Page 1

COMBILOG 1022

Data Logger

Hardware Manual Version 1.04

Page 2

Issue: 22.01.2010

Technical data are subject to change!

Hardware Manual COMBILOG 1022

2

Page 3

Copyright 1995-2010, Theodor Friedrichs & CO

(Germany).

Copyrights: Operating instructions, manuals and software are

subject of copyright. Copying, duplication, translation, conversion into any electronic medium or any machine readable form,

as a whole or in parts, is not permitted, with the exception of

making a back-up copy of the software for saving purposes, insofar as this is technically feasible and is recommended by our

company. Contraventions will lead to compensation.

Limitation of Liability: No liability is assumed by Theodor

Friedrichs for damages and/or injury resulting from use of

equipment supplied by this company. In no event will Theodor

Friedrichs be liable for indirect or consequential damages whatsoever resulting from loss of use, data or profits arising out of

connection with the use of performance of Theodor Friedrichs

products. Theodor Friedrichs products are not designed, intended, or authorized for use as components and medical systems, or other applications indeed to support or sustain life, or

for any other application in which the failure of the Theodor

Friedrichs product(s) could create a situation where personal

injury or death may occur.

Any claims against Theodor Friedrichs in connection with the

hardware and software products described in this manual can

exclusively be based on the guarantee regulations. Any further

claims are excluded, in particular Theodor Friedrichs does not

give any guarantee as to the correctness of the contents of this

manual. Changes are subject to alteration and can be executed

any time without advanced notice.

Trade Marks: Without going into details, we want to point out

the usage of indications and entered trade marks, in particular

the indications and trade marks of Microsoft Corporation, In-

ternational Business Machines Corporation and Intel Corporation.

________________________________________

Hardware Manual COMBILOG 1022

3

Page 4

Hardware Manual COMBILOG 1022

4

Page 5

CHAPT ER S UR VE Y

Page

1 GENERAL PRELIMINARY REMARKS...............10

2 SYSTEM DESCRIPTION........................................12

3 INSTALLATION.......................................................19

4 SIGNAL PROCESSING..........................................28

5 FUNCTIONAL DESCRIPTION..............................34

6 DISPLAY / MENU OPERATION...........................60

7 DATA STORAGE.....................................................74

8 MASTER FUNCTION..............................................81

9 INITIATION AND TEST..........................................84

10 STRUCTURE OF THE BUS TOPOLOGY...........86

11 COMMUNICATION..................................................99

12 WEBSERVER.........................................................144

13 SPECIFICATIONS.................................................147

14 SIMPLIFIED DRAWINGS....................................154

Hardware Manual COMBILOG 1022

5

Page 6

TABLE O F CO NT EN TS

Page

1 GENERAL PRELIMINARY REMARKS...............10

1.1 About this Manual....................................................................10

1.2 Important Notice......................................................................10

1.3 Contact for Inquiries................................................................11

2 SYSTEM DESCRIPTION........................................12

2.1 System Overview.....................................................................12

2.2 Range of Application...............................................................13

2.3 Features..................................................................................15

2.4 Configuration Software............................................................17

3 INSTALLATION.......................................................19

3.1 Mounting / Fixing.....................................................................19

3.2 Protective System....................................................................19

3.3 Ambient Temperature..............................................................20

3.4 Front panel / Pin Assignment..................................................20

3.5 Connection .............................................................................22

3.6 Power Supply..........................................................................23

3.7 Bus Connection.......................................................................25

3.8 Sensor Connection..................................................................26

3.9 Several Sensors at one Data Logger......................................27

3.10 Module Jack............................................................................27

4 SIGNAL PROCESSING..........................................28

4.1 Analogue Inputs.......................................................................28

4.2 Digital Inputs/Outputs..............................................................28

4.3 Power Switch...........................................................................29

4.4 Internal Reference Voltage, Offset- and Drift Correction.........30

4.5 Internal Processing..................................................................31

4.6 Scan Rate and Power Consumption.......................................32

4.7 Signal Processing....................................................................33

Hardware Manual COMBILOG 1022

6

Page 7

5 FUNCTIONAL DESCRIPTION..............................34

5.1 Analogue Input Channel..........................................................35

5.1.1 Voltage Measurement.............................................................36

5.1.2 Current Measurement..............................................................38

5.1.3 Resistance Measurement........................................................40

5.2 Digital Input Channel...............................................................45

5.2.1 Digital Status Recording..........................................................46

5.2.2 Frequency Measurement.........................................................47

5.2.3 Progressive Counter................................................................49

5.3 Digital Output Channel............................................................50

5.3.1 Digital Status Output:...............................................................50

5.4 Arithmetic Channel..................................................................52

5.5 Setpoint Channel.....................................................................58

5.6 Alarm Channel.........................................................................58

5.7 Serial Channel.........................................................................58

5.8 Threshold Values.....................................................................58

5.9 Error Handling.........................................................................59

6 DISPLAY / MENU OPERATION...........................60

6.1 Display and Operation.............................................................60

6.2 Menu Items..............................................................................60

6.3 SD-Card...................................................................................72

6.3.1 Remove Card..........................................................................72

6.3.2 Firmware Update.....................................................................73

7 DATA STORAGE.....................................................74

7.1 General Remarks to Data Storage..........................................74

7.2 Modes of Data Storage............................................................74

7.3 Storage Medium......................................................................75

7.4 Internal Data Storage..............................................................76

7.5 External Data Storage with SD Card.......................................78

8 MASTER FUNCTION..............................................81

8.1 Master Function.......................................................................81

Hardware Manual COMBILOG 1022

7

Page 8

9 INITIATION AND TEST..........................................84

9.1 Before Connecting the Device.................................................84

9.2 After Connecting the Device....................................................84

9.3 Configuration of the Data Logger............................................84

10 STRUCTURE OF THE BUS TOPOLOGY...........86

10.1 Bus Interface...........................................................................87

10.2 Bus Structure...........................................................................88

10.3 Transmission Speed and Line Length.....................................89

10.4 Bus Cable................................................................................90

10.5 Bus Plug..................................................................................91

10.6 Bus Termination......................................................................92

10.7 Shielding..................................................................................94

10.8 PC Bus Connection.................................................................95

10.9 Potential Equalization..............................................................96

10.10 Adjustment of Address and Baud Rate...................................96

11 COMMUNICATION..................................................99

11.1 Bus Interface...........................................................................99

11.2 Bus Protocol............................................................................99

11.3 Data Format...........................................................................100

11.4 Output Format.......................................................................101

11.5 Transmission Sequence........................................................104

11.6 ASCII protocol.......................................................................106

11.6.1 Telegram Format for the ASCII Protocol...............................106

11.6.2 Instruction Set in the ASCII-Protocol.....................................109

11.7 PROFIBUS protocol..............................................................116

11.7.1 Telegram Format for the Profibus Protocol...........................116

11.7.2 Instruction Set in the PROFIBUS-Protocol............................120

11.8 MODBUS protocol.................................................................128

11.8.1 Telegram Format for the MODBUS-RTU Protocol................128

11.8.2 Instruction Set in MODBUS-RTU Protocol............................129

11.9 Sample Program....................................................................140

11.10 Autocall Function...................................................................141

Hardware Manual COMBILOG 1022

8

Page 9

11.11 Modem Connection...............................................................143

12 WEBSERVER.........................................................144

12.1 General..................................................................................144

12.2 System Info............................................................................144

12.3 System Log............................................................................144

12.4 Data View..............................................................................144

12.5 Data Logger...........................................................................145

12.6 Configuration / Login.............................................................145

12.7 Single Channel Configuration................................................145

12.8 Power Switch.........................................................................145

12.9 Serial Channel.......................................................................145

12.10 Logger Configuration.............................................................146

12.11 Password...............................................................................146

12.12 Protocol.................................................................................146

12.13 Logout....................................................................................146

13 SPECIFICATIONS.................................................147

13.1 Power Supply........................................................................147

13.2 Signal Inputs/Outputs............................................................147

13.3 Signal Processing..................................................................147

13.4 Analogue Inputs (8 per Module)............................................148

13.5 Digital Inputs/Outputs (6 per Module)....................................149

13.6 Interfaces...............................................................................149

13.7 Operating Conditions.............................................................151

13.8 Electromagnetic Compatibility...............................................151

13.9 Shell.......................................................................................152

13.10 Circuit....................................................................................152

13.11 Accessories / Notice for Orders.............................................152

14 SIMPLIFIED DRAWINGS....................................154

14.1 Front View.............................................................................154

Hardware Manual COMBILOG 1022

9

Page 10

1 GENERAL PRELIMINARY REMARKS

1.1 About this Manual

The manual contains all important information concerning the

function, installation and initiation of the data logger

COMBILOG 1022.

The description of the configuration software for the

COMBILOG-System is available as Online-Help within the configuration software COMBILOG.EXE.

1.2 Important Notice

Make sure to use the data logger COMBILOG 1022 exclusively

in accordance with the notices, technical data and operating

conditions mentioned in this manual. In case of inexpert handling or wrong application possible disturbances, measuring errors, effects on or from other appliances and facilities as well

as possible endangering of human lives or tangible assets cannot be excluded!

Therefore if you have not yet operated the data logger

COMBILOG 1022, you should first of all study this manual

thoroughly. While initiating or operating the appliance or in

case service is required always observe the notices given in

this manual.

Please note further that there are other special regulations to

be observed in case of application in potentially explosive surroundings (EExe, EExi, ...). These, however are not subject of

Hardware Manual COMBILOG 1022

10

Page 11

this manual, which only explains the general use of the data

logger COMBILOG 1022.

1.3 Contact for Inquiries

In case of inquiries concerning the data logger

COMBILOG 1022 please contact your local distributor or

directly Theodor Friedrichs & Co. GmbH.

Hardware Manual COMBILOG 1022

11

Page 12

2 SYSTEM DESCRIPTION

2.1 System Overview

The COMBILOG 1022 is a data logger with compact

design, combined with integrated LC-display and memory slot

suitable for SD cards.

This data logger was developed for meteorological, hydrological and environmental measuring systems, but it is equally suitable for countless further applications in industrial production.

The COMBILOG 1022 features high performance, compact

design (SMD components), low power consumption and moderate price.

The data logger is equipped with 8 analogue and 6 digital

measuring channels; further channels for numeric calculation

may be configured. Four serial interfaces RS232, RS485, USB

and Ethernet are built-in, featuring communication via ASCII,

PROFIBUS or MODBUS. Data storage is achieved by internal

Flash or SD memory card, optionally.

„SELECT“ switch and 4-line LCD on the front panel allow to

enter or modify a number of different modes and functions,

such as scan rate and averaging time, as well as offset or gain.

The COMBILOG 1022 can easily be mounted on a 35 mm

standard rail using its „snap-in“ clamp and is therefore suitable

for control cabinet installation or similar.

Thanks to its low power consumption, battery supplied systems

are possible, whereby the use of a solar panel enables any extension of measuring period.

Hardware Manual COMBILOG 1022

12

Page 13

For applications like outdoor use there is a version with stainless steel housing available, as well as various other accessories.

Configuring of the data logger is accomplished by means of an

easy to handle WINDOWSTM 98 / ME / NT / 2000 / XP software.

2.2 Range of Application

As described under (2.1), the most varying measurement tasks

can easily be accomplished by means of the COMBILOG 1022.

Some typical applications are e.g. measurement of temperature via resistance thermometers (Pt100), operation with combined sensors with current- or voltage output (e.g. wind speed

measurement with DC generator) or position measurement and

weight measurement by displacement transducers and force

transducers. With these applications the data logger

COMBILOG 1022 supports measuring methods with 2-, 3- and

4-wire technique. The signal processing required in accordance

with the sensors used, such as gain, linearisation, offset correction etc. can be adjusted individually by software. An external amplifier is not required.

The digital signal inputs can be used, for example, to connect

switches, initiators, digit emitters and oscillators. Thus status

indications can be collected and tasks like e.g. position measurements, displacement measurements, angular measurements, frequency measurements and timings can be carried

out. Furthermore special 8-bit-Graycode-transmitters can be

connected.

Special calculations of measured values are possible by arithmetic channels. In case the 8 analogue and 6 digital inputs are

not sufficient, other modules can be connected to the data

Hardware Manual COMBILOG 1022

13

Page 14

logger via the RS485 bus. In this case the COMBILOG is used

as a bus master to read the measured values from the slave

modules.

All data can be transmitted via the integrated RS485 communication interface to a subsequent control (PLC) or to a computer (PC). Up to 127 modules can be connected with the twowire line over distances of several km. At the same time the

communication interface features programming and configuring

the individual application from a PC.

If the data logger COMBILOG 1022 is not integrated in a bus,

an additional RS232-interface is available for the user. This interface allows only a point-to-point connection up to max. 20 m

(65 feet), but all functions of the RS485-interface remain available.

Furthermore the data logger can send messages in case of

user definable conditions automatically via modem or SMS.

A configuration program is included (requires Microsoft

WINDOWS 98,ME,NT,2000, XP).

Hardware Manual COMBILOG 1022

14

Page 15

2.3 Features

Function:

Measurement inputs for all common types of sensors for I,

U and R.

Several different sensors can be connected simultan-

eously

Measured values monitored by programmable thresholds

Detection of sensor errors

Detection of communication errors

Programmable error handling

Calculation of average values, minima, maxima, standard

deviation and other arithmetic functions

7 MByte Flash internal data storage, extendible with ex-

ternal SD card

Inputs and outputs:

8 analogue inputs (for 2-, 3- and 4-wire connection)

6 digital inputs/outputs (I/O ports), configurable

Power supply:

Power supply: +10 ... +30 VDC

All connections protected against excess voltage, excess

current and reverse polarity

Battery operation is possible due to low power consump-

tion

Display and operation:

LED-status indication for digital inputs/outputs

LED-status indication for malfunction and operation (ERR /

RUN)

Hardware Manual COMBILOG 1022

15

Page 16

LED-status indication for the ethernet interface

LC-display (4 x 16 characters) and push-/turn knob for op-

eration

Measured value processing:

Linearisation, scaling and conversion into physical units

Option to adjust, modify or reset the processing paramet-

ers individually

Master function to retrieve data from external modules

Programmable averaging

Automatic message transmission via modem or SMS

Non-volatile storage for program, parameters and data

Configuration:

Configurable with PC-software under

WINDOWS™ 98 / ME / NT / 2000 / XP

Menu-guided sensor selection in plain text

Free configuration of up to 32 channels

Data base for the most common sensors

Definition of user-specific sensors

Setting of type and principle of measurement

Display of pin assignment

Input of linearisation

Alarm settings

Programmable error handling

Arithmetic combination of sensor channels

Configurable measuring rate and averaging interval

Configuration on file (offline-operation)

Configuration via bus (online-operation)

Programming:

Allocation of address and baud rate via bus

Password to save the configuration and the data memory

Synchronizing of date and time with the host PC

Hardware Manual COMBILOG 1022

16

Page 17

Communication:

Integrated RS 485, RS 232, USB and Ethernet communic-

ation interface

Autonomous function independent of subsequent systems

Definition of the transmission protocol (ASCII and

PROFIBUS or MODBUS)

Definition of the telegram format (baudrate and parity)

Definition of the output format

(field length / decimals / unit)

Simple instruction set

Shell:

Compact structural shape

Attractive design

Fast mounting

Snap-on mounting on DIN rail 35 mm / 1.4 inch

Protection IP20

Plug-in screwed terminals

Module jack, ground connection

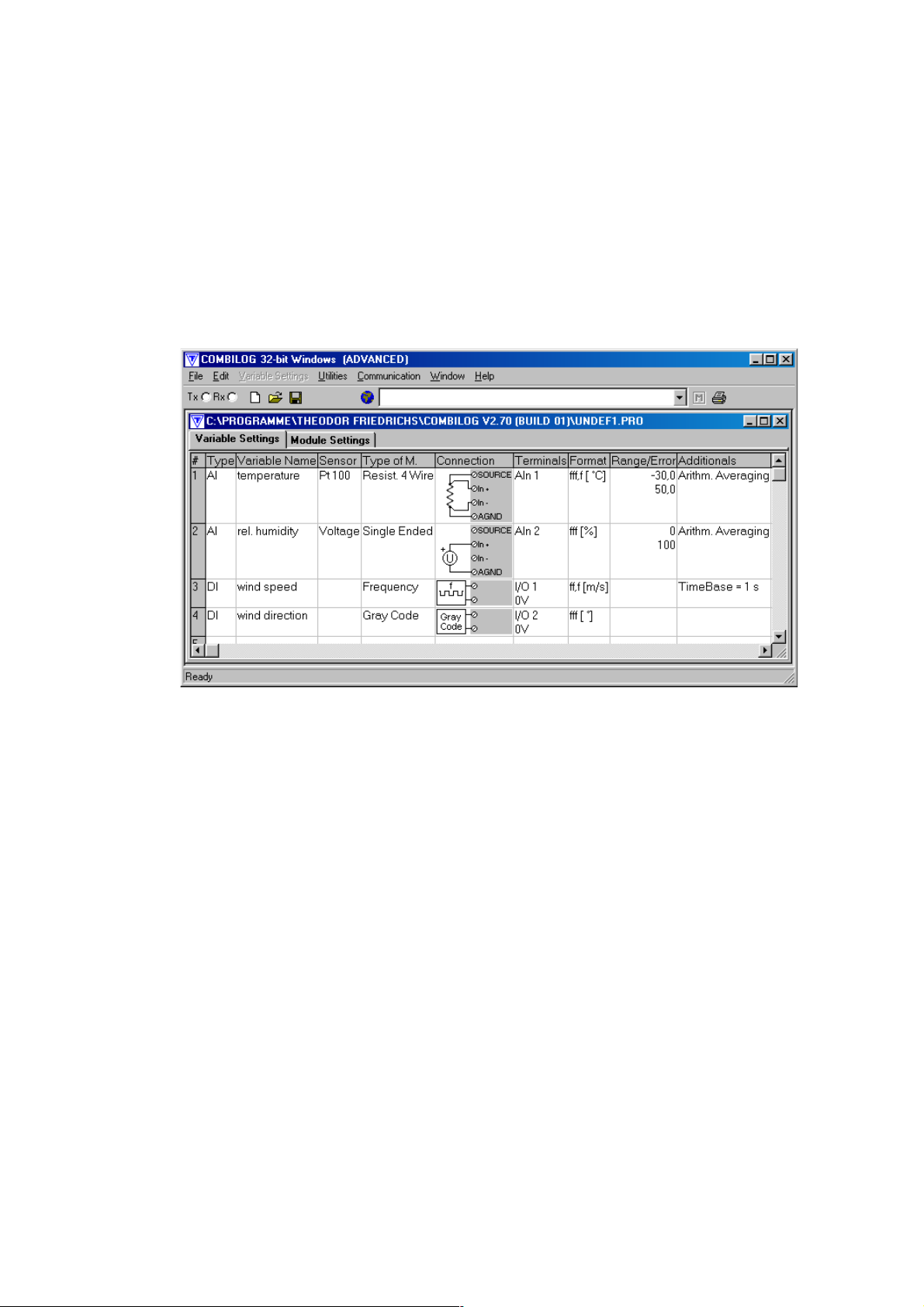

2.4 Configuration Software

The COMBILOG 1022 is delivered with a configuration software for MS WINDOWS 98/ME/NT/2000/XP. This software allows the individual configuration of the data logger.

Measuring channels are defined as variables in a variable

table.

Predefined sensors can be selected from the integrated database. The linearisation of the sensor signals will be performed

automatically. Additional sensors can be defined.

Additional parameters like scan rate, averaging interval, data

recording, error handling, automatic message generation, master function etc. are configurable. A password enables protection of the configuration and the stored data. Instantaneous

measured values can be watched directly.

Hardware Manual COMBILOG 1022

17

Page 18

In case a software update for the data logger is necessary, the

configuration program provides a download function, that

sends the new program to the logger.

Communication is supported via standard interface (RS232),

telephone or GSM modem or TCP/IP protocol.

Example for a configuration:

Hardware Manual COMBILOG 1022

18

Page 19

3 INSTALLATION

3.1 Mounting / Fixing

The data logger COMBILOG 1022 has a snap-on mounting for

installation on standard profile rails 35 mm (1.4 inch) according

to DIN EN 50022.

Installation on the DIN rail is performed by means of the four

straps on the rear side of the data logger. First push the two

straps on the bottom behind the notch of the DIN rail and then

press the data logger on the DIN rail until the two straps on the

top snap in.

In order to take the data logger off the DIN rail slide the module

lateral off the rail or in case it is not possible lift the data logger

slightly so that the straps on the top get off the notch and the

data logger can be taken off easily by pulling.

Attention: Refer to protection earth hints in chapter 3.5!

3.2 Protective System

The data logger has an IP20 protective system. For outdoor installations data logger COMBILOG 1022 can be installed in a

stainless housing type 9920, thus featuring IP66 standard.

Hardware Manual COMBILOG 1022

19

Page 20

3.3 Ambient Temperature

The admissible ambient temperature for the data logger

COMBILOG 1022 is -45 °C to +85 °C. The admissible ambient

temperature for the LC-Display is between -20°C and +60°C

and becoming very slow below 0°C.

Attention: For certain memory card types, differing temperat-

ure ranges have to be considered.

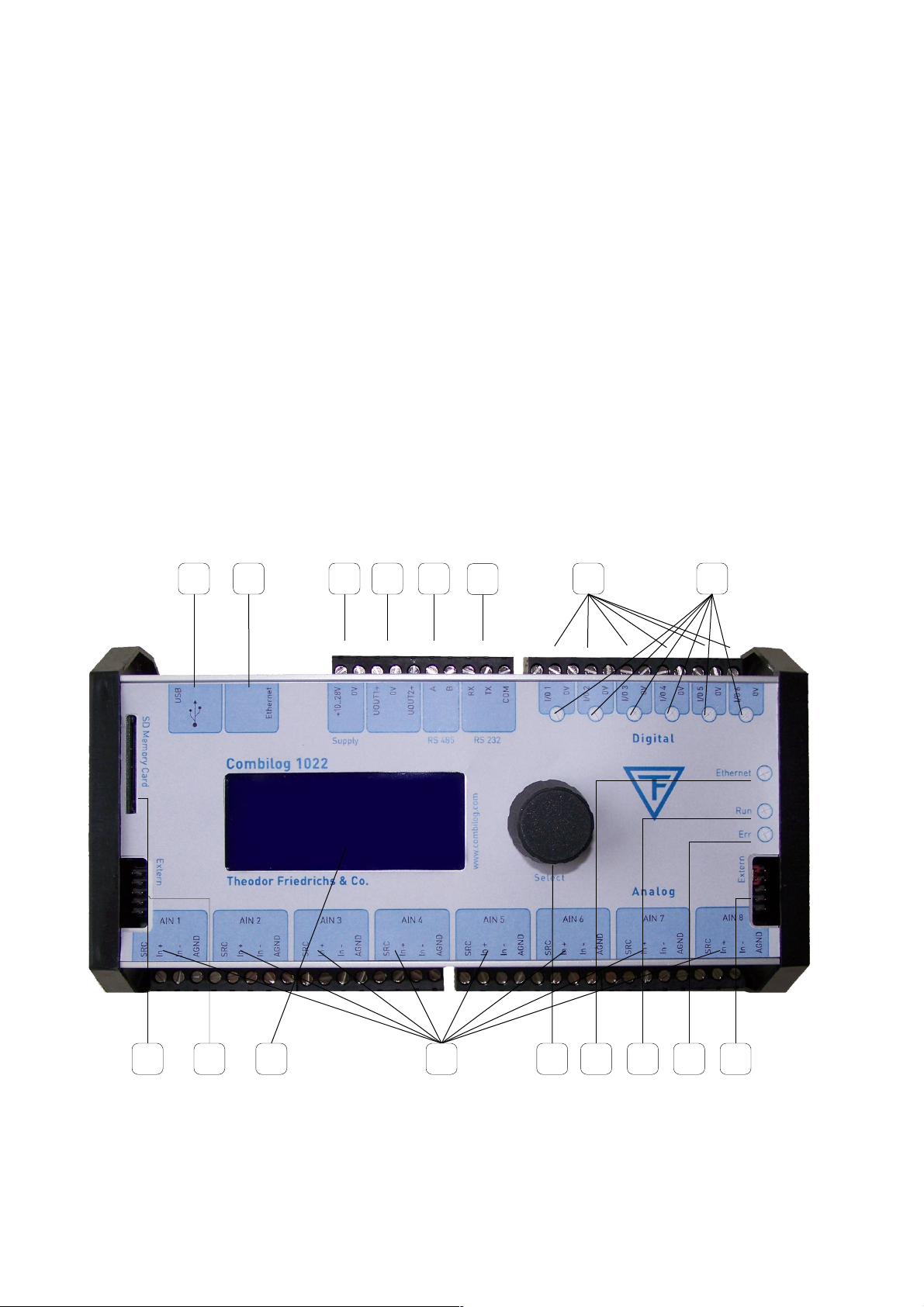

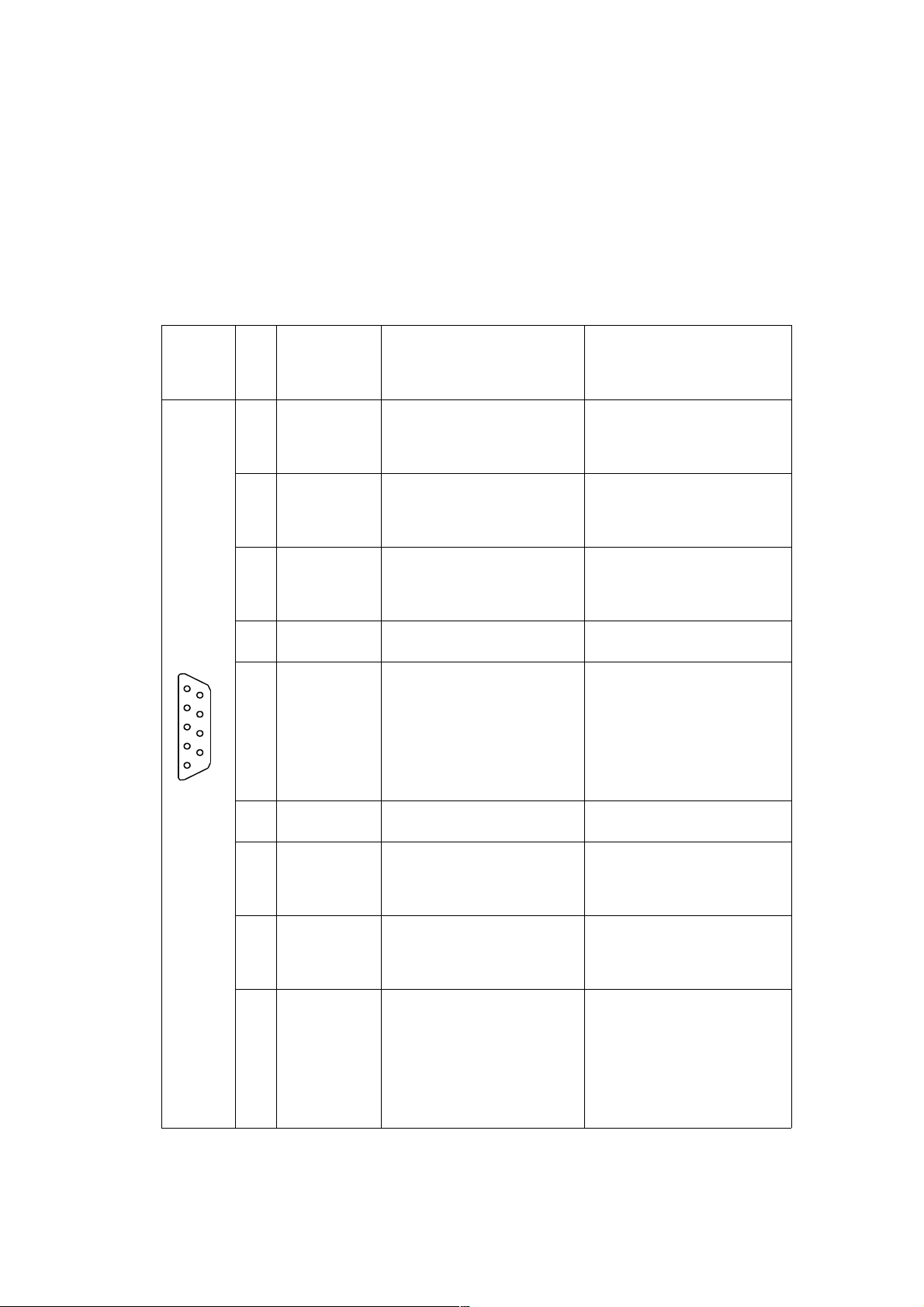

3.4 Front panel / Pin Assignment

The front panel of the data logger COMBILOG 1022 shows following elements:

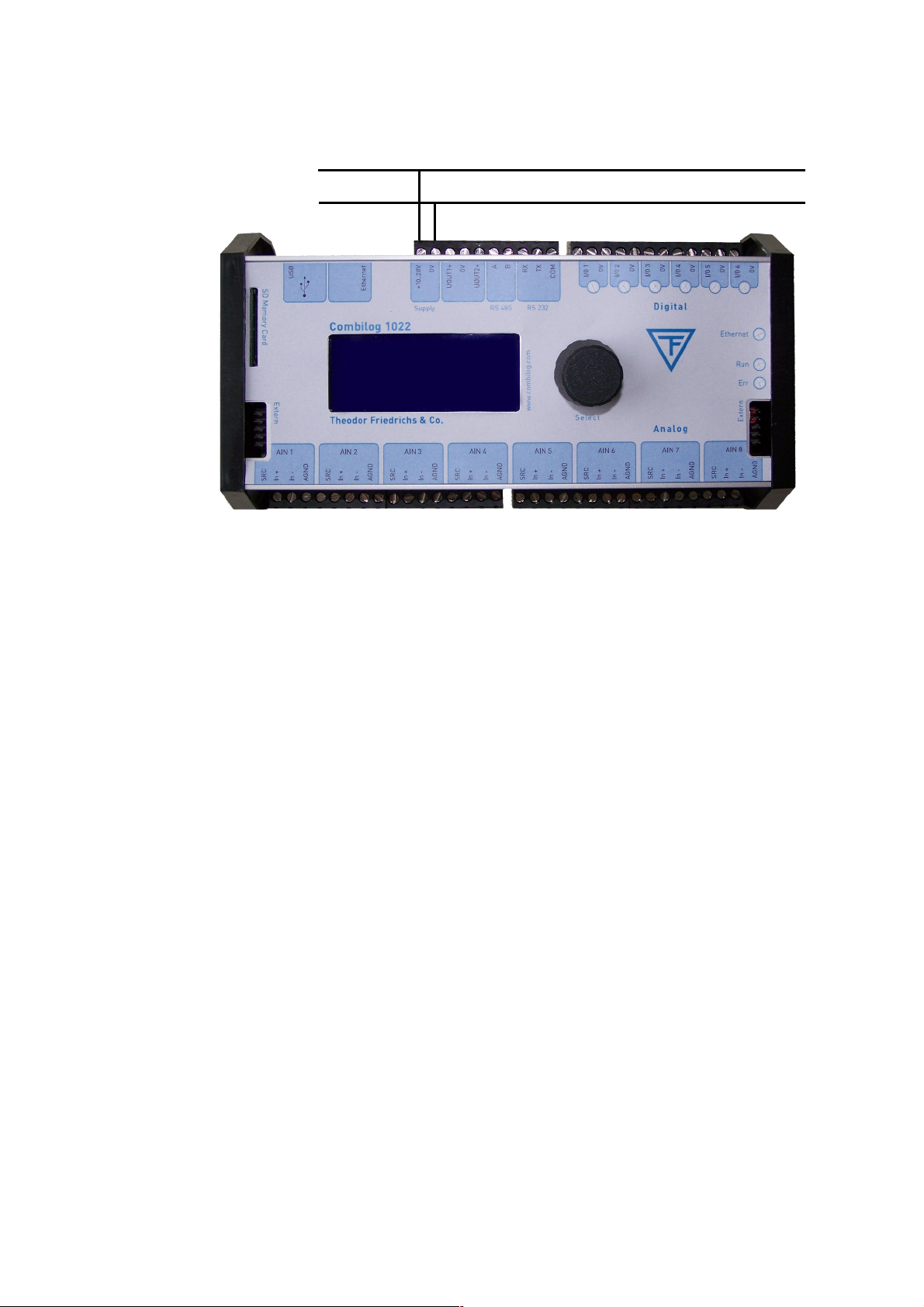

Figure 3.1 Front panel

Hardware Manual COMBILOG 1022

1

14 12 11 10 9

87

6

5432

1516 139

20

Page 21

Description of the parts:

Number Description Number Description

1 USB

9

Module jack connection

2 Ethernet 10 LED ERR (red)

3 Voltage supply 11 LED RUN (green)

4 Power switch 12 Ethernet Link / Traffic

5 RS485 13 Press/rotary knob

6 RS232

14

8 analogue inputs

7 6 digital I/Os

15

LC-display

8 Status-LEDs for digital I/Os

16

Interface for memory card

Table 3.1 Description of the parts on the front of the device

Pin assignment:

Terminal Assignment Terminal Assignment

+10..30V Voltage supply + I/O + Digital I/O 1…6

0V Voltage supply - 0 V Ground for digital I/Os

A RS485-bus interface A SOURCE Source output

B RS485-bus interface B In+ Analogue input +

RX RS232 receive In- Analogue input -

TX RS232 transmit

AGND

Ground for analogue input

COM RS232 ground

UOUT 1 / 2

Power switch output

Table 3.2 Pin assignment

Hardware Manual COMBILOG 1022

21

Page 22

3.5 Connection

Connection: plug-in screw terminals

Nominal cross section: 1.5 mm² (0.02 square inch)

unifilar/fine-strand (AWG 16)

Length of wire stripping : 6 mm (0.2 inch)

Alternatively available: LP-terminals (spring loaded)

(upon request)

Protection earth: 6.3mm series tabs at rear

side of housing

The best way to pull off the screw terminals is to use a small

screwdriver, placed as a lever between terminal and the front

of the data logger.

Not more than 2 leads should be connected with one clamp. In

this case the leads should have the same conductor cross section.

Note: Wire connection is only allowed during power off.

Note: In order to avoid influences from noise on the sensor sig-

nals shielded wires should be used for the power supply, the

bus connection and the signal lines.

ATTENTION: Before final installation, a suitable protection

earth cable with terminal has to be connected to the ground

connector at the back of the data logger. Assure that the connection has a low impedance after mounting.

Hardware Manual COMBILOG 1022

22

Page 23

3.6 Power Supply

Figure 3.2 Connection of the distribution voltage

Voltage range

+10 ... +30 VDC

Power input

0.1 W typical (up to 1.1W maximum, depending on config-

uration)

Internal protector (reversible)

excess current 0.5 A M

excess voltage

Hardware Manual COMBILOG 1022

U+

U-

Versorgungsspannung

Power Supply

23

Page 24

Non-regulated DC voltage between +10 and +30 VDC is sufficient for the power supply of the data logger COMBILOG 1022.

The input is protected against excess voltage and current and

against reverse polarity. The power consumption remains approximately constant over the total voltage range, due to the integrated switching controller.

Due to its low current consumption (max. 110 mA at 12 VDC)

the data logger can also be remote-fed via longer lines. Several

data loggers can be supplied parallel within the admissible

voltage range, considering the voltage drop in the lines. The

supply lines can also be installed in one common cable, together with the bus line, if required.

In order not to charge the data logger’s supply voltage unnecessarily, a separate power supply for sensors with a large current requirement is recommended.

Hardware Manual COMBILOG 1022

24

Page 25

3.7 Bus Connection

In general the data logger is connected to the bus by applying

the signal leads A and B of the incoming bus cable and A' and

B' of the outgoing bus cable together to one terminal on the

module (figure 3.3).

Alternatively the bus can also be connected by a "stub cable"

as shown in figure 3.4.

Owing to the removable terminal, the bus connection to other

data loggers remains valid, even if one data logger is replaced

by another.

Figure 3.3 Connection of the data logger to the bus

Note: When connecting the logger to the bus, the two bus interfaces A and B must not be interchanged.

Note: The stub cable should be as short as possible, not

longer than 30 cm (12 inch).

Hardware Manual COMBILOG 1022

25

Page 26

Figure 3.4 Connection of the data logger to the bus by a stub cable

3.8 Sensor Connection

The analogue and digital signal inputs and outputs are wired

according to measurement task, to the transducer (sensor) that

is used, and to the number of connected sensors. The pinout

arrangements for the various types of measurement are described in chapter 5. The respectively valid pin assignment is

determined by means of the configuration software.

Since the digital outputs are "passive" the processing of external elements always requires an external current supply. In case

of larger loads this should be independent of the data logger

supply.

At the connection of inductive loads a connection with a diode

is required in order to prevent possible damages by induced

voltage.

Hardware Manual COMBILOG 1022

26

Page 27

Following devices can be connected directly to the digital outputs: signal lamps, small relays, switching relays for larger

loads, acoustic signal installations, buzzer respectively beeper

etc., as long as the connected loads are not exceeding the values described in the technical data chapter 12.

3.9 Several Sensors at one Data Logger

The data logger COMBILOG 1022 can simultaneously receive

and process sensor signals from several different sensors. As

many sensors can be connected as there are analogue and digital signal inputs and outputs available (14 sensors max.;

8 analogue and 6 digital sensors).

3.10 Module Jack

The data logger COMBILOG 1022 has a bus connection facility

on the left and on the right side of the housing, featuring interconnection of the +10…30 VDC supply and the bus signal, for

several COMBILOG.

This kind of bus connection and of power supply is particularly

advantageous if several data loggers are mounted on one common profile rail side by side. In this case the connection via the

terminals can be dropped, except for one module.

Note: If some COMBILOG 1022 are connected using the mod-

ule jacks, the supply power has to be provided using the screw

terminals. The power supply via the module jacks has to be

used only for expansion modules.

Hardware Manual COMBILOG 1022

27

Page 28

Note: It is necessary to take care that the current at the Module

Jack is not higher than permitted. Thus, the power supply

preferably should be led to the centre of the module line. For

the same reason a 100 mA self resettable fuse protects the

module connector of the COMBILOG 1022 against short circuits.

The permanent current drawn from the module connector shall

not be higher than 100 mA.

Hardware Manual COMBILOG 1022

28

Page 29

4 SIGNAL PROCESSING

The data logger COMBILOG 1022 has eight analogue inputs

and six digital inputs/outputs. Several different sensor signals

as well as digital inputs and digital output signals can be connected and processed simultaneously.

4.1 Analogue Inputs

The analogue inputs serve to collect sensor signals, or to acquire control values respectively. They are particularly designed to measure voltages, currents and resistances.

There are 8 equal analogue inputs, each input can be configured individually.

Note: Overloads of more than ± 10 VDC will lead to false

measuring results in the according analogue input channel.

Overloads of more than ± 15 VDC will also have influence on

the measuring accuracy of the other input channels!

4.2 Digital Inputs/Outputs

The six digital inputs/outputs of the data logger can be configured - independent of each other - as inputs or as outputs.

The current status (in/out) is signalized by one LED each.

Hardware Manual COMBILOG 1022

29

Page 30

As inputs the I/Os can be used for collecting feed-back signals,

for measuring frequencies, as counters or for receiving special

serial 8-bit-Graycode signals. Status information can be issued

by the outputs. Thereby host-controlled or process-controlled

status outputs are possible.

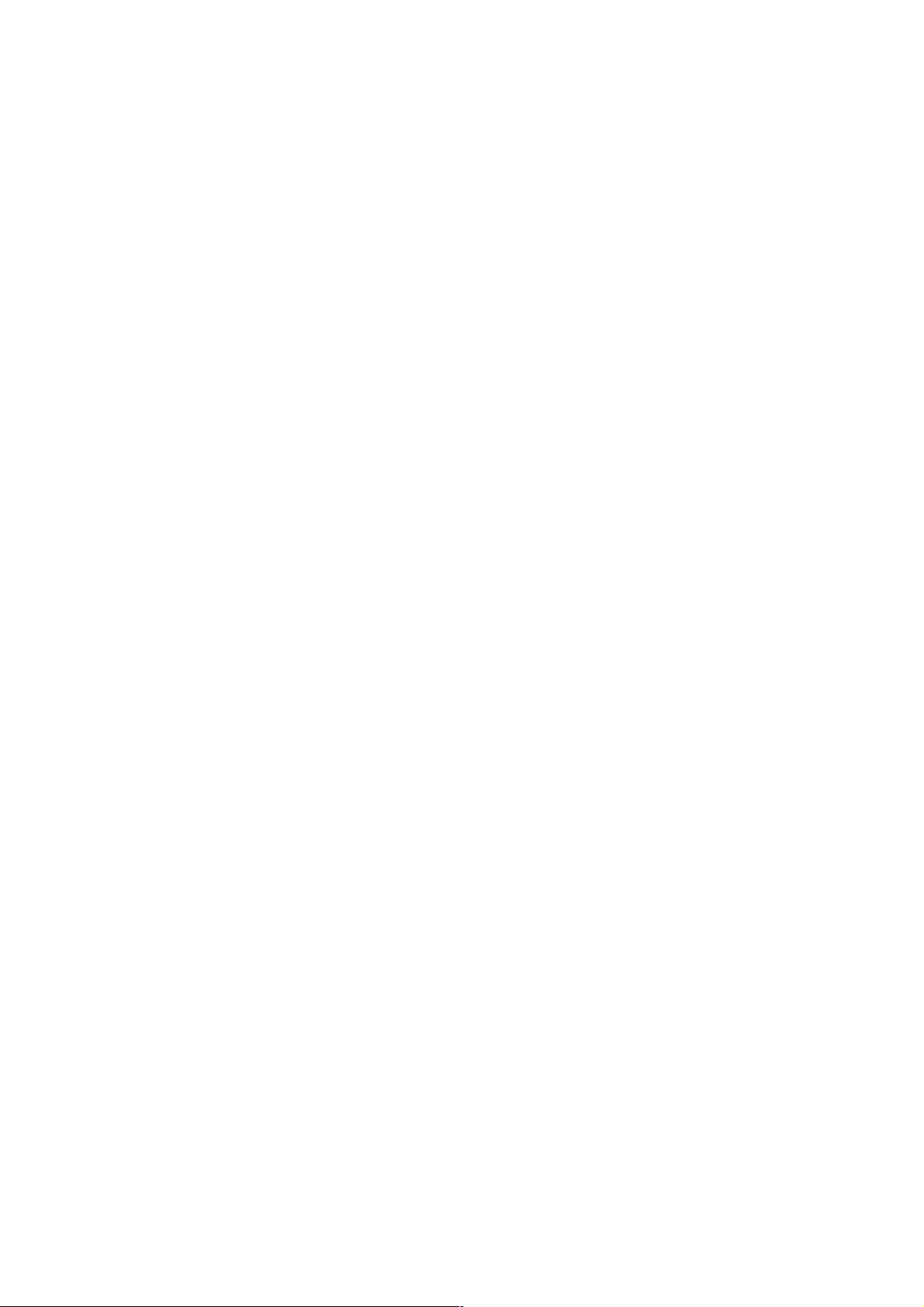

The digital inputs have an excess voltage protection (transil diodes), with nominal threshold 30 V. Input voltages between

2.0 VDC and 30 DC are interpreted as logic LOW ("0"), input

voltages lower than 0.9 V as logic HIGH ("1"). The maximum

input current is 1.5 mA.

Figure 4.1 Definition of signal levels and logic levels

The outputs are open-collector type with a maximum voltage of

30 VDC and a maximum current of 100 mA.

4.3 Power Switch

The data logger Combilog 1022 has two power switches which

act as voltage supplies for external sensors.

A power switch can be assigned to an analogue channel and

configured with a lead time (see chapter Power Switch ).

The supply is switch on with a configurable time before the selected analogue input channel will be measured.

Hardware Manual COMBILOG 1022

Signal level Logical level

30

Page 31

4.4 Internal Reference Voltage, Offset- and Drift Correction

An internal reference voltage serves to adjust the entire analogue signal processing automatically.

Especially for measurement of extreme low voltages, currents

and resistances, the configuration software features an additional compensation of temperature drift. With current- and

voltage measurement, this is realized by an internal offset

measurement. The measured offset is subsequently applied to

correct the measured values. For Maximum accuracy with current measurement (temperature drift less than 25 ppm/K) it is

recommended to accomplish the measurement via an external

shunt with a correspondingly low temperature coefficient (< 5

ppm/K). For this purpose, the input channel has to be configured as a voltage input.

For resistance measurement, a drift correction requires an additional input channel which has to be equipped with a suitable

reference resistance. This resistance should have a low temperature coefficient (< 5 ppm/K). In the configuration table, this

channel has to be defined as a reference channel with resistance input for drift correction, whereby the nominal value of this

resistance (at 20°C) has to be indicated.

Using the above described methods, the analogue inputs can

almost completely be kept free from temperature drift.

Hardware Manual COMBILOG 1022

31

Page 32

4.5 Internal Processing

Next to collecting the analogue input signals, the analogue multiplexer at the input of the circuit collects the internal reference

voltage. All these values are then transmitted to the programmable amplifier PGA, where the signals are amplified according to the kind and type of the connected sensors and then

supplied to the A/D converter.

The A/D converter digitalises all incoming signals with a definition of 16 bit and at a rate that can be preset for the module by

the user. The Sigma-Delta-procedure used for the A/D-conversion guarantees a high accuracy and a high linearisation. The

A/D-converter processes an integrated amplifier with the amplifier stages of 1, 2, 4, 8, 16, 32 and 64. For very small signals,

the module switches to an additional amplifier with amplifier

stages of 100, 200, 800 and 3200. The amplification in alignment with the accuracy and resolution of the calculated measuring values results from the selection of the measuring range

which will be configured by assistance of the configuration software.

This software also configures the ADC internal low pass filter,

depending on the mains frequency and desired ADC frequency

(selectable between 10 and 400 Hz). Standard configuration for

the low pass filter is 50 Hz.

The microprocessor µP now edits the measuring signal in digital form.

First the processor linearises and scales the signal and holds it

ready for transmission via bus in programmable units. Further

the processor monitors the measured values for excess of

freely programmable threshold values. Thus a monitoring of

Hardware Manual COMBILOG 1022

32

Page 33

failure or breaking of the sensing element or short-circuit can

also be realised. The data logger can be activated - by means

of appropriate configuration - to provide a corresponding signal

at the digital I/O in case of alarm. The digital I/Os are directly

addressed and monitored respectively by the microprocessor

µP.

Hereafter an arithmetical averaging of the values is carried out.

The average interval is the same for each channel and is adjustable in steps of 0.5, 1, 2, 3, 4, 5, 10, 15, 20 and 30

seconds, 1, 2, 3, 4, 5,10, 15, 20, 30 minutes, resp. 1, 2, 3, 4, 6,

8 and 12 hours. The calculated average values are finally

stored in the memory.

The special user program, the data for configuration, linearisation and scaling etc. that are required by the processor µP for

all tasks are retentively stored in a EEPROM.

The timing control of the data processing is realised by an internal real time clock buffered by Gold cap capacitor.

4.6 Scan Rate and Power Consumption

The A/D-converter digitalizes every signal at a rate that can be

preset by the user. The scan rate can be selected between

0.25 sec. and 1 hour. In this selected time period all configured

channels are scanned and processed correspondingly. The

power consumption of the data logger COMBILOG 1022 depends on this scan rate. Between the measuring cycles the

data logger will be set into a so-called “Sleep-Mode“. During

this mode the data logger needs only about 20 mA with supply

for the serial lines being active.

Note: A scan rate of 0.25 s causes an unsignificant higher variation of instantaneous values but does not affect the averaging.

Hardware Manual COMBILOG 1022

33

Page 34

4.7 Signal Processing

Arithmetical averaging is carried out using several measuring

values. The averaging interval, which is the same for all channels, can be set to one of the values 0.5, 1, 2, 3, 4, 5, 10, 15,

20, 30 seconds or 1, 2, 3, 4, 5, 10, 15, 20, 30 minutes or 1, 2,

3, 4, 6, 8, 12 hours respectively. The calculated values are finally stored in the memory.

With the configuration software the kind of averaging is selectable: Normal averaging or averaging of wind direction (consideres the discontinuity at NORTH). For counter variables not

the average, but the number of pulses is calculated.

A change of the average interval can be initiated by certain program conditions, thus featuring temporary higher time resolution of measured signals.

Hardware Manual COMBILOG 1022

34

Page 35

5 FUNCTIONAL DESCRIPTION

The data logger COMBILOG 1022 has a total of 32 logical

channels for the collection, processing and output of various

kinds of sensor information. These 32 channels can be configured as:

Analogue Input Channel

Digital Input Channel

Digital Output Channel

Arithmetic Channel

Setpoint Channel

Alarm Channel

For each channel various kinds of channel information and processing functions can be determined. The table in appendix C

gives a survey of the channel set-ups with the data logger

COMBILOG 1022. The channel set-ups are carried out by

means of the configuration software.

Hardware Manual COMBILOG 1022

35

Page 36

5.1 Analogue Input Channel

The Analogue Input Channel collects and processes the signals of the most common types of sensors. A large number of

standardised sensors is already stored in the COMBILOG internal sensor data base. Further sensors can be added by the

user.

Following measuring principles are provided:

Voltage measurement

Current measurement

Resistance measurement

Temperature measurement with thermocouples

For each of these principles the data logger COMBILOG 1022

offers several types of measurement. For voltage measurement the types of measurement single-ended and differential

can be used. Currents up to 25 mA are directly measured by

the data logger. Current measurements of more than 25 mA

can be carried out by measuring voltage drop at an external

shunt. Resistance measuring can be carried out in 2-, 3- and 4wire technique.

Each analogue input channel can be assigned an individual

sample rate (see chapter Single Channel Configuration ).

Hardware Manual COMBILOG 1022

36

Page 37

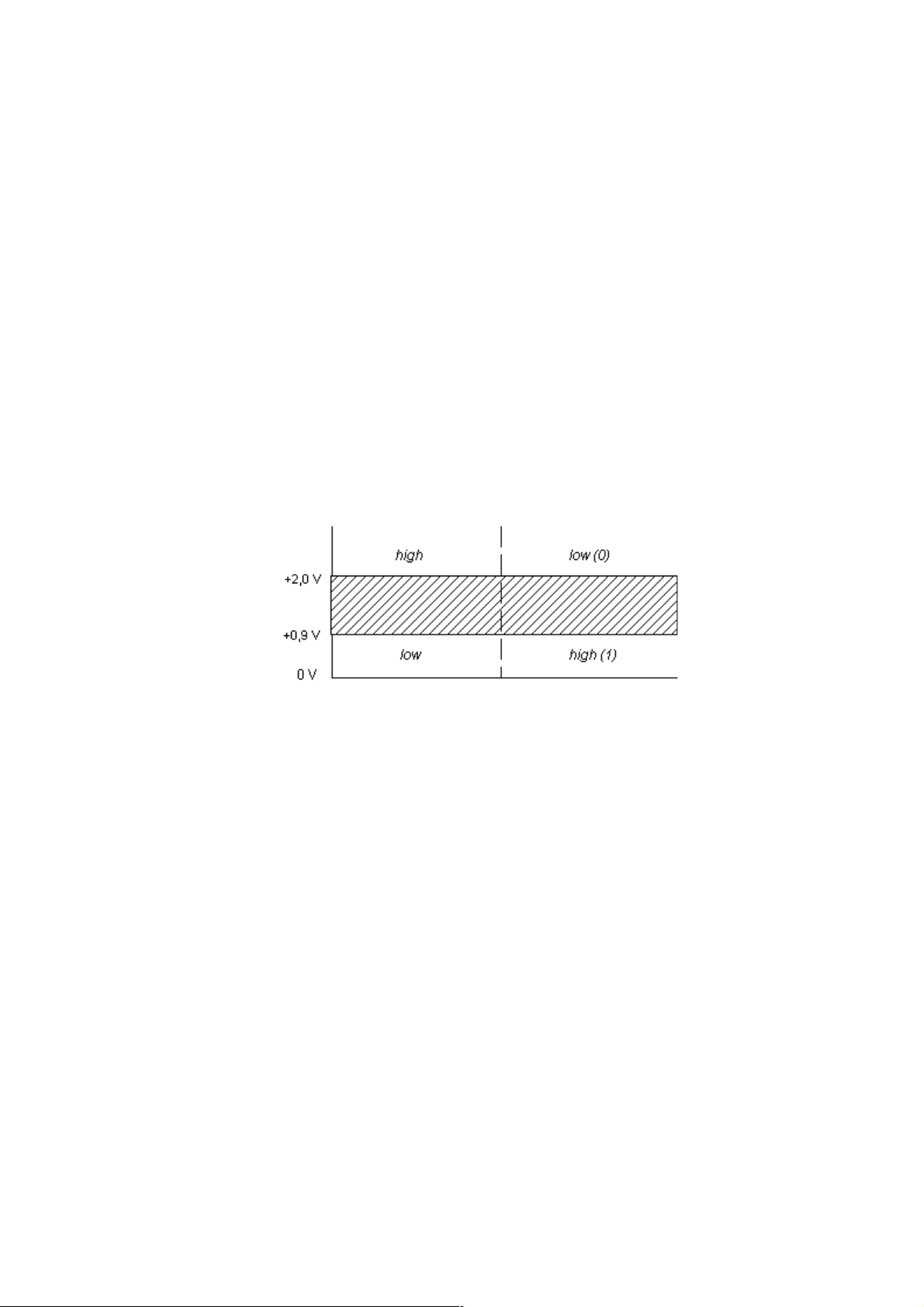

5.1.1 Voltage Measurement

Two methods are available for voltage measurement: singleended and differential measurement.

With the single-ended type the voltage to be measured is connected between an analogue input (In+) and analogue ground

(AGND). Differential measurements are realized by using two

analogue inputs (In+ and In-). Measuring range is between 0

and ±10 V.

Note: With differential measurements both voltages have to be

within 10 V referred to AGND (Common-Mode-Range).

It is recommended to connect the In- to A

GND

with a high ohmic

resistance.

Hardware Manual COMBILOG 1022

37

Page 38

Voltage Measurement

Figure 5.1 Voltage measurement - single-ended

Figure 5.2 Voltage measurement - differential

Hardware Manual COMBILOG 1022

Source

IN+

IN-

AGND

=

+

-

U1

U

U = U1

=

+

-

Anschlussschema Schaltung

Source

IN+

IN-

AGND

=

U

U = U2-U1

Anschlussschema Schaltung

= =U1U2

=

U1

U2

CircuitConnection scheme

Connection scheme Circuit

38

Page 39

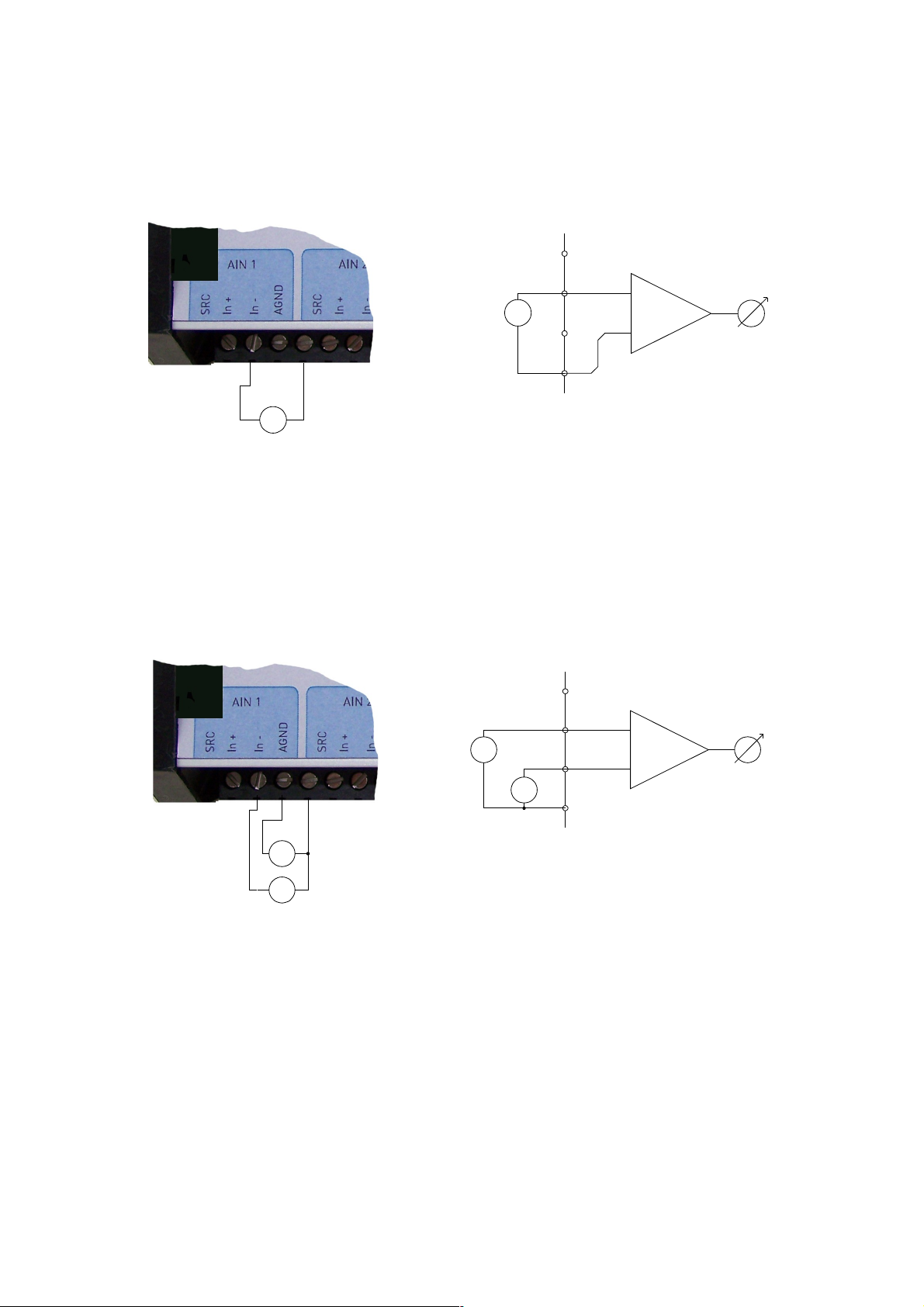

5.1.2 Current Measurement

For current measurement the current source is connected

between an analogue input (In+) and analogue ground (A

GND

).

The load required for measurement is controlled by an internal

resistor R

int

to 100 Ω. The power capacity of this shunt is lim-

ited to 125 mW. This results in a measuring range of 25 mA

maximum.

Higher currents can be measured by means of an external resistor which is connected parallel to the current source to the

analogue signal input and analogue ground (A

GND

). The power

capacity of this external shunt has to be adapted to the current

source to be measured, so that the voltage occurring at the

analogue input does not exceed +10 V. The analogue input is

configured as voltage input. The voltage has to be divided by

R

ext

.

Note: The precision of the current measurement with external

shunt depends on the precision of the resistor being used.

Note: The input resistance of the current measurement channel depends on the current to measure!

Hardware Manual COMBILOG 1022

39

Page 40

Current Measurement

Figure 5.3 Current measurement with internal shunt

Figure 5.4 Current measurement with external shunt

Hardware Manual COMBILOG 1022

Source

IN+

IN-

AGND

I

U

I = U / Rint

Anschlussschema Schaltung

Rint

Source

IN+

IN-

AGND

I

U

I = U / Rext

Anschlussschema Schaltung

Rext

Rext

Connection scheme Circuit

Connection scheme Circuit

40

Page 41

5.1.3 Resistance Measurement

Resistance measurement is carried out by means of voltage

measurement at a resistor, measuring the resulting voltage

drop. The constant current required for the resistance measurements is provided by the internal supply of the data logger.

For this purpose the sensor module connects a supply point internally with the analogue measurement input via a reference

resistor Ro. The voltage drop Uo via resistor Ro is required as a

reference for further signal processing by the module. The resistance value of the sensor can be calculated from the input

signals Ui as a multiple of the reference resistor Ro. Measuring

range is between 0 and 20 kΩ.

Note: The data logger COMBILOG 1022 supports resistance

measurement in 2-, 3- and 4-wire technique. With resistance

measurement in 2-wire technique the supply lines cause an additional voltage drop, thus distorting the measuring result and

influencing the measuring accuracy. Therefore it is necessary

to pay attention especially with resistance measurement in 2wire-technique. Wires with impedance as low as possible

should be used. Make sure that the leads are well connected to

the data logger and the sensor. With resistance measurement

using 3-wire technique the potential on the supply lines will be

subtracted by software. Therefore 2 measurements are necessary, resulting in double measuring time. With resistance

measurement in 4-wire technique the drop of potential is picked

up directly at the sensor, so that the measuring results are not

influenced by the supply lines.

Hardware Manual COMBILOG 1022

41

Page 42

Resistance Measurement

Figure 5.5 Resistance measurement in 2-wire technique

Figure 5.6 Resistance measurement in 3-wire technique

Figure 5.7 Resistance measurement in 4-wire technique

Hardware Manual COMBILOG 1022

Source

IN+

IN-

AGND

U

Rx = U/U0 * R0,

Anschlussschema Schaltung

Rx

Rx

Messwiderstand

RL

RL R0

=

U0

Rx = 2 * RL

Source

IN+

IN-

AGND

U1

Rx = (U1/U0-2*U2/U0) * R0,

Anschlussschema Schaltung

Rx

Rx

Messwiderstand

RL

RL R0

=

U0

U2

Rx = 0

Source

IN+

IN-

AGND

U2 - U3

Rx = (U2 - U3)/U0 * R0,

Anschlussschema Schaltung

Rx

Rx

Messwiderstand

RL

RL R0

=

U0

Rx = 0

Connection scheme Circuit

Connection scheme Circuit

Connection scheme Circuit

42

Page 43

Temperature Measurement with Thermocouple

Thermocouples consist of two “thermoelectric wires” made of

different materials (e.g. platinum and platinum rhodium) that

are welded to each other at one end. If the contact and the other ends of the thermoelectric wires have different temperatures,

a “thermoelectric voltage” Uth appears at the contact of both

thermoelectric wires. This voltage is largely proportional to the

temperature difference. It can be measured and used for

temperature measurement purposes. With data logger

COMBILOG 1022 the thermoelectric voltage is measured

differentially.

Since thermocouples can only measure a temperature difference (difference between temperature to be measured and

temperature at the connecting terminals on the sensor

module), a terminal temperature (internal cold junction compensation, TC

int

) or a known temperature reference (external

cold junction compensation, TC

ext

) also have to be determined.

With measurement of temperature with internal cold junction

compensation an additional temperature sensor is necessary to

measure the temperature ϑ

k

at the “cold” terminal. A special

cold junction terminal is available, where a Pt100 temperature

sensor is integrated directly in the terminal block. The temperature of the test point is determined on basis of linearization

trace to ϑ

x

= Lin(Ux+Lin

-1

ϑ

k

).

Hardware Manual COMBILOG 1022

43

Page 44

If the temperature is measured by external cold junction compensation, a second thermocouple of the same type is required, which is connected in series with the first one. The polarity is selected so that the thermoelectric voltages subtract

each other. The second thermocouple is set to a fixed refer-

ence temperature ϑr (mostly ϑ

r

= 0°C). The data logger then

calculates the temperature at the measuring position by means

of the linearisation curve as ϑ

x

= Lin(Ux+Lin

-1

ϑ

r

). The data log-

ger will be informed about the reference temperature ϑ

r

via the

configuration software (“cold junction temperature”).

Hardware Manual COMBILOG 1022

44

Page 45

Temperature Measurement with Thermocouple

Figure 5.8 Temperature measurement with internal cold junction

compensation by special terminal clamp ICJ 104

Figure 5.9 Temperature measurement with external cold junction

Hardware Manual COMBILOG 1022

Source

IN+

IN-

AGND

U1

ϑ

x = Lin (U2 + Lin-1 ϑk), ϑk = Lin (U1)

Anschlussschema Schaltung

1M

Ω

ϑ

k

R0

=

U0

U2

ϑ

x

ϑ

x

zusätzliches

Kaltstellenmodul

Source

IN+

IN-

AGND

ϑ

= Lin (U1 + Lin-1 ϑp)

Anschlussschema Schaltung

1M

Ω

ϑpϑ

1M

Ω

ϑ

p

ϑ

U1

Connection scheme Circuit

Connection scheme Circuit

45

Page 46

5.2 Digital Input Channel

The following functions can be realized by means of the Digital

Input Channel:

Digital status recording

Frequency measurement

Counter

8 bit Graycode transducers, Type 4122 / 4123

8 bit status input, with additional (external) module

The above mentioned functions are based on incremental

measurements except the digital status and Graycode recording. Incremental measuring means to count while measuring.

Pulses are counted e.g. from wind speed sensors.

Furthermore it is possible to connect up to 6 sensors with a

serial 8 bit Graycode output to the COMBILOG 1022, e.g. wind

direction sensor type 4122 / 4123.

By means of an external module type 1025 8 bit status signals

can be measured at each input. This module converts the 8 bit

into a serial signal, and the COMBILOG will compose it to 1

byte again.

Hardware Manual COMBILOG 1022

46

Page 47

5.2.1 Digital Status Recording

For the acquisition of digital status information (on/off,

closed/open, left/right, etc.) the signal fed to the digital input is

collected and is held ready for further processing in the data

logger COMBILOG 1022 or for transmission via bus.

The digital input is set (switch closed) as long as the signal

voltage remains under the threshold value of 1.0 V. The digital

information can be scanned as 1/0 information via bus.

Figure 5.10 Digital status recording

I/O 1

status

"0" "1" "0" "1"

signal diagram:

Hardware Manual COMBILOG 1022

Anschlussschema Schaltung

0V

I/O

+ 10V .. 30V

Connection scheme

Signal diagram:

Circuit

47

Page 48

5.2.2 Frequency Measurement

With frequency measurements the data logger counts the pulses within a certain time interval at the digital input. The user

can preset this time interval by setting the time base (TB) in the

range between 0.1 sec and 10 sec. The frequency is calculated

by the sensor module from the number of pulses and the time

base TB as:

frequency f =

number of impulses per time interval TB

length of time intervall TB

Hz

With frequency measurements always the negative signal edge

(1 -> 0) is counted.

The lower the frequency f, the larger the interval between two

pulses, and the larger the time base TB has to be. On the other

hand the updating of the measured value decreases with an increasing time base. Thus the time base should be selected so

as to make TB ≈ 1/fu, fu being the lowest frequency respectively

the smallest change in frequency to be determined by the data

logger. The error with frequency measurements thus amounts

to ∆f = fu = 1/TB.

Note: The high-end frequency for the frequency measurement,

i.e. the highest frequency to be measured. It is 4000 Hz.

Hardware Manual COMBILOG 1022

48

Page 49

Frequency Measurement

Figure 5.11 Frequency measurement

I/O 1

time base

TB TB TB

counting

1 2 3 1 2 3 1 2 3 1

measurand

(TB = 5 sec)

signal diagram:

- high level:

TB TB TB

1 2 1 1 2

- low level:

0,6 Hz 0,6 Hz 0,6 Hz

0,4 Hz 0,2 Hz 0,4 Hz

pulse

I/O 1

time base

counting

measurand

(TB = 5 sec)

pulse

Hardware Manual COMBILOG 1022

Anschlussschema Schaltung

0V

I/O

+ 10V .. 30V

f

f

Connection scheme

signal diagram:

Circuit

49

Page 50

5.2.3 Progressive Counter

When configuring a digital input as a progressive counter the

data logger COMBILOG 1022 constantly monitors the digital

input for a signal variation. If a negative signal edge (1 -> 0) occurs at the input, the current result is increased by 1.

The values may range from -2

31

to +(231-1) (about -2.1 to +2.1

billion). Above +231-1 the counting continues with -231. The values can be reset to zero via the bus interface or internally after

the procedure of the averaging interval.

Note: The maximum counting rate is 2400 Hz.

Note: After a voltage cut-off the counter is reset to zero.

Figure 5.12 Progressive Counter

+1 +1 +1 +1 +1

n+1 n+2 n+3 n+4 n+5

signal diagram:

I/O 1

counting

counting

measurand

pulse

Hardware Manual COMBILOG 1022

Anschlussschema Schaltung

0V

I/O

+ 10V .. 30V

Connection scheme Circuit

50

Page 51

5.3 Digital Output Channel

5.3.1 Digital Status Output

The digital output channel supports:

digital status output, host-controlled

digital status output, process-controlled

Via the digital inputs/outputs I/O 1 to I/O 6 on the data logger

COMBILOG 1022 digital status can be output in digital form,

according to the configuration. A typical case of application

would be e.g. the local output of an acoustic or optical signal in

case a limiting value is exceeded or undershot by a measured

value.

All outputs are open-collector.

The supply voltage can range from 10 up to 30 VDC. It has to

be either supplied externally or taken from the power supply of

the data logger.

The status of the digital output can be scanned as 1/0 information via bus.

With the host-controlled digital status output, the digital output

is set according to the status information received by the data

logger via bus.

With the process-controlled output of status information the

data logger monitors measured values, resp. sensor channels

from excess of default threshold values. The digital output is

set if one or several threshold conditions are fulfilled.

Hardware Manual COMBILOG 1022

51

Page 52

The thresholds can be freely defined by the user. The user can

also preset the logical signal level (see also the configuration

software COMBILOG.EXE).

Thus it is possible to activate a digital output depending on a

specified time or periodically. This can be realized in connection with an arithmetic channel, that can calculate the time or a

time interval from the internal real time clock. A typical application is to switch off a modem after a specified time to reduce

the power consumption of battery powered systems.

Figure 5.13 Digital status output

I/O 1

status

"0" "1" "0" "1"

signal diagram:

Hardware Manual COMBILOG 1022

Anschlussschema Schaltung

I/O

U+

Connection scheme Circuit

52

Page 53

5.4 Arithmetic Channel

By means of the arithmetic channel sensor channels and constants can be connected with each other via arithmetic operations. The result is allocated to the arithmetic channel. The formula can contain up to 20 operands. The calculation is performed with a stack depth of 20. The value is handled as a

4-byte floating point format with 24 significant bits according to

IEEE, standard 754. The full scale is –1037 to +1037.

A typical application for the arithmetic channel is e.g. the determination of a value that cannot be measured directly, but

calculated from other values (e.g. power as a product of

voltage and current). Or the arithmetic channel is used for further mathematical preparation of a measuring signal, in order

to obtain a particular desired format, linearisation or similar.

Special functions for which the existing commands are not sufficient, can be carried out by a user specific download program

for the COMBILOG 1022. For this case, some implemented

special functions can be used for assistance.

To integrate a serial channel the special function 1 is to be

used. The serial channel converts an ASCII telegram into a

float value. Two variants are possible to chose, constant length

or variable length. With constant length the conversion starts at

startposition and ends at startposition + length. With variable

length the conversion starts at startposition and ends at the first

delimiter character.

Should the conversion be unsuccessful the default value will be

taken.

The call to special function 1 is defined as:

Hardware Manual COMBILOG 1022

53

Page 54

spez1(INTERFACE; TYPE; START; VAR; DEFAULT)

• INTERFACE

• 1: RS232

• 2: RS485

• TYPE

• 1: constant length

• 2: variable length

• START: start position (starting with '0')

• VAR

• for TYPE = 1: value length

• for TYPE = 2: delimiter character (ASCII value)

• DEFAULT: on error this is value will be returned

In defining more than one arithmetic channel with this function

you can extract more than one value from one ASCII telegram.

To convert a variable value with start position 10, delimiter #,

interface RS485 and default value –1 from

“Value:_0023,6697#END” the call to spez1() should be

spez1(2; 2; 10; 35; -1) and the result is 3.6697.

With special function spez2() some special meteorological values can be calculated. The following functions are defined:

●spez2(air pressure; height; 1);

Calculates the air pressure on sea level out of air pressure at

given height.

●spez2(app_wind; fair_wind; wind_angle; 2);

Calculates the true wind speed out of apparent wind, fair wind

and the enclosed angle.

●spez2(temperature; radiance_balance; saturation_deficit ;

wind_speed; 3);

Calculates the evaporation acc. to Penman-Monteith.

Hardware Manual COMBILOG 1022

54

Page 55

Note: The calculation time of an Arithmetic Channel is

min 0.2 ms. The overall calculation time is the sum of the times

of all operands in the formula plus 0.2 ms. This has to be taken

into account when calculating the sample rate.

Hardware Manual COMBILOG 1022

55

Page 56

Arithmetic Operators

operations abbreviation time

Addition + 0.26 ms

Subtraction - 0.26 ms

Multiplication * 0.26 ms

Division / 0.26 ms

Modulo % 0.24 ms

Truncate value trunc 0.16 ms

Minimum value min 0.16 ms

Maximum value max 0.16 ms

Absolute value abs 0.16 ms

Square root sqrt 0.26 ms

Exponential function to base e exp 0.56 ms

Logarithm to base e In 0.26 ms

Logarithm to base 10 log 0.26 ms

Sine sin 0.44 ms

Cosine cos 0.44 ms

Tangent tan 0.66 ms

Inverse sine arcsin 0.70 ms

Inverse cosine arccos 0.70 ms

Inverse tangent arctan 0.62 ms

Lowest value from a selection Low 0.30 ms

Highest value from a selection high 0.30 ms

X

Y

power 1.64 ms

Integrator integ 0.18 ms

Differentiator deriv 0.18 ms

Read from external module read

Write to external module write

Time /seconds of the day) SecondsOfDay 0.18 ms

Sample rate SampleTime 0.18 ms

Free space on SD-Card SDSpace 0.20 ms

Hardware Manual COMBILOG 1022

56

Page 57

Free space in RAM RAMSpace 0,1 ms

Application specific function 1 spec 1

1)

Application specific function 2 spec 2

1)

Application specific function 3 spec 3

1)

Application specific function 4 spec 4

1)

1)No specification available as the time depends to the specific function and the program.

Table 5.1 Arithmetic operators and processing times

The times given in the above table are based on an operating frequency of 48 MHz.

Remarks:

Division (/)

When dividing by zero, the positive full scale (+1037) will be

assigned to the Arithmetic Channel if the numerator is

positive and the negative full scale (-1037) will be assigned

if the numerator is negative.

Square root (sqrt)

The square root of a negative number is zero.

Logarithm to Base e (In)

For a value ≤ 0 the negative full scale will be assigned to

the Arithmetic Channel.

Logarithm to Base10 (log)

For a value ≤ 0 the negative full scale will be assigned to

the Arithmetic Channel.

Arc functions (sin, cos, tan)

The arc values must be taken in radians (2π = 360°). If

calculating the tangent, the positive full scale will be as-

signed to the Arithmetic Channel for the arc value

2

π

and

the negative full scale for the arc value -

2

π

.

Inverse functions for sin (arcsin), cos (arccos), tan

(arctan)

Hardware Manual COMBILOG 1022

57

Page 58

The results of the inverse functions are given in radians

(2π = 360°). At the function arcsin the value +

2

π

will be

assigned to the Arithmetic Channel for a value >1 and the

value –

2

π

will be assigned for a value <-1. At the function

arccos the value 0 will be assigned to the Arithmetic

Channel for a value >1 and the value will be assigned for a

value <-1.

Minimum and maximum of a channel value (min, max)

With this function the minimum and maximum value of a

channel appeared since the last reset has been triggered

off can be determined (“pull-pointer-function”). The result

value can be reset to the actual value of the measured

channel via the bus or at the end of the average interval.

The functions read and write enable the data logger to re-

ceive measured values from other modules connected to

the same bus, resp. to send values to them (master function)

Note: Logic combinations, e.g. if-then relations, are not yet

possible respectively would require a user-specific software

(upon request).

Hardware Manual COMBILOG 1022

58

Page 59

5.5 Setpoint Channel

This channel features transmission of values via bus to the

data logger COMBILOG 1022. The values are allocated to the

setpoint-channel and are thus at the disposal of the data logger

for further processing.

A typical application for the setpoint-channel is e.g. the dynamic variation of control thresholds.

5.6 Alarm Channel

The Alarm Channel has the same features as the process-controlled digital output channel, the only difference is that the

status information is not output locally at the digital output, but

can only be scanned via the bus.

5.7 Serial Channel

The serial channel output transmits the ASCII formatted strings

of the logging channels onto the configured interface. The serial channel function can be configured using the build in web

page (see chapter 12.9)

5.8 Threshold Values

The user can preset the conditions for process-controlled digital status output on the data logger and for the output of an

alarm signal via bus. This is carried out by means of the configuration software COMBILOG.EXE.

Hardware Manual COMBILOG 1022

59

Page 60

5.9 Error Handling

The data logger COMBILOG 1022 can detect independently

certain defects, which are result of a line break, short-circuit or

communication interrupt, for example. For these defects the

user can preset a certain behaviour for the data logger via the

configuration software.

In case of a sensor failure the last valid value can be maintained, set to the corresponding limits or set to a default value.

Furthermore the COMBILOG 1022 can send messages via modem or SMS automatically to report errors or other conditions,

e.g. if the data memory capacity becomes zero.

Hardware Manual COMBILOG 1022

60

Page 61

6 DISPLAY / MENU OPERATION

6.1 Display and Operation

The data logger COMBILOG 1022 has a display with 4 lines of

16 characters each, in order to allow the indication of the

measured values of each channel. Furthermore the settings of

the data logger can be recalled and changed if desired (therefore the input by the press/ rotary knob must be unlocked; refer

to the corresponding section 6.2 “Menu Items“)

The operation is performed via the combined press/rotary knob

at the right side of the display. By turning the knob the menu

items or informations can sequentially be indicated. A confirmation or a call of a function is performed by pressing the knob.

6.2 Menu Items

In the following diagrams all display pictures with the corresponding operation steps are indicated. Following symbols are

used for the operation steps:

Symbols:

turn the knob clockwise

turn the knob counter clockwise

press the knob briefly (confirmation)

press the knob for approx. 1 second minimum

(abortion)

Hardware Manual COMBILOG 1022

61

Page 62

Main menu

Note: The number, designation and indication of the measured

value of the channels depend on the configuration.

Hardware Manual COMBILOG 1022

62

Page 63

Configuration menu

Note: If the push/turn selection knob is pressed at any point in

the configuration menu for about 1 second you will return to the

initial position in the main menu.

Hardware Manual COMBILOG 1022

63

Page 64

Setting of the display backlight

Note: The value of the display backlight can be set in steps

from 0 % to 100 %. With low values the display will be set dark

and with the value 100 % it will be set to maximum brightness.

Hardware Manual COMBILOG 1022

64

Page 65

Setting the scan rate and the averaging interval

Configuration menu

Note: The scan rate determines after which time interval the

measured values of the channels will be measured again. Scan

rate is selectable between 0.5 s and 1 h.

At “Averaging“ the averaging interval can be set. It determines

the time interval for the averaging of the measured values. Averaging interval is selectable between 1s and 12h.

In the example the measured values will be measured again

every 10 seconds and after 60 seconds the average value will

be calculated (here by means of 6 measured values).

Hardware Manual COMBILOG 1022

65

Page 66

Setting of the Automatic Switch Off and the

LED Display

Configuration menu

Note: With the automatic switch off function the data logger

can be set to the saving mode if no operation is made by the

press/ rotary knob in a certain time interval (30 seconds). In

this case the display will be set off until a further operation

takes place.

If “LEDs“ is set to ON the LED-display is switched on and the

two LEDs RUN and ERR on the front of the data logger show

the actual operating state (mode) of the data logger. With the

selection OFF the LEDs will be switched off.

Hardware Manual COMBILOG 1022

66

Page 67

Setting of the Baud Rate and the Address

Configuration menu

Note: Possible values for the baud rate are 2400, 4800, 9600,

19200 and 38400 bps. Additionally to the baud rate the parity

can be set . Possible values are N (no parity), E (even parity)

and O (odd parity).

For the address a value between 1 and 127 can be set.

Hardware Manual COMBILOG 1022

67

Page 68

Lock or unlock the press/rotary knob input

Configuration menu

Normally the changing of configuration parameters by the

press/rotary knob is locked (disabled). To change the parameter the press/rotary knob must be unlocked (enabled).

Note: If no operation is performed at the data logger for approx. 30 seconds it will return to the main menu and the

press/rotary knob input will automatically be locked.

Hardware Manual COMBILOG 1022

68

Page 69

Network settings

If the powersave feature for the ethernet interface is enabled

no connection can be established using this interface.

Due to the relatively high power consumption it is essential for

low power applications like mobile battery powered systems to

have the ethernet powersave function enabled.

The IP, gateway and netmask selection modifies the selected

address. The flashing number is actually selected for modification. Rotating the knob counts the number up or down while

pressing the knob selects the next number.

Hardware Manual COMBILOG 1022

69

Page 70

Channels settings

In order to change the values the press/rotary knob must be

pressed. Thereby a cursor will be set on the first character of

the value. Pressing the knob again moves the cursor one character to the right. The value at the place of the cursor can be

altered by turning the knob. Clockwise (=upwards) or counterclockwise (=downwards).

Note: Depending on the type of channel different settings can

be made.

(1) the definition of offset and factor is possible for the ana-

logue input channel, the digital input channel and the digital output channel. These settings are used to convert the

measurement value from the unit of the measured value to

the unit of the measurement display.

(2) For the setpoint channel a setpoint value can be defined

if this is allowed by the configuration software

COMBILOG.EXE. This value can be used by the data log-

ger for further processing (e.g. for the arithmetic channel).

For the arithmetic channel and the alarm channel no settings

can be made.

Hardware Manual COMBILOG 1022

70

Page 71

Display and delete the data memory

Main menu

The display shows the number of stored datasets and the maximum capacity of the data memory. The fourth line shows the

approximate time until the data memory is filled. This time is

displayed in days (d) or hours (h) and is calculated by the data

logger assumed that the average interval is constant.

Hardware Manual COMBILOG 1022

71

Page 72

Setting of the date and time

In order to change the date and the time the press/rotary knob

must be pressed when the time

(1)

respectively date

(2)

is displayed. For this purpose a cursor will be set on the first character of the date respectively time indication. Pressing the knob

again will move the cursor one character to the right. The value

at the place of the cursor can be altered by turning the knob.

Note: The time will be stopped if the press/rotary knob is

pressed in the main menu, date and time display. The time will

continue running if the date or time setting is confirmed by

pressing the knob.

Hardware Manual COMBILOG 1022

Configuration

Date / Time

Time change?

Combilog 1022

Date / Time

02.01.2009

00:05:10

Configuration

Date / Time

Date change?

Change+

Change-

Change+

Change-

Configuration

Date / Time

02.01.2009

Configuration

Date / Time

00:05:10

(2)

(1)

72

Page 73

6.3 SD-Card

If a SD-card is inserted into the card slot an additional menu

item is displayed in the main menu. Choosing this menu item

one can update the firmware of the data logger or eject the SDcard.

Hardware Manual COMBILOG 1022

SD-Card

>remove card

update files

Main menue

>SD-Card

Data recorder

Auto Powerdown

FIRMWARE

UPDATE

AND

RESTART

Change +

Change -

Change+

Change-

Do you want to

update with:

COMBL.BIN

[Yes/No]

Updatefiles

COMBL.BIN

73

Page 74

6.3.1 Remove Card

If a SD-card is configured as logging destination the card has

to be logged off of the system before removing it. Otherwise

written data can be lost.

For card removal you choose this menu item. The card will be

logged out of the system without any further question.

6.3.2 Firmware Update

Using the menu item 'update files' one can start the firmware

update procedure. Therefore a special firmware update file

must reside in the directory 'updates' on the SD-card.

After choosing ' update files' all files in the directory 'updates'

are presented for selection.

Selecting one file starts the update procedure after a security

question. If the file contents for some reason seems to be corrupted, the firmware update stops. If there was no error during

file checking the data logger starts the reprogramming and

starts a system reboot during which the new image is written

into the program flash.

Warning:

As a firmware update is a critical process a backup of all logged

data and of the configuration is highly recommended!

Hardware Manual COMBILOG 1022

74

Page 75

7 DATA STORAGE

7.1 General Remarks to Data Storage

The COMBILOG 1022 is able to store the calculated mean values. Data storage with the COMBILOG 1022 can be accomplished in three different manners:

Internal flash: 7 MByte are available as circulated buffer for

data recording.

External SD card: The records are continuously stored on this

card.