FRONT-LOADING ELECTRIC DRYER

Use &Care Guide

For questions about features, operation/performance, parts accessories or service, call: 1-800-422-1230

In Canada, call for assistance 1-800-461-5681, for installation and service, call: 1-800-807-6777 or visit our website at...

www.kitchenaid.com or www.KitchenAid.ca

SECADORA ELÉCTRICA DE CARGA FRONTAL

Manual de Usoy Cuidado

Si tiene preguntas respecto a las características, funcionamiento/rendimiento, partes, accesorios o servicio técnico, llame al: 1-800-422-1230

Para la instalación y el servicio técnico llame al: 1-800-807-6777 o visite nuestro sitio web en... www.kitchenaid.com

SÉCHEUSE ÉLECTRIQUE À CHARGEMENT

À L’AVANT

Guide d’utilisation etd’entretien

Au Canada, pour assistance composez le 1-800-461-5681, pour installation ou service composez le 1-800-807-6777

ou visitez notre site web à... www.KitchenAid.ca

Table of Contents/Índice/Table des matières...............................................................2-3

Models/Modelos/Modèles KEHS01P, YKEHS01P

8557328A

TABLE OF CONTENTS

ÍNDICE

DRYER SAFETY..............................................................................4

INSTALLATION INSTRUCTIONS..................................................5

Tools and Parts ............................................................................5

Options.........................................................................................5

Location Requirements ...............................................................5

Electrical Requirements - U.S.A. Only......................................... 7

Electrical Requirements - Canada Only.......................................8

Electrical Connection - U.S.A. Only.............................................9

Venting Requirements................................................................13

Plan Vent System.......................................................................14

Install Vent System.....................................................................15

Install Leveling Legs...................................................................15

Level Dryer .................................................................................16

Connect Vent..............................................................................16

Reverse Door Swing ..................................................................16

Complete Installation .................................................................17

DRYER USE ..................................................................................18

Starting Your Dryer.....................................................................18

Stopping Your Dryer ..................................................................19

Pausing or Restarting.................................................................19

Control Locked...........................................................................19

Loading.......................................................................................19

Drying and Cycle Tips................................................................19

Status Lights ..............................................................................20

Cycles.........................................................................................20

Additional Features ....................................................................21

Drying Rack................................................................................22

DRYER CARE ..............................................................................23

Cleaning the Dryer Location ......................................................23

Cleaning the Lint Screen............................................................23

Cleaning the Dryer Interior .........................................................23

Removing Accumulated Lint......................................................23

Vacation and Moving Care.........................................................23

Changing the Drum Light...........................................................24

TROUBLESHOOTING ..................................................................24

ASSISTANCE OR SERVICE.........................................................25

In the U.S.A. ...............................................................................25

In Canada ...................................................................................25

WARRANTY ..................................................................................26

SEGURIDAD DE LA SECADORA................................................27

INSTRUCCIONES DE INSTALACIÓN.........................................28

Herramientas y piezas................................................................28

Opciones ....................................................................................28

Requisitos de ubicación ............................................................28

Requisitos eléctricos - EE. UU...................................................30

Conexión eléctrica - Sólo en EE. UU. ........................................32

Requisitos de ventilación ...........................................................36

Planificación del sistema de ventilación ....................................36

Instalación del sistema de ventilación .......................................38

Instalación de las patas niveladoras..........................................38

Nivelación de la secadora..........................................................39

Conexión del ducto de escape..................................................39

Cómo invertir el cierre de la puerta............................................39

Complete la instalación..............................................................40

USO DE LA SECADORA ..............................................................41

Puesta en marcha de la secadora .............................................41

Detención de la marcha de la secadora ....................................42

Pausa o reanudación de la marcha ...........................................42

Control bloqueado .....................................................................42

Cómo cargar...............................................................................42

Sugerencias de ciclos y secado ................................................42

Luces de estado.........................................................................43

Ciclos..........................................................................................43

Características adicionales ........................................................44

Estante de secado......................................................................45

CUIDADO DE LA SECADORA....................................................46

Limpieza del lugar donde está la secadora...............................46

Limpieza del filtro de pelusa ......................................................46

Limpieza del interior de la secadora ..........................................47

Eliminación de pelusa acumulada .............................................47

Cuidado para las vacaciones y la mudanza..............................47

Cambio de la luz del tambor......................................................47

SOLUCIÓN DE PROBLEMAS......................................................48

AYUDA O SERVICIO TÉCNICO...................................................49

GARANTÍA.....................................................................................50

2

TABLE DES MATIÈRES

SÉCURITÉ DE LA SÉCHEUSE....................................................51

INSTRUCTIONS D'INSTALLATION ............................................52

Outillage et pièces nécessaires .................................................52

Options.......................................................................................52

Emplacement d’installation........................................................52

Spécifications électriques - Canada seulement........................54

Exigences concernant l’évacuation...........................................55

Planification du système d'évacuation......................................56

Installation du conduit d’évacuation..........................................57

Installation des pieds de nivellement.........................................58

Mise à niveau de la sécheuse....................................................58

Conduit d’évacuation.................................................................58

Inversion de l'ouverture de la porte ...........................................58

Achever l’installation ..................................................................60

UTILISATION DE LA SÉCHEUSE................................................61

Mise en marche de la sécheuse ................................................61

Arrêt de la sécheuse ..................................................................62

Arrêt ou remise en marche.........................................................62

Verrouillage des commandes ....................................................62

Chargement................................................................................62

Conseils pour le séchage et les programmes ...........................63

Témoins lumineux ......................................................................63

Programmes...............................................................................64

Caractéristiques supplémentaires .............................................65

Grille de séchage........................................................................66

ENTRETIEN DE LA SÉCHEUSE.................................................67

Nettoyage de l'emplacement de la sécheuse ...........................67

Nettoyage du filtre à charpie......................................................67

Nettoyage de l’intérieur de la sécheuse ....................................68

Retrait de la charpie accumulée ................................................68

Précautions à prendre pour les vacances et avant

un déménagement .....................................................................68

Changement de l’ampoule d’éclairage du tambour..................68

DÉPANNAGE ................................................................................69

ASSISTANCE OU SERVICE.........................................................70

GARANTIE.....................................................................................71

3

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

including the following:

■

Read all instructions before using the dryer.

■

Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

■

Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, drycleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

■

Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

■

Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

■

Do not reach into the dryer if the drum is moving.

■

Do not install or store the dryer where it will be exposed

to the weather.

■

Do not tamper with controls.

To reduce the risk of fire, electric shock, or injury to persons when using the dryer, follow basic precautions,

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

■

Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

■

Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

■

Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

■

Clean lint screen before or after each load.

■

Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

■

The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

■

See installation instructions for grounding requirements.

follow

SAVE THESE INSTRUCTIONS

4

INSTALLATION INSTRUCTIONS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the safety instructions provided with any tools

listed here.

■ Flat-blade screwdriver

■ Adjustable wrench that

opens to 1" (2.5 cm) or

hex-head socket wrench

(for adjusting dryer feet)

■ Level

■ Wire stripper (direct wire

installations)

Parts supplied

Remove parts packages from dryer drum. Check that all parts are

included.

4 Leveling legs

NOTE: Do not use leveling legs if installing the dryer on a

pedestal.

Parts needed

Check local codes. Check existing electrical supply and venting.

See “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

■ For close-clearance installations between 31.5" (80.01 cm)

and 37" (93.98 cm), see “Plan Vent System” section for

venting requirements.

■ #2 Phillips screwdriver

■ Vent clamps

■ Caulking gun and

compound (for installing

new exhaust vent)

■ Tin snips (new vent

installations)

■ ¼" nut driver

Options

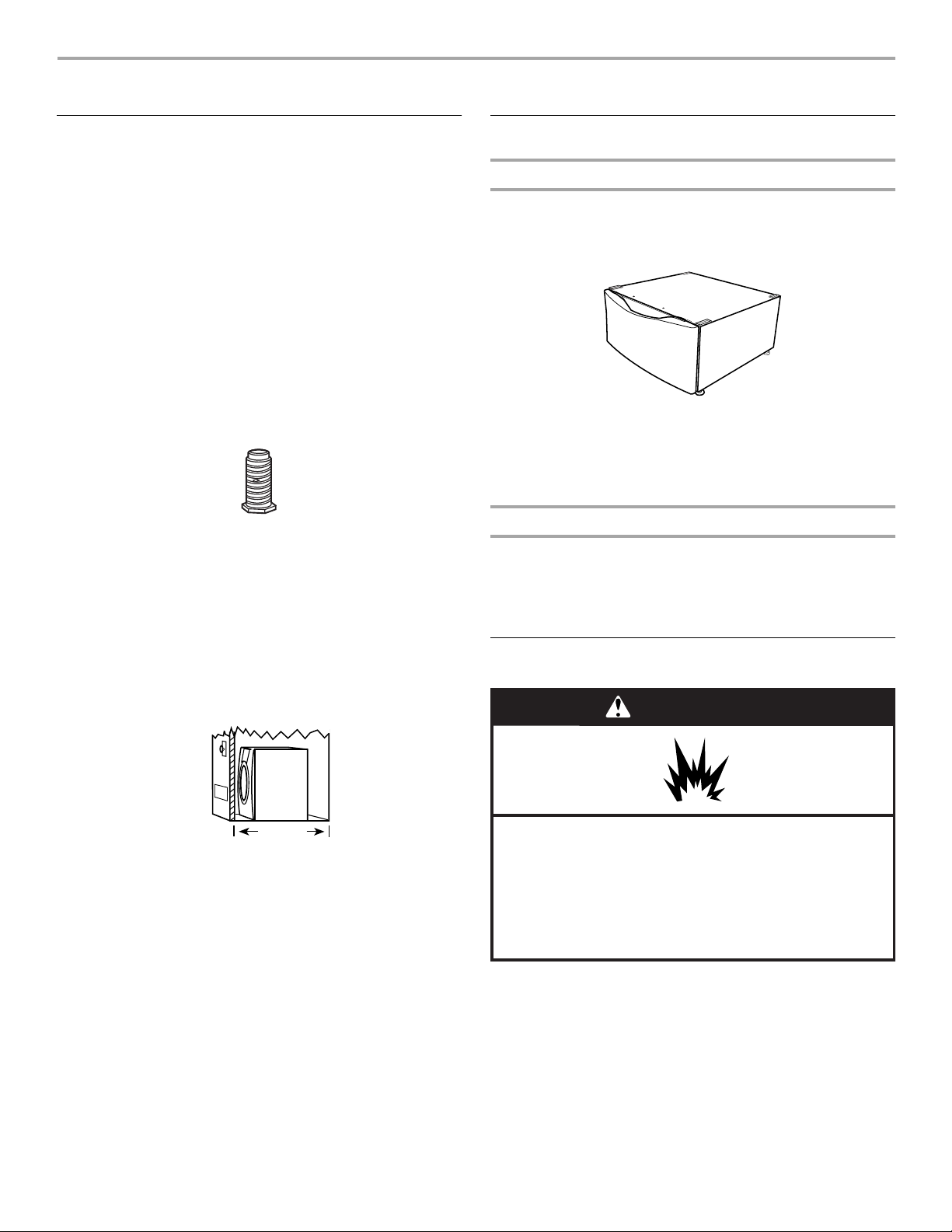

Pedestal

Are you placing the dryer on a pedestal? You may purchase a

pedestal separately for this dryer. This pedestal will add about

13" (33 cm) to the height of your unit for a total height of

approximately 51" (130 cm).

Optional pedestal

To order, call the dealer from whom you purchased your dryer or

refer to the “Assistance or Service” section of this manual. Ask

for Part Number LAB2700PMT (Meteorite) or LAB2700MQ0

(White).

Stack Kit

Are you planning to stack your washer and dryer? To do so, you

will need to purchase a Stack Kit.

To order, call the dealer from whom you purchased your dryer or

refer to the “Assistance or Service” section of this manual. Ask

for Part Number 8541503.

Location Requirements

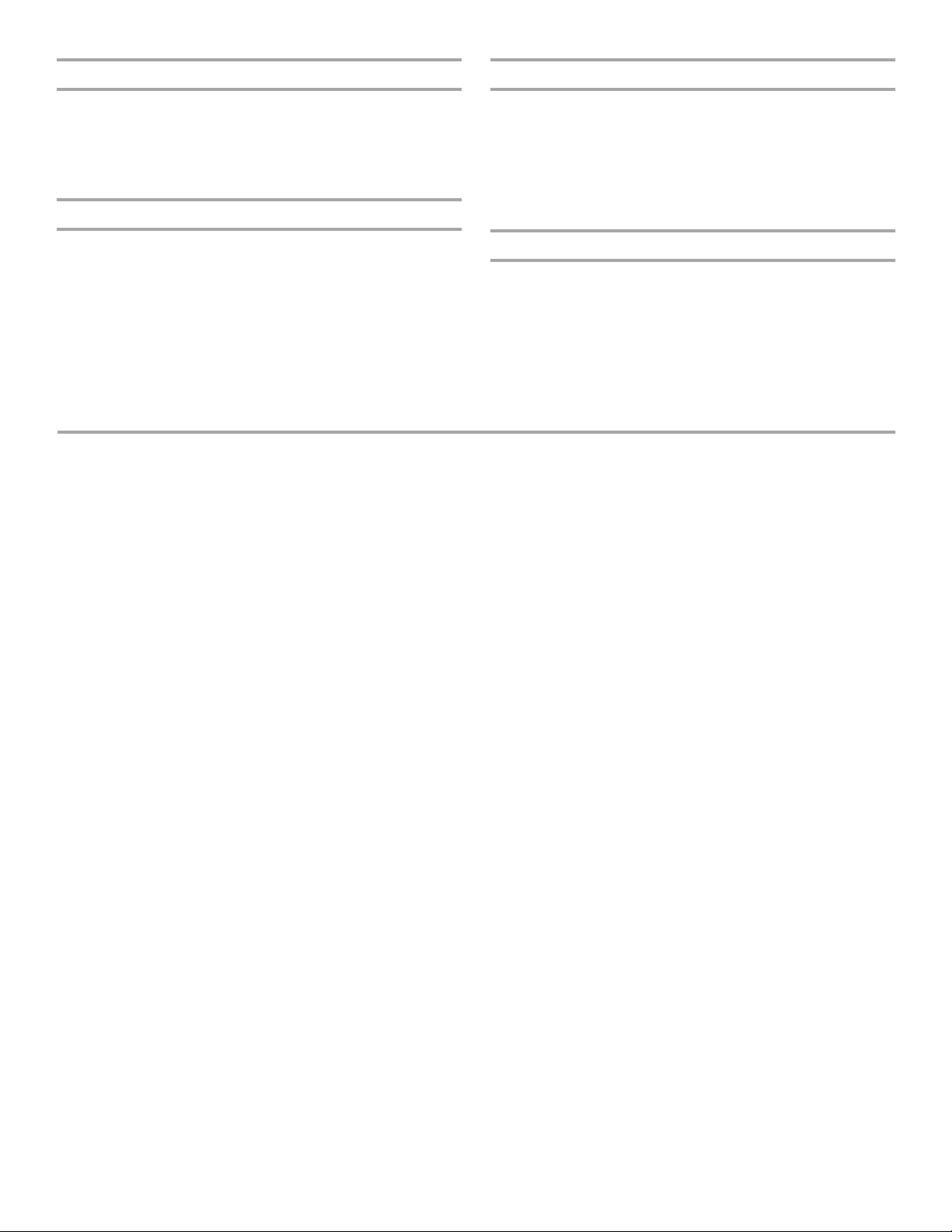

WARNING

37"

(93.98 cm)

Mobile home installations require metal exhaust system hardware

available for purchase from the dealer from whom you purchased

your dryer. For further information, please refer to the “Assistance

or Service” section of this manual.

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You will need

■ A location that allows for proper exhaust installation. See

“Venting Requirements.”

■ A separate 30 amp circuit.

■ A grounded electrical outlet located within 2 ft (61 cm) of

either side of the dryer. See “Electrical Requirements.”

5

■ A sturdy floor to support the total dryer weight of

200 lbs (90.7 kg). The combined weight of a companion

appliance should also be considered.

■ A level floor with a maximum slope of 1" (2.5 cm) under entire

dryer. If slope is greater than 1" (2.5 cm), install Extended

Dryer Feet Kit, Part Number 279810. Clothes may not tumble

properly and automatic sensor cycles may not operate

correctly if dryer is not level.

■ For a garage installation, you will need to place the dryer at

least 18" (46 cm) above the floor. If using a pedestal, you will

need an additional 6" (15.24 cm).

Do not operate your dryer at temperatures below 45ºF (7ºC). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. This can result in longer drying times.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes, or

sleeping quarters. Contact your local building inspector.

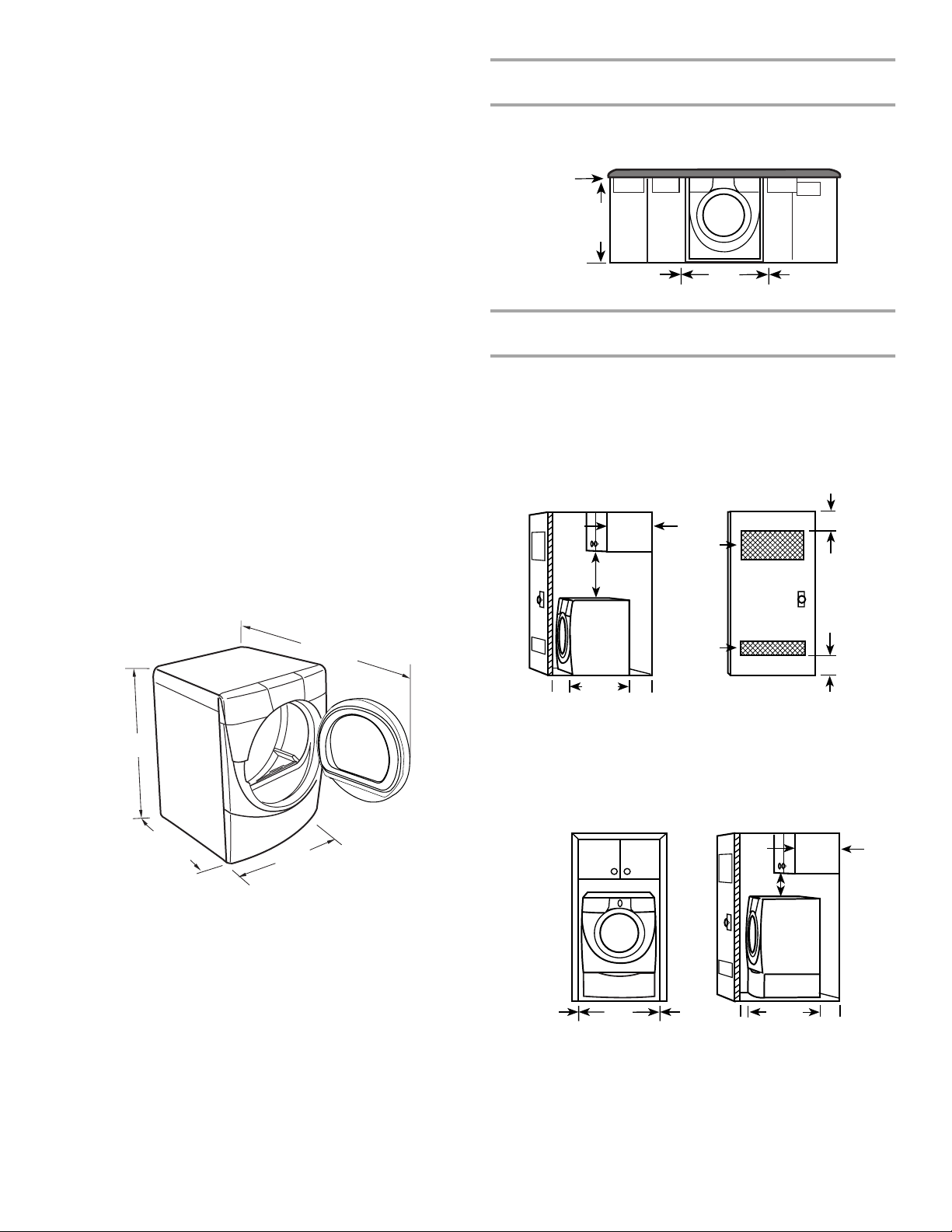

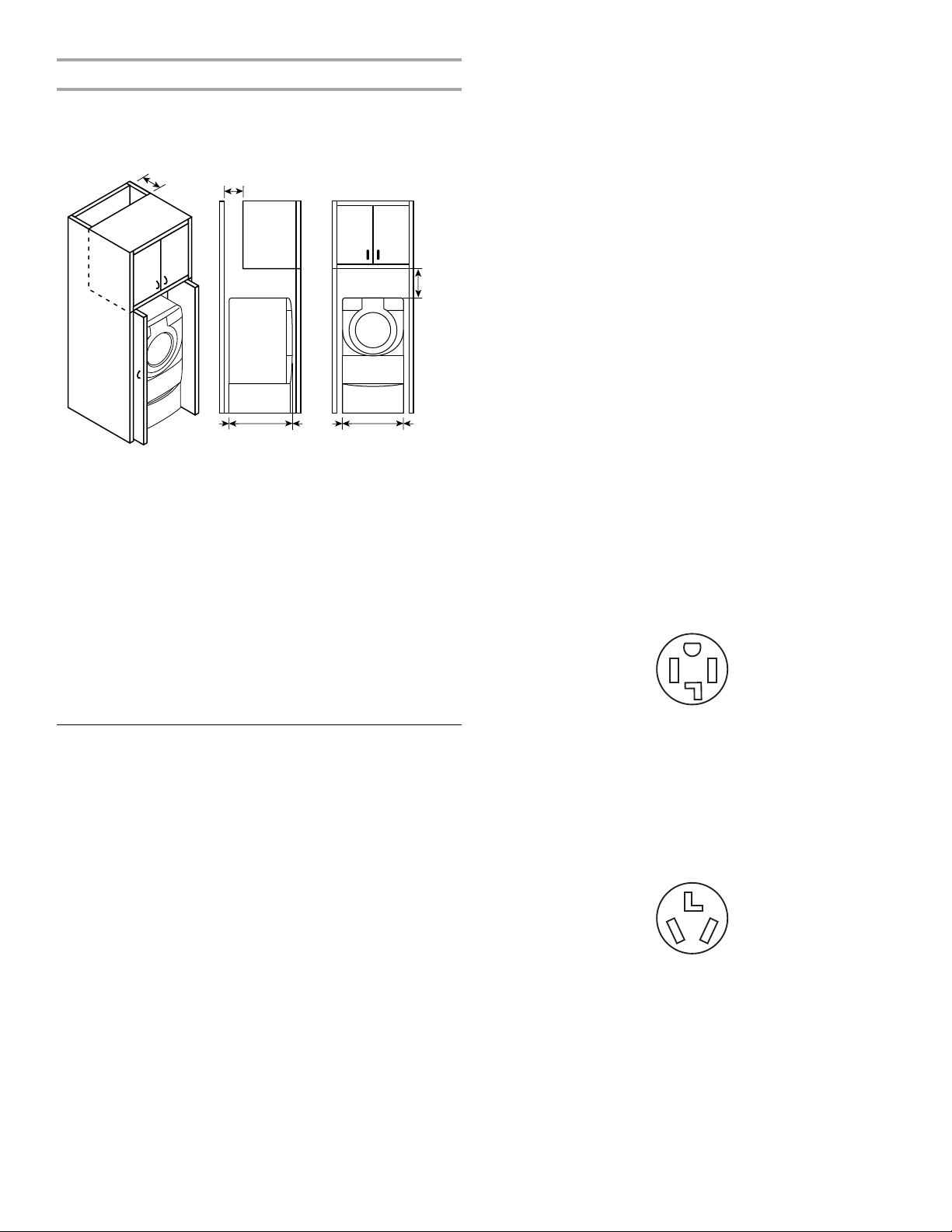

Installation clearances

■ The location must be large enough to fully open the dryer

door.

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door and

floor moldings.

■ Additional spacing of 1" (2.5 cm) on all sides of the dryer is

recommended to reduce noise transfer.

■ Companion appliance spacing should also be considered.

Dryer Dimensions

Minimum installation spacing for custom undercounter

installation

The dimensions shown are for the minimum spacing allowed.

Custom undercounter installation - Dryer only

0"

(0 cm)

38" min.

(96.52 cm)

0"

(0 cm)

27"

(68.6 cm)

0"

(0 cm)

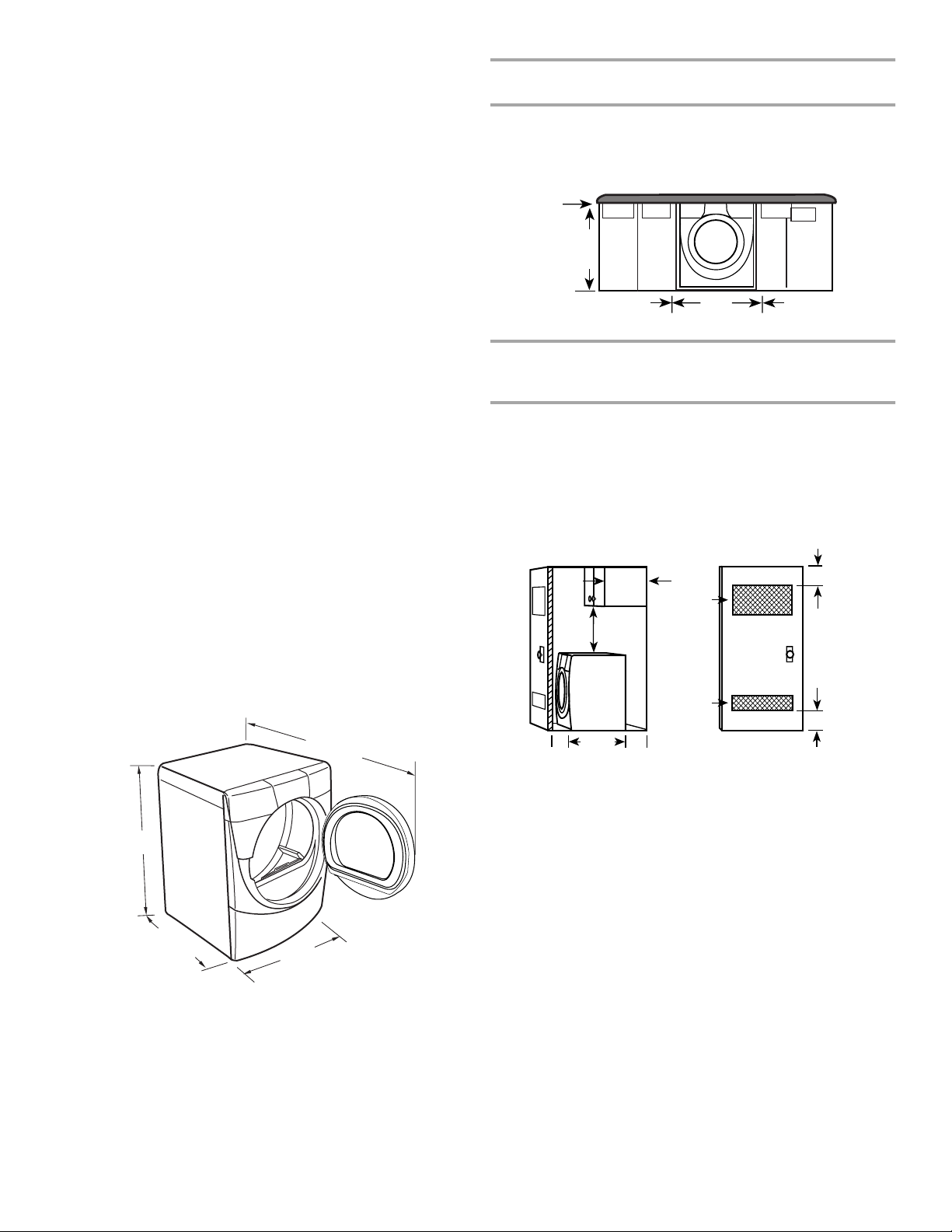

Minimum installation spacing for recessed or closet

installation, with or without a pedestal

■ The dimensions shown are for the minimum spacing allowed.

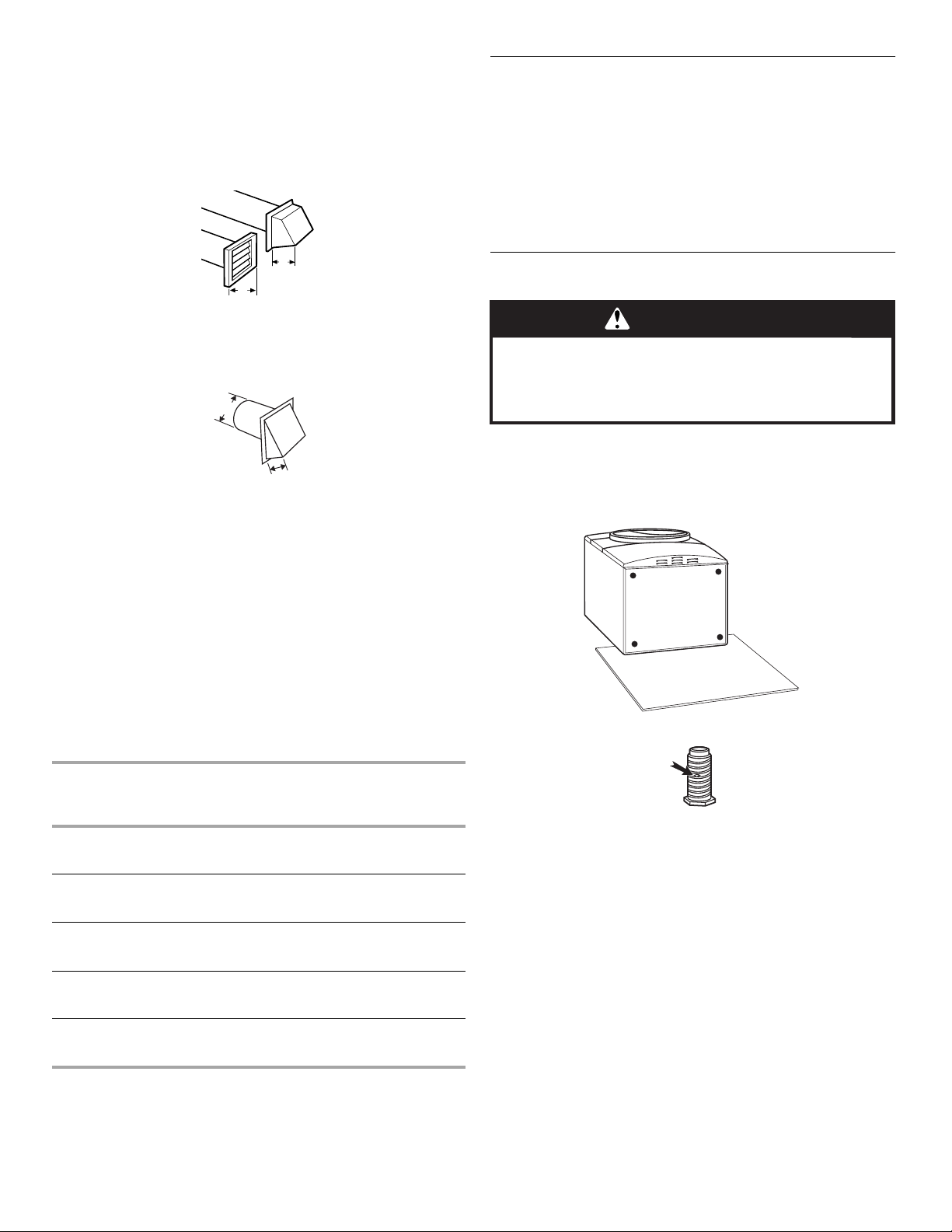

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

Closet installation - Dryer only

3"

14" max.

(35.6 cm)

18" min.

(45.72 cm)

48 in.

(310 cm2)

2

(7.6 cm)

51½"

(130.81 cm)

38"

(96.52 cm)

*31½"

(80 cm)

27"

(68.6 cm)

*Most installations require a minimum 5½" (14 cm) clearance

behind the dryer for the exhaust vent with elbow. See “Venting

Requirements.”

2

24 in.

(155 cm2)

0"

31½"

(80 cm)

0"

(0 cm)

B

(0 cm)

A

A. Side view - closet or confined area

B. Closet door with vents

Recessed or closet installation - Dryer on pedestal

14" max.

(35.6 cm)

18" min.

(45.72 cm)

0"

(0 cm)

27"

(68.6 cm)

0"

(0 cm)

0"

(0 cm)

31½"

(80 cm)

0"

(0 cm)

AB

A. Recessed area

B. Side view - closet or confined area

3"

(7.6 cm)

6

Minimum installation spacing for cabinet installation

)

■ The dimensions shown are for the minimum spacing allowed.

■ For cabinet installation, with a door, minimum ventilation

openings in the top of the cabinet are required.

7" (17.8 cm)

7" (17.8 cm)

9"

(22.9 cm

Electrical Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

■ This dryer is manufactured ready to install with a 3-wire

electrical supply connection. The green cabinet-grounding

conductor is permanently connected to the neutral conductor

(white wire) within the dryer. If the dryer is installed with a

4-wire electrical supply connection, the green cabinetgrounding conductor must be removed from the external

ground connector (green screw), and secured under the

neutral terminal (center or white wire) of the terminal block.

When the green cabinet-grounding conductor is secured

under the neutral terminal (center or white wire) of the

terminal block, the dryer cabinet is isolated from the neutral

conductor.

■ If local codes do not permit the connection of a cabinet

ground connector to the neutral wire, see “Optional 3-wire

connection” section.

■ Use a 4-wire conductor cord when the dryer is installed in a

mobile home or an area where local codes do not permit

grounding through the neutral.

0"

(0 cm)

31¹₂"

(80.0 cm)

0"

(0 cm)

0"

(0 cm)

27"

(68.6 cm)

0"

(0 cm)

Mobile home - Additional installation requirements

This dryer is suitable for mobile home installations. The installation must conform to the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 (formerly the Federal

Standard for Mobile Home Construction and Safety, Title 24,

HUD Part 280) or Standard CAN/CSA-Z240 MH.

Mobile home installations require:

■ Metal exhaust system hardware which is available for

purchase from your dealer.

■ Special provisions must be made in mobile homes to

introduce outside air into the dryer. The opening (such as a

nearby window) should be at least twice as large as the dryer

exhaust opening.

Electrical Requirements- U.S.A.Only

It is your responsibility

■ To contact a qualified electrical installer.

■ To be sure that the electrical connection is adequate and in

conformance with the National Electrical Code, ANSI/NFPA

70-latest edition and all local codes and ordinances.

The National Electric Code requires a 4-wire power supply

connection for homes built after 1996, dryer circuits involved

in remodeling after 1996, and all mobile home installations.

A copy of the above code standards can be obtained from:

National Fire Protection Association, One Batterymarch Park,

Quincy, MA 02269.

■ To supply the required 3 or 4 wire, single phase, 120/240-volt,

60-Hz., AC-only electrical supply (or 3 or 4 wire, 120/208-volt

electrical supply, if specified on the serial/rating plate) on a

separate 30-amp circuit, fused on both sides of the line. A

time-delay fuse or circuit breaker is recommended. Connect

to an individual branch circuit. Do not have a fuse in the

neutral or grounding circuit.

■ Do not use an extension cord.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

■ A UL listed 30 amp power supply cord, rated 120/240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

■ A UL listed strain relief.

If your outlet looks like this:

4-wire receptacle (14-30R)

Then choose a 4-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 4-wire power supply

cord, at least 4 ft (1.22 m) long, must have 4, 10-gauge copper

wires and match a 4-wire receptacle of NEMA Type 14-30R. The

ground wire (ground conductor) may be either green or bare. The

neutral conductor must be identified by a white cover.

If your outlet looks like this:

3-wire receptacle (10-30R)

Then choose a 3-wire power supply cord with ring or spade

terminals and UL listed strain relief. The 3-wire power supply

cord, at least 4 ft (1.22 m) long, must have 3, 10-gauge copper

wires and match a 3-wire receptacle of NEMA Type 10-30R.

7

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire)

and be:

■ Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), protected with flexible metallic conduit. All

current-carrying wires must be insulated.

■ 10-gauge solid copper wire (do not use aluminum).

■ At least 5 ft (1.52 m) long.

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer uses a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

■

For a permanently connected dryer:

This dryer must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the dryer.

WARNING:

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug on the power

supply cord: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

Improper connection of the equipment-

SAVE THESE INSTRUCTIONS

Electrical Requirements- CanadaOnly

WARNING

■ To supply the required 4 wire, single phase, 115/230-volt,

60-Hz., AC-only electrical supply on a separate 30-amp

circuit, fused on both sides of the line. A time-delay fuse or

circuit breaker is recommended. Connect to an individual

branch circuit.

■ This dryer is equipped with a CSA International Certified

Power Cord intended to be plugged into a standard 14-30R

wall receptacle. The cord is 5 ft (1.52 m) in length. Be sure

wall receptacle is within reach of dryer’s final location.

4-wire receptacle 14-30R

■ Do not use an extension cord.

If using a replacement power supply cord, it is recommended

that you use Power Supply Cord Replacement Part Number

9831317.

numbers located in the “Assistance or Service” section on this

manual.

For further information, please reference the service

GROUNDING INSTRUCTIONS

■

For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

Electrical Shock Hazard

Plug into a grounded 4 prong outlet.

Failure to do so can result in death or electrical shock.

It is your responsibility

■ To contact a qualified electrical installer.

■ To be sure that the electrical connection is adequate and in

conformance with the Canadian Electrical Code, C22.1-latest

edition and all local codes. A copy of the above codes

standard may be obtained from: Canadian Standards

Association, 178 Rexdale Blvd., Toronto, ON M9W 1R3

CANADA.

8

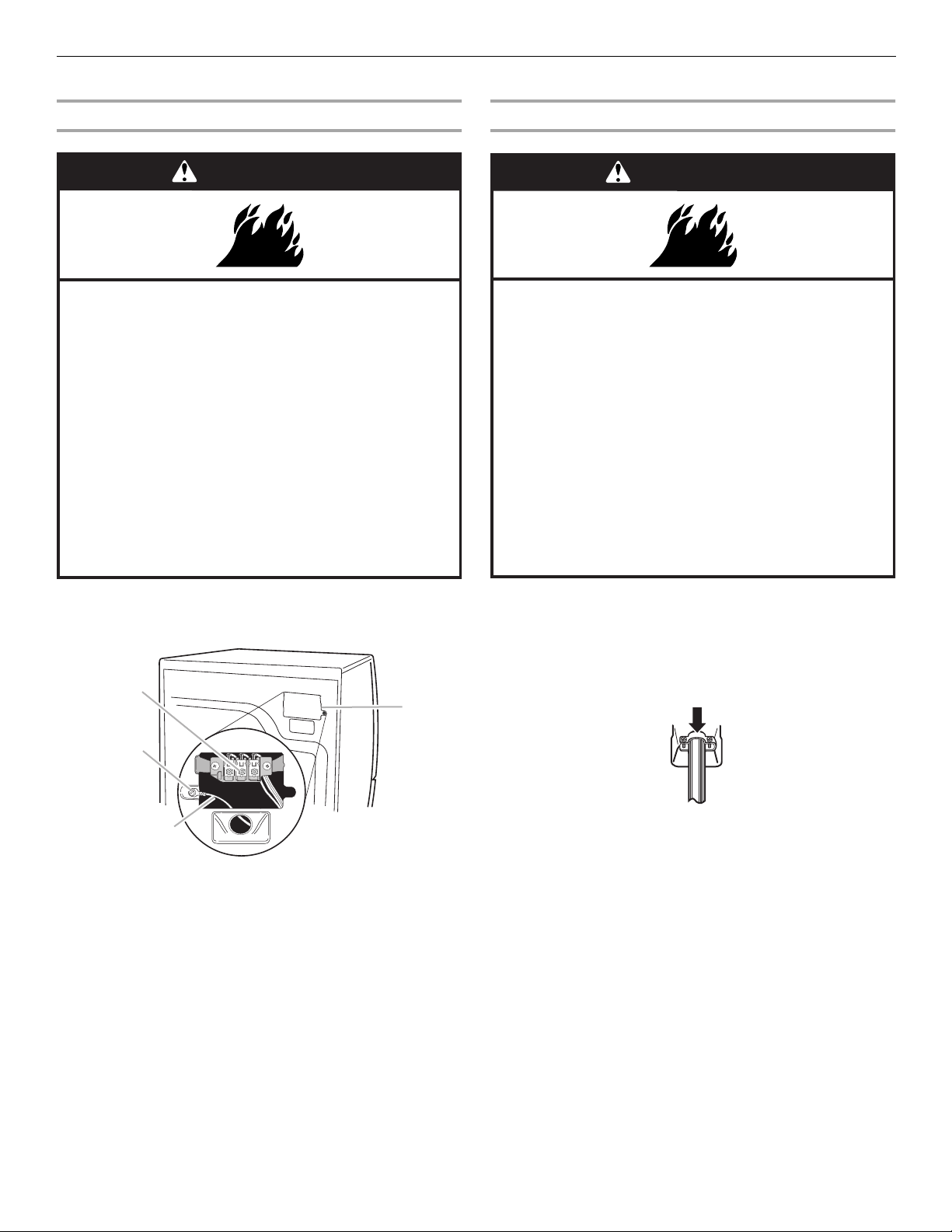

Electrical Connection- U.S.A.Only

Power Supply Cord

WARNING

Fire Hazard

Use a new UL listed 30 amp power supply cord.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

Direct Wire

WARNING

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center

terminal (silver).

Ground wire (green or bare wire) must be connected to

green ground connector.

Connect remaining 2 supply wires to remaining

2 terminals (gold).

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or

electrical shock.

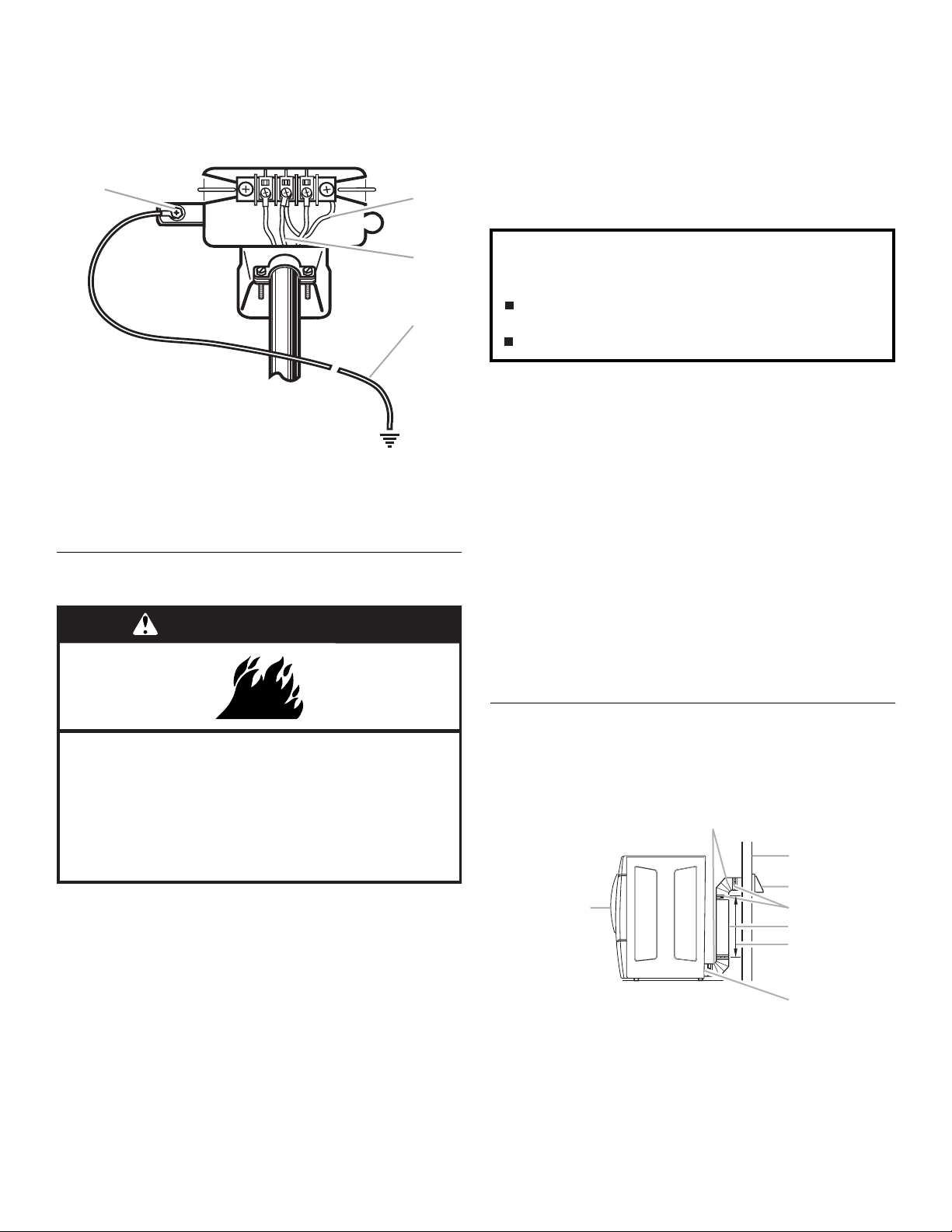

1. Disconnect power.

2. Remove the hold-down screw and terminal block cover.

C

D

B

A

A. Neutral grounding wire (green with yellow stripes)

B. External ground conductor screw

C. Center, silver-colored terminal block screw

D. Terminal block cover and hold-down screw

3. Assemble a ³⁄₄" (1.9 cm) UL listed strain relief (UL marking on

strain relief) into the hole below the terminal block opening.

Tighten strain relief screws just enough to hold the two clamp

sections together. Put power supply cord through the strain

relief. The strain relief should have a tight fit with the dryer

cabinet and be in a horizontal position.

4. Now complete installation following instructions for your type

of electrical connection:

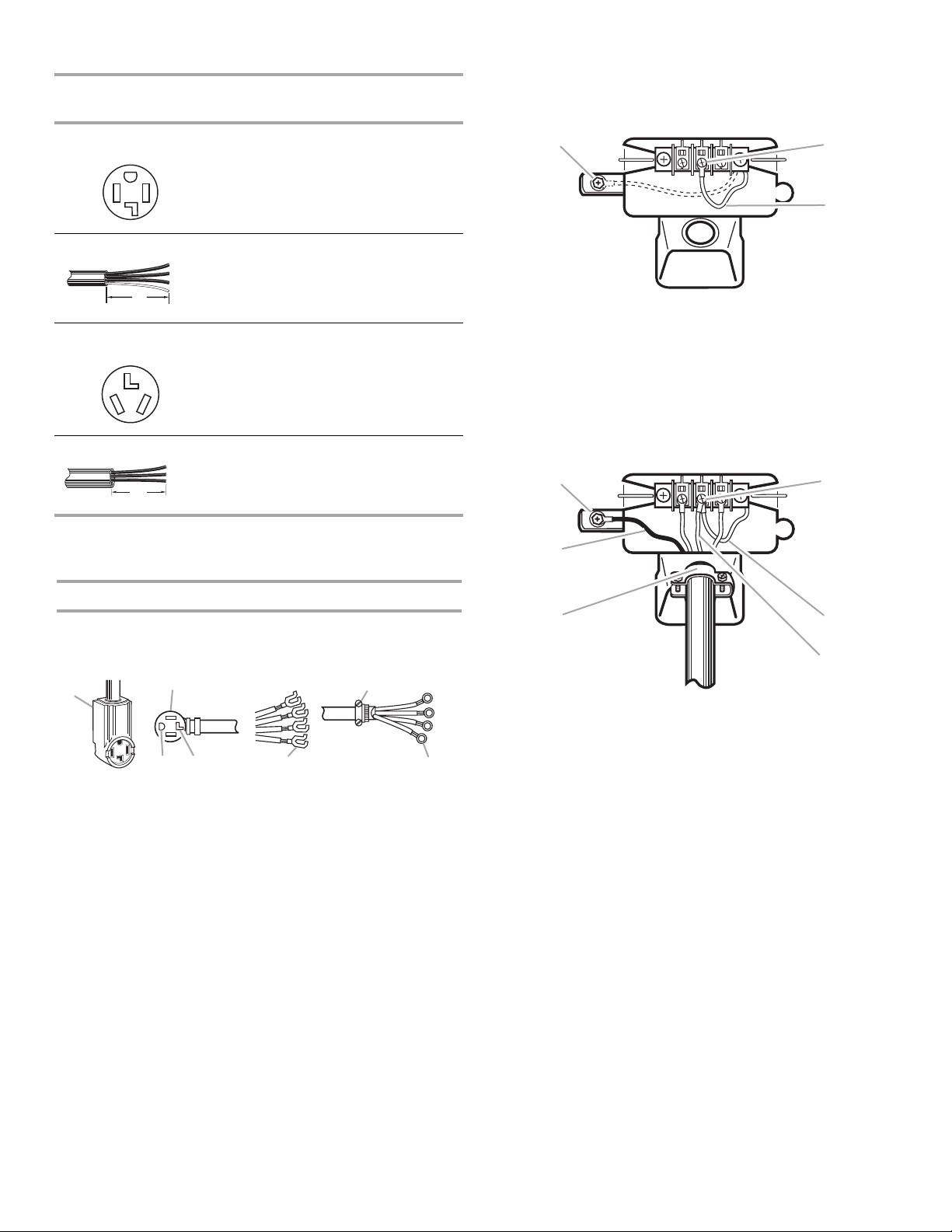

4-wire (recommended)

3-wire (if 4-wire is not available)

9

Electrical Connection Options

G

B

If your home has: And you will be

connecting to:

4-wire receptacle

(NEMA Type 14-30R)

A UL listed,

120/240 volt

minimum,

30 amp, dryer

power supply

cord*

Go to Section

4-wire connection:

Power supply cord

1. Remove center terminal block screw.

2. Remove neutral grounding wire (green with yellow stripes)

from external ground conductor screw. Fasten it under center,

silver-colored terminal block screw.

A

C

4-wire direct A fused

disconnect or

4-wire connection:

Direct Wire

circuit breaker

5"

(12.7 cm)

3-wire receptacle

(NEMA type 10-30R)

box*

A UL listed,

120/240 volt

3-wire connection:

Power supply cord

minimum,

30 amp, dryer

power supply

cord*

3-wire direct A fused

disconnect or

3½"

(8.9 cm)

circuit breaker

box*

3-wire connection:

Direct Wire

*If local codes do not permit the connection of a frame-grounding

conductor to the neutral wire, go to “Optional

3-wire Connection” section.

4-wire connection: Power supply cord

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit the use of 3-wire

connections.

A

BF

D

C

A. 4-wire receptacle (NEMA type 14-30R)

B. 4-prong plug

C. Ground prong

D. Neutral prong

E. Spade terminals with upturned ends

F. ¾" (1.9 cm) UL listed strain relief

G. Ring terminals

E

A. External ground conductor screw - Dotted line shows

position of NEUTRAL grounding wire before being

moved to center terminal block screw

B. Center silver-colored terminal block screw

C. Green/yellow wire of harness

3. Connect ground wire (green or bare) of power supply cord to

external ground conductor screw. Tighten screw.

4. Connect neutral wire (white or center wire) of power supply

cord under center screw of the terminal block.

A

D

B

C

E

F

A. External ground conductor screw

B. Ground wire (green or bare) wire of power supply cord

³⁄₄

" (1.9 cm) UL listed strain relief

C.

D. Center silver-colored terminal block screw

E. Neutral grounding wire (green with yellow stripes)

F. Neutral wire (white or center wire)

5. Connect the other wires to outer terminal block screws.

Tighten screws.

6. Tighten strain relief screws.

7. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

10

4-wire connection: Direct wire

B

D

E

3. Connect ground wire (green or bare) of power supply cable to

external ground conductor screw. Tighten screw.

IMPORTANT: A 4-wire connection is required for mobile homes

and where local codes do not permit the use of 3-wire

connections.

Direct wire cable must have 5 ft (1.52 m) of extra length so dryer

can be moved if needed.

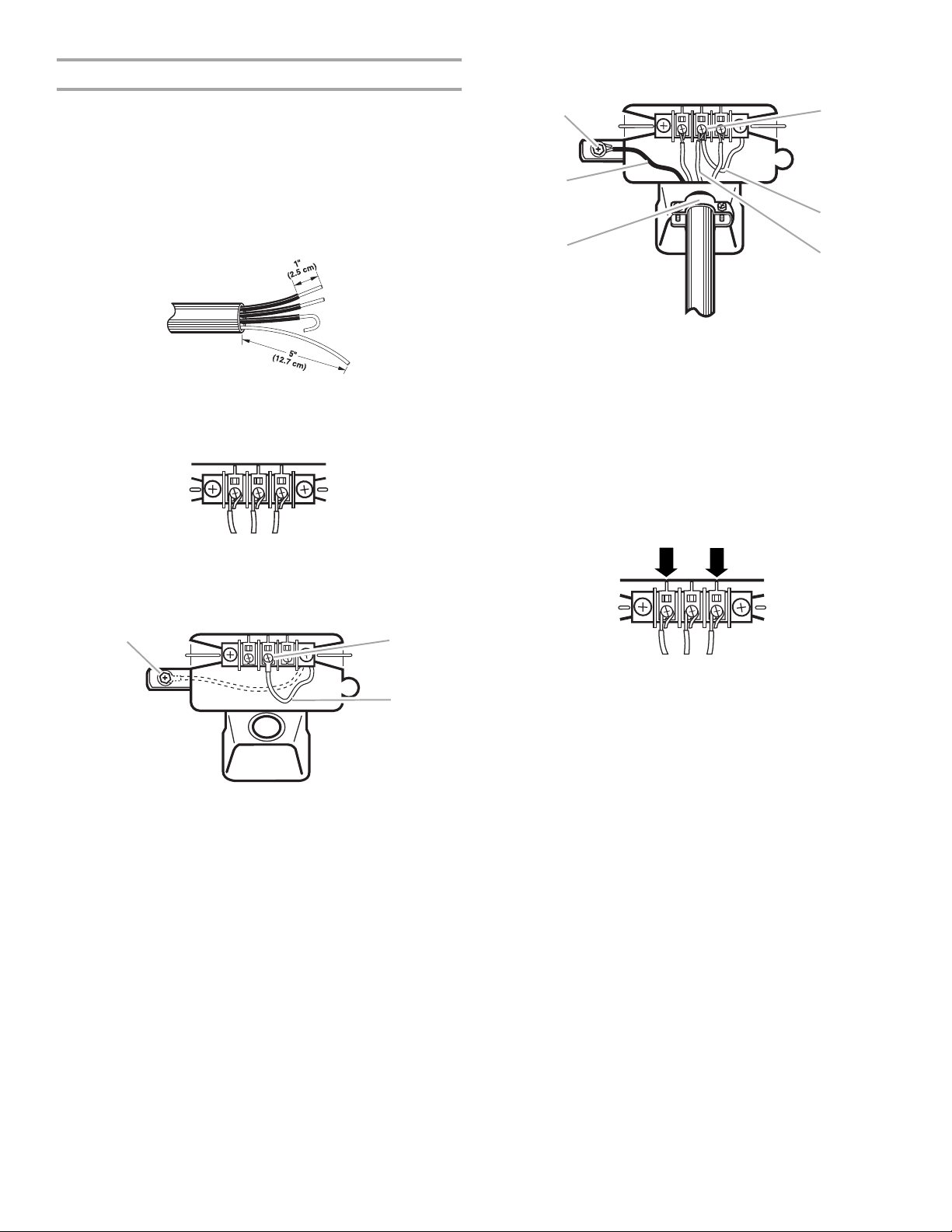

Strip 5" (12.7 cm) of outer covering from end of cable, leaving

bare ground wire at 5" (12.7 cm). Cut 1¹⁄₂" (3.8 cm) from 3

remaining wires. Strip insulation back 1" (2.5 cm). Shape ends of

wires into a hook shape.

When connecting to the terminal block, place the hooked end of

the wire under the screw of the terminal block (hook facing right),

squeeze hooked end together and tighten screw. See example

below.

1. Remove center terminal block screw.

2. Remove neutral grounding wire (green with yellow stripes)

from external ground conductor screw. Fasten it under center,

silver-colored terminal block screw.

A

B

C

A. External ground conductor screw

B. Green or bare copper wire of power supply cable

C.

³⁄₄

" (1.9 cm) UL listed strain relief

D. Center silver-colored terminal block screw

E. Neutral grounding wire (green with yellow stripes)

F. Neutral wire (white or center wire)

F

4. Place the hooked end of the neutral wire (white wire) of power

supply cable under the center screw of terminal block (hook

facing right). Squeeze hooked end together. Tighten screw.

5. Place the hooked ends of the other power supply cable wires

under the outer terminal block screws (hooks facing right).

Squeeze hooked ends together. Tighten screws.

A

C

A. External ground conductor screw - Dotted line shows

position of NEUTRAL grounding wire before being

moved to center terminal block screw

B. Center silver-colored terminal block screw

C. Green/yellow wire of harness

6. Tighten strain relief screws.

7. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

11

3-wire connection: Power supply cord

E

C

3-wire connection: Direct wire

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

B

D

E

A

C

A. 3-wire receptacle (NEMA type 10-30R)

B. 3-wire plug

C. Neutral prong

D. Spade terminals with up turned ends

³⁄₄

" (1.9 cm) UL listed strain relief

E.

F. R in g t er mi na ls

G. Neutral (white or center wire)

F

G

1. Loosen or remove center terminal block screw.

2. Connect neutral wire (white or center wire) of power supply

cord to the center, silver-colored terminal screw of the

terminal block. Tighten screw.

A

B

C

D

Use where local codes permit connecting cabinet-ground

conductor to neutral wire.

Direct wire cable must have 5 ft (1.52 m) of extra length so dryer

can be moved if needed.

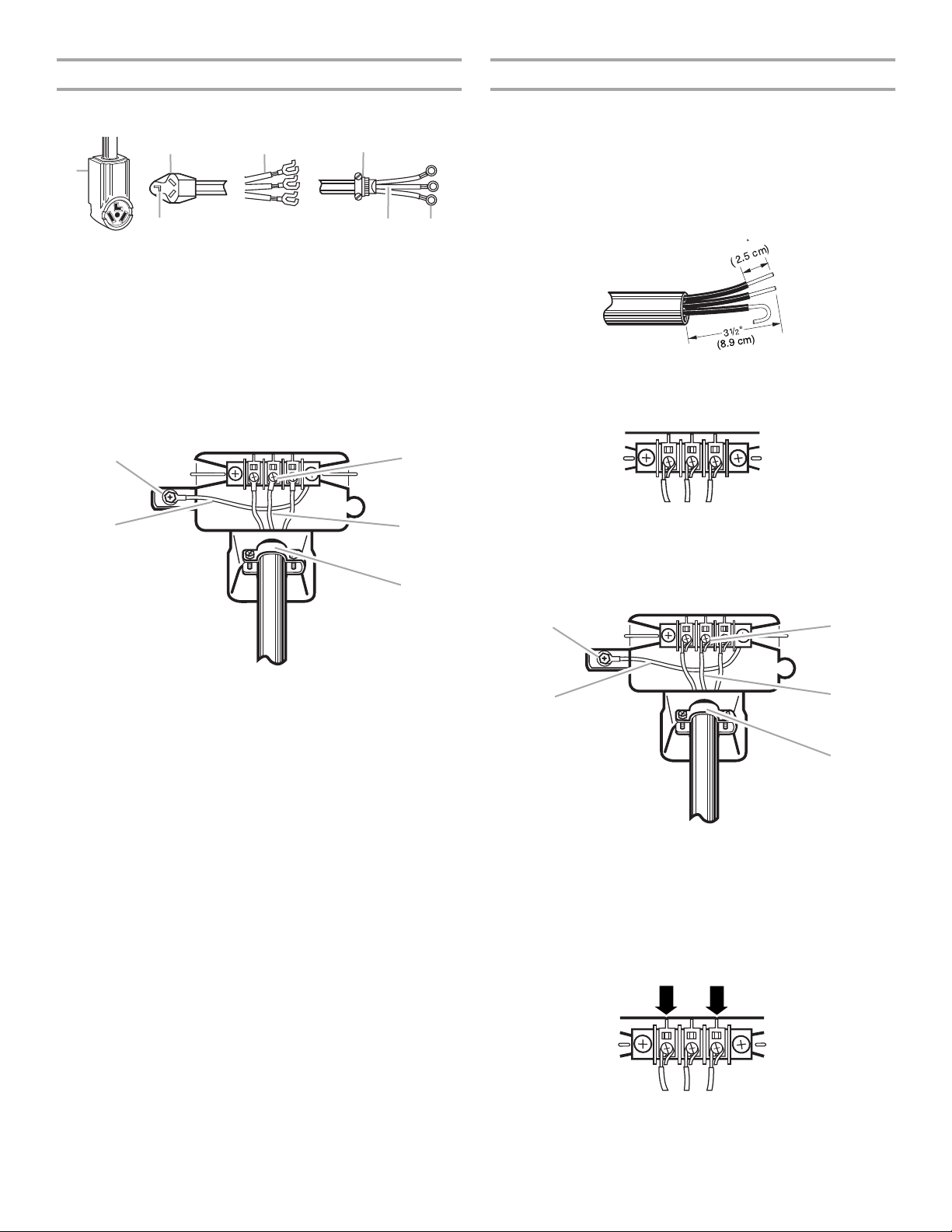

Strip 3¹⁄₂" (8.9 cm) of outer covering from end of cable. Strip

insulation back 1" (2.5 cm). If using 3-wire cable with ground

wire, cut bare wire even with outer covering. Shape ends of wires

into a hook shape.

1

When connecting to the terminal block, place the hooked end of

the wire under the screw of the terminal block (hook facing right),

squeeze hooked end together and tighten screw. See example

below.

1. Loosen or remove center terminal block screw.

2. Place the hooked end of the neutral wire (white or center wire)

of power supply cable under the center screw of terminal

block (hook facing right). Squeeze hooked end together.

Tighten screw.

A. External ground conductor screw

B. Neutral grounding wire (green with yellow stripes)

C. Center silver-colored terminal block screw

D. Neutral wire (white or center wire)

³⁄₄

" (1.9 cm) UL listed strain relief

E.

3. Connect the other wires to outer terminal block screws.

Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

A

B

D

E

A. External ground conductor screw

B. Neutral grounding wire (green with yellow stripes)

C. Center silver-colored terminal block screw

D. Neutral wire (white or center wire)

³⁄₄

" (1.9 cm) UL listed strain relief

E.

3. Place the hooked ends of the other power supply cable wires

under the outer terminal block screws (hooks facing right).

Squeeze hooked ends together. Tighten screws.

12

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

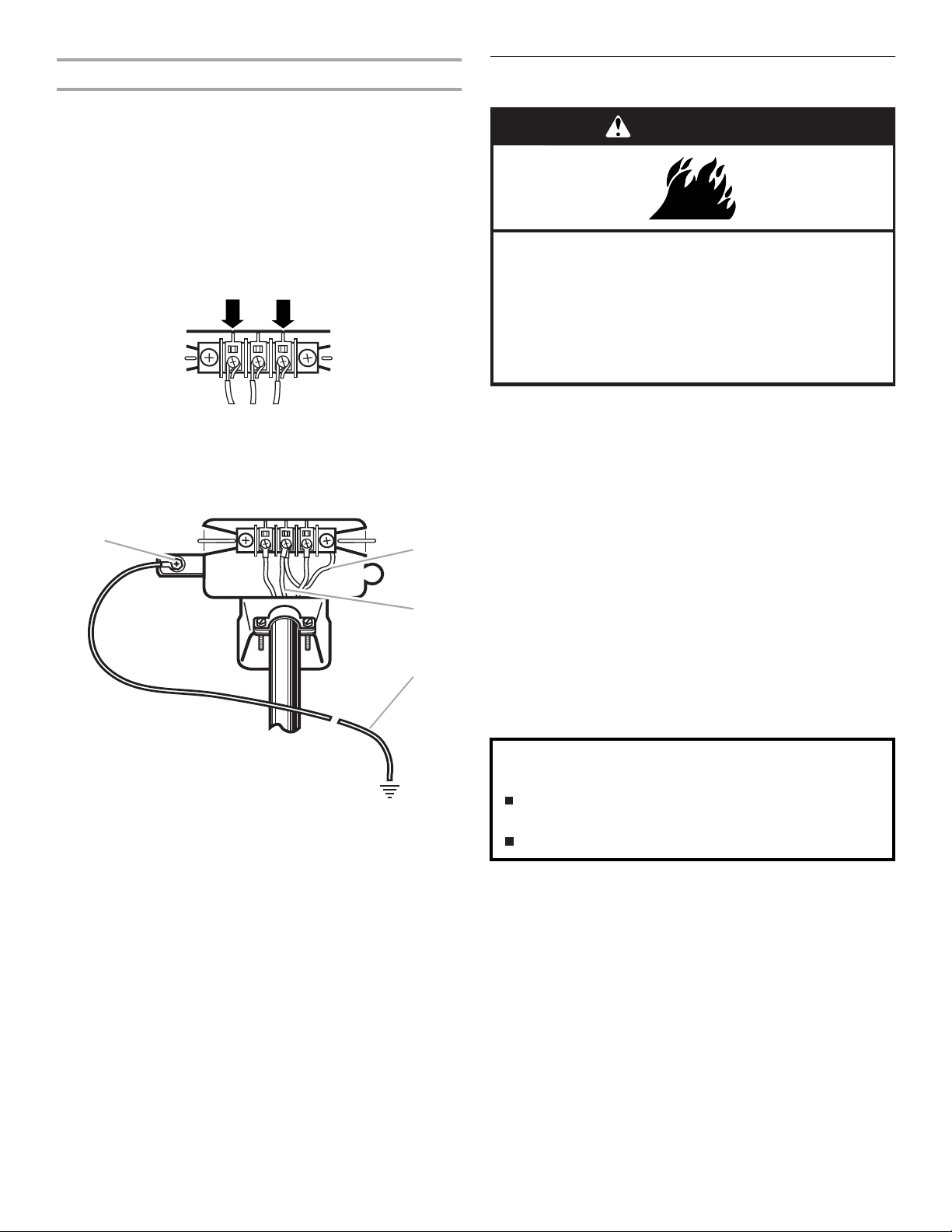

Optional 3-wire connection

D

Use for direct wire or power supply cord where local codes

do not permit connecting cabinet-ground conductor to

neutral wire.

1. Remove center terminal block screw.

2. Remove neutral grounding wire (green with yellow stripes)

from external ground conductor screw. Connect appliance

ground wire and the neutral wire (white or center wire) of

power supply cord/cable under center, silver-colored terminal

block screw. Tighten screw.

3. Connect the other wires to outer terminal block screws.

Tighten screws.

4. Tighten strain relief screws.

5. Insert tab of terminal block cover into slot of dryer rear panel.

Secure cover with hold-down screw.

6. Connect a separate copper ground wire from the external

ground conductor screw to an adequate ground.

A

B

C

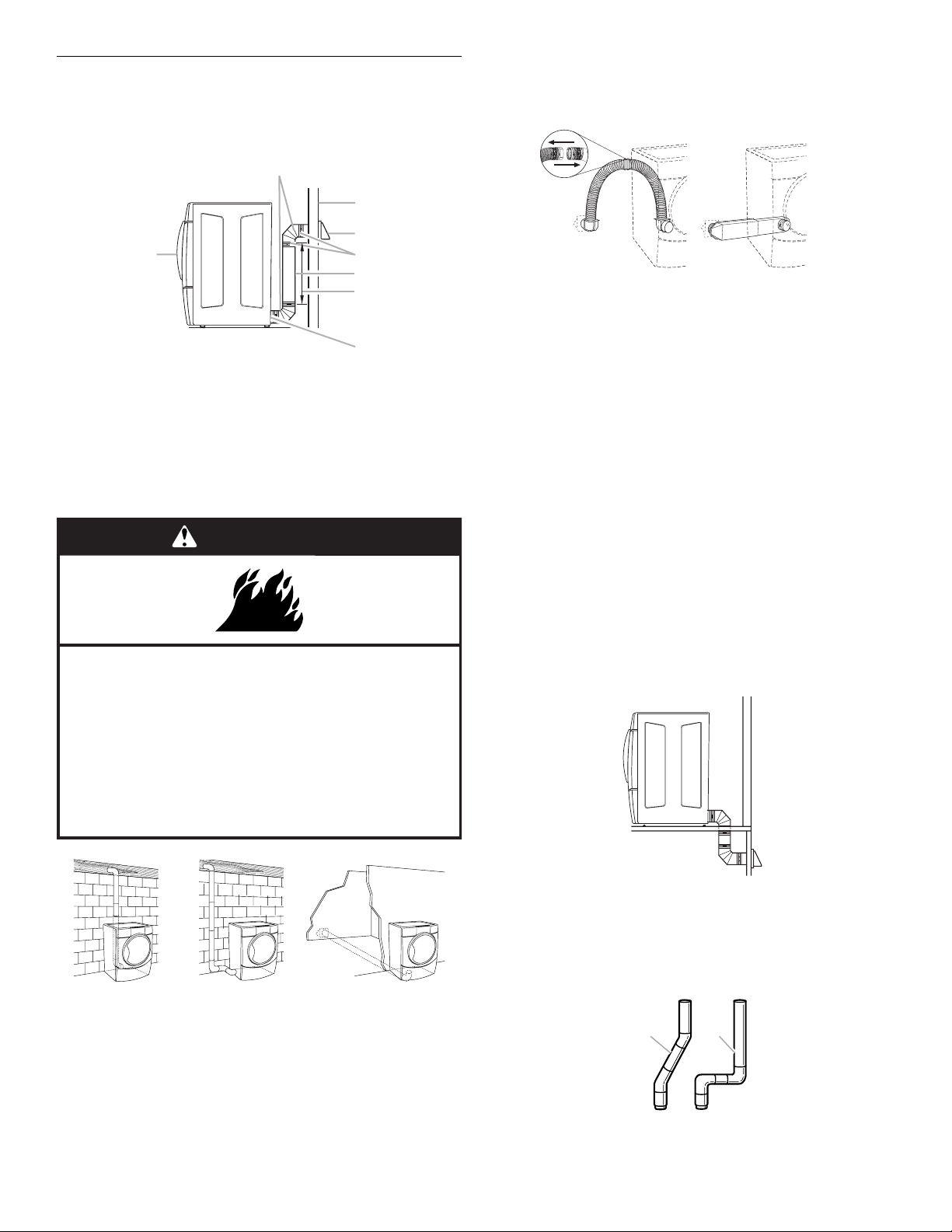

Venting Requirements

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

4" (10.2 cm) heavy metal exhaust vent and clamps must be used.

DURASAFE™ vent products are recommended.

DURASAFE™ vent products can be purchased from your dealer

or by calling Whirlpool Parts and Accessories. For more

information, see the “Assistance or Service” section of this

manual.

■ The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, or a concealed space of a building.

■ Do not use an exhaust hood with a magnetic latch.

■ Do not install flexible metal vent in enclosed walls, ceilings or

floors.

■ Use clamps to seal all joints. Exhaust vent must not be

connected or secured with screws or other fastening devices

which extend into the interior of the duct. Do not use duct

tape.

IMPORTANT: Observe all governing codes and ordinances.

A. External ground conductor screw

B. Neutral grounding wire (green with yellow stripes)

C. Neutral wire (white or center wire)

D. Grounding path determined by a qualified electrician

Improper venting can cause moisture and lint to collect

indoors, which may result in:

Moisture damage to woodwork, furniture, paint,

wallpaper, carpets, etc.

Housecleaning problems and health problems.

Use a heavy metal vent. Do not use plastic or metal foil vent.

Rigid metal vent is recommended to prevent crushing and

kinking.

Flexible metal vent must be fully extended and supported when

the dryer is in its final position. Remove excess flexible metal vent

to avoid sagging and kinking that can result in reduced airflow

and poor performance.

An exhaust hood should cap the vent to prevent rodents and

insects from entering the home.

Exhaust hood must be at least 12" (30.5 cm) from the ground or

any object that is in the path of the exhaust (such as flowers,

rocks or bushes, etc.).

If using an existing vent system, clean lint from the entire length

of the system and make sure exhaust hood is not plugged with

lint. Replace any plastic or metal foil vent with rigid metal or

flexible metal vent.

13

Plan Vent System

Typical exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

B

C

D

A

E

F

G

H

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

E. Clamps

F. Rigid metal or flexible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

Optional exhaust installations

This dryer can be converted to exhaust out the right side, left

side, or through the bottom. Contact your local dealer to have the

dryer converted.

WARNING

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best for

your installation. Two close-clearance installations are shown.

Refer to the manufacturer’s instructions.

AB

A. Over the top installation (also available with one

offset elbow)

B. Periscope installation

NOTE: The following kits for close clearance alternate

installations are available for purchase. Please see the

“Assistance or Service” section of this manual to order.

■ Over the top Installation:

Part Number 4396028

■ Periscope Installation (For use with dryer vent to wall vent

mismatch):

Part Number 4396037 - 0" (0 cm) to 18" (45.72 cm)

mismatch

Part Number 4396011 - 18" (45.72 cm) to 29" (73.66 cm)

mismatch

Part Number 4396014 - 29" (73.66 cm) to 50" (127 cm)

mismatch

Fire Hazard

Cover unused exhaust holes with one of the

following kits:

279818 (white)

280028 (meteorite)

Contact your local dealer.

Failure to follow these instructions can result in death,

fire, electrical shock, or serious injury.

A

A. Standard rear offset exhaust installation

B. Left or right side exhaust installation

C. Bottom exhaust installation (Not an option with

pedestal installations.)

B

C

Special provisions for mobile home installations

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

Determine vent length

1. Select the route that will provide the straightest and most

direct path outdoors. Plan the installation to use the fewest

number of elbows and turns. When using elbows or making

turns, allow as much room as possible. Bend vent gradually

to avoid kinking. Avoid 90º turns when possible.

better

good

14

2. Determine vent length.

The maximum length of the exhaust system depends upon:

■ The type of vent (rigid metal or flexible metal).

■ The number of elbows used.

■ Type of hood.

Recommended hood styles are shown here.

B

A

InstallVent System

1. Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

2. Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4" (10.2 cm) clamp.

3. Run vent to dryer location. Use the straightest path possible.

See “Determine vent length.” Avoid 90º turns. Use clamps to

seal all joints. Do not use duct tape, screws or other fastening

devices that extend into the interior of the vent to secure

vent.

4"

(10.2 cm)

4"

(10.2 cm)

A. Louvered hood style

B. Box hood style

The angled hood style (shown following) is acceptable.

4"

(10.2 cm)

2½"

(6.4 cm)

See the exhaust vent length chart that matches your hood

type for the maximum vent lengths you can use.

Exhaust systems longer than specified will:

■ Shorten the life of the dryer.

■ Reduce performance, resulting in longer drying times and

increased energy usage.

3. Determine the number of elbows you will need.

IMPORTANT: Do not use vent runs longer than those

specified in the Vent Length Chart.

The following chart helps you determine your maximum vent

length based on the number of 90° turns or elbows you will

need and the type of vent (rigid or flexible metal) and hood

that you will use.

Vent Length Chart

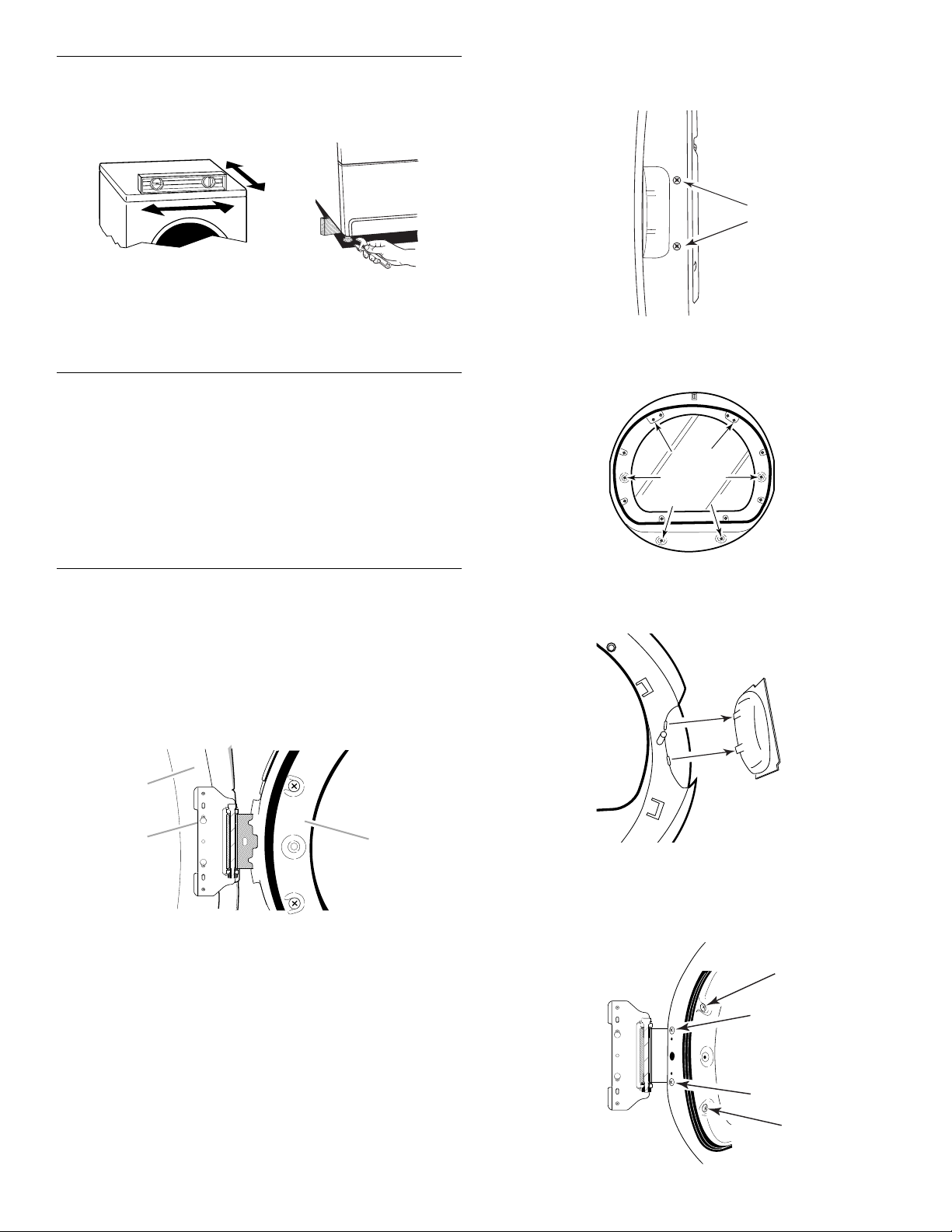

InstallLevelingLegs

WARNING

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. To protect the floor, use a large flat piece of cardboard from

the dryer carton. Place cardboard under the entire back edge

of the dryer. See illustration.

2. Firmly grasp the body of the dryer (not the console panel).

Gently lay the dryer on the cardboard.

3. Examine the leveling legs. Find the diamond marking.

Number of

90º turns

or elbows

0 Rigid metal

1 Rigid metal

2 Rigid metal

3 Rigid metal

4 Rigid metal

Type of

vent

Flexible metal

Flexible metal

Flexible metal

Flexible metal

Flexible metal

Box or

Louvered

hoods

64 ft (20 m)

36 ft (11 m)

54 ft (16.5 m)

31 ft (9.4 m)

44 ft (13.4 m)

27 ft (8.2 m)

35 ft (10.7 m)

25 ft (7.6 m)

27 ft (8.2 m)

23 ft (7 m)

Angled

hoods

58 ft (17.7 m)

28 ft (8.5 m)

48 ft (14.6 m)

23 ft (7 m)

38 ft (11.6 m)

19 ft (5.8 m)

29 ft (8.8 m)

17 ft (5.2 m)

21 ft (6.4 m)

15 ft (4.6 m)

NOTE: Side and bottom exhaust installations have a 90º turn

inside the dryer. To determine maximum exhaust length, add one

90º turn to the chart.

4. Screw the legs into the leg holes by hand. Use a wrench to

finish turning the legs until the diamond marking is no longer

visible.

5. Place a carton corner post under each of the 2 dryer back

corners. Stand the dryer up. Slide the dryer on the corner

posts until it is close to its final location. Leave enough room

to connect the exhaust vent.

6. Once connection is made and dryer is in final location,

remove corner posts and cardboard.

15

Level Dryer

C

Check the levelness of the dryer. Check levelness first

side to side, then front to back.

If the dryer is not level, prop up the dryer using a wood block.

Use a wrench to adjust the legs up or down and check again for

levelness.

NOTE: It might be necessary to level the dryer again after it has

been moved into its final position.

Connect Vent

1. Using a 4" (10.2 cm) clamp, connect vent to exhaust outlet in

dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Make sure the vent is secured

to exhaust hood with a 4" (10.2 cm) clamp.

2. Move dryer into final position. Do not crush or kink vent.

Make sure dryer is level.

3. (On gas models) Check to be sure there are no kinks in the

flexible gas line.

Reverse DoorSwing

You can change your door swing from a right-side opening to a

left-side opening, if desired.

3. Lay the dryer door on a flat, protected surface with the inside

door assembly facing up. Remove the last screw from Step 1.

Remove the 2 screws holding the handle to the door.

4. Remove the 6 screws to release the outer door assembly

from the inner door assembly (see illustration). It is important

that you remove only the 6 indicated screws.

5. Lift the inner door assembly off of the outer door assembly.

Unsnap the handle from the outer door assembly, move it to

the other side, and snap in. Set the outer door assembly

aside.

Remove the door

1. Open the dryer door. Remove the 4 screws that hold the door

hinge on the front panel of the dryer. Loosen, but do not

remove, the screw with the top keyhole opening last (second

from the top).

A

B

A. Dryer

B. Do not remove

C. Dryer door

2. Lift and pull forward on the door so that the keyhole clears

the screw head. Remove the door.

Reverse the hinge and hinge bracket

1. Place the inner door, screw head side up, on the work

surface.

2. Remove the 4 screws that hold the hinge to the door.

16

3. Remove the 2 screws that hold the handle bracket to the

B

C

door.

4. Move hinge to the other side and reattach with the 4 screws

removed in Step 2.

5. Move handle bracket to the other side and reattach with the 2

screws removed in Step 3.

6. Set the inner door assembly aside.

6. Insert a screw in the second opening from the top of the

hinge opening and partially tighten. Hang the door by placing

the top hinge keyhole over the second screw head and

tighten the screw. By putting this screw in first, the door will

hang in place while you insert and tighten the remaining 4

screws.

A

A. Dryer door

B. Dryer

C. Insert this screw first

Reinstalling the door

1. Check for fingerprints on the glass. Clean if necessary.

2. Place the inner door assembly into the outer door assembly.

Align the hinge in the opening on the side. To fit correctly, the

inside door assembly edge is completely inside the outside

door assembly edge.

3. Reassemble the inner and outer door assemblies with the

6 screws.

4. Replace the 2 handle screws for the door handle of the door

assembly.

5. Use a small flat-blade screwdriver to remove hole plugs in the

door opening. Slide the head of the screwdriver under the

cap of each hole plug, being careful not to scratch the dryer

surface. Lift up. Remove the hole plugs in the door opening

and insert in the opposite side.

7. Close the door and check that it latches securely.

Complete Installation

1. Check to be sure all parts are now installed. If there is an

extra part, go back through the steps to see which step was

skipped.

2. Check to be sure you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Check the dryer’s final location. Be sure the vent is not

crushed or kinked.

5. Check to be sure the dryer is level. See “Level Dryer.”

6. Plug into a grounded outlet. Turn power on.

7. Remove the blue protective film on the console and any tape

remaining on the dryer.

8. Read “Dryer Use.”

9. Wipe the dryer drum interior thoroughly with a damp cloth to

remove any dust.

10. Set the dryer on a full heat cycle (not an air cycle) for

20 minutes and start the dryer.

If the dryer will not start, check the following:

■ Controls are set in a running or “On” position.

■ Start button has been pushed firmly.

■ Dryer is plugged into a grounded outlet.

■ Electrical supply is connected.

■ House fuse is intact and tight, or circuit breaker has not

tripped.

■ Dryer door is closed.

11. When the dryer has been running for 5 minutes, open the

dryer door and feel for heat.

If you do not feel heat, turn the dryer off and check the

following:

■ There may be 2 fuses or circuit breakers for the dryer. Check

to make sure both fuses are intact and tight, or that both

circuit breakers have not tripped. If there is still no heat,

contact a qualified technician.

NOTE: You may notice a burning odor when the dryer is first

heated. This odor is common when the heating element is first

used. The odor will go away.

17

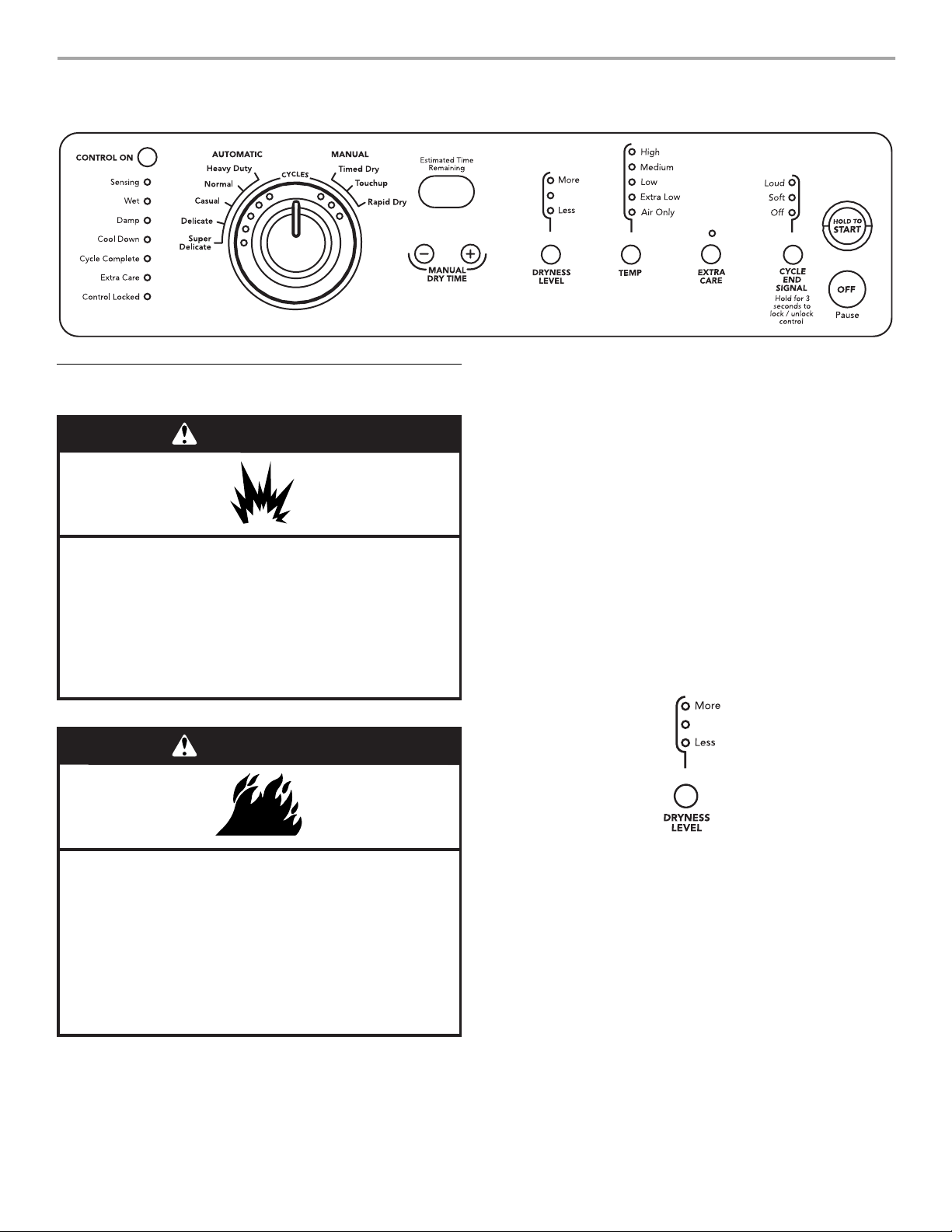

DRYER USE

Starting Your Dryer

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not dry anything that has ever had anything

flammable on it (even after washing).

Failure to follow these instructions can result in death,

explosion, or fire.

WARNING: To reduce the risk of fire, electric shock, or injury to

persons, read the IMPORTANT SAFETY INSTRUCTIONS before

operating this appliance.

The following is a guide to starting your dryer. Please refer to

specific sections of this manual for more detailed information.

1. Clean lint screen before or after each cycle. See “Cleaning

the Lint Screen.”

2. Place laundry into dryer and shut door. See “Loading.”

3. Rotate the dial to select either an Automatic or Manual Cycle

then press the CONTROL ON button. The preset settings and

drying time for the cycle chosen will be displayed.

To use an Automatic Cycle

■ Point the dial to an Automatic Cycle.

■ Select DRYNESS LEVEL to adjust how dry you want the

load to be. The time displayed is an estimated length of

the cycle based on the Dryness Level selected. As the

cycle runs, the control senses the dryness of the load and

adjusts the time automatically for the selected Dryness

Level.

WARNING

Fire Hazard

No washer can completely remove oil.

Do not dry anything that has ever had any type of oil on

it (including cooking oils).

Items containing foam, rubber, or plastic must be dried

on a clothesline or by using an Air Cycle.

Failure to follow these instructions can result in death

or fire.

18

NOTE: Time is not adjustable for Automatic Cycles. Pressing

the Manual Dry Time (- or +) buttons will cause a triple beep,

indicating that the time cannot be changed.

■ Press the EXTRA CARE feature button if this option is

desired.

■ Press the CYCLE END SIGNAL button to set signal

volume to desired level.

■ Press (and hold) HOLD TO START button until dryer starts

(about 1 second).

Once an Automatic cycle has started, the Extra Care feature

and the Cycle End Signal level can be adjusted. Press the

OFF button twice to stop the dryer and clear the settings,

allowing you to select another cycle and Dryness Level.

To use a Manual Cycle

■ Rotate the dial to select a Manual Cycle.

Press MANUAL DRY TIME (- or +) buttons until the desired

drying time is displayed. Tap - or + and the time will change

by 1-minute intervals. Press and hold - or + and the time will

change by 5-minute intervals. The initial time displayed is the

actual drying time.

Loading

Properly loading your dryer can lower your utility bill and prolong

the life of your garments.

Loading suggestions

■ Load the dryer by the amount of space items take up, not by

their weight.

■ Do not overload the dryer. This causes wrinkling and uneven

drying.

NOTE: The Manual Dry Time feature can be used only with

Manual Cycles.

■ Press TEMP until the desired temperature glows.

NOTE: Pressing the Dryness Level button will cause the triple

beep indicating that this option is not selectable. Also, a

Dryness Level is not indicated.

■ Press the EXTRA CARE feature button if this option is

desired.

■ Press the CYCLE END SIGNAL button to set volume to

desired level.

■ Press (and hold) HOLD TO START button until dryer starts

(about 1 second).

While a Manual Cycle is running, you can change the settings

for Time, Temperature, the Extra Care feature, and the Cycle

End Signal. Press the OFF button twice to stop the dryer and

clear the settings, allowing you to select another cycle.

StoppingYour Dryer

To stop your dryer at any time

Press OFF twice or open the door.

Pausing orRestarting

To pause the dryer at any time

Open the door or press OFF once.

To restart the dryer

Close the door and press (and hold) HOLD TO START button until

dryer starts.

NOTE: Drying will continue from where the cycle was interrupted

if you close the door and press Start within 5 minutes. If the cycle

is interrupted for more than 5 minutes, the dryer will shut off.

Select new cycle settings before restarting the dryer.

Control Locked

This feature allows you to lock your settings to prevent

unintended use of the dryer. You can also use the Control Locked

feature to prevent unintended cycle or option changes during

dryer operation.

To enable the Control Locked feature when dryer is

running:

Press and hold the CYCLE END SIGNAL button for 3 seconds.

The control is locked when a single beep is heard and the Control

Locked status light is on.

■ When the dryer is off, it is not necessary to press the Control

On button before activating the Control Locked feature.

To unlock:

Press and hold the CYCLE END SIGNAL button for 3 seconds to

turn this feature off.

NOTE: When the dryer is running and Control Locked is on, the

dryer can be stopped by pressing the Off button, but can’t be

restarted until the control is unlocked.

Super Capacity Plus Dryers

Heavy Work Clothes

4 jeans

4 workpants

4 workshirts

Towels

10 bath towels

10 hand towels

Mixed Load

3 sheets (1 king, 2 twin)

4 pillowcases

3 shirts

3 blouses

2 sweatpants

2 sweatshirts

14 washcloths

9 T-shirts

9 shorts

10 handkerchiefs

Drying andCycle Tips

Select the correct cycle and dryness level or temperature for your

load. If an Automatic Cycle is running, the display shows the

estimated cycle time when your dryer is automatically sensing

the dryness level of your load. If a Manual Cycle is running, the

display shows the exact number of minutes remaining in the

cycle.

Cool Down tumbles the load without heat during the last few

minutes of all cycles. Cool Down makes the loads easier to

handle and reduces wrinkling. The length of the Cool Down

depends on the load size and dryness level.

Drying tips

■ Follow care label directions when they are available.

■ If desired, add a fabric softener sheet. Follow package

instructions.

■ Remove the load from the dryer as soon as tumbling stops to

reduce wrinkling. This is especially important for permanent

press, knits, and synthetic fabrics.

■ Avoid drying heavy work clothes with lighter fabrics. This

could cause overdrying of lighter fabrics, leading to increased

shrinkage or wrinkling.

Cycle tips

■ Dry most loads using the preset cycle settings.

■ Refer to the Automatic or Manual Preset Cycle Settings chart

(in the “Cycles” section) for a guide to drying various loads.

■ Drying temperature and Dryness Level are preset when

you choose an Automatic Cycle. You can choose a

different dryness level, depending on your load by

pressing the DRYNESS LEVEL button to select MORE or

LESS.

■ If you wish to adjust the cycle length of a Manual Cycle,

you must press the MANUAL DRY TIME (- or +) buttons.

Adjust the temperature of a Manual Cycle by pressing

TEMP until the desired temperature is selected.

NOTE: You cannot choose a Dryness Level with Manual

Cycles.

19

StatusLights

You may follow the progress of your dryer with the drying status

indicator lights.

Sensing

When a cycle is first turned on, the SENSING light glows until a

wet item is detected.

■ In an Automatic cycle, if a wet item has not been detected

within 10 minutes, the Sensing light will turn off and the dryer

will shut down.

■ In a Manual cycle, if a wet item is not detected after

10 minutes the Wet light turns on and the selected cycle

continues.

Cycles

Select the drying cycle that matches the type of load you are

drying (see Automatic Preset or Manual Preset Cycle Settings

charts).

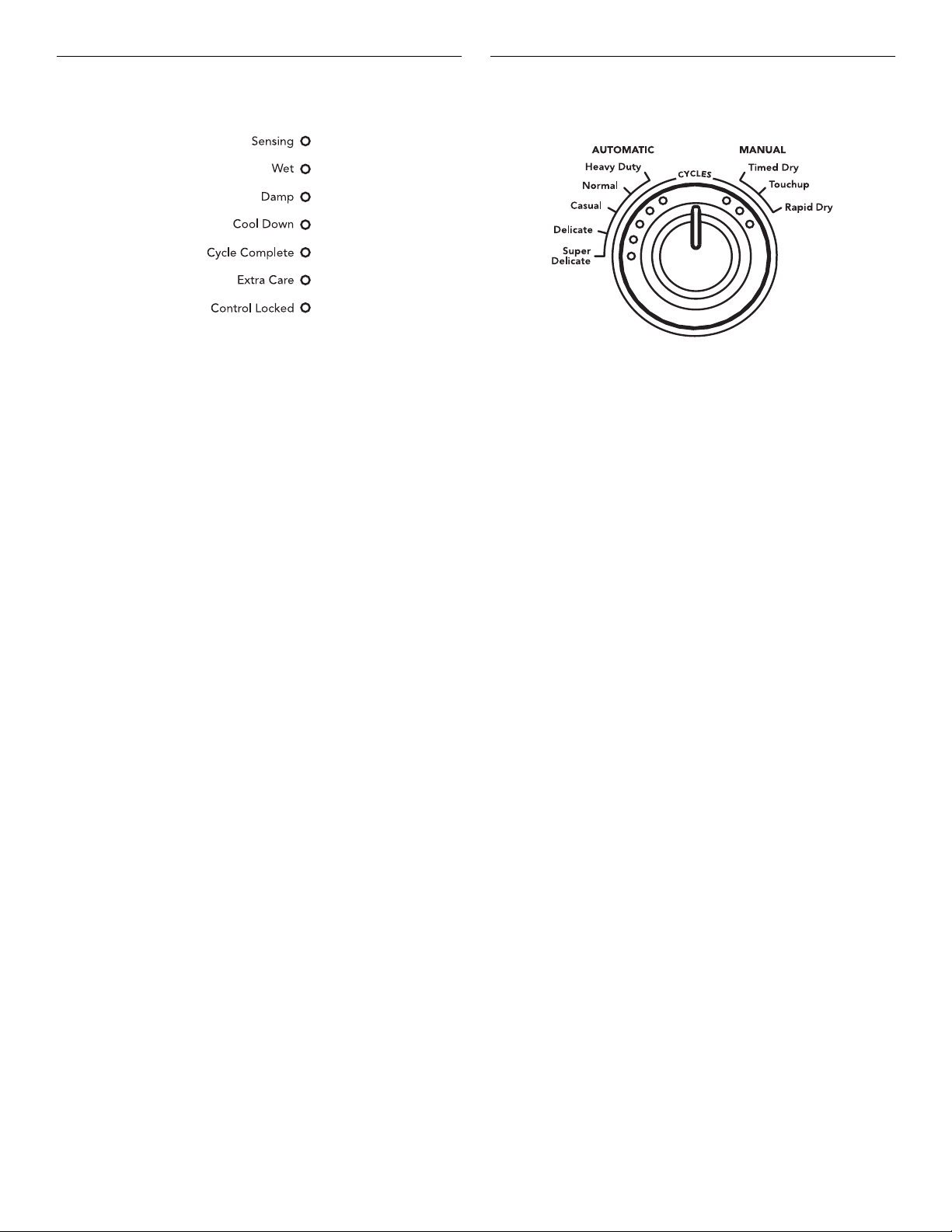

Cycle control knob

Automatic Cycles

Automatic Cycles allow you to match the cycle to the load you

are drying. See the following Automatic Preset Cycle Settings

chart. Each cycle dries certain fabrics at the recommended

temperature. A sensor detects the moisture in the load and

automatically adjusts the drying time for optimal drying.

Wet

The WET light will turn on when a wet item has been detected in

the dryer. The Wet light will remain on until:

■ The damp dry point is reached in an Automatic cycle.

■ The dryer enters the cool down period in a Manual cycle.

Damp

The DAMP light indicates that the load has reached the damp dry

level.

NOTE: The Damp light is not used with manual cycles.

Cool Down

The COOL DOWN light glows during the cool down part of the

cycle. Laundry is cooling down for ease in handling.

Cycle Complete

The CYCLE COMPLETE light glows when a drying cycle is

finished. If the Extra Care feature has been selected, the Extra

Care feature indicator light will also be on.

The Cycle Complete light turns off one hour after the end of a

drying cycle (including the Extra Care cycle of 2 hours), when Off

is pressed, or when the door is opened.

Extra Care Feature

The EXTRA CARE feature light glows when this option is

selected. This indicator stays on with the Cycle Complete light.

Heavy Duty

Use this cycle to get High heat for heavy fabrics such as cotton

towels or bedspreads.

Normal

Use this cycle to get Medium heat for drying sturdy fabrics such

as work clothes.

Casual

Use this cycle to get Medium heat for drying no-iron fabrics, such

as sport shirts, casual business clothes and permanent press

blends.

Delicate

Use this cycle to get Low heat for drying synthetic fabrics,

washable knit fabrics and no-iron finishes.

Super Delicate

Use this cycle to get Extra Low heat to gently dry items such as

lingerie, exercise wear, or sheer curtains.

Control Locked

The CONTROL LOCKED light glows when this option is enabled.

Indicator lights

Other indicator lights on the control panel show Cycle,

Temper-ature, and Cycle End Signal settings selected.

The time display will indicate the estimated or actual time

remaining in a cycle.

20

Automatic Preset Cycle Settings

Automatic Cycles

Load Type

HEAVY DUTY

Heavyweight, towels

NORMAL

Corduroys, work clothes

CASUAL

Permanent press, synthetics

DELICATE

Lingerie, blouses, washable

woolens

SUPER DELICATE

Exercise wear, sheer curtains, lace

*Estimated Time with Dryness Level (medium) setting.

Te mp . T im e *

(Minutes)

High 40

Medium 34

Medium 36

Low 28

Extra Low 22

Manual Cycles

Use Manual Cycles to select a specific amount of drying time and

a drying temperature. When a Manual Cycle is selected, the

ESTIMATED TIME REMAINING display shows the actual time

remaining in your cycle. You can change the actual time in the

cycle by pressing the Manual Dry Time (- or +) buttons.

Additional Features

Extra Care Feature

When you are unable to remove a load of clothes from the dryer

as soon as it stops, wrinkles can form. The Extra Care feature

periodically tumbles, rearranges and fluffs the load to help reduce

wrinkles.

■ Press the Extra Care feature to get up to 120 minutes of heat-

free, periodic tumbling at the end of a cycle.

■ Stop at any time by pressing the Extra Care feature or

opening the dryer door.

■ For the Casual Cycle, the Extra Care feature is preset to “On.”

The other Automatic Cycles will retain the Extra Care feature

setting. (For example, if you select the Extra Care feature in

the Normal cycle, the Extra Care feature will be on the next

time you select the Normal cycle.)

NOTE: If you do not select the Extra Care feature, the dryer stops

after the cool down period.

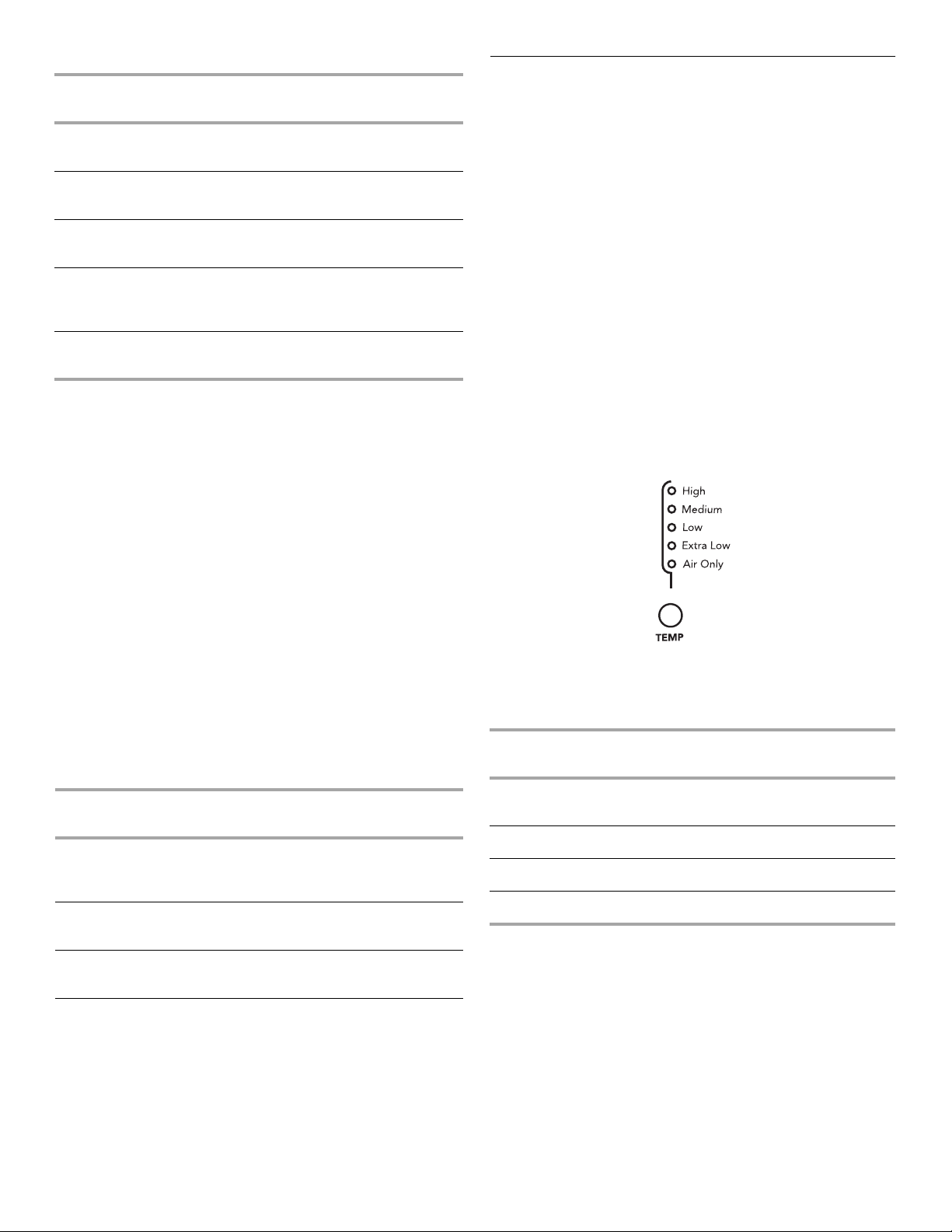

Temperature

Temperature settings are used with the Manual Cycles. Press

TEMP until the desired temperature setting glows. Temperature

settings cannot be used with the Automatic Cycles.

Timed Dry

Use this cycle to complete drying if items are still damp after an

Automatic Cycle. Timed Dry is also useful for drying heavyweight

and bulky items, such as bedspreads and work clothes.

Touchup

Use this setting to remove wrinkles from items, such as clothes

packed in a suitcase or items wrinkled from being left in the dryer

too long.

Rapid Dry

Use this cycle for drying small loads or loads that need a short

drying time.

Manual Preset Cycle Settings

Manual Cycles

Load Type

TIMED DRY

Heavyweight, bulk,

bedspreads, work clothes

TOUCHUP

Remove wrinkles

RAPID DRY

Small loads

Temp. Default Time

(Minutes)

High 40

Medium 20

High 27

Air Only

Use the Air Only setting for items that require drying without heat

such as rubber, plastic and heat-sensitive fabrics. This chart

shows examples of items that can be dried using Air Only.

Type of Load Time*

Foam rubber - pillows, padded bras,

stuffed toys

Plastic - Shower curtains, tablecloths 20 - 30

Rubber-backed rugs 40 - 50

Olefin, polypropylene, sheer nylon 10 - 20

*Reset time to complete drying, if needed.

(Minutes)

20 - 30

When using Air Only

■ Check to see that coverings are securely stitched.

■ Shake and fluff pillows by hand periodically during the cycle.

■ Dry item completely. Foam rubber pillows are slow to dry.

NOTE: Automatic Cycles are not available when using the Air

Only setting.

21

Cycle End Signal

The Cycle End Signal produces an audible sound when the

drying cycle is finished. Promptly removing clothes at the end of

the cycle reduces wrinkling.

Press and release the CYCLE END SIGNAL to adjust the sound

level or turn off the signal.

NOTE: When the Extra Care feature is selected and the Cycle

End Signal is on, an audible sound will emit every 5 minutes until

the clothes are removed, or the Extra Care feature is finished.

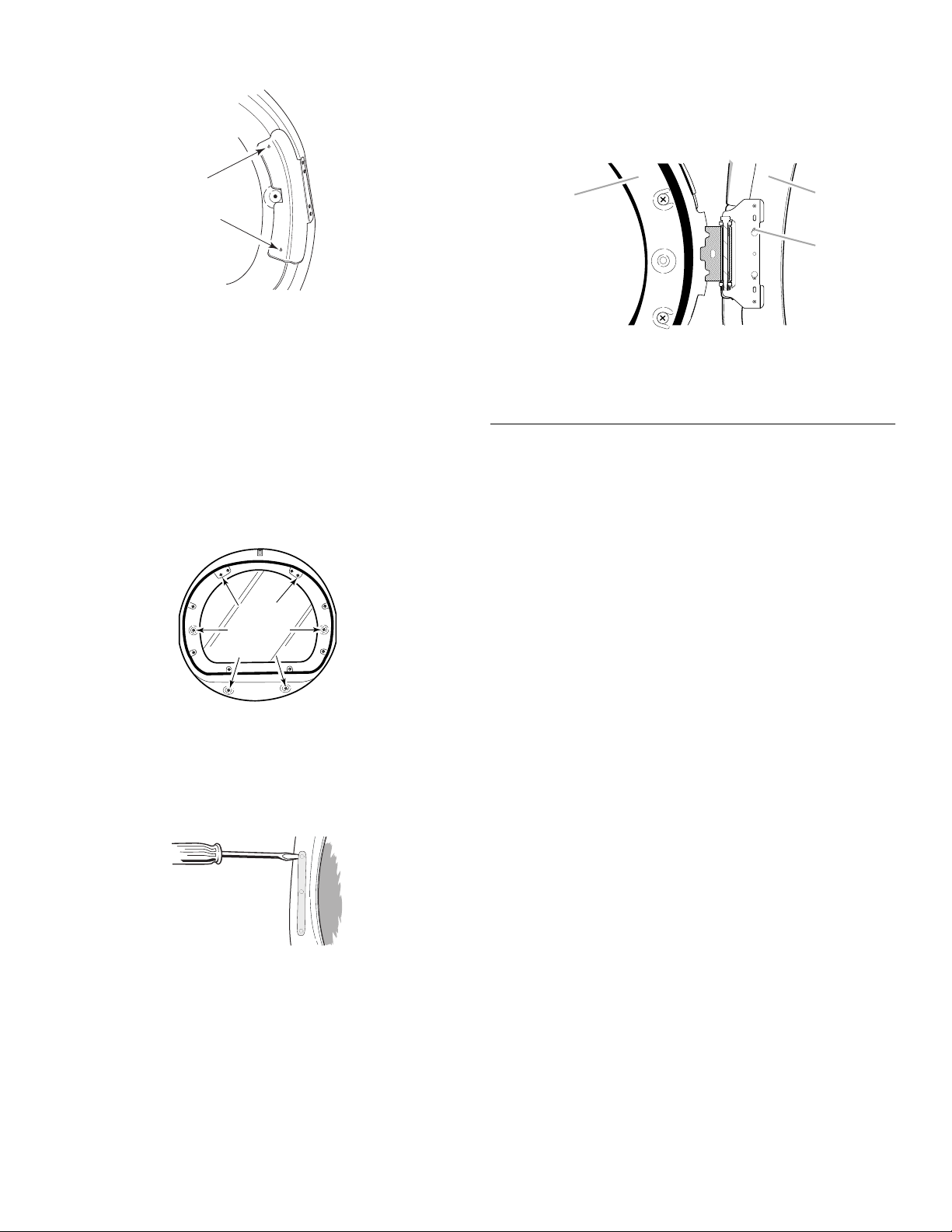

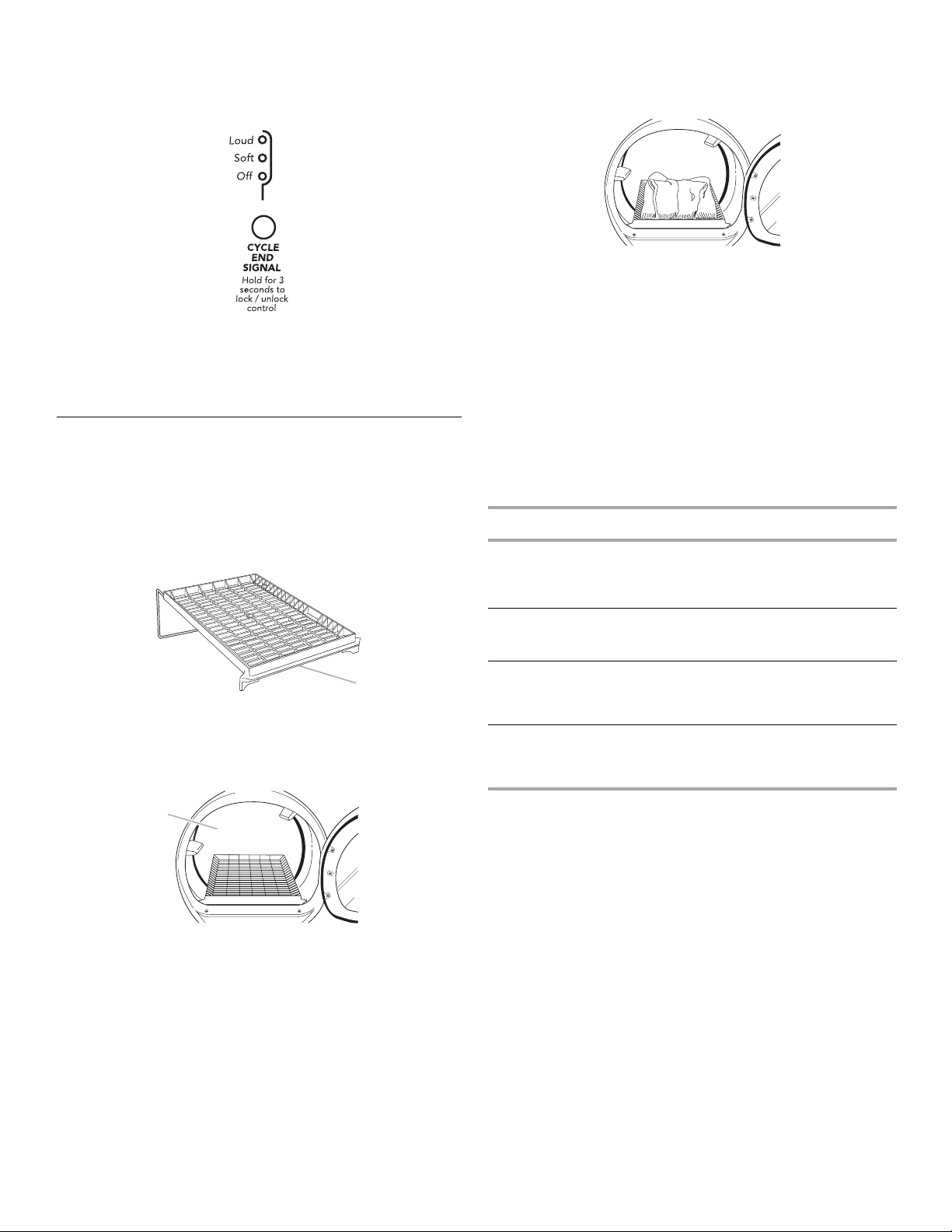

Drying Rack

The drying rack is useful for drying items you would not

necessarily want to tumble dry or that you would normally line dry

(for example, sweaters).

To use the drying rack

Do not remove the lint screen.

1. Open dryer door.

3. Put the wet items on top of the rack. Leave space between

the items so air can reach all the surfaces.

NOTE: Do not allow items to hang over the edge of the rack.

4. Close the door.

5. Select a timed drying cycle and temperature, or an air cycle

(see following chart). Items containing foam, rubber, or plastic

must be dried on a clothesline or by using the Air Only

temperature setting.

6. You must select a time by pressing the MANUAL DRY TIME

(- or +) buttons. Reset time as needed to complete drying.

Refer to the following table.

7. Press (and hold) HOLD TO START button (about 1 second).

NOTE: You must remove rack for normal tumbling. Do not use

automatic cycles with the drying rack.

This chart shows examples of items that can be rack dried and

the suggested cycle, temperature setting and drying time. Actual

drying time will depend on the amount of moisture items hold.

Rack Dry Setting Temp. Time*

Wool Sweaters

Block to shape and lay flat on

the rack

Timed

Dry

Low 60

A

A. Front edge

2. Place drying rack inside dryer drum, positioning the back wire

on the ledge of the inner dryer back panel. Push down on

front edge of drying rack to secure over the lint screen.

A

A. Dryer back panel

Stuffed toys or pillows

Cotton or polyester fiber filled

Stuffed toys or pillows

Foam rubber filled

Sneakers or canvas shoes Timed

*(Minutes) Reset time to complete drying, if needed.

Timed

Dry

Timed

Dry

Dry

Low 60

Air Only

(no

heat)

Air Only

(no

heat)

90

90

22

DRYER CARE

Cleaning theDryer Location

Keep dryer area clear and free from items that would obstruct the

flow of combustion and ventilation air.

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

Cleaning the LintScreen

Every load cleaning

The lint screen is located in the door opening of the dryer. Clean it

before or after each load. A screen blocked by lint can increase

drying time.

To clean

1. Pull the lint screen straight up. Roll lint off the screen with

your fingers. Do not rinse or wash screen to remove lint. Wet

lint is hard to remove.

Clean the lint screen with a nylon brush every 6 months, or more

frequently, if it becomes clogged due to a residue buildup.

To wash

1. Roll lint off the screen with your fingers.

2. Wet both sides of lint screen with hot water.

3. Wet a nylon brush with hot water and liquid detergent. Scrub

lint screen with the brush to remove residue buildup.

4. Rinse screen with hot water.

5. Thoroughly dry lint screen with a clean towel. Replace screen

in dryer.

Cleaning theDryer Interior

To clean dryer drum

1. Make a paste with powdered laundry detergent and very

warm water.

2. Apply paste to a soft cloth.

OR

Apply a liquid, nonflammable household cleaner to the

stained area and rub with a soft cloth until all excess dye and

stains are removed.

3. Wipe drum thoroughly with a damp cloth.

4. Tumble a load of clean cloths or towels to dry drum.

NOTE: Garments which contain unstable dyes, such as denim

blue jeans or brightly colored cotton items, may discolor the

dryer interior. These stains are not harmful to your dryer and will

not stain future loads of clothes. Dry unstable dye items inside

out to prevent dye transfer.

2. Push the lint screen firmly back into place.

IMPORTANT:

■ Do not run the dryer with the lint screen loose, damaged,

blocked, or missing. Doing so can cause overheating and

damage to both the dryer and fabrics.

■ Some towels made of synthetic fibers and natural fibers

(polyester and cotton blends) may shed more lint than other

towels, causing your dryer’s lint screen to fill up faster. Be

sure to remove lint from the lint screen before and after drying

new towels.

■ If lint falls off the screen into the dryer during removal, check

the exhaust hood and remove the lint. See “Vent ing

Requirements.”

As needed cleaning

Laundry detergent and fabric softener residue can build up on the

lint screen. This buildup can cause longer drying times for your

clothes, or cause the dryer to stop before your load is completely

dry. The screen is probably clogged if lint falls off while the screen

is in the dryer.

Removing AccumulatedLint

From Inside the Dryer Cabinet

Lint should be removed every 2 years or more often, depending

on dryer usage. Cleaning should be done by a qualified person.

From the Exhaust Vent

Lint should be removed every 2 years, or more often, depending

on dryer usage.

Vacation andMovingCare

Vacation care

Operate your dryer only when you are at home. If you will be on

vacation or not using your dryer for an extended period of time,

you should:

1. Unplug dryer or disconnect power.

2. Clean lint screen. See “Cleaning the Lint Screen.”

23

Moving care

Changing theDrum Light

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

1. Unplug dryer or disconnect power. Disconnect wiring if dryer

is direct wired.

2. Make sure leveling legs are secure in dryer base.

3. Use masking tape to secure dryer door.

The dryer light automatically turns on inside the dryer drum when

you open the door.

To change the drum light

1. Unplug dryer or disconnect power.

2. Open the dryer door. Locate the light bulb cover on the back

wall of the dryer. Remove the screw located in the lower right

corner of the cover. Remove the cover.

3. Turn bulb counterclockwise. Replace the bulb with a 10-watt

appliance bulb only. Replace the cover and secure with the

screw.

4. Plug in dryer or reconnect power.

TROUBLESHOOTING

First try the solutions suggested here and possibly avoid the cost of a service call...

Dryer displaying code message

■ Is the load too large and heavy to dry quickly?

Separate the load to tumble freely.

■ “PF” (power failure), check the following:

Was the drying cycle interrupted by a power failure?

Press (and hold) HOLD TO START button to restart the dryer.

■ “E” Variable (E1, E2, E3) service codes:

Call for service.

Clothes are not drying satisfactorily

■ Check the following:

Is the lint screen clogged with lint?

Is the exhaust vent or outside exhaust hood clogged with lint,

restricting air movement? Run the dryer for 5-10 minutes.

Hold your hand under the outside exhaust hood to check air

movement. If you do not feel air movement, clean exhaust

system of lint or replace exhaust vent with heavy metal or

flexible metal vent. See “Installation Instructions.”

Is the exhaust vent crushed or kinked? Replace with a heavy

metal or flexible metal vent. See “Installation Instructions.”

Has a fuse blown, or has a circuit breaker tripped? Electric

dryers use 2 household fuses or breakers. The drum may be

turning, but you may not have heat.

Has an air cycle been selected? Select the right cycle for the

types of garments being dried. See “Cycles.”

Is the automatic cycle ending early? The load may not be

contacting the electronic sensor strips. Level the dryer.

Are fabric softener sheets blocking the grille? Use only one

fabric softener sheet and only use it once.

■ Is the dryer located in a room with temperature below

45ºF (7ºC)?

Proper operation of dryer cycles requires temperatures above

45ºF (7ºC).

■ Was a cold rinse water used? Was the load very wet?

Expect longer drying times with items rinsed in cold water

and with items that hold moisture (cottons).