Page 1

Brewer MkIII

Spectrophotometer

Service manual

Page 2

REVISION HISTORY

REV

DESCRIPTION

DCN #

DATE

APPD

-

Initial Release

-----

98-11-06

TKLL

A

New Brewer Electronics

822

99-02-01

TKLL

B

Updated

868

99-08-13

C

Updated

55

05-10-21

KBo

D

Updated

9

06-02-03

KBo

E

Hamamatsu PMT

08-11-14

KBo

Page 3

ii

Page 4

iii

Page 5

Page 6

MKIII SERVICE MANUAL

1

TABLE OF CONTENTS

PREFACE ............................................................................................................................................... 3

1 PURPOSE AND APPLICATION ...................................................................................................... 3

2 EQUIPMENT REQUIRED ............................................................................................................... 3

3 MAJOR EQUIPMENT FAILURES ................................................................................................... 5

3.1 "No Operation" - No Power Indication ...................................................................................... 5

3.2 Trouble Shooting Sequence for "No Operation" Condition ........................................................ 6

4 OPERATING TEST FAILURES ..................................................................................................... 11

4.1 Mercury Lamp Circuit .............................................................................................................. 11

4.2 Trouble shooting a Mercury Lamp Test Failure ....................................................................... 11

4.3 Standard Lamp Circuit ............................................................................................................ 13

4.4 Standard Lamp Failure ........................................................................................................... 13

4.5 Trouble-shooting Standard Lamp Test Failure ........................................................................ 13

4.6 Light Detection System Failure ............................................................................................... 15

4.7 Trouble-shooting the Light Detection System ......................................................................... 15

4.8 Stepping motor control ............................................................................................................ 17

4.9 Photon Counter Circuitry ......................................................................................................... 17

4.10 High Speed Amp Board ....................................................................................................... 17

4.11 Ratemeter ............................................................................................................................ 18

4.12 Temperature monitor ........................................................................................................... 18

4.13 High voltage Circuits ........................................................................................................... 18

4.14 Clock / Calandar .................................................................................................................. 18

4.15 A/D Converter ...................................................................................................................... 18

4.16 Breather Desiccant Cartridge .............................................................................................. 19

4.17 Humidity Sensor (Optional) ................................................................................................ 19

5 TEST RESULTS OUT OF SPECIFICATION ................................................................................. 21

6 OPTICS CARE AND CLEANING .................................................................................................. 23

6.1 Optics Care ............................................................................................................................. 23

6.2 Optics Cleaning ....................................................................................................................... 23

7 AZIMUTH TRACKER .................................................................................................................... 25

7.1 Brewer Power Problems. ........................................................................................................ 25

7.2 Bewer Communications Problems .......................................................................................... 25

7.3 Tracker Electrical Problems .................................................................................................... 26

7.3.1 Sensor Problems .......................................................................................................... 26

7.3.2 No Tracker Operation. .................................................................................................. 26

7.4 Tracker Mechanical Problems ................................................................................................ 27

8 MAIN ELECTRONICS FIRMWARE / CONFIGURATION LOADING PROCEDURES .................. 29

8.1 Installation of Brewcmd Software ............................................................................................ 29

8.2 Restore Back to COSMAC Mode ............................................................................................ 29

8.3 New Configuration Upload ...................................................................................................... 30

8.4 Uploading new Firmware and configuration files .................................................................... 31

8.5 Main Board flat cable connections ............................................ Error! Bookmark not defined.

9 WARRANTY .................................................................................................................................. 33

TABLE OF CONTENTS

Page 7

MKIII SERVICE MANUAL

2

Recommendations by Environment Canada

Mark III Brewer Ozone Spectrophotometers are recommended by Environment Canada (EC) as

the significantly superior model of Brewer instrument with which to measure ozone in the ultraviolet

(UV) region of the spectrum. EC strongly discourages the use of other models of the Brewer

instrument for the measurement of ultraviolet radiation or ozone in the UV because of the much

poorer stray light performance of the single monochromator versions of the instrument.

Page 8

MKIII SERVICE MANUAL

3

PREFACE

This document has been developed to aid an operator when a Brewer Spectrophotometer stops

operating or whose operating characteristics have changed since leaving KIPP & ZONEN B.V.. It

has been developed from the experience of KIPP & ZONEN and present users of the Brewer. The

most likely electronic failures and ones which can be repaired in the field have been documented.

1 PURPOSE AND APPLICATION

The purpose of this manual is to help the operator diagnose problems with a Brewer

Spectrophotometer to an assembly level. Component level diagnostics will not be covered since

the replacement of many components may require instrument realignment or re-calibration.

Potentiometers should not be adjusted nor set screws removed without completely defining the

problem area. If the information in this document is not sufficient, it is recommended that the user

contact KIPP & ZONEN before dismantling of any assemblies beyond what is called for in this

manual.

In several cases the operator will be asked to replace components that are not included in spares

kits. In these cases please contact KIPP & ZONEN for information on obtaining the component.

2 EQUIPMENT REQUIRED

1) Volt-Ohmmeter, capable of measuring from 1 mV to 2000 volts DC.

2). A clip on or in-line current meter.

3). In place of the above items, a digital Volt-Ohmmeter, such as the one contained in the KIPP &

ZONEN UV Stability Kit is adequate except for Voltage readings of greater than 1000V.

4) An oscilloscope may be useful (1 millivolt; 20 megahertz bandwidth).

5) An external UVB lamp may be useful when the internal quartz-halogen lamp appears at fault.

6) If the control computer is suspect, a second computer with Brewer software loaded may be

needed.

7) A terminal communications program such as Telix, Procomm, Xtalk or Windows HyperTerminal.

Page 9

MKIII SERVICE MANUAL

4

Page 10

MKIII SERVICE MANUAL

5

3 MAJOR EQUIPMENT FAILURES

A major equipment failure is defined as a condition where there is no communication between the

Brewer Spectrophotometer (Brewer) and the external control computer (PC). Symptoms are that

no commands go to the Brewer, and no information is received by the PC. This is a "no operation"

condition.

3.1 "NO OPERATION" - NO POWER INDICATION

1. Reset the Brewer

If any problem is fixed at any point in this trouble shooting procedure attempt to launch the Brewer

Software.

When the Brewer Software is launched the Brewer should send the following message to the PC:

BREWER OZONE SPECTROPHOTOMETER

#nnnnn

AES SCI-TEC

CANADA

VERSION 1 Jan 01, 1998

If this message is received then communications has been established between the Brewer and

the control computer.

If the instrument does not reset (as seen by motors initializing), the problem is probably in the

Brewer, but may also be in the communications cable, the PC or the software.

A fresh set of software can be loaded onto the Computer from the original discs to eliminate it as a

potential problem. Ensure that the Brewer configuration files are preserved as they contain

important operating information such as the COM: port number. Check the configuration files to

ensure that none of the files have been corrupted.

2. Check Power

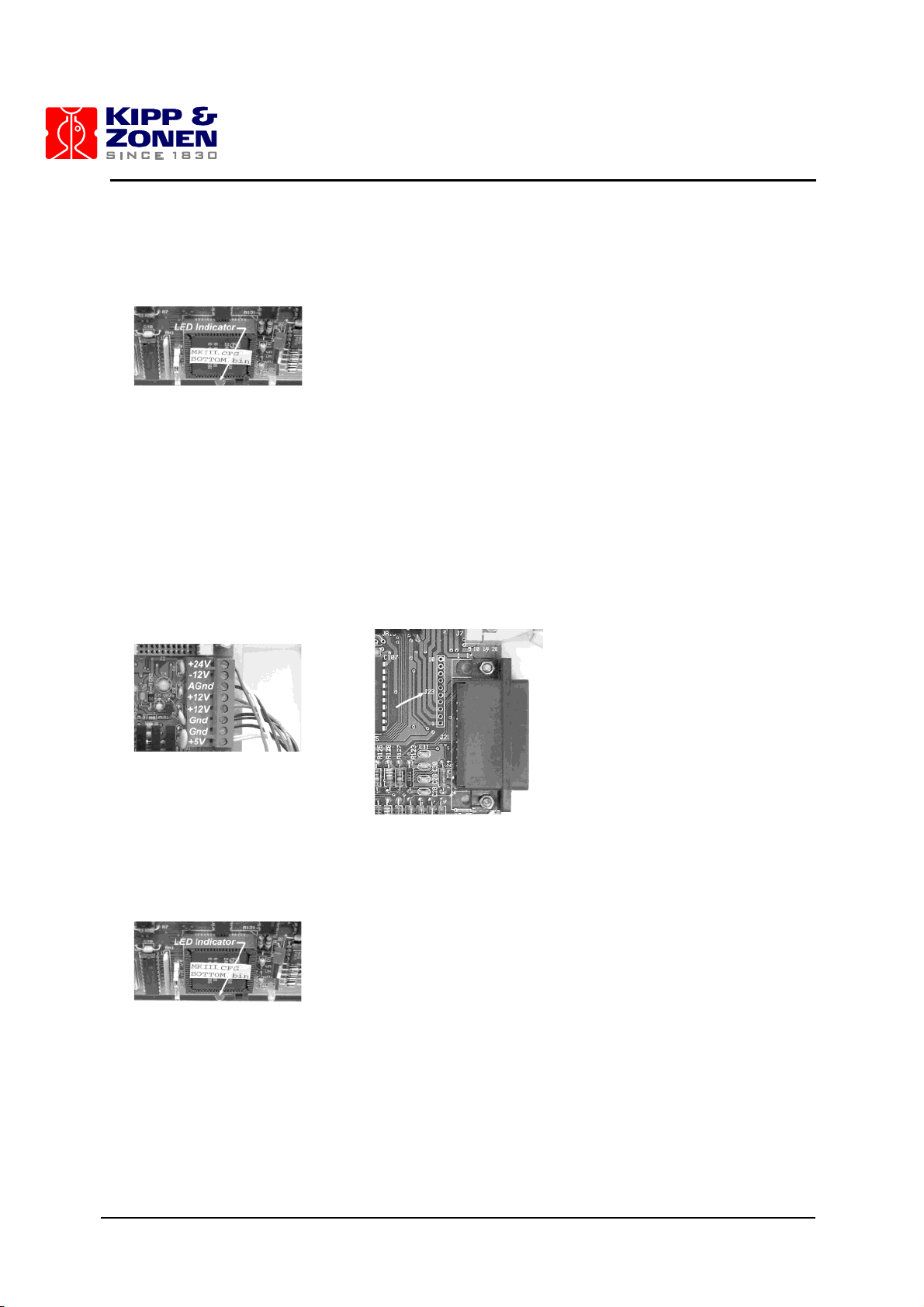

If the GREEN LED on the Brewer is illuminated, then there is power to the instrument, and the

Main Power Supply is producing 5V. If the LED is not illuminated, then the AC power source should

be checked at the AC outlet and the end to end continuity of the Power Cable tested. The AC

power should then be connected directly to the Brewer, bypassing the Tracker.

If there is still a no-power indication, then the Brewer top cover should be removed and the MAIN

power supply checked to see if it feels warmer than ambient.

3. Check Power Switch and Fuses

If the cover is not warm, then perhaps the Power Switch is defective, or a fuse requires

replacement. With power disconnected, use an Ohmmeter to confirm that the Switch is functional,

and check the two fuses next to the power supply cover as indicated in the photograph. If a fuse

needs changing, ensure that AC power is disconnected, and replace the fuse with the appropriate

spare.

To check the fuse inside the power supply, disconnect AC power from the Brewer, remove the

Main Power Supply cover (four 6-32 screws) and measure or visually inspect the fuse and replace

it if necessary. When re-installing the cover, ensure that the Power Supply connectors remain

connected.

3 MAJOR EQUIPMENT FAILURES

Page 11

MKIII SERVICE MANUAL

6

If the power supply appears to be normal, then the LED may be defective, or there may be a faulty

connection.

4. Measure Voltages

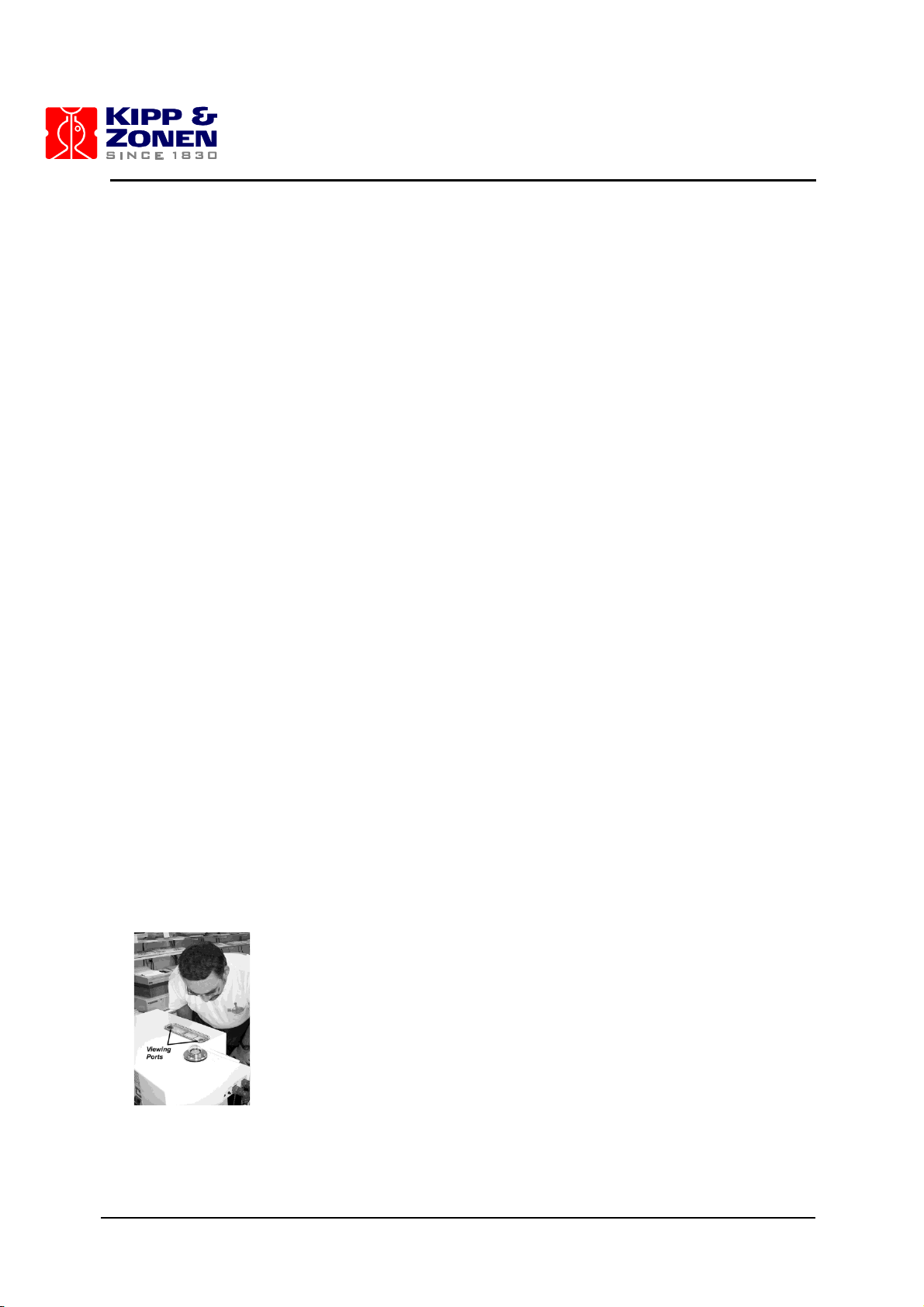

The main power supply voltages can be checked at the test points on J23 of the Main Electronics

board. (Refer to the chart for correct voltages).

Connector J23 Monitor

points

Pin 1 Pin 2 Pin 3 Pin 4 Pin

5

Pin

6

Pin

7

Pin

8

Pin 9 Pin

10 5v

5v

-5v

12v

12v

-12v

24v

2.5v

4.5v

Gnd

3.2 TROUBLE SHOOTING SEQUENCE FOR "NO OPERATION" CONDITION

It has been established that there is Power, motors reset, but that there is absolutely no

communication between the PC and the Brewer.

1. Reset

A software reset should be attempted after the "Brewer Failed to Respond" message appears on

the PC monitor, or the PC has tried a number of times to establish contact with the Brewer. The

software reset is done by pressing key on the PC following the error message, or launching the

Brewer software from the DOS prompt. If this fails to establish communications, the PC should be

given a ‘cold’ boot (power OFF/ON).

2. Check cables

If there is still no response, the cables should be inspected to ensure that a connector has not been

inadvertently removed or pulled out of place. The Communications cable to the Brewer from the

PC, as well as the power cable to the Brewer should be checked. All cables involving the linking of

peripherals should be checked to ensure that they are plugged in as well. After this has been done

another software reset can be tried.

3. Test serial port

Check that the computer serial port is operating correctly by running a serial communications

program such as Telix, Procomm, or Windows Hyper Terminal. Make sure the serial

communications program is set to 1200 baud, is in full duplex mode, and the correct serial port has

been selected. Refer to the communications program documentation for correct operation.

Remove the RS422 adapter from the back of the computer and connect pins 2 and 3 of the

computer serial port together. While running the communications program in full Duplex mode,

characters typed should be seen echoing to the monitor. Disconnecting the jumper wire should

stop the echo-back. This test confirms that the computer serial port is operating correctly. If the

computer did not echo the characters change the Brewer’s configuration to use another port (see

section 3.6 in the Operator’s Manual) or have the defective serial port repaired before doing any

further tests.

Page 12

MKIII SERVICE MANUAL

7

4. Test RS422 adapter

The RS422 adapter at the computer can be tested by removing the communications cable from the

adapter, connecting pins 1-3, plugging the adapter into the Computer COM: port, and checking for

echo-back as in step 3. Now switch connections to pins 2-4 and test again. The RS422 adapter is

operating correctly if characters echo back. If a fault is indicated, then either the adapter or the

power module is defective.

The power module output should be approximately +13V DC with no load or +9V with a load (the

centre pin is positive.) If the voltage is normal, then replace the RS422 adapter and test again.

5. Test communications cable

If the tests have passed to this point, the communications cable between the Brewer and the

computer can be tested. Reconnect the cable to the RS422 adapter and connect it back to the

computer. Remove the communications cable from the Tracker surge suppressor box and connect

a wire jumper to connect pins C-B. Test the cable by sending characters from the computer as in

step 3; move the jumper to connect pins I-J and test it again.

Reconnect the communication cable to the tracker and disconnect the communications cable at the

Brewer. Short pins C-B and then pins I-J and test as in step 4. If the test passes, reconnect the

cable to the Brewer and open the cover of the Brewer. Turn the power off and disconnect the IDC

connector (the IDC connector,J7, is the connector attached to the shielded ribbon cable shown in

the picture below) Use a small wire jumper to connect pins 2-8, and then pins 4-6, using the echoback test each time. (The IDC pins begin from 1 at the triangle stamped on the side of the

connector and increment in odd numbers on the same row - 1, 3, 5, 7, 9 on the first row and 2, 4, 6,

8, 10 on the next row, in the same direction). If the test fails at any point of this cable test

procedure the faulty connection should be repaired before proceeding to the next test. If all of

these procedures have positive results, then the problem lies in the Brewer Main Electronics Board.

Reconnect all the cabling to the instrument and continue to the next test.

As an alternative for testing cables, each line can be tested for continuity by measuring point to

point with a ohmmeter, using the appropriate schematic as a guide. The resistance through the

surge arrestor is 10 ohms so that a typical resistance should be 12 ohms from the RS422 adapter

to the IDC connector at the Brewer Main Electronics board.

3 MAJOR EQUIPMENT FAILURES

Page 13

MKIII SERVICE MANUAL

8

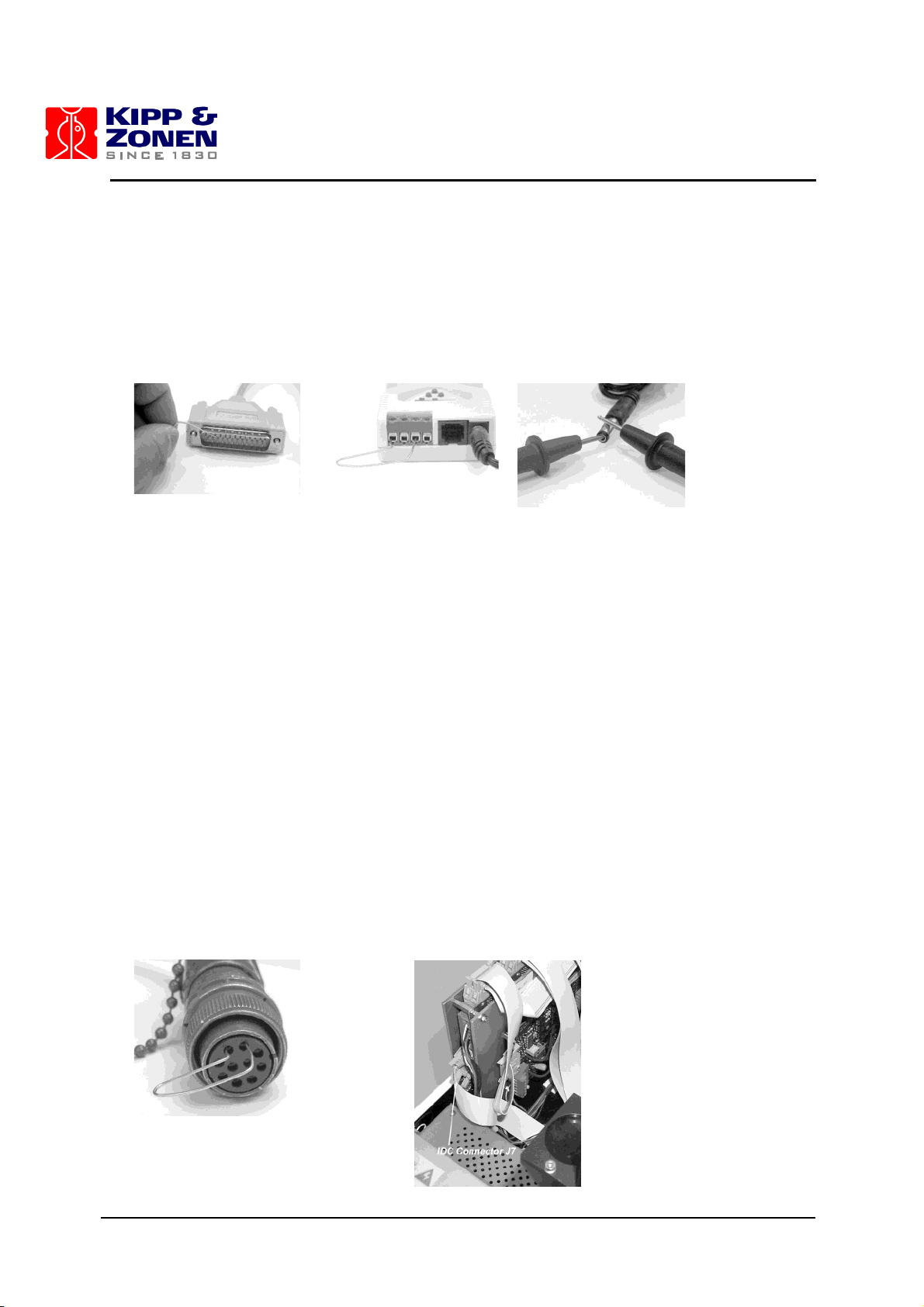

6. Line Driver

If the reset of the motors is heard and seen, but there is no message sent to the PC, then there

may be a problem with the line driver on the Main Electronics board. Ensure that power is turned

off and remove the Main Electronics cover plate and replace IC U11, (on a socket 2 inches up and

2 inches to the left of the LED). Make sure to use proper grounding precautions before touching

the electronics board. Leave the cover plate off and turn on the instrument. The motors should be

observed to reset and if the computer was left in the serial communications program, the Brewer

reset message will be displayed on the screen. Exit the communications program and launch the

Brewer operating program. Normal Brewer commands can be used for checking correct operation.

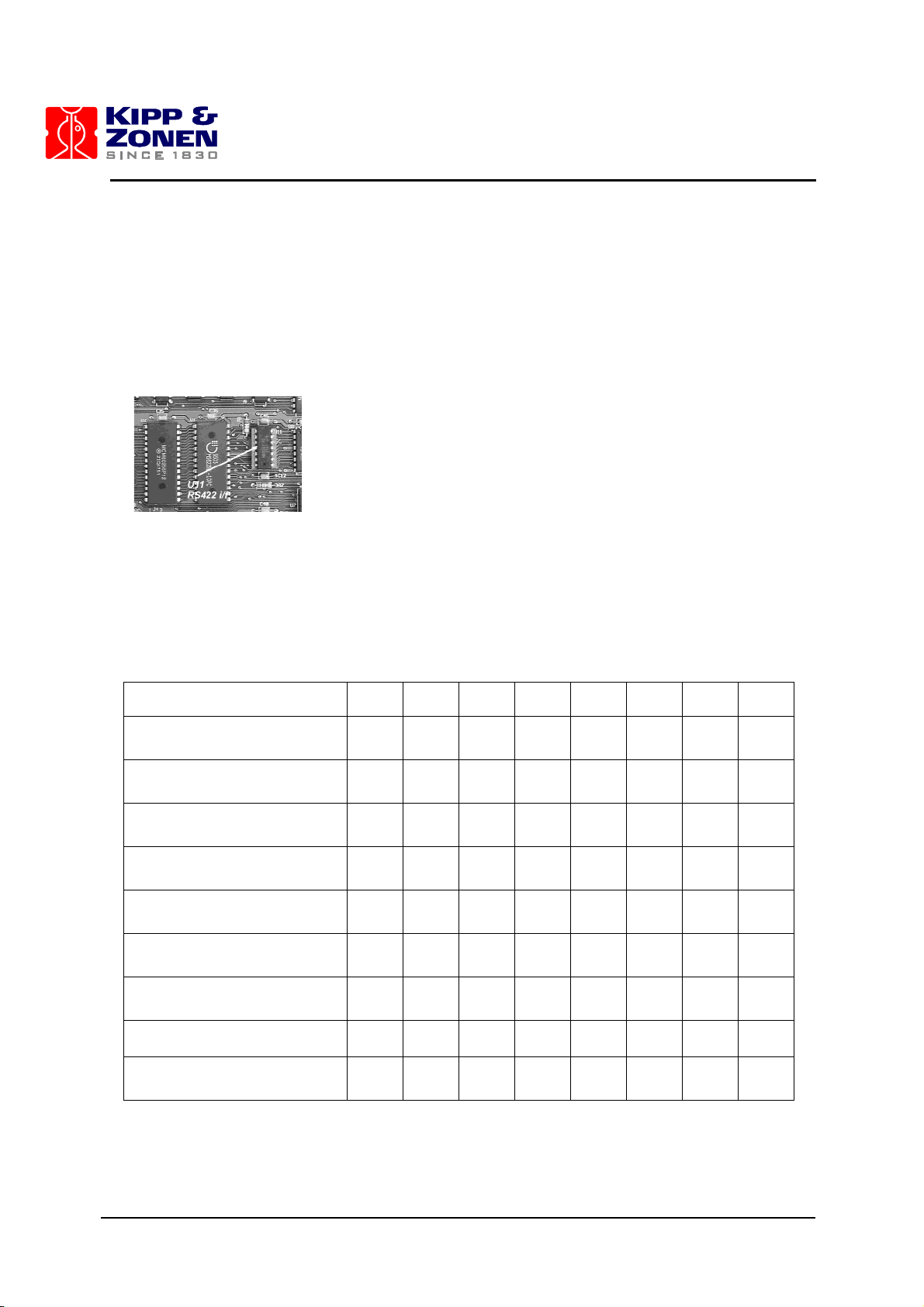

7. Check Mode of Microprocessor

If there is still no operation, there may be a firmware problem, or a problem on the Main Electronics

Board, so the functionality of this board should be tested.

There is a Red status LED located near the bottom left hand side of the board - it should be

flashing slowly in ‘Cosmac mode’ as per the following table. If the Brewer is in some other mode

change back to the Cosmac mode (step 10).

LED Mode indication

¼sec

¼sec

¼sec

¼sec

¼sec

¼sec

¼sec

¼sec

Cosmac mode normal

operation

On

Off

Off

Off

On

On

On

Off

Cosmac mode with

configuration missing

On

Off

Off

Off

On

Off

On

Off

Loadmode waiting for code

to be downloaded

On

Off

On

Off

On

Off

On

Off

Loadmode with bad flash

memory

On

On

On

On

Off

Off

Off

Off

Loadmode with good flash

memory

On

On

On

On

On

On

On

Off

Opmode with configuration

present

On

On

Off

Off

On

On

Off

Off

Opmode without

configuration present

On

On

Off

Off

On

Off

On

Off

Checking Flash memory

On

Off

On

Off

Off

Of

Off

Off

Changing from load to

cosmac or load mode

On

On

On

On

On

On

On

On

Page 14

MKIII SERVICE MANUAL

9

8. Check Voltages

If the LED is not flashing, then the correct voltages should be confirmed for the power supply on

the Main Electronics board J23, as per section 3.1.

9. Test Main Power Supply

If the power supply values have changed, the power connections should be checked. If they

appear normal, and the voltages are still not at proper levels, replacement should be considered.

However, there may be a short circuit in one of the assemblies causing the power supply to be

loaded. Shut the power off and disconnect the power connector J1 from the Main Electronics

board and from the J4 Lamp control board. Repeat the voltage measurements at the connector

and see if all the voltages are present. If the voltages are correct then determine which assembly

is at fault by installing the connectors one at a time. Replace the main power supply if necessary,

and ensure when first turned on that the assemblies are disconnected to allow setup of voltages to

correct values. The main 5 volts monitored at the main board should be set to 5.0 volts with the

single potentiometer on the main power supply.

10. Restore Brewer to Cosmac Mode

If the flashing LED on the Main Electronics board indicates that it is not in the cosmac mode, and

the software has not been successful in correcting it during the Reset sequence, then the following

procedure should be followed:

A. Exit the serial communications program and change to the subdirectory c:\bdata\nnn.

B.Type BREWCMD , and observe that the instrument has responded and note which mode is

indicated. The program should display the same mode as the mode observed on the status LED.

C. If the mode is ‘cosmac mode’ then type loadmode , and the display should return indicating

‘loadmode’. Now type opmode and within a few seconds the Brewer will be in opmode.

3 MAJOR EQUIPMENT FAILURES

Page 15

MKIII SERVICE MANUAL

10

D. Type readlog to display past error history, each line displayed will be a possible clue to the

problem that caused the failure. If motor failures have occurred, the status will tell you which motor

and what the failure is. Usually it is a sensor problem or a wiring problem that prevents the motor

from resetting. If no problems are displayed, then the system can be placed back into cosmac

mode for further testing.

E. Type loadmode and following the return of the prompt, type cosmacmode . The motors

will reset and within a minute the system will display the status that it is in cosmac mode.

F. Quit the Brewcmd program by typing quit .

11. Run Brewer Software.

Run the Brewer operating program by typing BREWER to check the correct operation of the

instrument. Select routines that you are familiar with and ensure that all functions and data appear

normal.

12. Replace Main Electronics Board

If no communications return when running Brewcmd then there may be a problem with the Main

Electronics Board.

Replace the Main Electronics board with a spare board, ensuring that all cables are reconnected to

the original connectors. Normally the spare Main Electronics board is preloaded with the same

parameters as those that came with the instrument. Therefore no reprogramming or uploading of

the configuration parameters are needed. If the configuration parameters have changed, then refer

to the procedure to upload new firmware and configuration data to the board, section 8.

The main board has a number of flat cables attached to it. The following lists the connectors for the

flat cables and the electronics they are connected with. “Top” (at the front) stands for pins 1-16.

“Bottom” (at the back) are pins 17-32:

J2 top BA-W77/A Lamp Board

J2 bottom BA-W77/B J1 on hv module

J13 top BA-W76/B iris

J13 bottom BA-W76/A zenith

J14 top BA-W76/B fw #1

J14 bottom BA-W76/B fw#2

J15 top BA-W76/A micrometer #2 (MKIII only)

J15 bottom BA-W76/A micrometer #1

J16 bottom BA-W76/C fw#3 (MK IV only}

J17 top BA-W76/B slitmask (shutter)

J17 bottom BA-W76/A azimuth

J12 top BA-W76/A control switch’s

J7 top Communication

J7 bottom humidity sensor

13. Contact KIPP & ZONEN

If you have followed this procedure and not located the problem contact KIPP & ZONEN for further

assistance.

Webpage: www.kippzonen.com

Email: info.holland@kippzonen.com

Page 16

MKIII SERVICE MANUAL

11

4 OPERATING TEST FAILURES

In the Brewer Spectrophotometer, most of the operating tests are done using either the mercury

lamp or the quartz-halogen lamp. If any of the other tests fail, the user should proceed immediately

to a mercury lamp test (HG) or a standard lamp test (SL).

Mercury lamp test failures and standard lamp test failures are two major problems which can occur.

In both cases calibration of the instrument may have been compromised. For the purpose of

troubleshooting, these two sections have been separated from the main part of the instrument.

The Light Detection System is made up of the zenith prism, foreoptics, spectrometer, slitmask,

PMT, High Voltage Circuitry, High Speed Amplifier (part of the PMT), interconnecting harnesses,

and the Main Electronics board which houses the photon counting circuits. Without this section

being operational, no testing, or measuring, can be done.

There are a few points to remember in the event there is a major failure somewhere in the system,

whether it is the Mercury Lamp, Standard Lamp, or Light Detection System.

The error message "lamp not on test terminated" is an indication of a failure, either in the

lamps or in the Light Detection System.

Changes in dark count may be symptomatic of a number of problems which may occur in the

Brewer.

If Dark Count begins to increase or becomes erratic, the slitmask may be at fault. Note that it is

normal for Dark Count to increase with temperature.

Dark Count changes may also indicate motor power supply problems, PMT performance problems,

or High Speed Amplifier problems.

If the dark count changes, there may be a changing optical condition in the Light Detection

System. A higher dark count can also be the result of a poor ground somewhere in the system or

high humidity inside the instrument. Grounding connections should be checked, especially between

the PMT housing and the Main Electronics.

The desiccant should be changed more frequently in higher humidity locations.

4.1 MERCURY LAMP CIRCUIT

The Mercury lamp circuitry (Fig 10-4.2) is a constant current source designed to keep the lamp

current constant throughout the temperature range of the instrument. A voltage regulator,

connected to a specially selected resistance wire, regulates the lamp current with minimal circuitry.

4.2 TROUBLE SHOOTING A MERCURY LAMP TEST FAILURE

The Mercury lamp test fails, and software responds with "lamp not on test terminated".

1. Check Motor Positions

Retry the test and look through each Viewing Port to see if the lamp turns on. Ensure that the

zenith prism and the filter wheels are in the correct position.

4 OPERATING TEST FAILURES

Page 17

MKIII SERVICE MANUAL

12

2. Check Temperature

Observe the temperature of instrument (TE). If the Brewer temperature is less than 0 degrees

Celsius, the lamp may be too cold and may not fire. If this is the case, the Standard Lamp may be

turned on for a few minutes to warm the Mercury lamp.

3. Check Lamp Voltage and Current

There is the possibility of a lamp failure. Perform an AP (A/D voltages printout) test. If the Mercury

Lamp current is 0.0, and the Mercury Lamp Voltage is near 15 volts, then the lamp is probably bad.

Measure the voltage across the lamp, pins 6 and 9 on P111. (Reference Figure 10.6-2.2). It should

be approximately 0 volts with the lamp off (B0) and 13 volts with the lamp on (B1).

4. Mercury Lamp Replacement

To replace the bulb, loosen the two thumb screws (item 6, Figure 10.6-2.2) and carefully withdraw

the lamp holder. Take care not to touch the new lamp with bare hands. Ensure the lamp is tight in

its socket and cleaned with isopropyl alcohol after replacement.

The quartz-halogen lamp should also be checked at this time, as blackening of the glass could

reduce the amount of HG light which is passing through it to the foreoptics. Re-assemble the HG

lamp by reversing the above steps and test the lamp with B1 and HG commands.

5. Check Micrometer Position

If the lamp is working fine, and light can be seen in the Viewing Ports, then the position of the

micrometer should be checked. Remove the “Spectrometer” cover and check to see that the

micrometers are in the correct position as indicated in the Final Test Record, and on the Log Sheet

taped to the Spectrometer cover. If the Micrometers are not where the Log Sheet indicates, they

should be adjusted manually and an HG test attempted again.

6. Attempt a Standard Lamp Test

If the test still fails, the problem could be in a misalignment of a component in the Spectrometer, a

problem in the slit mask, or a fault in the PMT or counting circuitry.

Attempt a standard lamp test. The standard lamp has a much higher intensity and does not depend

on the position of the micrometer and slitmask as much as the mercury lamp test.

If the standard lamp test operates correctly, the SL printout should be examined carefully to see if

any characteristics have changed. If the dark count has increased significantly, this may be an

indication that the alignment has changed and may require a mirror adjustment. Check to see if any

of the intensities or ratios have changed, which may indicate that the optics have deteriorated, or

the PMT performance or counting has degraded. If the standard lamp test results appear to be

normal, then KIPP & ZONEN should be contacted before proceeding.

7. Measure High Voltage

If the standard lamp test is not operational, then it can be assumed that there is an optical failure,

or a PMT failure. If the mercury lamp test is normal while the standard lamp has failed, this usually

indicates a problem with the lamp or the circuitry that controls the lamp.

The high voltage should be measured using a voltmeter and looking at test point E16 on the Main

Electronics board. There should be a voltage between 2.5 volts and 5 volts, which has been

factory set (see final test record for the setting), and should not be adjusted. This voltage is equal

Page 18

MKIII SERVICE MANUAL

13

to the actual high voltage divided by 409. There may be a variation of a volt or two of the high

voltage, but the voltage at test point should be very close to the final test record value. If it is

significantly different, the high voltage circuit may have failed. This will require a skilled technician

for repair or KIPP & ZONEN should be contacted.

8. Check Light Detection System

If the high voltage appears to be normal from the test point reading, then there is a possibility that

something has failed in the Light Detection System, reference Section 4.7.

4.3 STANDARD LAMP CIRCUIT

The standard lamp current regulator is similar to the Mercury lamp circuit except the resistance

wire is chosen to regulate the supply current with less variation than the mercury lamp. The circuit

maintains the operating current within 3 milliamps over a range of -20 to + 40 degrees C, and is

even more stable in the operating range of 10 to 30 degrees.

4.4 STANDARD LAMP FAILURE

The quartz-halogen (Standard) lamp is the lamp most frequently used in self diagnostics of the

Brewer. With it, calibration can be monitored, and correct operation of many systems can be

inferred.

The software for the standard lamp tests has been designed to give an error message in the event

of a failure. The message is "Lamp not on test terminated". The message may be somewhat

misleading in that there are many conditions which can make it appear that the Lamp is not on.

These conditions include PMT performance, filterwheel positioning, Zenith prism position, photon

counting electronics, and the I/O electronics used to turn the lamp on and off.

4.5 TROUBLE-SHOOTING STANDARD LAMP TEST FAILURE

Error message, "Lamp not on test terminated".

1. Check if Lamp is Burned Out

Retry the test and if the lamp is on, it will be seen through the viewing ports if the Filter Wheels, iris,

and the Zenith Prism have moved into the proper position. Perform an AP (A/D voltages printout)

test and compare results with previous tests, paying particular attention to standard lamp current

and voltage. The current, channel 14, will be approximately zero and the voltage, channel 15, will

exceed 14 volts if the lamp is unplugged or burnt out.

2. Attempt HG Test

If the test continues to fail, a mercury lamp test should be attempted. If the mercury lamp test

operates correctly, then the Light Detection System is probably operating correctly. If so, a

mercury lamp calibration should be done and the Standard Lamp test should be repeated.

4 OPERATING TEST FAILURES

Page 19

MKIII SERVICE MANUAL

14

3. Observe Slitmask Performance.

If the mercury lamp test is normal, the spectrometer cover should be removed and another

standard lamp test done while observing the slitmask. If the standard lamp fails again while the

slitmask is operating correctly, KIPP & ZONEN should be consulted.

4. Photon Counting Circuitry

If the mercury lamp test is not normal, there is probably a failure in the photon counting circuitry

and section 4.9 of this manual should be consulted.

5. Replace Standard Lamp

Before starting disassembly, it should be confirmed that the lamp filament is open circuit by

checking with an ohmmeter across pins 1 and 5 of J111 (lamp connector). Reference fig. 10.6.2-2.

The Standard Lamp is located above the mercury lamp and is attached to a removable plate.

Remove the two screws holding the plate. Replace the bulb with a new one, taking care not to

touch it with bare fingers- use a tissue or soft cloth and clean the lamp with isopropyl alcohol after

installation. If the bulb is blackened, it should be replaced regardless whether or not it is

operational.

Replace the connector assembly and test the lamp with the B2 command. Be sure to use B0 to

turn the lamp off.

Another standard lamp test should now be tried. If there is no success, there is a possibility of

circuit failure on the Lamp Control board, or the Main Electronics board.

6. Check Main Electronics Board

Send the command to turn the Standard Lamp circuit on (B2), and measure the voltage at pin15 of

U14 on the Main Electronics Board. The voltage should be +5 volts when the lamp is off and 0 volts

when the lamp is on.

If this voltage does not change, the Main Electronics board should be replaced, or KIPP & ZONEN

consulted.

7. Check Cable

If there was an indication of a 0 to 5V voltage swing at pin 15 of U14, but still no lamp operation,

the cable that connects the Main Electronics board to the Lamp Control board should be checked.

8. Test Lamp Control Board

If the cable it is good , the Lamp Control Board should be tested for correct operation. The lamp

control for the standard lamp is very simple - Q1 pin 2 supplies power to the current regulator VR2

(both components are on the bottom edge of the Lamp Control Board). Measure Q1 pin 2, and

when the standard lamp is commanded on, it should go to 17 volts. VR2 pin 2 should be 10 volts. If

it this point does not go to 10 volts, then the current regulator circuitry is faulty and must be

repaired or the complete board must be replaced. Refer to the lamp control board schematic Fig

10.4-2.

9. Test Lamp Cable

If the voltage at VR2 does change on command, then the lamp cable should be tested for

continuity.

Page 20

MKIII SERVICE MANUAL

15

4.6 LIGHT DETECTION SYSTEM FAILURE

A Light Detection System failure may show up in any or all of the diagnostic or measurement tests

of the Brewer. In Lamp diagnostics it will usually be shown on the Computer Display as "Lamp Not

On .. test terminated” message. In a measurement (DS for example), the counts may simply go to

zero, or some other incorrect number, depending on the nature of the failure. Results of Lamp tests

are predictable so an HG and/or SL should be attempted if there is any suspicion of a Light

Detection problem.

The Light Detection System is comprised of the foreoptics, spectrometer, micrometers, slit mask,

and the PMT (including the high speed amplifier). Adjustments of any of these assemblies should

be done with extreme caution, unless they are specified in this manual, as Instrument calibration

may be affected.

4.7 TROUBLE-SHOOTING THE LIGHT DETECTION SYSTEM

1. Confirm Motor Positions are Correct

If Lamp tests fail and the message "Lamp not on test terminated" is displayed, the SL command

should be issued. With the lamp on, the correct positions of the zenith prism, filterwheels, and iris

should be confirmed. The correct positions are printed to the screen when the SL command is

issued. Light from the lamp should seen in both view tubes.

2. Test Photon Counting Circuit

If the SL test fails the photon counting circuitry should be tested.

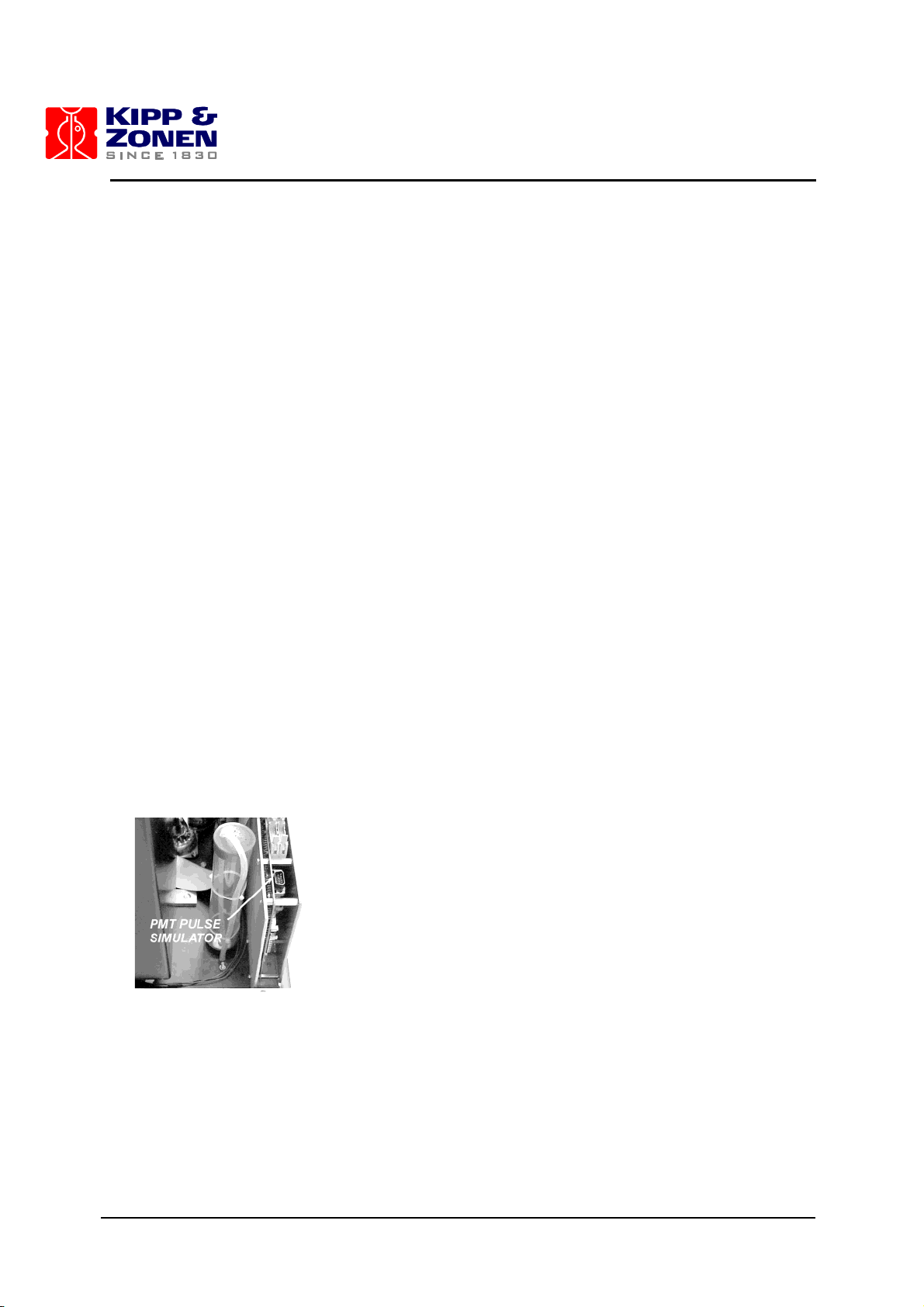

Turn off the power, remove the ribbon cable from the PMT output, and plug it into J22 of the Main

Electronics Board. This connector is the output of a 1MHz Pulse Simulator (see picture).

Turn on the Brewer power and from the Main Menu enter the Teletype command, TT. At the

teletype prompt, enter the command R,0,7,20;O. The display should show 8 numbers, each being

approximately 2,280,140 counts. Exit TT by pressing the Home key, turn off Brewer power, replace

the PMT cable, and turn power back on.

If the test is normal, the Counting System is operating correctly.

Now check components in the Spectrometer.

3. Check Micrometer Position

In a low light level and dry room, remove the Brewer cover and the Spectrometer cover. Confirm

that the micrometers are in the correct positions as indicated on the ‘Micrometer Position’ log sheet

that is taped to the Spectrometer cover.

4. Check Mirror and Grating

Check that the spherical mirrors, the gratings, and the two flat mirrors appear to be in place, and

that their mounting assemblies appear normal. ** TAKE CARE NOT TO TOUCH THE SURFACES

OF EITHER THE MIRRORS OR THE GRATINGS AS PERMANENT DAMAGE MAY OCCUR **** .

4 OPERATING TEST FAILURES

Page 21

MKIII SERVICE MANUAL

16

5. Test Slitmask

Slitmask operation can be confirmed by returning to Telytype operation (TT), sending the R,0,7,20

command, and noting that the slitmask moves back and forth pausing briefly at each of the 8

slitmask positions.

Commands R,X,X,20 (where X =0 to 7) can be sent in sequence. After each command a slot in the

slit mask should line up with a slot in the slit plate EXCEPT on command R,1,1,20, which is the

Dark Count position. If the slitmask does not move, or appears to move incorrectly, then the I/O

cable, Motor, or the motor control micro or motor driver IC on the Main Electronics board may be

faulty. The Main Electronics board should be replaced and another test attempted.

6.Check Dark Count

If the slitmask appears to be functioning correctly note what the count values are when the

command R,0,7,20;O is issued in Teletype. There is a very important difference between a count

rate of zero and a count rate near zero. A high count rate indicates correct operation. A low count

rate indicates that only dark count (a function of the PMT) is being measured and the light coming

through the slit mask is not being measured. A zero count rate indicates a problem with the PMT

or its electronics.

7. Measure High Voltage Test Point

Replace the Spectrometer cover, and remove the cover from the Main Electronics board.

Measure the high voltage test point E16 on the main electronics board (see picture), if it is not the

same as the value given in the Final Test Record, section 5.0, then adjust R4 on the high voltage

control board.

8. Check High Voltage Cable

If the test point voltage cannot be achieved, there may be a short circuit in the high voltage line

somewhere between the HV module and the actual PMT dynode chain. Care should be taken

when inspecting this area because there can be as much as 1800 volts at the connection points.

Check the high voltage cable for continuity.

9. Measure High Voltage at PMT

The rear cover of the PMT housing can be removed (turn CCW) and the actual high voltage

measured on the internal connector. This measurement must be done with a voltmeter rated for

2000 volts or by using a high voltage probe.

If the high voltage is still not as indicated on the Final Test Records, then contact KIPP & ZONEN.

10. Test High Speed Amp Board

If high voltage is correct, there may be a failure in the high speed amp board. TP1 on the high

speed amplifier board (inside the PMT housing) should read -10 millivolts (referenced to the HV

connector shield) or the value recorded in the Final Test Record, section 4.0. If the value of this

test point is incorrect, an adjustment of the on-board potentiometer can be attempted. If this test

fails, replace the high speed amplifier board.

If this test point is normal, the photon counter cable should be inspected to ensure that all

connections and wires are in tact. Finally, an oscilloscope can be used to monitor test point TP4 on

the high speed amp board, and then pins 1,2,3,4, and 12,13,14, 15 of the IC, SN75114N. There

should be clean square waves, the frequency of which should vary with light intensity.

Page 22

MKIII SERVICE MANUAL

17

If these signals are normal, consult KIPP & ZONEN before proceeding further. If any of the signals

are missing or are not clean square waves, replace this board.

11. Contact KIPP & ZONEN

If all of these tests fail, there is a probable fault in the PMT, and KIPP & ZONEN should be

contacted before proceeding.

4.8 STEPPING MOTOR CONTROL

The stepping motor control circuitry provides for the control of each stepping motor through

individual motor microprocessors and stepping motor driver integrated circuits. This type of motor

control allows the system to move the motors simultaneously, and to monitor the sensors very

efficiently. All of the motor microprocessors are controlled by the main processor through a serial

"I2C" bus. Each motor is optimized for speed and taylored to each function in the Brewer. The

configuration file is included with the control software to allow changes and updates to the system.

The configuration file is optimized for each instrument and normally does not require operator

modifications unless recommended by KIPP & ZONEN.

4.9 PHOTON COUNTER CIRCUITRY

A schematic diagram of the photon counter circuitry is given in figure 10.4-1. The photomultiplier

signal which has been amplified and divided by a line driver on the pulse amplifier board is

received by a line receiver on the Main Electronics board. This signal is fed to a pair of binary

counters. The outputs of the 2 counters are compared and if they differ by more then a set amount

the second counter is disabled and a “PMT counter failure” message is generated in the Firmware

Log. The counters are each connected to output ports which are connected to the data bus of the

system microprocessor.

The main gate is generated by an electronic circuit that provides a very precise gating signal to

enable counting for a specific length of time. The microprocessor decides when the pulse counting

circuitry is initiated and the circuitry then triggers the gate to allow counting of the photons.

4.10 HIGH SPEED AMP BOARD

The photomultiplier, and pulse amplifier board are enclosed inside the photomultiplier

subassembly. The sub assembly is designed to allow access to the pulse amplifying circuitry

without upsetting the alignment of the PMT or the optics.

The photomultiplier is an EMI 9125UVA type. It is enclosed in a magnetic shield at the high voltage

potential of the photo cathode. A small area on the shield is open to allow light to fall on the

cathode. A high voltage power supply provides stepped voltages to the photomultiplier through a

resistor divider circuit at the base of the tube. Since differential thermal expansion between the

photomultiplier glass and the PTFE base may cause tube breakage under extreme temperature

conditions, it is recommended that the photomultiplier housing never be subjected to temperatures

of less than -50C or greater than +60C.

The pulse amplifier board is located directly behind the base of the photomultiplier tube. This

circuitry accepts the photon pulse signals from the photomultiplier, amplifies them, discriminates

the signal level from current leakage, divides the amplified photon pulses by four, and finally

outputs the pulse on a line driver. Since the circuitry is extremely sensitive to feedback and RF

noise, it is located in close proximity to the photomultiplier.

4 OPERATING TEST FAILURES

Page 23

MKIII SERVICE MANUAL

18

4.11 RATEMETER

The ratemeter circuit provides a voltage output of the photon count rate. It consists of a twotransistor charge pump on the high speed amp board, and an integrator-amplifier on the Main

Electronics board. A transistor is connected as a current pump and driven by one of the outputs of

a J-K flip flop on the high speed amplifier board. The pulses from the flip flop are integrated by an

RC network then scaled by an op-amp.

4.12 TEMPERATURE MONITOR

The temperature monitor is a temperature sensitive bridge using YSI linearized thermistors. The

bridge output is amplified to produce a suitable scale for the A/D converter. There are six thermistor

circuits available, one of which is located in a hole drilled in the side of the front flange of the PMT

housing. The other five are used to measure temperature at points around the instrument as status

information. One of the sensors monitors outside temperature.

4.13 HIGH VOLTAGE CIRCUITS

The high voltage (600-1600 volts) for the photomultiplier (PMT) is provided by a DC-DC converter /

high voltage control circuit board.

4.14 CLOCK / CALANDAR

The real time clock/calendar circuit is a battery backed up clock with integral static random access

memory. A lithium battery is used to keep the clock operating when there is no power applied to

the Brewer. The clock is year 2000 compatible.

4.15 A/D CONVERTER

The A/D converter has a 10-bit conversion resolution and is built into the microprocessor. Analog

multiplexers are utilized to select the channel to monitor. The AP routine is the main routine that

accesses the data and displays the information on the PC monitor, saves it to a file, or prints it on

the printer.

Page 24

MKIII SERVICE MANUAL

19

4.16 BREATHER DESICCANT CARTRIDGE

The breather desiccant cartridge allows the Brewer to compensate for normal pressure changes,

while preventing the influx of moist air. Note that the breather desiccant does not remove moisture

from the Brewer. Extra desiccant is needed to remove moisture from inside the instrument.

Breather desiccant is housed in a plastic container with a breathing tube placed at the bottom of

the cartridge. The other end of the tube is connected to a port at the bottom on the underside of the

Brewer and is exposed to the outside air. As the air is drawn in from the outside, the air is dried as

it passes the desiccant. Reference figure 10.8.

4.17 HUMIDITY SENSOR (OPTIONAL)

The humidity sensor is a monolithic IC sensor that provides a voltage output proportional to relative

humidity. The sensor is buffered by an Op Amp and the output is connected to one of the analog

input channels of the A/D converter. A temperature sensor is located near the humidity sensor to

provide temperature compensation for the device. The two measured values, relative humidity and

temperature allow the absolute moisture to be calculated. The absolute humidity (grams/m3) value

is displayed on the PC screen along with a numerical “moisture index” value. Refer to Figure 10.4-5

for the sensor specifications and Figure 10.4-6 schematic for the humidity sensor assembly.

4 OPERATING TEST FAILURES

Page 25

MKIII SERVICE MANUAL

20

Page 26

MKIII SERVICE MANUAL

21

5 TEST RESULTS OUT OF SPECIFICATION

Whenever any diagnostic tests are out of specification, (SL, HG,DT,RS,) the following should be

done or considered.

1. If the deadtime has increased or decreased significantly, the High Speed Amplifier board

may be defective, the slitmask may have become misaligned, or a ground in the instrument

wiring may have become resistive. High moisture levels inside the instrument may also

cause abnormal deadtime results.

2. A test lamp may have deteriorated to the point where tests are affected, and the lamps

may require replacement. They can be inspected as mentioned in the previous sections,

and replaced if necessary.

3. The optical surfaces within the zenith prism may have become smudged with a fingerprint

or may have become dusty over a period of time. The prism should be cleaned, referring to

section 6.2.

4. The micrometer may be "sticking" and not in its exact location after a measurement or a

test. It should be inspected and the drive mechanism carefully cleaned with tissue and

isopropyl alcohol.

5. Dark count is a convenient characteristic to monitor as it is printed out in many tests and

measurements. Dark count changes may be the result of moisture, changes in the slit

mask, PMT, high Voltage, or counting circuitry.

6. When the dark count of an instrument changes, or becomes erratic, a slitmask Run-Stop

test should be done to see if there are any changes in the slitmask circuitry. If this does not

give any indication of the problem, there may be a ground somewhere which has become

resistive, and it should be checked.

7. The High voltage test can be done, and the results compared to those in the Final Test

Records.

8. Generally speaking PMT problems are not field repairable.

9. Desiccants should be changed at regular intervals. The frequency of desiccant change

depends on the climate. Desiccants will require changing much more frequently in humid

environments. Alternately the humidity indicator can be used to indicate that desiccant

needs changing – desiccant should be changed if the moisture index provided be the

electronic humidity sensor is greater then 10 or if the paper indicator for 40% humidity is no

longer blue. Desiccants can be removed and dried overnight at approximately 60 degrees

C if necessary.

If these checks fail to locate the problem, KIPP & ZONEN should be consulted as to further

investigation.

5 TEST RESULTS OUT OF SPECIFICATION

Page 27

MKIII SERVICE MANUAL

22

Page 28

MKIII SERVICE MANUAL

23

6 OPTICS CARE AND CLEANING

6.1 OPTICS CARE

- Never touch the polished surface of optics.

- Hold an optic only by its edges.

- Reduce the need for cleaning optics as much as possible.

6.2 OPTICS CLEANING

- Use latex gloves when handling or cleaning optics.

- Do not reuse cleaning materials.

SPECTROMETER MIRRORS, ND FILTERS, QUARTZ PRISMS AND LENSES: In the event of

dust, blow off with rubber hand pump (avoid using your breath) or use bottled dry nitrogen to

remove particles. In the event of grease or fingerprints, dampen a very soft cloth with methyl ethyl

alcohol and wipe gently. NOTE: Wipe marks will almost certainly remain. To remove the wipe

marks, dampen a soft tissue with a mixture of ether and isopropyl alcohol and wipe gently. The

tissue should be dampened to the extent that while wiping, the mixture evaporates one to two

millimeters behind the tissue.

QUARTZ DOME AND EXTERIOR QUARTZ WINDOW: Spray with window cleaner and wipe clean

with a soft cloth.

LAMPS: Dampen a soft cloth with methyl or ethyl alcohol and wipe gently.

POLARIZING FILTER: Use only a soft, dry cloth or tissue to remove dirt and finger marks. The filter

should always be wiped gently to avoid marring the finish.

DIFFRACTION GRATINGS: Do NOT touch or attempt to clean.

6 OPTICS CARE AND CLEANING

Page 29

MKIII SERVICE MANUAL

24

Page 30

MKIII SERVICE MANUAL

25

7 AZIMUTH TRACKER

Problems in the Azimuth Tracker affect the Brewer’s ability to track the sun, and thus any

measurement that depends on direct solar radiation may be in jeopardy.

Regardless of the problem, it is usually manifests itself as frequent failures of the Solar Siting test

(SI), or the Steps per Revolution test (SR).

The Main Electronics Board sends motion commands to the Tracker, and receives sensor

indications from the Tracker via the Azimuth Tracker connector on the front of the Brewer base.

Indirect problems can affect Brewer power and communications since both of these cables pass

through the Tracker housing assembly. Communications is routed through a surge suppressor

assembly mounted on the bottom of the Tracker, and Power is supplied to the Brewer via the

Tracker enclosure wherein a second set of surge suppressors is located.

If the surge suppressors in the communications line are faulty, a no-communications condition can

exist. The communication cable from the Computer can be connected to bypass the Tracker as a

troubleshooting aid in determining if the surge suppressor assembly is at fault.

Similarly, power can be connected directly to the Power Connector on the Brewer in the event that

a “no power” problem exists in the Brewer.

The Power switch on the Tracker will not affect power to the Brewer, but a failure of the fuse in the

Tracker will interrupt both Brewer and Tracker power.

Tracker problems can be either mechanical or electrical.

7.1 BREWER POWER PROBLEMS.

Power for the Brewer passes through the Tracker Case where it is connected to a set of MOV

surge suppressors. In the event of large transient voltages on the power cable, one or more of

these components may become damaged, and subsequently result in AC power short circuits

which may affect power to both the Brewer and the Tracker. Connecting the AC power directly to

the Brewer and observing if operation is restored is a method of troubleshooting this subassembly.

An ohmmeter can then be used to determine the specific component at fault. Power connections in

the Tracker, including the Fuse, can also be checked in the event of power problems in the Brewer.

7.2 BEWER COMMUNICATIONS PROBLEMS

A failure in the surge suppressor in the communications link can be checked by connecting the

communication cable from the Computer directly into the Brewer. If Brewer/Computer

communications are restored, the surge suppressor subassembly is likely at fault.

7 AZIMUTH TRACKER

Page 31

MKIII SERVICE MANUAL

26

7.3 TRACKER ELECTRICAL PROBLEMS

Electrical problems include AC power, power supply, motor driver board, stepper motor, and

sensor/blocker assembly.

7.3.1 Sensor Problems

The tracker is prevented from travelling past the zero (or North) position by a sensor that is

attached to the aluminum drive plate. A blocking device which rotates with the Tracker body cuts a

light beam in the sensor and the resulting change in sensor voltage output is detected by the

electronics.

If it is observed that there is frequent wrapping of the power and communications cable, or

activation of the safety switch, the sensor and its wiring should be tested.

1 With a DC voltmeter, monitor the sensor voltage at U3, pin 13 on the Main Electronics Board.

2 Pass a piece of paper (or other opaque material) through the sensor, and the voltage should

go from +5 volts in the blocked state to 0 volts in the non-blocked state.

3 At the Tracker, pin 5 of J201 should go between 0V and 5V as the sensor is unblocked and

then blocked.

4 Replace the sensor assembly and cables as necessary.

5 If the above tests shows the sensor and cables are good, then confirm that the blocker passes

through the sensor as the Tracked rotates.

6 If all of the tests are good, there could be a problem on the Main Electronics Board sensor

detecting circuitry, in which case KIPP & ZONEN should be consulted.

7.3.2 No Tracker Operation.

If the Green Power Indicator indicates no Tracker power, but the Brewer functions normally, a

problem in the Tracker is indicated.

The Tracker covers should be removed and the AC power to the Power Supply confirmed. If AC is

present then the +5 V output of the power supply should be measured. If no +5V is found, then the

Power supply is at fault and should be replaced.

If the Power supply is normal, then the safety switch should be inspected to confirm that it has not

been tripped by an over travel condition. The switch should be in the toggle position away from the

Tracker centre pedestal.

If the Power Supply and safety switch are both normal, and there is still no motor motion, then it

should be confirmed that the Brewer is outputting drive pulses to the Tracker.

1 Tracker movement pulses can be found on the cable going to the Tracker Driver Board BA-

C99, connector P201, pin 1. Square pulses, 0-5V in amplitude may be observed with an

oscilloscope, or an AC reading indication of 2 Volts can be seen with an AC Voltmeter.

2 Connect an Oscilloscope or Voltmeter to pin 1 of Connector P201 of the Board BA-C99 in the

Tracker. (lower left of the BA-C99)

3 From the Brewer Main Menu, go to the TeleType mode.

4 Send the Command M,2,1000 and pulses should be observed.

Page 32

MKIII SERVICE MANUAL

27

5 If no pulses are seen at the Tracker, then look on pin 4, J17T on the Main Electronics board.

This pin is the 2nd from the left on the top row of solder connections just behind J17T when

facing the removable plate of the Main Board.

6 If there are still no pulses, then remove the connector at the BA-C99 end and try again – this

will test for a short circuit in the cable

7 If the test fails again, then a fault is indicated in the motor driver circuitry on the Main

Electronics Board, and this board should be replaced.

8 If it is confirmed that pulses are going to the Tracker and if the Tracker Power Supply and

Safety Switch are both normal, and there is still no motor motion, then the motor Driver board

in the Tracker should be replaced.

9 Failure of the motor to move under command at this point indicates a possible motor failure, or

a failure of interconnecting cables. All interconnections should be inspected.

7.4 TRACKER MECHANICAL PROBLEMS

If the Tracker stepping motor is observed to rotate, but the Tracker does not turn, or turns

erratically, this is an indication of a mechanical problem.

The first check should be for cleanliness of the aluminum drive plate, and particles jamming

between drive gears.

A rare mechanical problem is the seizing of the main bearings, which can be checked by turning

Tracker power off and attempting to rotate the Tracker by hand. If the Tracker does not turn freely,

then KIPP & ZONEN should be consulted.

If the Tracker turns freely with no power, and the motor turns when an AZ or SR command is

issued, then a mechanical problem exists between the motor and the main drive plate.

Check the small motor gear and confirm that it is turning with the motor, and is not slipping on the

gear with which it is meshing. Also check for slippage between the stainless steel drive rod and the

large aluminum drive plate.

If the motor gear does not turn with the motor, then check the set screw which holds the gear to the

motor shaft. If the motor gear turns, then the spring tensions that provide drive friction between the

gears, the drive shaft, and the drive plate may require adjustment. (Ref Figure 7.1 and Section 5.4

of the Operator’s Manual).

A spring scale can be used at the top and bottom of the shaft and the tension adjustments set to

4kg at the top, and 9kg at the bottom tension point.

If the Tracker still does not turn, or gives inconsistent SR results, then KIPP & ZONEN should be

contacted for assistance.

7 AZIMUTH TRACKER

Page 33

MKIII SERVICE MANUAL

28

Figure 7.1 Tracker Drive Mechanism

Page 34

MKIII SERVICE MANUAL

29

8 MAIN ELECTRONICS FIRMWARE / CONFIGURATION LOADING

PROCEDURES

This procedure is used to upload new firmware for the BREWER Electronics or to update the

configuration files stored in flash memory. The only time this procedure is required is if the firmware

has been corrupted due to electrical surges or the memory had been replaced or if the

configuration has changed due to some physical changes to the sensor settings or position stops.

8.1 INSTALLATION OF BREWCMD SOFTWARE

Before using any of the procedures in this section the Brewcmd.exe software must be installed and

properly configured.

Exit out of the BREWER operating program to DOS.

Take the supplied configuration disk and put it into the computer used to reconfigure the BREWER.

Copy the files from the floppy disk a:\bdata\nnn to the c:\bdata\nnn subdirectory using the

command

copy a:\bdata\nnn\*.* c:\bdata\nnn !!

Edit the file c:\bdata\nnn\brewcmd.ini. Ensure that the com port setting indicated matches the

comport setting for your Brewer.

8.2 RESTORE BACK TO COSMAC MODE

In certain circumstances where the signal line is placed in a permanent Break signal condition, the

BREWER will continually try to reset but eventually it has determined that there is a problem and it

will halt trying to reset and go into Loadmode. This fault can happen when the RS422 cable has

been incorrectly wired or has shorted together to simulate a break condition. To confirm that the

processor is actually in loadmode, remove the weather proof cover of the BREWER and look down

into the Main electronics board between the cover plate and the microprocessor board. You should

see a flashing LED light and if it is in loadmode, it will be flashing quickly in 1/4 second intervals.

The procedure to restore the system back to the Cosmac mode of operation is as follows:

Change to the directory c:\bdata\nnn by typing the command cd\bdata\nnn

Run the program Brewcmd.exe by typing brewcmd This program is a utility to allow the user to

communicate to the BREWER Microprocessor and change operating modes or upload files.

If all the connections are correct, the display will reply that BREWER responded and at what baud

rate it is communicating. [Using load mode at 9600 baud, on com 1; tracing is

off]

It is expected that it will be in Loadmode but it could be in Opmode as well.

To return it to its normal operating mode, type cosmacmode

The instrument will reset itself by resetting all of its motors and the display will display the following

with other status information.

Motors Initializing.

When the instrument has completed resetting all of the motors, the display will now respond to low

level commands.

8 MAIN ELEC. FIRMWARE / CONFIG. LOADING PROCEDURES

Page 35

MKIII SERVICE MANUAL

30

Exit out of the Brewcmd program by typing quit and the computer will have returned to the

dos prompt.

Run the BREWER operating program and then ensure the time and date is correct.

8.3 NEW CONFIGURATION UPLOAD

If hardware changes have been made such as removing the zenith drive gear or adjusting the

micrometer drive sensor mask, then correct values for zero offset and other parameters must be

uploaded to the instrument for it to operate correctly. The procedure to upload the new

configuration file is listed below:

The configuration file that describes the characteristics of the instrument is named BREWnnn.cfg.

The nnn will be the instrument number. This file is an ASCII text file that describes all the technical

parameters of this particular instrument. This very same file should be uploaded to any

replacement BREWER Main Electronics board following the physical installation of the board. A

spare BREWER Main Electronics board will normally be sent with the latest configuration file stored

at KIPP & ZONEN. If the customer has changed any parameters in the field, it will not be

configured into that board and the customer will have to upload the latest file as described below:

Change to the directory c:\bdata\nnn by typing the command cd \bdata\nnn

Run Brewcmd.exe by typing brewcmd

[using cosmac mode at 1200 baud, on com 1: tracing is off ]should be

displayed

Type loadmode to change modes.

Waiting for the mode change to complete and when complete, the display will display

[using load mode at 1200 baud, on 1: tracing is off ]

Go into Opmode by typing opmode 9600

Trying Operating mode at 9600 baud is displayed until the display will display [using

operating mode at 9600 baud; on port 1; tracing is off ]

Send the configuration file to the microprocessor by typing putcfg brewnnn.cfg !(nnn is the

instrument number)

Wait approximately one minute to transfer

Type readlog to clear the log buffer

Type useconfig motors should now reset

When complete readlog to see if errors were encountered. Contact KIPP & ZONEN if the log

displays a problem.

Type save a number should appear. This tells you how many configuration writes you have left.

If the number is ‘1’ then the next time a configuration is sent, the top firmware must be written to

Flash memory and the configuration area is cleared to allow another 4 blocks of configuration files.

Go to Load mode by typing loadmode

Waiting for mode change to complete and

Trying load mode at 9600 baud is displayed until the display will display [using load

mode at 9600 baud, on com 1: tracing is off ]

Go into Cosmac mode by typing cosmacmode

Reading Cosmac mode reset message

Waiting for mode change to complete

Trying Cosmac mode at 1200 baud

Motors Initializing

Page 36

MKIII SERVICE MANUAL

31

These are some of the messages seen while going into the Cosmac mode.

Motors should reset and it is ready to run the BREWER operating program type quit to get out

of Brewcmd

To run the BREWER operating program type BREWER

8.4 UPLOADING NEW FIRMWARE AND CONFIGURATION FILES

As KIPP & ZONEN develops new firmware and features, it is now possible for the customer to

upgrade the firmware without having to open the cover to the BREWER. The New Electronics has

incorporated Flash electrically erasable program memory and the system is capable of being

updated from the PC. The procedure below will provide a step by step process to upload the

firmware and also upload the configuration file which is erased when the new firmware is loaded.

This disk is supplied with the instrument when first delivered or will be sent out to the customer

when firmware updates are done.

Copy the new top.bin or topv#r#.bin firmware file received from KIPP & ZONEN to the

c:\bdata\nnn subdirectory.

Change to the directory c:\bdata\nnn by typing the command

cd\bdata\nnn

Run Brewcmd.exe by typing brewcmd !

Eventually the following statement is displayed:

[using cosmac mode at 1200 baud, on com 1; tracing is off ]should be

displayed. If the command help !is entered, a list of available commands will be displayed.

Type loadmode to change modes.

Eventually the following statement is displayed:

[using loadmode at 1200 baud, on com 1: tracing is off]

Type loadmode 4800

Eventually the following statement is displayed:

[using loadmode at 4800 baud, on com 1: tracing is off]

Type load top.bin or topv#r#.bin !!!

(# will depend on the version number of the firmware.)

Wait until this task is completed (this will take a few minutes).

The display will display some messages below:

Erasing Flash memory

Writing file top.bin to flash ……

The display will show 112 moving dots to show its progress

Turn off the power of the instrument for approximately 10 seconds and turn it back on.

Go into Opmode by typing opmode 9600 !

Waiting for mode change to complete is displayed and eventually the fan turns on if the

heater option is ordered and the display will eventually display [using operating mode at

9600 baud, on com 1: tracing is off ]

Type readlog !to display any errors encountered.

Send the configuration file to the microprocessor by typing putcfg brewnnn.cfg

Wait a 1.5 minutes to transfer

Type readlog to clear the log buffer and see if any errors occurred during the configuration

installation.

Type useconfig motors should now initialize.

When complete readlog to confirm everything is ok

8 MAIN ELEC. FIRMWARE / CONFIG. LOADING PROCEDURES

Page 37

MKIII SERVICE MANUAL

32

Type save a number should appear. This tell you how many configuration writes you had left

when the save command was issued. The number of configuration writes left is one less then the

number displayed.

The number is ‘4’ should be displayed.

Go to Load mode by typing loadmode!

The display will eventually display [using load mode at 9600 baud, on com 1:

tracing is off ]

Go into Cosmac mode by typing cosmacmode!

A number of messages will appear and eventually the motors should initialize and it is ready to run

the BREWER operating program and display [using cosmac mode at 1200 baud, on com

1: tracing is off ]

type quit! to get out of Brewcmd

To run the BREWER operating program type BREWER!

Page 38

MKIII SERVICE MANUAL

33

9 WARRANTY

MANUFACTURER'S GUARANTEE / WARRANTY CERTIFICATE

NEW PRODUCT WARRANTY AND LIMITATION OF LIABILITY

KIPP & ZONEN hereby warrants to its products to be free from defects in material and

workmanship for a period of one year from date of purchase.

KIPP & ZONEN’s obligation under this warranty is strictly and exclusively limited to repairing or

replacing, at KIPP & ZONEN's discretion, any such equipment and / or parts thereof which have

failed under normal use and service. Expressly this warranty does not apply to any equipment and

/ or parts which have been improperly installed, been subject to abuse, neglect and / or accident.

The foregoing warranty is in lieu of any other warranties, expressed or implied, including without

limitation, any implied warranty of merchantability or fitness for a particular purpose, and of any

other obligations of liabilities whatsoever in any event for payment of any incidental or

consequential damages, including, without limitation damages or injury to a person or property.

An authorization must be obtained from KIPP & ZONEN prior to the return of any equipment or

parts thereof. Returned material is to be turned to the factory, or other location as may be directed

by KIPP & ZONEN, freight prepaid and will be returned freight prepaid. KIPP & ZONEN is not

responsible for any transportation, insurance, demurrage, brokerage, duties, or councillor charges,

etc.

This warranty is given to the original purchaser and may not be transferred without direct written

consent of KIPP & ZONEN.

Should an extended warranty be purchased, then the warranty statements in its entirety is

applicable for the entire period of time covered by the extended warranty.

In the absence of another prior agreement, this standard warranty statement will apply.

9 WARRANTY

Page 39

MKIII SERVICE MANUAL

34

Page 40

MKIII SERVICE MANUAL

35

10 BREWER REFERENCE DOCUMENTATION

Section 10.1 Overall Assembly and External Cables Figure

- Configuration Control Diagram 10.1-1.1

- BREWER System Drawing BS-C1000 10.1-2.1

- BREWER Assembly BA-C231 10.1-3.1

10.1-3.2

- Azimuth Tracker Option Kit BA-C91 10.1-4.1

BA-C91 10.1-4.2

BA-C113 10.1-4.3

- UVB Installation Kit BA-C114 / BA-C84 10.1-5.1

- Power Cable (External) BA-W12 10.1-6

- Data Cable (External) BA-W68 10.1-7

- Electronics Spares Kit List BA-C222 10.1-4.7

- Brewer Standard Spares Kit List BA-C112/B 10.1-4.8

- Tracker Stand Tie-Down Kit Installation 10.1-8

Page 41

MKIII SERVICE MANUAL

36

Figure 10.1-1.1

Page 42

37

Figure 10.1-2.1

Page 43

38

Figure 10.1-3.1

Page 44

39

Figure 10.1-3.2

Page 45

MKIII SERVICE MANUAL

40

BA-C231

BREWER MKIII DBL SPECTR

Item no.

Part No.

Description

Qty.

1

AM-BA-C05

BREWER FINAL TEST RECORD

--

3

IT-BA-C231

BREWER MKIII INITIAL TEST

--

4

MM-BA-C231

SPECTROPH MAINT MAN, MKIII

1.00

5

OM-BA-C231

SPECTROPH OPER MAN, MKIII

1.00

6

BA-C84

OPTION C KIT, UVB

1.00

7

BA-C112/B

SPARES KIT, STD, NEW ELECT

1.00

8

BA-C191/B

COMPL OPT ASSY, MKIII, DOUBLE

1.00

9

BA-C194

WEATHERPROOF COVER ASSY

1.00

10

BA-C208

MKIII SHIPPING CRATE

1.00

11

BA-C220/B

BASE ASSY, MKIII

1.00

15

BA-E71/B

MAIN POWER SUPPLY KIT,W/O

DESIC

1.00

16

BA-E116

BREWER OPERATING S/W

1.00

17

BA-E118

BREWER UTILITIES S/W

1.00

18

BA-E124

ELECTRONIC PCB BRKT ASSY

1.00

22

BA-UO7

F/W MAIN BRD, DOWNLOADABLE

1.00

24

BA-W76/A

CABLE ASSY,MAIN TO MTR, 29

5.00

25

BA-W76/B

CABLE ASSY,MAIN TO MTR, 27

4.00

26

BA-W77/A

CABLE ASSY,MAIN TO LMP, 11

1.00

27

BA-W77/B

CABLE ASSY,MAIN TO HV, 16

1.00

28

BA-W78

CABLE ASSY,HV BRD TO PMT

1.00

29

BA-W79

CABLE ASSY,THERM TEMP PROBE

1.00

30

BA-W82

CABLE ASSY, DC, MAIN/LAMP

1.00

31

BA-W83

CABLE ASSY, LAMP

1.00

34

BM-C82

CONTROL PANEL

1.00

35

BM-C105

NAMEPLATE,ALTERED

1.00

36

BM-C202

SHIPPING FOAM,CNTRL PANEL

1.00

37

BM-C218

MODF'D SCREW,EXT TMP SNSR

1.00

38

BM-C162

FOAM, HIGH DENSITY, 27X19X4

2.00

39

BM-C211

FOAM HIGH DENSITY, 27X25X4

4.00

42

12103081

DECAL, SCI-TEC LOGO

1.00

46

12501365-2

DESICCANT HOLDER ASSY

1.00

48

81-90-620

LOCK, CONN SLIDE POST

2.00

49

81-90-630

LOCK, CONN SL RET (15)

1.00

52

83-30-450

BUMPER RUBBR 1/8 HOLE, 3/

4.00

55

83-40-485

NUT 4-40 SL RG HX THIN SS

2.00

59

83-51-752

SCREW 2-56 X 1/4 BUTTON HD

2.00

60

83-51-762

SCREW 4-40 X 5/16 BUTTON H

2.00

61

83-51-804

SCREW,8-32 X 1/2 BUTTON H

3.00

62

83-79-048

SCREW 4-40X5/16 SKT HD

2.00

63

83-79-049

SCREW 4-40 X 3/8 HSC SS

5.00

64

83-79-152

SCREW 1/4-28 X 1/2 HSC SS

3.00

70

83-95-008

WASHER #4 FLAT NYLON

1.00

71

83-95-609

WASHER, 1/4 LOCK INT TH S

3.00

72

83-95-748

WASHER #4, SPLIT LOCKS

2.00

73

83-95-786

WASHER, #8 SCREW 3/8 OD X

3.00

74

83-95-604

WASHER #4 LOCK INT TH SS

2.00

80

85-10-145

ADHESIVE, SEALANT LOCTITE

0.50

81

85-10-150

ADHESIVE, SEALANT RTV

0.50

85

85-80-440

CABLE-TIE MOUNT, 3/4"SQ

3.00

86

85-80-450

CABLE-TIE 4-1/8X.1 NYL 18

6.00

Page 46

41

Figure 10.1.4-1

Page 47

42

Page 48

43

Figure 10.1-4.2

Page 49

44

Page 50

MKIII SERVICE MANUAL

45

BA-C91

Item No.

Part Number

Description

120V Qty

230V Qty

1

BM-C100

Nameplate, Altered, Azimuth Tracker

1.00

1.00 2 BS-C91