Page 1

KiitchenAPd

Qn

30” Electric

Freestanding

Range

IMPORTANT:

Read and save

these instructions.

IMPORTANT:

Installer: Leave Installation Instructions

with the homeowner.

Homeowner: Keep Installation

Instructions for future reference.

Save Installation Instructions for local

electrical inspector’s use.

I

I

InstruCtIons

Part No. 9750520 Rev A

Page 2

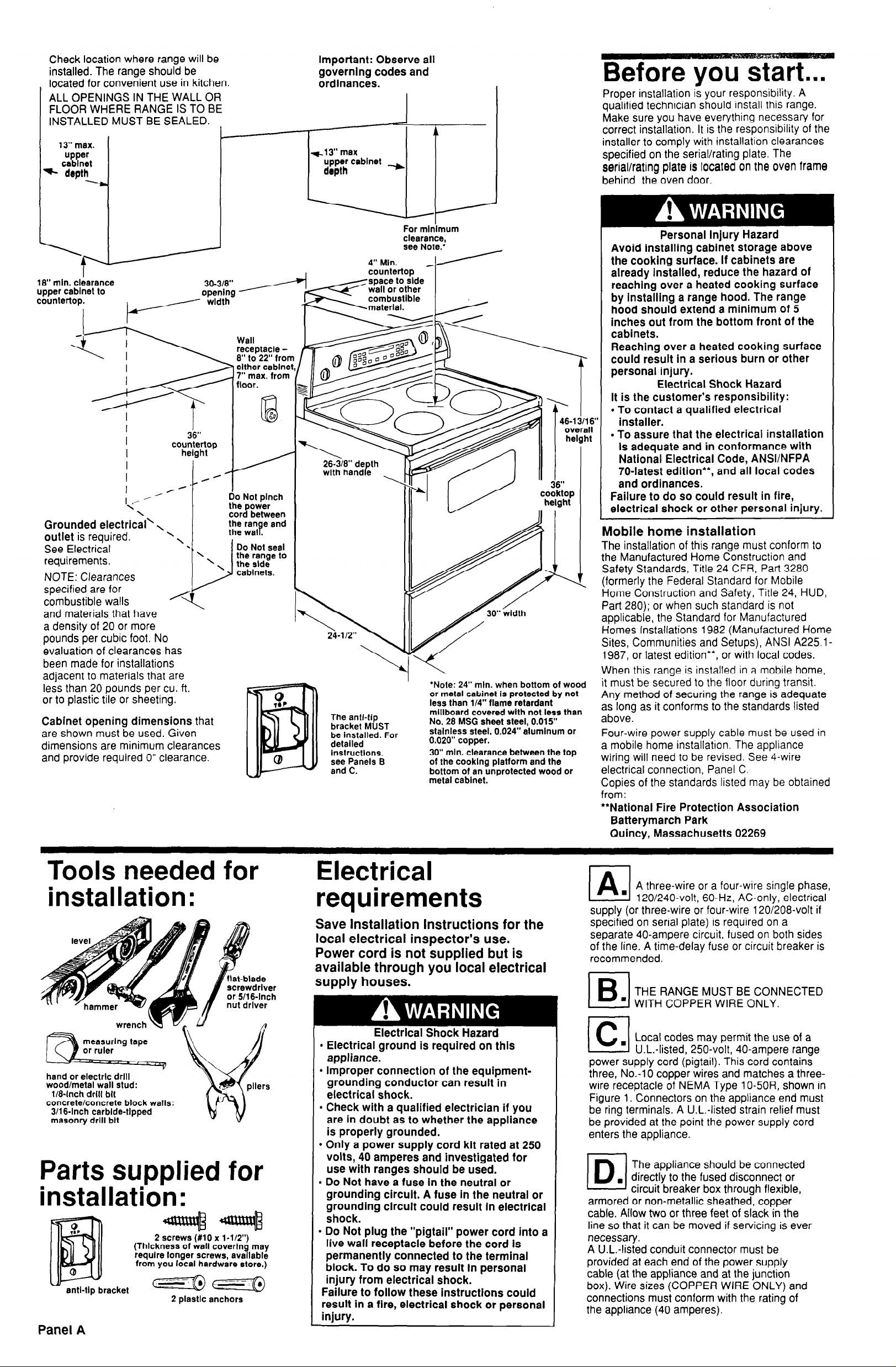

Check location where range will be

installed. The range should be

located for convenient use in kitchen.

ALL OPENINGS IN THE WALL OR

FLOOR WHERE RANGE IS TO BE

INSTALLED MUST BE SEALED.

13” max.

upper

cabinet

+- depth

Important: Observe all

governlng codes and

ordinances.

~13” max

upper

cabinet ~

depth

Before you start...

Proper installation is your responsibility. A

qualified technician should install this range.

Make sure you have everything necessary for

correct installation. It is the responsibility of the

installer to comply with installation clearances

specified on the serial/rating plate. The

serial/rating plate is located on the oven frame

behind

the oven door.

18” min. clearance

upper cabinet to

countertop.

I

+y

I

I

/ wldth

I

I

I //I ///’

I ., ’

\

Grounded electricil\ ,

outlet is reauired.

See Electric’al

requirements.

NOTE: Clearances

specified are for

combustible walls

and materials that have

a density of 20 or more

pounds per cubic foot. No

evaluation of clearances has

been made for installations

adjacent to materials that are

less than 20 pounds per cu. ft.

or to plastic tile or sheeting.

Cablnet opening dimensions that

are shown must be used. Given

dimensions are minimum clearances

and provide required 0” clearance.

\

openlng

36”

countertop

helght

\

\

\

\

/ I

-JY

30-3/8”

cord between

the ran e and

the wal ? .

\

\

.

Wall

receptacle 6” to 22” fron

elther cablne

7” max. from

floor.

o Not pinch

18 power

Do Not seal

the range to

the slde

cabinets.

4” Min.

. . see “:r-

counrenop 1

The an&tip

bracket MUST

be Installed. For

detalled

lnstructlons.

see Panels B

and C.

For minimum

clearance,

.

*Note: 24” mln. when bottom of wood

or metal cabinet Is protected by not

less than 114” flame retardant

mlllboard covered wlth not less than

No. 26 MSG sheet steel, 0.015”

stalnless steel, 0.024” alumlnum or

0.020” copper.

30” mln. clearance between the top

of the cooklng platform and the

bottom of an unprotected wood or

metal cabinet.

Personal Injury Hazard

Avoid installing cabinet storage above

the cooking surface. If cabinets are

already Installed, reduce the hazard of

reaching over a heated cooking surface

by Installing a range hood. The range

hood should extend a minimum of 5

inches out from the bottom front of the

cabinets.

Reaching over a heated cooking surface

could result in a serious burn or other

personal injury.

Electrical Shock Hazard

It is the customer’s responsibility:

l

To contact a qualified electrical

installer.

l

To assure that the electrical installation

Is adequate and in conformance with

National Electrical Code, ANSVNFPA

70-latest edition**, and all local codes

and ordinances.

Failure to do so could result in fire,

electrical shock or other personal injury.

L

Mobile home installation

The installation of this range must conform to

the Manufactured Home Construction and

Safety Standards, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile

t

Home Construction and Safety, Title 24, HUD,

Part 280); or when such standard is not

applicable, the Standard for Manufactured

Homes Installations 1982 (Manufactured Home

Sites, Communities and Setups), ANSI A2251 -

1987, or latest edition*‘, or with local codes.

When this range is installed in a mobile home,

it must be secured to the floor during transit.

Any method of securing the range is adequate

as long as it conforms to the standards listed

above.

Four-wire power supply cable must be used in

a mobile home installation. The appliance

wiring will need to be revised. See 4-wire

electrical connection, Panel C.

Copies of the standards listed may be obtained

from:

**National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

Tools needed for Electrical

installation:

hand or electric drill

wood/metal wall stud:

l/B-Inch drill blt

concrete/concrete block walls:

3116.Inch carblde-tlpped

masonry drill blt

Parts supplied for

installation:

2 screws (#lo x l-112”)

(Thickness of wall coverln may

Panel A

requlre longer screws, ava lable

from you local hardware store.)

:ket

2 plastic anchors

9

requirements

Save Installation Instructions for the

local electrical inspector’s use.

Power cord is not supplied but is

available through you local electrical

supply houses.

Electrlcal Shock Hazard

. Electrical ground is required on thls

appliance.

l

Improper connection of the equipmentgrounding conductor can result in

electrical shock.

l

Check with a qualified electrician if you

are in doubt as to whether the appliance

is properly grounded.

l

Only a power supply cord kit rated at 250

volts, 40 amperes and investigated for

use with ranges should be used.

l

Do Not have a fuse in the neutral or

grounding circuit. A fuse in the neutral or

grounding circuit could result in electrical

shock.

l

Do Not plug the “pigtail” power cord into a

live wall receptacle before the cord Is

permanently connected to the terminal

block. To do so may result in personal

injury from electrical shock.

Failure to follow these instructions could

result in a fire, electrical shock or personal

injury.

. A three-wire or a four-wire single phase,

(A/

supply (or three-wire or four-wire 120/208-volt if

specified on serial plate) is required on a

separate 40-ampere circuit, fused on both sides

of the line. A time-delay fuse or circuit breaker is

recommended.

/c.(

power supply cord (pigtail). This cord’ contains

three, No.-1 0 copper wires and matches a threewire receptacle of NEMA Type 1 O-50R, shown in

Figure 1. Connectors on the appliance end must

be ring terminals. A U.L.-listed strain relief must

be provided at the point the power supply cord

enters the appliance.

ID.I

- circuit breaker box through flexible,

armored or non-metallic sheathed, copper

cable. Allow two or three feet of slack in the

line so that it can be moved if servicing is ever

necessary.

A U.L.-listed conduit connector must be

provided at each end of the power supply

cable (at the appliance and at the junction

box). Wire sizes (COPPER WIRE ONLY) and

connections must conform with the rating of

the appliance (40 amperes).

120/240-volt, 60-Hz, AC-only, electrical

THE RANGE MUST BE CONNECTED

WITH COPPER WIRE ONLY.

Local codes may permit the use of a

U.L.-listed, 250-volt, 40-ampere range

The appliance should be connected

directly to the fused disconnect or

Page 3

IF CONNECTING TO A 4-WIRE

’ ELECTRICAL SYSTEM: This aooliance

/E

is manufactured with ground connected ii

cabinet. The ground must be revised so the

green grounding wire of the 4-wire power cord is

connected to the cabinet. See 4-wire electrical

connection section, Panel C.

When a 4-wire receptacle of NEMA type 14-50R

is used (See Figure 2), a matching U.L.-listed, 4wire, 250-volt, 40-ampere, range power supply

cord (pigtail) must be used. This cord contains

four copper conductors with ring terminals on the

appliance end, terminating in a NEMA Type 1450P plug on the supply end. The fourth

(grounding) conductor must be identified by a

green or green/yellow cover and the neutral

conductor by a white cover. Cord should be Type

SRD or SRDT with a U.L.-listed strain relief and

be at least four feet long.

The MINIMUM conductor sizes for the copper 4wire power cord are:

40 ampere circuit

2, No.-8 conductors

1, No.-1 0 white neutral

1, No.-8 green grounding

n The wiring diagram is also located on

EJ

the back of the range.

3-wire electrical connection

See Panel C for 4-wire electrical connection.

Conduit

Knock-out opening

for 40.amDere

If appliance is to be connected directly to

fused disconnect or circuit breaker b&x:

Assemble a U.L.-listed conduit connector in the

conduit connector opening provided. Insert the

power supply cable through the conduit connector,

allowing enough slack to easily attach the wiring to

the terminal block.

Dower %

U.L. listed

conduit

connector

\

connector

opening

centerline

I

7

,=‘c

. To mount anti-tip bracket to wood

(12(

that is closest to the center of the range location.

(Note: Wall stud should Not be more than 12

inches to the right or left of center of range

location.) Measure and mark at the center of the

wail stud a distance of 44 inches up from the

floor.

To mount anti-tip bracket to concrete or

concrete block wall: Measure and mark on the

rear wall at the center of the range location a

distance 44 inches up from the floor. (Note: Antitip bracket can Not be installed more than 12

inches to the right or left of center of range

location.)

or metal wall stud: Find the wall stud

3-wire wall

receplacle

(lo-50R)

Figure 1

4-wlre wall

receptacle

(14~50R)

Figure 2

Now start...

With range in kitchen.

Remove racks and other parts

from inside oven.

Take 4 cardboard corners from the

carton. Stack one cardboard corner

top of another. Repeat with other two corners.

Place corners lengthwise on the floor in back of

range.

. Firmly grasp the range and gently lay it

P-J

141

Use adiustable wrench

to loo& leveling legs four complete turns.

on its back on the cardboard corners.

. Pull cardboard shipping base firmly

to remove.

on

If a U.L.-listed, 40.ampere range power supply

cord (pigtail) is used: Remove the knockout for

the 40.ampere power supply cord.

Assemble a U.L.-listed strain relief in the hole.

Insert the power supply cord through the strain

relief, allowing enough slack to easily attach the

wiring to the terminal block.

Do not loosen the factory installed nuts already

installed on the terminal block.

Use only ring-type terminals to connect the

power supply. To secure the power supply

cord, use the 3/8” brass nuts taped to cabinet

below the terminal block.

Be sure the wiring

This appliance is manufactured with the

neutral terminal connected to the cabinet. If

local codes Do Not permit grounding through

the neutral, a four-wire power supply cord

rated 250.volts, 40.amperes and investigated

for use with ranges must be used. See 4-wire

electrical connection, Panel C.

BEI

terminal block. Connect the other two wires to the

outer terminal screws on the terminal block. Use

ring-type terminals only. Connect with the brass nuts

attached to the range. Do Not loosen factoryinstalled nuts already on the terminal. Check that

nuts are tight to insure proper electrical connection.

ml

screws of the conduit connector. Replace terminal

block cover.

, Connect the neutral (white) wore to the

silver-colored terminal screw on the

, Tighten the strain relief clamping

screws or the locking ring and clamping

nuts are installed tight.

Electrical Shock Hazard

l

Take special care when drilling holes into

the wall. Electrical wires may be

concealed behind the wall covering.

l

Locate the electrical circuits that could be

affected by the installation of this bracket

and turn off the power to these circuits.

Failure to follow these instructions may

result in electrical shock or other

personal injury.

Property Damage

l

Contact a qualified installer for the best

procedure to drill mounting holes through

the type of wall covering (i.e. ceramic tile)

and into wall stud, concrete or concrete

block wall.

l

Before moving range across floor, check

that range is on shipping base or slide

range onto cardboard or hardboard.

Failure to follow these instructions may

result in damage to wall or floor covering.

1 I

I 1

. Line up

1131

mounting hole on

anti-tip bracket with

mark on wall. Use a

pencil to mark the

location of the top

and bottom mounting holes. Remove bracket. if

wail covering is ceramic tile, drill a 3/l 6-inch

hole through tile only. Then proceed as follows:

For wood or metal wail studs:

Drill l/8” holes at each mounting hole location

through wall and into stud.

For concrete or concrete block wall:

Drill 3/l 6” holes (l -3/4-inch minimum deep) at

each mounting hole location. Tap plastic anchors

into mounting holes with hammer.

the “TOP”

1

4b”

IF

-~-

\I i

‘, i

‘I)r

, Place cardboard or hardboard in front

El

17

,I,

181

of range. Stand range back up.

I Remove the shipping materials including

tape and protective film from range.

fermlnal nuts

. Remove the terminal block cover located

on the back of range.

Panel B

l

To prevent tipping, install range anti-tip

bracket.

l

Anti-tip bracket must be attached to a

wood or metal wail stud, or concrete or

concrete block wall.

l

Do Not attach anti-tip bracket to a cabinet.

l

Save these Installation Instructions. If

range is moved to a new location, the

anti-tip bracket must be removed and

reinstalled in the new location.

on bracket with

holes on wall,

making sure that

the “TOP”

mounting hole on

bracket is lined up

with top hole in wall. Securely fasten bracket to

wall using screws provided.

Plug range power supply cord into

arounded outlet. Carefully slide ranae

into position until range is approximately 2 incGes

from rear wall. Remove shipping base, cardboard

or hardboard from under the range.

’

,

Page 4

Push cable,

located on rear of

range, up and into the two

hooks on the anti-tip

bracket. Check that cable is

secure in both hooks by

pulling cable towards range.

If cable comes out of hooks,

reposition cable to insure that

in both anti-tip bracket hooks.

final position.

. If installing the range in a mobile

/17/

the floor. Any method of securing the range is

adequate as long as it conforms to the standards

listed in the Mobile Home Installation

Instructions, Panel A.

back. If range is not level, adjust the leveling legs

up or down until the range is level.

Note: Oven must be level for satisfactory baking

conditions.

home, you MUST secure the range to

Place rack in oven. Place level on

rack, first side to side; then front to

cable fits securely

Slide range into

OFF

LO n HI

each surface unit

control knob to “HI”

position. Check the

operation of the

cooktop elements and indicator lights.

“88:88” should appear in the clock

120

“TIME, HR AND-MIN will light up in the display.

“0:OO” will appear and the “:” will be flashing.

Press the number buttons for the correct time of

day. Press “Start/Enter” button to start the clock.

“350”” will appear in the temperature display. The

ON, Bake Element, Outer Broil Element and

Oven Cavity symbols will light up in the display.

Press the “Start/Enter” button.

The bottom element should glow red and the

indicator light should be on. The upper element

should become hot but not glow red. The oven

indicator light goes off when the oven is

preheated.

Press “Cancel/OFF” button.

122

“500”” will appear in the temperature display. The

ON, Inner and Outer Broil Elements and Oven

Cavity symbols will light up in the display. Press

the “Start/Enter” button.

The top element should glow red and the

indicator light should be on.

Press the “Cancel/OFF” button.

n

disolav. Press the “Clock Set” button.

Check the operation of the oven

element. Press the “BAKE” button.

. Check the operation of the broil

element. Press the “BROIL” button.

To get the most efficient use from your

new electric range, read your KitchenAid

Use and Care Guide. Keep Installation

Instructions and Guide close to the

electric

range

for easy reference.

4-wire electrical connection

Use this wiring method for mobile homes and

whenever 4.wire installation is required.

U.L. llsted

conduit

connecxor

If appliance is to be connected directly

to fused disconnect or circuit breaker

box: Assemble a U.L.-listed conduit connector in

the conduit connector opening provided. Inset-f the

power supply cable through the conduit connector,

allowing enough slack to easily attach the wiring to

the terminal block.

U.L.-&ted

strain relief

show

I

----‘ClampIng screws

If a U.L.-listed, 40-ampere range power supply

cord (pigtail) is used:

Remove the knockout for the 40.ampere power

supply cord. Assemble a U.L.-listed strain relief in

the hole. Insert the power supply cord through the

strain relief, allowing enough slack to easily attach

the wiring to the terminal block.

Do not loosen the factory installed nuts already

installed on the terminal block.

8.9. IO. 11.15. ‘6.

18.

IW

Numbers

correspond

to steps.

Remove the grounding-link screw from

the range frame. Save the grounding

screw. Bend up rhe grounding link so that it does

not contact the range.

ding

Green Insulated

wire

l-z-l-

. -Connect the green grounding wire to the

lk.l

removed in Step B. The green grounding wire

must be attached first and must not contact any

other terminal.

Sllver-colored

terminal block

screw

range using the grounding screw

Panel C

Green Insulated

wlre

- U.L. llsted strain

relief shown.

. Connect the neutral (white) wire to the

PI

the terminal block. Connect the other two wires to

the outer terminals on the terminal block. Use ringtype terminals only. Connect and securely tighten

the brass nuts that are provided on a plastic strip

attached to the range. Do Not loosen the factor-y

installed nuts already on the terminal.

Be sure that the nuts are installed tight.

(El

of the conduit connector. Replace the terminal

block cover.

center, silver-colored terminal screw on

. Tighten the strain relief clamping screws

or the locking ring and clamping screws

Continue installation at Step 12, Panel B.

Page 5

If the range does

If you need

If you need

,not operate...

l

Check that the circuit breaker is not tripped or

the fuse blown.

l

Check that power supply cord is plugged into

wall receptacle.

NOTE:

Refer to Use and Care Guide for operating

instructions and cleaning instructions.

Personal Injury/Product Damage Hazard

Do Not step, lean or sit on the range drawer

or door.

Failure to follow this instruction could

result in personal injury and/or product

damage.

For cleaning and

maintenance...

If removing the range is necessary for cleaning or

maintenance, disconnect the electric supply.

If electrical supply is inaccessible, lift the range

slightly at the front and pull the range away from

the wall. Pull the range out only as far as

necessary to disconnect the electric supply line.

Remove the cable from the anti-tip bracket and

remove range to complete cleaning or

maintenance.

Move range back into operating position. Insert

cable into anti-tip bracket. Level the range.

Reconnect the electrical supply. Make sure that

cable is secure in anti-tip bracket.

assistance...

The KitchenAid Consumer Assistance Center

will answer any questions about operating or

maintaining your range not covered in the

Installation Instructions. The KitchenAid

Consumer Assistance Center is open 24 hours

a day, 7 days a week. Just dial 800-422-l 230 the call is free.

When you call, you will need the range model

number and serial number. Both numbers can

be found on the serial/rating plate located on

the oven frame behind the door.

service...

In the event that your KitchenAid appliance

should need service, call the dealer from whom

you purchased the appliance or a KitchenAid-

authorized service company. A KitchenAidauthorized service company is listed in the

Yellow Pages of your telephone directory under

“Appliances - Household - Major - Service or

Repair”. You can also obtain the service

company’s name and telephone number by

dialing, free, within the continental United States,

the KitchenAid Consumer Assistance Center

telephone number, 800-422-I 230. A special

operator will tell you the name and number of

your nearest KitchenAid-authorized service

company.

Maintain the quality built into your appliance call a KitchenAid-authorized service company.

Part No. 9750520 Rev. A

0 1996 KitchenAid.

8 Registered Trademark of KitchenAid

Prepared by KitchenAid, Benton Harbor, Michigan 49022

Loading...

Loading...