Page 1

Instruction Manual

Large Aperture Scintillometer

LAS

Page 2

1

IMPORTANT USER INFORMATION

Reading this entire manual is essential for full

understanding of the proper use and safe operation of this product

Should you have any comments on this manual we will be pleased to receive them at:

Kipp & Zonen B.V.

Delftechpark 36

2628 XH Delft Holland

P.O. Box 507 2600 AM Delft Holland

Phone +31 (0)15 2755210

Fax +31 (0)15 2620351

Email info@kippzonen.com

Web www.kippzonen.com

Kipp & Zonen reserves the right to make changes to the specifications without prior notice.

WARRANTY AND LIABILITY

Kipp & Zonen guarantees that the product delivered has been thoroughly tested to ensure that it

meets its published specifications. The warranty included in the conditions of delivery is valid only if

the product has been installed and used according to the instructions supplied by Kipp & Zonen.

Kipp & Zonen shall in no event be liable for incidental or consequential damages, including without

limitation, lost profits, loss of income, loss of business opportunities, loss of use and other related

exposures, however caused, arising from the faulty and incorrect use of the product. User made

modifications can affect the validity of the CE declaration.

COPYRIGHT© 2006 KIPP & ZONEN

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted in any form or by any means, without permission in written form from the company.

Manual version: 0706

Page 3

2

Throughout the manual symbols are used to indicate to the user important information. The meaning

of these symbols is as follows:

The exclamation mark within an equilateral triangle is intended to alert the user to the

presence of important operating, maintenance and safety information

Page 4

3

TABLE OF CONTENTS

IMPORTANT USER INFORMATION.......................................................................................1

WARRANTY AND LIABILITY .............................................................................................................. 1

COPYRIGHT© 2006 KIPP & ZONEN.................................................................................................. 1

TABLE OF CONTENTS...........................................................................................................3

LIST OF SYMBOLS.................................................................................................................5

SYMBOLS............................................................................................................................................ 5

ABBREVIATIONS ................................................................................................................................ 6

1. GENERAL INFORMATION .................................................................................................7

1.1 INTRODUCTION TO LAS-BET AND LAS-RET SYSTEMS.......................................................... 7

1.2 MANUAL ...................................................................................................................................... 10

2. TECHNICAL DATA............................................................................................................11

2.1 LAS / XLAS .................................................................................................................................. 11

2.2 WEATHER STATION AND SENSORS....................................................................................... 11

2.3 RF TELEMETRY LINK................................................................................................................. 12

3. INSTALLATION AND SET-UP ..........................................................................................13

3.1 DELIVERY ................................................................................................................................... 13

3.2 STEP BY STEP INSTALLATION PROCEDURE ........................................................................ 15

3.2.1 Site selection ......................................................................................................................... 15

3.2.2 Installing LAS / XLAS ............................................................................................................ 16

3.2.3 Power supply LAS / XLAS..................................................................................................... 16

3.2.4 Installing weather station....................................................................................................... 18

3.2.4.1 Site selection .................................................................................................................. 18

3.2.4.2 Installation of mast and mounting of sensors ................................................................. 19

3.2.4.3 Mounting enclosure, solar panel and connecting wires ................................................. 24

4. SOFTWARE.......................................................................................................................29

4.1 COMBILOG SUPPORT SOFTWARE.......................................................................................... 29

4.1.1 Setting communication parameters....................................................................................... 29

4.1.2 Original COMBILOG module settings and programs............................................................ 31

4.2 PCI-SWAP-BOX SOFTWARE..................................................................................................... 33

4.3 PCMCIA FLASH MEMORY CARD SOFTWARE (CardWare) .................................................... 34

4.3.1 Installing CardWare software ................................................................................................ 34

4.3.2 Reading PCMCIA Flash Memory Cards ............................................................................... 34

4.4 EVATION DATA PROCESSING SOFTWARE............................................................................ 35

4.4.1 Installing EVATION ............................................................................................................... 35

4.4.2 Installing Modified Algorithms ............................................................................................... 36

4.4.3 Getting started....................................................................................................................... 37

5. OPERATION ......................................................................................................................39

5.1 REAL-TIME MONITORING OF MEASUREMENTS.................................................................... 39

5.1.1 Via COMBILOG support software ......................................................................................... 39

5.1.2 Via display of COMBILOG .................................................................................................... 41

5.2 CALIBRATION COEFFICIENTS ................................................................................................. 41

5.3 DATA FILES ................................................................................................................................ 42

6. MAINTENANCE.................................................................................................................43

7. TROUBLE SHOOTING......................................................................................................45

Page 5

4

APPENDIX 1 – TESTING RF TELEMETRY LINK ................................................................46

APPENDIX 2 – DIP SWITCH SETTINGS RF MODEM .........................................................49

APPENDIX 3 – MOUNTING ANTENNAS .............................................................................51

APPENDIX 4 – SERIAL PORT CONNECTIONS ..................................................................53

APPENDIX 5 – INSTALLATION FORM ................................................................................ 55

APPENDIX 6 – INSPECTION PROCEDURE ........................................................................59

APPENDIX 7 – SETTING DATE / TIME COMBILOG ...........................................................65

APPENDIX 8 – FORMAT PCMCIA FLASH MEMORY CARDS ...........................................69

APPENDIX 9 – CONNECTION PLAN LAS-BET & LAS-RET ..............................................70

Page 6

5

LIST OF SYMBOLS

SYMBOLS

C

n

2

structure parameter of the refractive index of air [m

-2/3

] (

()

12

2

2

10−=

CN

U

n

C )

C

T

2

structure parameter of temperature [K2 m

-2/3

]

C

Q

2

structure parameter of humidity [kg2 m-6 m

-2/3

]

d zero-displacement height [m]

D aperture diameter of receiver and transmitter unit [m]

f

T

universal stability function [-]

g gravitational acceleration [∼9.81 m s

-2

]

G

s

soil heat flux [W m-2]

G

1

, HFP1 soil heat flux plate 1 [W m-2]

G

2

, HFP2 soil heat flux plate 2 [W m-2]

H sensible heat flux [W m

-2

]

L path length [m]

L

v

latent heat of vaporization [~2.45 × 106 J kg-1 @ 20 oC]

L

v

E latent heat flux (or evaporation ET) [W m-2] [mm day-1]

(conversion [W m

-2

] ↔ [mm day-1]: 1 W m-2 = Lv/86400 ≅ 0.0353 mm day-1)

L

MO

Obukhov length [m]

Pot potentiometer path length setting at Path length knob [-]

P air pressure [Pa]

Press air pressure [hPa]

(conversion [Pa] ↔ [hPa]: 1 hPa = 100 Pa = 1 mbar)

PU

CN2

scaled C

n

2

[m

-2/3

] (C

n

2

= PU

CN2

⋅10

-15

)

Q absolute humidity [kg m

-3

]

Q* net radiation [W m

-2

]

R

d

specific gas constant for dry air [∼287 J K-1 kg-1]

RH relative humidity [%]

R

n

net radiation [W m-2]

R

v

specific gas constant for water vapour [∼461.5 J K-1 kg-1]

T absolute air temperature [K]

T+ air temperature upper level [

o

C]

T- air temperature lower level [

o

C][

(conversion K [Kelvin] ↔

o

C [Celsius]: × oC = × + 273.15 K)

T

*

temperature scale [K]

u wind speed [m s

-1

]

u

*

friction velocity [m s-1]

U

CN2

log C

n

2

signal [V] (

(

)

12

2

2

10−=

CN

U

n

C ) [-5 V to 0 V]

U

DEMOD

demodulated signal [V] (U

DEMOD

= I) [-1 V to 0 V]

WD wind direction [

o

]

z

LAS

(effective) height LAS or XLAS [m]

z

0

aerodynamic roughness length [m]

z

u

height wind speed measurements [m]

Page 7

6

β

Bowen ratio [-] (β = H/LvE)

λ wavelength of EM radiation (880 nm) [m]

ρ

density of air [kg m-3] [∼1.2 kg m-3 (at sea level (1013 hPa)!)]

2

σ

variance

2

ln I

σ

of natural logarithm of intensity fluctuations ( ln(I) ) [-]

22

IU

DEMOD

σσ

= of U

DEMOD

or intensity I [V2]

2

2CN

U

σ

of U

CN2

[V2]

ABBREVIATIONS

BET Basic Evapo-Transpiration system

(X)LAS (eXtra) Large Aperture Scintillometer

MOST Monin-Obukhov Similarity Theory

A relationship describing the vertical behavior of non-dimensionalized mean

flow and turbulence properties within the Surface Layer as a function of the

Monin–Obukhov key parameters.

PBL Planetary Boundary Layer

The PBL is the lowest region of the troposphere, which is directly affected by

heating and cooling of the earth surface. In general the depth of the PBL

varies between 100m to 2000m. The depth of the PBL increases during the

day, when the surface is heated by the sun and decreases during the night

due to radiative cooling.

RET Radio Evapo-Transpiration system

RS Roughness Sublayer

Lowest part of the SL, where the flow is influenced by individual roughness

elements. Consequently, the SL can be divided into the Constant Flux Layer

and the Roughness Sublayer. The height of the Roughness Sublayer strongly

depends on the height (size and form) of the roughness elements, but also on

the distribution. Usually, over tall vegetation 3 times the obstacle height is

taken as the height of the Roughness Sublayer.

SL Surface Layer

In general in the lowest 10% of the PBL the surface fluxes are constant with

height, this part of the PBL is also known as the Constant Flux Layer or

Surface Layer (SL). Therefore fluxes measured in the SL can be considered

as being representative fluxes for the heat and mass exchange processes

between the atmosphere and the surface. In general the SL varies between

20m to 100m and like the PBL increases during the day and decreases again

during the night.

Page 8

7

1. GENERAL INFORMATION

1.1 INTRODUCTION TO LAS-BET AND LAS-RET SYSTEMS

The LAS-BET and LAS-RET (ET stands for evapotranspiration) systems are scintillometer based

surface flux monitoring systems, specially intended for earth energy balance and water management

studies. Evapo-transpiration is an important term of the surface energy budget

sv

GELHQ ++=

*

[W m-2], (1)

where Q

*

(or Rn) is the available energy known as the net radiation, H the sensible heat flux, LvE the

latent heat flux and G

s

the soil heat flux. In some cases extra storage and/or advective terms can be

added to the surface energy balance. The evapo-transpiration (ET), which stands for the evaporation

(E) from bare soil and the transpiration (T) by vegetation, is linked to the latent heat flux (L

v

E) as

follows

v

v

L

EL

ET =

, (2)

where L

v

is the latent heat of vaporisation (the energy required to evaporate 1 kg of water, Lv ∼ 2.45 ×

10

6

J kg-1). This means that ET can be expressed as an energy flux (LvE in [W m-2], mostly used in

used in meteorology) or as a mass flux (ET in [mm day

-1

], mostly used in hydrology). Approximately 1

W m

-2

is equal to 0.0353 mm day-1. The latent heat flux or ET is an important term of the soil water

balance

outputinput −=∆S , (3)

where ∆S is the change of storage of water in the soil, which is the result of the amount of input into

the soil (e.g. due to rainfall or irrigation) minus the amount of loss of water (e.g. due to

evapotranspiration, surface-runoff or drainage).

The LAS-BET and LAS-RET have been developed to provide area-representative surface fluxes of

sensible heat (H) and latent heat (L

v

E). Most unique feature of the both systems is the line of sight

path-integrating capabilities of the (eXtra) Large Aperture Scintillometer (LAS / XLAS). This allows the

user to measure area-averaged surface fluxes of sensible heat at scales of 0.2 to 8 km, over both

homogenous and moderate heterogeneous areas. So far most traditional measurement techniques

(e.g. Eddy-Covariance method, Flux-Profile method, Bowen-ratio method and Lysimeters) are actually

point (in-situ) measurements and therefore less representative for large (natural and therefore

heterogeneous) areas.

Basically, the LAS-BET and LAS-RET system consist of two parts, namely a scintillometer (LAS or a

XLAS) and a weather station (developed by Theodor Friedrichs & Co). The structure parameter (C

n

2

)

measured by the LAS / XLAS and additional meteorological data (air temperature at 2 levels, wind

speed and air pressure) collected by the weather station are used to determine the surface flux of

sensible heat H. By adding a net radiometer and soil heat flux sensors, the latent heat flux can be

derived, via

sv

GHQEL −−= * , (4)

Page 9

8

i.e. LvE is the residual term of the energy balance. Both the LAS-BET and the LAS-RET system

provide L

v

E according to the latter step.

Although the LAS-BET and LAS-RET provide the same output (H and L

v

E) they differ in complexity

and flexibility. The LAS-BET comprises a LAS (or a XLAS), a number of meteorological sensors

(tower and arms are optional), a data logger and a software package. The data logger collects the

output from all sensors including the LAS / XLAS. Signal cables limit the distance between the data

logger and the sensors meaning that the LAS / XLAS receiver and the sensors must be roughly

located at the same site as the data logger.

LAS-T ransmitter

LAS-Receiver

Datalogger (Mas ter)

U

Cn2

and U

demod

RF Modem 2

RF Modem 1

U

Cn2

and U

demod

Wireless RF

communicat ion

LAS-system

Meteor ologic al tower and sens ors:

Compu ter with PC MCIA card read er and EV ATION

software

Datalogger (Slav e)

Field statio n

U

Cn2

,U

demod

and me teorol. da ta

(2 Mb Flash card or RS-232)

Net radiat ion

Soil heat f lux

Temper ature / humidity

Wind speed / dire ction

RS-485

RS-485

Wireless RF

communicat ion

Figure 1: Schematic overview of the LAS-RET system. This system consists of a LAS / XLAS

scintillometer, which is measured by a COMBILOG data logger (SLAVE). Using two RF radio modems the

data from the LAS (U

Cn2

and U

demod

) is transmitted to the central COMBILOG data logger (MASTER)

located at the weather station. Here all measured data is stored on a 2 Mb flash card. Once the data of the

Flash card has been stored on a computer the EVATION software processes the data to fluxes of sensible

heat and evaporation. The weather station comprises a 4 m tower and a number of sensors.

In order to improve the flexibility of installation, especially the site selection of the LAS / XLAS and the

meteorological tower, the LAS-RET system is equipped with a 2.4 GHz RF link. The RF link transmits

the signal output from the LAS / XLAS receiver to the main data logger of the meteorological station.

Page 10

9

This station comprises sensors, a mast with cross arms and cable guys, a data logger and a power

supply (battery and solar panel). In this way the user is able to place the meteorological station up to

5km away from the LAS / XLAS receiver, preferably near the centre of the path of the LAS / XLAS or

at another representative spot. The RF telemetry link operates at 2.4 GHz, which is license free

globally

1

. Extra advantage: all data including the signals of the LAS / XLAS are stored centrally at the

meteorological tower on a 2Mb PCMCIA flash card.

The data processing of the LAS-BET and LAS-RET systems is done by a software program, called

EVATION (stands for eva

potranspiration). This user-friendly program, developed by Kipp & Zonen,

processes the data to (daily) fluxes of sensible and latent heat. In Figure 1 an overview is shown of the

LAS-RET system. Figure 2 shows the LAS-BET system (without the RF telemetry link).

LAS-T ransmitt er

LAS-R eceive r

Datalogger (Master)

U

Cn2

and U

demod

LAS-system

Meteorol ogical sensors:

Computer with PCMCIA c ard reader and EVATION

software

Net r adiation

Soil heat flux

Tem perature / hu midit y

Wind speed / direction

U

Cn2

,U

demod

and m eteo rol. data

(2 Mb Flash card or R S-232)

Figure 2: Schematic overview of the LAS-BET system. This system consists of a LAS / XLAS

scintillometer and a number of meteorological sensors. All sensors (including the LAS) are measured by

1 COMBILOG data logger. The data is stored on a 2 Mb flash card. Once the data of the Flash card has

been stored on a computer, the EVATION software processes the data to fluxes of sensible heat and

evaporation.

1

Optional license free bands are: 915 MHz (US & Canada) and 922 MHz (Australia & Israel)

Page 11

10

Some LAS-BET and LAS-RET features are:

• Area-representative fluxes of sensible heat and (actual) evaporation (scale 0.2 km to 8 km

2

)

• RF telemetry link between LAS / XLAS receiver and weather station

3

. Advantages of the RF

link: the site selection of the weather station with respect to the LAS / XLAS is more flexible;

ALL data is centrally stored at one location (PCMCIA flash fard).

• (Optional) Switching power supplies with universal AC input and backup batteries provide

continuous operation in areas that have occasional net power drops.

• Solar battery powered weather station for flexible site selection

2

.

• Easy downloading of data using 2 Mb PCMCIA flash cards.

Some features of EVATION:

• Runs on Windows 98/NT/2000/ME/XP platforms

• User-friendly but offers also special tools for experts

• Handles multiple LAS-BET and/or LAS-RET set-ups

• Uses research-grade processing algorithms

• Handles multiple processing algorithms

4

• Built-in effective LAS / XLAS height calculator

• Data and flux averaging to daily means (e.g. ET in [mm day

-1

])

• Configurable output allows analysis of wide range of meteorological quantities (i.e. turbulent

surface fluxes, atmospheric stability, structure parameters)

• Automatic organizing of data files

1.2 MANUAL

This instruction manual is intended for customers who have purchased the LAS-BET or LAS-RET

system. It includes all the main information necessary to properly install and operate the systems.

More detailed information such as the operating specifications of a specific sensor/instrument can be

found in the separate delivered manuals.

2

Depending on atmospheric conditions

3

Applies to LAS-RET system only

4

Depending on LAS-BET / LAS-RET configuration

Page 12

11

2. TECHNICAL DATA

2.1 LAS / XLAS

The operating specifications of the LAS / XLAS can be found in the LAS instruction manual.

2.2 WEATHER STATION AND SENSORS

Table 1: Operating specifications of sensors. For detailed information see manuals of supplied sensors.

Note that the LAS-BET and LAS-RET system are not supplied with a relative humidity sensor. Instead a

default value is used of 50%.

COMBILOG 1020 Data logger

Operating temperature -30 oC to +60 oC

Voltage and power Nominal 12 VDC (~ 40 mA)

Analogue inputs 8 (16-bit)

Digital I/O 6

Interfaces RS-232/RS-485

Data storage - 256 kb internal RAM

- PCMCIA Flash Memory Card (2Mb)

Temperature sensor

Range -40

o

C to +60 oC

Output PT100 (4-wire)

Calibration Sensors are individually calibrated between

-20

o

C to 50oC with an accuracy of 0.01oC @ 0oC

Wind speed sensor

Operating temperature -25 oC to +80 oC

Range 0 – 60 m s-1

Voltage and power sensor

Voltage and power heater

Nominal 12 VDC (~2 mA)

Nominal 12 VDC (max 7 Watt)

Output Digital: 0 – 600 Hz (corresp.; 0 – 60 m s-1)

Wind direction sensor

Operating temperature -25 oC to +80 oC

Range 0 – 360o

Voltage and power sensor

Voltage and power heater

Nominal 12 VDC (~2 mA)

Nominal 12 VDC (max 7 Watt)

Output 8-bit Gray Code

Air pressure sensor

Operating temperature -25 oC to +70 oC

Range 600 – 1050 hPa

Voltage and power Nominal 12 VDC (~10 mA)

Output 0.3 – 4.9 VDC

Net radiation sensor (Kipp &

Zonen NR-Lite)

Operating temperature -30 oC to +70 oC

Range

± 2500 W m

-2

Output

± 25 mV

Soil heat flux sensor

Operating temperature -30 oC to +70 oC

Range

± 2000 W m

-2

Output

± 20 mV

Kipp & Zonen reserves the right to make changes to the specifications without prior notice.

Page 13

12

The LAS-BET and LAS-RET systems are not supplied with a relative humidity sensor. Instead a

default value is used (50%). Note that the uncertainties in RH have little effect on the sensible heat

flux and the evapotranspiration.

2.3 RF TELEMETRY LINK

Table 2: Operating specifications RF telemetry and antenna.

RF Modem 2.4 GHz (X24-019PKI-R)

Manufacturer MaxStream

(www.maxstream.net)

Operating

temperature

-40 oC to +85 oC

Frequency 2.4000-2.4835 GHz

(World wide license free)

Spread spectrum

type

Frequency hopping, Wide band

FM modulator

Interface RS-232/RS-485/RS-422

Voltage Nominal 12 VDC

Power ~200 mA (mode dependant)

Serial data

throughout

19.2 kbps

RF baud rate 20 kbps

Transmit power

output

50 mW (17 dBm)

Receiver sensitivity -102 dBm

Antenna

Operating

temperature

-45 oC to +70 oC

Frequency 2.4000 – 2.4835 GHz

Type Vagi (directional)

Gain 16 dBi

Impedance 50 Ohm

Range

∼ 5 km

Kipp & Zonen reserves the right to make changes to the specifications without prior notice.

Page 14

13

3. INSTALLATION AND SET-UP

3.1 DELIVERY

In general the delivery of the LAS-BET and LAS-RET includes the following items

5

:

Scintillometer

part:

LAS-BET LAS-RET

BET = Basic Evapo-Transpiration system

Flux station for measuring fluxes at field scale

LAS or XLAS scintillometer

• Telescopes

• 2× 5 m cable

• 2× sun / weather cover

Optional:

• 2× Power Box

for transmitter and

receiver, includes:

o AC/DC converter

o NET AC and power/signal

cables

• 2× Switching Power Box

for LAS

transmitter and receiver, includes:

o AC/DC converter with dual

output

o NET AC and power/signal

cables

o Battery (~85 Ah)

• Tripods

RET = Radio Evapo-Transpiration System

Flux station for measuring fluxes at kilometre scale

LAS or XLAS scintillometer:

• Telescopes

• 2× 5 m cable

• 2× sun / weather cover

• Stainless steel housing (protection class

IP65) containing:

o COMBILOG data logger

o Overvoltage protection

o 2.4 GHz RF modem, directional

antenna, mounting kit and cable

(~5 m)

Optional:

• 2× Power Box

for transmitter and

receiver, includes:

o AC/DC converter

o NET AC and power/signal

cables

• 2× Switching Power Box

for LAS

transmitter and receiver, includes:

o AC/DC converter with dual

output

o NET AC and power/signal

cables

o Battery (~85 Ah)

• Tripods

Kipp & Zonen reserves the right to make changes to the specifications without prior notice.

5

Depending on LAS-BET / LAS-RET configuration

Page 15

14

Weather station and/or sensors4

LAS-BET LAS-RET

BET = Basic Evapo-Transpiration system

Flux station for measuring fluxes at field scale

Meteorological sensors:

• Temperature sensor* (upper level)

• Temperature sensor* (lower level)

• Wind speed sensor

• Net radiation sensor (NR-Lite)

• Soil heat flux plates (2×)

• Stainless steel housing (Protection class

IP65) containing:

o COMBILOG data logger (plus 2

Mb PCMCIA Flash memory

cards)

o Overvoltage protection

o Barotransmitter

Optional:

• Aluminium mast (4 m) with cable guys,

grounding and sensor arms (similar to

LAS-RET)

RET = Radio Evapo-Transpiration System

Flux station for measuring fluxes at kilometre

scale

Meteorological station:

• Aluminium mast (4 m, with steel guys,

base plate and earth pins)

• Lightning rod and grounding rod

• U-shaped cross arm for:

o Wind direction sensor

o Wind speed sensor

• Two-sided cross arm (upper level) for:

o Temperature sensor*

o Net radiation sensor

• One-sided cross arm (lower level) for:

o Temperature sensor*

• Soil heat flux plates (2×)

• Stainless steel housing (protection

class IP65) containing:

o COMBILOG data logger (plus

2 Mb PCMCIA Flash memory

cards)

o Overvoltage protection

o Barotranmsmitter

o Solar controller

o Battery (~12V/85Ah)

o Solar panel (~100 Watt)

o 2.4 GHz RF modem,

directional antenna, mounting

kit and cable (~5 m)

*The air temperature sensors are individually calibrated (between –20oC to +50oC) and have an accuracy of 0.01oC @ 0oC in

order to determine the stability of the atmosphere.

Kipp & Zonen reserves the right to make changes to the specifications without prior notice.

Additional components

• Data logger support software (supplied on 1 CD)

• PCMCIA flash card reader (built-in version, installation software/drivers, supplied on 2

CD’s)

• Radio modem software xstreamCTU

(plus additional parts: ½-wave dipole antenna, loopback

adapter, null modem adapter (male-to-male), male & female RS-485/422 adapter, AC power

adapter, 9 volt battery adapter)

• EVATION software (supplied on 1 CD)

• Additional algorithms for EVATION

6

• Instruction manuals of supplied sensors and components

• 1 CD containing original COMBILOG programs with calibration coefficients, pdf file of

LAS-system manual, xstreamCTU software)

6

Depending on LAS-BET / LAS-RET configuration

Page 16

15

3.2 STEP BY STEP INSTALLATION PROCEDURE

3.2.1 Site selection

For the installation of the LAS-system it is important that the following aspects are taken into account

in order to have a reliable operational system:

The scintillometer (see also LAS instruction manual):

• Orientation optical path:

1)

it is advised to install the scintillometer such that the

orientation of the path is north-south to prevent direct sunlight into the

transmitter/receiver unit;

2)

Install the LAS in a way that the path is (near) horizontal

along the surface and that it is measuring within the constant flux layer and within the

saturation free region;

3)

The optical path must be free from obstacles, such as trees or

high buildings.

• Minimum height: depending on the surface conditions and the planned path length. First, the

effective height of the scintillometer should be high enough to avoid saturation of the signal.

For example high buildings, robust towers or surface topography can be used to mount the

scintillometer (see e.g. Figure 3). Second, for reliable flux derivations the LAS / XLAS must

measure within the so-called Constant Flux Layer of the Surface Layer (above the Roughness

Sublayer), where MOST is applicable. For further instructions the reader is referred to section

3.3 of the LAS instruction manual!

• Availability of net AC power (in case no solar-battery power is used).

The weather station:

• A spot that is representative for the area of interest, away from forest edges or other rough

surface elements.

• A spot, which is preferably near the centre of the path of the scintillometer (as the LAS / XLAS

is most sensitive in the centre of its path).

• Availability of net AC power (in case no solar-battery power is used).

• In case a RF telemetry link is used (based on RF modems and antennas) the installation

requirements of RF communication devices must be considered also. For detailed information

the reader is referred to APPENDIX 3 – MOUNTING ANTENNAS.

The site selection of the LAS / XLAS and weather station involves an iterative procedure:

1. Select a proper site for the LAS / XLAS (Transmitter and Receiver), such that the

observations of the instrument are representative for the area of interest, thereby taking into

account the installation requirements of the LAS / XLAS.

2. Select a representative site for the weather station, also taking into account the installation

requirements of the station (see above and section 3.2.4.1 Site selection).

3. Check the RF telemetry link (see APPENDIX 1 – TESTING RF TELEMETRY LINK)

a. Communication established → continue with step 4

b. Communication fails → go back to step 1 and/or 2

c. If one uses no RF telemetry link → skip step 3 and continue with step 4

4. Check scintillometer path for saturation and MOST applicability (see section 3.3 of LAS

instruction manual)

a. No saturation and in compliance with MOST → continue with step 4

b. Saturation is highly possible → go back to step 1

5. Install the weather station and the LAS / XLAS (and RF telemetry link)

→ go to next paragraph for further instructions

Page 17

16

Transmitter

Field station

Optical path

RF path

Receiver

H

L

v

E

Figure 3: Schematic picture of a scintillometer installed over a valley. The weather station is located in the

valley.

3.2.2 Installing LAS / XLAS

For reliable C

n

2

and flux (H and LvE) measurements it is important to meet the installation

requirements of the LAS / XLAS. These are:

o The LAS/XLAS must be placed on a robust and vibration free contruction.

o Avoid saturation of the signal by installing the LAS / XLAS at a minimum level (depends on

surface conditions and path length).

o Be certain that the LAS / XLAS is measuring in the Constant Flux Layer for reliable flux

derivations of the C

n

2

signal using MOST (depends on surface characteristics).

For detailed information the reader is referred to section 3.3.1, 3.3.2 and 3.4 of the LAS instruction

manual.

3.2.3 Power supply LAS / XLAS

Depending on the customer’s request the power supply of the LAS / XLAS can be as follows:

1. (Optional) Power Box (12VDC/3.5A, manufactured by Kipp & Zonen).

2. (Optional) Switching Power Box (12VDC/10.5A & 12VDC/0.5A, with built-in backup battery

(85Ah), manufactured by Kipp & Zonen,).

3. Alternative power supply (AC/DC converter, solar-battery power) with output specifications

that meet the requirements of the LAS / XLAS and additional components.

Page 18

17

LAS - ReceiverLAS - Tran smitter

Steel enclosure

U

Cn2

and

U

demod

sig nals

Signal s

12 VDC / ~0.5 A

12 VDC / ~3 A

(+ window heater)

12 VDC / ~0.3 A

12 VDC / ~4 A

max

(+ heaters)

12 VDC / ~ 0.2 A

12 VDC / ~ 3 A

(+ window heat er)

12 VDC

Figure 4: Required power supplies for LAS-BET system: 1 for the LAS-Transmitter and 1 for the LASReceiver + data logger and sensors.

LAS - Recei ver

LAS - Transm itter

Steel enclosure we ather station

U

Cn2

and

U

demod

signals

Signals

12 VDC

2.4 GHz

RF link

12 VDC / ~0.5 A

12 VDC / ~3 A

(+ window heater)

Solar p anel

(~100 W)

12 VDC / ~0.4 A

12 VDC / ~3.2 A

(+ window heat er)

12 VDC / ~0.2 A

12 VDC / ~3 A

(+ window heater)

Steel enc losure

Figure 5: Required power supplies for LAS-RET system: 1 for the LAS-Transmitter and 1 for the LASReceiver + data logger and RF modem. The weather station operates on solar-battery power.

Page 19

18

3.2.4 Installing weather station

3.2.4.1 Site selection

Selecting an appropriate site for the weather station is critical in order to obtain accurate data. In

general the site should be representative for the area of interest and away from the influence of

obstructions such as buildings, trees and other objects that might disturb the measurements (e.g.

sprinklers). Use as rule of thumb:

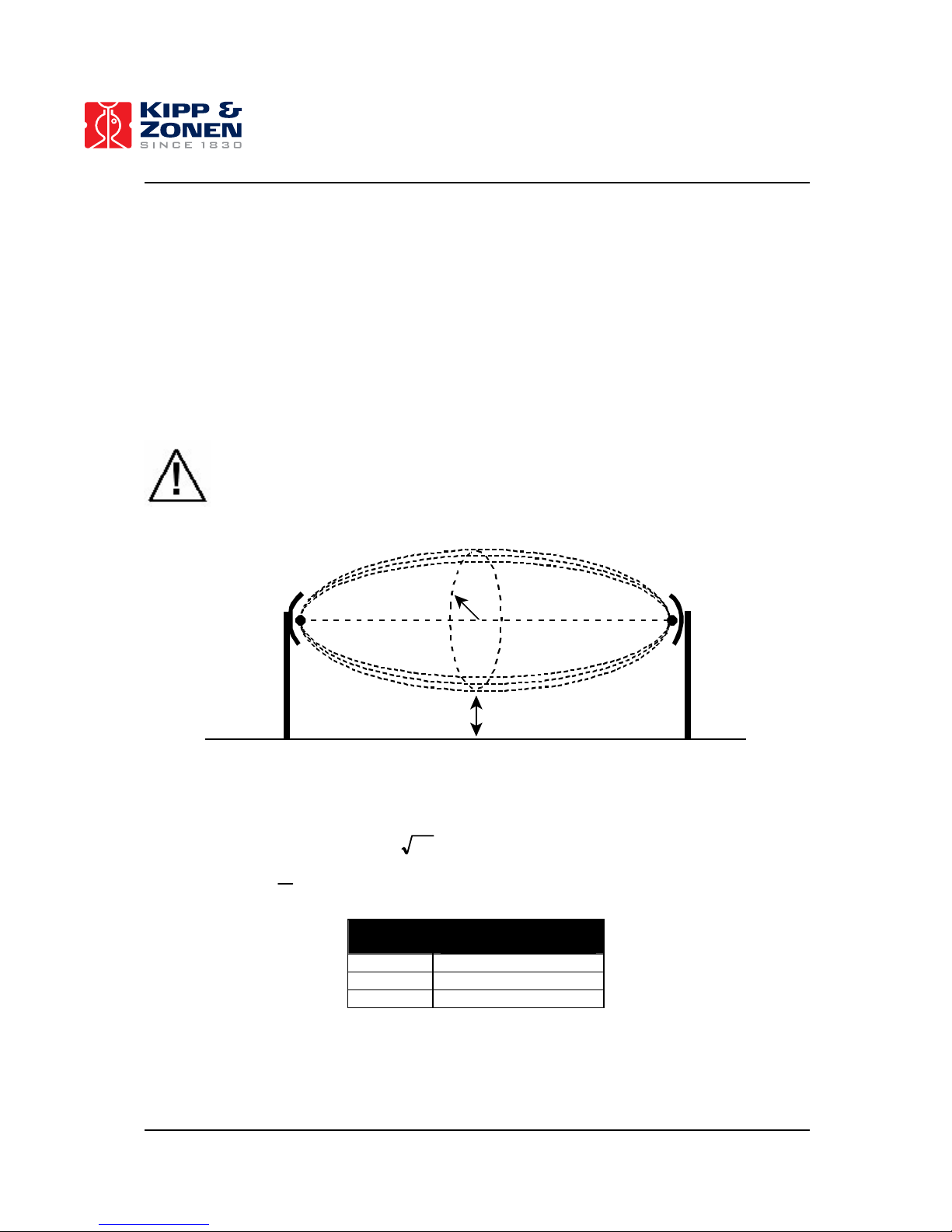

h10distanceminimum = (5)

where h is height of the obstacle(s).

Checklist: - Terrain must be free from obstacles that might influence the wind speed,

temperature and radiation measurements.

- Terrain must be flat. As the anchoring of the mast is based on 3 provided earth nails

the soil must be strong enough to keep the loads (also during rainy periods). If

one expects that this is not the case replace the anchoring by a concrete

foundation.

- A clear line-of-sight path between the antenna in the tower and the antenna at the

LAS-receiver site in order to have a reliable RF telecommunication link.

- The site must NOT be located near commercial transmitters as their powerful signal

can overwhelm the RF radio modem leading to communication problems.

It is strongly advised first to check whether the selected site meets all above-mentioned requirements

before installing the weather station.

Page 20

19

3.2.4.2 Installation of mast and mounting of sensors

The mast is pre-assembled, still horizontally on the ground in accordance with dimension sketch

shown in Figure 11. Hereby care has to be taken that the admissible clamping zone is not exceeded

(indicated by an upper and lower mark with red stripes in between for each section). The mast’s

nominal length is gained when clamping the sections at their lower marks. The base plate with its

centre pin is screwed to the lowest section’s bottom.

Figure 6: Clamping zone of mast sections are indicated by red stripes printed on the mast sections.

Sensor arms (a one-sided, a two-sided and an U-cross arm), sensors (temperature, relative humidity,

net radiation, wind speed and wind direction), lightning rod, antenna are equally pre-assembled

according to the individual system configuration (see Table 3 and Figure 7 to Figure 11). Connect the

antenna cable to the antenna and use self-amalgamating tape to prevent water entering the

connector. Use cable ties to fix all sensor cables to the mast/arms and lead them to the lower end of

the mast, where at a later stage the steel enclosure will be mounted.

Figure 7: Mast, sensors, cables and guys are pre-assembled before the mast is erected.

Page 21

20

Figure 8: Protect all antenna connectors from water using self-amalgamating tape.

The complete guys, consisting of 3 wires and 1 collar, incl. accessories, are supplied pre-assembled.

The lower guy ends are 0.3 m longer than theoretically required in order to balance the mast on an

uneven surface. Apart from that, a surface as plain and tight as possible should be selected for the

weather station! Two guy ends have to be equipped with a plain thimble, while the third one gets an

additional spanner, featuring a fine alignment after erection (see Figure 10).

After having defined the exact position of the mast, the mast is erected by two persons. While one

person holds the mast in upright position the second person can determine the precise locations

where the earth nails have to be driven into the soil (see Figure 9 and Figure 13). The nails should

have an angle of about 20

o

with respect to the vertical (Figure 11).

Figure 9: Determine the precise location of the nails using the guys.

The earth nail with additional spanner must be done as last. Before you determine the exact position

of the last earth nail, first set the spanner to maximum range so you have enough room for adjusting

the spanner for levelling the mast precisely (using a water balance). Finally, the base plate of the mast

can be fixed using 4 small nails and the mast can be grounded via the grounding rod.

Page 22

21

Figure 10: Fine adjustment of the spanner for levelling the mast.

Important: The wire tension has to be moderate and equal. By no means bending forces are

allowed to be applied to the mast!

Important: It is very important to check the anchoring for correct and tight position,

frequently. Especially after high wind speeds occurred. If the soil seems not to be tight

enough to keep the loads, the anchoring has to be replaced by concrete foundations. If

the load lengthens the wires, their length has to be readjusted. The wire condition has to

be checked frequently. Damaged wires have to be replaced at once!

48mm

50mm

60mm

55mm

4.0m

3.0m

1.7m

2.0m

20

o

Figure 11: Dimension sketch of 4 m mast. The earth nails should have an angle of about 20o with the

vertical.

Page 23

22

Important: The minimum distance between the upper and lower temperature sensor

should be at least 1.7 m in order to measure a reliable temperature gradient, with the

lower temperature at a height lower than 1m! When the sensors are positioned too

close to each other (or both installed too high) no distinctive diurnal temperature

gradient can be measured along the day. This will lead to misinterpretation of the

atmospheric stability by the EVATION software.

Table 3: Typical sensor height and orientation of sensors in the 4 m mast.

Sensor Typical

Height/depth

Arm Orientation/Direction

1 Wind speed (u)

± 4.4 m

U-cross arm -

2 Wind direction (WD)

± 4.2 m

U-cross arm -

3 Antenna

± 3.5 m

- To LAS-Receiver

4 Air Temperature (upper

level) (T

+

)

± 2.7 m

Two-sided cross arm Opposite of radiation sensor

5 Net radiation (Q* or Rn)

± 2.7 m

Two-sided cross arm South on N. Hemisphere

North on S. Hemisphere

6 Air Temperature (lower

level) (T

-

)

± 0.5 m

One-sided cross arm Below upper temperature

sensor (lower temp. sensor

must be lower than 0.8m! ;

distance between upper and

lower temp. sensor must be

at least 1.7 m!)

7 Soil heat flux plate 1 (G1

or HFP

1

)

0.003 – 0.03 m - At same side of mast as the net

radiation sensor

8 Soil heat flux plate 2 (G2

or HFP

2

)

0.003 – 0.03 m - At same side of mast as the net

radiation sensor

9 Air pressure (P) - Inside enclosure 9 Solar panel At the base of

the tower

Use extendable arms

and small pins

South on N. Hemisphere

North on S. Hemisphere

10 Enclosure for data

logger and power supply

At the base of

the tower

- Opposite of solar panel

Page 24

23

Lightning rod

Wind direction

Wind speed

Temperature

Net radiation

Steel housing

Temperature

Solar panel

Earth pin

Antenna

0.45m

1.2m

1.7m !!

~ 0.6m !!

Figure 12: Overview of 4 m mast equipped with sensors, antenna, solar panel and steel enclosure for data

logger, power supply (battery) and RF modem.

Page 25

24

120

o

Guys

Steel enclosure

T/RH sensor on 2-sided arm

Mast and

base plate

Net radiation sensor

Solar panel

Earth nails

Figure 13: 4 m mast seen from above, showing the orientation of the sensors, enclosure, arms and guys.

The last sensors that have to be installed are the soil heat flux plates. Place them at the same side of

the mast where the net radiation sensor is mounted, preferably at a spot that is not disturbed by

footsteps. Remember that the measurements should be representative for a large area! Do not

position the plates directly beneath the net radiation sensor, as they may disturb the net radiation

measurements. Depending on the soil type and the presence of vegetation the plates are buried at a

depth of about 0.03 m (bare soil conditions) or just beneath the surface at 0.003 m (fully covered soil).

In the latter case the amount of ‘missing’ flux is as small as possible. Note that plates at depths of 10

cm can underestimate the soil heat flux by more than 50%! Prevent that the plates are measuring in

air gaps or cracks (i.e. avoid air gaps between the soil and the plates)! When using more than 1 plate,

burry them at the same depth. It is safest to install plates at depth’s of > 3 cm from the side, to prevent

disturbance of the covering soil layer!

3.2.4.3 Mounting enclosure, solar panel and connecting wires

Once the mast (plus arms and sensors) is erected and levelled, the stainless steel enclosure plus the

solar panel can be fixed on the mast. The solar panel should be facing south (on Northern

hemisphere) or north (on Southern hemisphere) to have maximum insolation over the year. The solar

panel is partly fixed on the mast and partly on the ground using 2 earth nails such that it is tilted to

have maximum efficiency. Use the extendable legs of the solar panel to get the desired tilt angle.

Once the tilt angle is set, use the 2 earth nails to fix the legs on the ground.

The enclosure is best mounted opposite of the solar panel. All cables (signal, antenna and power)

enter the enclosure at the bottom through the cable ducts. Connect all sensor cables to the data

logger (via the over voltage protection, see Figure 15) according to the connection plan (see

APPENDIX 9 – CONNECTION PLAN) and the antenna cable to the RF modem via the adapter and

lightning arrestor). Finally, the power cable of the solar panel can be connected to the solar controller.

Ensure correct polarity (brown is + and blue is - )!!!

Page 26

25

Figure 14: The steel enclosure is fixed to the mast opposite of the solar panel that is facing south (or

north on southern hemisphere) and mounted as low as possible in order to leave enough flexibility for the

lower temperature sensor. Finally, the wires are led into the enclosure via the cable ducts.

Important: do not place the solar panel directly beneath the radiation sensor. Reflected solar

radiation from the solar panel to the radiation sensor will significantly disturb the

measurements.

Once the enclosure and the solar panel are properly fixed and all sensor cables are connected, the

battery can be placed inside the enclosure. Connect the battery-power cables of the solar controller to

the battery poles. Ensure correct polarity (brown is + and blue is - )!!! The data logger will

automatically start measuring.

Once again, check that everything is properly fixed in the mast (i.e. the levelling of the net radiation

sensor, the alignment/orientation of the antenna), preferably using a small portable ladder. Verify that

the sensors and the RF link are working properly (see section 5. OPERATION and APPENDIX 6 –

INSPECTION PROCEDURE) including the date and time setting of the COMBILOG data loggers. To

change date and time go to APPENDIX 7 – SETTING DATE / TIME COMBILOG. In case you have

multiple COMBILOG data loggers, check them all.

When the system is working properly roll up redundant signal, antenna and power cables and fix them

to the mast (between the solar panel and the enclosure) using cable ties. Do not lay the cables on the

ground as insects and small animals might damage the cables.

As final step we recommend to fill in the Installation Form of the LAS-system (see APPENDIX 5 –

INSTALLATION FORM). This Installation Form will be used to configure the EVATION software (see

Section 4.4 EVATION DATA PROCESSING SOFTWARE).

Site latitude

[o]

Tilt angle

[o]

0 – 10 10

11 – 20 Latitude + 5

21 – 45 Latitude + 10

46 – 65 Latitude + 15

> 65 80

Tilt angle

Solar panel

Ground

Page 27

26

Measurem ent

signal

Power terminal

with internal

fuse

Power/sig nal

cables

Over vol tage

protectio n

12 VDC Power

RS485

Antenn a cable

RF modem

Solar panel

Solar controller

with internal fuse

12 VDC Battery

plus external fuse

Adapter and

lightning arrestor

To PC

RS232

Steel enclosure weather station

‘Load’ (1 2 VDC)

Pressure sensor

Earthing

Sensors

Figure 15: Overview of steel enclosure of weather station with RF-Telemetry link (LAS-RET system). The

data from the LAS/XLAS is collected by the MASTER COMBILOG via the RF-telemetry link (i.e. via the RF

modem and the RS-485 port of the COMBILOG).

Measurem ent

signa l

Power terminal

with internal

fuse

Power/signal

cable s

Over voltage

protectio n

12 VDC Power

To PC

RS232

Steel enclosure

12 VD C power

Pressure sensor

Earthing

LAS- Receiver + Sensors

Figure 16: Overview of steel enclosure of LAS-BET system. The power source for the LAS-Receiver, data

logger and sensors must be 12 VDC.

Page 28

27

Figure 17: Operational weather station of LAS-RET system.

Page 29

28

Page 30

29

4. SOFTWARE

The software required for the LAS-BET / LAS-RET system consists of the following software

programs:

1. COMBILOG support software

To (re)configurate COMBILOG data loggers

2. PCI Swap-box Software

7

Drivers and manual for PCMCIA FLASH Memory Card reader

3. CardWare (PCCard Control)

To read PCMCIA FLASH Memory Cards

4. EVATION data processing software

To process data from the weather station (and LAS / XLAS) to surface fluxes

5. Modified algorithms for EVATION

8

4.1 COMBILOG SUPPORT SOFTWARE

The COMBILOG support software enables the user to communicate with the COMBILOG data

loggers, via the RS-232 interface. In this way the user can re-configure the data logger program,

monitor measurements real time, change date and time, and download data from the internal

memory

(NOT from the PCMCIA Flash card!). Note that the COMBILOG data loggers are pre-configured by

Kipp & Zonen and will automatically start measuring once connected to a power supply!

The installation of the COMBILOG support software is carried out as follows:

• Insert the installation CD into the selected drive (included in manual COMBILOG Data logger)

• In case the installation does not start automatically, invoke “SETUP.exe” on the COMBILOG

CD-ROM

• Follow the instructions given by the installation program

After successful installation a new program group called COMBILOG V×.×× (Icon:

) is created.

4.1.1 Setting communication parameters

Once the COMBILOG support software is started for the first time, the communication parameters

have to be configured in order to communicate with the COMBILOG data loggers. Click on

Communication and go to Parameters. A new window appears (see Figure 18). Set the

communication parameters as follows:

Interface Kind : RS-232 RF-modem

Parameters:

ComPort : COM1

Baudrate : 19200

Char Format : 8n1

Add. Timeout : 1000 ms

7

In case one uses a portable computer with built-in PCMCIA interface the SWAP-Box software is not required.

8

Depending on configuration LAS-BET / LAS-RET system

Page 31

30

Then click on OK. The software is now ready to communicate with the COMBILIOG data loggers.

Figure 18: Setting of communication parameters in COMBILOG software.

How to communicate with COMBILOG data loggers?

• Start the COMBILOG support software.

• Connect the PC to the (MASTER) COMBILOG data logger (= “weather station”) using the

connected RS-232 interface cable.

• Click on File and go to Scan Bus. The software will automatically scan for connected

COMBILOG data loggers.

• A list of found COMBILOG data loggers will appear on screen (see Figure 19). Depending on

the configuration mode of the COMBILOG data logger, i.e. MASTER or SLAVE, one or more

COMBILOG data loggers will appear on screen (typical names are “Weather Station” and/or

“LAS”). If the PC is connected to the RS-232 of the SLAVE, the MASTER data logger will not

be visible!

• The user can now select one of these data loggers to communicate with.

Figure 19: The COMBILOG software will scan the RS-232 interface for available COMBILOG data loggers.

Page 32

31

4.1.2 Original COMBILOG module settings and programs

Depending on the LAS-BET / LAS-RET configuration either 1 or 2 (or more) COMBILOG data loggers

are included in the system. The data logger(s) are pre-configured by Kipp & Zonen and will

automatically start measuring once connected to a power supply. If necessary the user can reconfigure the data loggers using the COMBILOG support software, e.g. when extra sensors are

connected. For further instructions the user is referred to the COMBILOG instruction manual and

COMBILOG support software. The original program(s) of each data logger can be found on the

supplied CD.

In general the main configuration of the COMBILOG data loggers of the LAS-systems is as follows:

A. LAS-system with RF telemetry link (= LAS-RET, see Figure 1)

A.1 Original configuration COMBILOG 1 (Type 1020, MASTER) (see Figure 20):

Location: Station-RET

Name: Kipp

Filter freq.: 50Hz or 60Hz rejection

Auto off: Disabled

LED: Enabled

Address: 1

Protocol: Profibus/ASCII

Baud rate: 19200

Char format: 8n1

Answer delay: 1 Char Timeout

Timeout: 1 s

A.2 Original configuration COMBILOG 2 (Type 1020, SLAVE) (see Figure 21):

Location: LAS-RET

Name: Kipp

Filter freq.: 50Hz or 60Hz rejection

Auto off: Disabled

LED: Enabled

Address: 2

Protocol: Profibus/ASCII

Baud rate: 19200

Char format: 8n1

Answer delay: 1 Char Timeout

Timeout: 1 s

Page 33

32

B. LAS system without RF telemetry link (= LAS-BET, see Figure 2)

B.1 Original configuration COMBILOG (Type 1020, MASTER) (see Figure 20):

Location: LAS-BET

Name: Kipp

Filter freq.: 50Hz or 60Hz rejection

Auto off: Disabled

LED: Enabled

Address: 1

Protocol: Profibus/ASCII

Baud rate: 19200

Char format: 8n1

Answer delay: 1 Char Timeout

Timeout: 1 s

Figure 20: COMBILOG module settings ‘Weather station’.

Page 34

33

Figure 21: COMBILOG module settings ‘LAS’.

4.2 PCI-SWAP-BOX SOFTWARE

The PCI-SwapBox software is part of the PCMCIA card reader package and is intended for desktop

computers that are not equipped with a PCMCIA card reader. The installation involves two steps: the

hardware installation of the reader in the desktop PC and the software installation of the drivers. For

further instructions the reader is referred to the PCI SwapBox installation CD.

Figure 22: PCI-SwapBox card reader for desktop computers.

Page 35

34

4.3 PCMCIA FLASH MEMORY CARD SOFTWARE (CardWare)

In order to read the PCMCIA flash memory cards using either a standard built-in PCMCIA card reader

(applies to most portable computers) or the PCI SwapBox reader (see section 4.2, applies to most

desktop computers), the user has to install the provided CardWare software. CardWare allows the

user to ‘use’ the PCMCIA flash memory cards as if they were normal floppy or hard disk drives.

4.3.1 Installing CardWare software

In most cases, the following quick install procedure is all you need to know about CardWare. Once

installed, CardWare automatically configures your system to recognize almost all PC Cards, with no

intervention needed on your part. If you have special installation requirements, see Chapter "Installing

CardWare" in the CardWare manual (see “CardWare2000_XP.pdf”) for a detailed description of the

process. To install the CardWare software:

1. Remove all PC Cards from your system.

2. Run the “CWMEM2K.exe” installation program from the CD and follow the prompts through

the first screens, clicking Next or Finish to move from screen to screen.

3. When the program ends, restart your system.

4. After entering the serial number you will get a fully functional version. The serial number is

delivered separately in the file “LICENCE.txt” (available on the same CD).

5. The software is installed now. CardWare should load and automatically detect insertion and

removal of PC Cards any time during system operation.

For details, see Chapter "Cardware Installation Options" in the manual (“CardWare2000_XP.pdf”).

Once the CardWare software is installed, the user can select during each booting sequence of the

computer between two configuration profiles, namely the original configuration or the CardWare

configuration. Select CardWare configuration when using the PCMCIA flash memory cards, otherwise

select original configuration (to avoid conflicts with i.e. memory sticks or other memory cards).

Figure 23: CardWare for Windows.

4.3.2 Reading PCMCIA Flash Memory Cards

To read PCMCIA cards proceed as follows:

• Start the computer and select from the boot option CardWare configuration. The computer is

now able to understand the special format of the PCMCIA cards.

Page 36

35

• Insert the PCMCIA card in the PCMCIA reader. The icon will appear in the task bar on

your computer.

• Go to this new disk via “My Computer” or via “Microsoft Explorer”. On this disk the file

COMBILOG.log can be found.

• Copy this file to the input subdirectory of your working directory in EVATION (see 4.4.3

Getting started) and rename the copied file (e.g. YYMMDD_STATION.log). Do NOT move,

delete or rename the COMBILOG.log file from the PCMCIA flash card!

• In order to avoid crashing of Windows, eject the PCMCIA flash card using the eject/unplug

hardware button in the task bar of your computer (

). An alternative option is to use PCCard

control software (see Figure 45 or Figure 46).

• In case the COMBILOG.log file is accidentally deleted or removed. Go to APPENDIX 8 –

FORMAT PCMCIA FLASH MEMORY CARDS for further instructions.

Important: The function Eject Card should be used before removing the card from the device!

Important: PCMCIA flash memory cards cannot be read without the CardWare software!

Important: Never move, delete or rename the COMBILOG.log file from the PCMCIA flash

memory card!

4.4 EVATION DATA PROCESSING SOFTWARE

4.4.1 Installing EVATION

Once the data from the PCMCIA flash cards are stored on the hard disk of the PC, the provided

EVATION software can process the collected data to fluxes of sensible heat and evaporation. The

EVATION software can organise and process data for multiple LAS-BET / LAS-RET stations (using

selectable working directories, which in turn consist of in/output and configuration directories).

Insert the EVATION CD-ROM in your PC to start the installation of EVATION. In case the installation

does not start automatically, invoke “SETUP.EXE” on the EVATION CD-ROM. All installed files reside

in the selected EVATION program directory. After successful installation a new program group called

EVATION is created. Start this program by clicking on the EVATION icon (

).

Page 37

36

Figure 24: EVATION – LAS EVApoTranspiratION software.

4.4.2 Installing Modified Algorithms

Depending on the configuration of the LAS-system, the user may have to install an additional modified

algorithm, which is required for the data processing to fluxes. EVATION is equipped with a default

algorithm, specially designed for the LAS-BET / LAS-RET systems. Depending on the requested

LAS-system and the supplied sensors this algorithm has been modified based on a compromise of

calculating reliable fluxes and user friendliness. Note that the output of the EVATION software (i.e.

calculation of the sensible heat flux H and/or latent heat flux L

v

E) is depending on the LAS-system

configuration.

Figure 25: Depending on the LAS-ET (RF) configuration the standard or modified algorithm is selected.

The installation of additional modified algorithms is done separately and is done only after successful

installation of the EVATION software. Modified algorithms can be found on separately delivered CD

Page 38

37

and are installed simply by clicking on ‘SETUP.EXE” and following the installation procedure. After

successful installation the user can select between the different algorithms in the configuration menu

of the EVATION software (see Figure 25).

Important: The use of an incorrect algorithm can lead to processing errors! Therefore

carefully check if the selected algorithm applies to your LAS-BET / LAS-RET system!

Depending on the delivered LAS-system a modified algorithm (on a separate CD) is included.

4.4.3 Getting started

EVATION is a user-friendly software program that allows the user to process LAS measurements to

surface fluxes of sensible heat and evaporation. Before the data of a LAS-system can be processed to

fluxes, first some configurations have to be set in EVATION. The configuration involves a number of

small steps (see Figure 26). First, a working directory (consists of an input subdirectory, an output

subdirectory and a configuration subdirectory) has to be selected or configured. In case one uses

more than 1 LAS-system, separate working directories have to be selected for each system. Once a

working directory is selected EVATION will create subdirectories labelled “input”, “output”, “config” and

“auxiliary”. Next the configuration of the LAS-system has to be entered in the EVATION software. This

is done via the configuration window. Here, various parameters have to be set, such as LAS-type,

sensor height (or depth), scintillometer path length, terrain characteristics (e.g. surface roughness),

required algorithm (see section 4.4.2 Installing Modified Algorithms and Figure 25), and configuration

of the output ‘flux’ files. To get familiar with EVATION we recommend first studying the help file before

continuing with EVATION. The help file can be viewed by clicking on help, and following contents.

Figure 26: EVATION configuration menu.

Page 39

38

Page 40

39

5. OPERATION

Once the LAS / XLAS and the weather station are installed and connected to a power source, the

data logger of the LAS-BET / LAS-RET system will automatically start measuring. All COMBILOG

data loggers are pre-configured by Kipp & Zonen start automatically when connected to a power

source. The actual measurements can be monitored using the display on the COMBILOG data logger

or via the COMBILOG support software on a computer that is connected to the COMBILOG’s RS-232

interface.

5.1 REAL-TIME MONITORING OF MEASUREMENTS

5.1.1 Via COMBILOG support software

Once a PC is connected to the COMBILOG data logger of the weather station ALL measurements

can be monitored real-time. After selecting either the “weather station” or “LAS” labelled data logger

(see 4.1.1 Setting communication parameters), the actual measurements can be viewed via the

Measure window (see Figure 27 and Figure 28). In Table 4 the range and units of all measurement

signals are given.

Figure 27: Real time monitoring of measurements of “weather station” (MASTER) data logger via the

COMBILOG support software.

Note that for the LAS-RET system the COMBILOG data logger at the weather station is the MASTER

data logger and the COMBILOG data logger at the LAS-receiver is the SLAVE data logger. This

means that a PC, which is connected to the MASTER (= “weather station”) data logger, can monitor

the measurements of both the MASTER as well as the SLAVE (= “LAS”) data logger. The MASTER is

“transparent”. When the PC is connected to the SLAVE data logger, the MASTER cannot be

monitored! The “transparent” mode of the MASTER allows reprogramming (and downloading of data)

of the SLAVE data logger via the RS-232 of the MASTER.

Page 41

40

Figure 28: Real time monitoring of LAS/XLAS measurements of “LAS” (SLAVE) data logger via the

COMBILOG support software (applies to LAS-RET system!).

Table 4: Symbol, measurement range and units of (optional) sensors of LAS-systems.

Sensors Symbol Unit Range

1 Air temperature upper level

(Derived from upper PT100)

T+

o

C -20 to +50 oC

2 Air temperature lower level

(Derived from lower PT100)

T-

o

C -20 to +50 oC

3 Relative humidity DRH %

Default @ 50 %

9

4 Air pressure Pres hPa 600 to 1050 hPa

5 Wind speed U m s-1 0 to 60 m s-1

6 Wind direction WD or DWD

o

0 to 360 o

7 Soil heat flux plate 1

G

1

or HFP1-sn×××

W m

-2

-200 to +200 W m-2

8 Soil heat flux plate 2

G

2

or HFP2-sn×××

W m

-2

-200 to +200 W m-2

9 Net radiation

Rn-sn×××

W m-2 -250 to +1500 W m-2

10 Resistance upper PT100

PT100-sn××× Ω 80 to 120 Ω

11 Resistance lower PT100

PT100-sn××× Ω 80 to 120 Ω

LAS/XLAS signals Symbol Unit Range

1 Scaled C

n

2

(= PUCn21000)

(C

n

2

= PUCn21000 * 1.10

-15

)

PUCn21000 m

-2/3

0.01 to 1000 m

-2/3

2 Standard deviation of PUCn21000 Std PUCn21000 m

-2/3

3 U

CN2

(expressed as a voltage)

()

12

2

2

10−=

CN

U

n

C

Cn2 V -5 to 0 V

4 Standard deviation of U

CN2

(expressed as a

voltage)

Std Cn2 V

5 Signal strength (U

Demod

) Demod mV -1000 to 0 mV

6 Standard deviation of signal strength (U

Demod

) Std Demod mV

9

The LAS-BET and RET system are not supplied with a humidity sensor. Instead a default value of 50% is used

(the default value can be easily altered).

Page 42

41

5.1.2 Via display of COMBILOG

The output of each channel can also be monitored on the display of the COMBILOG using the

“SELECT” press/rotary knob on the data logger. Simply by rotating the press/rotary the Main Menu

can be scanned, which includes the actual measurements of each sensor plus the units (see Figure

29).

Combilog 1020+

U 3.xx

Dat e: dd. mm.yy

Time: hh.mm. ss

LOG: 0 253k b

free: 2 7d

PCMCIA: 1904kb

free: 100d

Chan 1

xx [units]

Chan x

xx [units]

Figure 29: Main menu of COMBILOG to monitor the actual measurement output of each sensors (see

Chan. 1 to Chan. X). Description symbols:

3 …. Turn knob clockwise

4 …. Turn knob counter clockwise

5.2 CALIBRATION COEFFICIENTS

Some of the sensors of the LAS-BET / LAS-RET system are supplied with calibration certificates, e.g.

the radiation sensors, the soil heat flux plates and PT100 temperature sensors. The calibration

constants can be found in either the separate instruction manuals or in the original COMBILOG data

logger programs, which is programmed into the COMBILOG’s internal memory. The original

COMBILOG programs plus applied calibration constants are available on the supplied CD (see also

4.1.2 Original COMBILOG module settings and programs).

Page 43

42

5.3 DATA FILES

The data files of the COMBILOG data logger (via PCMCIA Flash Cards) are formatted as follows

(columns, separated by tabs):

1. Date

2. Time (= Begin-Time of interval !!!)

3. Air temperature upper sensor [T+,

o

C]

4. Air temperature lower sensor [T-,

o

C]

5. Relative humidity [DRH, default @ 50%]

6. Air pressure [P, hPa]

7. Wind speed [u, m s

-1

]

8. Wind direction [WD or DWD,

o

]

9. Soil heat flux (plate 1) [G

1

or HFP1, W m-2]

10. Soil heat flux (plate 2) [G

2

or HFP2, W m-2]

11. Net radiation [Q* or R

n

, W m-2]

12. Scaled C

n

2

[PU

CN2

, m

-2/3

]

13. Standard deviation of scaled C

n

2

[m

-2/3

]

14. Demod (= signal strength) [U

DEMOD

, mV]

15. Standard deviation of Demod [mV]

The number of columns (in this case 15) is constant and independent of the sensor configuration of

the LAS-system. In case fewer sensors are used dummy values are placed (-9999) in the ‘empty’

columns of the specific missing sensor. Note that the columns may not be interchanged! A more

detailed description of the data files and format can be found in the help file of the EVATION software.

Page 44

43

6. MAINTENANCE

To be certain that the quality of the measurements is of high standard, care must be taken with the

maintenance of the weather station. A visual inspection routine of the weather station, at regular

intervals (~2 weeks) is therefore highly recommended (for more information go to APPENDIX 6 –

INSPECTION PROCEDURE).

Page 45

44

Page 46

45

7. TROUBLE SHOOTING

The guidelines given in APPENDIX 6 – INSPECTION PROCEDURE help you to maintain the LASBET / LAS-RET system and if necessary to isolate “hardware” related problems such as:

• Power source problems of the weather station (e.g. short circuits, blown fuses, loose cables,

battery status, etc)

• Sensor problems of the weather station, such as the net radiation, soil heat flux, air pressure,

air temperature, wind speed and direction sensors (e.g. loose or damaged cables, dirt,

leveling, sensor failure etc).

• LAS / LAS related problems (e.g. power failure transmitter/receiver units, blown fuses,

misalignment, poor visibility, etc)

• RF telemetry problems between receiver and weather station (e.g. power failure, misalignment

antennas, cable/connector damages, RF modem failure, etc)

If necessary, consult the separate manual of a specific sensor for further information and instructions

to solve problems.

For “software” related problems, isolate which software program appears to give problems and consult

the available help files for further instructions.

If still no satisfactory answer/solution is found after reviewing this manual, the separate instruction

manuals and/or help files, please contact your supplier or Kipp & Zonen.

Page 47

46

APPENDIX 1 – TESTING RF TELEMETRY LINK

Requirements:

• 1 × (portable) computer (Windows 95/98/2000, NT or XP) with an available RS-232 serial port.

• 2 × XStream-PKG-R RF Modems configured in RS-232 mode (see APPENDIX 2 – DIP

SWITCH SETTINGS RF MODEM).

• 1 × standard 1:1 RS-232 cable with one 9-pin Sub-D male and one 9-pin Sub-D female

connector.

• 1 × serial loop-back adapter

• 2 × 9V battery clip and 9V battery (or 2 × power adapters).

• 2 × Yagi/Vagi antennas and antenna kits (cables, adapters and surge protection)

• XCTU configuration software

Installing the XCTU software:

• Double-click the “setup-XCTU.exe” file located in the “Software” folder of the included CD.

• Follow the prompts of the installation screens.

Hardware set-up:

1. Connect one RF modem (Radio1) to the PC serial port using the RS-232 cable.

2. Attach the serial loop-back adapter to the DB-9 serial connector of the second RF modem

(Radio2). The serial loop-back adapter configures Radio2 to function as a repeater by looping

serial data back into the radio for retransmission.

3. Check that both RF modems operate in RS-232 mode (see APPENDIX 2 – DIP SWITCH

SETTINGS RF MODEM).

4. Attach the directional Yagi/Vagi antennas (plus cables, adapters and lightning arrestors) to

Radio1 and Radio2. For mounting instructions of the antennas the reader is referred to

APPENDIX 3 – MOUNTING ANTENNAS.

5. Power Radio1 and Radio2 using the supplied power adapters or 9V battery clips.

Figure 30: Hardware set-up for RF communication test between Radio1 (located at weather station site)

and Radio2 (located at LAS-Receiver site).

Procedure for testing RF communication link between the selected sites of the weather station and the

LAS-Receiver:

1. Start the XCTU software program.

2. Select the PC Serial com port from the dropdown list that will be used to connect to Radio1

(see tab “Setup”). Generally COM1 is used. COM set-up should be as follows: Baud 19200;

Flow control: NONE; Data Bits: 8; Parity: NONE; Stop Bits: 1 (see Figure 31).

Page 48

47

3. Go to "Com Test" tab.

4. Check the box in the "RSSI" section to enable its display (Figure 32).

5. Choose the "Loop Back" option in the "Com Direction" section (Figure 32).

6. Click the "Start" button to begin the range test (Figure 32).

7. Monitor the signal strength indicator quality of sent/received data. If necessary move antennas

(re-align, height, position) for better signal strength.

Figure 31: Configuration COM port of PC.

Figure 32: Communication test of RF telemetry link.

Important: This radio equipment is approved only for mobile and base station transmitting

devices, separation distances of (i) 20 centimeters or more for antennas with gains < 6 dBi

or (ii) 2 meters or more for antennas with gains ≥ 6 dBi should be maintained between the

antenna of this device and nearby persons during operation. To ensure compliance,

operation at distances closer than this is not recommended.

Page 49

48

Page 50

49

APPENDIX 2 – DIP SWITCH SETTINGS RF MODEM

1. DIP Switches RF Modem

RS-485 operation (for communication with COMBILOG data loggers using RS-485 interface cable):

(2-Wire half duplex)

RS-232 operation (for communication with PC using RS-232 interface cable):

2. Advanced RF Modem configuration

While XStream-PKG-R RF modems operate out-of-box without configuration, you can use the

supplied Xstream-CTU configuration software to change the parameter settings of the RF modems

(default settings RF modem, see Figure 33) such as:

• Changing Interface baud rates

• Advanced addressing capabilities, such as DT and HP (see below)

• etc

In case two or more LAS-RET stations are operational within several kilometres and the user(s)

experience communication problems, the following settings can be modified:

• Module Address (DT): Used to set the Module Address of the module. Only modules with the

same Module Address can communicate.

• Network Number (HP): Adjusting the network number allows the module to hop on a different

hopping sequence. This allows independent networks of modules to operate in the same

vicinity.

Important: Be sure that data loggers that have to communicate with each other have the

same Module Address (DT) and same Network number (HP)!

Page 51

50

Figure 33: Configuration screen and default settings of supplied RF modems.

Page 52

51

APPENDIX 3 – MOUNTING ANTENNAS

Warning: Do not install antennas near power lines. Serious electrocution hazard exists. You

can be killed!

The supplied antenna for the radio modem at the LAS receiver side is a 16 dBi Vagi-type (2.4 GHz

system) directional antenna, specifically designed to transmit in one particular direction allowing long

range applications. The antennas can be mounted horizontally (horizontal polarization) or vertically

(vertical polarization) (see Figure 34). To have radio communication both antennas must have the

same polarization (in general vertically)!

Figure 34: Vagi in horizontal polarization (left) and in vertical polarization (right).

The antennas come with a standard N-female connector and can be connected to one end of the