Page 1

SGR series • Smart Pyrgeometer

Instruction Manual

Page 2

2

Page 3

.

Dear customer, thank you for purchasing a Kipp & Zonen instrument. It is essential that you read this manual completely for a

full understanding of the proper and safe installation, use, maintenance and operation of your new SGR series pyrgeometer.

We understand that no instruction manual is perfect, so should you have any comments regarding this manual we will be

pleased to receive them at:

Kipp & Zonen B.V.

Delftechpark 36, 2628 XH Delft, - or

P.O. Box 507, 2600 AM Delft,

The Netherlands

+31 15 2755 210

support@kippzonen.com

www.kippzonen.com

Warranty and liability

Kipp & Zonen guarantees that the product delivered has been thoroughly tested to ensure that it meets its published specifications.

The warranty included in the conditions of delivery is valid only if the product has been installed and used according to the

instructions supplied by Kipp & Zonen.

Kipp & Zonen shall in no event be liable for incidental or consequential damages, including without limitation, lost profits, loss

of income, loss of business opportunities, loss of use and other related exposures, however incurred, arising from the incorrect

use of the product.

Modifications made by the user may affect the instrument performance, void the warranty, or affect the validity of the CE

declaration or other approvals and compliances to applicable International Standards.

Copyright © 2017 Kipp & Zonen B.V.

All rights are reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form

or by any means, without authorisation by Kipp & Zonen.

Kipp & Zonen reserves the right to make changes to this manual, brochures, specifications and other product documentation

without prior notice.

Manual document number: V1704

Publication date: 1

st

April 2017

Important User Information

3

Page 4

4

Page 5

This Declaration of Conformity is compliant with the European Standard EN 45014 General Criteria for supplier’s Declaration of Conformity. The basis for the criteria has been found

in international documentation, particularly in ISO/IEC, Guide 22, 1982, Information on manufacturer’s Declaration of Conformity with standards or other technical specifications

Declaration of Conformity

Kipp & Zonen B.V.

Delftechpark 36, 2628 XH Delft

P.O. Box 507, 2600 AM Delft

The Netherlands

declares under our sole responsibility that the product

SGR3 and SGR4 Smart Pyrgeometer

to which this declaration relates, is in conformity with European Harmonised Standards

as published in the Official Journal of the EU, based on the following standard

following the provisions

also, this device complies to

Del, 7 February 2017

E. Valks - CEO

Kipp & Zonen B.V.

[EMC - FCC] Title 47CFR part 15

[EMC - Emissions]

[EMC - Immunity]

[Environmental Aairs]

EN 61326-2-3:2013

EN 61326-2-3:2013

EN 50581:2012

EMC-directive

RoHS Directive

2014/30/EU

2011/65/EU

Page 6

6

Page 7

7

Using this table

Click on any item in the table of contents to be taken directly to the relevant page.

Click on the bottom of any page to be taken back to the table of contents.

....................................................................................................................................................................................................................................................................................................................

...........................................................................................................................................................................................................................................................................................................................

....................................................................................................................................................................................................................................................................................................................................

...................................................................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................................................

.........................................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................

..................................................................................................................................................................

.......................................................................................................................................................................

....................................................................................................................................

....................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................................................................

......................................................................................................................................................................................................................................................................................................................

...........................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................

...........................................................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................................................................................................................

...........................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................................................................................

.........................................................................................................................................................................................................................................................................................................................................

......................................................................................................................................................................................................................................................................................................................................................

........................................................................................................................................................................................

.............................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................................................................................................

.........................................................................................................................................................................................................................................................................................................

Important User Information

Declaration of Conformity

1 Introduction

1.1 Product overview

1.2 Key parts of the SGR3

1.3 Key parts of the SGR4

2 Installation and operation

2.1 Included with the product

2.2 Mechanical installation

2.2.1 Installation for measurement of long-wave downward radiation

2.2.2 Installation for measurement of radiation on inclined surfaces

2.2.3 Installation for measurement of upward long-wave radiation

2.2.4 Installation for shaded measurement of downward long-wave radiation

2.2.5 Installation for measurement of net long-wave radiation

2.3 Electrical connections

2.3.1 Power connection

2.3.2 Data connection

2.3.3 Analogue voltage output

2.3.4 Analogue current output

2.3.5 Recommended cable types

2.4 Operation

2.4.1 Overcast sky

2.4.2 Clear sky

2.4.3 Measurements during a sunny day

2.5 Measurement uncertainty

2.6 Maintenance

3 Accessories

3.1 Diffuse radiation measurement

3.2 Ventilation

3.3 Mountings

3.4 Cables

4 SmartExplorer software and Modbus® communication

5 Principle components of pyrgeometers

5.1 Window

5.2 Detector

5.3 Temperature sensor

5.4 Housing

5.5 Cable and connector

3

5

9

9

10

10

11

11

11

11

13

13

13

14

15

15

16

17

18

18

18

19

19

19

20

21

23

23

23

23

23

25

27

27

27

28

28

28

Table of Contents

Page 8

8

..................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................................

................................................................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................................................................

.........................................................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................

......................................................................................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................................................................................

....................................................................................................................................................................................................................................................................................................

...........................................................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................................................................................

...........................................................................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................

.................................................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................................................................................................

..................................................................................................................................................................................................................................................................................

....................................................................................................................................................................................................................................................................................................................

...........................................................................................................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................................................

.............................................................................................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................................................

....................................................................................................................................................................................................................................................................................................................

..............................................................................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................................................................................

............................................................................................................................................................................................................................................................................................................................................................

...............................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................................................

...........................................................................................................................................................................................................................................................................................

........................................................................................................................................................................................................................................................................................

.....................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................

6 Pyrgeometer physical properties

6.1 Spectral range

6.2 Sensitivity

6.3 Response time

6.4 Non-linearity

6.5 Temperature dependence

6.6 Tilt error

6.7 Window heating oset

6.8 Zero oset B due to ambient temperature changes

6.9 Operating temperature

6.10 Field of view

6.11 Directional response

6.12 Maximum irradiance

6.13 Non-stability

6.14 Spectral selectivity

6.15 Environmental

6.16 Uncertainty

7 Maintenance and recalibration

7.1 Daily maintenance

7.2 Monthly maintenance

7.3 Yearly maintenance

7.4 Calibration

7.4.1 Calibration principle

7.4.2 Traceability to World Radiometric Reference

7.4.3 Recalibration

8 SGR models

8.1 SGR4

8.2 Specifications

9 Frequently asked questions

10 Trouble shooting

11 Keyword index

Appendices

A. Modbus®

A.1 Modbus® commands

A.2 Input registers

A.3 Most important registers

A.4 Holding registers

A.5 Read input register

A.6 Discrete inputs

A.7 Coils

A.8 Read write holding registers

A.9 Read discrete inputs

A.10 Read write discrete coils

A.11 Requesting serial number

A.12 Simple demonstration program

B. List of World and Regional Radiation Centres

C. Recalibration service

29

29

29

30

30

30

30

31

31

31

31

31

31

31

31

31

31

33

33

33

33

33

33

34

34

35

35

35

37

39

41

43

43

43

43

45

46

46

49

50

50

50

52

53

54

55

56

Page 9

.

Throughout this manual the following symbols are used to indicate to the user important information.

General warning about conditions, other than those caused by high voltage electricity, which may result in physical

injury and/or damage to the equipment or cause the equipment to not operate correctly.

Note Useful information for the user

1.1 Product overview

According to the World Meteorological Organisation (WMO) a pyrgeometer is the designated type of instrument for the measurement

long-wave atmospheric radiation.

A SGR series pyrgeometer is a high quality radiometer designed for measuring long-wave irradiance on a plane surface (radiant

flux, W/m

2

) which results from radiation incident from the hemisphere above the instrument.

This manual, together with the instruction sheet, gives information related to installation, maintenance, calibration, product

specifications and applications of the SGR series. Both the SGR3 and SGR4 pyrgeometers are described, even though they have

a different construction, the general definitions and principles apply to both models.

The physical construction and detectors are identical to the CGR3 and CGR4. The addition of the Smart interface affects specifications

and the number of pins on the connector. Both instruments have a Modbus® RS-485 interface that provides all required information;

in addition the analogue output provides the temperature corrected Downward Radiation.

Both the type of radiation and the range for the analogue output can be set by using the Modbus® interface and the free SmartEx-

plorer software.

The Modbus® interfaces for all SGR’s, SMP’s, SHP1 etc. are fully identical, both for the used registers and the physical connector.

If any questions should remain, please contact your local Kipp & Zonen representative or e-mail the Kipp & Zonen customer and

product support department at: support@kippzonen.com

Please go to www.kippzonen.com for information about other Kipp & Zonen products, or to check for any updates to this manual.

1. Introduction

9

Page 10

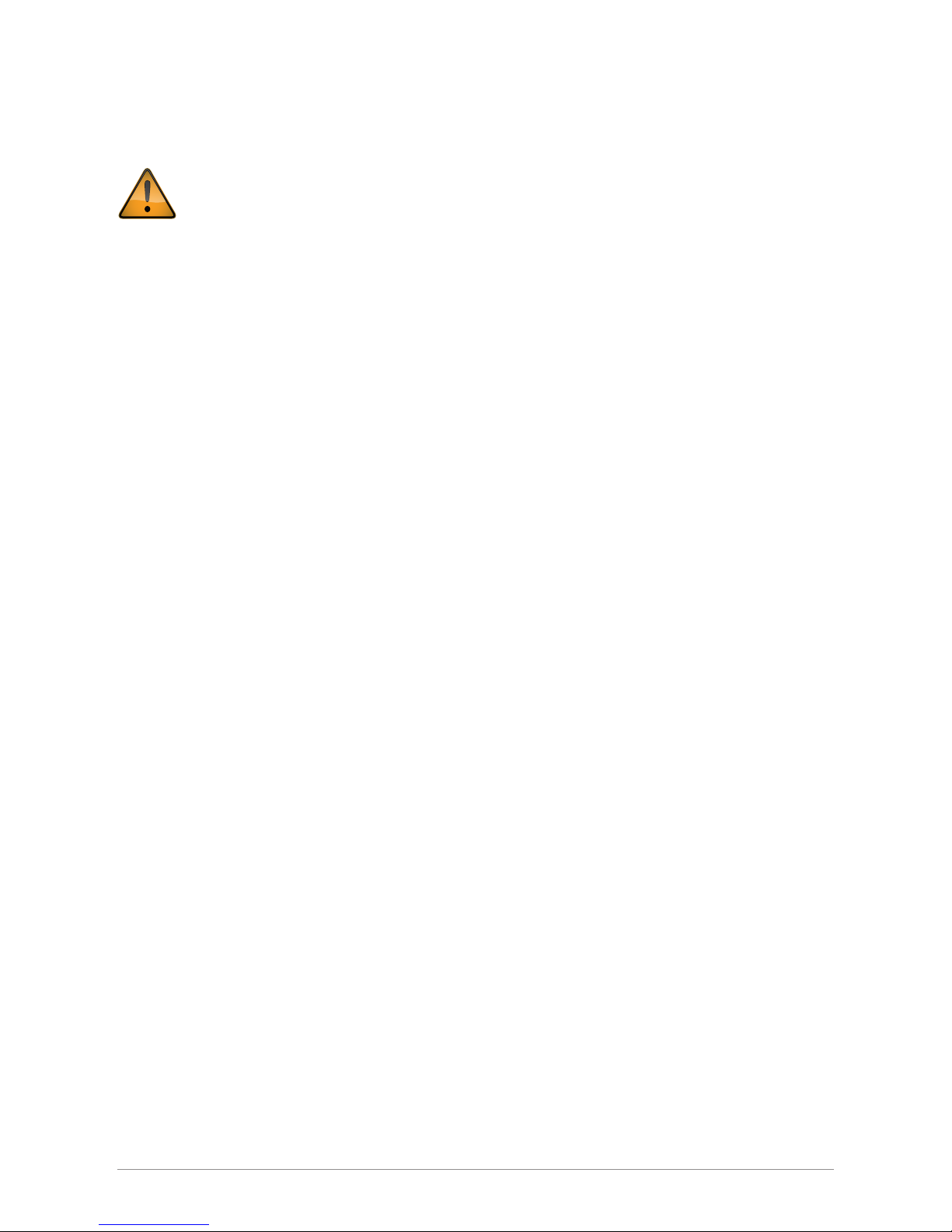

1.2 Key parts of the SGR3

1.3 Key parts of the SGR4

10

silicon window

housing

detector

sun shield

bubble level

connector

fixed foot adjustable feet

desiccant

desiccant

glass window

housing

detector

sun shield

bubble level

connector

fixed foot adjustable feet

smart interface

smart interface

Page 11

Please follow the instructions in this section carefully for the mechanical and electrical installation of the SGR series pyrgeometers.

Do not turn on power to the instrument until instructed to do so.

Note Do not connect the instrument to a computer until instructed to do so.

Note Do not turn on power to the operating computer until instructed to do so.

2.1 Included with the product

Check the contents of the shipment for completeness (see below) and note whether any damage has occurred during transport.

If there is damage, a claim should be filed with the carrier immediately. In the case of damage and/or the contents are incom-

plete, contact your local Kipp & Zonen representative or e-mail the Kipp & Zonen customer and product support department at:

support@kippzonen.com

Although all SGR radiometers are weatherproof and suitable for harsh environmental conditions, they have some delicate

mechanical parts. Please keep the original packaging for safe transport of the radiometer to the measurement site or for use

when returning the radiometer for calibration.

The following items are included with SGR series pyrgeometers:

1. Radiometer

2. Sun shield

3. Optional cable, pre-wired with 8-pins connector or connector only for customer cable

4. Test reports

5. Instruction sheet

6. Radiometer fixing kit

The calibration certificate supplied with the instrument is valid for 1 year from the date of first use by the customer, subject to the

variations in performance due to specific operating conditions that are given in the instrument specifications. The calibration

certificate is dated relative to the time of manufacture, or recalibration, but the instrument does not undergo any sensitivity

changes when kept in the original packing and not exposed to light. From the moment the instrument is taken from its packaging

and exposed to irradiance the sensitivity will deviate slightly with time. See the 'non-stability' performance (maximum sensitivity

change per year) given in the radiometer specification list.

2.2 Mechanical installation

The mechanical installation of the radiometer depends upon the measuring purpose. Different measuring methods will be

explained in the next paragraphs.

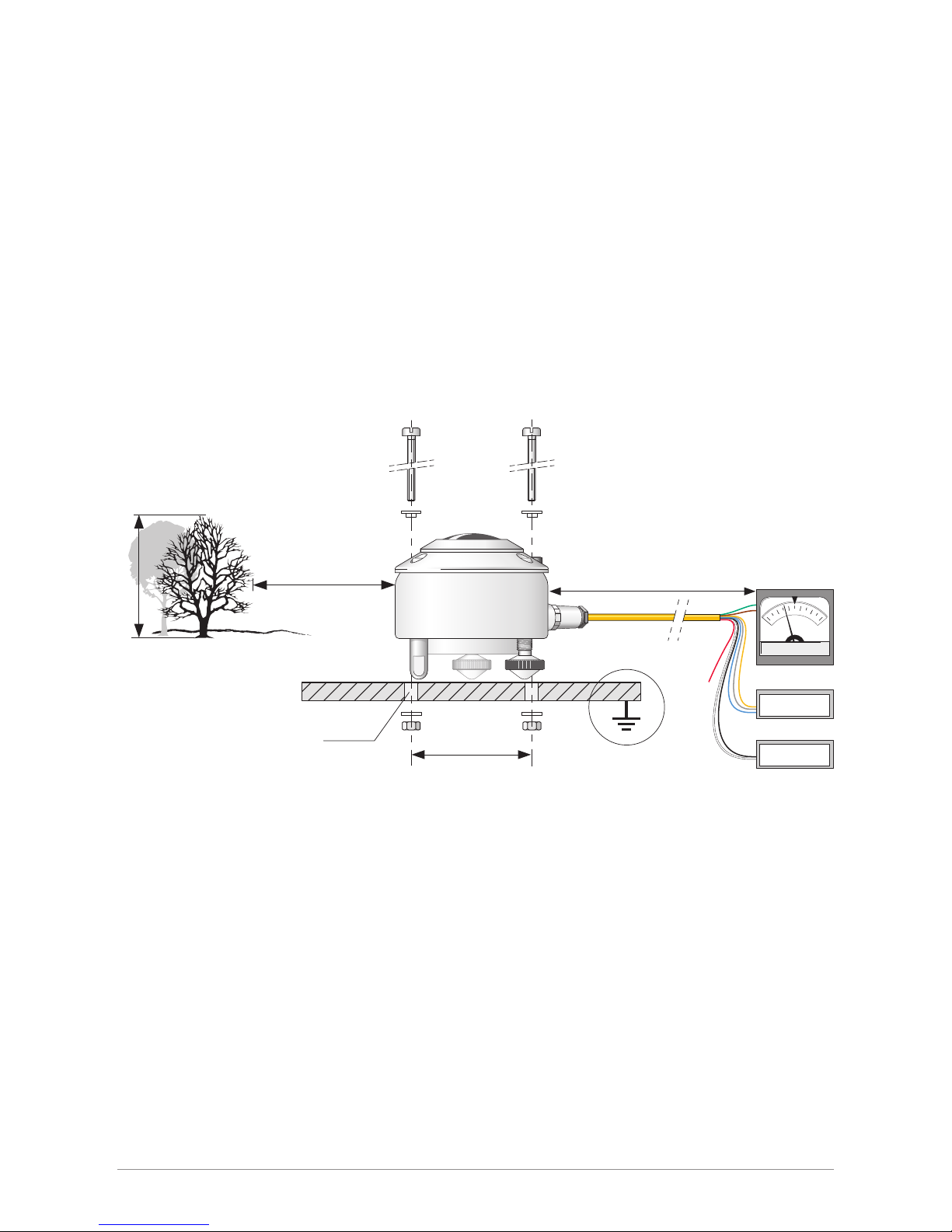

2.2.1 Installation for measurement of long-wave downward radiation

The following steps must be carefully taken for optimal performance of the instrument. The tools required to fit an SGR series

pyrgeometer to a support are a 4 mm (M5 socket head screw) Allen key and a 8 mm (M5 nut) wrench / spanner.

2. Installation and operation

11

Page 12

SGR-V or SGR-A

h

>10 x h

Ø5.2 mm (2x)

65 mm

max. 100 m

5 to 30 VDC

power supply

Modbus® RS-485

V / mA

0.0

0.2

0.4

0.6

0.8

1.0

Pyrgeometer installation

Step 1. Location

Ideally the site for the pyrgeometer should be free from any obstructions to the horizon above the plane of the sensing element. If

this is not possible, the site should be chosen in such a way that any obstruction over the azimuth range should have an elevation

not exceeding 10°. In particular, no sources of heat (such as ventilation / heating outlets) should be within the field of view.

Step 2. Mounting

The SGR pyrgeometer is provided with two holes for 5 mm bolts. Two each of stainless steel bolts, washers, nuts and nylon insulation

rings are provided in the fixing kit. The pyrgeometer should first be secured lightly with the bolts to a solid and stable mounting stand

or platform. After in recalibration the nylon insulators must be replaced with new ones to prevent corrosion.

The mounting stand temperature can vary over a wider range than the air temperature. Temperature fluctuations of the pyrgeometer

body can produce offset signals, therefore it is recommended to isolate the pyrgeometer thermally from the mounting stand by

placing it on its levelling screws. Ensure that there is a good electrical contact with earth to conduct away currents in the cable

shield induced by lightning.

Note After recalibration and/or reinstallation the nylon insulators must be replaced with new ones to maintain durability.

Step 3. Orientation

In principle no special orientation of the instrument is required, although the World Meteorological Organisation (WMO)

recommends that the signal lead is pointed towards the nearest pole, to minimise heating of the electrical connections.

Step 4. Level pyrgeometer

Accurate measurement of the global radiation requires proper levelling of the thermopile surface. Level the instrument by turning

the two levelling screws to bring the bubble of the spirit level centrally within the marked ring. For easy levelling, first use the

screw nearest to the spirit level. When the SGR4 pyrgeometer is placed horizontally using the bubble level, or when it is mounted

with its base directly on a horizontal plane, the thermopile is horizontal within 0.1°. For the SGR3 this is 0.2°.

12

Page 13

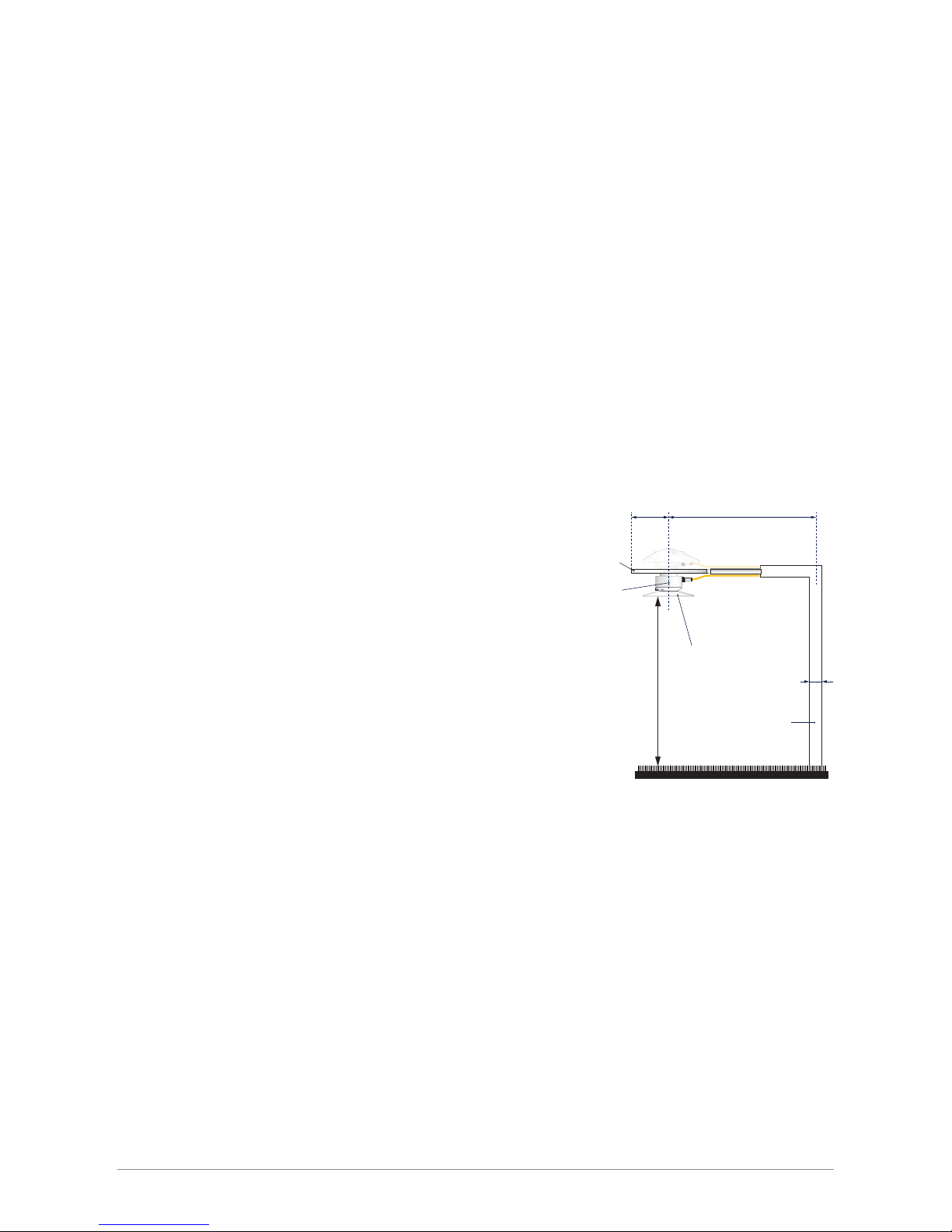

Upward long-wave radiation

Mounting plate

R S

h d

lower screen

always point the cables

to the nearest pole

pyrgeometer

Mast

The mounting device should not interfere significantly with the field

of view of the instrument. The upper plate prevents excessive heating

of the pyrgeometer body by solar radiation and, if large enough, it

keeps the lower screen free of precipitation. The lower glare screen

prevents direct illumination of the window by the sun at sunrise and

sunset and is available as an accessory kit for the SGR series.

The mast shown intercepts a fraction D/2πS of the radiation coming

from the ground. In the most unfavourable situation (sun at zenith)

the pyrgeometer shadow decreases the signal by a factor R²/H².

A rule of thumb is:A black shadow with radius = 0.1 H on the field

below decreases the signal by 1% and 99% of the signal will

originate from an area with radius 10 H.

Step 5. Secure pyrgeometer

Secure the pyrgeometer tightly with the two stainless steel bolts. The two nylon washers prevent contact corrosion. Ensure that

the pyrgeometer maintains the correct levelled position!

Step 6. Fit cable and sun shield

Locate the cable plug correctly in the radiometer socket (it only fits one way) and screw the plug locking ring hand-tight. Finally,

clip on the sun shield to prevent excessive heating of the radiometer body. The bubble level is visible through the top of the

pyrgeometer sun shield for routine checks.

2.2.2 Installation for measurement of radiation on inclined surfaces

It is advised to pre-adjust the levelling screws on a horizontal surface for easy orientation of the instrument parallel to the inclined

surface. Because the temperature of the mounting stand is expected to rise considerably (more than 10 °C above air temperature),

the housing must be thermally isolated by the levelling screws from the stand. This will promote a thermal equilibrium between

the window and the housing and decrease zero offset signals.

2.2.3 Installation for measurement of upward long-wave radiation

In the inverted position the pyrgeometer measures radiation from the ground. According to the WMO the height should be 1 to 2 m

above a uniform surface covered by short grass.

2.2.4 Installation for shaded measurement of downward long-wave radiation

For measuring atmospheric radiation with SGR pyrgeometers it is desirable to shield the instrument from the direct short-wave

solar radiation which may heat up the pyrgeometer window and cause significant thermal offsets. The direct solar radiation is

intercepted by a small disk or sphere. The shadow of the disk must cover the pyrgeometer window completely. However, to follow

the sun's apparent motion, a power-driven tracking device is necessary.

This can be done using a Kipp & Zonen sun tracker, such as the model SOLYS2, designed to track the sun accurately under all

weather conditions. More information about the combination of pyrgeometer and tracker is given in the sun tracker manual.

Alternatively, a static shadow ring can be used to intercept the direct solar radiation; but it is less accurate and may require periodic

manual adjustment. At times the shadow ring also intercepts a proportion of the diffuse sky radiation. Therefore, corrections for this

to the recorded data are necessary.

13

Page 14

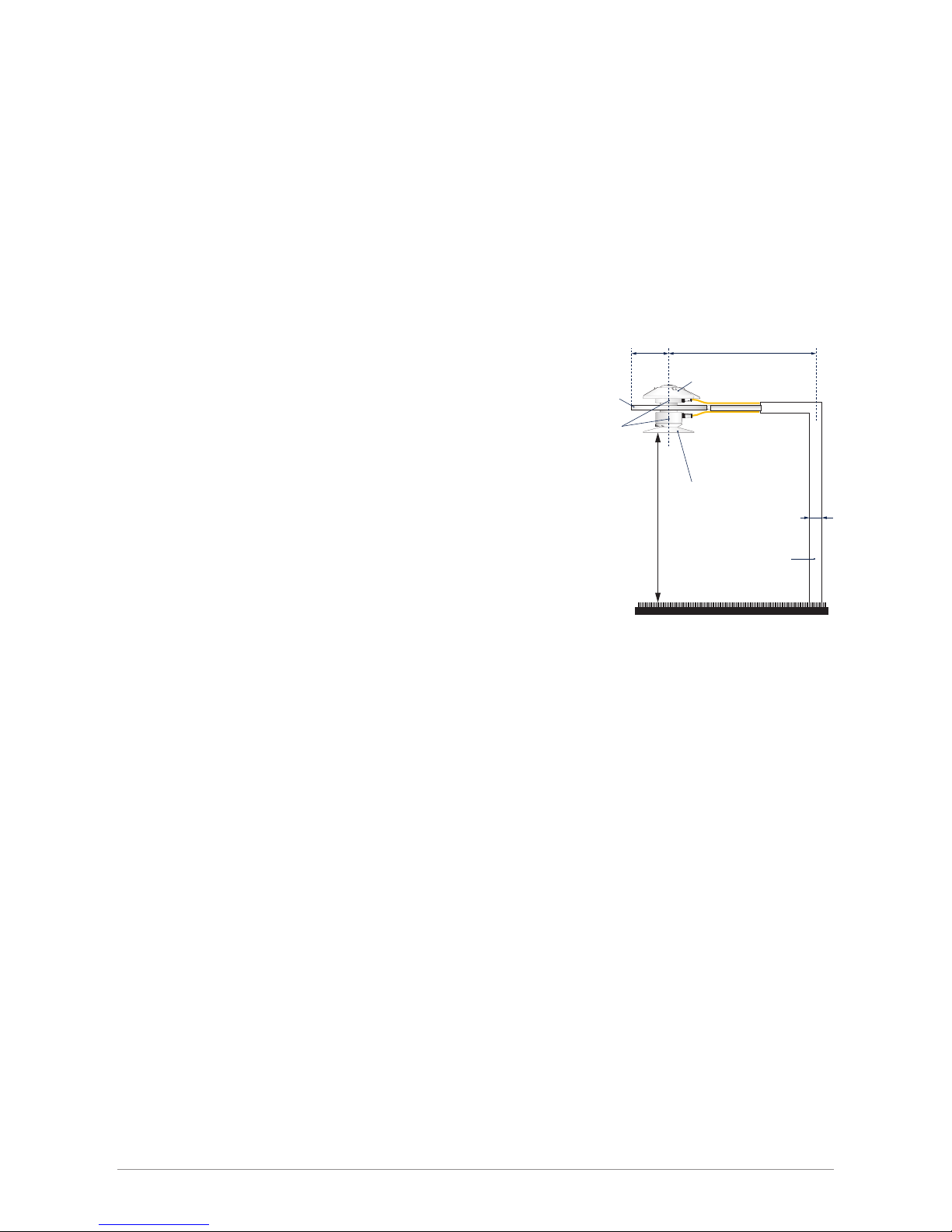

Net radiation configuration

Mounting plate

Upper screen

R S

h d

lower screen

always point the cables

to the nearest pole

pyrgeometer

Mast

The requirements for installation of the upper and lower pyrgeometers

are the same as in paragraphs for downward and upward long-wave

radiation. According to the WMO the pyrgeometer configuration

should be 1 to 2 meter above an uniform surface covered by short

grass.

The mast shown intercepts a fraction D/2πS of the radiation that is

coming from the ground. In the most unfavourable situation (sun at

zenith) the pyrgeometer shadow decreases the signal by a factor R²/H².

When determining the net long-wave radiation, it is not strictly necessary

to record the pyrgeometer housing temperatures. Assuming that the

temperatures of the upper and lower housings are equal, it can be

cancelled from the equation for net-radiation.

Kipp & Zonen produces a universal shadow ring, model CM121, which is suitable for use at all latitudes. In the CM121 manual,

installation instructions and correction factors are given.

In practice the SGR4 does not require shading from direct short-wave solar radiation because the window-heating effect, when

suitably ventilated, is negligible due to the unique construction of the pyrgeometer.

2.2.5 Installation for measurement of net long-wave radiation

A net pyrgeometer measures both the downward atmospheric long-wave radiation and the upward long-wave radiation from the

surface below. It can be configured from two SGR-series pyrgeometers and a suitable mounting plate. In the case of the SGR3, two

instruments can be simply mounted back-to-back and an optional mounting rod fitted.

However, if the upward and downward radiation components are to be measured separately it is necessary to record the individual

housing temperatures to calculate the radiation values.

Using the combination of a net pyrgeometer (two SGR3 or SGR4 instruments) and an albedometer (two SMP6 or SMP11) the net

total radiation (energy balance) can be calculated with high accuracy from the four component values. Problems with dew

deposition, frost, etc, can be minimised by using the Kipp & Zonen CVF4 ventilation unit with optional heating.

This has many advantages over conventional net total radiation sensors with plastic (polyethylene) windows. These cannot

provide individual short and long-wave radiation values and cannot separate upward and downward contributions. The soft

plastic windows do not fully protect the sensor from the thermal effects of wind and rain, are easily soiled, are difficult to clean

and require regular replacement.

14

Page 15

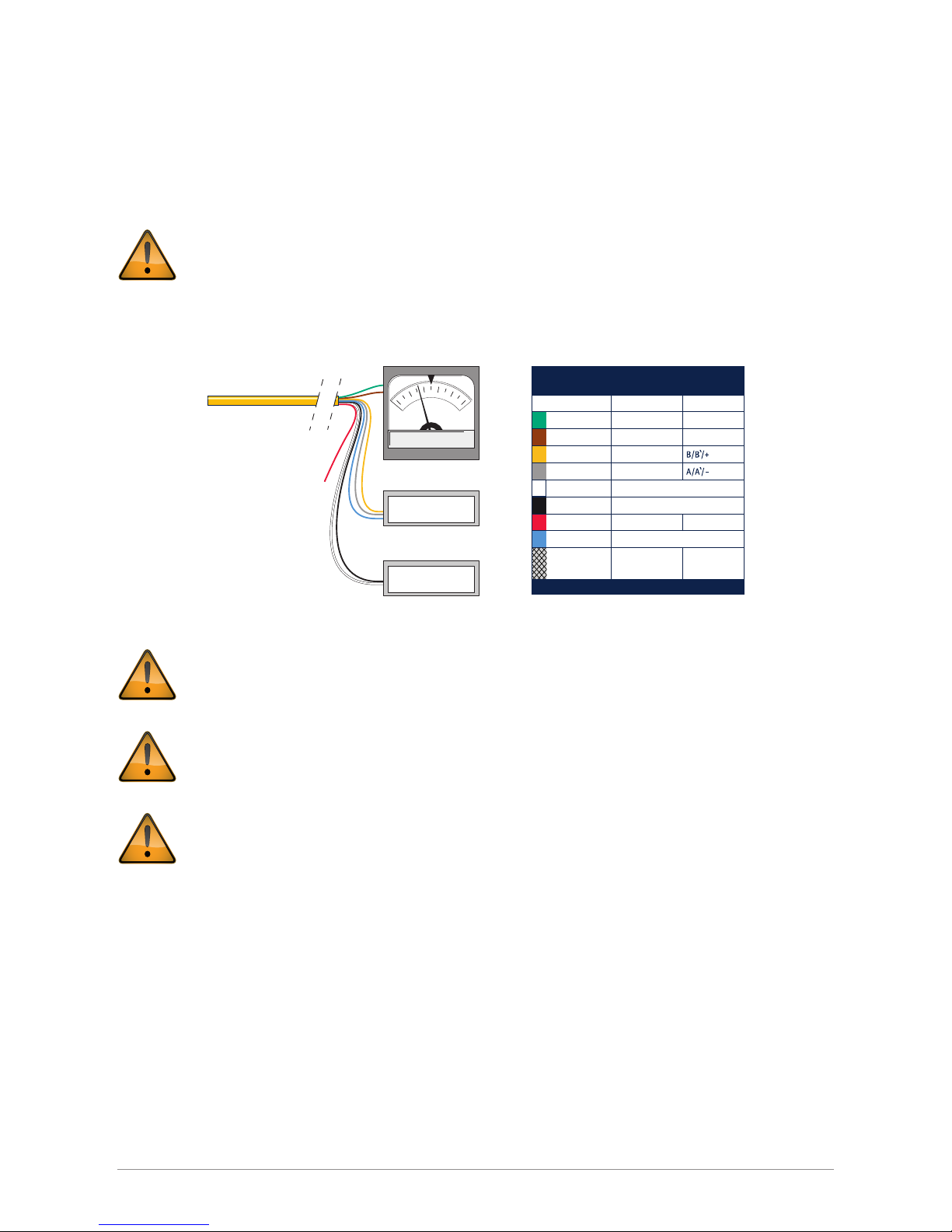

2.3 Electrical connections

The SGR pyrgeometers can be supplied with a waterproof connector pre-wired to 10 m of high quality yellow cable with 8 wires

and a shield covered with a black sleeve. Longer cables are available as options. The colour code of the wires and the connector

pin numbers are shown below and on the instruction sheet.

Special attention is needed to prevent power or ground loops when connecting the SGR to multiple readout devices.

Connecting the RS-485 to a grounded circuit and the analogue output to a floating circuit can cause unacceptable

ground loops. This may cause differential voltages outside the SGR specifications and will damage the unit. We

recommend using either the analogue or the digital output but not both. The maximum differential between either

of the Modbus® RS-485 lines (yellow and grey) and the power ground / RS-485 common line (black) is 70 VDC.

First connect all wires before plugging into the radiometer

The shield of the cable is connected to the aluminium radiometer housing through the connector body. Preferably,

secure the radiometer with its levelling screws on a metal support with a good connection to ground (e.g. by using

a lightning conductor) and do not connect the cable shield at the readout end.

If there is no good ground connection at the pyrgeometer, the shield at the cable end should be connected to ground

at the readout equipment. Lightning can induce high voltages in the shield but these will be led off at the pyrgeometer

or readout equipment.

Note Long cables may be used, but the cable resistance must be smaller than 0.1% of the impedance of the readout

equipment for the analogue outputs and may affect the baud rate of the RS-485 digital connection.

2.3.1 Power connection

The minimum power supply voltage for SGR pyrgeometers is 5 VDC. However, for optimal performance it is advised to use

12 VDC, especially when long cables are used. 5-volt power can only be used in combination with a short cable, maximum 10 m.

It is advised to protect the output of the power supply with a fast blowing fuse of maximum 250 mA rating.

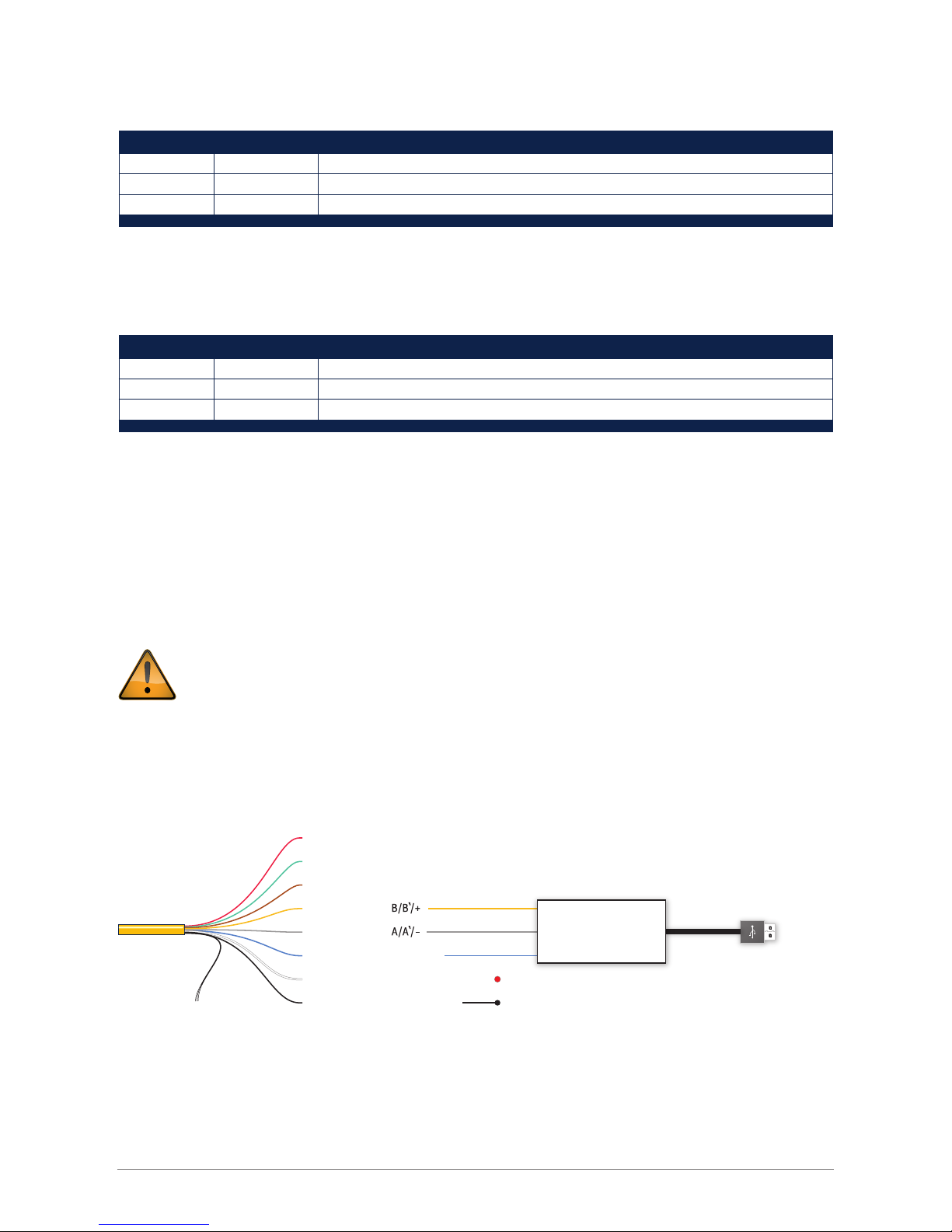

Radiometer Connection

Wire Function Connect with

Red

Blue

HousingShield

Not connectedNone

Modbus® common / Ground

Analogue out V+/4-20 mA(+)

Analogue ground V

-

/4-20 mA(-)

Modbus® RS-485

Modbus® RS-485

Power 5 to 30 VDC

(12 V recommended)

Power ground / RS-485 Common

Ground *

White

Black

Yellow

Brown

Green

Grey

5

1

2

8

7

* Connect to ground if radiometer not grounded

4

6

3

SGR-V or SGR-A

5 to 30 VDC

power supply

Modbus® RS-485

V / mA

0.0

0.2

0.4

0.6

0.8

1.0

15

Page 16

Typical power consumption SGR-V for maximum output (1 V)

5 VDC 50 mW (approx. 10.0 mA)

12 VDC 55 mW (approx. 4.5 mA)

24 VDC 60 mW (approx. 2.5 mA)

.

Maximum power consumption 65 mW at the highest input voltage.

Maximum input current 12.5 mA at the lowest input voltage.

Maximum inrush current 200 mA.

Typical power consumption SGR-A for max output (20 mA)

5 VDC 77 mW (approx. 28 mA with 100 Ω load resistor)

12 VDC 83 mW (approx. 24 mA with 100 Ω load resistor)

24 VDC 100 mW (approx. 6 mA with 100 Ω load resistor)

The above mW values represent the dissipation within the SGR-A. For the total power the energy in the load resistor has to

be added.

For supply voltages below 12 Volts or above 20 Volts it is advised to use a load resistor of less than 500 Ω to keep the power

consumption as low as possible.

2.3.2 Data connection

Connection to a Personal Computer by Universal Serial Bus (USB)

The connection depends on the use of a RS-485 to USB converter.

The converter must have galvanic isolation between the inputs and outputs to prevent possible damage to the SGR

digital interface. This is particularly an issue with portable computers (laptops, etc.) in which the power supplies

can generate large voltage spikes.

A suitable converter is the model USOPTL4 from B & B Electronics. One end has the USB connector to the PC the other end has

a connector with screw terminals for the instrument wires. This RS-485 converter is powered from the USB interface, so no

additional power adaptor is necessary.

*Note Switches on the converter should be set for RS-485, 2-wire operation and Echo off.

Shield - ground connection

SGR connections to USB

USB to PC

Not connected

Analogue out +

Analogue out

-

Modbus® RS-485

Modbus® RS-485

Modbus® common / Ground

Power 5 to 30 VDC

Power ground / RS-485 common

+ V

-

V

RS-485 / USB converter

Common

*

16

Page 17

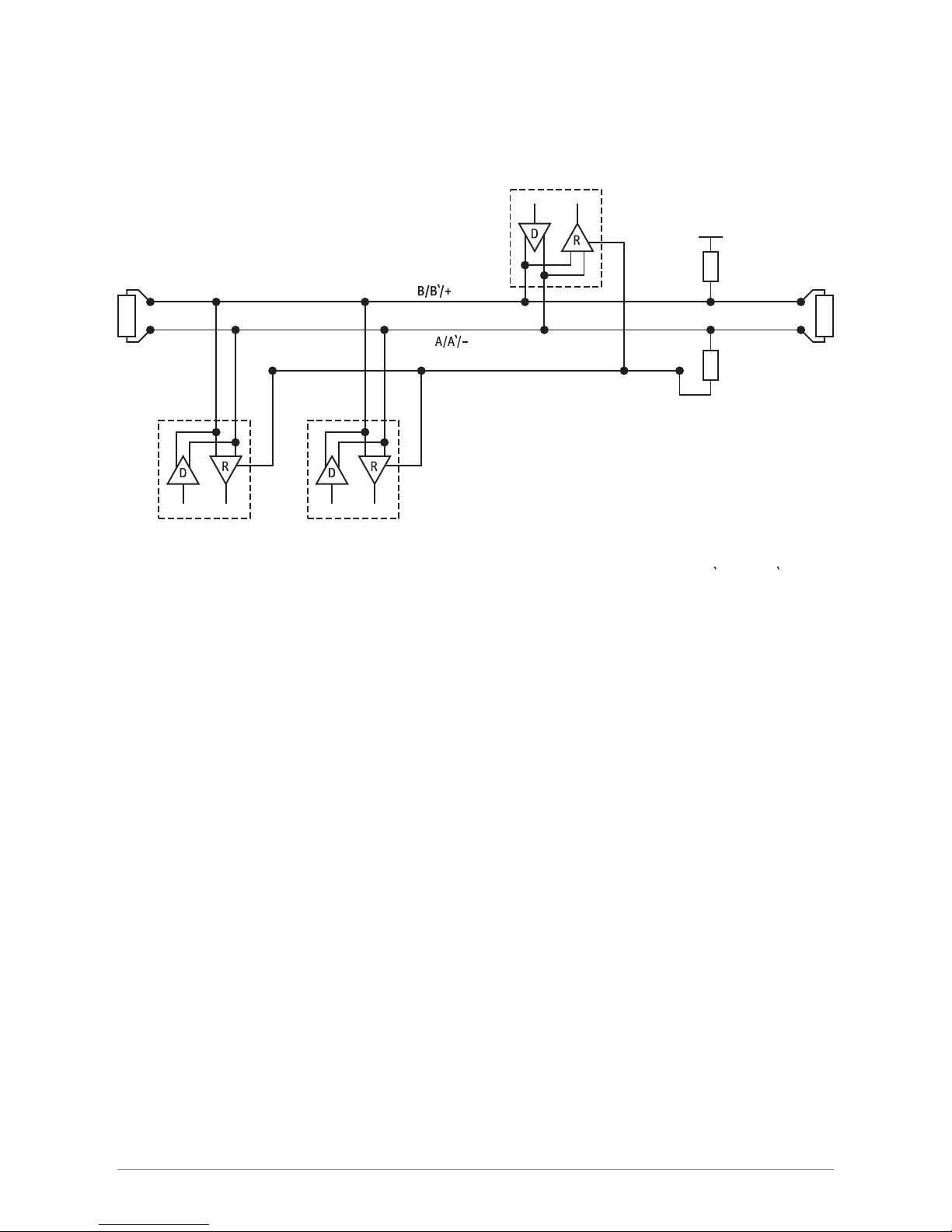

Connection to a RS-485 Network

The digital interface can be connected to a 2-wire RS-485 network as shown below.

The slaves and master may be a SGR pyrgeometer or other devices. If a SGR pyrgeometer is the last device on the network a

line terminator (LT), consisting of a 120 Ω or 150 Ω resistor, must be connected between terminals A/A'/- and B/B'/+. Never

place this line termination on the derivation cable. It is also required to install the pull up and pull down resistors as shown.

The value of these resistors must be between 650 Ω and 850 Ω.

2.3.3 Analogue voltage output

The SGR-V (voltage output versions) have been factory set such that an output of 0 Volts represents 0 W/m² (this will never be

reached in practice), and the full-scale output of 1 Volt represents 1000 W/m².

The voltage output range in W/m² can be changed by the user with the supplied PC software. The maximum recommended

irradiance for all SGR pyrgeometers is 1000 W/m².

The default setting 0 to 1 Volt represents 0 to 1000 W/m².

The downward atmospheric long-wave radiation (

L

d↓

) for the default setting can be simply calculated as shown below.

L

d↓

= Downward atmospheric long-wave radiation [W/m²]

V = Output of radiometer [Volt]

If the pyrgeometer is used in atmospheric conditions it is advised to keep the range as factory default.

Slave 1 Slave n

Master

Common

Balanced pair

LT LT

Pull down

Pull up

5 V

L

d↓

= (V x 1000)

17

Page 18

2.3.4 Analogue current output

The SGR-A (current output versions) have been factory set such that an output of 4 mA represents 0 W/m² and the full-scale

output of 20 mA represents 1000 W/m².

The current output range in W/m² can be changed by the user with the supplied PC software. The maximum recommended

irradiance for the SGR pyrgeometers is 1000 W/m².

Negative inputs will make the output go below 4 mA and no zero offset is needed. For the default setting of 4 to 20 mA representing

0 to 1000 W/m². The irradiance value (

L

d↓

) for the default setting can be simply calculated as shown below.

L

d↓

= Downward atmospheric long-wave radiation [W/m²]

mA = Output of radiometer [mA]

2.3.5 Recommended cable types

Where cables need to be extended, or the customer prefers to provide their own cables, they should be suitable for outdoor used

and UV resistant.

Recommended types

RS-485 Ethernet CAT 5 shielded twisted pair (STP)

0 to 1 V Shielded 2-core signal cable

4 to 20 mA Shielded twisted pair control cable

2.4 Operation

After completing the installation the pyrgeometer will be ready for operation. The downward atmospheric long-wave radiation

is calculated automatically inside the pyrgeometers with formula L

d

by measuring the detector output voltage U

emf

[µV], the

housing temperature T

b

[K], and taking the sensitivity calibration factor S [µV/W/m²] into account.

Note The net radiation term (U

emf

/S) is mostly negative, so the calculated downward atmospheric long-wave radiation

is smaller than the detector’s upward irradiance (5.67 • 10

-8

• T4).

In the Baseline Surface Radiation Network (BSRN) manual (WMO/TD-No.897) an extended formula is described. This formula

corrects for window heating and so called ‘solar radiation leakage’. Due to the very low window heating offset and optimal

spectral cut-on wavelength, these corrections are not necessary for the pyrgeometer.

Ld↓ = (mA-4) x (1000/16)

18

formula L

d

= Downward atmospheric long-wave radiation [W/m²]

Net radiation (difference between the downward [W/m²]

= longwave radiation emitted from the atmosphere

and the upward irradiance of the SGR detector)

= Upward irradiance of the SGR detector [W/m²]

Ld= + 5.67 • 10

-8

• T

4

U

emf

S

b

L

d

5.67 • 10

-8

• T

4

b

U

emf

S

b

Page 19

To be certain that the quality of the data is of a high standard, care must be taken with daily maintenance of the pyrgeometer.

Once a voltage measurement is taken, nothing can be done to retrospectively improve the quality of that measurement.

During field measurements the pyrgeometer is exposed to varying atmospheric conditions with typical radiating properties.

Therefore we define the two most common conditions as ‘overcast sky’ and ‘clear sky’.

2.4.1 Overcast sky

Typical for a cloudy overcast sky is that radiation emitted by the earth is absorbed 100% by the clouds. Therefore, the overcast

sky will re-emit the radiation (

L

d↓

) 100%.

In theory, the net radiation (U

emf

/S) will be zero, so the pyrgeometer detector output voltage (U

emf

) will be zero. In practice,

the detector output shows a small negative voltage (a few W/m²), due to a small heat exchange between the relatively warm

pyrgeometer and the colder sky.

In this case the calculated atmospheric long-wave radiation (

L

d↓

) shows a relatively large positive value. In the case of rain, the

detector output will read zero, because water deposited on the pyrgeometer window is a perfect infrared absorber.

Cloudy overcast sky condition

2.4.2 Clear sky

Clear sky conditions differ in that there is a relatively large heat loss caused by the atmospheric window. The amount of

re-emitted radiation by a clear sky is smaller compared to the overcast sky condition. Because of the heat loss in the upward

direction, the thermopile hot junctions will cool down and show a relatively large negative net radiation value (from -90 to

-130 W/m²). Therefore, the calculated atmospheric long-wave radiation (

L

d↓

) shows a relative small positive value.

Clear sky condition

Atmosphere T

atm

Earth’s surface T

earth

>T

atm

Net radiation (-90 to -130 W/m

2

)

Downward radiation

(Relatively small value)

Upward radiation

Atmosphere T

atm

Earth’s surface T

earth

>T

atm

Net radiation (0 to -5 W/m

2

)

Downward radiation

(Relatively large value)

Upward radiation

19

Page 20

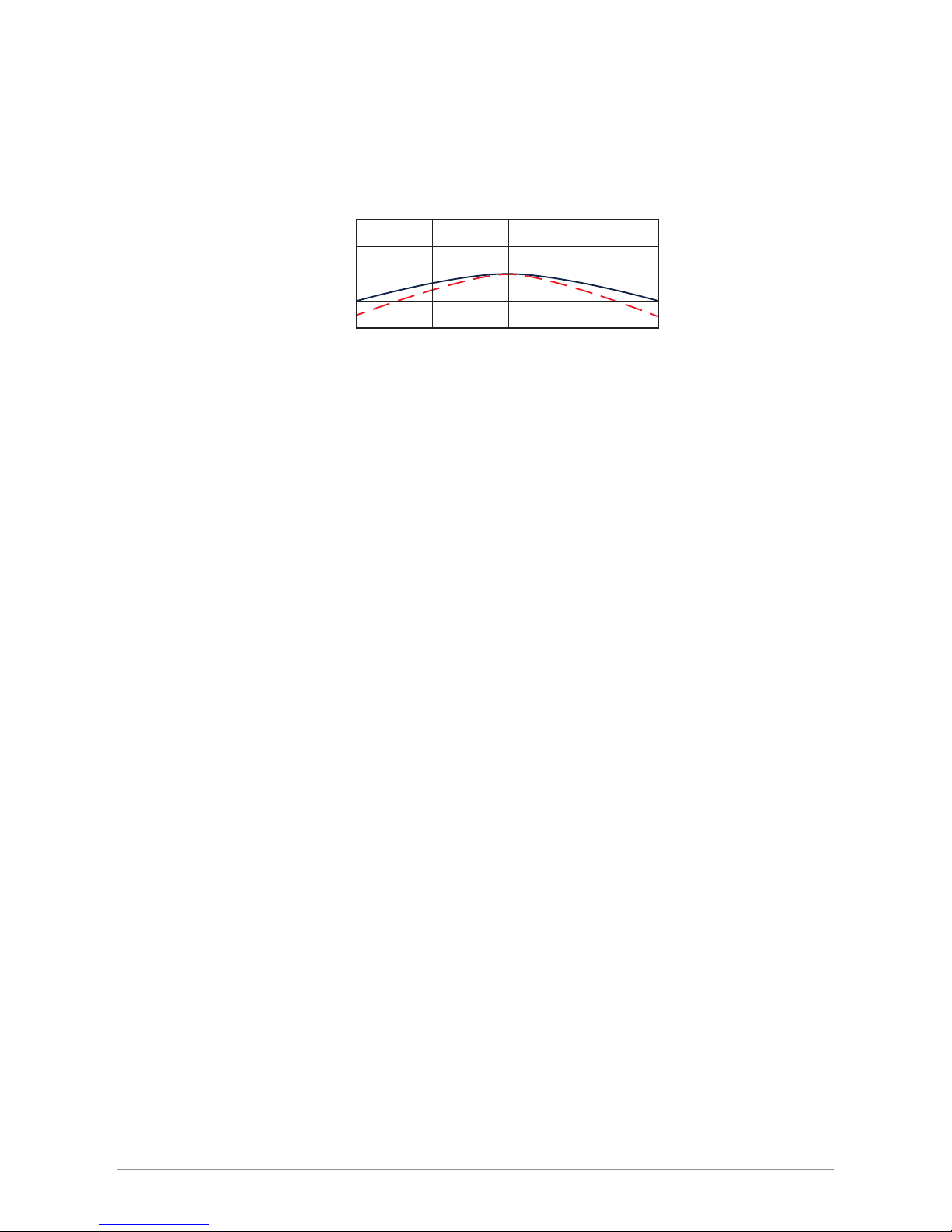

2.4.3 Measurements during a sunny day

The SGR4 differs from all other pyrgeometers in that it allows accurate daytime measurements on sunny days without the need

for a shading device. Due to the unique construction of the SGR4, solar radiation of up to 1000 W/m² induces window heating

of less than 4 W/m² in the overall calculated downward radiation.

Formula 1 can be applied without any problems with the following exception; one must take note of the amount of infrared

radiation in the solar spectrum. The amount of solar infrared radiation depends on many parameters; for example the water vapour

content in the atmosphere (humidity), location of the SGR4 at a certain altitude and the sun’s declination angle. The next graph

indicates the possible infrared radiation in the solar spectrum in the case of low water content in the atmosphere. The amount of

solar infrared detected at the SGR4 (and the SGR3) is expected to be very low (0 to 3 W/m²) because of the filter cut-on at 4.5 µm.

Other types of pyrgeometers can exhibit 0 to 10 W/m².

Direct solar irradiance in Davos, Switzerland at solar noon in mid-September

2.5 Measurement uncertainty

When a pyrgeometer is in operation, the performance of it is correlated to a number of parameters, such as temperature, level of

irradiance, angle of incidence, etc. Normally, the supplied sensitivity figure is used to calculate the irradiances. If the conditions

differ significantly from calibration conditions, uncertainty in the calculated irradiances must be expected.

Kipp & Zonen expects maximum uncertainty below 3% for daily totals for the SGR4 pyrgeometer. This remaining uncertainty can

be reduced further if the sensitivity of the pyrgeometer under the prevailing conditions is used, with corrections calculated

from the effects of parameters such as temperature and non-linearity. This is especially convenient with a programmable data

acquisition system.

Amount of Longwave Radiation in the Solar Spectrum

Wavelenght [µm]

Power [W cm

-2

µm]

(Davos at solar noon, mid of September)

0.00125

0.001

0.00075

0

2.5 5 7.5 10 12.5 15

0.000250.00025

Filter cut-on

20

Page 21

For the SGR4 the effect of each parameter on the sensitivity can be shown separately. The non-linearity error, the sensitivity

variation with irradiance, is the same for any SGR4.

Non-linear sensitivity variation with irradiance of a SGR4 pyrgeometer

2.6 Maintenance

Once installed the pyrgeometer needs little maintenance. The window must be cleaned and inspected regularly, ideally every

morning. On clear windless nights the window temperature of horizontally placed pyrgeometers will decrease, even to the dew point

temperature of the air, due to infrared radiation exchange with the cold sky. (The effective sky temperature can be 30°C lower than

the ground temperature). In this case dew, glazed frost or hoar frost can be precipitated on the top of the window and can stay there

for several hours in the morning. An ice cap on the window is a strong diffuser and increases the pyrgeometer signal drastically, up

to 100% in the first hours after sunrise. Hoar frost disappears due to solar radiation during the morning, but should be wiped of as

soon as possible manually.

The window of the pyrgeometer can be ventilated continuously by a heated blower to keep the window above the dew point

temperature. The need for heating strongly depends upon local climatological circumstances. Generally, heating is advised during

cold seasons when frost and dew can be expected. The Kipp & Zonen CVF4 ventilation unit is specially designed for unattended

operation under most weather conditions and has a choice of heating levels.

Note The SGR3 pyrgeometer can be used with the CVF4 ventilation unit but is less effective.

A periodic check is to ensure that the pyrgeometer is level. The pyrgeometer sensitivity changes with time and with exposure to

radiation. Calibration every two years is advised.

To keep the detector and electronics dry and to prevent condensation forming inside the windows with temperature changes an

internal desiccant is used to absorb humidity within the pyrgeometer and lasts for 10 year. The desiccant will be exchanged when

these instruments comes back to a Kipp & Zonen service location for recalibration.

Horizontal

90 degrees tilt

-250

-1

-0.5

0

0.5

1

0

Irradiance [W/m2]

Non-linearity

Sensitivity variation

[%]

250

21

Page 22

22

Page 23

.

Below is a brief description of the accessories available for SGR series pyrgeometers. Detailed information can be found on our

website, where the brochures and manuals for these accessories can be viewed and downloaded.

3.1 Diffuse radiation measurement

For measuring diffuse radiation a shading device is required. Kipp & Zonen can offer several options for SGR pyrgeometers:

Shadow ring CM121B for a SGR3 or an unventilated SGR4

Shadow ring CM121C for a ventilated SGR4

This shadow ring needs to be adjusted manually every 3-5 days and corrections made for the sky obscuration by the ring.

An automated and more accurate way to measure diffuse radiation is to use an automatic sun tracker fitted with a shading

mechanism:

SOLYS2 sun tracker + shading ball assembly

SOLYS Gear Drive sun tracker + shading ball assembly

3.2 Ventilation

To further improve measurement accuracy of the SGR4 pyrgeometers the CVF4 ventilation unit can be used. CVF4 has a tacho

output to monitor the fan speed and 5 or 10 Watt heater. The advantages of a CVF4 are:

Lower thermal offsets

No precipitation or condensation on the window

Less dirt on the window

Frost, snow or ice can be melted

Less frequent cleaning required

3.3 Mountings

For mounting pyrgeometers the following plates and brackets are available:

Mounting rod for SGR3

CMF1 mounting fixture with rod for mounting one or two unventilated SGR4’s

CMF4 mounting plate with rod for mounting one or two ventilated SGR4’s

CMB1 mounting bracket to fix and adjust a mounting rod to a mast, pole or wall

Adjustable tilt mounting kit allows tilting of a SGR pyrgeometer, It has a clear scale for setting the desired angle.

3.4 Cables

Different cable lenghts with pre-wired waterproof connector plug, or a connector only can be supplied.

10 m cable with connector

25 m cable with connector

50 m cable with connector

Connector only, no cable

3. Accessories

23

Page 24

24

Page 25

25

.

The SmartExplorer software allows you to configure a smart sensor and to collect real-time data. SmartExplorer runs on a PC

with Windows Vista, 7 or 8 and when installing downloads the .NET 4.5 frame work from the Microsoft Server. When using the

software on site, make sure the software is already installed on your laptop.

To connect a smart radiometer to a PC, a RS-485 to USB converter is required. Recommended is using an isolated version like

the ‘USOPTL4’ from B&B for safety and protection of the PC.

• Configuration makes it possible to configure a smart sensor ‘out of the box’ and test the smart sensor before the sensor is used

in an operational network.

• The SmartExplorer software can use a RS-485 to USB or Ethernet interface to connect to a PC

• Collecting data makes it possible to store data from the smart sensor in a comma separated file. The comma separated file is

created at the beginning of every new day or at the beginning of the first day of the week.

• The SmartExplorer software can also be used to monitor and/or log up to 10 instruments simultaneously and works with all

smart radiometers (SMP, SHP, SGR, SUV)

Please check the separate SmartExplorer manual for detailed information about the set-up, monitoring and data logging of the

smart sensors. The latest version of the manual can be downloaded the from the relevant product page under the tab ‘Download’

from our website.

The factory default communication parameters for all Smarts are:

• The factory default Baud rate of a smart sensor is ‘19200 baud’

• The factory default Size and Parity is ‘8 bits - even - 1 stopbit’

• The factory default Modbus® address is 1

4. SmartExplorer software and Modbus® communication

Page 26

26

Page 27

The detector of the Kipp & Zonen SGR series pyrgeometer is based on a passive thermal sensing element called a thermopile.

Although the detector construction differs from model to model, the fundamental working principle is applicable to all SGR series

radiometers.

The thermopile responds to the total power absorbed by the black surface coating, which is a nonspectrally selective paint, and warm

up. The heat generated flows through a thermal resistance to the heat-sink (the pyrgeometer body). The temperature difference

across the thermal resistance of the detector is converted into a voltage as a linear function of the absorbed long-wave irradiance.

The rise of temperature is easily affected by wind, rain and thermal radiation losses to the environment ('cold' sky). Therefore the

detector is shielded by a silicon meniscus window (the entry-level SGR3 has a flat silicon window). To keep the detector and

electronics dry and to prevent condensation forming inside the windows with temperature changes an internal desiccant is used

to absorb humidity within the pyrgeometer.

5.1 Window

The inner surface of the silicon window has an interference filter deposited on it for transmitting the long-wave radiation and

blocking the short-wave solar radiation from reaching the detector. The silicon window material and the deposited ‘solar blind’

filter defines the spectral measurement range of the pyrgeometer.

The silicon window allows transmittance of the atmospheric long-wave radiation up to approximately 42 µm and about 50 to

60% of the radiation spectrum will be transmitted through to the detector. The outer surface of the window has a hard-carbon,

diamond-like layer, deposited as additional protection against environmental influences in harsh environments and to smooth

out the window transmission beyond 30 µm.

The solar blind filter is opaque to radiation below 4.5 µm, known as the cut-on wavelength. Currently most pyrgeometers have

their cut-on at a lower wavelength. Problems may occur in the case of clear sunny days with low humidity. In the solar spectrum

between 2.5 and 4.5 µm there can still be an amount of infrared solar radiation up to 10 W/m², which should not be included in

the measurement. This unwanted fraction is blocked in the SGR4 by the filter coating.

SGR4 uses a specially designed pure silicon window. Although the window is not hemispherical, SGR4 has a 180° field of view

with good cosine response. A big advantage of the meniscus shaped window over the typical hemispherical window is the

ability to deposit more uniform coatings on the window surface. Deposition of a uniform filter coating on a strongly curved

surface is very difficult and unpredictable process. To avoid these problems Kipp & Zonen developed a window with excellent

optical quality due to the optimised shape and coating uniformity.

The solar radiation absorbed by the window is conducted away very effectively by a unique construction in the SGR4. Even in

full sunlight the window heating effect is very low compared to that of other pyrgeometers on the market. This allows accurate

daytime measurements without the need for a shading disk. It also eliminates the need for window heating compensation by

using the correction formula and window temperature sensors.

5.2 Detector

The thermopile sensing element is made up of a large number of thermocouple junction pairs connected electrically in series. The

absorption of thermal radiation by one of the thermocouple junctions, called the active (or ‘hot’) junction, increases its temperature.

The differential temperature between the active junction and a reference (‘cold’) junction kept at a fixed temperature produces an

electromotive force directly proportional to the differential temperature created. This is a thermoelectric effect. The sensitivity of a

pyrgeometer depends on the individual physical properties of the thermopile and construction. The sensitivity of each thermopile

is unique and therefore each radiometer has unique calibration factor, even with the same radiometer model.

5. Principle components of pyrgeometers

27

Page 28

On the top surface of the sensor a black paint is deposited which has a very rough structure containing many micro-cavities that

effectively ‘trap’ more than 95% of the incident radiation in a broad spectral range. Furthermore, the spectral selectivity is less

than 3%. This means that within the spectral range of the pyrgeometer, the absorption for each wavelength is equal to within

3%. The black painted sensing element forms the detector. Considering the long-term stability of the instrument, the black paint

is one of the most crucial and delicate parts of the pyrgeometer. Kipp & Zonen black paint gives the best possible stability over

a long period of time under all meteorological circumstances.

5.3 Temperature sensor

The housing temperature sensor is a crucial part of a pyrgeometer and is needed to calculate the downward long-wave radiation

component. The body temperature sensor represents the ‘absolute’ temperature of the detector surface and therefore it is

mounted close to the cold junctions of the detector. A housing temperature sensor is fitted as standard to the SGR pyrgeometers.

5.4 Housing

The radiometer housing accommodates all fundamental pygeometer parts. The anodized Aluminium parts are light weight and

give a high mechanical and thermal stability to the instrument. Due to its fine mechanical construction all pyrgeometers are

virtually sealed and comply to the international standard IP 67. Each pyrgeometer model can be leveled by using the bubble

level and two leveling feet. For ease of maintenance the bubble level is situated next to the window of the instrument and due

to the special shape of the sun shield it is visible from above. The sun shield acts to protects all the external parts from radiation

and to reduce solar heating of the housing.

5.5 Cable and connector

For ease of installation and replacement during recalibration of the radiometer, the SGR series are provided with a weather

proof signal cable connector.

Kipp & Zonen radiometers use a custom-made cable that is selected with a high UV resistance and low electrical resistance.

The shield of the cable is connected to the metal body of the connector and preferably should be connected to ground at the

readout equipment. Cables come pre-wired to the connector plug in a range of lengths.

28

Page 29

6.1 Spectral range

The spectral properties of the pyrgeometer are mainly determined by the filter characteristics of the silicon window and the

coatings. The application is primarily to measure long-wave downward atmospheric radiation. The spectral range is from 4.5 to

42 µm, where most of this radiation is present.

Pyrgeometer spectral window properties

The atmosphere is transparent to long-wave radiation emitted by the Earth’s surface in certain wavelength intervals, particularly

within a spectral range of approximately 8 to 14 µm. This is called the ‘atmospheric window’. Within this spectral range the Earth

is able to maintain an equilibrium temperature by losing a certain quantity of heat gained each day from the sun.

The sun radiates approximately as a blackbody at an equivalent temperature of 5770K. Almost 99% of its emitted energy is

contained in wavelengths less than 4µm, called short-wave radiation. The equivalent radiant temperature of the Earth’s surface

is about 275K. More than 99% of this energy is emitted at wavelengths greater than 3 µm and is called long-wave, thermal, or

infrared radiation.

Downward long-wave radiation is a result of atmospheric re-emission. Re-emission is the reversible effect of absorption of

long-wave radiation emitted by the Earth and by chemical elements such as water (H₂O), Oxygen (O₂), Ozone (O₃), Carbon

dioxide (CO₂), etc. These elements are the main emitters of long-wave radiation in the atmosphere. The remaining unabsorbed

portion of the Earth’s radiation escapes into outer space. Under clear skies an object can be cooled below ambient air tempera-

ture by radiative heat loss to the sky.

Observing the earth from outer space, a blackbody is seen in a range of 8 to 14 µm with a temperature of 14 °C and outside this

wavelength range a blackbody of -60°C. Under clear sky conditions in a reverse direction, outer space can be observed in the

same spectral range.

Atmospheric radiation

6.2 Sensitivity

The radiometer thermopile sensitivity is mainly determined by the physical properties of the detector itself. The thermoelectric

power, thermal conductivity of the junctions and the overall dimensions of the sensing element are related to its sensitivity.

6. Pyrgeometer physical properties

Wavelenght [µm]

Transmittance [%]

100

50

0

1 10 100

SGR4 window transmittance

Amplitude

Wavelength [µm]

5

75°

60°

0°

90°

0

5 10 15 20 25

29

Page 30

6.3 Response time

Any measuring device requires a certain time to react to a change in the parameter being measured. The radiometer requires

time to respond to change in the incident radiation. The response time is normally quoted as the time for the output to reach

95% (sometimes 63%) of the final value following a step-change in irradiance. It is determined by the physical properties of the

thermopile and the radiometer construction. SGR series pyrgeometers have a fast response, which makes them suitable for

measuring far infrared radiation (FIR) under variable weather conditions.

6.4 Non-linearity

The non-linearity of a pyrgeometer is the percentage deviation in the sensitivity over a net irradiance range from -250 to +250 W/m²

compared to the sensitivity calibration irradiance of -100 W/m². The non-linearity effect is due to convective and radiative heat

losses at the black absorber surface which make the conditional thermal equilibrium of the radiometer non-linear.

6.5 Temperature dependence

The sensitivity change of the pyrgeometer with ambient temperature is related to the thermodynamics of the radiometer

construction. For the SGR3 this dependency is measured for a large series of instruments and the average dependency is corrected

by the Smart Interface. This gives the SGR3 a better temperature performance than the CGR3.

For every SGR4 the temperature dependency is individually measured and corrected. This correction is over a range of -40 to +70°C.

The corrected value is available via the analogue and digital outputs.

6.6 Tilt error

This is the deviation from the sensitivity at 0° tilt (exactly horizontal) over the range from 0° to 90° tilt. The tilt response is

proportional to the incident radiation. The error could be corrected for, in applications where it is necessary to install the

pyrgeometer on an inclined surface, but is usually insignificant.

6.7 Window heating oset

Currently the major source of error concerning common pyrgeometer measurements is caused by the so-called ‘window heating

offset’. When a pyrgeometer is exposed to the sun, heating of the silicon window occurs due to absorption of solar radiation by the

material. As a consequence the window of most types of pyrgeometer will heat up proportionally to the solar irradiance.

The resulting temperature difference between window and thermopile will cause heat transfer by radiation and convection to the

sensor. This affects the net thermal radiation as measured by the thermopile and is commonly referred to as the ‘window heating

offset’. The result is measurement of a too high value for downward long-wave radiation.

This offset is not easily reduced by ventilation, which only cools off 50 W/m²/°C at maximum while solar radiation can be