KitchenAid KBFC42FS, KBFO42FS Technical Education

TECHNICAL EDUCATION

JOB AID 4317402

KAR-17

BUILT-IN FRENCH DOOR

BOTTOM-MOUNT

REFRIGERATOR

MODELS: KBFC42FS & KBFO42FS

FORWARD

This KitchenAid Job Aid, “Built-In French Door Bottom-Mount Refrigerator” (Part No.4317402),

provides the In-Home Service Professional with information on the installation, operation, and

service of the Built-In French Door Bottom-Mount Refrigerator. For specific information on the

model being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with the refrigerator

The Wiring Diagrams used in this Job Aid are typical and should be used for training purposes

only. Always use the Wiring Diagram supplied with the product when servicing the refrigerator.

.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide information that will enable the In-Home Service Professional

to properly diagnose malfunctions and repair the Built-In French Door Bottom-Mount Refrigera-

.

tor

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the refrigerator to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on

our products by anyone other than authorized In-Home Service Professionals.

Copyright © 2006, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

Page

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Refrigerator Safety

Model & Serial Number Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Model & Serial Number Label And Tech Sheet Locations . . . . . . . . . . . . . . . . . . . . . . . . 1-3

ALLATION INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

INST

ater Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

W

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

PRODUCT OPERA

Theory Of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Refrigerator Use

COMPONENT ACCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

Removing

A Refrigerator Light Socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

The User Interface Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

The Refrigerator Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

The Refrigerator Motorized Air Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

A Refrigerator Temp-Controlled Motorized Air Door . . . . . . . . . . . . . . . . . . . . 4-7

A Temp-Controlled Drawer Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

The Heated Flipper Mullion And An Actuator/Electrical Contact . . . . . . . . . . 4-10

The Unit Compartment Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

A Refrigerator Door Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

A Refrigerator Door Skin And Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

A Refrigerator Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

The Freezer Drawer Slides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

The Freezer Drawer Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

The Ice Maker & Fill Tube Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

The Ice Maker Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

The Evaporator Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

The Bimetal, Defrost Heater, And Evaporator . . . . . . . . . . . . . . . . . . . . . . . . 4-27

The Water Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

The Water Filter Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

- iii -

COMPONENT TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Heated Flipper Mullion

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Motorized Air Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Power Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

24V Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Condenser Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Evaporator Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Compressor & Inverter

Door/Drawer Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Fill Tube Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Defrost Heater & Bimetal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Water Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Main Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

DIAGNOSTICS & TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

TECH TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Adjusting

Adjusting

A Refrigerator Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

The Freezer Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

- iv -

WARNING

DANGER

GENERAL

REFRIGERATOR SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

ou can be killed or seriously injured if you don’t

Y

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the

chance of injury, and tell you what can happen if the instructions are not followed.

1-1

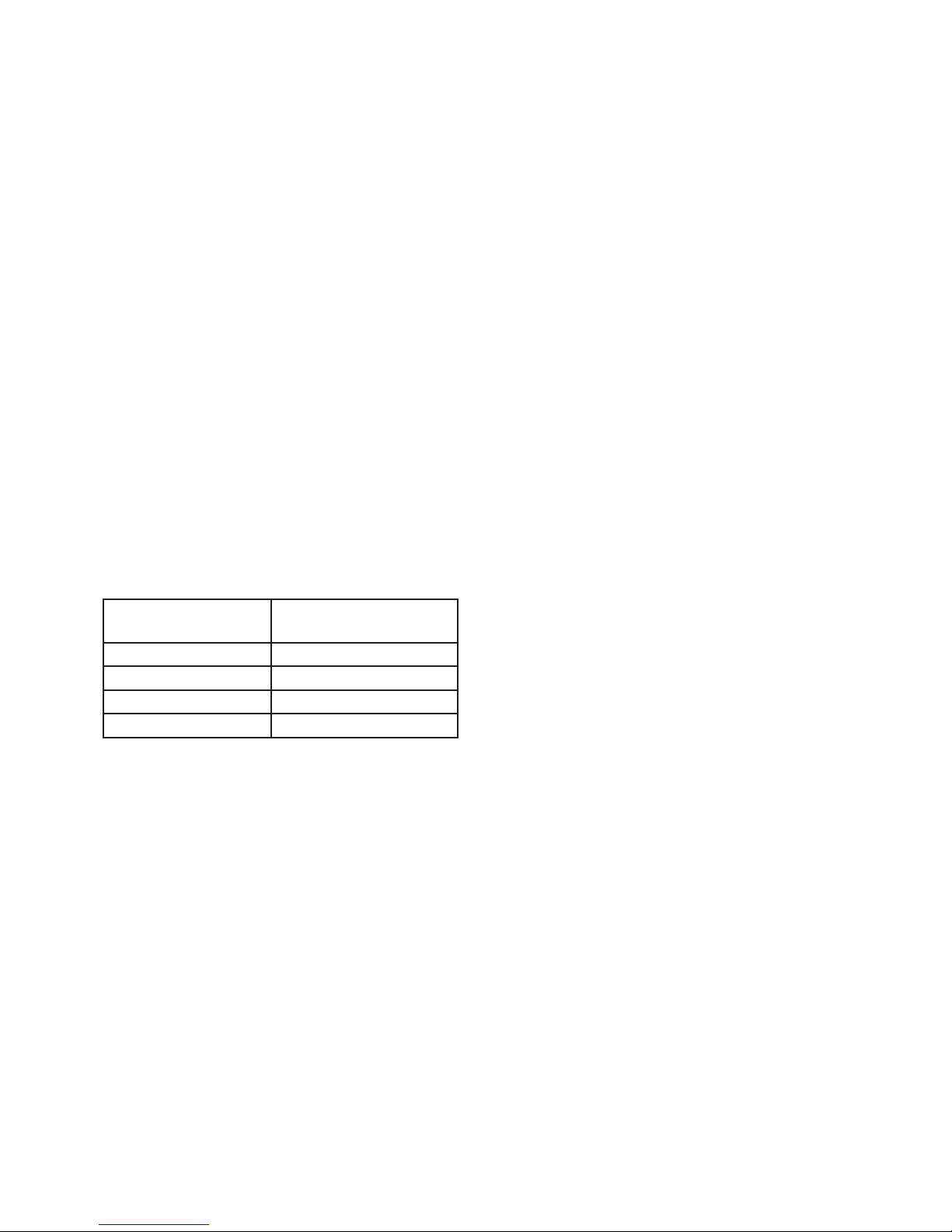

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER K BF C 42 F S S 00

PRODUCT GROUP

K = KitchenAid

PRODUCT IDENTIFICATION

BF = BTM Freezer, French Door

MERCHANDISING SCHEME / SERIES

C = Wrap Around Stainless Steel

O = Overlay Model

WIDTH

42 = 42˝

MODEL FEATURES

F = Factory Installed Ice Maker & Filter

YEAR OF INTRODUCTION

S = 2006

COLOR CODE

X = No Color

S = Stainless

ENGINEERING CHANGE DIGITS

SERIAL NUMBER

SERIAL NUMBER Q T 21 10001

MANUFACTURING LOCATION

Q = LaVergne, TN

YEAR OF PRODUCTION

T = 2006

WEEK OF PRODUCTION

21st Week

PRODUCT SEQUENCE NUMBER

1-2

MODEL & SERIAL NUMBER LABEL

AND TECH SHEET LOCATIONS

The Model/Serial Number label and Tech Sheet locations are shown below.

Model & Serial Number Label Location

(On Upper Left Side Of Refrigerator Liner)

Tech Sheet Location

1-3

— NOTES —

1-4

INSTALLATION INFORMATION

WATER SUPPLY REQUIREMENTS

Water Pressure

A cold water supply with water pressure between 30 and 120 psi (207-827 kPa) is required

maker.

Reverse Osmosis Water Supply

IMPORTANT: The pressure of the water sup-

ply

going to the water inlet valve of the refrigerator

(207-827 kPa).

If

connected to your cold water supply, the water

needs to be a minimum of 40 psi.

to operate the water dispenser and ice

coming out of a reverse osmosis system

needs to be between 30 and 120 psi

a reverse osmosis water filtration system is

pressure to the reverse osmosis system

If the water pressure to the reverse osmosis

system is less than 40 to 60 psi (276-414 kPa):

Check to see whether the sediment filter

•

in the reverse osmosis system is blocked.

Replace the filter if necessary.

•

Allow the storage tank on the reverse osmosis system to refill after heavy usage.

the refrigerator has a water filter, it may

•

If

further reduce the water pressure when

used in conjunction with a reverse osmosis

system. Remove the water filter.

2-1

— NOTES —

2-2

PRODUCT OPERATION

Max Cool

Reset

Cooling

Door Open

Over Temperature

Call Service

Alarms

Holiday Mode Energy Saver

ON/OFF

THEORY OF OPERATION

THE ELECTRONIC CONTROL

OVERVIEW

The KitchenAid Built-In French Door BottomMount Refrigerator Constant Flow Temperature

Management System uses two thermistors

to monitor temperature changes inside the

refrigerator and freezer compartments. Two

electronic control boards are used in the re-

rigerator: a main electronic control board,

f

and a low voltage (Phoenix) board. The main

electronic control board manages the operation

of the variable capacity compressor (VCC), a

variable speed evaporator fan motor, and a

variable position air door. The air door allows

independent temperature control of the refrigerator and freezer compartments.

main electronic control board seeks the

The

most efficient means possible to maintain

temperatures as it controls the operation and

speed of the compressor and the evaporator

fan motor. Higher fan speed is used before

increasing the compressor speed to minimize

power consumption. A nearly constant run

time is sought at the lowest possible fan and

compressor speed.

Freezer

to –5°F (–15°C to –21°C). Refrigerator temperatures

to 1°C).

The

of the main electronic control board utilizes

“pulsed defrost” technology to perform the

defrost function (see page 3-4).

temperatures can be set from 5°F

can be set from 45°F to 33°F, (7°C

Adaptive Defrost Control (ADC) portion

PANEL

The main electronic control board monitors the

water valve for total elapsed time and gallons

of water used. The number displayed on the

Water Filter Indicator (WFI) is the percentage

of filter usage remaining.

The numeric display can be set for Fahrenheit

or Celsius and displays the actual temperatures.

The display range for the refrigerator is from

27°F to 70°F (–2.8°C to 21°C). The normal

freezer

–23°C

(

display range is from –10°F to 70°F

to 21°C). Temperatures above or below

these limits will be displayed at the correspond-

temperature limit. During Max Cool, the

ing

freezer display will read –5°F (–21°C), and the

refrigerator will read 34°F (1°C).

display will show the temperature setting

The

any time the actual temperature is within ±6°F

the customer setting. This will prevent con-

of

over temperature fluctuations when the

cern

doors are opened. The customer setting will

also be displayed during the defrost period,

and 30 minutes after defrost. Press the temperature

adjustment key to view the current

temperature setting, or to change the setting.

When the temperature adjustment key is used

to change the temperature setting, the display

will brighten for 5 seconds.

vailable features include:

A

Water Filter Indicator

•

Max Cool

•

Over-T

•

Holiday Mode

•

Energy Saver Mode

•

emperature Alarm

3-1

TEMPERATURE CONTROL

The main electronic control board checks the

resistance of the thermistors, and compares it

to both the customer temperature settings and

the last thermistor reading taken. This information

cooling operation, and if a change is necessary

in the damper setting, or the evaporator fan or

compressor speed.

When

ing mode, the air door partially opens, and the

compressor and evaporator fan motors start to

run at maximum rpm. The air door will gradually

move to its fully open position.

As

nears the selected temperature setting, the

electronic control compares the temperatures

in both compartments. The compartment that

has the greatest need for cooling will control

the speed of the evaporator fan motor.

Freezer Temperature Control —

Temperature Increasing

When the freezer calls for cooling, the compressor

the chart on page 3-3), and the evaporator fan

begins to run at 2000 rpm. The compressor and

evaporator speeds are continuously updated.

Speed changes are made based on:

•

•

If the temperature increases 4°F above the

selected

fan speed begins to gradually increase. The

evaporator fan motor reaches the maximum

speed of 3000 rpm at 5°F above the selected

emperature setting, and the compressor speed

t

begins to gradually increase. A maximum compressor

9°F above the selected temperature setting.

is used to determine when to begin a

a warm refrigerator is first put into a cool-

the actual temperature in the refrigerator

begins to run at minimum rpm, (see

difference between the actual tempera-

The

ture and the selected temperature settings.

The rate of temperature change.

temperature setting, the evaporator

speed of 4500 rpm will be reached at

Freezer Temperature Control —

Temperature Decreasing

When the freezer temperature begins to de-

rease, the process will reverse. The com-

c

ressor speed decreases, followed by the

p

evaporator fan speed.

Refrigerator T

Temperature Increasing

When the refrigerator calls for cooling while the

freezer is satisfied, the air door begins to open,

and the evaporator fan starts to run at minimum

speed. If the temperature continues to rise, the

air door will continue to open. If the temperature

continues to rise after the air door is fully open,

the evaporator fan speed will gradually increase

to a maximum of 3000 rpm. If the temperature

continues to rise, the compressor starts to run,

or if it has already been running, begins to in-

rease in speed.

c

Refrigerator Temperature Control —

Temperature Decreasing

As the refrigerator temperature approaches

the selected setting, the control compares the

temperatures in both compartments to determine

speed. If the freezer is further from the selected

temperature setting, it controls the fan speed,

and the air door begins to close, thus reducing

the airflow to the refrigerator.

If the freezer is satisfied, the air door remains

open, and the fan speed begins to decrease.

When the selected temperature setting is

reached, the air door closes.

which compartment will control the fan

emperature Control —

3-2

COMPRESSOR

COMPRESSOR PROTECTION

The main control board supplies a 5 vdc, peakto-peak square wave, at 54 to 150 Hz, to the

inverter board. A standard VOM will read approximately

plies

the variable capacity compressor with

2.5 vdc. The inverter board sup-

three-phase 230 vac. Varying the voltage and

frequency to the inverter board changes the

speed of the compressor. The compressor can

run at speeds of 1620 to 4500 rpm.

NOTE: It is not necessary, nor is it recommended, to test the output of the inverter board.

While

the compressor is running, its speed is

continuously updated. Speed is determined

after analyzing two factors:

difference between the actual tempera-

The

•

ture and the selected temperature settings.

The rate of temperature change.

•

Minimum compressor speed is based on the

freezer’s selected temperature setting, as

shown in the following chart.

Freezer Temperature Compressor

Setting (°F)

6 to –2 1620 rpm

–3 1800 rpm

–4 2000 rpm

–5 2200 rpm

compressor generally cycles on and off

The

Minimum Speed

according to the cut-in and cut-out temperatures

of the freezer, however, the refrigerator

can turn on the compressor if the evaporator

fan is at maximum speed and the refrigerator

temperatures are not dropping.

To protect the compressor and maintain efficiency, minimum compressor off time is pro-

rammed into the main control board. When the

g

compressor turns off, a minimum of 7 minutes

must elapse before allowing a restart.

t the end of the 7-minute period, the condenser

A

fan motor starts, and the main control board

sends the compressor speed signal to the

inverter. The compressor will not start for an

additional minute, due to the inverter delay.

The inverter utilizes a current-limiting device

and thermal protection that eliminates the need

for a compressor-mounted thermal protector.

The inverter will not allow a compressor restart

for 8 minutes after the compressor turns off.

This inverter delay will not occur after a power

interruption, because inverter memory is lost

(see “Power Interruption” on page 3-4).

EVAPORATOR FAN MOTOR

The evaporator fan motor is a 12 vdc, variable

speed motor. The motor has four wires:

A blue wire that is not used.

•

A red wire provides a constant 12 vdc.

•

A yellow wire provides a variable voltage

•

of between 5 vdc and 17 vdc to control the

motor speed from 2000 to 3000 rpm.

white wire provides a common return.

A

•

EVAPORATOR FAN &

AIR DOOR DELAY

After defrost, an evaporator fan delay prevents

unnecessary movement of warm, moist air

through the refrigerator by chilling the evapora-

prior to starting the fan. Immediately after

tor

defrost drip time, the compressor starts at

4500 rpm, but the evaporator fan is delayed for

8 minutes. Also, the air door remains closed

during the 8-minute delay.

3-3

AIR DOOR

The air door is driven by a reversible DC stepper

motor. The motor operates on a 12 vdc, peakto-peak square wave. Voltage is delivered to

the air door in a series of short pulses. It is not

possible to obtain a reliable voltage reading

with a VOM.

eparate windings are used to move the air door

S

open or closed. The door can be in any position

from 0 to 90 degrees. The air door is used to

fine-tune the airflow to the refrigerator.

The refrigerator temperature determines the

opening of the air door. When the refrigerator

requires cooling, if the evaporator fan motor

is already running for the freezer, the air door

partially opens, and then adjusts, if necessary.

While the refrigerator is cooling, the door will be

adjusting continuously to maintain or recover

refrigerator temperature.

ADAPTIVE DEFROST

The adaptive defrost control function of the main

electronic control board allows the refrigerator

to enter a defrost mode only when it is needed.

When powered up for the first time, the control

initiates a defrost cycle after 8 hours of compressor

of defrost heating time and compressor run

time, the control will continuously adapt the

time between defrosts to optimize efficiency.

Time between defrost periods will vary between

8 and 100+ hours.

efrost will occur immediately when the com-

D

pressor has run at 4000 rpm or greater for 1 hour,

and 8 hours have elapsed since the last defrost.

run time. By monitoring the duration

PULSED DEFROST

For the first 2 minutes of defrost, the heater is

on continuously. It will then cycle off for 1 min-

and back on for 2 minutes. The heater will

ute,

continue to cycle at this ratio until the bimetal

opens, or until 33 minutes has elapsed. At this

point, heat is discontinued, and a 4-minute “drip

time” begins. This allows the water to drain be-

the refrigerator returns to a cooling mode.

fore

Maximum defrost time, (pulsed heat on/off time

+ drip time) is 37 minutes.

When

is open, the time to defrost is reset to 8 hours,

and the control will time through the entire

37-minute defrost period. During diagnostics

this will allow a technician time to look for

heater operation, and if necessary, bypass

the bimetal.

entering a defrost cycle, if the bimetal

POWER INTERRUPTION

After a power interruption, the following events

will occur:

he refrigerator returns to the same operating

T

•

mode and settings in use prior to the power in-

erruption. If the unit was off, it remains off.

t

Initially, the compressor, evaporator fan, and

•

condenser fan motors will be off.

The air door will close, and then adjust to the

•

proper opening. The evaporator fan starts

when the air door opens.

he adaptive defrost control resets the

T

•

compressor run time counter to 0, and if the

freezer is above 20°F, the time to defrost is

set to 8 hours.

the freezer temperature is below 12°F

If

•

(

–11.1°C

delay of 7 minutes. If the freezer temperature

immediately

), the compressor starts after a

is above 12°F, the compressor starts

.

FAILURE DEFAULTS

In the event of a thermistor, or keypad failure,

the main electronic control board uses one of

the following default modes, which will continue

until the failure is corrected.

Refrigerator Thermistor

the main electronic control board senses an

If

open or a shorted thermistor, the air door and

the evaporator fan motor will begin to operate

on a timed on and off cycle, based on current

selected temperature settings. The evaporator

fan motor will run when the air door is open.

mid-settings of 37°F / 3°C, the air door will

At

open for 16 minutes, and close for 30 minutes.

Setting the freezer colder, or the refrigerator

warmer, will reduce the door-open time. Setting

the freezer warmer, or the refrigerator colder,

will increase the door-open time.

3-4

Freezer Thermistor

If the main electronic control board senses an

open or a shorted thermistor, the compressor

and the evaporator fan motor will begin to operate

time is based on current selected temperature

settings.

A

sor and the evaporator fan motors will run for

35 minutes, and be off for 25 minutes. Setting

the freezer colder will increase the run time.

Setting the freezer warmer will decrease the

run time.

The compressor will run at minimum speed.

The evaporator fan will also run at minimum

speed, unless the refrigerator compartment

requests a higher speed.

Keypad

I

the keypad is not working, it reverts to the default

refrigerator

Evaporator Fan Motor

If

compressor will run at 4500 rpm for an indefinite

period, except during the defrost periods.

on a timed on and off cycle. The cycle

t mid-settings of 37°F / 3°C, the compres-

f the main electronic control board detects that

temperature settings of 37°F (3°C) in the

, and 0°F (–18°C) in the freezer.

the evaporator fan motor malfunctions, the

MAX COOL MODE

Max Cool changes the refrigerator temperature setting to 34°F (1°C) and the freezer to

–5°F (–21°C) for 24 hours. During Max Cool,

freezer and refrigerator temperature dis-

the

plays

the actual temperatures.

In

than 1 hour. The control returns to the previo

temperature settings are changed.

show the new temperature settings, not

most cases the motors run 100% for more

us user setting after 24 hours, or any time the

AUTOMATIC MAX ICE

Automatic Max Ice operates any time the ice

maker water valve is energized. The duration

of Automatic Max Ice is 1-1/2 hours. During

Automatic Max Ice the following occurs:

•

•

•

•

freezer display shows the user tem-

The

perature settings and not the actual temperature.

freezer temperature setting changes to

The

–5°F (–21°C).

The evaporator fan runs at 3000 rpm.

The

compressor runs the entire 1-1/2 hour

mode. Speed is determined by the difference between actual freezer temperature

and –5°F (–21°C).

HOLIDAY MODE

The Holiday Mode may be used for the following occasions:

On vacation.

•

Religious observance (Sabbath Mode).

•

When the Holiday Mode is selected, the

•

corresponding backlit blue LED flashes for

5 seconds, and then remains on, to indicate

that the feature is activated.

3-5

In the Holiday Mode the following occurs:

Temperature selections remain at the current

•

setting, but are not displayed.

Water Filter Indicator is not displayed,

The

•

but monitoring continues.

The alarms are disabled.

•

The ice maker is disabled.

•

The interior lights are disabled.

•

T

he temperature displays and all of the LEDs

•

will be off, except for the Holiday Mode and

Cooling On/Off LEDs. The Holiday Mode and

Cooling On/Off LEDs will illuminate regardless of the door position.

eypad operation is disabled, with the excep-

K

•

tion

of the Holiday Mode key, or the Power

On/Off key.

MASTER ALARM RESET

Pressing the Over Temperature Reset will turn

off the audio alarm, but does not affect the indicator

Reset is pressed. The indicator light will turn off

once the Over Temperature Reset is pressed

a second time. The audio alarm will not sound

again for the current condition that caused the

alarm until a new condition occurs.

A

turning the power to the refrigerator off and

on again. The indicator light will turn on again

after the Over Temperature Reset is pressed,

if the condition that caused the alarm is still

present.

light the first time the Over Temperature

Master Alarm Reset can be performed by

CALL SERVICE ALARM

The Holiday Mode will be cancelled when the

following occurs:

Pressing

•

keypads.

hen the Holiday Mode is cancelled, the

W

Holiday Mode LED turns off, and the control

reverts to the settings in use prior to activation.

All inactive devices are restored, and the Water

Filter Indicator is updated.

Adaptive Defrost Control function contin-

The

ues during the Holiday Mode, but the control

will defrost at a fixed 12-hour interval.

the Power On/Off, or Holiday Mode

OVER TEMPERATURE ALARM

The Over Temperature Alarm sounds, and the

indicator light flashes when either the refrigera-

temperature exceeds 48°F (9°C), or the

tor

freezer

over

display flashes to show the user which compartment

temperature(s) returns to normal, but the red

Over Temperature LED will continue to flash

(refer to “Master Alarm Reset” to reset the Over

Temperature Alarm).

temperature exceeds 15°F (–9°C) for

1-1/2 hours. The appropriate temperature

is effected. The alarm stops if the

Call Service is a visual and audio signal that

alerts the user that the refrigerator needs

service. The Call Service Alarm will sound

when:

Either thermistor has failed.

•

over-temperature condition occurs for

An

•

3 hours or more.

Reset using Master Alarm Reset.

•

Communication is lost with either the low

•

voltage Phoenix or main electronic control

board.

DOOR OPEN ALARM

If any door is left open for more than 10 minutes, the interior lights will be disabled, the

Door Open icon will flash, and the alarm will

sound. If the door is closed during the alarm

operation, the alarm will reset.

SALES DEMONSTRATION MODE

This mode provides a sequential display of

the temperature displays and feature LEDs.

To enter the Demonstration Mode, press and

hold the Max Cool and Power On/Off keys for

2 seconds. If the refrigerator or freezer door

is open for 10 minutes, the interior lights will

turn off.

3-6

LOW VOLTAGE PHOENIX

CONTROL BOARD

A low voltage transformer, located on the left

side of the unit compartment, supplies 24 volts

ac to the Phoenix control board.

Phoenix control provides the following

The

functions:

ommunicates with both ingredient care

C

•

center pans.

Provides

•

center pans to operate the LED lighting in

each ingredient care center pan.

Monitors

•

center pan.

Controls

•

baffle for each ingredient care center pan.

Provides 24 volts dc to the heated flipper

•

mullion to prevent condensation on the flipper mullion.

Communicates

•

trol. This includes the status of the refrigerator

door switches and evaporator fan motor.

The two controls communicate and work together

control operates the ingredient care center

pan LED lighting and the mullion heater but it

does not get direct input on the position of the

refrigerator door switches. In order to operate

the LED pan lighting at the proper time, the

main control monitors the refrigerator door

switches and sends a communication on the

data line to let the Phoenix control know when

a refrigerator door is opened.

Phoenix control supplies 24 volts dc to the

The

mullion heater when both refrigerator doors are

closed. When a refrigerator door is opened, or

an ingredient care center pan air door change

is needed, the output of the Phoenix control

board is switched from the mullion heater to

the ingredient care center pan.

24 volts dc to both ingredient care

a thermistor in each ingredient care

the operation of the motorized air

with the main electronic con-

to provide proper function. The Phoenix

Ingredient Care Center

emperature Control

T

The control monitors the temperature of each

ingredient care center pan by means of a

thermistor located in the top of each pan.

When cooling is needed the Phoenix control

sends a request to the main control board to

operate the evaporator fan motor. The Phoenix

control board does not have direct control of

the evaporator fan motor. The Phoenix control

also sends a 12 vdc, peak to peak square wave

to the ingredient care center air door to open

the door.

The ingredient care center air door will be in

one of five possible positions based on the

ingredient care center user setting. The air

door will close at any setting when the proper

temperature has been reached. Here are the

four possible positions and temperatures for

each setting.

•

Closed.

When the refrigerator compartment is call-

ing

for cooling and the freezer is satisfied.

This allows the refrigerator to cool faster.

- Any setting when proper pan temperature

has been achieved.

When the refrigerator is in holiday mode.

-

- When the refrigerator is in defrost mode.

Deli—40°F, open at a 10° angle.

•

Produce—39°F, open at a 20° angle.

•

Meats—33°F, open at a 30° angle.

•

Quick Chill—25°F, open at a 45° angle.

•

When Quick Chill is selected, the pan

temperature is set to 25°F, and the freezer

temperature

evaporator

at high speed until the set temperature is

reached. When the hour has timed out, the

ingredient care center user interface and

the freezer temperature both return to the

previous customer settings.

is set to –5°F, for one hour. The

fan motor operates and runs

3-7

AIR CIRCULATION

In order to ensure proper temperatures, you

need to permit airflow between the refrigerator

and freezer sections. As shown in the illustra-

cool air enters the freezer section through

tion,

vents in the rear and top. The air flows forward

through the freezer section and recirculates

under the freezer floor. Cool air enters the refrigerator

and across shelves to the doors and recirculates

to return air vents at the bottom.

section through the top, flows down

is important not to block any of the vents with

It

food items. If the vents are blocked, airflow will

be restricted, and the temperature management

system will not function properly.

IMPORTANT: Because air circulates between

both sections, any odors formed in one section

will transfer to the other. Keep both sections

clean, and wrap or cover foods tightly to help

avoid the transfer of odors from food to ice.

3-8

REFRIGERATOR USE

MAX COOL

The Max Cool feature assists with periods of

heavy ice usage, full grocery loads, or temporarily warm room temperatures.

ress MAX COOL to turn on the Max Cool fea-

P

•

ture. The Max Cool indicator light will remain

on for 24 hours unless manually turned off.

NOTE: The temperature display will remain at

34°F (1°C) and –5°F (–21°C) for the refrigera-

or and freezer compartments, respectively,

t

while the Max Cool feature is enabled. After

24 hours, the refrigerator returns to the previous temperature set points.

HOLIDAY MODE

The Holiday Mode feature is designed for the

traveler or for those whose religious observanc-

require turning off the lights and ice maker.

es

By selecting this feature, the temperature set

points and Deli Pan settings remain unchanged,

the ice maker will be disabled and the interior

lights will turn off. For most efficient refrigerator

operation, it is recommended to exit the Holiday

Mode when it is no longer required.

ress HOLIDAY MODE to turn on the Holiday

P

•

Mode feature. This feature will remain on until

Holiday Mode is pressed again.

ENERGY SAVER™ FEATURE

(42˝ BOTTOM MOUNT ONLY)

The Energy Saver feature controls the heaters

located inside the hinged seal between the re-

rigerator doors. The heaters help keep external

f

moisture from forming on the hinged seal.

Press

•

this feature for low humidity conditions. The

ring around the control will be lit when Energy

Saver is on. If moisture begins to collect on

the hinged seal between the doors, press

ENERGY SAVER control again to turn off

this feature.

ENERGY SAVER control to turn on

ALARM FUNCTIONS

Master Alarm Reset

Pressing Alarm Reset once will turn off the audio

alarm and indicator light. The audio alarm will

not sound again for the current condition that

caused the alarm until a new condition occurs

or until a Master Alarm Reset is performed.

A Master Alarm Reset can be performed by

pressing Cooling (ON/OFF) twice or by turning

the power to the refrigerator off and on again.

After performing a Master Alarm Reset, the

indicator light will reactivate if the condition that

caused the alarm is still present.

NOTE: If the Max Cool feature has been selected

feature, then the set points will remain at 34°F

(1°C) and -5°F (-21°C) for the refrigerator and

freezer

Max Cool feature times out. The refrigerator

will then return to the previous temperature set

points chosen prior to the selection of the Max

Cool feature, but the lights and ice maker will

remain off until the Holiday Mode is pressed

again.

prior to turning on the Holiday Mode

compartments, respectively, until the

Door Open

The Door Open indicator light will flash, an

alarm will sound and the interior lights will turn

off when a door has been open for longer than

10 minutes. When the door is closed, the audio

alarm will reset and turn off, but the Door Open

indicator light will continue to flash until the

temperature is equal to or below 45°F (7°C)

15°F (-9°C) for the refrigerator and freezer

and

compartments, respectively

NOTE: T

dicator light, see “Master Alarm Reset.”

o deactivate the audio alarm and in-

.

3-9

Over Temperature

A. ON/OF F control

A

A. Crisper pans

B. Deli pans

A

B

B

IMPORTANT: If the Over Temperature Alarm

activates, your food may spoil (see “Power

Interruptions” in the Use and Care Guide for

additional information). Minimize door openings

until temperatures return to normal.

Over Temperature feature is designed to

The

let you know when either the refrigerator temperature

emperature rises above 15°F

t

rises above 48°F (9°C) or the freezer

(–9°C) for longer

than 1-1/2 hours. The audio alarm will shut off

automatically when the temperature returns

to normal, but the indicator light will continue

to flash until the Alarm is pressed to let you

know that an over temperature condition has

occurred.

the over temperature condition is still present

If

when an Over Temperature Reset is performed,

the indicator light will continue to reactivate

every 1-1/2 hours until refrigerator and freezer

temperatures are below 48°F (9°C) and 15°F

(–9°C), respectively.

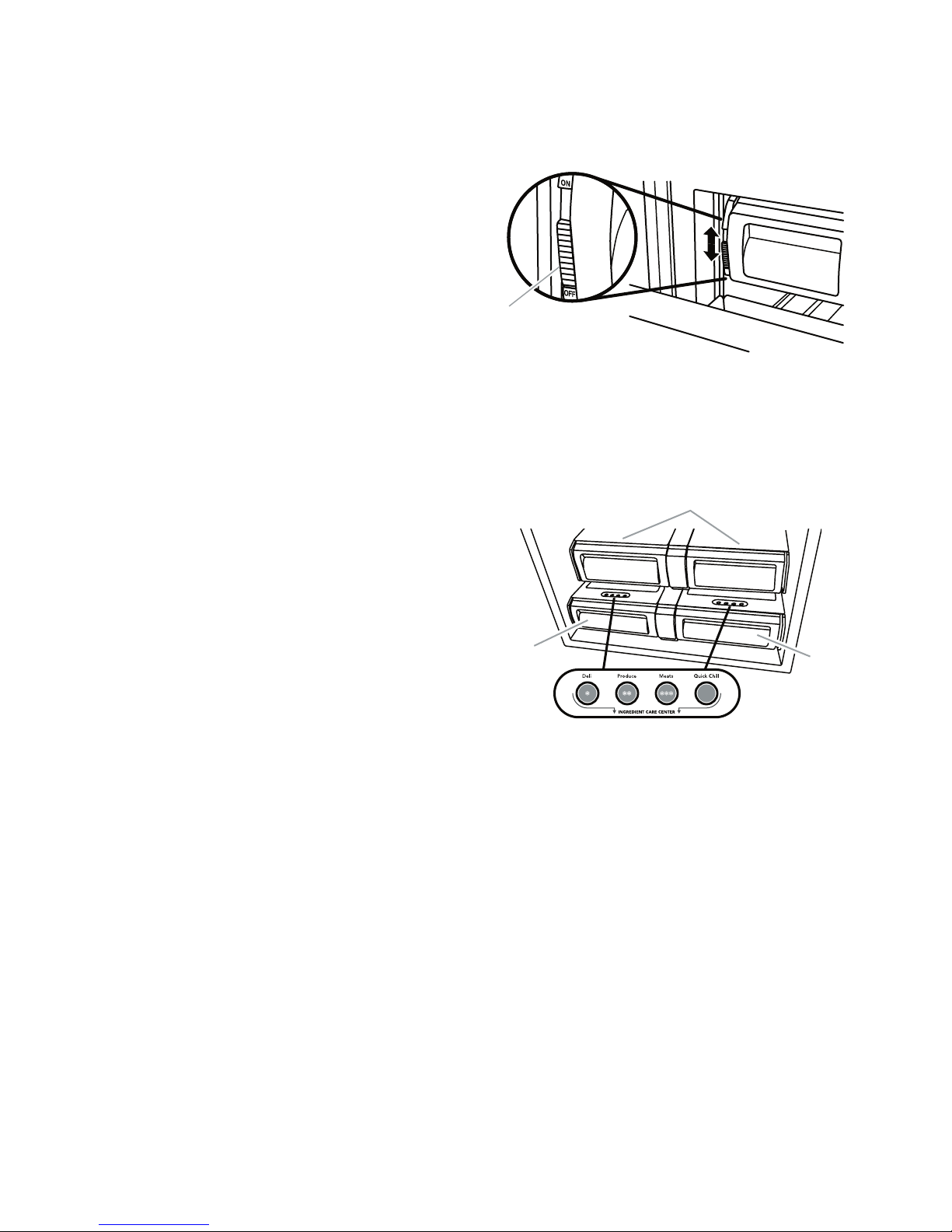

2. To manually turn off the ice maker, slide

the ice maker ON/OFF control to the OFF

(down) position as shown.

DELI/CRISPER PANS

The 42˝ (106.7 cm) model includes two deli pans

and two crisper pans, while the 36˝

model has one deli pan and one crisper pan.

(91.4 cm)

OTE: To deactivate the audio alarm and indi-

N

cator light, see “Master Alarm Reset.”

ICE MAKER

Turn the Ice Maker ON/OFF

The ice maker ON/OFF control is located on

the left-hand side of the ice bin.

To turn on the ice maker, slide the ice maker

1.

ON/OFF control to the ON (up) position.

NOTE: Your ice maker has an automatic

shutof

fill the ice storage bin. The ice maker sensors

but the ice maker control will remain in the

ON (up) position.

f. As ice is made, the ice cubes will

will automatically stop ice production,

Deli Pan Settings

Ingredient Care Center control panel lo-

The

cated above each deli pan has the following

three temperature settings: Deli, Produce,

Meats (Cold to Coldest) and the Quick Chill

setting. Select the appropriate setting for the

food being stored.

3-10

Meat Storage Guide

Quick Chill Setting

Store most meat in original wrapping as long

as it is airtight and moisture-proof. Rewrap if

necessary. When storing meat longer than the

times shown below, freeze the meat.

Fresh fish or shellfish: Use same day as purchased.

Chicken, ground beef, variety meat (liver, etc.): 1-2 days.

Cold cuts, steaks & roasts: 3-5 days.

Cured meats: 7-10 days.

Leftovers: Cover leftovers with plastic wrap, aluminum foil,

or plastic containers with tight lids.

Each deli pan has a Quick Chill setting. Activating this selection lowers the temperature of the

pan for a period of one hour.

NOTE: This will lower the deli pan temperature

below the freezing point for liquids.

3-11

— NOTES —

3-12

COMPONENT ACCESS

WARNING

This section instructs you on how to service components inside the Built-In French Door BottomMount Refrigerator. The components and their locations are shown below.

COMPONENT LOCATIONS

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

Unit Compartment Components

Inverter

Compressor

Condenser Fan Motor

24V

Transformer

Power Switch

4-1

Main Control Board

Low Voltage Control Board

Loading...

Loading...