Page 1

INSTALLATION INSTRUCTIONS FOR CUSTOM PANEL

UNDERCOUNTER DISHWASHER

IMPORTANT: Before installing your dishwasher, please use this instruction sheet as a supplement to the installation instructions.

STAINLESS STEEL TUB

Custom Panel Models Only

Gather these additional tools and parts before starting

attachment of the custom panel. Read and follow the

instructions provided in this instruction sheet.

Additional Tools Needed:

■ 3/32" drill bit

†

■ Torx

T15 screwdriver

Additional Parts Supplied with Custom Panel Models:

■ 4 – Plastic studs (attached to each other by runners)

■ 4 – Short screws (10-16 hex-head screw)

■ 4 – Long screws (8-18 Torx head screws)

■ 1 – Template (located inside Use and Care Guide bag

assembly)

■ 1 – Instruction sheet (located inside Use and Care Guide bag

assembly)

NOTE: The screws supplied are used for only 3/4" (19 mm) thick

wooden panel. If the wooden panel is less than 3/4" (19 mm)

thick, customer must purchase screws locally.

Make sure all these parts are included in the literature package.

If parts are not included, call 1-800-422-1230.

In Canada, call 1-800-807-6777.

Install Custom Panel

Follow Steps Below:

A customer supplied door panel and handle (together) must

weigh no more than 16 lbs (7.3 kg) and must be made to specic

dimensions. It is recommended that a cabinetmaker cut the

customer panel because of the precise dimensions needed.

NOTES:

■ The handle for the custom panel is not included.

■ All mounting hardware supplied is for a 3/4" (19 mm) thick

wood panel. If a thinner wood panel or materials other than

wood are used, it is the customer’s responsibility to obtain the

proper length screws and adjust the pilot holes accordingly.

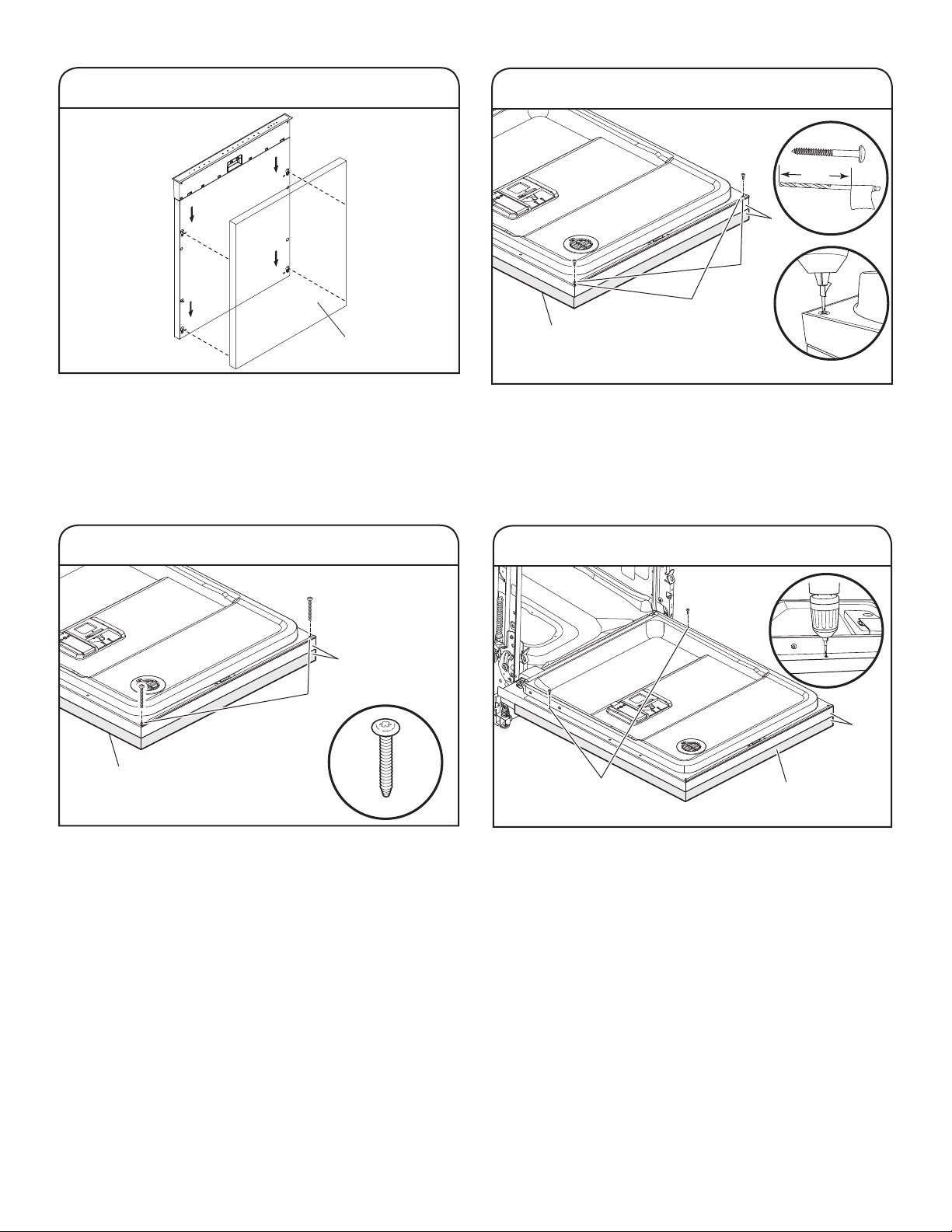

WARNING

Excessive Weight Hazard

Use two or more people to move and install

dishwasher.

Failure to do so can result in back or other injury.

Stand dishwasher upright

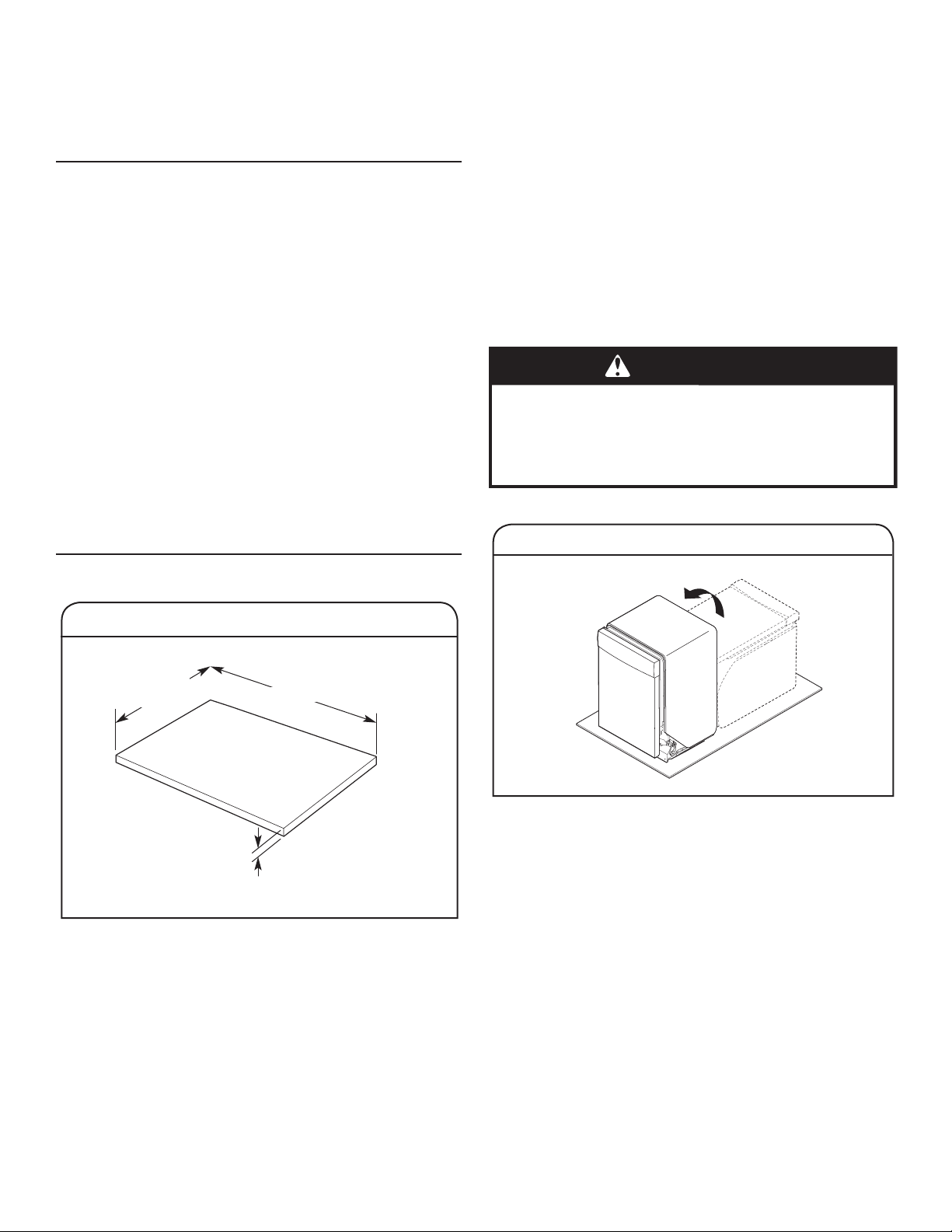

Custom panel dimensions

235/8"

(600 mm)

2915/16"(760 mm)

3/4" (19 mm)

Using 2 or more people, stand the dishwasher up.

†

TORX and T15 are trademarks of Acument Intellectual Properties, LLC.

W11428482A

1

Page 2

1. Attach handle 2. Panel template

6" (152.4 mm)

Install the custom hardware handle(s) on the front of the wooden

panel inside dotted line.

IMPORTANT: If the handle is attached from the back of the

custom panel, the screw holes should be countersunk for the

screw heads to be ush with the panel. If the handle is attached

to the front of the custom panel, the screw lengths cannot

exceed the panel thickness.

Top of panel

Wood Panel Template

Center Line

Pilot

holes

W11460372

Using the template provided, attach it to the backside of the

custom panel with tape. Make sure that the center of the

template is aligned with the center of the wooden panel and top

of the template is aligned to the top face of the wooden panel.

3. Predrill custom panel holes

5/8"

(16 mm)

3/32"

NOTE: Do not drill deeper then 5/8" (16 mm) to keep from

drilling through panel. Pilot hole depths given are for

3/4" (19 mm) thick panel.

Mark 4 pilot holes on the wooden panel using the template

provided. Pre-drill 4 pilot holes using a 3/32" drill bit. Use

tape to mark the drill bit to gauge hole depth. Drill pilot holes

approximately 5/8" (16 mm) into the custom panel.

NOTE: If re-using a custom panel from a previous dishwasher,

rst check to make sure the overall size of the panel will work

for the new application. Remove the panel from the previous

product. Lay the drilling template on the new holes and ensure

the holes are in the correct location. Drill the holes per the

template as needed.

4. Attach plastic studs

Plastic studs attached

with 4 short screws

Visible side

Attach the 4 plastic studs to the wooden panel using the four

5/16" hex-head (short) screws provided.

2

Page 3

5. Attach custom panel

Wooden panel

assembly

6. Align top edges of panel to door

1½"

Align top

edges

Remove 2 short screws

Customer

supplied

panel

and replace with long

screws provided

Align the studs on the custom wood panel to the keyhole

slots on the door assembly. Ensure that all 4 plastic studs are

engaged in the keyhole slots. Slide wood panel down until the

top surface of the wooden panel is ush with the top of the door.

7. Install custom panel

Align top

edges

Drill through

this hole

1/8"

screw

Customer

supplied

panel

Open the door and align top edges. Use tape to mark a 3/32"

drill bit to gauge the hole depth of approximately 1½" (38 mm).

Drill pilot holes into the top corners of the door, using hole in liner

as a guide.

8. Remove the short screws

Align top

edges

Remove 2 short screws

and replace with long

screws provided.

Customer

supplied

panel

Using a Torx T15 screwdriver, install two #8 x 1/8" (long) screws

in top corners to secure custom wood panel in place.

Remove the short screws (4th from top) on either side of the inner

door panel. Use tape to mark a 3/32" drill bit to gauge the hole

depth of approximately 1½" (38 mm). Drill 2 pilot holes using the

door liner hole as a guide into the panel. Install the 2 remaining

long screws.

3

Page 4

Hinge Spring Adjustment Instruction

If door tension is insufcient to support the weight of the door, adjustment of the hinge spring tension may be needed.

1. Close dishwasher door

Make sure that the dishwasher door is closed at all times while

hinge spring tension is being adjusted. Adjusting the hinge

spring tension while the door is partially or fully open can cause

damage to the hinge.

3. Access hinge spring adjuster

2. Remove dishwasher from the cabinet

The dishwasher should be partially or fully removed from

under the cabinet to grant access to the hinge spring tension

adjustment mechanism.

4. Spring adjustment setting

Hinge

spring

tension

adjuster

Hinge spring

tension adjuster

With the dishwasher partially or fully removed from the cabinet,

the hinge spring tension adjusters can be accessed at the front

sides of the dishwasher.

4

Each of the two hinges (right side and left side) have 3 different

spring tension adjustments. All dishwasher models leave the

factory with the hinges set in the lowest spring tension setting.

This setting is suitable for lighter door panels. Heavier door

panels will require adjustment of the hinge spring tension to

prevent the door from falling open when its unlatched.

Page 5

5. Three spring adjustment

6. Adjusting the spring tension

Each hinge has 3 different spring tension levels that it can be

set to. The current tension level is indicated by an arrow. 1 is

the lowest spring tension for light doors and 3 is the highest for

heavier doors. 2 is the middle tension for door panel weights that

fall between heavy and light.

7. Place the dishwasher back under the cabinet to prevent it

from tipping while the door is opened and closed to check for

proper spring tension. If the door is too stiff, back the hinges

off one step to reduce spring tension by rotating the nut

counterclockwise. If the door falls open on its own, increase

the spring tension by rotating the nut one step clockwise.

Rotate the adjuster nut using a 3/4" open end wrench or

adjustable wrench one or two steps in the clockwise direction

when viewed from above to increase spring tension.

8. Once the desired spring tension has been set the dishwasher

can be installed under the counter per the steps shown in the

instruction manual.

5

Page 6

INSTRUCTIONS D’INSTALLATION

POUR PANNEAU SUR MESURE LAVE-VAISSELLE

SOUS COMPTOIR CUVE EN ACIER INOXYDABLE

IMPORTANT: Avant d’installer le lave-vaisselle, utiliser cette che d’instruction en complément des instructions d’installation.

Modèles à panneau

personnaliséuniquement

Rassembler ces outils et pièces supplémentaires avant

d’entreprendre l’installation du panneau personnalisé.

Lire et observer les instructions d’installation fournies

danscetteche d’instruction.

Outillage supplémentaire nécessaire:

■ Foret de 3/32 po

■ Tournevis Torx

Pièces supplémentaires fournies avec les modèles à

panneau personnalisé:

■ 4 – pitons en plastique (attachés les uns aux autres par

desglissières)

■ 4 – vis courtes (vis à tête hexagonale de 10-16)

■ 4 – vis longues (vis Torx de 8-18)

■ 1 – gabarit (situé dans le sachet du guide d’utilisation et

d’entretien)

■ 1 – feuille d’instructions (situé dans le sachet du guide

d’utilisation et d’entretien)

REMARQUE: Les vis fournies ne peuvent être utilisées

qu’avecun panneau de bois d’une épaisseur de 3/4po (19mm).

Sil’épaisseur du panneau de bois est inférieure à 3/4po

(19mm), l’utilisateur doit acheter les vis dans un magasin local.

S’assurer que toutes ces pièces sont comprises avec le sachet

de documentation.

Si ce n’est pas le cas, composer le 1-800-422-1230.

Au Canada, composer le 1800807-6777.

†

T15

Suivre les étapes ci-dessous:

Un panneau de porte avec poignée (ensemble) acheté par le

client ne doit pas peser plus de 16lb (7,3kg) et doit respecter

des dimensions spéciques. On recommande que le panneau

personnalisé soit réalisé par un ébéniste du fait de la nécessité

d’exactitude de l’usinage.

REMARQUES:

■ La poignée destinée au panneau personnalisé n’est pas

comprise.

■ Tout le matériel de montage fourni convient à un panneau de

bois de 3/4po (19mm) d’épaisseur. Si l’on utilise un panneau

de bois plus mince ou d’autres matériaux que le bois,

ilincombe au client d’obtenir des vis de longueur appropriée

etd’ajuster les avant-trous en fonction.

AVERTISSEMENT

Risque du poids excessif

Utiliser deux personnes ou plus pour déplacer et

installer le lave-vaisselle.

Le non-respect de cette instruction peut causer une

blessure au dos ou d'autre blessure.

Redresser le lave-vaisselle

Installation du panneau personnalisé

Dimensions du panneau personnalisé

235/8 po

(600mm)

29 15/16po (760mm)

3/4po (19mm)

À l’aide d’au moins deux personnes, mettre le lave-vaisselle en

position verticale.

†

TORX et T15 sont des marques déposées de Acument Intellectual Properties, LLC.

6

Page 7

1. Fixer la poignée

2. Gabarit de panneau

Haut du panneau

6po (152,4mm)

Gabarit de panneau de bois

Installer la ou les poignées de quincaillerie personnalisées à

l’avant du panneau de bois à l’intérieur de la ligne pointillée.

IMPORTANT: Si la poignée est xée à l’arrière du panneau

personnalisé, les trous de vis doivent fraisés de façon à ce

queles têtes de vis soient en afeurement avec le panneau.

Si la poignée est xée à l’avant du panneau personnalisé, la

longueur des vis ne doit pas excéder l’épaisseur du panneau.

3. Prépercer des trous dans

lepanneau personnalisé

5/8po

(16mm)

Ligne axiale

Avant-

trous

W11460372

En utilisant le gabarit fourni, le xer à l’arrière du panneau

personnalisé avec du ruban adhésif. S’assurer que le centre du

gabarit est aligné avec le centre du panneau de bois et que le

haut du gabarit est aligné avec la face supérieure du panneau

debois.

4. Fixer les pitons en plastique

Pitons en plastique

xés avec 4 vis courtes

3/32po

REMARQUE: Ne pas percer plus profondément que

5/8po (16mm) pour ne pas percer à travers le panneau.

Lesprofondeurs des avants-trous indiquées sont pour des

panneaux de 3/4po (19mm) d’épaisseur.

Marquer 4 avants-trous sur le panneau de bois à l’aide du

gabarit fourni. Prépercer 4 avant-trous en utilisant le foret de

3/32 po (4,8mm). Utiliser du ruban adhésif pour marquer le foret

an demesurer la profondeur du trou. Percer des avants-trous

d’environ 5/8po (16mm) dans le panneau personnalisé.

REMARQUE: Si un panneau personnalisé d’un lave-vaisselle

précédent est réutilisé, vérier d’abord que la taille globale du

panneau fonctionnera pour la nouvelle application. Retirer le

panneau du produit précédent. Poser le gabarit de perçage

sur les nouveaux trous et s’assurer que les trous sont au bon

endroit. Percer les trous selon le gabarit, le cas échéant.

Côté visible

Fixer les 4 pitons en plastique au panneau de bois à l’aide des

4vis courtes à tête hexagonale de 5/16po fournies.

7

Page 8

5. Fixer le panneau personnalisé

Panneau debois

Aligner les goujons du panneau de bois personnalisé avec les

encoches en trou de serrure de la porte. Vérier que les 4 pitons

en plastique sont bien engagés dans les encoches en trou de

serrure. Glisser le panneau de bois vers le bas jusqu’à ce que sa

surface soit en afeurement avec le sommet de la porte.

6. Aligner les bords supérieurs du

panneau sur la porte

1½po

Aligner

les rives

supérieures

Ôter 2 vis courtes;

Panneau

acheté par le

client

Aligner les rives supérieures du panneau sur la porte Utiliser du

ruban pour marque sur le foret de 3/32po la profondeur de trou

à ne pas dépasser d’environ 11/2po (38mm). Percer des avanttrous dans les coins supérieurs de la porte, en utilisant le trou

dans la doublure comme guide.

remplacer celles-ci par

les vis longues fournies.

7. Installation du panneau personnalisé

Aligner les rives

supérieures

Percer à travers

ce trou

Vis de

Panneau

acheté par

le client

À l’aide d’un tournevis Torx T15, serrer deux longues vis nº 8 x

1/8po dans les coins supérieurs pour xer le panneau de bois

personnalisé.

1/8po

8. Retirer les vis courtes

Aligner

les rives

supérieures

Ôter 2 vis courtes;

remplacer celles-ci par

les vis longues fournies.

Enlever les vis courtes (4e à partir du haut) de chaque côté de

l’intérieur du panneau de porte. Utiliser du ruban pour marque

sur le foret de 3/32po la profondeur de trou à ne pas dépasser

d’environ 11/2po (38mm). Percer 2 avant-trous dans le

panneau en utilisant les trous de montage de la porte comme

guide. Fixer les 2 vis longues restantes.

Panneau

acheté par

le client

8

Page 9

Instruction de réglage du ressort de charnière

Si la tension de la porte est insufsante pour supporter le poids de la porte, un réglage de la tension du ressort de charnière peut

s’avérer nécessaire.

1. Fermer la porte du lave-vaisselle

S’assurer que la porte du lave-vaisselle est fermée en tout temps

pendant le réglage de la tension du ressort de charnière. Leréglage

de la tension du ressort de la charnière lorsque la porte est

partiellement ou complètement ouverte risque d’endommager la

charnière.

3. Accès au dispositif de réglage du

ressort de charnière

2. Retirer le lave-vaisselle de la caisse

Le lave-vaisselle doit être partiellement ou complètement retiré

de sous l’armoire pour permettre l’accès au mécanisme de

réglage de la tension du ressort de charnière.

4. Réglage de tension du ressort

Dispositif

de réglage

de la

tension du

ressort de

charnière

Dispositif de réglage

de la tension du

ressort de charnière

Une fois le lave-vaisselle partiellement ou complètement retiré

de l’armoire, les dispositifs de réglage de tension du ressort de

charnière sont accessibles sur les côtés avant du lave-vaisselle.

Chacune des deux charnières (côté droit et côté gauche)

comporte 3 réglages de tension de ressort différents.

Touslesmodèles de lave-vaisselle quittent l’usine avec les

charnières réglées sur le réglage de tension de ressort le plus

bas. Ceréglage convient aux panneaux de porte plus légers.

Lespanneaux de porte plus lourds nécessiteront un ajustement

de la tension du ressort de charnière pour empêcher la porte de

s’ouvrir lorsqu’elle est déverrouillée.

9

Page 10

5. Trois réglages de ressort

6. Ajuster la tension du ressort

Chaque charnière comporte 3 niveaux de tension de ressort

différents sur lesquels elle peut être réglée. Le niveau de tension

actuel est indiqué par une èche. 1 est la tension de ressort la

plus basse pour les portes légères et 3 est la plus élevée pour

les portes plus lourdes. 2 est la tension moyenne pour les poids

des panneaux de porte qui se situent entre lourd et léger.

7. Remettre le lave-vaisselle sous l’armoire pour l’empêcher

de basculer pendant que la porte est ouverte et fermée pour

vérier la tension du ressort. Si la porte est trop rigide, reculer

les charnières d’un cran pour réduire la tension du ressort en

tournant l’écrou dans le sens antihoraire. Si la porte s’ouvre

d’elle-même, augmenter la tension du ressort en tournant

l’écrou d’un cran dans le sens horaire.

Tourner l’écrou de réglage à l’aide d’une clé à fourche de 3/4po

ou d’une clé à molette d’un ou deux cran dans le sens horaire vu

de dessus pour augmenter la tension du ressort.

8. Une fois la tension du ressort souhaitée réglée, le lave-

vaisselle peut être installé sous le comptoir selon les étapes

indiquées dans le manuel d’instructions.

10

Page 11

INSTRUCCIONES DE INSTALACIÓN PARA PANEL A LA

MEDIDA PARA LAVAVAJILLAS BAJO MOSTRADOR CON

TINA DE ACERO INOXIDABLE

IMPORTANTE: Antes de instalar la lavavajillas, use esta Hoja de instrucciones como complemento de las Instrucciones de instalación.

Solo para modelos con panel a la medida

Reúna estas herramientas y piezas adicionales antes de

comenzar a instalar el panel a la medida. Lea y siga las

instrucciones provistas en esta hoja de instrucciones.

Herramientas adicionales necesarias:

■ Broca de 3/32"

■ Destornillador Torx

Piezas adicionales proporcionadas con los modelos con

panel a la medida:

■ 4 taquetes de plástico (sujetados entre sí por correderas)

■ 4 tornillos cortos (tornillo de cabeza hexagonal 10-16)

■ 4 tornillos largos (tornillo de cabeza Torx 8-18)

■ 1 plantilla (ubicada dentro de la bolsa con el Manual de uso y

cuidado)

■ 1 hoja de instrucciones (ubicada dentro de la bolsa con el

Manual de uso y cuidado)

NOTA: Los tornillos provistos son para usar únicamente en

un panel de madera de 3/4" (19mm) de espesor. Si el panel

de madera tiene menos de 3/4" (19 mm) de espesor, el cliente

debecomprar los tornillos en su localidad.

Compruebe que se hayan incluido todas estas piezas en el

paquete con el material impreso.

Si faltan piezas, llame al 1-800-422-1230.

En Canadá, llame al 1-800-807-6777.

†

T15

Siga los pasos a continuación:

El panel y la manija de la puerta (juntos) provistos por el cliente

deben pesar no más de 16 lb (7,3 kg) y se deben fabricar según

dimensiones especícas. Es recomendable que un fabricante

de gabinetes corte el panel provisto por el cliente, yaque se

necesitan dimensiones precisas.

NOTAS:

■ No se incluye la manija para el panel a la medida.

■ Todos los herrajes provistos para el montaje son para un panel

de madera de 3/4" (19 mm) de espesor. Si se utiliza un panel de

madera con menor espesor o materiales que no sean madera,

será responsabilidad del cliente obtener los tornillos del largo

adecuado y ajustar los oricios pilotos en consecuencia.

ADVERTENCIA

Peligro de Peso Excesivo

Use dos o más personas para mover e instalar

la lavavajillas.

No seguir esta instrucción puede ocasionar una

lesión en la espalda u otro tipo de lesiones.

Ponga la lavavajillas de pie

Instalación del panel a la medida

Dimensiones del panel a la medida

235/8"

(600 mm)

2915/16" (760mm)*

3/4" (19 mm)

Entre dos o más personas, pongan la lavavajillas de pie.

†

TORX y T15 son marcas comerciales de Acument Intellectual Properties, LLC.

11

Page 12

1. Instale la manija

2. Plantilla del panel

6" (152,4mm)

Instale las manijas a la medida en la parte frontal del panel de

madera, dentro de la línea punteada.

IMPORTANTE: Si la manija se ja en la parte trasera del panel a

la medida, los oricios para los tornillos deberán estar avellanados

para que las cabezas de los tornillos queden alineadas con el

panel. Si la manija se ja en la parte frontal del panel a la medida,

el largo de los tornillos no puede exceder el grosor del panel.

Parte superior

del panel

Plantilla del panel de madera

Línea central

Oricios

piloto

W11460372

Fije la plantilla provista a la parte de atrás del panel a la medida

con cinta adhesiva. Asegúrese de que el centro de la plantilla

esté alineado con el centro del panel de madera y que la parte

de arriba de la plantilla esté alineada con la cara superior del

panel de madera.

3. Taladre previamente los

oricios del panel a la medida

5/8"

(16mm)

3/32"

NOTA: No taladre a una profundidad mayor de 5/8" (16mm)

para evitar taladrar a través del panel. Las profundidades de los

oricios piloto provistas son para un panel de 3/4" (19mm) de

grosor.

Marque 4 oricios piloto en el panel de madera utilizando la

plantilla provista. Taladre previamente 4 oricios piloto con

una broca de 3/32". Use cinta adhesiva para marcar la broca y

así medir la profundidad del oricio. Taladre oricios piloto de

una profundidad aproximada de 5/8" (16mm) en el panel a la

medida.

NOTA: Si reutiliza un panel a la medida de una lavavajillas anterior,

primero revise si el tamaño general del panel sirve para la nueva

aplicación. Retire el panel del producto anterior. Coloque la plantilla

sobre los oricios nuevos y controle que estén en la ubicación

correcta. Taladre los oricios que necesite según la plantilla.

4. Instale los taquetes plásticos

Taquetes de plástico jados

con 4 tornillos cortos

Lado visible

Fije los 4 taquetes de plástico en el panel de madera con los

cuatro tornillos de cabeza hexagonal de 5/16" (cortos) que se

proveen.

12

Page 13

5. Instale el panel a la medida

Ensamblaje del

panel de madera

Alinee los taquetes del panel a la medida con las ranuras en

forma de bocallave ubicadas en el ensamblaje de la puerta.

Asegúrese de que los 4 taquetes de plástico estén dentro de las

ranuras de bocallave. Deslice el panel de madera hacia abajo

hasta que la supercie superior del panel de madera esté al ras

con la parte superior de la puerta.

6. Alinee los bordes superiores del

panel con la puerta

1½"

Alinee

losbordes

superiores

Retire los 2 tornillos

Panel provisto

por el cliente

Abra la puerta y alinee los bordes superiores. Use cinta para

marcar una broca de 3/32" a n de medir la profundidad del

oricio de aproximadamente 1½" (38mm). Taladre oricios piloto

en las esquinas superiores de la puerta usando el oricio en el

revestimiento como guía.

cortos y reemplácelos

con los tornillos largos

provistos.

7. Instalación del panel a la medida

Alinee los bordes

superiores

Taladre a través

de este oricio

Tornillo

Panel

provisto por

el cliente

Con un destornillador Torx T15, instale dos tornillos n.° 8 x 1/8"

(largos) en las esquinas superiores para jar el panel de madera

a la medida en su lugar.

de 1/8"

8. Retire los tornillos cortos

Alinee

los

bordes

superiores

Retire los 2 tornillos cortos

yreemplácelos con los

tornilloslargos provistos.

Retire los tornillos cortos (los cuartos desde la parte superior)

acada lado del panel interno de la puerta. Use cinta para marcar

una broca de 3/32" a n de medir la profundidad del oricio de

aproximadamente 1½" (38mm). Taladre 2 oricios piloto en el

panel tomando el oricio del revestimiento de la puerta como

guía. Instale los 2 tornillos largos restantes.

Panel provisto

por el cliente

13

Page 14

Instrucciones para ajustar el resorte de la bisagra

Si la tensión de la puerta no es suciente para sostener el peso de la puerta, es posible que se deba ajustar la tensión del resorte de

la bisagra.

1. Cierre la puerta de la lavavajillas.

Asegúrese de que la puerta de la lavavajillas esté cerrada en

todo momento mientras se ajusta la tensión del resorte de la

bisagra. Ajustar la tensión del resorte mientras la puerta está

abierta de manera parcial o total puede generar daños a la

bisagra.

3. Acceda al regulador del

resorte de la bisagra

2. Retire la lavavajillas del gabinete.

La lavavajillas se debe retirar de manera total o parcial del

gabinete para poder acceder al mecanismo de ajuste de tensión

del resorte de la bisagra.

4. Ajuste el resorte

Regulador

de tensión

del resorte

de la

bisagra

Regulador de

tensión del resorte

de la bisagra

Una vez que se haya retirado la lavavajillas del gabinete de

manera total o parcial, se podrá acceder a los reguladores de

tensión de los resortes de las bisagras que se encuentran a los

lados de la parte frontal de la lavavajillas.

14

Cada una de las bisagras (de la izquierda y de la derecha)

tienen 3 niveles diferentes de tensión de los resortes. Todos

los modelos de lavavajillas salen de fábrica con las bisagras

jadas en el nivel de tensión de resorte más bajo. Este nivel es

apto para los paneles de puerta más ligeros. Para los paneles

más pesados, se deberá ajustar el nivel de tensión del resorte

de la bisagra para evitar que la puerta se abra cuando no esté

trabada.

Page 15

5. Tres niveles de ajuste del resorte

6. Ajuste la tensión del resorte

Cada bisagra tiene 3 niveles diferentes para ajustar la tensión

del resorte. El nivel de tensión actual se indica con una echa.

Elnúmero 1 es el nivel de tensión más bajo, que sirve para

puertas ligeras, y 3 es el nivel más alto, que sirve para puertas

más pesadas. El número 2 es un nivel de tensión medio que

sirvepara paneles de puerta que tienen un peso intermedio.

7. Vuelva a colocar la lavavajillas en el gabinete para evitar que

se tumbe hacia adelante mientras la puerta está abierta,

y cierre la puerta para comprobar que la tensión sea la

adecuada. Sila puerta está demasiado dura, gire la tuerca

reguladora hacia la izquierda para bajar un nivel de tensión.

Si la puerta se abre sola, gire la tuerca reguladora hacia la

derecha para aumentar la tensión del resorte.

Para aumentar la tensión, gire la tuerca reguladora uno o dos

puntos hacia la derecha con una llave de extremo abierto de

3/4" o una llave ajustable.

8. Una vez que se haya congurado la tensión deseada, se

puede instalar la lavavajillas bajo el mostrador según los

pasos que seindican en el manual de instrucciones.

W11428482A

®

/™ ©2020 All rights reserved.

Tous droits réservés.

Todos los derechos reservados.

07/20

Loading...

Loading...