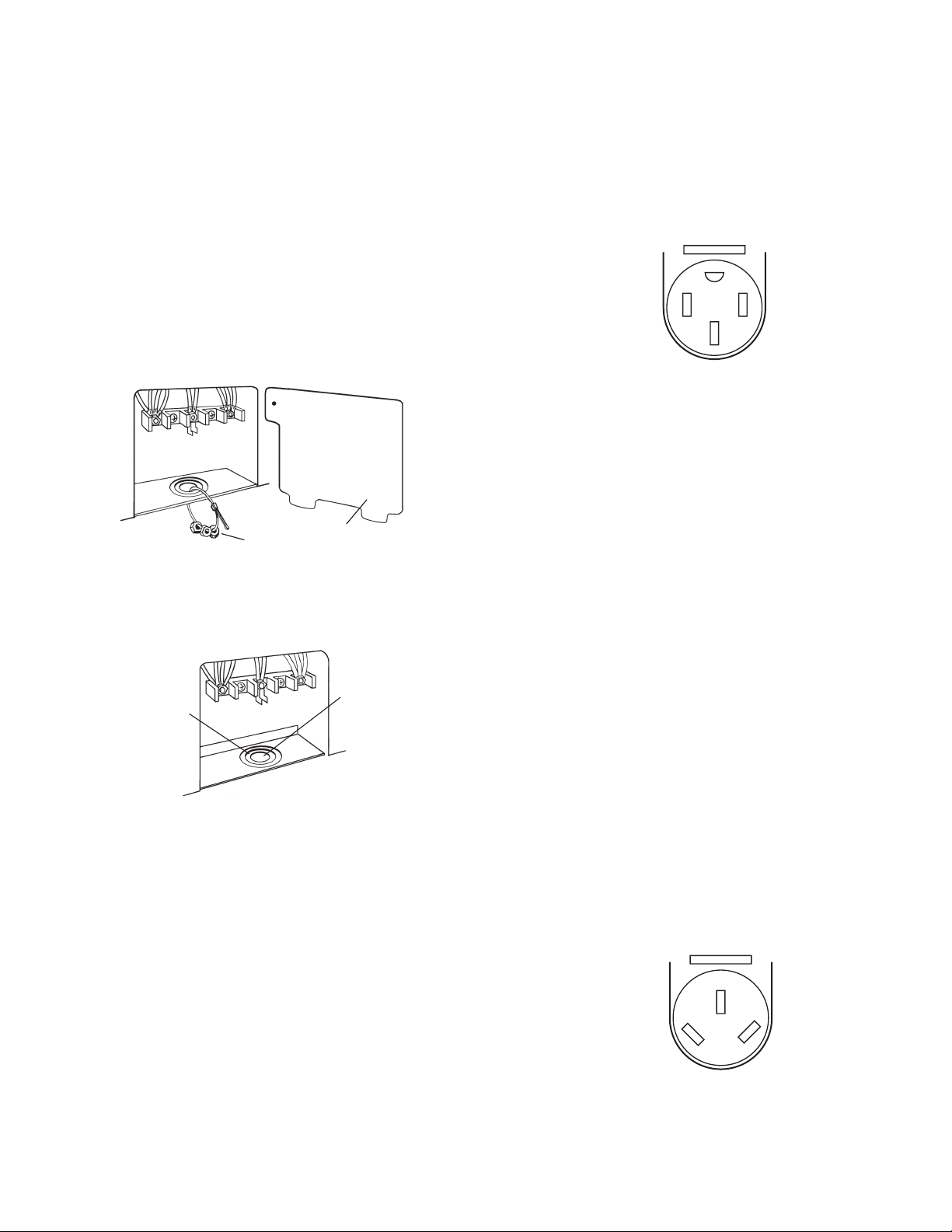

4-Wire Electrical System

This range is manufactured with the ground

connected to the cabinet. The ground must be

revised so that the green grounding wire of the

4-wire power supply cord is connected to the

cabinet (refer to the “4-wire Electrical Connection” section).

4-Wire

Receptacle

14-50R

When a 4-wire receptacle of NEMA type 1450R is used, a matching U.L.-listed, 4-wire,

250-volt, 40-ampere range power supply cord

(pigtail) must be used.

This cord contains four copper conductors with

ring terminals at the appliance end, terminated

in a NEMA type 14-50P plug on the supply end.

The fourth (grounding) conductor must be identified by a green or green/yellow cover, and the

neutral conductor by a white cover. The cord

should be type SRD, or SRDT, with a U.L.listed strain relief, and be at least four

feet long.

G

XY

W

knockout

opening for

40-ampere

power supply

cord

knockout

opening for

power

supply cable

Depending on the electrical supply, make the

4-wire or the 3-wire connection to the range,

following the instructions under the “Power

Supply Cord Connection,” (page 2-3), or the

“Direct Wire Connection” (page 2-5).

The minimum conductor sizes for the copper

4-wire power cord are:

(2) #8 conductors

(1) #10 white neutral

(1) #8 green grounding

3-Wire Electrical System

Local codes may permit the use of a U.L.listed, 250-volt, 40-ampere range power supply cord (pigtail). This cord contains three # 10

copper wires, and matches a three-wire receptacle of NEMA Type 10-50R.

3-Wire

Receptacle

10-50R

Connectors on the appliance end must be

provided at the point the power supply cord

enters the appliance.

W

XY

2-2

Page 15

POWER SUPPLY CORD

CONNECTION

WARNING

Electrical Shock Hazard

7. Depending on the type of electrical system, proceed to “4-Wire Electrical Connection,” or “3-Wire Electrical Connection,” (on page 2-4), and complete the

wiring.

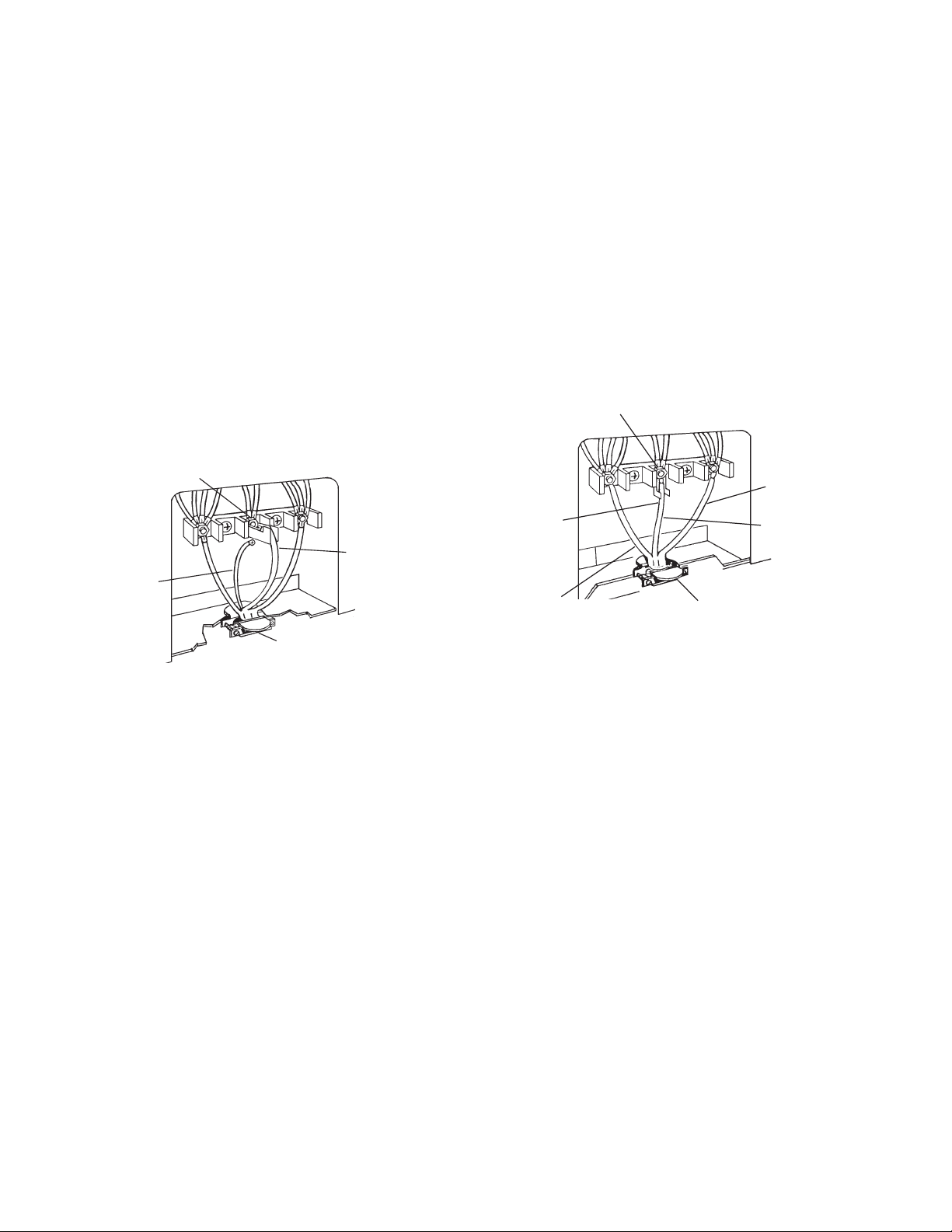

4-Wire Electrical Connection

Use this method for mobile homes, and whenever 4-wire installation is required.

1. Remove the ground-link screw from the

range frame and set the screw aside.

Turn power supply off before connecting

wires.

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

Warning: Improper connection of the equipment-grounding conductor can result in a

risk of electric shock.

Check with a qualified electrician, or serviceman, if you are in doubt as to whether

the appliance is properly grounded.

Do not modify the power supply cord plug.

If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

1. Disconnect the power supply.

2. Remove the screws from the terminal block

cover.

3. Remove the 3/8″ brass nuts that are at-

tached to the knockout opening and set

them aside. Use these brass nuts to secure the ring-type terminals on the power

supply cord to the terminal block screws.

2. Bend the ground link up so that it does not

contact the range.

ground link

3. Connect the green ground wire on the

power supply cord to the ground link screw

hole in the range with the ground-link

screw you removed earlier. Make sure

that the bare ground wire does not contact

the adjacent terminal block connections.

ground-link

screw

green

ground

wire

ground-link

screw

NOTE: Use only ring-type terminals to connect

the power supply cord.

4. Remove the knockout for the 40-ampere

power supply cord.

5. Mount a U.L.-listed strain relief in the knockout opening.

6. Insert the power supply cord through

the strain relief, and allow enough

slack so you can easily attach the wiring to

the terminal block.

2-3

Page 16

NOTE: Do not loosen the factory-installed

nuts on the terminal block when you perform

the following steps.

4. Connect the neutral (white) wire of the

power supply cord to the center, silvercolored terminal screw on the terminal

block, and secure it with one of the 3/8″

brass nuts that you set aside earlier.

5. Connect the remaining two power supply

cord wires to the outer terminals of the

terminal block, and secure them with 3/8″

brass nuts.

6. Tighten the strain relief screws to secure

the power supply cord.

7. Install the terminal block cover.

silver-colored terminal

block screw

1. Connect the neutral (white) wire of the

power supply cord to the center, silvercolored terminal screw on the terminal

block, and secure it with one of the 3/8″

brass nuts that you set aside earlier.

2. Connect the remaining two power supply

cord wires to the outer terminals of the

terminal block, and secure them with 3/8″

brass nuts.

3. Tighten the strain relief screws to secure

the power supply cord.

4. Install the terminal block cover.

silver-colored terminal

block screw

line 2

neutral wire

(center wire)

green

ground

wire

U.L. listed strain relief

and 40-ampere range

power supply cord

3-Wire Electrical Connection

Use this method only if local codes permit connecting a cabinet-grounded conductor to the

neutral wire of the power supply cord.

NOTE: Do not loosen the factory-installed nuts

on the terminal block when you perform the

following steps.

ground

link

line 1

neutral

(center wire)

U.L.-listed strain relief

and 40-ampere range

power supply cord

2-4

Page 17

DIRECT WIRE CONNECTION

WARNING

4. Disconnect the power supply.

5. Remove the screws from the terminal block

cover.

6. Remove the 3/8″ brass nuts that are at-

tached to the knockout opening and set

them aside. Use these brass nuts to secure the ring-type terminals on the power

supply cord to the terminal block screws.

Electrical Shock Hazard

Turn power supply off before connecting

wires.

Electrically ground range.

Failure to do so can result in death, fire, or

electrical shock.

This range must be connected to a grounded, metallic, permanent wiring system, or a

ground connector should be connected to

the ground terminal, or to the ground wire

lead on the range.

The conductors at the terminal block must

be copper wire only.

If the house has aluminum wiring, perform

steps 1 through 3, otherwise skip those steps.

1. Connect a section of 8-gauge, solid copper wire to the terminal block.

2. Connect the aluminum wiring to the added

section of copper wire using special connectors that were designed by Underwriters Laboratories for joining copper to alu

minum. Follow the procedure recom

mended by the manufacturer to connect

the wires.

NOTE: Use only ring-type terminals to connect

the power supply cord.

7. Remove the knockout for the 40- ampere

power supply cord.

8. Mount a U.L.-listed strain relief in the knockout opening.

U .L.-listed

conduit

connector

9. Strip 3″ of outer covering from the end of

each wire on the power supply cord.

10. Form a hook in the bare wire ends of the

power supply cord.

3"

3. The aluminum-to-copper connections must

conform with local codes and industry

accepted wiring practice.

1"

11. Insert the power supply cord through the

strain relief, and allow enough slack so

you can easily attach the wiring to the

terminal block.

12. Depending on the type of electrical system, proceed to “4-Wire Electrical Connection,” (on page 2-6), or “3-Wire Electrical Connection,” (on page 2-7), and complete the wiring.

2-5

Page 18

4-Wire Electrical Connection

1. Remove the ground-link screw from the

range frame and set the screw aside.

2. Bend the ground link up so that it does not

contact the range.

ground-link

ground link

screw

NOTE: Do not loosen the factory-installed nuts

on the terminal block when you perform the

following steps.

4. Connect the neutral (white) wire of the

power supply cord to the center, silvercolored terminal screw on the terminal

block, and secure it with one of the 3/8″

brass nuts that you set aside earlier.

5. Connect the remaining two power supply

cord wires to the outer terminals of the

terminal block, and secure them with 3/8″

brass nuts.

3. Connect the green ground wire on the

power supply cord to the ground link screw

hole in the range with the ground-link

screw you removed earlier. Make sure

that the bare ground wire does not contact

the adjacent terminal block connections.

ground-link

screw

bare wire

from power

supply cable

6. Tighten the strain relief screws to secure

the power supply cord.

7. Install the terminal block cover.

silver

-colored terminal

block screw

neutral wire

(white wire)

bare wire

from power

supply cable

U.L. listed conduit

connector and power

supply cable

2-6

Page 19

3-Wire Electrical Connection

Use this method only if local codes permit connecting a cabinet-grounded conductor to the

neutral wire of the power supply cord.

NOTE: Do not loosen the factory-installed nuts

on the terminal block when you perform the

following steps.

1. Connect the neutral (white) wire of the

power supply cord to the center, silvercolored terminal screw on the terminal

block, and secure it with one of the 3/8″

brass nuts that you set aside earlier.

2. Connect the remaining two power supply

cord wires to the outer terminals of the

terminal block, and secure them with 3/8″

brass nuts.

3. Tighten the strain relief screws to secure

the power supply cord.

4. Install the terminal block cover.

silver-colored terminal

block screw

line 2

ground

link

line 1

neutral wire

(white wire)

U.L. listed conduit

connector and power

supply cable

2-7

Page 20

MOVING THE RANGE

WARNING

Tip-Over Hazard

A child or adult can tip the range and

be killed.

Connect anti-tip bracket to rear range

foot.

Reconnect the anti-tip bracket, if the

range is moved.

Failure to follow these instructions can

result in death or serious burns to children and adults.

Before moving the range, slide it onto a piece

of cardboard, or hardboard, to prevent damaging the floor covering, and perform the following steps:

1. Unplug range or disconnect power.

2. Slide the range forward and disengage

the foot with the anti-tip bracket. IMPOR-

TANT: Make sure the anti-tip bracket is

securely attached to floor.

3. Slide range back so the rear foot engages

in the anti-tip bracket.

4. Check to see that the range is level.

5. Reconnect the electrical supply cord.

2-8

Page 21

THEORY OF OPERATION

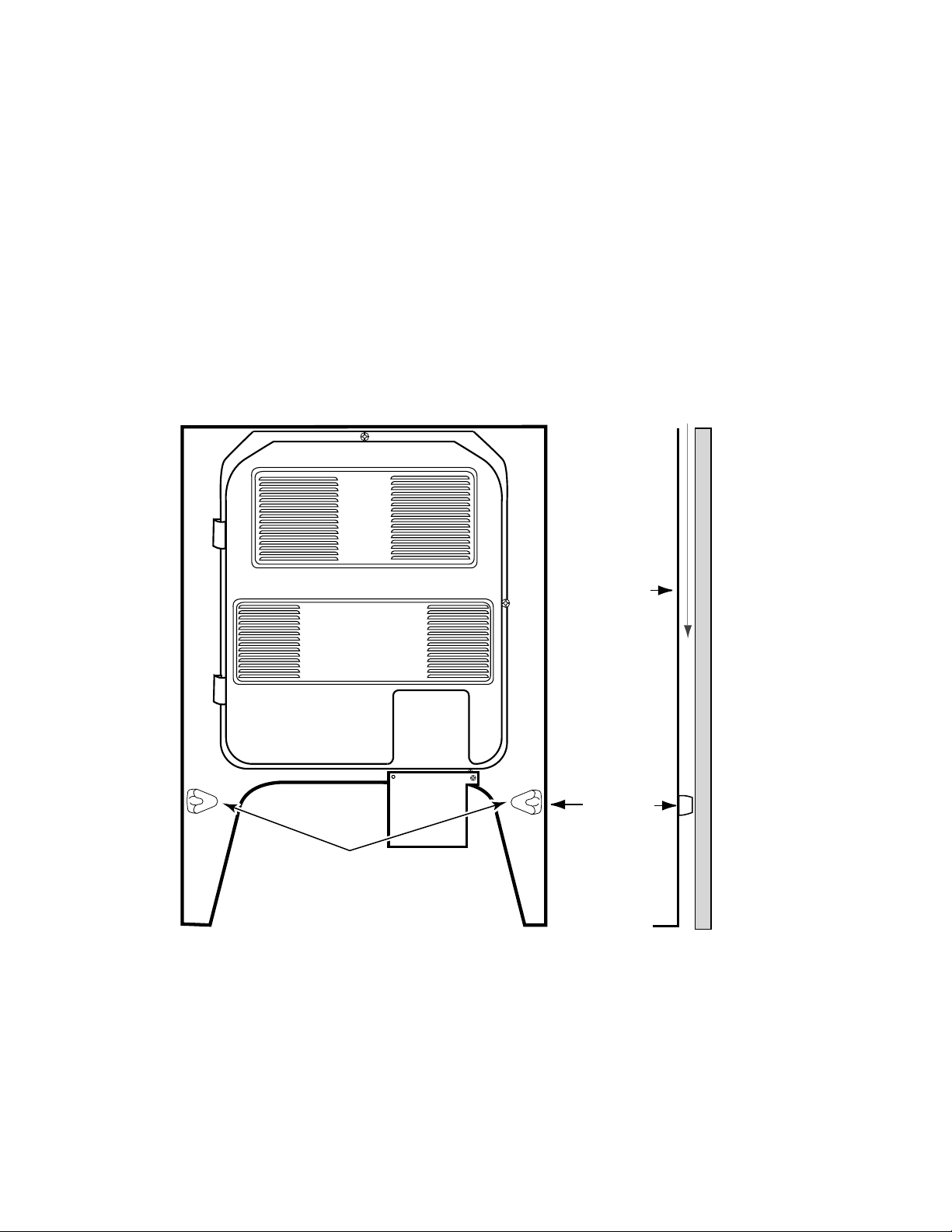

AIR FLOW — REAR PANEL

The electric range needs sufficient air to properly cool the oven. In addition, proper air flow

through the electric range also keeps the front

control panel from becoming too hot while the

elements are operating, and causing operational problems.

To help provide the proper air flow along the

back of the range, the rear panel of the range

has a spacer on each side toward the bottom.

When the range is installed, these spacers

should just come in contact with the surface of

the wall. If they are accidentally bent in, proper

spacing will be lost, and the oven will not heat

properly. Also, the front control panel may become overly warm, and cause the bimetal

switches to trip, shutting down the operation.

If any of these problems occur, it is most likely

because of air flow restrictions.

AIRFLOW

REAR

PANEL

EXTRUDED

SPACERS

ON REAR PANEL

WALL

SPACER

SIDE VIEW

3-1

Page 22

COOLING FAN AIR FLOW

The cooling fan is in series with the cooling

fan bimetal switch, which is located under the

right side of the control panel. When the temperature of the chassis reaches 40˚C (104˚F),

the bimetal switch closes, and turns on the

cooling fan.

The cooling fan draws air from inside the base

of the cabinet. It forces the air up the air channel, which is located under the left side panel,

AIR FLOWS FROM

CONTROL PANEL

UNDER RANGE TOP

OVEN VENT FOR

OVEN EXHAUST

AIR FLOWS

INTO

REAR PANEL

LOUVERS

AIR INLETS

UNDER

CONTROL

PANEL

to the opening at the end of the control panel.

Air then flows across the chassis below the

control panel, and cools it. Air enters through

the series of holes in front of the range top,

flows beneath it, and exits to the outside

through slots in the rear panel. When the control panel chassis temperature drops below

40˚C (104˚F), the bimetal switch opens, and

turns the cooling fan off.

COOLING FAN

BIMETAL SWITCH

COOLING FAN

AIR CHANNEL

DOOR

LATCH SW.

DLB RELAY

V

1B

SURF

IND.

LIGHT

L2

R

R

R

L1

BK

BI - METAL SW FAN N.O.

YY

BI-METAL SW

AMBIENT N.C.

BK

DOOR

SW.

OVEN

TEMP

SENSOR

W

BK

BK

GND

BK

L2L1

P

LF

H1 H2

BK

2ABK2B

1A 1B

V

BU

SURF

IND.

LIGHT

LF

G

P

BK

Y

Y

V

V

H1 H2

Y

M

OVEN CONTROL

P4-3

TRANSFORMER

P3-3

OVEN LIGHT

P3-4

LATCH RELAY

P3-6

P3-7

P2-2

BROIL RELAY

P2-3

OR P6

BAKE RELAY

P3-5

L2L1

LR

2AY2B

1A 1B

LR

RELAY

V

HOT SURFACE

IND. LIGHTS

GND

W

W

DOOR LOCK

SOLENOID

1B

V

P

OVEN LT.

W

BU

R

RR

H1 H2

R

BU

RR

N.O.

COM

L2L1

2ABU2B

1A

P

P4-1

P4-4

P4-5

P3-1

P3-2

P2-1

P2-4

L1

H1 H2

BR

W

R

BR

BU

BU

V

R

RF

2ABR2B

1A

BU

BROIL ELEMENT

BAKE ELEMENT

L2

RF

3-2

N

SUR.

IND.

LIGHT

P

H1

H2

N

N

INF.SWITCH

(OPTIONAL)

COIL ELEMENT

L2

L1

Page 23

THE BIMETAL SWITCHES

There are two bimetal switches on the electric

range. The switches operate as follows:

• Ambient Bimetal Switch (N.C.)

(Inset #1) —This switch is located under the left side of the control console.

It opens the L1 circuit to the electronic

control board if the console temperature

reaches 96˚C/205˚F.

FAN BIMETAL

AMBIENT

BIMETAL SWITCH

W

Inset #2

COOLING

SWITCH

Inset #1

L1

BK

BI - METAL SW FAN N.O.

DOOR

SW.

OVEN

TEMP

SENSOR

BK

BK

BK

P

LF

• Cooling Fan Bimetal Switch (N.O.)

(Inset #2) —This switch is located un-

der the right side of the control console.

It turns the cooling fan on if the console

temperature reaches 70˚C/158˚F.

GND

YY

BI-METAL SW

AMBIENT N.C.

BK

GND

L2L1

M

P4-3

BK

Y

P3-3

Y

P3-4

V

P3-6

V

P3-7

P2-2

P2-3

OR P6

G

P3-5

P

LR

W

OVEN CONTROL

TRANSFORMER

OVEN LIGHT

RELAY

LATCH RELAY

BROIL RELAY

BAKE RELAY

L2L1

P

P4-1

P4-4

P4-5

P3-1

P3-2

P2-1

P2-4

L1

W

R

BR

BU

BU

BROIL ELEMENT

V

R

L2

RF

W

DOOR LOCK

SOLENOID

BAKE ELEMENT

P

OVEN LT.

W

BU

R

RR

N.O.

COM

L2L1

DOOR

LATCH SW.

DLB RELAY

L2

R

R

R

H1 H2

BK

2ABK2B

1A 1B

V

BU

SURF

IND.

LIGHT

LF

N

H1 H2

Y

2AY2B

1A 1B

V

HOT SURFACE

LR

IND. LIGHTS

H1 H2

BR

BU

2ABR2B

1A

V

RF

SUR.

IND.

LIGHT

H1 H2

R

2ABU2B

1B

1B

P

N

1A

V

BU

RR

L1

H1

H2

L2

SURF

IND.

LIGHT

N

INF. SWITCH

(OPTIONAL)

COIL ELEMENT

3-3

Page 24

THE SURFACE ELEMENT LIMITER

The surface element limiter is a safety device

that is mounted in the surface element circuit .

MAINTOP SENSING ROD HEATING COIL

INSULATION LIMITER

ELEMENT

TERMINALS

LIMITER

TERMINALS

L1

BK

BI - METAL SW FAN N.O.

YY

BI-METAL SW

AMBIENT N.C.

BK

DOOR

SW.

OVEN

TEMP

SENSOR

W

BK

BK

GND

BK

P

L2L1

LF

M

OVEN CONTROL

P4-3

Y

Y

V

V

P3-3

P3-4

P3-6

P3-7

P2-2

P2-3

OR P6

P3-5

LR

TRANSFORMER

OVEN LIGHT

RELAY

LATCH RELAY

BROIL RELAY

BAKE RELAY

L2L1

BK

G

P

GND

W

W

P4-1

R

P4-4

DOOR LOCK

BR

BU

BU

BROIL ELEMENT

V

R

L2

RF

SOLENOID

BAKE ELEMENT

P4-5

P3-1

P3-2

P2-1

P2-4

L1

P

The limiter monitors the temperature of the

cooktop glass in two ways:

a)Circuit 1A to 2A, which is a normally-

closed (N.C.) switch, opens at 1025˚F

and protects the ceran glass from heat

damage.

b)Circuit 1B to 2B, which is a normally-

open switch (N.O.) switch, closes and

turns on the hot surface indicator lights

if the temperature of the cooktop is

greater than 150˚F. This switch will remain closed until the ceran glass is

warm enough to touch.

2A 2B

1A

1B

L2

R

OVEN LT.

W

W

N.O.

COM

BU

P

DOOR

LATCH SW.

R

DLB RELAY

R

L2L1

RR

R

2A 2B

1A

1B

H1 H2

BK

2ABK2B

1A 1B

V

BU

SURF

N

IND.

LIGHT

LF

H1 H2

Y

2AY2B

1A 1B

V

HOT SURFACE

LR

IND. LIGHTS

H1 H2

BR

BU

2ABR2B

1A

V

RF

SUR.

IND.

LIGHT

H1 H2

R

2ABU2B

1B

1B

P

N

1A

V

BU

RR

L1

H1

H2

L2

SURF

IND.

LIGHT

N

INF.SWITCH

(OPTIONAL)

COIL ELEMENT

3-4

Page 25

THE DOOR LOCK SOLENOID & DOOR LATCH SWITCH

The door lock solenoid operates on a 120-volt

pulse from the electronic control board. When

the door is in the unlocked position, the plunger

is extended. When the door latch switch is

open, the control senses that the door is unlocked. When the door latch switch closes, the

control senses that the door is locked. The door

latch switch, mounted on the solenoid bracket,

is in the N.O. (normally-open) position. During

DOOR

UNLOCKED

LATCH

ACTUATOR

ROD

DOOR LATCH

SWITCH OPEN

The Door Lock Solenoid

(Door Unlocked)

the self-clean cycle, the control board sends a

120-volt pulse to the solenoid windings, which

pulls the plunger in, and moves the latch actuator rod to lock the oven door. The movement of the rod also actuates the door latch

switch and closes it. When the self-clean cycle

is over, the control board sends a 120-volt pulse

to the solenoid, the plunger is pushed out, the

latch actuator rod releases the door, and the

door latch switch opens.

DOOR UNLOCKED

DOOR

LOCKED

LATCH

ACTUATOR

ROD

The Door Lock Solenoid

(Door Locked)

PLUNGER OUT

DOOR LATCH

SWITCH CLOSED

PLUNGER IN

DOOR LOCKED

SOLENOID

120 VAC

SOLENOID

120 VAC

DOOR

LATCH SW.

DLB RELAY

1B

V

SURF

IND.

LIGHT

N

INF.SWITCH

(OPTIONAL)

COIL ELEMENT

L2

R

R

R

L1

BK

BI - METAL SW FAN N.O.

YY

BI-METALSW

AMBIENT N.C.

BK

DOOR

SW.

OVEN

TEMP

SENSOR

W

BK

BK

GND

BK

L2L1

P

LF

H1 H2

BK

2ABK2B

1A 1B

BU

SURF

IND.

LIGHT

N

V

LF

M

OVEN CONTROL

P4-3

TRANSFORMER

BK

Y

P3-3

OVEN LIGHT

RELAY

Y

P3-4

V

LATCH RELAY

P3-6

V

P3-7

P2-2

BROIL RELAY

P2-3

OR P6

P3-5

LR

H1 H2

Y

BAKE RELAY

L2L1

2AY2B

1A 1B

V

HOT SURFACE

LR

IND.LIGHTS

G

P

GND

W

W

DOOR LOCK

SOLENOID

1B

V

SUR.

IND.

P

N

P

L1

H1

OVEN LT.

W

BU

R

H1 H2

R

BU

RR

N.O.

COM

RR

2ABU2B

1A

L2

H2

L2L1

P

P4-1

P4-4

P4-5

P3-1

P3-2

P2-1

P2-4

L1

H1 H2

BR

W

R

BR

BU

BU

V

R

RF

2ABR2B

1A

BU

BROIL ELEMENT

BAKE ELEMENT

L2

RF

LIGHT

3-5

Page 26

HOW THE SELF-CLEAN CYCLE WORKS

The Self-Clean cycle uses high heat to burn

away soil and grease from inside the oven.

During this cycle, the oven will get much hotter than it does under normal baking and broiling conditions (see the following chart).

AFTER 30 MINUTES OF CLEAN

L1

The oven is preset for a 3-1/2 hour Self-Clean

cycle. However, you can adjust this cycle time

to between 2-1/2 and 4-1/2 hours. The chart

shows a normal 3-1/2 hour Self-Clean cycle.

Note that although the heating turns off after

3 hours, the door will remain locked for an additional 1/2 hour so the oven can cool sufficiently.

During the Self-Clean cycle, the bake element

is on all the time. If the door latch switch is not

activated during the clean operation, the cycle

is terminated and the display will show “close

door.”

L2

MICROCOMPUTER

BAKE

ELEMENT

P2-4P2-3

DLB

RELAY

3-6

Page 27

COMPONENT ACCESS

This section instructs you on how to service each component inside the range. The range

components and their locations are shown below.

COMPONENT LOCATIONS

Indicator Light

Single Element

Infinite Switch

Dual Element

Infinite Switch

Oven Light

Meat Probe Jack

Dual Broil

Element

Convection Bake

Element & Fan Motor

Double Line

Break Relay

Cooling

Fan Motor

Hot Surface Indicators

Door Latch Assembly

Element & Limiter

Electronic Oven Control

Cooling Fan

Bimetal Switch

Ambient Bimetal

Switch

Door Switch

Oven Temperature

Sensor

Hidden Bake Element

4-1

Page 28

REMOVING THE CONTROL PANEL,

AN INFINITE SWITCH & BIMETAL SWITCH

WARNING

Bottom Control Panel Screws

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Pull the range forward far enough to access the end cap screws.

3. To remove the control panel:

a) Remove the screw from each end cap.

End Cap

Screw

c) Lift the front of the control panel, pull it

forward, and slide the front edge of the

cooktop glass out of the slot in the front

of the panel.

d) Rotate the control panel up and over so

the bottom side faces up.

Infinite Switches

Single Dual

Ambient (N.C.)

Bimetal Switch

Opens @ 96°C (205°F)

Resets @ 74°C (165°F)

Single Element

Infinite Switches

Cooling Fan (N.O.)

Bimetal Switch

Resets @ 70°C (158°F)

Closes @ 60°C (140°F)

4. To remove an infinite switch:

Control Panel

b) Open the oven door and remove the

three screws from the bottom of the

control panel (see the photo at the top

of the right column).

4-2

a) Pull the knob off the switch you wish to

service and remove the nut and fiber

flat washer.

Remove Knob

Remove Nut &

Fiber Flat Washer

b) Remove the wires from the infinite

switch terminals and remove the switch.

NOTE: The terminal callouts are shown

on the next page.

Page 29

(3) Single Infinite Switch

5. To remove a bimetal switch:

L2

H2

L1

PH1

a) Remove the wires from the terminals.

b) Remove the mounting screw.

(1) Dual Infinite Switch

L2

Ambient

Bimetal Switch

Screw

REASSEMBLY NOTE: When reinstalling the

Cooling Fan

Bimetal Switch

Screw

control panel, insert the groove in the front of

the panel over the front edge of the cooktop

glass, and lower it onto the front of the range.

Be careful not to pinch any of the wires be-

4

P2

tween the front edge of the control panel and

the chassis.

L1

L3

NOTE: Refer to the Tech Sheet Wiring Diagram that is supplied with the unit to determine

the wiring for the infinite switch you are servicing.

Front Edge Of

Cooktop Glass

Groove In

Control Panel

4-3

Page 30

REMOVING THE ELECTRONIC OVEN CONTROL

AND AN INDICATOR LIGHT

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Remove the control panel from its

subchassis, (see page 4-2 for the procedure), and rotate it forward onto the cooktop

glass.

b) Press down on the ribbon cable release

arm, and disconnect the ribbon cable

from the connector at P9.

Ribbon Cable Connector

Ribbon Cable Release

c) Remove the screws from the board.

d) Straighten the bracket tabs at the top

and bottom of the board, and remove

the board from the bracket.

(2) Indicator Lights

Electronic Oven Control

(3) Indicator Lights

3. To remove the electronic oven control:

a) Disconnect the wire connectors at P1,

J1, P2, P3, and P4.

Screw

Screw

P1

J1

P9

P2

Tabs

4. To remove an indicator light:

a) Push on the body and slide it off the

shoulder of the lens.

b) Disconnect the two indicator wires.

Lens

Push

Wires

P4

Screw

P3

Indicator Light

4-4

Page 31

REMOVING AN ELEMENT & LIMITER AND

THE HOT SURFACE INDICATOR ASSEMBLY

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Remove the control panel from its

subchassis, (see page 4-2 for the procedure), and rotate it forward onto the cooktop

glass.

3. Remove the five screws and flat washer

from the control panel subchassis.

2 Screws

Screw & Flat Washer

Subchassis

2 Screws

5. To remove an element and limiter:

a) Remove the wires from the element

and limiter terminals.

b) Remove the screw, or pull the end of

the retaining rod out of the bracket, and

remove the element and limiter from

the bottom of the cooktop.

4. Move the control panel back into place

over the chassis, then lift the front of the

cooktop assembly, and prop it up with a

piece of board so that you can access the

components (see the photo at the top of

the next column). CAUTION: Be careful

that the cooktop does not accidentally fall.

4-5

Retaining Rod

(Pull Out)

Retaining

Rod Screws

Continued on the next page.

Page 32

c) Lay the element and limiter on a work

surface. Remove the screws from the

limiter and remove it from the element.

NOTE: Be careful when you remove

the limiter that you do not break the

sensor tube (see below).

Limiter

Screws

6. To remove the hot surface indicator

assembly:

a) Disconnect the hot surface indicator

wires.

Black Brown

Sensor Tube

Yellow Violet Blue

b) Grasp the hot surface indicator assem-

bly and push it toward the front of the

unit, then pull down the rear edge,

unclip the locking arms from the

cooktop, and remove the assembly.

Locking Arms

Hot Surface

Indicator

Assembly

4-6

Page 33

REMOVING THE COOKTOP GLASS

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Pull the range out of its mounting location

so that you can access the side trim.

3. Remove the control panel from its

subchassis, (see page 4-2 for the procedure), and set it on the subchassis.

4. Remove the two screws from the left and

right side trim. Do not remove the trim at

this time.

6. Loosen the left and right tension bracket

screws and remove the brackets from

behind the side trim.

7. Remove the wire clip from the left side

trim.

Left Tension

Bracket & Clip

Right Tension

Bracket

Right Side

Trim Screws

5. Raise the cooktop and prop it up (see

steps 3 and 4 on page 4-5 for the procedure).

Continued on the next page.

4-7

Page 34

8. Pull the left and right side trim off the

cooktop. To remove the trim, lift it away

from the cooktop glass, and pull the back

off the rear trim.

Lift Side Trim

Off Cooktop Glass

10. Lift the front of the cooktop glass, pull it

forward from under the rear trim, and

remove the glass from the cooktop.

IMPORTANT: When you reinstall the

cooktop glass, keep the side edges of the

glass inside the four alignment tabs (two

on each side). If the glass is over the tabs,

it could break when you lower it.

Keep Glass Inside

Alignment Tabs

Pull Side Trim Off Rear Trim

9. Lower the cooktop.

Lift Front Of Glass & Pull Off Cooktop

11. To remove the vent grate from the left rear

corner of the cooktop:

a) Remove the two indicated rear trim

screws and pull the trim away just to

clear the edge of the grate.

Rear Trim Screws

4-8

Page 35

b) Lift the tabs out of their slots in the

chassis and remove the grate.

Lift Grate

Off Cooktop

Rear Trim

NOTE: The two rear trim tension brackets may

fall out of their mounting locations in the rear

trim strip when you move it. If so, be sure to

reinstall them before lowering the cooktop.

Rear Trim Tension Brackets

4-9

Page 36

REMOVING THE DOOR LATCH ASSEMBLY

& THE DOOR SWITCH

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Pull the range away from the wall so that

you can access the rear of the unit.

3. To remove the door latch assembly:

a) Remove the top and side screws from

the rear panel and loosen the three

bottom screws, then pull the tabs out of

their slots, and remove the panel.

Door Latch Assembly

b) Disconnect the 3-wire connector from

the door latch switch terminals.

c) Disconnect the wires from the door

latch solenoid terminals.

d) Remove the two screws from the door

latch assembly and remove it from the

unit.

Door Latch Switch

Screw

(1 of 2)

3-Wire Connector

2 Screws

Rear Panel

Loosen 3 Screws

Door Latch Solenoid

Terminals

REASSEMBLY NOTE: When you reinstall the

door latch assembly, make sure that the door

latch switch actuator is over the latching rod, as

shown.

Door Latch

Switch Actuator

Latching Rod

4-10

Page 37

4. To remove the door switch:

a) Remove the oven door and set it aside

(see page 4-22 for the procedure).

b) Open the storage drawer several inches.

Storage Drawer

c) Remove the two rear screws from the

right side panel.

Screw

d) Slide the side panel forward and un-

hook the top edge from the front screw,

then tilt the top of the side panel out so

you can access the door switch.

Slide Forward & Tilt

Top Of Panel Out

Side Panel

e) Push the door switch out of the unit and

disconnect the wires from the terminals.

Screw

Door Switch

4-11

Page 38

REMOVING THE DUAL BROIL ELEMENT

AND THE HIDDEN BAKE ELEMENT

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Open the oven door and remove the racks

from inside the oven.

b) Pull the element forward and unhook

the front bracket tabs from the liner

slots, then pull the element wires

through the liner holes, and disconnect

them from the terminals.

2 Red Wires Blue & Violet Wires

Tab

Tab

3. To remove the dual broil element:

a)Remove the two screws from the dual

broil element brackets.

Dual Broil Element

Bracket Screws

4. To remove the hidden bake element:

a) Remove the right side panel (see page

4-19 for the procedure).

b) Spread the insulation away from the

front of the hidden bake element.

Insulation

4-12

Page 39

c) Disconnect the two wire connectors

from the hidden bake element terminals.

d) Remove the element shield screw from

the right end of the shield.

Element Shield Screw

f) Remove the hidden bake element from

the unit, and place it on a work surface.

Element Wires

e) Pull the hidden bake element and its

shield to the right and unhook the left

and right tabs.

Unhook Tab From Slot

Hidden Bake Element Shield

Unhook End From Slot

Right End

Pull Out

Pull Out

g) Remove the two bracket screws, and

remove the shield from the element.

Element Shield Screw

Left End

4-13

Page 40

REMOVING THE CONVECTION

BAKE ELEMENT & FAN MOTOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Open the oven door and remove the racks

from inside the oven.

3. Remove the two screws from the convection fan motor cover, then unhook the

bottom tab from the liner slot, and remove

the cover.

Screw &

Lockwasher

Convection Fan

Motor Cover

Screw &

Lockwasher

Cover Tab

Convection Bake Element & Fan Motor

4. To remove the convection bake ele-

ment:

a) Remove the three screws from the ele-

ment bracket and bottom clip.

Convection Bake Element Bracket Screws

4-14

Bottom Clip Screw

Page 41

b) Pull the bake element forward so the

wire connectors are accessible, then

disconnect the wires from the terminals. NOTE: Be careful that the wires

do not pull back into the oven liner hole.

Convection Bake Element Wires

b) Pull the range away from the wall so

that you can access the rear of the unit.

c) Remove the rear panel (see step 3a on

page 4-10 for the procedure).

Convection Fan Motor

5. To remove the convection fan motor:

a) Use a large screwdriver or a 13 mm

socket, and remove the cap nut (clockwise) from the convection fan, then pull

the fan off the convection fan motor

shaft.

Convection

Fan

Cap Nut

d) Remove the three screws from the con-

vection fan motor.

e) Disconnect the wires from the termi-

nals.

Convection Fan Motor Wires

4-15

3 Screws

Page 42

REMOVING AN OVEN LIGHT SOCKET ASSEMBLY

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Open the oven door and remove the racks

from inside the oven.

3. Unscrew the lens and bulb from the oven

light socket assembly and remove them.

CAUTION: Be careful not to scratch or chip the

oven liner paint when you remove the oven

light socket in the next step.

4. Use a screwdriver and bend the clips on

the oven light socket away from the edges

of the liner hole, and pull the socket out of

the liner. NOTE: If it is too difficult to remove the socket from the front of the oven,

you will have to push the socket out from

the back of the unit.

Socket Clip

Left Oven Light

Oven Light Lens

Right Oven Light

5. Disconnect the wires from the socket terminals.

Socket

Wires

Oven Light Bulb

(Viewed From Rear Panel)

4-16

Page 43

REMOVING THE MEAT PROBE JACK

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

5. Lift the spring-loaded cap on the meat

probe jack.

Meat Probe Cap

1. Unplug range or disconnect power.

2. Open the oven door and remove the racks

from inside the oven.

3. Pull the range away from the wall so that

you can access the left side of the unit.

4. Remove the left side panel (see page 4-19

for the procedure).

Meat Probe Jack

6. Use a 16mm socket and remove the meat

probe jack nut and felt washer from the

oven liner.

16mm Socket

7. Remove the metal sleeve and disconnect

the wires from the meat probe jack terminals, then remove the jack from the unit.

Metal Sleeve

4-17

Meat Probe Jack

Violet & Red Wires

Page 44

REMOVING THE OVEN TEMPERATURE SENSOR

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

3. Remove the screw from the temperature

sensor bracket.

Sensor Bracket Screw

1. Unplug range or disconnect power.

2. Open the oven door and remove the racks

from inside the oven.

Oven Temperature Sensor

4. Pull the oven temperature sensor wire

and connector out of the oven liner.

5. Disconnect the oven temperature sensor connector and remove the sensor.

Pull Connector Through Liner Hole

4-18

Page 45

REMOVING A SIDE PANEL

WARNING

6. From the rear of the unit, reach inside and

remove the screw from the bottom of the

side panel.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Pull the range away from the wall so that

you can access the rear of the unit.

3. Remove the oven door and set it aside

(see page 4-22 for the procedure).

4. Pull the storage drawer out as far as it will

go.

5. Remove the two rear screws from the side

panel.

Remove Bottom

Side Panel Screw

7. Slide the side panel forward and unhook

the front edge, then tilt the top of the side

panel out, and lift the panel from the unit.

Slide Forward & Tilt

Top Of Panel Out

Screw

Side Panel

Screw

(Inside)

Screw

NOTE: When reinstalling the side panel, set

the bottom edge on the rail, hook the front edge

at the top and bottom, and install the two rear

screws; then install the bottom screw from

inside the rear of the unit.

4-19

Page 46

REMOVING THE DOUBLE LINE BREAK (DLB) RELAY

AND THE COOLING FAN MOTOR

5. To remove the double line break (DLB)

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Open the oven door and remove the racks

from inside the oven.

3. Pull the range away from the wall so that

you can access the rear of the unit.

relay:

a) Disconnect the wire connectors from

the relay terminals.

b) Remove one of the two relay mounting

screws and loosen the other screw.

Slide the relay out from under the loose

screw and remove it from the housing.

2 Wht

Red Yel Red

4. Remove the left side panel (see page 4-19

for the procedure).

DLB Relay

Cooling Fan Motor

Loosen Screw Remove Screw

6. To remove the cooling fan motor:

a) Disconnect the wire connectors from

the cooling fan motor terminals.

Motor

Wires

b) Remove the storage drawer from the

front of the unit.

4-20

Page 47

c) From the storage drawer area, remove

the front housing screw and loosen the

other two screws.

d) Slide two of the three motor housing

brackets out from under the two screws,

and the other bracket out of the slot in

the chassis, and remove the housing.

e) Remove the three cooling fan motor

mounting screws and remove the motor from the housing.

Cooling Fan Motor Screws

Remove This Screw

Loosen These Screws

Housing

4-21

Page 48

REMOVING THE OVEN DOOR

1. To remove the oven door, open the door to

its first stop.

2. Grasp the sides of the door, lift it slightly,

and pull the door forward until the hinge

hangers are partially out of the slots in the

chassis. Do not completely remove the

hinge hangers from the slots, since there

will be spring tension on them.

Partially Remove

Door

3. Reposition the angle of the door to its

vertical position to remove the spring tension on the hinge hangers, then pull the

hangers the rest of the way out of the

chassis slots.

Hinge Hanger

Keep Door

Vertical

To reinstall the oven door:

1. Grasp the sides of the door and insert the

hinge hangers into the hinge slots. Lift the

door slightly and push in at the bottom until

the hangers are fully installed in the unit.

NOTE: If the hinge hangers are not seated

properly, the door will not close tightly and

may be off-center. To seat the hinge hangers, keep the door vertical, then lift it

slightly, and push in on the bottom until the

hangers are fully seated.

2. Open and close the oven door to make

sure that it operates and seals properly.

4-22

Page 49

REMOVING THE DECORATIVE GLASS, THE OVEN DOOR

HANDLE, THE HINGES, AND THE OVEN DOOR GLASS

1. Remove the oven door from the range

(see page 4-22 for the procedure).

2. Place the oven door on a padded work

surface with the decorative glass and

handle facing up and the bottom edge

facing the front.

3. To remove the decorative glass:

a) Remove the four decorative glass re-

tainer screws, and remove the retainer

and two side trims.

b) Lift the decorative glass off the door.

Decorative Glass Retainer Screws (4)

5. To remove a hinge:

a) Remove the two bottom screws from

the hinge you are servicing. NOTE: If

you are removing both hinges, remove

the steam deflector. Note how the deflector is mounted between the two

hinges.

b) Remove the bracket and retainer screw

from the top of the hinge.

Bracket &

Retainer

Screw

Steam Deflector

4. To remove the door handle:

a) Lift the air vent and handle off the door.

Air Vent

Handle

b) Remove the four handle screws (two

on each side) from the air vent and

remove the handle.

Handle Screws (4)

Steam

Deflector

Bottom Hinge Screws

c) Remove the bracket, retainer, and hinge

from the door.

Retainer

Bracket

Hinge

Continued on the next page.

4-23

Page 50

6. To remove the inner and outer oven

door glass:

a) Lift the insulation retaining plate off the

door.

Insulation Retaining Plate

b) Remove the insulation and outer oven

glass from the door.

Insulation

Outer Oven Glass

c) Remove the screws from the seven

oven glass spacer retaining brackets

and remove the brackets. NOTE: When

you reinstall the brackets, make sure

that you position the arrows on the

brackets towards the glass spacer.

d) Lift the glass spacer and the inner oven

glass off the door.

Oven Glass Spacer

Arrow

Spacer Retaining

Bracket (1 of 7)

e) If you are replacing the rope insulation,

remove it from around the oven glass

opening in the door.

Inner Oven Glass

4-24

Rope Insulation

Page 51

REMOVING THE OVEN DOOR GASKET

4. Pull the oven liner forward to loosen the

WARNING

oven door gasket from the front of the unit.

5. Starting at one end, pull the gasket out of

the liner hole, and remove it from around

the liner and the second hole.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

1. Unplug range or disconnect power.

2. Pull the range away from the wall so that

you can access the rear of the unit.

3. Loosen the two oven liner screws so that

the inside of the hex-head skirt is approximately 1/2″ from the chassis.

Pull Oven Liner Forward

To Release Gasket

Pull Door Gasket Out Of Hole

And Remove From Liner

REASSEMBLY NOTE: After the door gasket is

installed, make sure that it is even along the

surface of the door when the door is closed.

2 Oven Liner Screws

4-25

Page 52

— NOTES —

4-26

Page 53

COMPONENT TESTING

Before testing any of the components, perform

the following checks:

• The most common cause for control failure is

corrosion on connectors. Therefore, disconnecting and reconnecting wires will be necessary throughout test procedures.

• All tests/checks should be made with a VOM

or DVM having a sensitivity of 20,000 ohmsper-volt DC, or greater.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

BIMETAL SWITCH

• Check all connections before replacing components, looking for broken or loose wires,

failed terminals, or wires not pressed into

connectors far enough.

• Resistance checks must be made with power

cord unplugged from outlet, and with wiring

harness or connectors disconnected.

WARNING

Refer to page 4-2 for the procedure for servicing a bimetal switch.

1. Unplug range or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. For the ambient bimetal switch (N.C.),

touch the ohmmeter test leads to the terminals. The meter should indicate continuity (0 Ω).

4. For the cooling fan bimetal switch

(N.O.), touch the ohmmeter test leads to

the terminals. The meter should indicate

an open circuit (infinite).

Ambient Bimetal Switch (N.C.)

Opens @ 96°C (205°F)

Resets @ 74°C (165°F)

Cooling Fan Bimetal Switch (N.O.)

Resets @ 70°C (158°F)

Closes @ 60°C (140°F)

5-1

Page 54

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

SINGLE ELEMENT

INFINITE SWITCHES

WARNING

Electrical Shock Hazard

Refer to page 4-2 for the procedure for servicing a single element infinite switch.

NOTE: Refer to the Wiring Diagram that is

supplied with the unit to determine the wiring

for the infinite switch you are servicing.

1. Unplug range or disconnect power.

2. Set the ohmmeter to the R x 1 scale.

3. Turn the appropriate infinite switch to the

On position.

4. Touch the ohmmeter test leads to terminals L1 and P. The meter should indicate

continuity (0 Ω).

5. Touch the ohmmeter test leads to terminals L1 and H1. The meter should indicate

continuity (0 Ω).

6. Touch the ohmmeter test leads to terminals L2 and H2. The meter should indicate

continuity (0 Ω).

H2

L1

P

H1

P

H1

L1

L2

H2

L2

5-2

Page 55

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

DUAL ELEMENT INFINITE

SWITCH (OPTIONAL)

4

S2

4a

S1

S2

P1

P2

P1

P2

2

S1

1. Unplug range or disconnect power.

2. Set the ohmmeter to the R X 1 scale.

3. Turn the dual element infinite switch to the

“single” position.

4. Touch the ohmmeter test leads to the

following terminals. The meter should indicate continuity (0 Ω):

a) S1 - S2

b) P1 - 2

c) P2 - 4

5. Set the ohmmeter to the R X 1K scale.

6. Touch the ohmmeter test leads to terminals 2 and 4. The meter should indicate

approximately 5200 Ω.

7. Turn the dual element infinite switch to the

“dual” position.

8. Set the ohmmeter to the R X 1 scale.

4a

4

2

Refer to page 4-2 for the procedure for servicing the dual element infinite switch.

NOTE: Refer to the Wiring Diagram that is