Page 1

LOGBOX SD

Datalogger

Instruction Manual

Page 2

2

DECLARATION OF CONFORMITY

Manufacturer:

Kipp & Zonen B.V.

Delftechpark 36

2628 XH Delft

the Netherlands

T +31 15 2755 210

F +31 15 2620 351

info@kippzonen.com

http://www.kippzonen.com

Description of the product:

Ultra-low power data logger

Type:

LOGBOX SD

The indicated product corresponds to the regulation of the following European Directives:

204/108/EEC

This is provided by the compliance with the following standards:

EN 61000-6-3, EN 61000-6-2, EN61000-4-6, EN 61000-4-4, EN 61000-4-2.

Date:

11.1.2008

Issued by:

B.A.H. Dieterink

President

KIPP & ZONEN B.V.

Page 3

3

TABLE OF CONTENTS

DECLARATION OF CONFORMITY ...................................................................................................................................... 2

!

LOGBOX SD ................................................................................................................................................................................ 2!

TABLE OF CONTENTS ............................................................................................................................................................ 3!

1! NOTES .................................................................................................................................................................................. 4!

2! WARRANTY AND LIABILITY ........................................................................................................................................ 5!

3! INTRODUCTION ............................................................................................................................................................... 6!

4! SPECIFICATIONS .............................................................................................................................................................. 7!

5! OVERVIEW .......................................................................................................................................................................... 8!

6! HARDWARE ....................................................................................................................................................................... 9!

7! QUICK START ................................................................................................................................................................ 13!

8! CONNECTING MULTIPLE SENSORS DIFFERENTIAL ........................................................................................ 15!

9! CONNECTING A PT-100 ............................................................................................................................................. 16!

10! CONNECTING A THERMISTOR. ......................................................................................................................... 17!

11! PC CONFIGURATION SOFTWARE ..................................................................................................................... 18!

11.1! Toolbar ............................................................................................................................... 19!

11.2! Sensor configuration. (Analog) ............................................................................................ 20!

11.3! Polynomial section. ............................................................................................................. 22!

11.4! Baud rate settings. .............................................................................................................. 23!

11.5! Logging options. ................................................................................................................. 24!

11.6! Sensor configuration. (Digital) ............................................................................................. 25!

11.7! Writing options to memory card. ......................................................................................... 26!

11.8! Sending or reading the entire configuration. ....................................................................... 27!

11.9! Downloading logdata. ......................................................................................................... 28!

12! POLYNOMIALS CALCULATION FOR SENSORS ............................................................................................ 31!

13! POLYNOMIALS CALCULATION FOR PT100 AND THERMISTOR .......................................................... 32!

14! FIRMWARE ................................................................................................................................................................. 39!

15! SERVICE MODE ........................................................................................................................................................ 40!

16! APPLICATION EXAMPLES .................................................................................................................................... 47!

17! FAQ .............................................................................................................................................................................. 49!

Page 4

4

1 NOTES

Reading this entire manual is recommended for a full understanding of this product.

The exclamation mark within an equilateral triangle is intended to alert the user to the

presence of important operating and maintenance instructions in the literature

accompanying the instrument.

KIPP & ZONEN reserve the right to make changes in the specifications without prior notice.

Page 5

5

2 WARRANTY AND LIABILITY

KIPP & ZONEN guarantees that the product delivered has been thoroughly tested to ensure

that it meets its published specifications. The warranty included in the conditions of delivery

is valid only if the product has been installed and used according to the instructions

supplied by KIPP & ZONEN. This product is under warranty for 24 months from the date of

purchase.

Modifications made by the customer or on customer request can affect the validity of the CE

declaration.

KIPP & ZONEN shall in no event be liable for incidental or consequential damages, including

without limitation, lost profits, loss of income, loss of business opportunities, loss of use

and other related exposures, however caused, arising from the faulty and incorrect use of

the product.

COPYRIGHT 2008 KIPP & ZONEN

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system or transmitted in any form or by any means, without permission in written form from

the company.

In the case you have questions, comments or need technical support, please contact us at

the following address:

Kipp & Zonen B.V.

Delftechpark 36

2628 XH Delft

the Netherlands

T +31 15 2755 234

F +31 15 2620 351

support@kippzonen.com

www.kippzonen.com

Note: in case technical support is required please add the configuration file of the

Software interface, the log files in TXT or XLS format, add the serial number of the

Logbox SD, and please describe your inquiry in as much detail as possible.

Version: 1012

Page 6

6

3 INTRODUCTION

LOGBOX SD is a data logger for slow varying signals and accepts low voltage signals. It

features low noise, high resolution and low power consumption.

LOGBOX SD is a universal data logger, configurable by software, suitable for mobile as well

as permanent installation used in laboratory and in the field. It can be used under all

weather conditions. A mounting plate for installation on a mast is provided.

The LOGBOX SD was designed with the above criteria in mind. Employing latest high

technology we are proud to present you a measuring system, which is simple in use, offers

high precision measurement and all features which are expected from today’s data loggers.

It is configurable by the user by PC configuration software or a set of simple serial

commands. The applications range from meteorology, metrology, environmental monitoring,

industry, research, at schools and laboratory.

Page 7

7

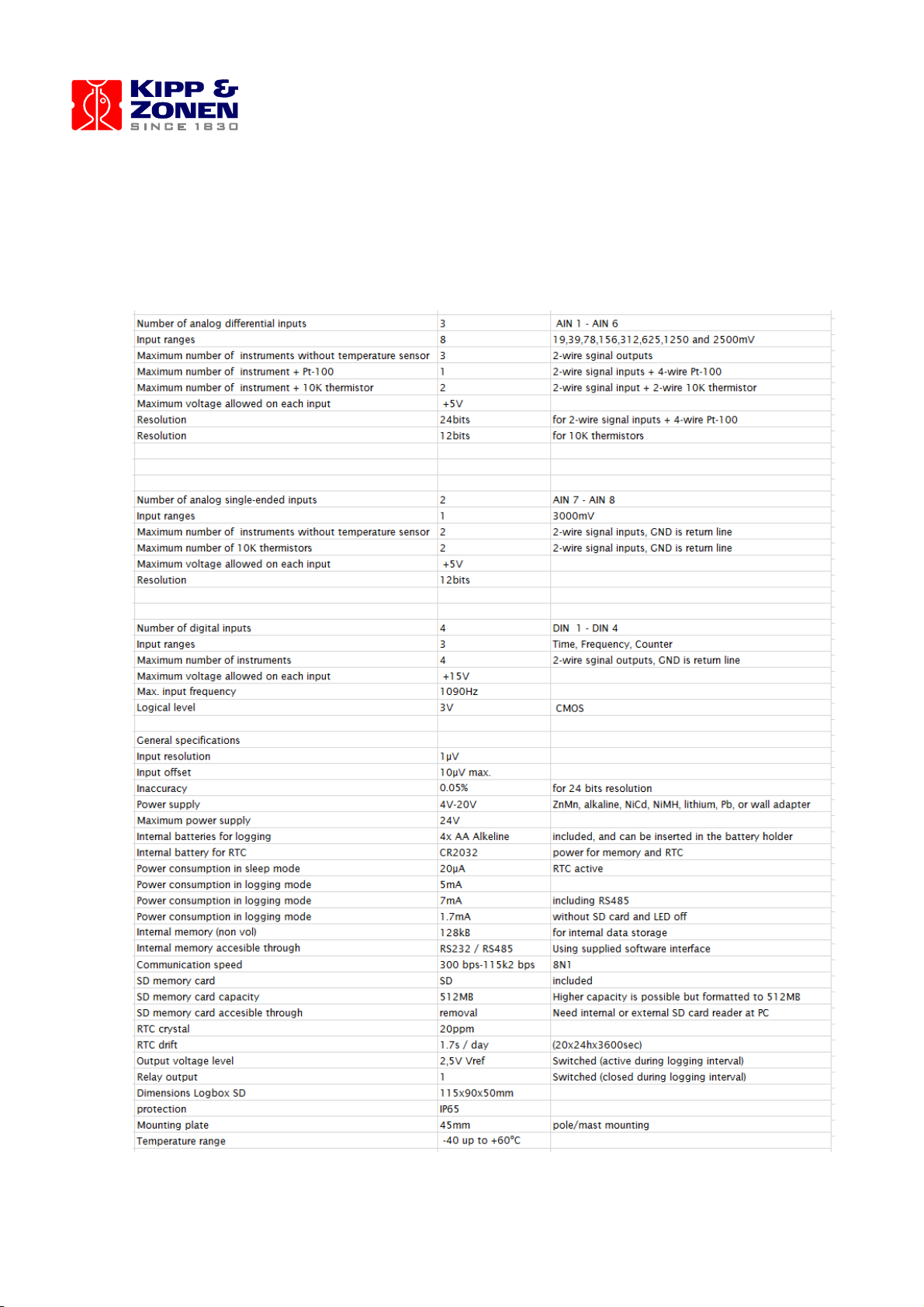

4 SPECIFICATIONS

Page 8

8

5 OVERVIEW

LOGBOX SD is designed for measuring, processing, recording (data logging) of measured

data in real time for the needs of meteorology and slow signals analyses.

It employs eight analogue inputs, which can be configured by software as unipolar inputs

with 12 bits resolution or as unipolar/bipolar differential inputs with 24 bit resolution.

With definition of polynomial coefficients (of the 3-rd order) measured values are converted

to engineering units.

Four digital inputs are configurable by software for measuring frequency, time (logical level)

or as counters. Again, with definition of polynomial coefficients (of the 3-rd order) the

measured values are converted to engineering units.

For data logging 128kB of memory is available. This EEPROM type memory will keep data

even after total disconnection of the battery. Additionally, user can insert the SD memory

card for long time data storage. Hardware and software support for temperature sensors like

PT100 and thermistor are provided.

For communication the LOGBOX SD uses either RS232 or RS485 communication port.

Selection is made by the jumper on the board. Supported communication speeds are in the

range from 300bps up to 115200bps.

The Real Time Clock circuit keep track of time and date. There is lithium battery of standard

size and with ultra low power design. Operational life is more than 10000 hours.

For signalling and switching external devices the LOGBOX SD has built-in relay ports capable

to handle currents up to 300mA and voltages up to 60Vdc

Additionally a reference voltage of 2.5Vdc is available.

Page 9

9

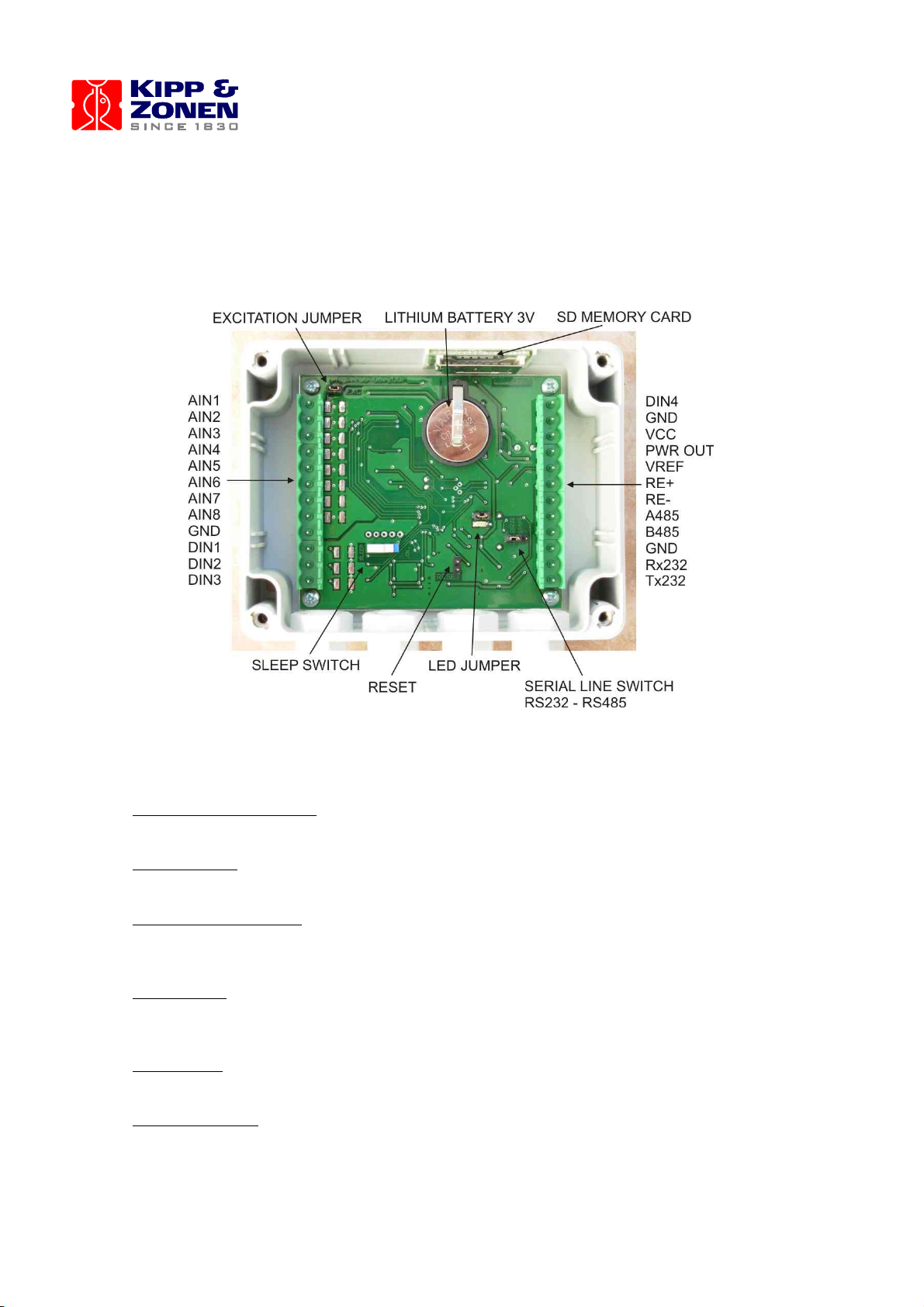

6 HARDWARE

Mechanical solution of LOGBOX SD is based on single board design with minimal

dimensions and weight.

Fi

Outer dimensions 115mm (width), 90mm (height) a 50mm (depth) makes it suitable for

mobile applications, too. Connectors inside are located on left and right side, from the

bottom there are inputs for sensor cables. Thanks to clear layout the user can easily

connect relatively large number of sensors. For better access to input connections,

connectors are divided by three.

The mounting plate can be used to connect the LOGBOX SD to a mast of 40 mm or

smaller. Unused cable glands are closed with an inside plug. The user can mount extra

cable glands to support more cable entries.

Page 10

10

For permanent installation it is possible to use four screws M4 for fixing, while achieving

IP65 class protection.

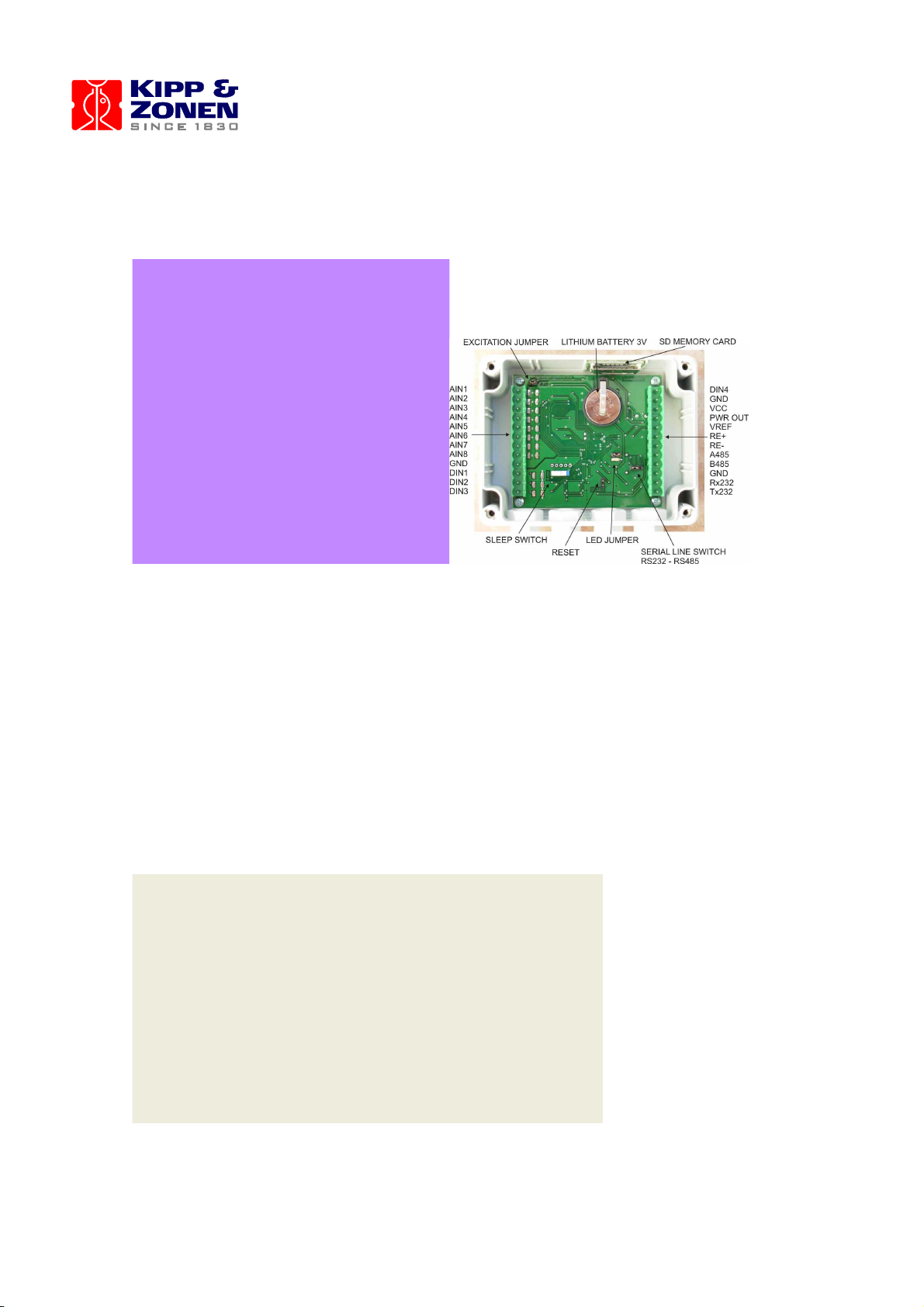

Fig.8 Inside view – description of connectors

LOGBOX SD board has the following components:

Lithium battery, CR2032 - It is power supply reserved for real time clock.

During normal operation the RTC is powered by the available power supply.

Jumper RESET – by shorting the jumper you will reset the instrument. It is not necessary to

use it by the user – it is reserved for production purposes.

Selector of serial line – selects one of RS232 or RS485 by jumper. Output pins on the

connector on the right side are following: RS232 include signals RX, TX and GND.

RS485 include signals A and B.

SLEEP switch – small switch for turning LOGBOX SD to transport mode (sleep except real time

clock). It is used for exchanging the SD card, during transportation for saving main battery

or when data logger is not used.

EXC jumper – this jumper serves as excitation for PT100 sensors. It is connected with a

6.8kohm resistor from power supply to AIN1. If PT100 is not used, do not connect it.

SD memory card – any SD memory card larger than 128MB can be used. If the card is more

than 512MB, LOGBOX SD will format the card for maximum of 512MB. The card is used only

for data storage and is not intended for more manipulation (deleting or other operations).

Deleting and moving files are much faster on a PC computer.

When using the SD card the logging to memory should be set to Circular. Otherwise the

logging stops after the (internal memory is full.

Page 11

11

Connector for main battery – the user can connect any type of battery (ZnMn, alkaline, NiCd,

NiMH, lithium, Pb accu, solar panel, mains adapter) with output voltage in the range of 4Vdc

– 20Vdc.

LED jumper – when jumper is closed, LED diode will indicate the operation. For maximum

power savings open the jumper. The LED indicates also when communication with SD card

can be performed. So, if LED is on, do not manipulate (remove or insert) SD card.

Otherwise, data could be either lost or partially damaged.

If the SD card is not used it should be removed to extend battery life.

Relay output RE+ and RE- – this is optically isolated polarized solid relay output, primary

used for switching external devices. These contacts can be used for switching power

supplies for external sensors that do not share a common ground with the LOGBOX SD.

The relay contacts are normally open and close during measurement interval. The LOGBOX

SD then takes after the programmed delay a measurement. After that the relay opens again

to switch off the sensor and limit the power consumption.

The relay can handle 60 VDC @ 300 mA.

PWR OUT output – switched battery output for powering local sensors or instruments.

VREF output – switched reference voltage of 2.5V for bridge or similar instruments.

The instrument is mounted in a plastic enclosure (IP65 protection class) allowing outdoor

installations. For smaller measuring systems it is possible to use 4 pieces of AA battery

(mignon) inside the battery compartment which is attached to the lid of the enclosure. This

results in a compact and portable solution of the LOGBOX SD.

The electronic design of the LOGBOX SD allows precision measurements with high

resolution. For this purpose it is equipped with two types of analog to digital converters.

They differ in resolution (12 bits or 24 bits), configuration options, speed of conversion and

applications for which they are used. Inputs for both converters are physically the same and

are configured by the software. It is possible to setup 8 unipolar inputs or 3 differential

inputs and 2 unipolar inputs or combinations.

Data logger has one ground potential (referenced to power supply GND. There are three

connectors with GND potential – all are internally connected and allow comfortable

connection of battery, RS232 serial line and analog and digital inputs.

For setting up configuration of analog inputs there are few basic rules.

The highest priority is for 24 bits differential measurements, then 12 bit single ended

measurements. Depending on priority it is necessary to configure analog inputs from AIN1

to AIN8. Practically it means that if the user wants to measure differential signal with 24 bits

resolution, this input must be located on AIN1, AIN2 (pair). If the user wants to measure two

differential inputs, they must be located on AIN1, AIN2 and AIN3, AIN4 (pairs). Only after the

differential inputs there can be single ended 12 bit resolution inputs (if any).

Digital inputs can be configured for measuring frequency, time (when digital input is in high

logical state) or as a counter. After defining polynomial coefficients of the 3-rd order it is

converted to engineering units. The advantage is that measuring of digital inputs is active

also during sleep time (during whole period of logging). That means if logging is configured

every minute, frequency represents mean value over one minute. If it is configured as

counter, it will measure number of counts per one minute and if it is configured for time

measurement, it represents number of seconds when input was in logical high level over one

minute. The same applies to all logging intervals over one minute.

With logging intervals of 10s, 20s and 30s only counter and time options are available.

Page 12

12

When long time data recording is required, it is possible to use the SD memory card.

LOGBOX SD can accept any memory size above 128MB. After inserting the card in the data

logger, processor checks size of the card and proper formatting. If necessary, LOGBOX SD

will format the card (its own format) and starts to write data to SD memory card. If the user

wants to remove the card, it is recommended to put the data logger to sleep mode first

and wait until indication LED turns off. Then the file is correctly closed and the card can

be removed. It is possible to read it directly in your card reader in the PC. In the case the

user will remove the card during run mode (but LED must be off), files on the card will

remain, but the last file will be not correctly closed but still readable on the PC.

The whole design is oriented to ultra-low power consumption (design of power management

circuitry). During logging interval (which can be selected from 10 seconds to 60 minutes) it

is necessary to switch the instrument to sleep mode when measurements are not active. This

way it maximizes battery life. Power consumption during measurement is less than 5mA, in

the sleep mode it is about 20uA (without SD card). This periodical switching is performed by

the power management circuitry itself and user does not need to care for it. Measuring on

digital inputs is active during all the time.

As many sensors have a start up-time after power on, it is necessary to make measurements

after their outputs are fully settled. The delay has to be adjusted to the slowest sensor. This

feature is included in LOGBOX SD. The delay parameter sets the time after power up from

sleep mode to actual measurements. It can be in the range from 0 to 9 seconds. There is

built in solid state relay and battery switch for switching power to the sensors. No other

switching devices are necessary.

For the real time circuit there is a separate clock battery. It is a lithium battery with 3V

nominal voltage, type CR2032. Exchange is simple for the user. After change of the battery,

it is necessary to readjust time and date.

LOGBOX SD is working in three basic modes: measuring, sleep and transport. During

measuring period all components are active; all measurements based on actual configuration

are performed, measured values are converted to engineering units. Then record of output

values is stored in the memory and SD card and data are sent to the serial line (both RS232

and RS485). Finally, LOGBOX SD goes to sleep mode.

In sleep mode there is activity only in real time circuit, digital inputs measurements and

serial line (RS232) input. This situation lasts for the whole logging period. During sleep

mode it is also possible to switch to service mode (to setup configuration). After pressing

CTRL+BREAK once (on PC in terminal mode) it is activated. Escape back to sleep mode is

done with the Q command.

Transport mode is equivalent to switch off. It is intended for use during transport or long

time storage. During this period only real time (clock) circuitry runs and all other parts are

not functional. In transport mode it is necessary to remove SD card for power saving.

Page 13

13

7 QUICK START

LOGBOX SD is supplied ready for use. After unpacking it is necessary to open the case with

four screws.

After removing the cover switch the instrument from transport mode to measuring mode by

switch (from position SLEEP to position ON).

Now connect main battery to power terminals. Battery must be in the range 4...20Vdc.

For power supply there is holder for four AA type batteries. You can use them, or use

different appropriate (external) power supply.

Page 14

14

Last step is to connect the (supplied) serial cable RS232 with the computer. The LOGBOX SD

software can be used to setup the logger and related sensors. Or setup your communication

software on your computer (e.i. HyperTerminal) for standard speed 115200bps, 8 data bits,

1 stop bit, parity none and handshaking none. Then you will see measured data from

LOGBOX SD.

LOGBOX SD is ready to operate. Depending on saved configuration LOGBOX SD performs

measurement, logging and printout of measured data on serial line, which can be seen on

the computer. Setting up the hardware and software configuration is described in the

next chapters.

Page 15

15

8 CONNECTING MULTIPLE SENSORS DIFFERENTIAL

This configuration allows you to connect up to 3 sensors on the analog input 1-6 which have

an output up to 2500mV.

-AIN1 & AIN2 (first sensor)

-AIN3 & AIN4 (second sensor)

-AIN5 & AIN6 (third sensor)

And it’s possible to connect up to two sensors on the analog inputs 7 and 8 which have an

output up to 3000mV. (Only 12 bits, 3V range)

-AIN7 & GND

-AIN8 & GND

Please note that AIN7 and AIN8 can only be used to connect sensors which have a slightly

higher voltage output up to 3Vdc (Like our UVS sensors) or for 10K thermistors.

How to configure the software will be explained in chapter 14

Page 16

16

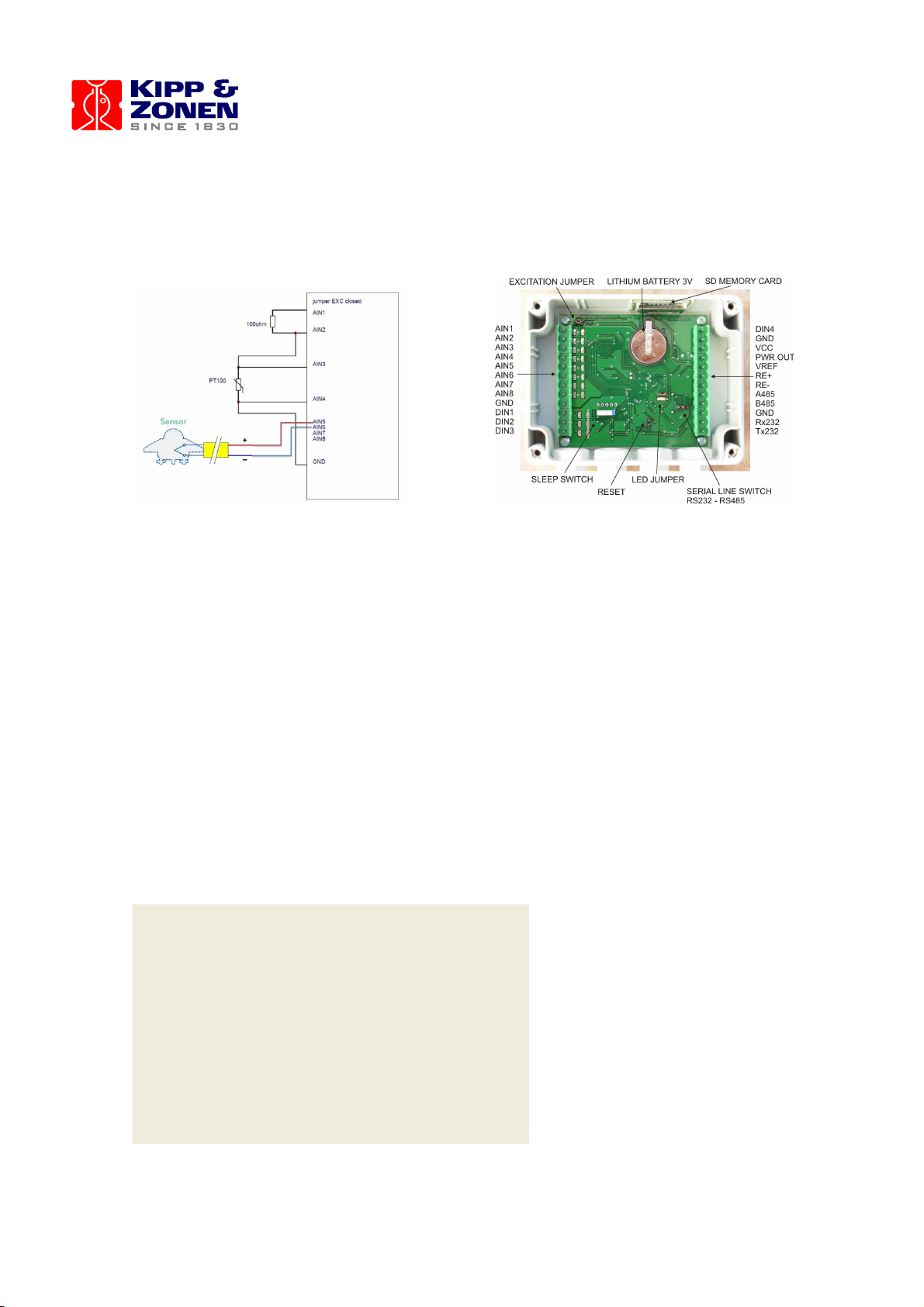

9 CONNECTING A PT-100

This configuration allows you to connect up to one PT100 temperature sensors:

-AIN1 & AIN2 (100R reference resistor)

-AIN3 & AIN4 (current)

-AIN2 & GND (measuring PT100)

Besides the Pt-100 it’s possible to connect up to one sensor on the analog input which has

an output up to 2500mV between AIN 5 and AIN 6.

-AIN5 & AIN6 (only sensor)

And it’s possible to connect up to two sensors on the analog inputs 7 and 8 which have an

output up to 3000mV. (Only 12 bits, 3V range)

-AIN7 & GND

-AIN8 & GND

Please note that AIN7 and AIN8 can only be used to connect sensors which have a slightly

higher voltage output up to 3Vdc (Like our UVS sensors) or for 10K thermistors.

How to configure the software will be explained in chapter 11

Page 17

17

10 CONNECTING A THERMISTOR.

In the above illustration one 10K thermistor is connector to AIN 6 but in practice it can be

connected to any of the eight analog inputs.

-VREF & AINx (measuring 10k thermistor)

-AINx & GND (10k reference resistor)

It`s common for a Pyrgeometer or Pyranometer to have one 10K thermistor.

So two of these instruments in total can be connected

-AIN1 & AIN2 (first sensor)

-AIN3 & AIN4 (second sensor)

-AIN 5 (first 10K thermistor)

-Ain 6 (second 10K thermistor)

And it’s possible to connect up to two sensors on the analog inputs 7 and 8 which have an

output up to 3000mV. (Only 12 bits, 3V range)

-AIN7 & GND

-AIN8 & GND

Please note that AIN7 and AIN8 can only be used to connect sensors which have a slightly

higher voltage output up to 3Vdc (Like our UVS sensors) or for 10K thermistors.

How to configure the software will be explained in chapter 11

Page 18

18

11 PC CONFIGURATION SOFTWARE

The PC Configuration software is designed for easy set up of the LOGBOX SD for the used

radiometers or sensors. It is very intuitive in use and a full configuration can be made in

just a few minutes. The LOGBOX SD software is a simple executable file, without the need

for further installation. It is compatible with Win9x, Win2000 and WinXP operating

systems.

First of all it is necessary to copy LOGBOX SD.exe and sensor.ini files to your computer.

Open the supplied CD in a window. Select both files (LOGBOX SD.exe and sensor.ini).

Select the directory on your local computer where you want to store LOGBOX SD files and

copy them there. There is no need for further installation. For maximum comfort it is

possible to create shortcut on your desktop.

After starting the software, following window will appear.

1: Toolbar.

2: Sensor configuration. (Analog)

3: Polynomial section.

4: Bit rate settings.

5: Logging options.

6: Sensor configuration. (Digital)

7: Writing options to memory card.

8: Sending or reading the entire configuration.

Page 19

19

11.1 Toolbar

The top menu offers the following:

In this menu you can create new configurations (New) and save them (Save As…), or you can

open existing configuration (Open…). Last four configurations are directly accessible. With

Exit you will close the application.

Edit menu will allow to perform undo command, which is usable during creating or

modifying the configuration.

The View menu offers turn on or off toolbar and status bars. Then, there are two basic

windows: Config Sensor window and Download data window.

The Setup menu will allows to select the serial port on your computer (COM1 to COM10).

Then you can select output file for download (either .txt file or .xls file). For .txt files you

can select the separation character (space, tab or comma). It is mostly used for

customizing output files. In the event you need to suppress unused channels from the

LOGBOX SD, you can do this by activating the Suppress unused channels option.

New , open , save , undo , configuration area , download area

Page 20

20

11.2 Sensor configuration. (Analog)

In the first window [Analog] you can select all parameters of the analog inputs. The program

has incorporated basic control over resolution rules for inputs, described in hardware

section. Analog input, which should be logged, must be checked.

Second item is for user predefined sensors. Sensor description is included in sensor.ini file,

with strictly defined syntax. Because not every sensor can be connected to any input read

the manual for more explanation.

Important: when selecting a pre-defined sensor from the list, all remaining parameters

are automatically selected.

Next parameter is type of connection. You can select single ended or differential. In the case

of differential measurement software will automatically disable the following channel

(differential input needs two physical channels, see examples in chapter 8)

Page 21

21

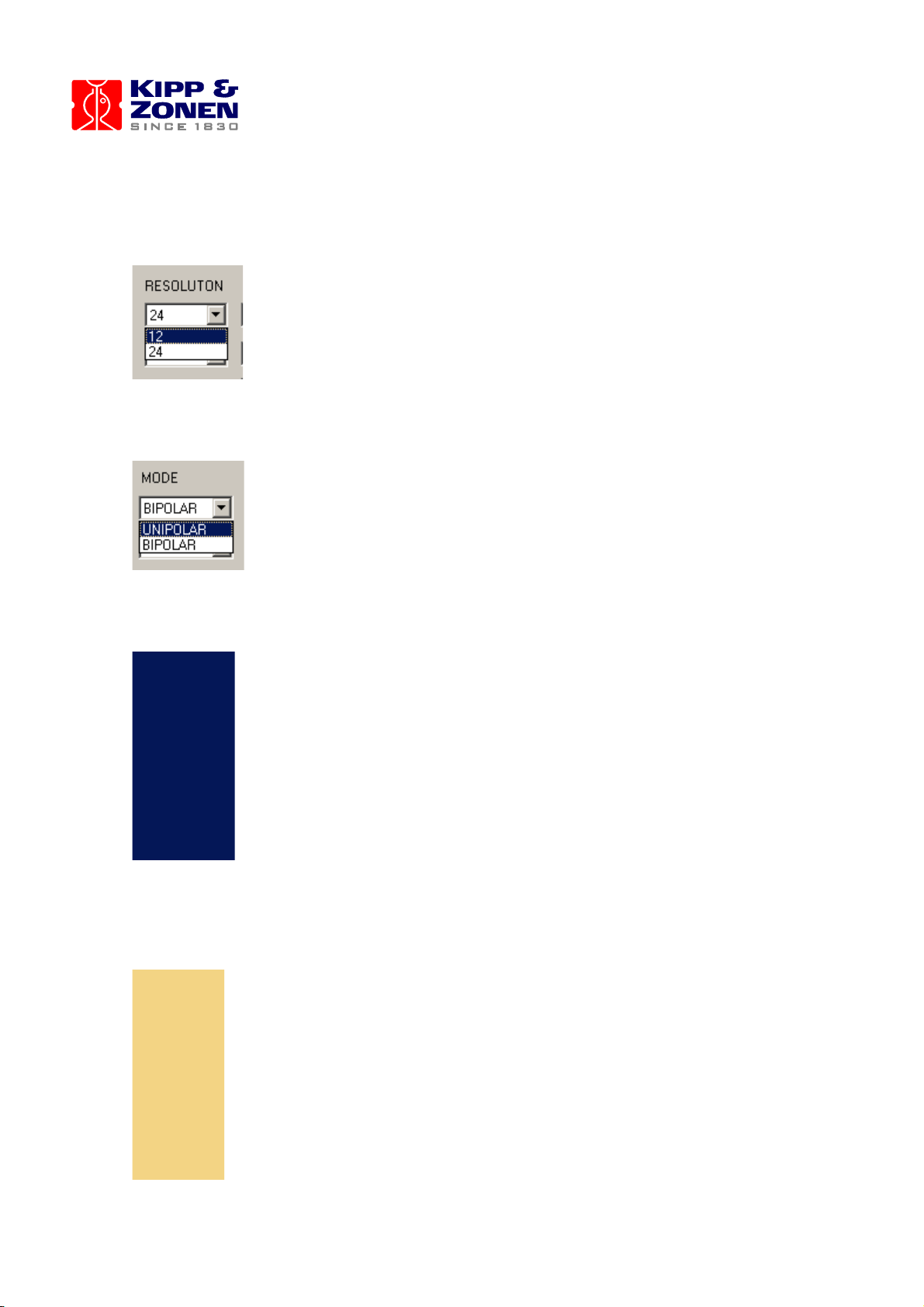

Resolution can be set for 12 or 24 bits. 24bits resolution is used for low level signals. This

type of measurements takes longer time (approximately 1 second per measurement).

Input mode can be selected to unipolar or bipolar. Bipolar mode is mostly selected for 24 bit

differential resolution.

Input voltage range is selected for 24 bit resolution only and can be selected from one of

eight available ranges.

For each input one of eight polynomials can be selected for calculation to engineering units.

None can be selected as well. Please, note that eight polynomials are common for all analog

and digital units.

Page 22

22

Last parameter for analog inputs is the ratio. Ratio is only checked for appropriate analog

input. Ratio is used primary for PT100 measurement. If ratio is selected, it‘s output value is

calculated as ratio of selected analog input voltage measured to analog input 1 voltage

input. Only then polynomial calculation is applied. Ratio option is available for two analog

inputs only.

Analog inputs 7 and 8 can only be setup for single ended, 12 bit resolution, unipolar input,

and 3000mV range only. Polynomial coefficients are available.

11.3 Polynomial section.

The coefficients window shows all set polynomials. For enabling any of the polynomial

coefficients, it must be checked in enable check box. When selecting a PT100 or Thermistor

the polynomial coefficients are automatically entered in this box.

Important: There are additional chapters, 12 and 13, which explains how to enter your

own polynomials for the sensors (Sensitivity depended) and for usage of a different

PT100 or Thermistor.

Page 23

23

11.4 Baud rate settings.

Next window is for serial line speed setup. Speed can be selected from the range 300bps up

to 115200bps. Please, note that 8 bit, no parity, 1 stop bit and no hardware control is used.

Serial line speed applies only to serial line during measurement. If you will go to service

mode, 115200bps is set automatically.

Page 24

24

11.5 Logging options.

In the logging window the logging period can be selected in the range of 10 seconds up to

1hour.

Sensor start-up delay can be selected in the range from 0 seconds up to 9 seconds.

Memory management (for the internal memory of 128 kB) has the following options: circular

(after the memory is full, the oldest data will be over written) or on-stop (after all memory is

used, new data will no longer be stored in memory, even though the measurements will be

performed). Important: When using the SD card the logging to memory should be set to

Circular. Otherwise the logging stops after the (internal) memory is full.

Page 25

25

11.6 Sensor configuration. (Digital)

In the Digital window you can enable and configure the parameters for the digital inputs.

The Digital input, which should be active, must be checked.

Important: The CSD 3 sunshine duration output can only be used on DIN3.

Next, it is possible to setup type of input measured (time, frequency or counter).

For each input one of eight polynomials can be selected for calculation to engineering units.

None can be selected as well. Please, note that eight polynomials are common for all analog

and digital units.

Page 26

26

11.7 Writing options to memory card.

For SD memory card there is one more window. If you want to use SD card for data storage it

is necessary to check Use SD Card box. Otherwise, data logger will not communicate with SD

card. This option is usable when the user has no SD card or wants to use data logger only

for short time logging and need faster response from data logger.

Important: When using the SD card the “logging to memory” should be set to Circular.

Otherwise the logging stops after the (internal) memory is full.

Physical writing period to SD card is selectable. Reasonable time is 1 minute for 10 second

logging interval or 1 hour for longer than 1 minute logging interval. The logging file is not

closed after the write interval to allow more data to be added in the same file.

Finally, it is necessary to setup file closing interval. Most usable interval is 24 hours, which

generates one file per day. This will close the current file and start a new one.

Page 27

27

11.8 Sending or reading the entire configuration.

Additionally, there are two buttons. First one is used for read configuration from LOGBOX SD

data logger. It is especially valuable if you have lost your configuration files or if you have

LOGBOX SD with unknown configuration. Send Config is used to setup the LOGBOX SD with

the currently entered and on screen displayed configuration.

Page 28

28

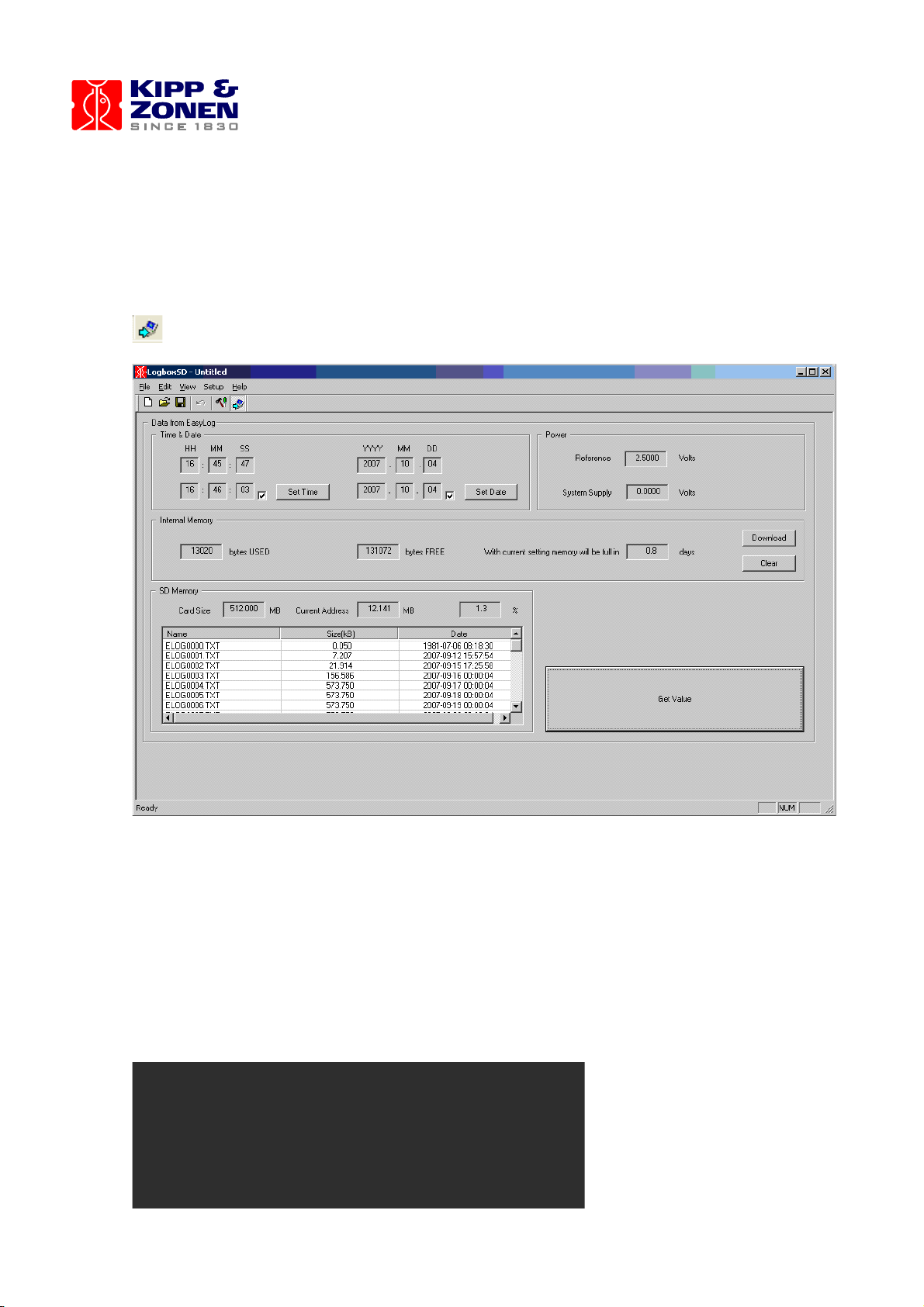

11.9 Downloading logdata.

The Download screen can be accessed by View/Download Data menu or by clicking on the

icon.

This screen is divided into four windows.

-Time & Date

-Internal Memory

-Power

-SD Memory.

Power window shows reference voltage setup in LOGBOX SD. This value is read from data

logger and updates when the “Get Values” button is clicked.

The “system supply” is an internal electronic feature which is not relevant for users of the

Logbox SD.

Page 29

29

The Internal Memory window shows (after Get Values command) the actual value of the used

and free memory. Also, automatically it is calculated how much time it will take to fill the

internal memory with the current configuration. The total logging time to fill internal

memory depends on how many channels are logged and the logging interval.

Also, there is a download button, which will start downloading the measured data from

internal memory of LOGBOX SD. First it will ask for file type and location for saving.

Page 30

30

During download, there is progress bar indicating actual status of download.

Time & Date window shows actual setup of LOGBOX SD (after Get Value command) or the

user can setup individually time and date. If Windows system time and date is used, check

the option.

The Last window shows files stored on SD memory card. It is updated only after Get Values

command. In this window user can see the card size, current address for writing and how

much percent is used on the card. As there can be many files on the card with long time data

logging and with some configurations each file can be relatively big, this command can take

a longer time to execute.

Page 31

31

12 POLYNOMIALS CALCULATION FOR SENSORS

This section will explain how to change the polynomial to be applied when you are using radiometers

inside the Logbox SD graphical user interface.

Each pre-defined radiometer has a default Polynomial. (A1) This could be set to100 or 10, and needs to be

changed to have a correct reliable output in W/m².

Step1 : Look at your radiometer, and locate the sensitivity. This is located on the radiometer itself and on

the calibration certificate. (Example: 22,14µV/W/m

2

)

Step2: Calculate your own polynomial by applying the next formula : A1=1000/sensitivity

The reason for his is that the Logbox SD is measuring in mV and not in µV.

Step 3: Change your polynomial with the outcome of the formula. (1000/22,14µV/W/m

2

= 45.16)

Page 32

32

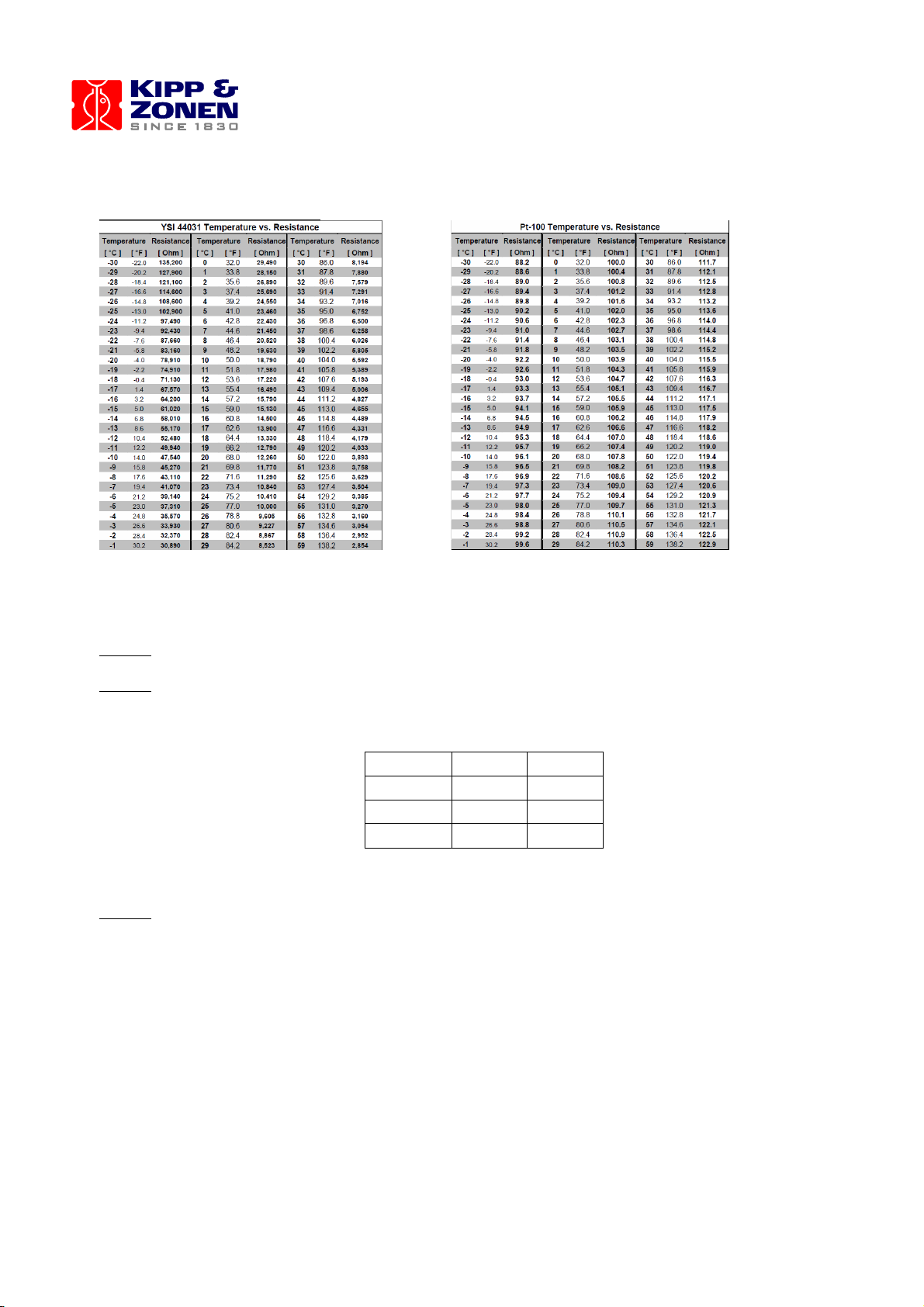

13 POLYNOMIALS CALCULATION FOR PT100 AND THERMISTOR

This section will explain how to create your own polynomials to be applied when you are using other PT100

or TH10K components with different specifications.

When selecting the pre-defined PT100 or TH10K in the analog section it uses the pre-defined polynomials

to calculate the output in ˚C.

Kipp & Zonen uses a particular PT100 or TH10K which can be purchased in different classes, behaving

differently to temperature changes.

Therefore it’s vital to create a perfect polynomial for temperature sensors other than those from Kipp &

Zonen to have a correct and reliable output.

Each component has its own behavior.

The next two illustration, Figure 1 and 2, will describe the behavior of a PT100 and TH10K which we use at

Kipp & Zonen and can be located inside most product manuals:

Page 33

33

Figure 1 Figure 2

Let’s begin to create our own polynomials:

Step 1: Collect the information as shown in figure 1 and 2.

Step 2: Insert this information in an excel sheet. (See Figure 3)

It is advisable to insert all the data. (The example only shows 4 values)

135,200

-30

-22

127,900

-29

-20,2

-18,4

114,600

-27

-16,6

Figure 3.

Step 3: Translate this information into a graphical chart. (See figure 4)

Page 34

Figure 4.

Step 4: Time to add a trendline by right clicking on the line inside the graphical chart and select “add

trendline””

-Select the polynomial option, put it on 3

rd

degree , and do not forget to put a checkmark in the box “display

equation on chart” at the options.

An example is shown in Figure 5, where Excel 2007 ism used to do this.

34

Page 35

Step5 : The result will be :

Figure 5.

Step 6: Adding the polynomials into the Logbox SD graphical user interface.

This will result in an output of ˚C

35

Page 36

If you want to have the output displayed in Kelvin or Fahrenheitplease make sure to create the graphical

chart using the Fahrenheit or Kelvin information which result in a different polynomial.

36

Page 37

37

Polynomials for UVS:

Polynomial in mV:

To have the output values recorded in mV (miliVolt) we will have to enter the following

polynomial

A1=1

If you are only interested in the UV values recorded by the instrument you would probably

like to have these reading in W/m².

Polynomial in W/m²:

To have the output values recorded in W/m² we will need to make some calculations using

the mean sensitivity values of the UVS instruments.

The mean sensitivity values can be located on the supplied calibration certificates.

Example:

The calibration certificate tells us that the mean sensitivity of the UVA = 30.083 W/m²/V and

the mean sensitivity of the UVB =1.879 W/m²/V.

In order to have the correct engineering units, W/m², we need to apply the following

equation:

A1=Mean sensitivity/1000

A1 (UVA)=30.083/1000=0.030083

A1 (UVB)=1.879/1000=0.001879

Now we can enter them inside the coefficient area:

The illustration above will result in the UVA and UVB readings to be in W/m² and the

temperature to be in V.

Please note that this cannot be used in combination with the Uviator application.

Uviator requires all outputs to be in Volt!

Page 38

38

Polynomial in Kelvin:

This section will explain how to have the temperature readings to be in Kelvin.

Inside the manual of the UVS you will find a table to convert the Voltage output of the UVS

into the temperature (°C)

You can enter these values inside Excel and add a trend line through the graphic

representations.

This will provide you with the Polynomial (3

rd

degree) to be entered inside the Logbox SD

coefficient area.

The trend line (polynomial to the 3

rd

order) results in:

y = 2E-09x

3

- 1E-05x2 + 0.0461x + 230.32

These values can be entered directly into the coefficient area.

Suggested is to extend the number of decimals for more accurate readings.

y = 0.000000001978925x

3

- 0.000012526108741x2 + 0.046056883951248x +

230.315474954755000

The output of UVA and UVB is in voltage and the temperature readings are in K.

Please note that this cannot be used in combination with the Uviator application.

Uviator requires all outputs to be in Volt!

Page 39

39

14 FIRMWARE

The Firmware inside LOGBOX SD is relatively comprehensive. It is due to the complex control

functions: measuring analog and digital inputs, auto calibrations, real time calculations,

calculations to engineering units based on polynomial of the 3-rd order, data logging to the

memory, service of output ports, communication ports RS232 and RS485, power

management and user interface.

User interface offers the following analog inputs setup options:

12 bit resolution for unipolar input range 0...2,5V

24 bit resolution for unipolar input ranges 0...2,5V down to 0 ... 20mV

24 bit resolution for bipolar input ranges +/-2,5V down to +/-20mV

All other functions (auto calibration, digital filtering, settling time...) the software controls

autonomously.

User interface for digital inputs offers following options:

Frequency measurement during logging interval

Pulse counting during logging interval

Time of logical one (high state) measurement during logging interval

All digital input measurements are active also during sleep period in measuring mode.

Software controls automatically power consumption.

Communication ports can be configured for speeds from 300bps up to 115200bps. Service

mode is always with speed 115200bps, regardless of set communication speed. It is due to

faster data download from the memory in service mode. You need to have a correct setup on

your communication software on the PC.

Service mode is accessible only on RS232 serial line.

All other functions (real time circuitry, logging to the memory, power management) are

controlled by the software without need of user action.

After switching on LOGBOX SD is in measuring mode. That means that there is logging

interval. At the beginning of this interval LOGBOX SD performs all analog measurements (if

there is “set delay” longer than 0 sec, measurements are activated only after current delay).

Then all calculations and data logging is in progress. After that sequence, LOGBOX SD goes

to sleep mode until next logging interval.

Page 40

40

15 SERVICE MODE

To access service mode, you need to wake up LOGBOX SD from sleep mode. You will type CTRL+BREAK

on your serial line once. If there is no response after about 5 seconds, try again (data logger is serial

line sensitive only for about 50% of time due to low power operation). Then, your communication

software must be set for communication speed 115200bps, as service mode is accessible with this

speed only. You will receive following answer from the LOGBOX SD:

LOGBOX SD (C) Physicus. Version T2.07.217 Jun 19 2007

Service mode started.

>

Now all setup commands are available.

Summary of setup commands:

? – displays current setup

?

LOGBOX SD (C) Physicus. Version T2.07.217 Jun 19 2007

LogMode: CIRCULAR

LogAddress: 91336

CircEndAddress: 131040

LogInterval: 5 minutes

SdWrittingInterval: 10 minutes

SdFileClose: 24 hours

Delay: 0

BaudRate: 115200

Temperature[mV]: 1083.8, AVcc[mV]: 3106.4

ReferenceVoltage: 2500.000 mV

DateTime: 2005-03-11 11:22:56

OK

T – time setup with syntax HH MM SS (HH-hour, MM-minute, SS-second)

T

Enter HH MM SS

19 09 10

You've entered 19:09:10

<Y> = set, else = quit

Y

SET.

D – date setup with syntax YYYY MM DD (YYYY-year, MM-month, DD-day)

D

Enter YYYY MM DD

2005 11 27

You've entered: 2005-11-27

<Y> = set, else = quit

Y

SET.

0

Clear all logging memory

Page 41

41

0

Are you sure that you want to erase all logs?!

CAP<Y> = erase, else = quit

Y

ERASED.

OK

F

Save configuration to the memory

U

Setup communication speed for serial line

U

You can use the following baud rates:

300 1200 2400 4800 9600 19200 38400 57600 115200

Switch between them by <SPACE> and confirm by <ENTER>

Baud Rate = 115200

If you type <SPACE> you will roll over mentioned intervals. If you will type <ENTER> you will receive

following response:

FINAL Baud Rate = 115200

I

Setup logging interval

I

You can use the following logging intervals:

1 2 3 4 5 6 10 12 15 20 30 60 minutes, 10 20 30 seconds & FAST

Switch between them by <SPACE> and confirm by <ENTER>

LogInterval = 1 minutes

If you type <SPACE> you will roll over mentioned intervals. If you will type <ENTER> you will receive

following response:

FINAL LogInterval = 1 minutes

V

Setup writing interval on SD card

V

You can use the following SD card WRITTING intervals:

1,2,3,4,5,6,10,12,15,20,30 minutes, 1,2,3,4,5,6,12,24 hours & NEVER

Switch between them by <SPACE> and confirm by <ENTER>

SDWriting = 1 minutes

If you type <SPACE> you will roll over mentioned intervals. If you will type <ENTER> you will receive

following response

Page 42

42

FINAL SDWritting = 1 minutes

J

Setup file close interval on SD card

J

You can use the following SD card FILE_CLOSING intervals:

10 20 30 minutes, 1, 2, 3, 4, 5, 6, 12, 24 hours and Always

Switch between them by <SPACE> and confirm by <ENTER>

If you type <SPACE> you will roll over mentioned intrevals. If you will type <ENTER> you will receive

following response

FINAL SdFileClose = 24 hours

l

Type all data in memory

l

2004-11-27 10:46:03 55.778 61.274 61.268 / / / 0.888 0.785 / / / /

2004-11-27 10:47:03 55.781 61.284 61.288 / / / 0.745 0.705 / / / /

2004-11-27 10:48:03 55.773 61.329 61.333 / / / 0.637 0.640 / / / /

2004-11-27 10:49:03 55.771 61.188 61.178 / / / 0.667 0.633 / / / /

Q

Quit service mode

To access configuration commands, you will need to type space in service mode. Then you have

available following configuration commands:

Analog inputs configuration commands

AE

Clear all settings for analog inputs

AG0

Disable 24 bit resolution measurements

AG1

Enable 24 bit resolution measurements

AGP

Enable ratio measurement of A2 to A1

AGp

Disable ratio measurement of A2 to A1

AGQ

Enable ratio measurement of A3 to A1

AGq

Disable ratio measurement of A3 to A1

A[X]W7 (X represents analog input. X [1...5])

Page 43

43

Assign for A[X] 24 bit resolution

A[X]WI (X represents analog input. X [1...8])

Assign for A[X] 12 bit resolution

A[X]IS (X represents analog input. X [1...5])

Set A[X] for single ended input. Only for 24 bit resolution

A[X]ID (X represents analog input. X [1...3])

Set A[X] for differential input. Only for 24 bit resolution

A[X]IU (X represents analog input. X [1...5])

Set A[X] for unipolar input. Only for 24 bit resolution

A[X]IB (X represents analog input. X [1...5])

Set A[X] for bipolar input. Only for 24 bit resolution

A[X]G[Y] (X represents analog input, Y represents input range. X [1...5], Y[0...8])

Set A[X] for Y input range as follows:

Y

Input range

1

2.5V

2

1.25V

3

625mV

4

312mV

5

156mV

6

78mV

7

39mV

8

19mV

A[X]P[Y] (X represents analog input, Y represents nr. of polynomial. X [1...8], Y[0...8])

Set polynomial coefficients of P[Y] to analog input A[X]

If Y=0, no polynomial is used

Digital inputs configuration commands

BE

Clear all settings for bipolar inputs

B[X]C1 (X represent digital input. X [1...4])

Enable digital input X for counter function

B[X]C0 (X represent digital input. X [1...4])

Disable digital input X for counter function

B[X]F1 (X represent digital input. X [1...4])

Enable digital input X for frequency function

B[X]F0 (X represent digital input. X [1...4])

Disable digital input X for frequency function

B[X]P[Y] (X represents digital input, Y represents nr. of polynomial. X [1...4], Y[0...8])

Set polynomial coefficient of P[Y] to digital input B[X]

If Y=0, no polynomial is used

Polynomial coefficients configuration commands

PE

Clear all settings for polynomial coefficient

Page 44

44

P[X][Y] (X represents indexed nr. of polynomial, Y represents coefficient. Y[any real number])

Set up coefficients of polynomial

15.1.1 P40

=0

OK

>P41

P41

=10000

OK

>P42

P42

=125E-7

OK

>P43

P43

-321.245

OK

P?

Returns all coefficients of all polynomials

P?

1: 0 2.25 0.0009813 0

2: Not set.

3: Not set.

4: 0 10000 125E-7 –321.245

5: Not set.

6: Not set.

7: Not set.

8: Not set.

OK

Other configuration commands

LE

Clear all settings for logging

L[X]1 (X represents analog or digital input. X[1...9, A, B, C])

Enable logging of input X

L[X]0 (X represents analog or digital input. X[1...9, A, B, C])

Disable logging of input X

LMC

Sets logging memory to circulate. If the memory is full, it will overwrite the oldest logs.

LMS

Sets logging memory to stop if the memory is full.

D[X] (X [0...9])

Set delay for x seconds

Q

Quit service mode

In service mode you can go to SD card setup by pressing S command.

In SD Card Setup there are following commands:

Page 45

45

Checks for card format. If wrong, it will format the card and prepare for data logging. If the card

format is ok and there are logged files it will display all files on the card.

?

Wait a minute. Checking the SD card.

LOGBOX SD SD card format OK.

ELOG0000.TXT 51 2007-06-16 13:21:06

ELOG0001.TXT 512 2007-06-16 13:22:00

ELOG0002.TXT 4886 2007-06-16 13:30:00

ELOG0003.TXT 7922 2007-06-16 13:40:00

ELOG0004.TXT 7922 2007-06-16 13:50:00

ELOG0005.TXT 7922 2007-06-16 14:00:00

ELOG0006.TXT 7922 2007-06-16 14:10:00

...

ELOG0278.TXT 773632 2007-09-11 21:22:04

SD card size: 127139840 Bytes

Next File: ELOG0279.TXT at 96894976

L

This command will print all the files on the card.

L

ELOG0000.TXT 51 2007-06-16 13:21:06

ELOG0001.TXT 512 2007-06-16 13:22:00

ELOG0002.TXT 4886 2007-06-16 13:30:00

ELOG0003.TXT 7922 2007-06-16 13:40:00

ELOG0004.TXT 7922 2007-06-16 13:50:00

ELOG0005.TXT 7922 2007-06-16 14:00:00

ELOG0006.TXT 7922 2007-06-16 14:10:00

...

ELOG0278.TXT 773632 2007-09-11 21:22:04

SD card size: 127139840 Bytes

Next File: ELOG0279.TXT at 96894976

T

Typing one file.

T

Enter the file number.

1

File# 1:

ELOG0001.TXT 512 2007-06-16 13:22:00

2007-06-16 13:21:10 1374658.942 1374701.858 1304443.121 1304.373 1372.565 1372.650

1367.556 1339.601 0.0 0.0 0.0 0.0

2007-06-16 13:21:20 1381304.150 1381299.381 1311226.487 1311.039 1376.227 1376.276

1370.968 1343.812 0.0 0.0 0.0 0.0

2007-06-16 13:21:30 1387620.087 1387422.199 1318446.398 1318.361 1380.752 1380.780

1374.732 1348.118 0.0 0.0 0.0 0.0

2007-06-16 13:21:40 1393612.976 1393628.359 1326034.784 1325.889 1386.068 1386.058

1379.219 1353.073 0.0 0.

The end of file.

OK

Q

Escape from SD Card Setup menu.

Format of logged data is as follows:

YYYY-MM-DD HH:MM:SS AIN1 AIN2... AIN8 DIN1 DIN2... DIN4

Page 46

46

Channels, which are disabled for logging are indicated with „/“.

YYYY - year

MM - month

DD - day

HH - hour

MM - minute

SS - second

AIN1...AIN8 – analog input calculated to engineering units

DIN1...DIN4 – digital input calculated to engineering units

In the memory each group fills the same memory space:

Date - 4 bytes

Time - 4 bytes

Analog channel - 4 bytes

Digital channel - 4 bytes

Page 47

47

16 APPLICATION EXAMPLES

Example 1.

Connection of relative humidity and temperature sensors.

Example 2.

Memory capacity calculation

Let’s assume we measure and store data from channels AIN1, AIN2 and DIN1 every 5

minutes. Now calculate how many bytes will take one record:

Date – 4 bytes

Time – 4 bytes

AIN1- 4 bytes

AIN2 – 4 bytes

DIN1 – 4 bytes

Together it is 20 bytes for one record. Internal memory capacity is 128kB (about 131000

bytes) and therefore we can store

131000/20=6550 records

Every 5 minutes record will make 12 records per hour. Nr. of recorded hours:

6550/12=545 hours and it is about 22 days (more than 3 weeks).

Page 48

48

Example 3.

Calculation of battery capacity

Let’s assume we measure temperature, relative humidity and global radiation. Measuring

interval is one minute. Requested autonomy for battery is 7 days.

Now we will calculate power consumption of each component of the system.

For temperature measurement we will use PT100, where excitation current is 1mA

maximum. We need to add delay of 5 second to settle the output.

For relative humidity measurement we can use HumiAir8 sensor. It has power consumption

6mA max. Again, delay to stabilize output is 5 seconds.

For global radiation measurement we can use a pyranometer. Power consumption is zero.

Power consumption of LOGBOX SD during measuring period is 5mA, in sleep mode it is

20uA.

Power consumption during measurement:

1mA + 6mA + 5mA = 12mA

Power consumption during sleep mode:

0+0+0+20uA=20uA

Mean power consumption from the battery:

(12mA x 5s + 0.020mA x 55s)/60s=1.018mA

Number of hours:

24hours x 7days = 168 hours

Required minimum battery capacity:

168hours x 1,018mA= 0,1711Ah

4 AA alkaline batteries are recommended for maximal logging time.

Recommendations: The LOGBOX SD data logger is a high precision instrument. For

maximum accuracy apply standard guidelines for low noise operation. Avoid strong

electromagnetic field disturbance (do not install near HF antennas, electrical motors or

generators). Use short cables. Use shielded cables and connect shield to ground connection.

Proper grounding with maximum shielding is necessary. With extreme HF disturbance a

degraded accuracy can be expected.

Connectors Layout

Page 49

49

17 FAQ

• Q: What is the extension of the log file?

• A: The extension is .TXT or .XLS Using the software interface you can select to save

this as a text -or Excel file.

• Q: What is the format of the log file ?

• A: The format uses columns, an example is given :

• Q: What do the values represent at A1, A2 ,A3 , A7 etc. in the log ?

• A: In the columns after time and date the radiation values are shown of the

connected instruments in W/m

2.

• Q: Is the data inside the Log file real time ?

• A: No, the data is not real time as it is retrieved afterwards.

• Q: How do I connect a Pyranometer with PT100 to the Data logger ?

• A: Here is a picture how a PT100 should be connected.

(PT100 uses four input channels nr 1,2 ,3 and 4)

You have 4 channels left, nr 5,6,7, and 8, to connect other sensors.

(which are used to connect the instrument)

• Q: Does the internal battery stops working when you power the Logbox SD with an

external power supply. In this case, will you still have power available for excitation

on the Power Out connection ?

• A: The LOGBOX SD has one input for power.

There you connect either the internal battery or an external power source. (both is

not possible)

So external power will not switch of the battery.

PWR OUT will provide whatever power is connected as power source for the LOGBOX

SD.

Page 50

50

• Q: Can you explain something how a data logger works ?

• A: Every logger has an A/D converter with a certain resolution (number of bits) - you

see often 10, 12, 16 or 24 bits resolution

A logger also has a fixed number of analog input ranges - you see often 20 mV, 100

mV, 1 V, 5 V and 10 Volt ranges

Let’s take for example we use a logger with 12 bits resolution and 5 Volt input

range.

This means that the 5 Volt is divided in 2¹² steps. This is 5/4096 = 0.00122 Volt per

step

So the smallest detectable change on the input is 1.22 mV

If we connect an SP Lite with a sensitivity of 75 μVolt/W/m²

One Watt (change) will give 0.075 mV (change) on the output.

So we need a change of 1.22 / 0.075 = 16.2 Watt/m² before we see a change in the

Logger output.

As you can understand this is not acceptable

A minimum of 1 W/m² should be detected (preferably a factor 10 times better)

This can be achieved in lowering the input range to 100 mV (50 times better)

Or selecting a higher resolution e.g. 16 bits (instead of 12 bits) this is 16 times

better. ( 2¹⁶- 2¹² = 2⁴ = 16 )

• Q: What is the difference between single ended and differential?

• A: With differential inputs, two signal wires run from each signal source to the Data

logger. One goes to a + input and one to a - input. Two high-impedance amplifiers

monitor the voltage between the input and the interface ground. The outputs of the

two amplifiers are then subtracted by a third amplifier to give the difference between

the + and - inputs, meaning that any voltage common to both wires is removed.

By selecting a differential method automatically the first two inputs AIN 1 and AIN 2

for example will be the + and – input.

With single-ended inputs you connect one wire from each signal source to the data

acquisition interface. The measurement is the difference between the signal and the

ground or earth at the data logger. (which will be AIN 6 on the Logbox SD)

How to connect CNR 1 or CNR 4 to the Logbox SD

• A: All connected as single ended and only in combination with a 10K thermistor.

Page 51

51

AIN 1 = Plus from CMPupw

AIN 2 = Plus from CMPdown

AIN 3 = Plus from CGRupw

AIN 4 = Plus from CGRdown

AIN 6 = common ground for all above instruments.

Vref = 10K thermistor

AIN 5 = 10K thermistor & 10K reference resistor

GND = 10K reference resistor.

The next illustration displays the software configuration:

Please do not forget to enter the Polynomials P2 - P5 inside the coefficient area.

And please be aware of the multiplexing principle inside the Logbox SD, it will take at least a full

second before each measurement is performed. Meaning there will be a 4second time shift

between the measurement taken of the first channel and the measurement taken on the fourth

channel. (Albedo measurements should be taken on the same time interval.)

Page 52

Our customer support remains at your disposal for any maintenance or repair, calibration,

supplies and spares.

Für Servicearbeiten und Kalibrierung, Verbrauchsmaterial und Ersatzteile steht Ihnen unsere

Customer Support Abteilung zur Verfügung.

Notre service ‘Support Clientèle’ reste à votre entière disposition pour tout problème de

maintenance, réparation ou d’étalonnage ainsi que pour les accessoires et pièces de rechange.

Nuestro servicio de atención al cliente esta a su disposición para cualquier actuación de

mantenimiento, reparación, calibración y suministro de repuestos.

HEAD OFFICE

Kipp & Zonen B.V.

Delftechpark 36, 2628 XH Delft

P.O. Box 507, 2600 AM Delft

The Netherlands

T: +31 (0) 15 2755 210

F: +31 (0) 15 2620 351

info@kippzonen.com

SALES OFFICES

Kipp & Zonen France S.A.R.L.

7 Avenue Clément Ader

ZA Ponroy - Bâtiment M

94420 Le Plessis Trévi

France

Kipp & Zonen Asia Pacific Pte. Ltd.

81 Clemenceau Avenue

#04-15/16 UE Square

Singapore 239917

Kipp & Zonen USA Inc.

125 Wilbur Place

Bohemia

NY 11716

United States of America

Go to www.kippzonen.com for your local distributor or contact your local sales office

se

+33 (0) 1 49 62 41 04

T:

F: +33 (0) 1 49 62 41 02

kipp.france@kippzonen.com

T: +65 (0) 6735 5033

F: +65 (0) 6735 8019

kipp.singapore@kippzonen.com

T: +1 (0) 631 589 2065

F: +1 (0) 631 589 2068

kipp.usa@kippzonen.com

Passion for Precision

Loading...

Loading...