Page 1

CM 4

High Temperature Pyranometer

Instruction Manual

Page 2

IMPORTANT USER INFORMATION

Reading this entire manual is recommended for full

understanding of the use of this product.

The exclamation mark within an equilateral triangle is in tended to alert the user

to the presence of important operating and main te nance instructio ns in the

literature accompanying the instrument.

Should you have any comments on this manual we will be pleased to receive

them at:

Kipp & Zonen B.V.

Delftechpark 36

2628 XH Delft Holland

P.O. Box 507 2600 AM Delft Holland

Phone +31 (0)15 2755210

Fax +31 (0)15 2620351

Email info@kippzonen.com

Web www.kippzonen.com

Kipp & Zonen reserve the right to make change s to the specifications w ithou t

prior notice.

WARRANTY AND LIABILITY

Kipp & Zonen guarantees that the product delivered has been thorough ly

tested to ensure that it meets its published specifications. The warranty

included in the conditions o f de li very is valid only if the product has been

installed and used according to the instructions supplie d by Kipp & Zonen.

Kipp & Zonen shall in no event be liable for inciden tal or con sequen tial

damages, including without li mi tation, lost profits, loss of income, loss o f

business opportunities, loss of use and o th er re lated exposures, however

caused, arising from the faulty and incorrec t use of th e product.

User made modifications can affect the validity of the CE declaration.

1

Page 3

COPYRIGHT© 2010 KIPP & ZONEN

All rights reserved. No part of this publication may be repro duced , store d in a

retrieval system or transmitted in any form or by any means, without

permission in written form from the company.

Manual version 1007

2

Page 4

CALIBRATION CERTIFICATE

The calibration certificate supplied with the instrument is valid from

the date of first use. Even though the calibration certificate is dated

relative to manufacture the instrument does not undergo any

sensitivity changes when kept in the original packing. From the

moment the instrument is taken from it’s packaging and exposed to

irradiance the sensitivity will deviate with time. See also the 'nonstability' performance (max. sensitivity change / year) given in the

radiometer specification list.

3

Page 5

DECLARATION OF CONFORMITY

According to EC guideline 89/336/EEC

We Kipp & Zonen B.V.

Delftechpark 36

2628 XH Delft

The Netherlands

Declare under our sole responsibility that the product

Type: CM 4

Name: High Temperature Pyranometer

To which this declaration relates is in conformity with the following standards

Imissions EN 50082-1 Group standard

Emissions EN 50081-1 Group standard

EN 55022

Following the provisions of the directive

4

B.A.H. Dieterink

President

KIPP & ZONEN B.V.

Page 6

5

Page 7

6

Page 8

TABLE OF CONTENTS

IMPORTANT USER INFORMATION..............................................1

CALIBRATION CERTIFICATE.......................................................2

DECLARATION OF CONFORMITY ...............................................4

1 GENERAL INFORMATION........................................................9

1.1 INTRODUCTION ...................................................................9

1.2 PHYSICAL PRINCIPLES OF THE PYRANOMETER ....................10

1.2.1 Temperature Dependency...........................................11

1.2.2 Spectral properties of the glass dome.........................13

1.2.3 Directional / Cosine response......................................14

1.2.4 Non-linearity.................................................................15

2 LIST OF SPECIFICATIONS.....................................................17

3 INSTALLATION .......................................................................21

3.1 DELIVERY.........................................................................21

3.2 MECHANICAL INSTALLATION ..............................................21

3.2.1 Outdoor installation......................................................22

3.2.2 Indoor installation.........................................................22

3.3 ELECTRICAL CONNECTION .................................................23

4 OPERATION ........................................................................27

5 MAINTENANCE.......................................................................29

6 CALIBRATION ........................................................................31

6.1 INITIAL CALIBRATION..........................................................31

6.2 RECALIBRATION................................................................31

6.3 CALIBRATION PROCEDURE AT KIPP & ZONEN .....................33

6.3.1 The facility....................................................................33

6.3.2 Procedure ....................................................................33

6.3.3 Calculation...................................................................34

6.3.4 Zero offset....................................................................34

7

Page 9

6.3.5 Traceability to World Radiometric Reference..............35

7 FREQUENTLY ASKED QUESTIONS (FAQ’S).......................37

8 TROUBLE SHOOTING............................................................39

9 PART NUMBERS / SPARE PARTS / OPTIONS.....................41

APPENDIX I PYRANOMETER CLASSIFICATION

ACCORDING TO WMO GUIDE 1996............43

APPENDIX II PT-100 SPECIFICATIONS.............................45

APPENDIX III LIST OF WORLD AND REGIONAL

RADIATION CENTRES..................................47

APPENDIX IV RECALIBRATION SERVICE .........................49

8

Page 10

1. GENERAL INFORMATION

1 GENERAL INFORMATION

1.1 INTRODUCTION

The CM 4 High Temperature Pyranometer is an instrument for

measuring solar or artificial light irradiance. The instrument is

specially designed for usage under extreme irradiance and

temperature conditions. With an operating temperature range of

-40°C to +150°C and measurement up to 4000 W/m² it is a unique

product. All the radiometer components, including the signal cable,

are specially selected for their ability to withstand these extremely

high temperatures and irradiances.

In particular the CM4 has been developed for applications in an

industrial environment. The pyranometer is designed for both

continuous indoor and outdoor use. Because of the fact that it has a

flat spectral sensitivity from roughly 0.3 to 3 microns, its calibration is

valid for natural sunlight and for most types of artificial light (e.g.

Xenon lamps, halogen lamps).

CM 4 features:

• Robust and high temperature resistant construction and

cable

• Unique temperature compensation of sensor sensitivity

• Low non-linearity

• Exchangeable with meteorological field pyranometers

• Easy maintenance with easily accessible drying cartridge

• Built-in Pt-100 4-wire temperature sensor

9

Page 11

The CM 4 Pyranometer complies with specifications according to the

ISO 9060 standard, as defined in the ‘Guide to meteorological

Instruments and Methods of Observation’, sixth edition, 1996, of the

World Meteorological Organisation (WMO*) – Geneva – Switzerlan d.

* The WMO classification is adapted from the international standard

ISO 9060 (1990).

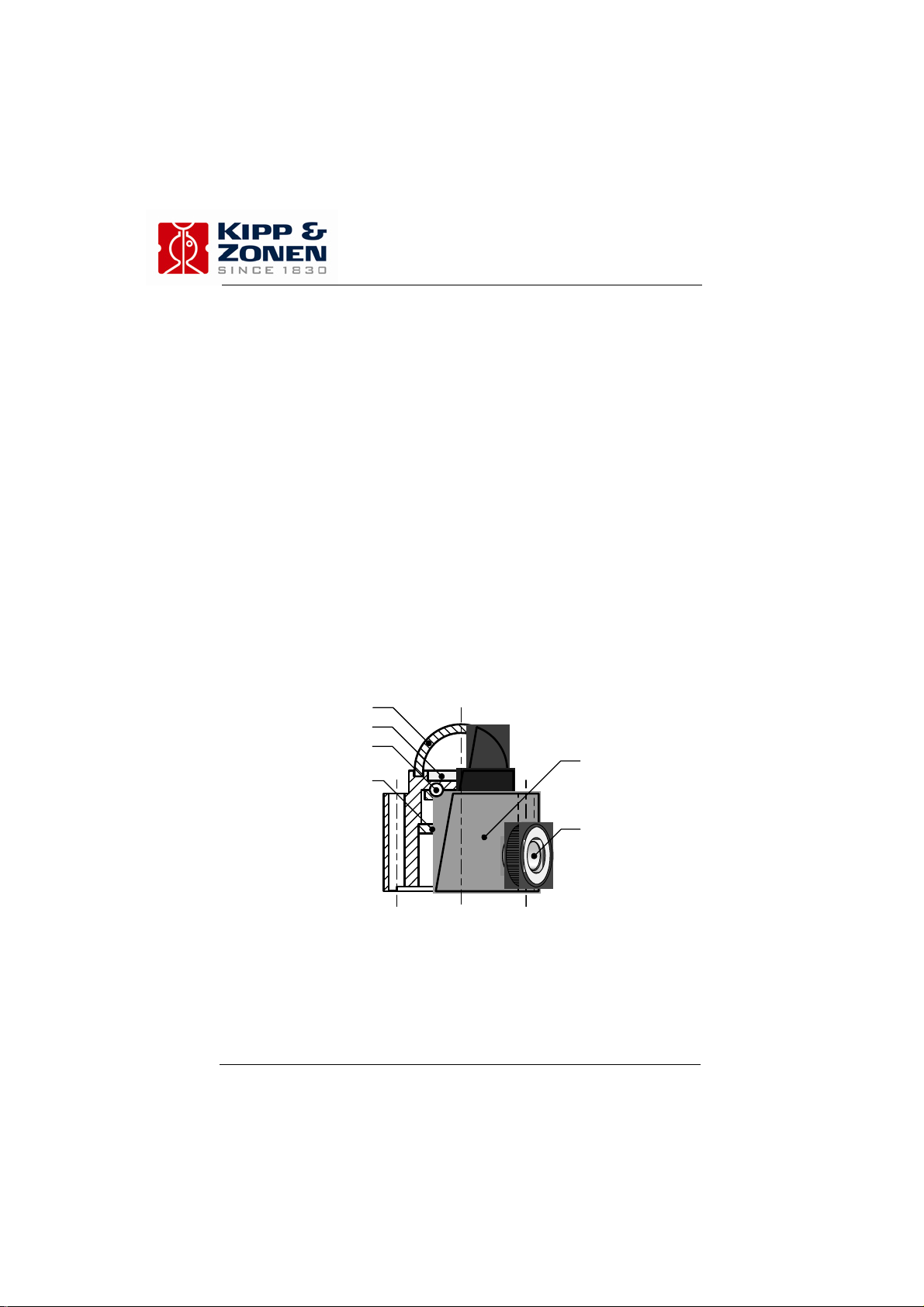

1.2 PHYSICAL PRINCIPLES OF THE PYRANOMETER

The pyranometer basically consists of a thermopile detector,

aluminium housing, a glass dome and a special cable. The CM4 is

provided with a Pt-100 temperature sensor to monitor the

pyranometer body temperature during operation. A drawing of the

pyranometer is shown in figure 1.1.

temperature sensor

Figure 1.1: CM 4 Pyranometer construction details.

Important: To avoid entry of water vapour it is strongly

glass dome

sensing element

housing

Circuit board

drying cartridge

recommended not to open the bottom plate of the

radiometer under any circumstances.

10

Page 12

1. GENERAL INFORMATION

The thermopile surface is coated with black absorbent paint.

Absorbed radiation is converted into heat which flows through the

thermal resistance of the thermopile to the heat-sink. The

temperature difference (ΔT) across the thermal resistance of the

detector is converted into a voltage.

Most electrical and physical specifications are determined by the

thermopile. The thermopile and the dome determine the spectral

specifications. The optimal geometry of both the glass dome and the

thermopile enables the pyranometer to have a 180° field of view with

good cosine response.

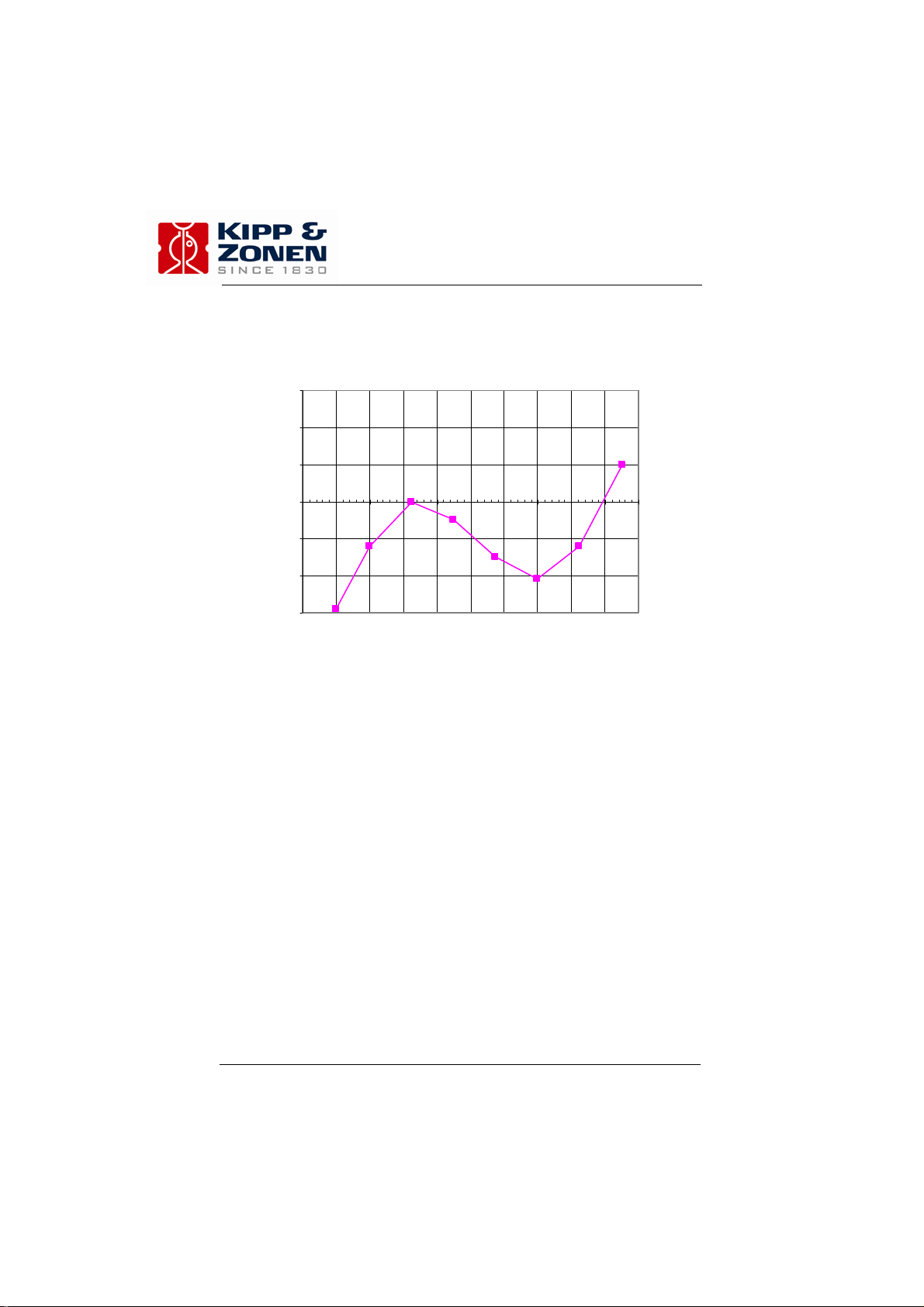

1.2.1 Temperature Dependency

One of the physical principles of a pyranometer is that at a constant

irradiance the detector sensitivity changes with the instrument

temperature. ISO 9060 defines this temperature response as the

percentage deviation due to a change in the ambient temperature

within a specific range of 50 K. The CM 4 temperature dependency

however is specified within an range of 170 K. To keep the

pyranometer performance acceptable the instrument output signal is

electrically compensated. Due to the perfectly balanced

thermoelectric construction the CM 4 temperature dependence is

kept within a deviation of 3%, within the range of -20 °C to 0 °C, 2%

within the range of 0 °C to +100 °C and 3% within the range of +100

°C to +150 °C .

After manufacturing, each instrument is individually checked for its

temperature dependency performance. This is measured in 8 steps

of 25 °C from -25 °C to +150 °C. A typical temperature response of

an electrically compensated CM 4 is given in figure 1.2.

11

Page 13

Temper ature dependenc y of the

sensitivity

3.000

2.000

1.000

0.000

[%]

-1.000

-2.000

Temperature dependency

-3.000

-40 -20 0 20 40 60 80 100 120 140 160

Instrument t e mperature ( ° C)

Figure 1.2: Typical temperature dependency curve of the CM 4.

The CM 4 High Temperature Pyranometer is supplied with its own

individual graph of temperature dependence of sensitivity. Monitoring

the temperature during operation will allow easy data correction

afterwards for improved measurement accuracy. The table in

Appendix II lists how to interpret the Pt-100 output readings.

To guarantee long-term stability the CM 4 circuitry consists of high

temperature resistant components, such that continuous high

irradiance measurements have a minimum effect on the durability or

the stability of the instrument.

12

Page 14

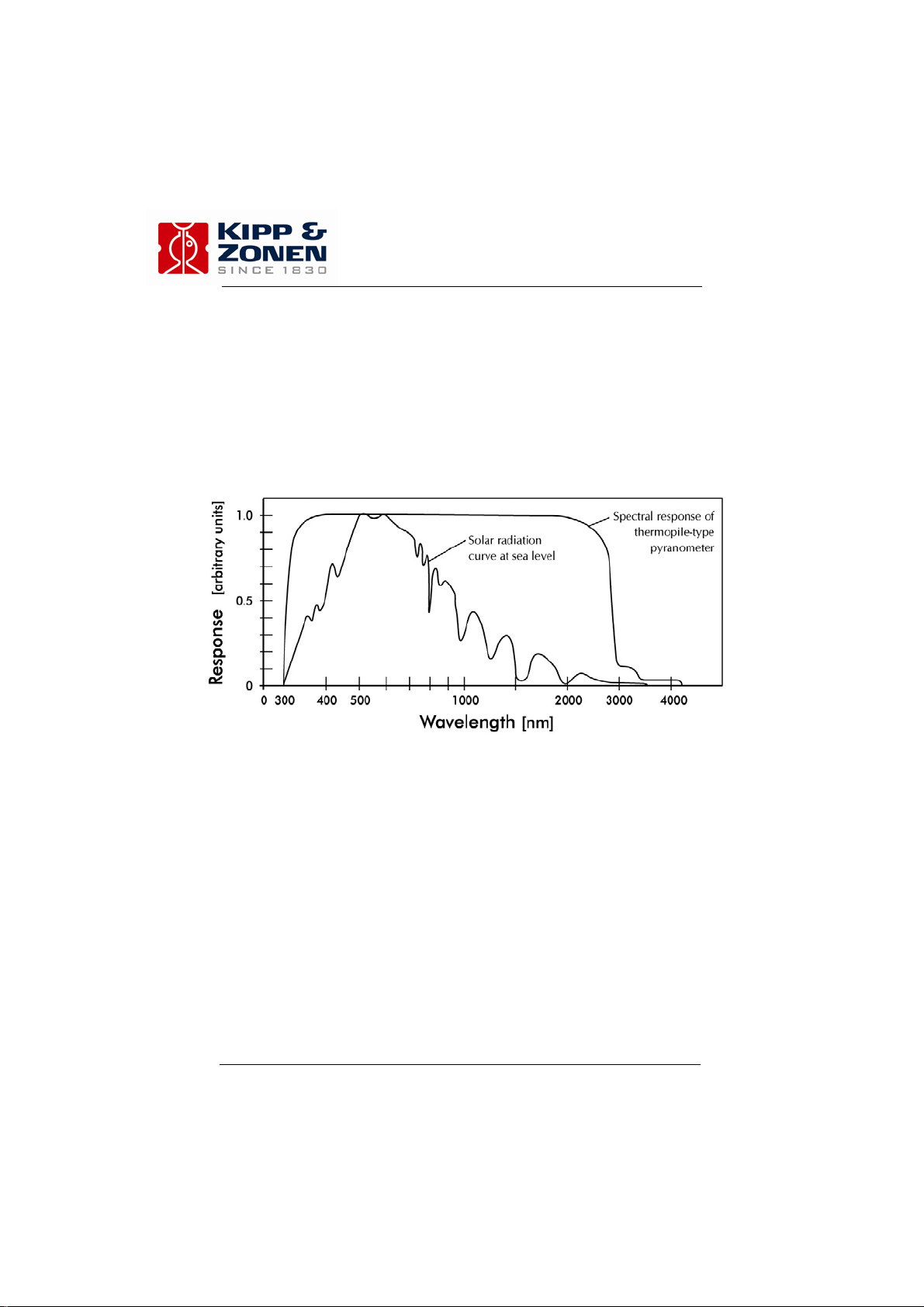

1.2.2 Spectral properties of the glass dome

The spectral properties of a pyranometer are determined by the

properties of the black absorbent paint and the glass dome. The

spectral response is given in figure 1.3.

1. GENERAL INFORMATION

Figure 1.3: The spectral transmission of the glass dome pyranometer

combined with the spectrum of the sun under a clear sky.

13

Page 15

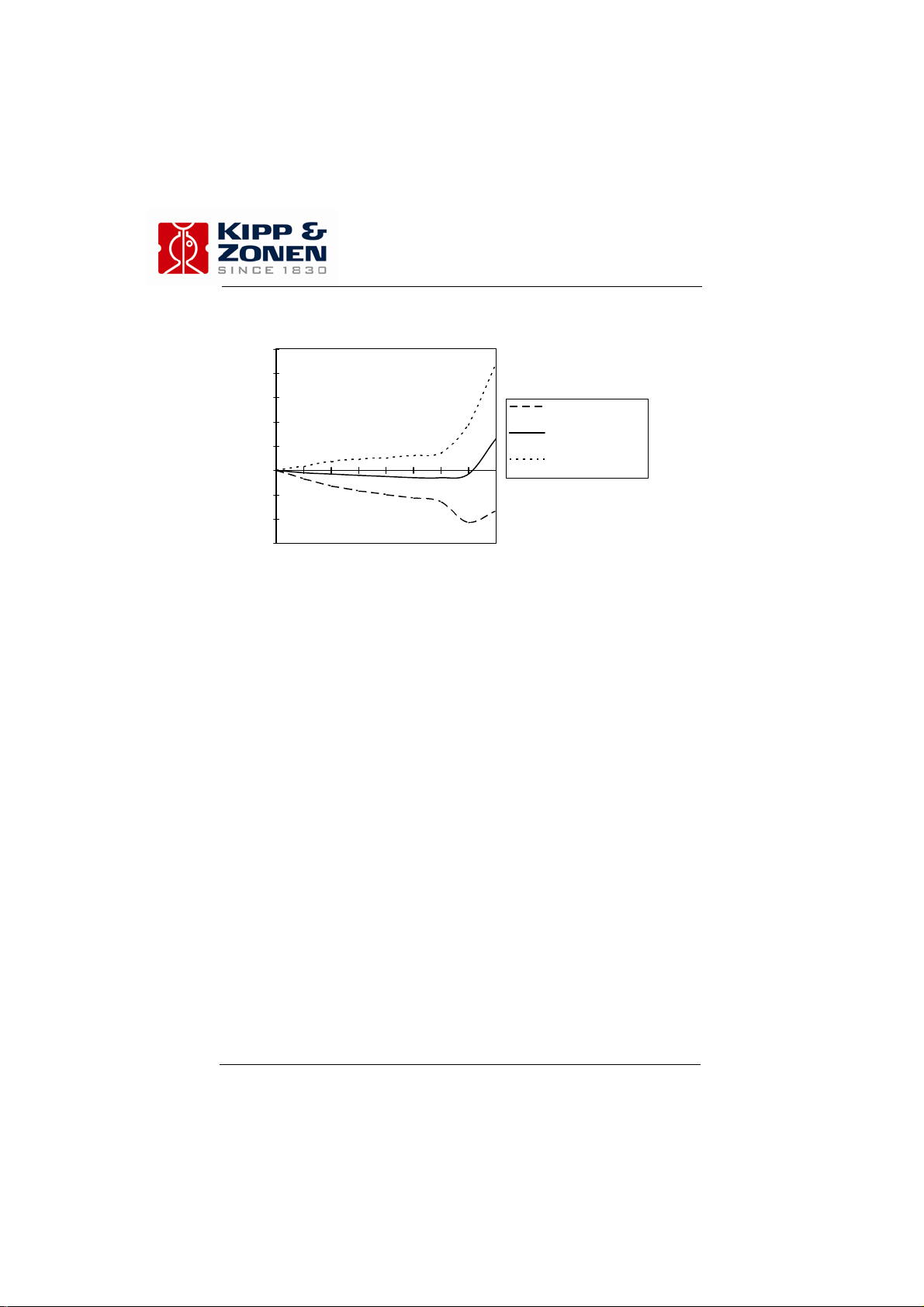

1.2.3 Directional / Cosine response

The measurement of the radiation falling on a plane surface (also

called irradiance or radiative flux) requires two assumptions: that the

surface is spectrally black (that it absorbs all radiation of all

wavelengths) and that it has a 180° field of view. Another way of

expressing these directional properties is to say that the sensor has

to comply with an ideal cosine response. ISO 9060 defines the

cosine response (or directional response) as the range of errors

caused by assuming that the normal incidence responsitivity is valid

for all directions when measuring with a beam radiation whose

normal angle of incidence irradiance is 1000 W/m².

A perfect cosine response will show maximum sensitivity (1) at an

angle of incidence of 0° (perpendicular to the sensor surface) and

zero sensitivity at an angle of incidence of 90° (radiation passing

over the sensor surface). In between 0 and 90 degrees the sensitivity

should be proportional the cosine of the angle of incidence. Figure

1.4 shows the typical curve and the maximum percentage deviation

of a CM 4 pyranometer. The vertical axis shows the deviation from

ideal behaviour, expressed in percents of the ideal value.

14

Page 16

1. GENERAL INFORMATION

10

8

6

4

2

[%]

0

0 1020304050607080

-2

-4

-6

degrees

min. cosine error

%

typical cosine error

%

max. cosine error

%

Figure 1.4: The mean cosine response of the pyranometer. With the angle

of incidence on the horizontal axis and the percentage deviation

from ideal cosine behaviour on the vertical axis.

1.2.4 Non-linearity

Non-linearity is the error of the sensitivity variation as a function of

the variation in irradiance. ISO 9060 defines non-linearity of an

instrument as its percentage deviation from the responsitivity at 500

W/m² due to the change in irradiance within 100 W/m² to 1000 W/m².

The linearity however is strongly related to the pyranometer design

and body. Due to a thermal gradient over the hot and cold junctions

(by absorption of radiation) heat convection at the detector surface

causes a non-linearity effect. The CM 4 detector construction has

been designed to keep the thermal gradient very low. Even when the

pyranometer is exposed to a very intense artificial radiating source

the non-linearity of the sensor sensitivity is small. The CM 4 nonlinearity is show in figure 1.5.

15

Page 17

1.01

1.00

0.99

0.98

0.97

Relative error [-]

0.96

0 500 1000 1500 2000 2500

Irradiance [W/m²]

Figure 1.5: CM 4 non-linearity, sensitivity variation as a function of

the irradiance, with 500 W/m² as reference level during

calibration.

16

Page 18

2 LIST OF SPECIFICATION S

Spectral range: 300 to 2800 nm, 50% points

Sensitivity: 7 µV/Wm

Impedance: 500 to 2000 Ω

Response time: 18 s (95% response)

< 8 s (63% response)

Non-linearity: Max. 3 % (0 - 2500 W/m

Directional error (at 80°

with a 1000 W/m² beam): ± 20 W/m²

Temperature dependence

of sensitivity: 3 % (-20 °C to +0 °C)

2 % (0 °C to +100 °C)

3 % (+100 °C to +150 °C)

Tilt error: Max. 1% deviation when facing

downwards

Zero-offset due to

temperature changes: Max. 4 W/m

change.

Zero-offset due to FIR

(200 W/m

Operating temperature: -40 °C to +150 °C

Field of view: 180° (2 π sr)

Max irradiance: 4000 W/m

Non-stability: ± 1% sensitivity change per year

2

): ± 15 W/m2

SPECIFICATIONS

-2

(nominal)

2

)

2

offset for 5 K/h temp.

2

17

Page 19

Temperature sensor: Pt-100

Construction:

Receiver paint: Carbon Black

Dome: Glass

Desiccant: Silica gel

Materials: Anodised aluminium case

Stainless steel screws etc

Viton O-rings

Drying cartridge aluminium and glass lid

Cable material: 6-wire shielded cable

Pt-100 specifications: Type Heraeus M-GX 1013, DIN

IEC 751. Class A, See Appendix II

Shock / vibration: IEC 721-3-2-2m2

CE according to EC guideline

89/336/EEC 73/23/EEC

Environmental: Intended for continuous outdoor or

indoor use.

Humidity 0 - 100% RH

Weight: 200 g

Cable length: Standard 10 m;

Dimensions in mm: See figure 2.1

18

Page 20

Figure 2.1: CM 4 Dimensions.

SPECIFICATIONS

19

Page 21

20

Page 22

3. INSTALLATION

3 INSTALLATION

Reading the installation instruction before installation is

recommended for full understanding of the use of this product.

3.1 DELIVERY

Check the contents of the shipment for completeness (see below)

and note whether any damage has occurred during transport. If there

is damage, a claim should be filed with the carrier immediately. In

this case, and also if the contents are incomplete, your dealer should

be notified in order to facilitate the repair or replacement of the

instrument.

The CM 4 pyranometer delivery will include the following items:

1. CM 4 pyranometer

2. Calibration certificate

3. Manual

4. Temperature dependency data

5. 2 x desiccant packs

Unpacking

Keep the original packaging for later shipments!

Although all sensors are weatherproof and suitable for rough

ambient conditions, they do partially consist of delicate mechanical

parts. For this type of equipment, keep the original shipment

packaging to safely transport the equipment to the measurement

site.

3.2 MECHANICAL INSTALLATION

The mechanical installation of the pyranometer depends upon the

measurement purpose. Different measurement methods are

explained in the next sections.

21

Page 23

3.2.1 Outdoor installation

When installed permanently, the pyranometer can be attached to its

mounting platform by means of the holes that are drilled through the

body, see figure 2.1.

Preferred orientation is with the cable pointing to the nearest pole.

When installed on a mast, preferred orientation is such that no

shadow is cast on the pyranometer during any time of the day. In the

Northern hemisphere this implies that the pyranometer should be

south of the mast.

The pyranometer can be used to measure reflected radiation, for

instance when pointed towards the earth in the inverted position.

When measuring reflected radiation (as an albedometer) it is advised

to do this at a height of at least 1.5 meters above the surface, to

avoid shading effects and to promote spatial averaging.

3.2.2 Indoor installation

When continuously used for indoor purposes the instrument should

preferably be attached to a mounting platform by means of the holes

that are drilled through the body, see figure 2.1. However, this might

not always be possible, for instance if the instrument is relocated or

moved regularly. What is recommended in these cases is to relocate

the instrument in the same place as much as possible, attempting to

repeat the same measurement conditions e.g. with respect to a fixed

offset from a light reflecting wall or any other object.

In the case of measuring the light irradiance on tilted surfaces it is

recommended to tilt and fix the radiometer at the same inclination as

the surface.

22

Page 24

3. INSTALLATION

3.3 ELECTRICAL CONNECTION

The CM 4 is provided with a special 10 m cable with six leads and a

shield covered with a black sleeve.

The colour code is: red = plus

blue = minus

Shield = case

Pt-100 temperature sensor (4 – wire connection)

White: Pt 100 (combined with black)

Black: Pt 100 (combined with white

Green: Pt 100 (combined with yellow)

Yellow: Pt 100 (combined with green)

The shield is directly connected to the case. Preferably the shield

should be connected to the same ground at the readout equipment,

to reduce cable noise. The cable must be firmly secured to minimise

spurious response during any mechanical movement or vibration

(pressing the cable produces voltage spikes, a tribo-electric effect

and capacitance effect).

Looking at the circuit diagram of figure 3.1, it is clear that the

impedance of the readout equipment is loading the thermistor circuit

and the thermopile. This can increase the temperature dependency

of the pyranometer. The sensitivity is affected more than 0.1% when

the load resistance is less than 1.5 MΩ. For this reason we

recommend the use of readout equipment with an input impedance

of 1.5 MΩ or more, such as potentiometric recorders, digital

voltmeters, etc. The solar integrators and chart recorders available

from Kipp & Zonen meet these requirements. Extension cables may

be used, but the cable resistance must be smaller than 0.1% of the

impedance of the readout equipment.

23

Page 25

Figure 3.1: Circuit diagram of the CM 4 Pyranometer and connection to

readout equipment.

It is evident that application of attenuator circuits to the CM 4 output

in order to modify the calibration factor is not recommended because

the temperature response will also be affected. However, recorders

with a variable voltage range can be set so that the result can be

read out directly in W/m

2

.

A considerable input bias current in the readout equipment can

produce a voltage of several micro-volts across the impedance of the

pyranometer. The correct measured zero signal can be verified with

a resistance replacing the pyranometer impedance at the input

terminals.

With the availability of a low voltage analogue input module with A/D

converter the pyranometer can be connected to a computer or data

acquisition system. The span and resolution of the A/D converter in

the module must allow a system sensitivity of about 1 bit per W/m

2

.

24

Page 26

3. INSTALLATION

For amplification of the pyranometer signal Kipp & Zonen

recommends the 4-20 mA Signal Amplifier, available from Kipp &

Zonen. This amplifier converts the micro-Volt output from the

pyranometer into a standard 4–20 mA signal.

Zero and Span adjustment of the pyranometer signal are provided.

25

Page 27

26

Page 28

4. OPERATION

4 OPERATION

After completing the installation the pyranometer will be ready for

operation.

The irradiance value (E) can be simply computed by dividing the

output signal (U

) of the pyranometer by its sensitivity (S

emf

ensitivity

) as

shown in formula 1, or by multiplication of the voltage value with the

reciprocal of the sensitivity, often called the calibration factor. The

CM 4 pyranometer sensitivity is given in the supplied calibration

certificate.

For calculation of the solar irradiance the following formula must be

applied:

U

E

=

S

ensitivity

emf

(Formula 1)

E = Global radiation [W/m

= Output of pyranometer [μV]

U

emf

S

= Sensitivity of pyranometer [μV/W/m2]

ensitivity

2

]

27

Page 29

28

Page 30

5. MAINTENANCE

5 MAINTENANCE

Once installed the pyranometer needs little maintenance. The

pyranometer dome must be kept clean and inspected regularly.

Ensure that the silica gel is still coloured orange. When the orange

silica gel in the drying cartridge is turned completely transparent

(normally after several months), it must be replaced by active silicagel

as supplied in the small refill packs. The content of one pack is

sufficient for one complete refill.

In humid areas it is usual to replace the desiccant twice a year.

The replacement interval is affected by humidity, variations in air

pressure and the extent of temperature changes.

Some tips when changing the desiccant:

- Do not remove the desiccant cartridge unnecessarily.

- Dirt in combination with water is the main cause of corrosion.

Make sure the surfaces of the pyranometer and the cartridge

that touch the rubber sealing ring are clean.

- For a better seal, the rubber ring is normally coated with

silicon grease (Vaseline can also be used). If the rubber ring

looks dry apply some grease to it.

29

Page 31

30

Page 32

6. CALIBRATION

6 CALIBRATION

6.1 INITIAL CALIBRATION

The ideal pyranometer should always have a constant ratio of

voltage output to irradiance level (outside the instrument in the plane

of the sensing element). This ratio is called sensitivity (S

ensitivity

) or

responsivity.

The calibration (sensitivity) factor of a particular pyranometer is

unique. It is determined in the manufacturer's laboratory by

comparison against a reference pyranometer.

The reference pyranometer is regularly calibrated outdoors at the

World Radiation Centre in Davos, Switzerland. Of course the

spectral content of the laboratory lamp differs from the outdoor solar

spectrum at the Radiation Centre. However, this has no

consequences for the transfer of calibration, because the reference

pyranometer and the pyranometer under test have the same black

coating and glass dome.

The supplied calibration factor is determined under the following

conditions:

An ambient temperature of 20°C.

For a horizontal pyranometer as well as for a tilted pyranometer.

Normal incident radiation of 500 W/m

2

.

Spectral content the same as clear sky solar radiation.

6.2 RECALIBRATION

The pyranometer sensitivity changes with time and with exposure to

radiation, this deviation is also known as the non-stability.

Periodically a radiometer calibration is advised, at least every two

years. Recalibration can be done at Kipp & Zonen. When sending

back a pyranometer to Kipp & Zonen for recalibration it is

recommended to use the recalibration form in the back of this

manual, Appendix IV.

31

Page 33

Accurate calibrations can also be done outdoors under clear

conditions by comparison to a reference pyrheliometer. Many

National Weather Services have calibration facilities. Their standard

pyrheliometer is compared with the World Radiometric Reference

(maintained at Davos, Switzerland) embodied by several absolute

pyrheliometers (black body cavity type).

The comparisons are performed indoors or outdoors at one of the

regional Radiation Centres, see Appendix III. These institutes

sometimes offer calibration services.

There are several procedures for transferring calibration from a

narrow field of view instrument (pyrheliometer) to a wide field of view

instrument (pyranometer). For example, the direct component of the

solar radiation is eliminated temporarily from the pyranometer by

shading the whole outer dome of the instrument with a disk. There is

however no thermal equilibrium with this method and some

pyranometer models show zero-offset drift.

There is another procedure, during which the pyranometer to be

calibrated remains in its normal operating condition. This

'component' method involves measuring the direct component with a

pyrheliometer and the diffuse component with a disk shaded

pyranometer. As, during a clear day, the diffuse irradiance is only

about 10% of the global radiation, the sensitivity of the second

pyranometer does not need to be known very accurately. Both

procedures are suitable to recalibrate a pyranometer. The latter is

extensively described in International standard ISO 9846. A

summary of calibration methods is also found in the WMO guide of

1996.

Another procedure to recalibrate pyranometers is described in the

International Standard ISO 9847. Here the pyranometer to be

calibrated is compared to a reference pyranometer under clear sky

conditions. The pyranometers must be mounted side by side so that

each views the same sky dome. It is desirable to integrate, or

average, the outputs over a period of time and then compute the

calibration constants on the basis of these averages. This reduces

the errors due to changing parameters during the day.

32

Page 34

6. CALIBRATION

6.3 CALIBRATION PROCEDURE AT KIPP & ZONEN

6.3.1 The facility

The calibration facility at Kipp & Zonen consists of a good quality film

sun (Osram) fed by an AC voltage stabiliser. This is used as an

artificial sun. It embodies a 150 W Metal Halide lamp with compact

filament.

To minimise stray light from the walls and the operator, the light is

limited to a small cone around the two pyranometers. The unknown

pyranometer 'a' and the standard pyranometer 'b' are placed side by

side on a small table. The table can rotate to interchange the

positions (1 and 2) of the pyranometers. The lamp is centred on the

rotating axis of this table. Actually there is no normal incidence of the

radiation, but the angle of incidence is the same for both

pyranometers (3°) so this cannot give rise to errors. The two

pyranometers are not levelled with the screws, but placed on their

bases. The effect of a small tilt is almost zero (Compare cos. 3° =

0.9986 and cos. 4° = 0.9976). The irradiance of the pyranometers is

approx. 500 W/m

2

. The colour temperature of the light is 3300 K.

6.3.2 Procedure

After illuminating for 70 s, the output voltages of both pyranometers

are integrated over 20 s with a solar integrator. Next, a blackened

‘hat’ covers both pyranometers. After 70 s the zero offset signal of

both pyranometers is integrated again.

The problem of the zero offset is described below. This zero offset

has to be subtracted to obtain the response due to illumination. So

we get responses A and B respectively.

The irradiance at position 1 (pyranometer 'a') may be slightly

different from that at position 2 (pyranometer 'b') due to asymmetry in

33

Page 35

+

the lamp optics etc. Therefore the pyranometers are interchanged

and the whole procedure is repeated. We get another pair of values:

A' and B'.

6.3.3 Calculation

The sensitivity of the unknown pyranometer is calculated using

formula 2:

=

+

(Formula 2)

⋅

sS

ba

'

BB

'

AA

Sb = Sensitivity of the reference pyranometer at 20 °C.

A = Output of test pyranometer at position 1

A’ = Output of test pyranometer at position 2

B = Output of reference pyranometer at position 2

B’ = Output of reference pyranometer at position 1

S

= Sensitivity of the test pyranometer at 20 °C.

a

Output = mean value at 100% response minus zero offset signal

6.3.4 Zero offset

The lamp housing and diaphragms are emitting long wave infrared

radiation, which heats up the glass dome. When the pyranometers

are shaded, there still remains a small signal up to + 20 µV due to

longwave infrared radiation from the dome to the sensor. This zero

offset is decreasing with a time constant (1/e) of several minutes.

A zero offset is also embodied in the response due to illumination. To

correct for this unwanted response, the zero offset read after 70 s

shading is subtracted.

34

Page 36

6. CALIBRATION

6.3.5 Traceability to World Radiometric Reference

Working reference pyranometers are maintained at Kipp & Zonen.

Each reference pyranometer is characterised. Linearity, temperature

dependence curve and directional response are well kno wn.

The working reference pyranometers are calibrated each year at the

World Radiation Center in Davos, Switzerland, according to the

component method.

35

Page 37

36

Page 38

7 FREQUENTLY ASKED QUESTIONS

7 FREQUENTLY ASKED QUESTIONS (FAQ’s)

The most frequently asked questions are listed below.

1. Negative output during measurements?

This error is related to the zero offset type A. Normally this zero

offset is present when the dome has a different temperature from the

cold junctions of the sensor. In practice this is always the case when

there is very large and cold object close to the pyranometer. The

emitted heat by the glass dome is attracted from the body (by

conduction in the dome) and from the air (by convection and heat

conductivity). The dome is cooling down too and will attract heat from

the body by conduction and from the sensor by the net infrared

radiation. The latter heat flow is opposite to the heat flow from the

absorbed solar radiation and causes the well known zero

depression. This negative zero offset is always present, however,

hidden within the thermopile signal.

2. What is the primary entry point for humidity?

The desiccant cartridge and cable gland have equal chances to

transport some moisture. Also the silicon glue of the domes is not

completely watertight.

When care is not taken one can easily make the desiccant

cartridge the primary entry point. See chapter 5 for the

maintenance of the CM 4 Pyranometer.

Note: Water vapour transport through the cable is also possible when

the open end of the cable at the readout device is in a humid

environment.

37

Page 39

38

Page 40

8 TROUBLE SHOOTING

8 TROUBLE SHOOTING

The following contains a procedure for checking the instrument in

case it appears that it does not function as one could expect.

Trouble shooting:

Output signal fails or shows improbable results:

Check the wires, whether they are properly connected to the

readout equipment.

Check the dome and the drying cartridge, they should be clear. If

water is deposited on the inside, please change the desiccant. If

too much water is deposited the instrument should be dried

internally.

Check the instrument impedance (500 - 2000 Ohm)

Check datalogger or integrator offset by connecting a dummy

load (500 - 2000 Ohm resistor). This should give a “zero”

reading.

If water or ice is deposited to the outside of the dome, clean the

dome. Usually water droplets will evaporate in less than one hour.

Any visible damage or malfunction should be reported to your dealer,

who will suggest appropriate action.

39

Page 41

40

Page 42

9 PART NUMBERS / SPARE PARTS / OPTIONS

9 PART NUMBERS / SPARE PARTS / OPTIONS

Description Part no.

Drying Cartridge kit 0356 111

(incl. Cartridge, Cover, Rubber Ring)

Silica gel refill pack 2643 951

41

Page 43

42

Page 44

APPENDIX I PYRA NOMETER CLASSIFICATION

ACCORDING TO WMO GUIDE 1996

Characteristics

ISO 9060 classification

Response time (95 percent response) < 15 s < 30 s < 60 s

Zero offset:

(a) Response to 200 W/m

net thermal radiation

(ventilated)

(b) Response 5 K/h change

in ambient temperature

Resolution (smallest detectable

change)

Stability (change per year,

percentage of full scale)

Directional response of beam

radiation

(The range of errors caused by

assuming that the normal incidence

responsivity is valid for all directions

when measuring, from any direction,

a beam radiation whose normal

incidence irradiance is 1000 W/m

Temperature response (percentage

of maximum due to any change of

ambient temperature within an

interval of 50 K)

Non-linearity (percentage deviation

from the responsivity at 500 W/m

due to any change of irradiance

within the range 100 to 1000 W/m

Spectral sensitivity (percentage of

deviation of the product of spectral

absorptance and spectral

transmittance from the corresponding

mean within the range of 0.3 to 3 μm)

Tilt response (percentage deviation

from the responsivity at 0° tilt,

horizontal, due to change in tilt from

0° to 90° at 1000 W/m

2

2

irradiance)

2

)

2

2

High

quality

Secondary

standard

± 7 W/m

± 2 W/m

± 1 W/m

± 0.8 ± 1.5 ± 3.0

± 10 W/m

± 2 ± 4 ± 8

± 0.5 ± 1 ± 3

)

± 2 ± 5 ± 10

± 0.5 ± 2 ± 5

Good

quality

First class Second class

2

2

2

± 15 W/m

± 4 W/m

± 5 W/m2 ± 10 W/m2

2

± 20 W/m2 ± 30 W/m2

2

2

Moderate

quality

± 30 W/m

± 8 W/m

2

2

43

Page 45

Achievable uncertainty, 95 percent

confidence level

Hourly totals

Daily totals

3%

2%

8%

5%

20%

10%

44

Page 46

APPENDIX II PT-100 SPECIFICATIONS

Temp.

[°C]

-40

-39

-38

-37

-36

-35

-34

-33

-32

-31

-30

-29

-28

-27

-26

-25

-24

-23

-22

-21

-20

-19

-18

-17

-16

-15

-14

-13

-12

-11

-10

-9

Resistance

[Ω]

84,27

84,67

85,06

85,46

85,85

86,25

86,64

87,04

87,43

87,83

88,22

88,62

89,01

89,40

89,80

90,19

90,59

90,98

91,37

91,77

92,16

92,55

92,95

93,34

93,73

94,12

94,52

94,91

95,30

95,69

96,09

96,48

Temp.

[°C]

-8

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Resistance

[Ω]

96,87

97,26

97,65

98,04

98,44

98,83

99,22

99,61

100,00

100,39

100,78

101,17

101,56

101,95

102,34

102,73

103,12

103,51

103,90

104,29

104,68

105,07

105,46

105,85

106,24

106,63

107,02

107,40

107,79

108,18

108,57

108,96

Temp.

[°C]

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

Resistance

[Ω]

109,35

109,73

110,12

110,51

110,90

111,29

111,67

112,06

112,45

112,83

113,22

113,61

114,00

114,38

114,77

115,15

115,54

115,93

116,31

116,70

117,08

117,47

117,86

118,24

118,63

119,01

119,40

119,78

120,17

120,55

120,94

121,32

45

Page 47

Temp.

[°C]

Resistance

[Ω]

Temp.

[°C]

Resistance

[Ω]

Temp.

[°C]

Resistance

[Ω]

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

121,71

122,09

122,47

122,86

123,24

123,63

124,01

124,39

124,78

125,16

125,54

125,93

126,31

126,69

127,08

127,46

127,84

128,22

128,61

128,99

129,37

129,75

130,13

130,52

130,90

131,28

131,66

132,04

132,42

132,80

133,18

133,57

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

133,95

134,33

134,71

135,09

135,47

135,85

136,23

136,61

136,99

137,37

137,75

138,13

138,51

138,88

139,26

139,64

140,02

140,40

140,78

141,16

141,54

141,91

142,29

142,67

143,05

143,43

143,80

144,18

144,56

144,94

145,31

145,69

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

146,07

146,44

146,82

147,20

147,58

147,95

148,33

148,70

149,08

149,46

149,83

150,21

150,58

150,96

151,33

151,71

152,08

152,46

152,83

153,21

153,58

153,96

154,33

154,71

155,08

155,46

155,83

156,20

156,58

156,95

157,33

46

Page 48

APPENDIX III LIST OF WORLD AND REGIONAL

RADIATION CENTRES

World Radiation Centres

St. Petersburg (Russia)

Regional Radiation Centres

Region I Africa: Cairo (Egypt)

Khartoum (Sudan)

Kinshasa (Zaire)

Lagos (Nigeria)

Tamanrasset (Algeria)

Tunis (Tunisia)

Region II Asia: Poona (India)

Tokyo (Japan)

Region III South America: Buenos Aires

(Argentina)

Region IV North and Central America: Toronto (Canada)

Washington (U.S.A.)

Region V South West Pacific: Aspendale (Australia)

Region VI Europe: Bracknell (United Kingdom)

Budapest (Hungary)

Davos (Switzerland)

St. Petersburg (Russia)

Norrköping (Sweden)

Trappes/Carpentras

(France)

Davos (Switzerland)

Uccle (Belgium)

MOH Hamburg (Germany

47

Page 49

48

Page 50

APPENDIX IV RECALIBRATION SERVICE

Pyranometers, UV-meters, Pyrgeometers &

Sunshine duration sensors

Kipp & Zonen solar radiation measurement instruments comply with

the most demanding international standards. In order to maintain the

specified performance of these instruments, Kipp & Zonen

recommends calibration of their instruments at least every two years.

This can be done at the Kipp & Zonen factory. Here, recalibration to

the highest standards can be performed at low cost. Recalibration

can usually be performed within four weeks. If required, urgent

recalibration can be accomplished in three weeks or less (subject to

scheduling restrictions). Kipp & Zonen will confirm the duration of

recalibration at all times. Please note that special quantity

recalibration discounts are available.

For your convenience we have attached three fax forms to schedule

the recalibration of your instrument(s) at Kipp & Zonen.

49

Page 51

50

Page 52

Name :

Company/Institute :

Address :

Postcode + City :

Country :

Phone :

Fax :

E-mail :

RECALIBRATION FORM

I would like to receive a price estimate for recalibration

I would like to submit my instruments for recalibration

Type/Model: Qty: Requested deliv ery time

Conformation by Kipp & Zonen

□ Yes, the dates are acceptable to us

I intend to send the instrument(s) to

Kipp & Zonen on:

. . . . . ./. . . . . ./. . . . . .

I would like to receive the instrument(s)

back on:

. . . . . ./. . . . . ./. . . . . .

□ No, unfortunately the dates do not fit into our calibration

schedule. We suggest the following dates:

. . . . . ./. . . . . ./. . . . . .

. . . . . ./. . . . . ./. . . . . .

Fax: +31 15 2620 351 or mail to:

Kipp & Zonen, P.O. Box 507, 2600AM Delft, The

Netherlands

51

Page 53

Our customer support remains at your disposal for any maintenance or repair, calibration,

supplies and spares.

Für Servicearbeiten und Kalibrierung, Verbrauchsmaterial und Ersatzteile steht Ihnen unsere

Customer Support Abteilung zur Verfügung.

Notre service 'Support Clientèle' reste à votre entière disposition pour tout problème de

maintenance, réparation ou d'étalonnage ainsi que pour les accessoires et pièces de rechange.

Nuestro apoyo del cliente se queda a su disposición para cualquier mantenimiento o la

reparación, la calibración, los suministros y reserva.

HEA D OFFICE

Kipp & Zonen B.V.

Delftechpark 36, 2628 XH Delft

P.O. Box 507, 2600 AM Delft

The Netherlands

T: +31 (0) 15 2755 210

F: +31 (0) 15 2620 351

info@kippzonen.com

SALES OFFICES

Kipp & Zonen France S.A.R.L.

7 Avenue Clément Ader

ZA Ponroy - Bâtiment M

94420 Le Plessis Trévise

France

Kipp & Zonen Asia Pacific Pte. Ltd.

81 Clemenceau Avenue

#04-15/16 UE Square

Singapore 239917

Kipp & Zonen USA Inc.

125 Wilbur Place

Bohemia

NY 11716

United States of America

Go to www.kippzonen.com for your local distributor or contact your local sales office

T:

+33 (0) 1 49 62 41 04

F: +33 (0) 1 49 62 41 02

kipp.france@kippzonen.com

T: +65 (0) 6735 5033

F: +65 (0) 6735 8019

kipp.singapore@kippzonen.com

T: +1 (0) 631 589 2065

F: +1 (0) 631 589 2068

kipp.usa@kippzonen.com

Passion for Precision

Loading...

Loading...