Page 1

LP GAS CONVERSION INSTRUCTIONS

W10597146B

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

IMPORTANT:

Installer: Leave installation instructions with the homeowner.

Homeowner: Keep installation instructions for future reference.

IMPORTANT :

Installateur : Remettre les instructions d'installation au propriétaire.

Propriétaire : Conserver les instructions d'installation pour référence ultérieure.

For WCG, MGC, KCGS and ICS5/6 Model Series

INSTRUCTIONS DE CONVERSION - GAZ PROPANE

Pour séries de modèles WCG, MGC, KCGS et ICS5/6

Table of Contents/Table des matières

COOKTOP SAFETY........................................................................1

Tools and Parts ............................................................................2

Convert from Natural Gas to LP Gas...........................................3

Convert from LP Gas to Natural Gas...........................................6

Lighting the Electronic Igniters ....................................................8

Flame Height Adjustment.............................................................8

Complete Burner Adjustment ......................................................9

SÉCURITÉ DE LA TABLE DE CUISSON ....................................10

Outillage et pièces......................................................................11

Conversion de gaz naturel à propane........................................12

Conversion de propane à gaz naturel........................................15

Allumeurs électroniques - allumage...........................................17

Réglage de la taille des flammes ...............................................18

Achever le réglage des brûleurs.................................................19

COOKTOP SAFETY

Page 2

Tools and Parts

WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

– Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

•

Do not try to light any appliance.

•

Do not touch any electrical switch.

•

Do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

•

If you cannot reach your gas supplier, call the fire department.

– Installation and service must be performed by a qualified installer, service agency or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell gas” instructions.

In the State of Massachusetts, the following installation instructions apply:

■ Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

■ If using a ball valve, it shall be a T-handle type.

■ A flexible gas connector, when used, must not exceed 3 feet.

†®TORX is a registered trademark of Acument Intellectual Properties, LLC.

Gather the required tools and parts necessary for correct LP gas

conversion.

Tools needed

■ Flat-blade screwdriver

■ ³⁄₃₂" (#0 [2.0 mm]) flat-blade screwdriver (screwdriver shaft

must be a minimum of 2" [5.1 cm] long)

■ Adjustable wrench

■ 7.0 mm nut driver

■ 7.0 mm wrench

■ T10 Torx

Parts needed

For models KCGS550ESS, KCGS556ESS, KCGS950ESS and

KCGS956ESS use the following parts:

■ LP orifice package (W10676662)

■ Conversion instructions (W10597146A)

For all other models use the following parts:

■ LP orifice package (W10676661)

■ Conversion instructions (W10597146A)

2

®†

adapter

High Altitude Conversion

To convert the cooktop for elevations above 6,560 ft (1999.5 m),

order a High Altitude Conversion Kit.

For models KCGS550ESS, KCGS556ESS, KCGS950ESS and

KCGS956ESS use the following parts:

■ Part Number W10679116 - LP high altitude

■ Part Number W10679118 - Natural gas high altitude

For all other models use the following parts:

■ Part Number W10679114 - LP high altitude

■ Part Number W10679113 - Natural gas high altitude

To order, see the “Assistance or Service” section of the User

Guide.

IMPORTANT: Gas conversions from Natural gas to LP gas must

be done by a qualified installer. Before proceeding with

conversion, shut off the gas supply to the cooktop prior to

disconnecting the electrical power.

Page 3

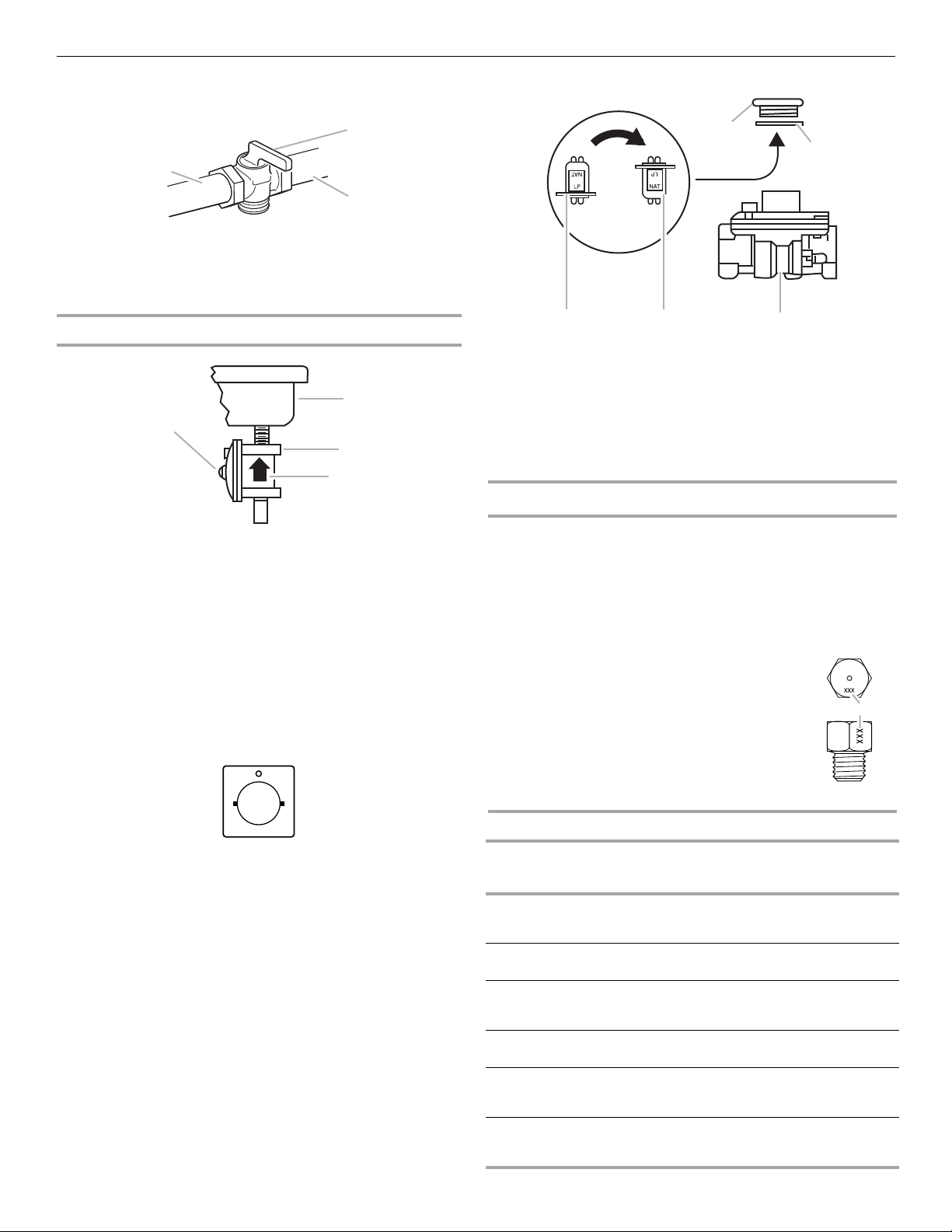

To Convert Gas Pressure Regulator

WARNING

This conversion kit shall be installed by a

qualified service agency in accordance

with the manufacturer's instructions and

all applicable codes and requirements of

the authority having jurisdiction. If the

information in these instructions is not

followed exactly, a fire, explosion or

production of carbon monoxide may

result causing property damage, personal

injury or loss of life. The qualified service

agency is responsible for the proper

installation of this kit. The installation is

not proper and complete until the

operation of the converted appliance is

checked as specified in the

manufacturer's instructions supplied with

this kit.

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 14" (36 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

A

B

C

A

B

C

D

A

B

CDE

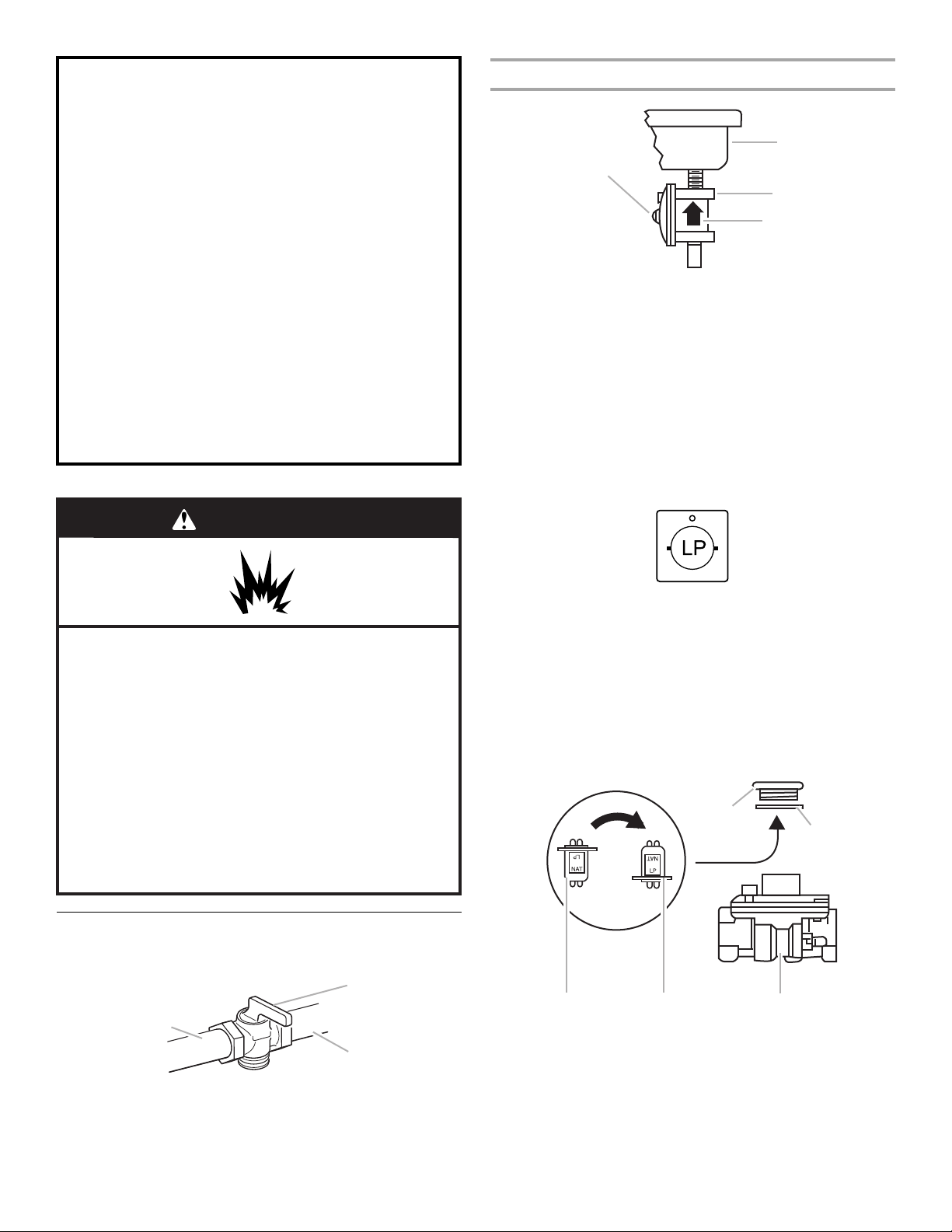

A. Access cap

B. Rear of cooktop

C. Gas pressure regulator

D. Gas flow

3. Determine the type of regulator you have:

Style 1: The cap has a slot and “NAT” printed on it.

Remove access cap by using a flat-blade screwdriver or coin,

turning the access cap counterclockwise.

The gas pressure regulator has 2 settings that are stamped

on either side of the cap. Turn the cap and reinstall into

regulator with the stamp “LP” visible from the outside of the

regulator.

Convert from Natural Gas to LP Gas

1. Turn manual shutoff valve to the closed position.

A. To cooktop

B. Shutoff valve (closed position)

C. Gas supply line

2. Unplug cooktop or disconnect power.

Style 2: The cap does not have a slot and requires a wrench

to be removed.

Remove the access cap by using a wrench, turning the

access cap counterclockwise.

Remove spring retainer from the cap by pushing against the

flat side of the spring retainer. Look at the spring retainer to

locate the “NAT” or “LP” position. Turn over the spring

retainer so the “LP” is showing on the bottom. Snap the

spring retainer back into the cap. Reinstall the cap onto the

regulator.

A. Access cap

B. Gasket

C. Gas pressure regulator

D. LP position

E. NAT position

3

Page 4

4. Test the gas pressure regulator and gas supply line.

A

A

B

D

C

E

A

The regulator must be checked at a minimum 1" (2.5 cm)

water column above the set pressure. The inlet pressure to

the regulator should be as follows for operation and checking

the regulator setting:

LP Gas:

Minimum pressure 10" (25.4 cm) W.C.P.

Supply pressure 14" (35.5 cm) W.C.P.

Gas Supply Pressure Testing

Line pressure testing above ½ psi gauge (14" WCP)

The cooktop and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

½ psi (3.5 kPa).

Line pressure testing at ½ psi gauge (14" WCP) or lower

The cooktop must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than ½ psi (3.5 kPa).

5. If the burner grates are installed, remove them.

Use the following charts to match the correct gas orifice spud

with the burner location and model being converted.

LP Gas Orifice Spud Chart for Kit W10676661

Burner

Rating

5,000 BTU Green 66 0.66 mm

7,000 BTU White 75 0.75 mm

8,000 BTU Orange 79 0.79 mm

11,000 BTU Red 97 0.97 mm

13,000 BTU Yellow 108 1.08 mm

16,000 BTU Pink 115 1.15 mm

12,000 BTU

Inner

Outer

Color Stamp

Brown

Brown

(A)

85

48

Size

0.85 mm

0.48 mm

A. Size stamp

LP Gas Orifice Spud Chart for Kit W10676662

Burner

Rating

5,000 BTU White 66 0.66 mm

6,000 BTU Green 70 0.70 mm

9,100 BTU Black 89 0.89 mm

11,000 BTU Orange 97 0.97 mm

13,000 BTU

Inner

Outer

14,000 BTU

Inner

Outer

16,000 BTU

Inner

Outer

9,000 BTU

Inner

Outer

Color Stamp

Blue

Brown

Blue

Ye ll o w

Blue

Red

Pink

Pink

(A)

45

97

45

101

45

105

40

80

Size

0.45 mm

0.97 mm

0.45 mm

1.01 mm

0.45 mm

1.05 mm

0.40 mm

0.80 mm

Burner Models for Kit W10676662

Model No. Left

KCGS550E

KCGS556E

KCGS950ES

KCGS956ES

Front

White89Black97Brown45Blue70Green89Black89Black

White89Black

White89Black97Brown45Blue70Green80Pink40Pink

White97Orange

66

66

66

66

Left

Center

Rear

Yellow45Blue70Green89Black89Black

Center

Inner

Outer

101

105

Red45Blue70Green80Pink40Pink

Right

Rear

Burner locations

A. Size stamp

Right

Right

Front

Front

Inner

Outer

Burner Models for Kit W10676661

Model No. Left

WCG51US0D

MGC7430D

ICS500DS00

WCG75US0D

MGC9530D66Green

WCG97US0D

KCGS350E

ICS655DS00

WCG51US6D

MGC7536D75White75White

WCG97US6D

MGC9536D

KCGS356E

Front

Green

White79Orange85Brown48Brown66Green75White75White

White75White85Brown48Brown66Green97Red97Red

66

75

75

Left

Rear

108

Yellow

115

Pink

Center

Inner

Ye ll o w

Center

Outer

N/A N/A 97

N/A N/A 97

108

108

Yellow66Green97Red97Red

Right

Right

Front

Inner

Right

Front

Outer

Rear

Red75White75White

Red75White75White

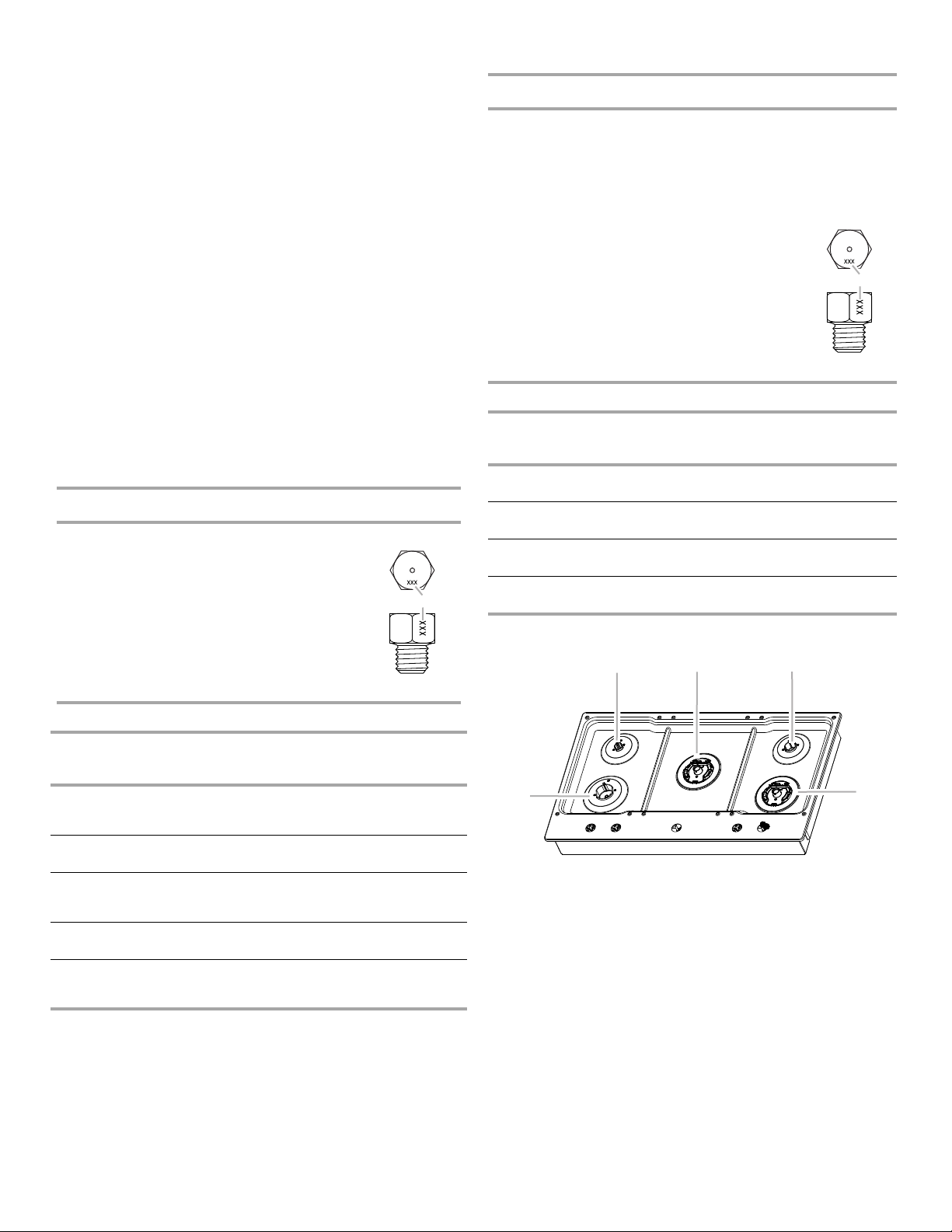

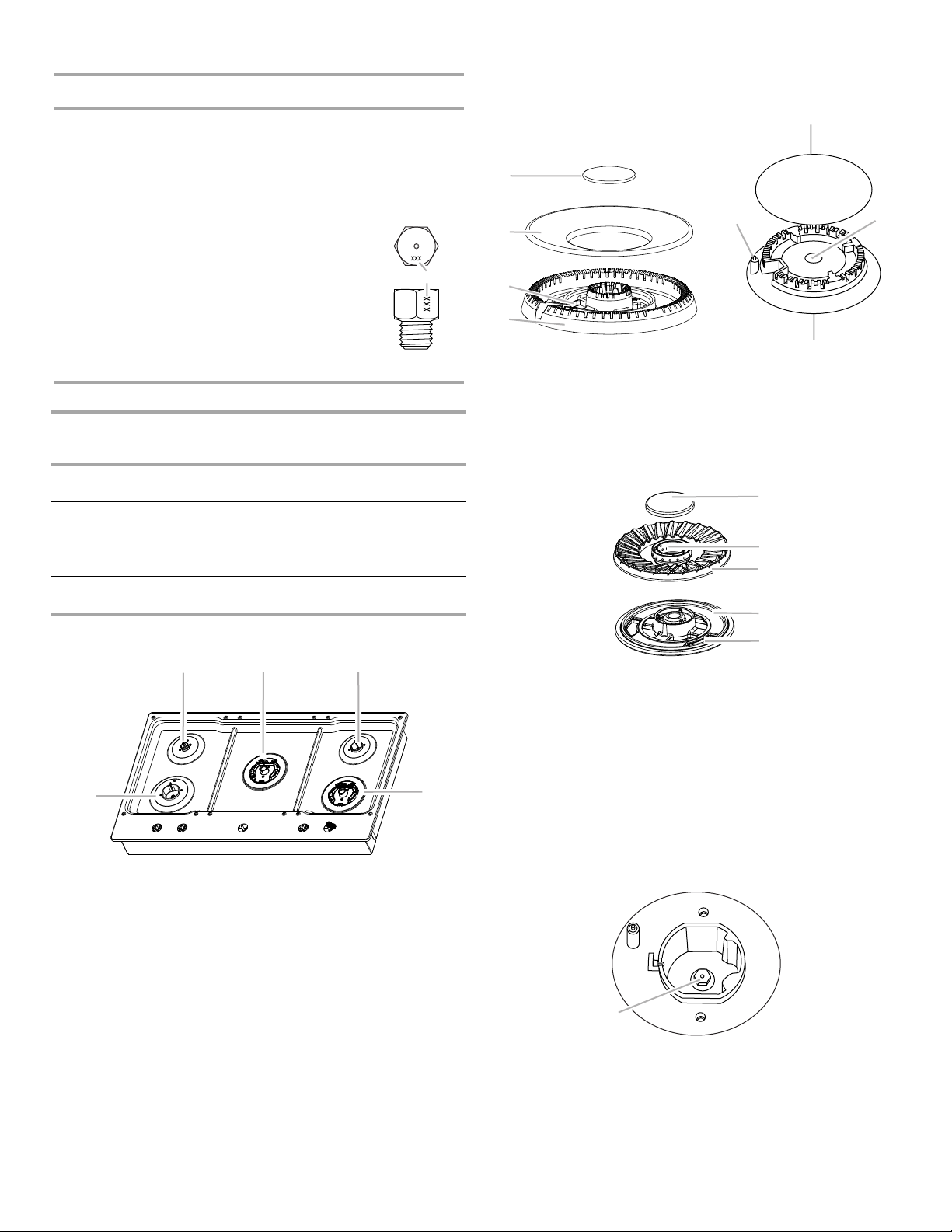

A. Left front

B. Left rear

C. Center

D. Right rear

E. Right front

6. Remove all burner caps and burner bases (see the User

Guide for burner reference).

To remove the burner base for the Dual Flame and Dual Tier

Ultra Torch burners use a Torx

®

T10 driver to remove the screw.

4

Page 5

Dual Tier Ultra Burner

D

A

B

C

A

B

C

D

E

D

A

B

C

A

A

B

A

B

A

B

C

B

C

A

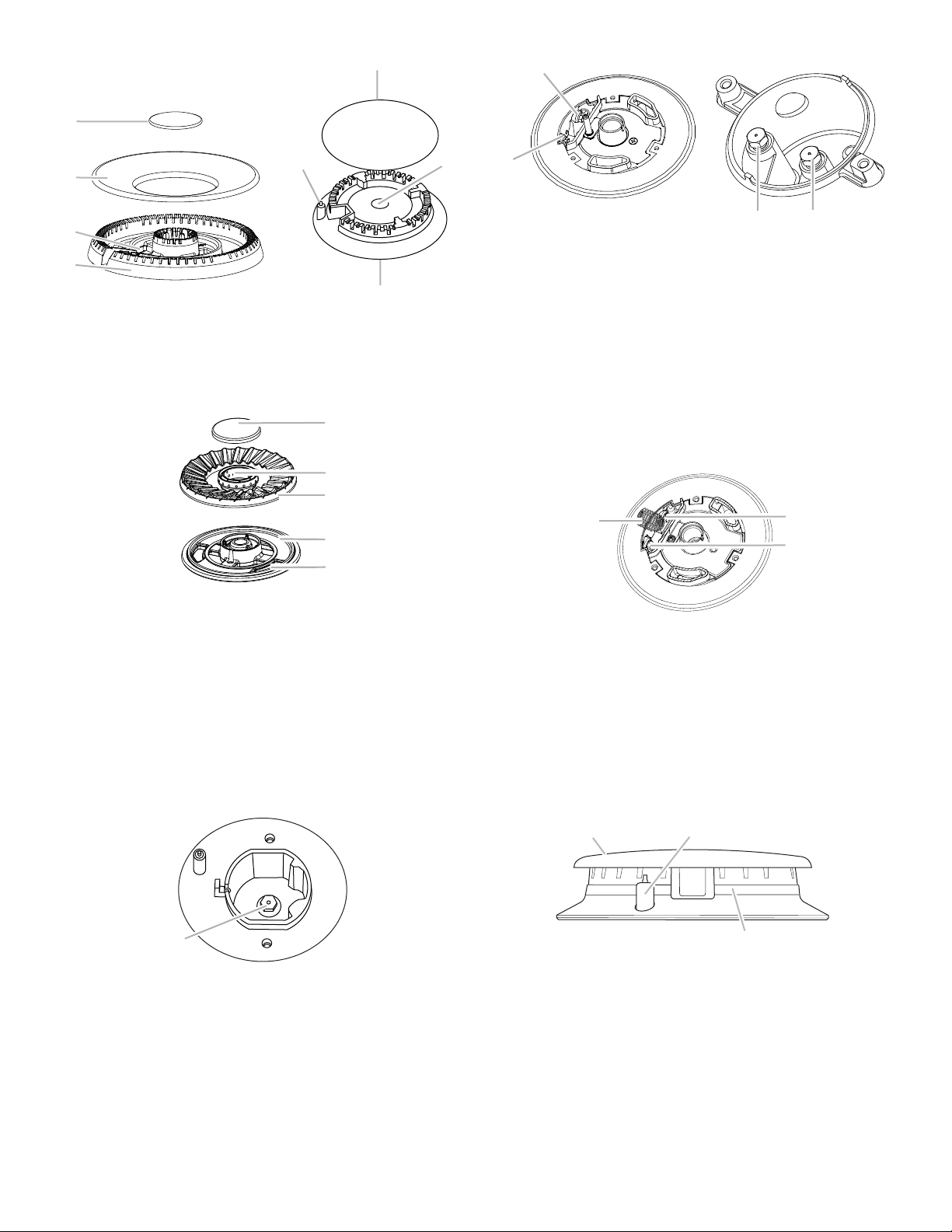

A. Inner burner cap

B. Outer burner cap

C. Gas tube opening

D. Burner base

Even-Heat™ Torch Burner

A. Inner burner cap

B. Inner burner base

C. Outer burner base

D. Burner support

E. Gas tube opening

Standard and Dual Flame

A. Burner cap

B. Igniter electrode

C. Burner base

D. Gas tube opening

7. To Convert Standard Burner:

■ Use 7.0 mm wrench to loosen and remove the orifice

spud (A).

■ Set gas orifice spud aside.

■ Replace with correct LP gas orifice spud. See LP gas

orifice spud charts.

Dual Tier Ultra Burner

A. Inner orifice spud

B. Outer orifice spud

Dual Flame Burners

A. Inner orifice spud

B. Outer orifice spud

9. To Convert Even-Heat™ Torch Burner

■ Remove the spring that is shown in the following

illustration (C).

■ Use 7.0 mm wrench to loosen and remove the inner

orifice spud (A) and the outer orifice spud (B).

■ Set gas orifice spuds aside.

■ Replace with correct LP gas orifice spud. See the LP gas

orifice spud charts.

■ Return the spring to its original location.

A. Inner orifice spud

B. Outer orifice spud

C. Spring

IMPORTANT: Place Natural gas orifice spuds in plastic parts

bag for future use and keep with package containing

literature.

10. Replace sheet of insulation.

11. Replace burner bases and burner caps.

The igniter electrode is ceramic and could break during

conversion. Be sure that the electrode comes through the hole

in the burner smoothly while you are replacing the burner base.

A. Burner cap

A. Orifice spud

B. Electrode

C. Burner base

8. To Convert Dual Tier Ultra and Dual Flame Burners:

■ Use 7.0 mm wrench to loosen and remove the inner

orifice spud (A) and the outer orifice spud (B).

■ Set gas orifice spuds aside.

■ Replace with correct LP gas orifice spuds. See the LP gas

orifice spud charts.

12. Open shutoff valve in the gas supply line. The valve is open

when the handle is parallel to the gas pipe.

13. Plug in cooktop or reconnect power.

REMEMBER: Once you have completed converting all of the

cooktop burners, test the cooktop for leaks by brushing on

an approved noncorrosive leak-detection solution. If bubbles

appear, a leak is indicated. Correct any leaks found.

14. To adjust single and dual valves, see the “Flame Height

Adjustment” section.

5

Page 6

Convert from LP Gas to Natural Gas

A

B

C

A

B

C

D

NAT

A

B

CDE

A

1. Turn manual shutoff valve to the closed position.

A. To cooktop

B. Shutoff valve (closed position)

C. Gas supply line

2. Unplug cooktop or disconnect power.

To Convert Gas Pressure Regulator

A. Access cap

B. Rear of cooktop

C. Gas pressure regulator

D. Gas flow

3. Determine the type of regulator you have:

Style 1: The cap has a slot and “LP” printed on it.

Remove access cap by using a flat-blade screwdriver or coin,

turning the access cap counterclockwise.

The gas pressure regulator has 2 settings that are stamped

on either side of the cap. Turn the cap and reinstall into

regulator with the stamp “NAT” visible from the outside of the

regulator.

A. Access cap

B. Gasket

C. Gas pressure regulator

D. NAT position

E. LP position

4. If the burner grates are installed, remove them.

Use the following charts to match the correct gas orifice spud

with the burner location and model being converted.

Natural Gas Orifice Spud Chart for Kit W10676661

Burner

Rating

5,000 BTU Green 99 0.99 mm

9,100 BTU White or

10,000 BTU Orange 135 1.35

12,00 BTU Red or

15,000 BTU Yellow 175 1.75 mm

18,00 BTU Pink 189 1.89 mm

17,000 BTU

Inner

Outer

18,00 BTU

Inner

Outer

19,000 BTU

Inner

Outer

Color Stamp

no color

Blue

Red

Red

Brown

Brown

White

White

(A)

130 1.30 mm

150 1.50 mm

175

57

180

57

185

57

Size

1.75 mm

0.57 mm

1.80 mm

0.57 mm

1.85 mm

0.57 mm

A. Size stamp

Style 2: The cap does not have a slot and requires a wrench

to be removed.

Remove the access cap by using a wrench, turning the

access cap counterclockwise.

Remove spring retainer from the cap by pushing against the

flat side of the spring retainer. Look at the spring retainer to

locate the “NAT” or “LP” position. Turn over the spring

retainer so the “NAT” is showing on the bottom. Snap the

spring retainer back into the cap. Reinstall the cap onto the

regulator.

6

Burner Models for Kit W10676661

Model No. Left

WCG51US0D

MGC7430D

ICS500DS00

WCG75US0D

MGC9530D99Green

WCG97US09

KCGS350E

ICS655DS00

WCG51US6D

MGC7536D

WCG97US6D

MGC9536D

KCGS356E

Front

Green

130

color

130

White

130

color

130

color

99

No

No

No

Left

Rear

175

Ye ll ow

189

Pink

135

Orange

130

White

130

No

color

130

No

color

Center

Inner

N/A N/A 150

N/A N/A 150

175

Red

175

Ye ll ow

180

Brown57Brown99Green

185

White57White99Green

Center

Outer

Ye ll o w99Green

Right

Rear

Red

Red

175

Red99Green

175

Right

Front

Inner

130

White

130

White

130

No

color

150

Red

150

Blue

150

Blue

Right

Front

Outer

130

White

130

White

130

No

color

150

Red

150

Blue

150

Blue

Page 7

Natural Gas Orifice Spud Chart for Kit W10676662

A

B

D

C

E

A

D

A

B

C

A

B

C

D

E

D

A

B

C

A

Burner

Rating

6,000 BTU White 110 1.10 mm

7,000 BTU Green 118 1.18 mm

10,000 BTU Black 142 1.42 mm

12,00 BTU Orange 155 1.55 mm

17,000 BTU

Inner

Other

18,000

Inner

Outer

20,000 BTU

Inner

Outer

10,000 BTU

Inner

Outer

Color Stamp

Blue

Brown

Blue

Yellow

Blue

Red

Pink

Pink

(A)

91

167

91

172

91

185

N/A N/A

Size

0.91 mm

1.67 mm

0.91 mm

1.72 mm

0.91 mm

1.85 mm

Burner Models for Kit W10676662

Model No. Left

KCGS550E

KCGS556E

KCGS950ES

KCGS956ES

Front

110

White

110

White

110

White

110

White

Left

Rear

142

Black

142

Black

142

Black

155

Orange

Center

Brown91Blue

Ye ll o w91Blue

Brown91Blue

Center

Inner

Outer

167

172

167

185

Red91Blue

Right

Rear

118

Green

118

Green

118

Green

118

Green

A. Size stamp

Right

Right

Front

Front

Inner

Outer

142

Black

Black

142

Black

142

142

Black

N/A N/A

N/A N/A

To remove the burner base for the Dual Flame and Dual Tier

Ultra Torch burners use a Torx

®

T10 driver to remove the

screw.

Dual Tier Ultra Burner

A. Inner burner cap

B. Outer burner cap

C. Gas tube opening

D. Burner base

Standard and Dual

Flame

A. Burner cap

B. Igniter electrode

C. Burner base

D. Gas tube opening

Burner locations

Even-Heat™ Torch Burner

A. Inner burner cap

B. Inner burner base

C. Outer burner base

D. Burner support

E. Gas tube opening

6. To Convert Standard Burner:

■ Use 7.0 mm wrench to loosen and remove the orifice

spud (A).

■ Set gas orifice spud aside.

■ Replace with correct Natural gas orifice spud. See Natural

A. Left front

B. Left rear

C. Center

D. Right rear

E. Right front

5. Remove all burner caps and burner bases (see the User

Guide for burner reference).

7. To Convert Dual Tier Ultra and Dual Flame Burners:

gas orifice spud charts.

A. Orifice spud

■ Use 7.0 mm wrench to loosen and remove the inner

orifice spud (A) and the outer orifice spud (B).

■ Set gas orifice spuds aside.

7

Page 8

■ Replace with correct Natural gas orifice spuds. See the

A

B

A

B

A

B

C

B

C

A

Natural gas orifice spud charts.

Dual Tier Ultra Burner

A. Inner orifice spud

B. Outer orifice spud

Dual Flame Burners

A. Inner orifice spud

B. Outer orifice spud

8. To Convert Even-Heat™ Torch Burner

■ Remove the spring that is shown in the following

illustration (C).

■ Use 7.0 mm wrench to loosen and remove the inner

orifice spud (A) and the outer orifice spud (B).

■ Set gas orifice spuds aside.

■ Replace with correct Natural gas orifice spud. See the

Natural gas orifice spud charts.

■ Return the spring to its original location.

12. Plug in cooktop or reconnect power.

REMEMBER: Once you have completed converting all of the

cooktop burners, test the cooktop for leaks by brushing on

an approved noncorrosive leak-detection solution. If bubbles

appear, a leak is indicated. Correct any leaks found.

13. To adjust single and dual valves, see the “Flame Height

Adjustment” section.

Lighting the Electronic Igniters

The cooktop burners use electronic igniters in place of standing

pilots. When the cooktop control knob is pushed in, the system

creates a spark to light the burner. This sparking continues until

the control knob is turned to the desired setting.

To Check Operation of the Cooktop Burners:

1. Push in and turn knobs to the ignition position (see the User

Guide for additional information). The cooktop burner flame

should light within 4 seconds. The first time a burner is lit, it

may take longer than 4 seconds to light because of air in the

gas line. Do not leave the knob in the ignition position after

the burner lights.

A. Inner orifice spud

B. Outer orifice spud

C. Spring

IMPORTANT: Place Natural gas orifice spuds in plastic parts

bag for future use and keep with package containing

literature.

9. Replace sheet of insulation.

10. Replace burner bases and burner caps.

The igniter electrode is ceramic and could break during

conversion. Be sure that the electrode comes through the

hole in the burner smoothly while you are replacing the burner

base.

2. If burners do not light properly, turn the control knob to the

Off position. Make sure the burner caps are in the proper

position.

3. Check that the power supply cord is plugged in. Check that

the circuit breaker has not tripped or the household fuse has

not blown.

4. Check that the shutoff valve is in the open position.

5. Check burner operation again.

If one or all of the burners do not light at this point, see

“Assistance or Service” section in the User Guide.

Flame Height Adjustment

Each burner flame has been factory set to the lowest position

available to provide reliable and constant reignition of the burner.

However, each burner can be adjusted.

NOTE: If your model number begins with KGCS5 or KGCS9, call

service, as this operation will require opening the unit.

To Adjust:

The flame can be adjusted using the adjustment screws

underneath the control knob.

NOTE: Check the Use and Care Guide for information on each

burner to determine whether they are single or dual flame. Adjust

the valves accordingly.

Adjustment for Single Valve

A. Burner cap

B. Electrode

C. Burner base

11. Open shutoff valve in the gas supply line. The valve is open

when the handle is parallel to the gas pipe.

1. Set the burner flame to LO.

2. Remove the control knob.

3. Hold knob stem with a pair of pliers. Use a ³⁄₃₂" (#0 [2.0 mm])

flat-blade screwdriver to turn the screw located within the

shaft of the control knob stem until the flame is the proper

size.

8

Page 9

A.

B

C

A

A

B

M

e

d

A

B

C

B

A

A

B

³⁄₃₂

" (#0 [2.0 mm]) flat-blade screwdriver

(screwdriver shaft must be a minimum of

2" [5.1 cm] long)

B. Control knob stem opening

C. Adjustment screw location

4. For LP gas conversion:

Completely tighten screw “C” to set the minimum flame

height.

For Natural gas conversion:

Tighten screw “C” to reduce flame height. Loosen screw to

increase flame height. See “Complete Burner Adjustment”

section.

5. Replace the control knob.

6. Test the flame by turning the control from LO to HI, checking

the flame at each setting.

Adjustment for Dual Valve

To Adjust Inner Crown Flame:

1. Set the inner crown flame to LO.

A. Inner crown

B. Outer crown

2. Remove the control knob.

3. Remove the black rubber grommet.

4. Using needle-nose pliers, remove the gray shield inside the

burner valve opening.

5. For LP gas conversion:

Completely tighten screw “A” to set the minimum flame

height.

For Natural gas conversion:

Tighten screw “A” to reduce flame height. Loosen screw to

increase flame height. See “Complete Burner Adjustment”

section.

A. Inner crown adjustment screw

B. Outer crown adjustment screw

6. Replace the control knob.

To Adjust Outer Crown Flame:

1. Set the outer crown flame to LO.

2. Remove the control knob.

3. For LP gas conversion:

Completely tighten screw “B” to set the minimum flame

height.

For Natural gas conversion:

Tighten screw “B” to reduce flame height. Loosen screw to

increase flame height. See “Complete Burner Adjustment”

section.

4. Replace the gray shield. Use a screwdriver to help push the

shield into place.

5. Replace the black rubber grommet.

6. Replace the control knob.

7. Test the flame by turning the control from LO to HI, checking

the flame at each setting.

Complete Burner Adjustment

1. Check burner flame(s) for a proper size and shape. The

cooktop low burner flame should be a steady blue flame

approximately ¹⁄₄" (0.64 cm) high.

A. Low flame

B. High flame

2. Completely fill out the conversion label and attach label to

bottom of the cooktop next to the rating tag. Do not cover the

A. Control knob

B. Black rubber grommet

C. Gray shield

rating tag with the conversion label.

IMPORTANT: Place gas orifice spuds in plastic parts bag for

future use and keep with package containing literature.

Read “Sealed Surface Burners” section in the Use and Care

Guide supplied with your cooktop.

9

Page 10

SÉCURITÉ DE LA TABLE DE CUISSON

Risque possible de décès ou de blessure grave si vous ne

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

AVERTISSEMENT

DANGER

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signifient :

AVERTISSEMENT : Si les renseignements dans ce manuel ne sont pas exactement

observés, un incendie ou une explosion peut survenir, causant des dommages au

produit, des blessures ou un décès.

– Ne pas entreposer ni utiliser de l’essence ou d’autres vapeurs ou liquides inflammables

à proximité de cet appareil ou de tout autre appareil électroménager.

– QUE FAIRE DANS LE CAS D’UNE ODEUR DE GAZ :

•

Ne pas tenter d’allumer un appareil.

•

Ne pas toucher à un commutateur électrique.

•

Ne pas utiliser le téléphone se trouvant sur les lieux.

•

Appeler immédiatement le fournisseur de gaz à partir du téléphone d'un voisin. Suivre

ses instructions.

•

À défaut de joindre votre fournisseur de gaz, appeler les pompiers.

– L’installation et l’entretien doivent être effectués par un installateur qualifié, une agence

de service ou le fournisseur de gaz.

AVERTISSEMENT : L’odorat ne permet pas toujours la détection d’une fuite de gaz.

Les distributeurs de gaz recommandent l’emploi d’un détecteur de gaz (homologation UL ou CSA).

Pour d’autre information, contacter le fournisseur de gaz local.

En cas de détection d’une fuite de gaz, exécuter les instructions “Que faire dans le cas d’une odeur de gaz”.

10

Page 11

Outillage et pièces

Dans l’État du Massachusetts, les instructions d’installation suivantes sont applicables :

■ Les travaux d’installation et réparation doivent être exécutés par un plombier ou tuyauteur qualifié ou licencié, ou par le

personnel qualifié d’une entreprise licenciée par l’État du Massachusetts.

■ Si une vanne à boisseau sphérique est utilisée, elle doit comporter une manette “T”.

■ Si un conduit de raccordement flexible est utilisé, sa longueur ne doit pas dépasser 3 pi.

†®TORX est une marque dèposèe de Acument Intellectual Properties, LLC.

AVERTISSEMENT

Cet ensemble de conversion doit être

installé par le personnel qualifié d'une

agence de service en conformité avec les

instructions du fabricant et les

prescriptions de tous les codes en vigueur

et des autorités juridictionnelles. Si les

présentes instructions ne sont pas

rigoureusement respectées, ceci peut

provoquer un incendie, une explosion ou

la génération de monoxyde de carbone

provoquant des dommages corporels ou

matériels, ou même la mort. La

responsabilité de l'installation correcte de

cet ensemble de conversion incombe au

personnel qualifié d'une agence de

service. L'installation n'est pas correcte et

complète avant que le bon fonctionnement

de l'appareil converti ait été vérifié sur la

base des spécifications présentées dans

les instructions du fabricant fournies avec

cet ensemble de pièces.

Rassembler les outils et composants nécessaires pour

l'exécution correcte de la conversion pour l'alimentation au gaz

propane.

Outillage nécessaire

■ Tournevis à lame plate

■ Tournevis à lame plate de ³⁄₃₂" (#0 [2,0 mm]) (la longueur de la

tige du tournevis doit être d'au moins 2" [5,1 cm])

■ Clé à molette

■ Tourne-écrou de 7 mm

■ Clé de 7 mm

®†

■ Adaptador Torx

Pièces nécessaires

Pour les modèles KCGS550ESS, KCGS556ESS, KCGS950ESS

et KCGS956ESS, utiliser les pièces suivantes :

■ Ensemble de gicleurs pour gaz propane (W10676662)

■ Instructions pour la conversion (W10597146A)

Pour les autres modèles, utiliser les pièces suivantes :

■ Ensemble de gicleurs pour gaz propane (W10676661)

■ Instructions pour la conversion (W10597146A)

Conversion pour altitude élevée

T10

IMPORTANT : L'opération de conversion de l'appareil pour

l'alimentation au gaz propane au lieu de gaz naturel doit être

exécutée par un installateur qualifié. Avant d'entreprendre la

conversion, fermer l'arrivée de gaz avant d'interrompre

l'alimentation électrique de l'appareil.

Pour convertir la table de cuisson pour l'utilisation à une altitude

supérieure à 6 560 pi (1999,5 m), commander un ensemble de

conversion pour altitude élevée.

Pour les modèles KCGS550ESS, KCGS556ESS, KCGS950ESS

et KCGS956ESS, utiliser les pièces suivantes :

Pour les autres modèles, utiliser les pièces suivantes :

Pour la commande, voir la section “Assistance ou service” dans

le Guide d'utilisation et d'entretien.

■ Produit numéro W10679116 - altitude élevée - propane

■ Produit numéro W10679116 - altitude élevée - gaz naturel

■ Produit numéro W10679114 - altitude élevée - propane

■ Produit numéro W10679113 - altitude élevée - gaz naturel

11

Page 12

3. Déterminer le type du détendeur :

AVERTISSEMENT

Risque d'explosion

Utiliser une canalisation neuve d'arrivée de gaz

approuvée par la CSA International.

Installer un robinet d'arrêt.

Bien serrer chaque organe de connexion de la

canalisation de gaz.

En cas de connexion au gaz propane, demander à une

personne qualifiée de s'assurer que la pression de gaz

ne dépasse pas 36 cm (14 po) de la colonne d'eau.

Par personne qualifiée, on comprend :

le personnel autorisé de chauffage,

le personnel autorisé d'une compagnie de gaz, et

le personnel d'entretien autorisé.

Le non-respect de ces instructions peut causer

un décès, une explosion ou un incendie.

A

B

C

A

B

C

D

A

B

CDE

Style 1 : Le chapeau comporte une rainure et la mention

“NAT”.

Utiliser un tournevis à lame plate ou une pièce de monnaie

pour dévisser le chapeau de l'ouverture d'accès; faire tourner

le chapeau dans le sens antihoraire.

Deux positions sont possibles pour le détendeur;

l'information correspondante est gravée de chaque côté du

chapeau. Orienter le chapeau correctement, et réinstaller le

chapeau sur le détendeur; la mention “LP” doit être visible

depuis l'extérieur du détendeur.

Style 2 : Le chapeau ne comporte pas de rainure; on doit

utiliser une clé pour la dépose.

Utiliser une clé pour enlever le chapeau de l'ouverture

d'accès; faire tourner le chapeau dans le sens antihoraire.

Ôter le ressort de retenue qui se trouve sous le chapeau pousser contre le côté plat du ressort de retenue. Examiner le

ressort de retenue pour identifier la position “NAT” ou “LP”.

Orienter correctement le ressort de retenue pour que la

mention “LP” soit au fond. Réinstaller le ressort de retenue

dans le chapeau. Réinstaller le chapeau sur le détendeur.

Conversion de gaz naturel à propane

1. Fermer le robinet d'arrêt manuel.

A. Vers table de cuisson

B. Robinet d'arrêt (position de fermeture)

C. Canalisation de gaz

2. Débrancher la table de cuisson ou déconnecter la source de

courant électrique.

Conversion du détendeur

12

A. Chapeau de l'ouverture d'accès

B. Arrière de la table de cuisson

C. Détendeur

D. Sens de circulation du gaz

A. Chapeau de l'ouverture d'accès

B. Joint d'étanchéité

C. Détendeur

4. Tester le détendeur et la canalisation de gaz.

On doit tester le détendeur sous une pression supérieure d'au

moins 1" (2,5 cm) (colonne d'eau) à la pression de réglage.

Pour le fonctionnement et le contrôle du réglage du

détendeur, il faut que la pression d'admission au détendeur

corresponde aux indications ci-dessous :

Gaz propane :

Pression minimum 10" (25,4 cm) (colonne d'eau)

Pression de service 14" (35,5 cm) (colonne d'eau)

Test de pressurisation de la canalisation de gaz

Pressurisation à une pression supérieure à ½ lb/po² (14" -

colonne d'eau)

Lors de tout test de pressurisation de ce système à une

pression supérieure à ½ lb/po² (3,5 kPa), on doit déconnecter

l'appareil et son robinet d'arrêt individuel de la canalisation

de gaz.

D. Position LP

E. Position NAT

Page 13

Pressurisation à une pression relative de ½ lb/po² (14" -

A

A

B

D

C

E

A

D

A

B

C

A

B

C

D

colonne d'eau) ou moins

Lors de tout test de pressurisation de la canalisation de gaz à

une pression égale ou inférieure à ½ lb/po² (3,5 kPa), on doit

isoler l'appareil de la canalisation de gaz en fermant son

robinet d'arrêt manuel individuel.

5. Enlever les grilles de brûleur si elles sont installées.

Dans les tableaux qui suivent, choisir le gicleur approprié selon

le modèle de l'appareil et l'emplacement du brûleur à convertir.

Tableau des gicleurs pour propane pour ensemble

W10676661

Puissance

thermique

5 000 BTU Vert 66 0,66 mm

7 000 BTU Blanc 75 0,75 mm

8 000 BTU Orange 79 0,79 mm

11 000 BTU Rouge 97 0,97 mm

13 000 BTU Jaune 108 1,08 mm

16 000 BTU Rose 115 1,15 mm

12 000 BTU

Intérieur

Extérieur

Couleur Indication

Marron

Marron

(A)

85

48

Taille

0,85 mm

0,48 mm

A. Indication

de la

taille

Modèle de brûleur pour ensemble W10676661

Modèle n° Avant

WCG51US0D

MGC7430D

ICS500DS00

WCG75US0D

MGC9530D

WCG97US0D

KCGS350E

ICS655DS00

WCG51US6D

MGC7536D75Blanc75Blanc

WCG97US6D

MGC9536D

KCGS356E

gauche

Arrière

gauche

66

Vert

66

Vert

75

Blanc79Orange85Marron48Marron66Vert75Blanc75Blanc

75

Blanc75Blanc85Marron48Marron66Vert97Rouge97Rouge

108

Jaune

115

Rose

Centre

intérieur

Centre

extérieur

N/A N/A 97

N/A N/A 97

108

Jaune

108

Jaune66Vert97Rouge97Rouge

Ar-

Avant

rière

droit

droit

intérieur

Rouge75Blanc75Blanc

Rouge75Blanc75Blanc

Avant

droit

extérieur

Modèles de brûleur pour ensemble W10676662

Modèle n° Avant

KCGS550E

KCGS556E

KCGS950ES

KCGS956ES

Ar-

gau-

rière

che

gauche

66

Blanc89Noir97Marron45Bleu70Vert89Noir89Noir

66

Blanc89Noir

66

Blanc89Noir97Marron45Bleu70Vert80Rose40Rose

66

Blanc97Orange

Centre

intérieur

Jaune45Bleu70Vert89Noir89Noir

Rouge45Bleu70Vert80Rose40Rose

101

105

Centre

extérieur

Arrière

droit

Avant

droit

intérieur

Avant

droit

extérieur

Positions des brûleurs

A. Avant gauche

B. Arrière gauche

C. Centre

6. Retirer tous les chapeaux et les bases des brûleurs (consulter

le Guide d'utilisation pour des informations sur les brûleurs).

Pour retirer la base des brûleurs à double flamme et des

brûleurs torches Dual Tier Ultra, utiliser un tournevis Torx

T10 pour retirer la vis.

D. Arrière droit

E. Avant droit

®

Tableau des gicleurs pour propane pour ensemble

W10676662

Puissance

thermique

5 000 BTU

6 000 BTU

9 100 BTU

11 000 BTU

13 000 BTU

Intérieur

Extérieur

14 000 BTU

Intérieur

Extérieur

16 000 BTU

Intérieur

Extérieur

9 000 BTU

Intérieur

Extérieur

Couleur Indication

Blanc 66 0,66 mm

Vert 70 0,70 mm

Noir 89 0,89 mm

Orange 97 0,97 mm

Bleu

Marron4597

Bleu

Jaune

Bleu

Rouge

Rose

Rose

(A)

45

101

45

105

40

80

Taille

0,45 mm

0,97 mm

0,45 mm

1,01 mm

0,45 mm

1,05 mm

0,40 mm

0,80 mm

A. Indication

de la

taille

Brûleur Dual Tier Ultra

A. Chapeau de brûleur interne

B. Chapeau du brûleur externe

C. Ouverture du tuyau de gaz

D. Base du brûleur

Brûleur standard et brûleur

à double flamme

A. Chapeau de brûleur

B. Électrode d’allumeur

C. Base du brûleur

D. Ouverture du tuyau de

gaz

13

Page 14

Brûleur torche Even-Heat™

E

D

A

B

C

A

A

B

A

B

A

B

C

B

C

A

A. Chapeau de brûleur interne

B. Base de brûleur interne

C. Base de brûleur externe

D. Support de brûleur

E. Ouverture du tube d’arrivée de

gaz

7. Conversion d’un brûleur standard :

■ Utiliser une clé de 7,0 mm pour desserrer et enlever le

gicleur (A).

■ Conserver le gicleur de gaz.

■ Installer le gicleur de gaz correct pour propane. Voir les

tableaux de sélection des gicleurs pour gaz propane.

A. Gicleur

9. Conversion des brûleurs torche Even-Heat™

■ Retirer le ressort tel qu’indiqué sur l'illustration suivante

(C).

■ À l’aide d’une clé de 7 mm, desserrer et retirer le gicleur

intérieur (A) et le gicleur extérieur (B).

■ Conserver les gicleurs du brûleur à part.

■ Remplacer par un gicleur pour gaz propane de taille

correcte. Voir le tableau de sélection des gicleurs pour

gaz propane.

■ Replacer le ressort à sa position initiale.

A. Gicleur intérieu

B. Gicleur extérieur

C. Ressort

IMPORTANT : Placer les gicleurs pour gaz naturel dans le

sachet plastique de pièces, pour réutilisation ultérieure;

conserver le sachet avec le manuel d'utilisation et les autres

documents.

10. Réinstaller la feuille de matériau isolant.

11. Réinstaller les bases et chapeaux de brûleurs.

IMPORTANT : L'électrode d'allumage est un composant en

céramique qui pourrait se briser durant le processus de

conversion. Lors de la réinstallation de la base du brûleur,

veiller à ce que l'électrode puisse glisser librement dans le

trou de la tête du brûleur.

8. Conversion d’un brûleur Dual Tier Ultra et brûleur à

double flemme :

■ À l’aide d’une clé de 7 mm, desserrer et retirer le gicleur

intérieur (A) et le gicleur extérieur (B).

■ Conserver le gicleur de gaz.

■ Installer le gicleur de gaz correct pour propane. Voir le

tableau de sélection des gicleurs pour gaz propane.

A. Chapeau de brûleur

B. Électrode

C. Base du brûleur

12. Ouvrir le robinet d'arrêt de la canalisation de gaz. Le robinet

est ouvert lorsque la manette est parallèle à la canalisation.

13. Brancher la table de cuisson ou reconnecter la source de

courant électrique.

NE PAS OUBLIER : Après avoir exécuté la conversion de

chaque brûleur de la table de cuisson, effectuer un test de

recherche des fuites : appliquer sur les connexions du circuit

Brûleur Dual Tier Ultra

A. Gicleur intérieur

B. Gicleur extérieur

Brûleur à double flemme

A. Gicleur intérieur

B. Gicleur extérieur

de gaz une solution homologuée (non corrosive) de détection

des fuites. La formation de bulles indique la présence d'une

fuite. Veiller à éliminer toute fuite détectée.

14. Régler le robinet simple et le robinet double tel qu'indiqué à la

section “Réglage de la taille des flammes”.

14

Page 15

Conversion de propane à gaz naturel

A

B

C

A

B

C

D

NAT

A

B

CDE

A

1. Fermer le robinet d'arrêt manuel.

A. Vers table de cuisson

B. Robinet d'arrêt (position de fermeture)

C. Canalisation de gaz

2. Débrancher la table de cuisson ou déconnecter la source de

courant électrique.

Conversion du détendeur

A. Chapeau de l'ouverture d'accès

B. Arrière de la table de cuisson

C. Détendeur

D. Sens de circulation du gaz

3. Déterminer le type du détendeur :

Style 1 : Le chapeau comporte une rainure et la mention

“LP”.

Utiliser un tournevis à lame plate ou une pièce de monnaie

pour dévisser le chapeau de l'ouverture d'accès; faire tourner

le chapeau dans le sens antihoraire.

Deux positions sont possibles pour le détendeur;

l'information correspondante est gravée de chaque côté du

chapeau. Orienter le chapeau correctement, et réinstaller le

chapeau sur le détendeur; la mention “NAT” doit être visible

depuis l'extérieur du détendeur.

A. Chapeau de l'ouverture d'accès

B. Joint d'étanchéité

C. Détendeur

D. Position NAT

E. Position LP

4. Enlever les grilles de brûleur si elles sont installées.

Dans les tableaux qui suivent, choisir le gicleur approprié

selon le modèle de l'appareil et l'emplacement du brûleur à

convertir.

Tableau des gicleurs pour gaz naturel pour ensemble

W10676661

Puissance

thermique

5 000 BTU Vert 99 0,99 mm

9 100 BTU Blanc ou

10 000 BTU Orange 135 1,35

12 000 BTU Rouge ou

15 000 BTU Jaune 175 1,75 mm

18 000 BTU Rose 189 1,89 mm

17 000 BTU

Intérieur

Extérieur

18 000 BTU

Intérieur

Extérieur

19 000 BTU

Intérieur

Extérieur

Couleur Indication

sans

couleur

bleu

Rouge

Rouge

Marron

Marron

Blanc

Blanc

(A)

130 1,30 mm

150 1,50 mm

175

57

180

57

185

57

Taille

1,75 mm

0,57 mm

1,80 mm

0,57 mm

1,85 mm

0,57 mm

A. Indication

de la

taille

Style 2 : Le chapeau ne comporte pas de rainure; on doit

utiliser une clé pour la dépose.

Utiliser une clé pour enlever le chapeau de l'ouverture

d'accès; faire tourner le chapeau dans le sens antihoraire.

Ôter le ressort de retenue qui se trouve sous le chapeau en

poussant contre le côté plat du ressort de retenue. Examiner

le ressort de retenue pour identifier la position “NAT” ou “LP”.

Orienter correctement le ressort de retenue pour que la

mention “NAT” soit au fond. Réinstaller le ressort de retenue

dans le chapeau. Réinstaller le chapeau sur le détendeur.

Modèles de brûleur pour ensemble W10676661

Modèle n° Avant

WCG51US0D

MGC7430D

ICS500DS00

WCG75US0D

MGC9530D99Vert

WCG97US09

KCGS350E

ICS655DS00

WCG51US6D

MGC7536D

gauche

99

Vert

130

Sans

coul-

eur

130

Blanc

Arrière

gauche

175

Jaune

189

Rose

135

Orange

130

Blanc

Centre

intérieur

Rouge

Centre

Ar-

exté-

rière

rieur

droit

N/A N/A 150

N/A N/A 150

175

175

Jaune

175

Rouge99Vert

175

Jaune99Vert

Rouge

Rouge

Avant

droit

intérieur

130

Blanc

130

Blanc

130

Sans

coul-

eur

150

Rouge

Avant

droit

extérieur

130

Blanc

130

Blanc

130

Sans

coul-

eur

150

Rouge

15

Page 16

Modèle n° Avant

A

B

D

C

E

A

D

A

B

C

A

B

C

D

E

D

A

B

C

A

WCG97US6D

MGC9536D

KCGS356E

gauche

130

Sans

coul-

eur

130

Sans

coul-

eur

Arrière

gauche

130

Sans

coul-

eur

130

Sans

coul-

eur

Centre

intérieur

Marron57Marron99Vert

Centre

extérieur

180

185

Blanc57Blanc99Vert

Arrière

droit

Avant

droit

intérieur

150

Bleu

150

Bleu

Tableau des gicleurs pour gaz naturel pour ensemble

W10676662

Puissance

thermique

6 000 BTU Blanc 110 1,10 mm

7 000 BTU Vert 118 1,18 mm

10 000 BTU Noir 142 1,42 mm

12 000 BTU Orange 155 1,55 mm

17 000 BTU

Intérieur

Autre

18,000

Intérieur

Extérieur

20 000 BTU

Intérieur

Extérieur

10 000 BTU

Intérieur

Extérieur

Couleur Indication

Bleu

Marron

Bleu

Jaune

Bleu

Rouge

Rose

Rose

(A)

91

167

91

172

91

185

N/A N/A

Taille

0,91 mm

1,67 mm

0,91 mm

1,72 mm

0,91 mm

1,85 mm

A. Indication

de la

taille

Avant

droit

extérieur

150

Bleu

150

Bleu

5. Retirer tous les chapeaux et les bases des brûleurs (consulter

le Guide d'utilisation pour des informations sur les brûleurs).

Pour retirer la base des brûleurs à double flamme et des

brûleurs torches Dual Tier Ultra, utiliser un tournevis Torx

®

T10 pour retirer la vis.

Brûleur Dual Tier Ultra

A. Chapeau de brûleur interne

B. Chapeau du brûleur externe

C. Ouverture du tuyau de gaz

D. Base du brûleur

Brûleur standard et brûleur

double flamme

A. Chapeau de brûleur

B. Électrode d’allumeur

C. Base du brûleur

D. Ouverture du tuyau de

gaz

Modèles de brûleur pour ensemble W10676662

Modèle n° Avant

KCGS550E

KCGS556E

KCGS950ES

KCGS956ES

gauche

110

Blanc

110

Blanc

110

Blanc

110

Blanc

Arrière

gauche

142

Noir

142

Noir

142

Noir

155

Orange

Centre

intérieur

Marron91Bleu

Jaune91Bleu

Marron91Bleu

Rouge91Bleu

167

172

167

185

Centre

extérieur

Arrière

droit

118

Vert

118

Vert

118

Vert

118

Vert

Avant

droit

intérieur

142

Noir

142

Noir

N/A N/A

N/A N/A

Avant

droit

extérieur

142

Noir

142

Noir

Brûleur torche Even-Heat™

A. Chapeau de brûleur interne

B. Base de brûleur interne

C. Base de brûleur externe

D. Support de brûleur

E. Ouverture du tuyau de gaz

6. Conversion d’un brûleur standard :

Positions des brûleurs

■ Utiliser une clé de 7,0 mm pour desserrer et enlever le

gicleur (A).

■ Conserver le gicleur de gaz.

■ Installer le gicleur de gaz correct pour gaz naturel. Voir les

tableaux de sélection des gicleurs pour pour gaz naturel.

A. Avant gauche

B. Arrière gauche

C. Centre

D. Arrière droit

E. Avant droit

16

A. Gicleur

Page 17

7. Conversion d’un brûleur Dual Tier Ultra et brûleur à

A

B

A

B

A

B

C

B

C

A

double flamme :

■ À l’aide d’une clé de 7 mm, desserrer et retirer le le gicleur

intérieur (A) et le gicleur extérieur (B).

■ Conserver le gicleur de gaz.

■ Remplacer par des gicleurs pour gaz naturel de taille

correcte. Voir les tableaux de sélection des gicleurs pour

gaz naturel.

Brûleur Dual Tier Ultra

A. Gicleur intérieur

B. Gicleur extérieur

Brûleur à double flamme

A. Gicleur intérieur

B. Gicleur extérieur

8. Conversion des brûleurs torche Even-Heat™

■ Retirer le ressort tel qu'indiqué sur l'illustration suivante

(C).

■ À l'aide d'une clé de 7 mm, desserrer et retirer le gicleur

intérieur (A) et le gicleur extérieur (B).

■ Conserver les gicleurs

■ Remplacer par un gicleur pour gaz naturel de taille

correcte. Voir le tableau de sélection des gicleurs pour

gaz naturel.

■ Replacer le ressort à sa position initiale.

A. Chapeau de brûleur

B. Électrode

C. Base du brûleur

11. Ouvrir le robinet d'arrêt de la canalisation de gaz. Le robinet

est ouvert lorsque la manette est parallèle à la canalisation.

12. Brancher la table de cuisson ou reconnecter la source de

courant électrique.

NE PAS OUBLIER : Après avoir exécuté la conversion de

chaque brûleur de la table de cuisson, effectuer un test de

recherche des fuites : appliquer sur les connexions du circuit

de gaz une solution homologuée (non corrosive) de détection

des fuites. La formation de bulles indique la présence d'une

fuite. Veiller à éliminer toute fuite détectée.

13. Régler le robinet simple et le robinet double tel qu'indiqué à la

section “Réglage de la taille des flammes”.

Allumeurs électroniques - allumage

À la place d'une flamme de veille, les brûleurs de la table de

cuisson sont dotés d'un allumeur électronique. Lorsque

l'utilisateur appuie sur le bouton de commande, le système

génère des étincelles pour l'inflammation du gaz sur le brûleur. La

génération d'étincelles se poursuit jusqu'au moment où

l'utilisateur ramène le bouton de commande à la position de

réglage désirée.

Contrôle du fonctionnement des brûleurs de la table de

cuisson :

1. Placer le bouton de commande à la position contact

(enfoncer et faire tourner). Voir le guide d'utilisation pour plus

de renseignements. Le gaz doit s'enflammer sur le brûleur en

moins de 4 secondes. Lors de l'allumage initial du brûleur, le

délai d'allumage peut être supérieur à 4 secondes du fait de

la présence d'air dans la canalisation de gaz. Après

l'inflammation du gaz, ne pas laisser le bouton à la position

A. Gicleur intérieur

B. Gicleur extérieur

C. Ressort

IMPORTANT : Placer les gicleurs pour gaz naturel dans le

sachet plastique de pièces, pour réutilisation ultérieure;

conserver le sachet avec le manuel d'utilisation et les autres

documents.

9. Réinstaller la feuille de matériau isolant.

10. Réinstaller les bases et chapeaux de brûleurs.

IMPORTANT : L'électrode d'allumage est un composant en

céramique qui pourrait se briser durant le processus de

conversion. Lors de la réinstallation de la base du brûleur,

veiller à ce que l'électrode puisse glisser librement dans le

trou de la tête du brûleur.

contact.

2. Si le brûleur ne s'allume pas correctement, ramener le bouton

de commande à la position OFF (arrêt). Veiller à ce que le

chapeau de brûleur soit à la position correcte.

3. Vérifier que le cordon d'alimentation est branché. Déterminer

si le disjoncteur s'est ouvert ou si un fusible est grillé.

4. Vérifier que le robinet d'arrêt de la canalisation de gaz est à la

position d'ouverture.

5. Contrôler de nouveau le fonctionnement du brûleur.

Si l'un des brûleurs ne peut toujours pas s'allumer ou si aucun

des brûleurs ne s'allume, voir la section “Assistance ou service”

dans le Guide d'utilisation.

17

Page 18

Réglage de la taille des flammes

B

C

A

A

B

M

e

d

A

B

C

B

A

Chaque brûleur a été réglé à l'usine de telle manière que pour la

position du robinet de gaz correspondant au débit thermique

minimum, le dispositif de rallumage du brûleur fonctionne

constamment d'une manière fiable; cependant il est possible

d'effectuer un réglage sur chaque brûleur.

REMARQUE : Si le numéro de modèle de votre appareil

commence par KGCS5 ou par KGCS9, appeler pour demander

une intervention de dépannage car cette opération nécessite

l'ouverture de l'appareil.

Réglage :

Les vis de réglage situées sous le bouton de commande

permettent de régler la configuration des flammes.

REMARQUE : Consulter le guide d'utilisation et d'entretien pour

déterminer si chaque brûleur est à flamme simple ou double.

Effectuer les réglages appropriés sur les gicleurs

Réglage pour robinet double

Réglage de la couronne de flammes interne :

1. Placer le bouton de commande de la couronne interne à la

position correspondant au débit thermique minimum (LO).

A. Couronne interne

B. Couronne externe

Réglage pour robinet simple

1. Placer le bouton de commande du brûleur à la position

correspondant au débit thermique minimum (LO).

2. Ôter le bouton de commande.

2. Ôter le bouton de commande.

3. Ôter la bague de caoutchouc noir.

4. Utiliser une pince à bec effilé pour retirer le disque de

séparation gris qui se trouve à l'intérieur de l'ouverture du

robinet du brûleur.

3. Immobiliser la tige du bouton de commande du robinet de

gaz avec une pince. Utiliser un petit tournevis à lame plate

³⁄₃₂" (#0 [2,0 mm]) pour faire tourner la vis de réglage située à

l'intérieur de la tige du bouton de commande du robinet, pour

établir la taille correcte des flammes.

A. Bouton de commande

B. Bague de caoutchouc noir

C. Disque de séparation gris

A. Tournevis à lame plate

longueur de la tige du tournevis doit être d'au

moins 2" [5,1 cm])

B. Ouverture de la tige de commande du robinet

C. Position de la vis de réglage

³⁄₃₂

" (#0 [2,0 mm]) (la

4. Conversion pour l'alimentation au propane :

Serrer complètement la vis “C” pour établir la hauteur

5. Conversion pour l'alimentation au propane :

Serrer complètement la vis “A” pour établir la hauteur

minimum des flammes.

Conversion pour l'alimentation au gaz naturel :

Serrer la vis “A” pour réduire la hauteur des flammes.

Desserrer la vis pour augmenter la hauteur des flammes. Voir

la section “Achever le réglage des brûleurs”.

minimum des flammes.

Conversion pour l'alimentation au gaz naturel :

Serrer la vis “C” pour réduire la hauteur des flammes.

Desserrer la vis pour augmenter la hauteur des flammes. Voir

la section “Achever le réglage des brûleurs”.

5. Réinstaller le bouton de commande.

6. Évaluer la taille des flammes : faire tourner le bouton de

commande entre les positions LO (débit thermique minimum)

et HI (débit thermique maximum) et évaluer la hauteur des

flammes à chaque position de réglage.

6. Réinstaller le bouton de commande.

A. Vis de réglage pour couronne de flammes interne

B. Vis de réglage pour couronne de flammes externe

18

Page 19

Réglage de la couronne de flammes externe :

A

B

1. Placer le bouton de commande de la couronne externe à la

position correspondant au débit thermique minimum (LO).

2. Ôter le bouton de commande.

3. Conversion pour l'alimentation au propane :

Serrer complètement la vis “B” pour établir la hauteur

minimum des flammes.

Conversion pour l'alimentation au gaz naturel :

Serrer la vis “B” pour réduire la hauteur des flammes.

Desserrer la vis pour augmenter la hauteur des flammes. Voir

la section “Achever le réglage des brûleurs”.

4. Réinstaller le disque de séparation gris. Utiliser un tournevis

pour pousser la pièce en place.

5. Réinstaller la bague de caoutchouc noir.

6. Réinstaller le bouton de commande.

7. Évaluer la taille des flammes : faire tourner le bouton de

commande entre les positions LO (débit thermique minimum)

et HI (débit thermique maximum) et évaluer la hauteur des

flammes à chaque position de réglage.

Achever le réglage des brûleurs

1. Contrôler la taille et la forme des flammes sur chaque brûleur.

Pour le réglage au débit thermique minimum, on doit

observer des flammes stables bleues de ¼" (0,64 cm).

A. Petites flammes

B. Grandes flammes

2. Compléter l'étiquette de conversion et fixer l'étiquette au bas

de la table de cuisson, à côté de la plaque signalétique. Ne

pas recouvrir la plaque signalétique avec l'étiquette.

IMPORTANT : Conserver les gicleurs avec les présentes

instructions, pour utilisation ultérieure.

Consulter la section “Brûleurs de surface scellés” dans le Guide

d'utilisation et d'entretien fourni avec l'appareil.

19

Page 20

W10597146B

®

/™ ©2014. Used under license in Canada. All rights reserved.

Utilisé sous licence au Canada. Tous droits réservés.

6/14

Printed in U.S.A.

Imprimé aux É.-U.

Loading...

Loading...