Page 1

2 AP

2-Axis Sun Tracker / Positioner Gear Drive

Instruction Manual

Page 2

IMPORTANT USER INFORMATION

IMPORTANT USER INFORMATION

Reading this entire manual is essential for full understanding of the proper

use and safe operation of this product

Should you have any comments on this manual we will be pleased to receive them at:

Kipp & Zonen B.V.

Delftechpark 36

2628 XH Delft Holland

P.O. Box 507 2600 AM Delft Holland

Phone +31 (0)15 2755210

Fax +31 (0)15 2620351

Email info@kippzonen.com

Web www.kippzonen.com

Kipp & Zonen reserves the right to make changes to the specifications without prior notice.

WARRANTY AND LIABILITY

Kipp & Zonen guarantees that the product delivered has been thoroughly tested to ensure that it meets its

published specifications. The warranty included in the conditions of delivery is valid only if the product has

been installed and used according to the instructions supplied by Kipp & Zonen.

Kipp & Zonen shall in no event be liable for incidental or consequential damages, including without

limitation, lost profits, loss of income, loss of business opportunities, loss of use and other related

exposures, however caused, arising from the faulty and incorrect use of the product.

User made modifications can affect the validity of the CE declaration.

COPYRIGHT

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted in any form or by any means, without permission in written form from the company.

©

2005 KIPP & ZONEN

1

Page 3

IMPORTANT USER INFORMATION

Use the reserved place below to write down the version number of the supplied Win2AP operating

software. The software version number is given on the original CD-ROM label or can be retrieved

from the “about” pull down menu in Win2AP:

Manual version: 0706

Throughout the manual and inside the 2AP instrument symbols are used to indicate to the user

important information. The meaning of the symbols is as follows:

The exclamation mark within an equilateral triangle is intended to alert the user to the

presence of important operating, maintenance or safety information

Caution, risk of electric shock

Protective conductor terminal

Direct Current (DC)

Alternating Current (AC)

2

Page 4

IMPORTANT USER INFORMATION

DECLARATION OF CONFORMITY

According to EC guideline 89/336/EEC 73/23/EEC

We: Kipp & Zonen B.V.

Delftechpark 36

2628 XH Delft

The Netherlands

Declare under our sole responsibility that the product:

Type: 2AP Gear Drive

Name: Two-Axis Positioner and Tracker

To which this declaration relates is in conformity with the following European, harmonized and

published standards at date of this declaration:

EN 61326-1:2000

EN 61010-1:2001

Following the provisions of the directive:

EMC-directive : 89/336/EEC

Amendment to the above directive: 93/68/EEC

Low Voltage Directive 73/23/EEC

These conclusions are based on test reports:

1003/2AP/EMC

Delft,

March 03/15/02

ce-test PO box 563 2600 AN DELFT

B.A.H. Dieterink

President

KIPP & ZONEN B.V.

3

Page 5

IMPORTANT USER INFORMATION

4

Page 6

TABLE OF CONTENTS

TABLE OF CONTENTS

IMPORTANT USER INFORMATION ...................................................................................................................... 1

DECLARATION OF CONFORMITY ........................................................................................................................ 3

TABLE OF CONTENTS .......................................................................................................................................... 5

1 GENERAL INFORMATION............................................................................................................................. 7

1.1 INTRODUCTION TO THE 2AP ............................................................................................................... 7

1.2 MANUAL.................................................................................................................................................. 8

1.3 WIN2AP SOFTWARE.............................................................................................................................. 8

2 TECHNICAL DATA ......................................................................................................................................... 9

2.1 SPECIFICATIONS OF THE 2AP............................................................................................................. 9

3 SAFETY INFORMATION.............................................................................................................................. 11

3.1 POWER SUPPLY AND FUSE RATINGS ...............................................................................................11

3.2 DATA AND POWER CABLE CONNECTIONS.......................................................................................13

3.3 ENVIRONMENTAL CONDITIONS .........................................................................................................16

3.4 SUNTRACKER AND POSITIONER .......................................................................................................17

4 INSTALLATION AND SETUP ....................................................................................................................... 18

4.1 WIN2AP SOFTWARE.............................................................................................................................18

4.1.1 System Requirements................................................................................................................ 18

4.1.2 Installation.................................................................................................................................. 18

4.1.3 Win2AP Overview...................................................................................................................... 19

4.1.4 Selecting the 2AP Purpose........................................................................................................ 21

4.2 MINIMUM OPERATING AREA...............................................................................................................22

4.2.1 Installing the 360° Limit Option .................................................................................................. 24

4.3 MOUNTING THE 2AP ............................................................................................................................26

4.4 LEVELLING THE 2AP ............................................................................................................................28

4.5 ACCESSORY INSTALLATION...............................................................................................................29

4.5.1 Tripod Floor Stand..................................................................................................................... 29

4.5.2 Rear Mounting Plate .................................................................................................................. 31

4.5.3 Large Side Mounting Plate......................................................................................................... 34

4.5.4 Pointing and Shading Ball Assembly ......................................................................................... 37

4.5.5 Sun Sensor................................................................................................................................ 41

4.5.6 Attaching Instruments to the 2AP .............................................................................................. 45

4.5.7 Cold Weather Cover .................................................................................................................. 48

4.6 COMMISSIONING 2AP AS SUNTRACKER...........................................................................................49

4.6.1 Setting the Time......................................................................................................................... 49

4.6.2 Setting the Location................................................................................................................... 50

4.6.3 Start Suntracking ....................................................................................................................... 51

4.6.4 Sighting Adjustment without Sun Sensor ................................................................................... 51

4.6.5 Sighting Adjustment with Sun Sensor ........................................................................................ 52

4.7 COMMISSIONING 2AP AS POSITIONER .............................................................................................57

4.7.1 2AP Azimuth and Zenith Orientation.......................................................................................... 57

4.7.2 Mounting the 2AP as Positioner................................................................................................. 58

4.7.3 Adapting the 2AP Zenith Range ................................................................................................ 60

4.7.4 Configuring the 2AP for Positioner Purpose .............................................................................. 62

4.8 SAVING CONFIGURATION AS DEFAULT PARAMETERS ..................................................................64

5

Page 7

TABLE OF CONTENTS

5 OPERATION................................................................................................................................................. 66

5.1 RUN SUNTRACKER ..............................................................................................................................66

5.2 SUN SENSOR OBSERVATIONS...........................................................................................................68

5.3 RUN POSITIONER .................................................................................................................................68

5.3.1 Positioner Main Window ............................................................................................................ 68

5.3.2 Defining Instrument Targets....................................................................................................... 71

5.3.3 Target Types.............................................................................................................................. 74

5.3.4 Moving to Targets...................................................................................................................... 77

5.3.5 Manual Override ........................................................................................................................ 77

5.3.6 Monitoring 2AP Position During Operation ................................................................................ 77

5.3.7 On-line Help and Positioner Information .................................................................................... 78

5.4 CMD UTILITY .........................................................................................................................................79

5.4.1 CMD Utility Operation................................................................................................................ 79

6 REFERENCE INFORMATION...................................................................................................................... 82

6.1 PHYSICAL INTERFACE.........................................................................................................................82

6.2 SOFTWARE INTERFACE ......................................................................................................................82

6.2.1 Configuration Commands ..........................................................................................................83

6.2.2 Operation Commands................................................................................................................ 87

6.2.3 Status Commands ..................................................................................................................... 89

6.3 ERROR CODES .....................................................................................................................................92

6.4 GENERATING THE FED CHECK SEQUENCE .....................................................................................94

6.5 EVENT LOGS.........................................................................................................................................94

6.6 LOG ITEMS ............................................................................................................................................94

7 MAINTENANCE............................................................................................................................................ 98

8 SOLVING PROBLEMS ............................................................................................................................... 101

8.1 PROBLEM CHECK-LIST ......................................................................................................................102

8.2 TROUBLE SHOOTING.........................................................................................................................103

Appendix I............................................................................................................................................................ 105

6

Page 8

TECHNICAL DATA

1 GENERAL INFORMATION

1.1 INTRODUCTION TO THE 2AP

The 2AP two-axis tracker and positioner is an all-weather positioning platform used to point

specialized instruments at the sun’s movement across the sky or at stationary targets. It has been

designed to provide reliable, affordable positioning for small and medium sized payloads. Its

accuracy is excellent for solar monitoring applications.

When configured to operate as a solar tracker, unattended stand-alone operation is provided

through the 2AP’s embedded microcomputer-controlled azimuth and zenith positioning mechanism.

As a PC-based positioner, the 2AP is controlled and monitored by a full-time connection to a host

computer running the Win2AP software. Serial cable or modem interfacing can be used for

communications with the tracker.

The 2AP Gear Drive (2AP GD) is an all weather instrument providing optimal performance even in

the most harsh climates (from equatorial to Polar regions) and/or when the highest performance is a

necessity. The 2AP Gear Drive features high accuracy, resolution and repeatability, and great

torque.

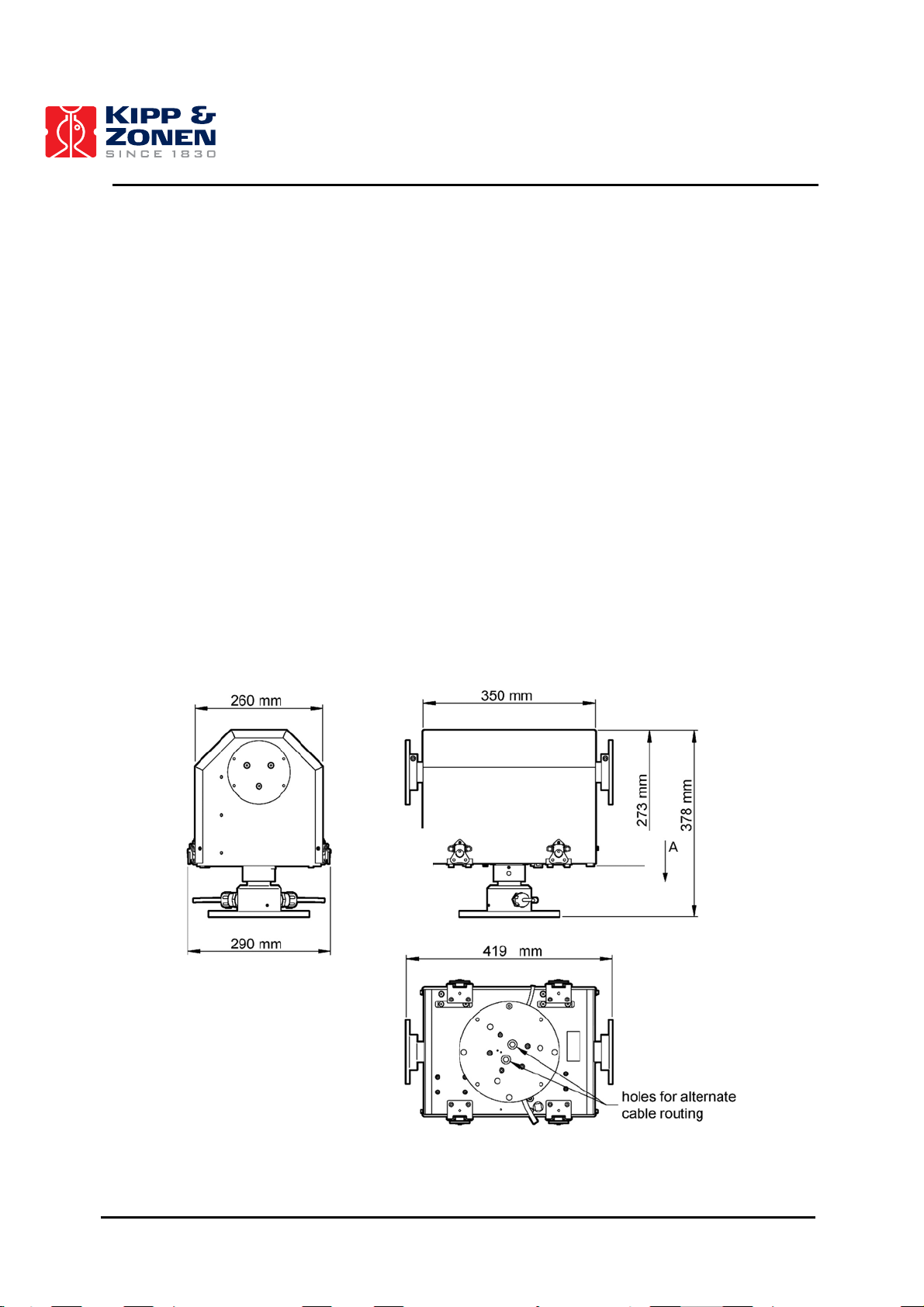

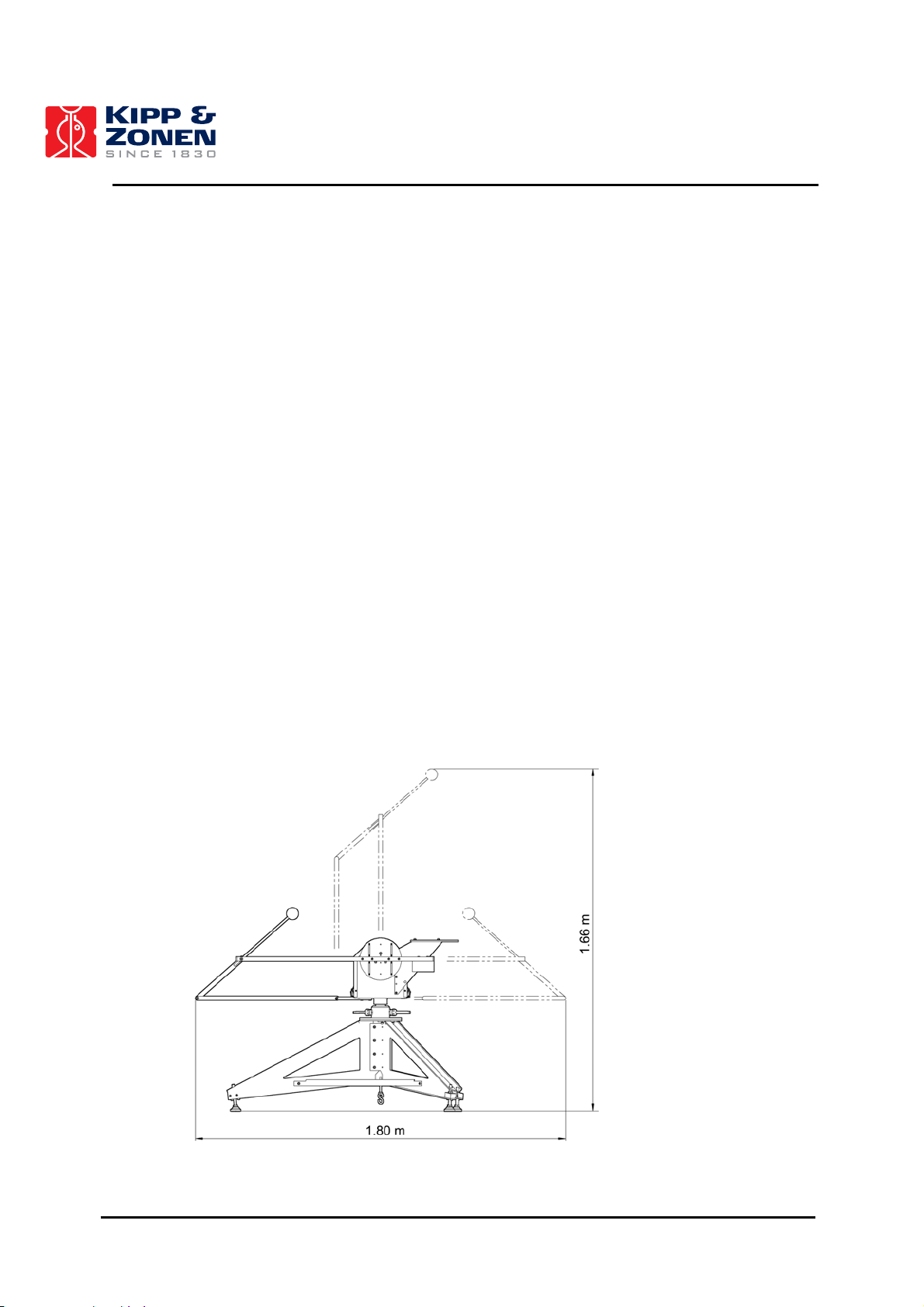

A standard 2AP with no accessories is shown in Figure 1.1. Figure 1.2 shows the 2AP Gear Drive’s

most important parts.

Figure 1.1: 2AP Outline Dimensions.

7

Page 9

TECHNICAL DATA

Figure 1.2: 2AP Gear Drive most important parts.

1.2 MANUAL

The 2AP INSTRUCTION MANUAL is intended for customers who have purchased the 2AP Gear

Drive with some or all of the accessory items that can be used to enhance or expand its capabilities.

It includes all the information necessary to install and operate the 2AP for stand-alone and PCbased suntracking and positioning purposes.

1.3 WIN2AP SOFTWARE

The Win2AP software comprises a set of utility programs designed to support the use of the 2AP.

The software can be used to set up and run the 2AP as a suntracker or as positioner. The utilities

run on an IBM compatible computer connected to the 2AP RS232 serial port. The software is

intended for the use of the scientist using the 2AP and the technicians installing the 2AP. The

software has several functions:

• Post delivery check

• To aid the preparation of the 2AP installation and setup

• To provide on-screen guidance of the 2AP setup on location

• To configure the 2AP as a suntracker or positioner

• To facilitate sending commands to, and displaying responses from the 2AP

• To provide a tool for verifying the validity of connections to the 2AP

8

Page 10

TECHNICAL DATA

2 TECHNICAL DATA

2.1 SPECIFICATIONS OF THE 2AP

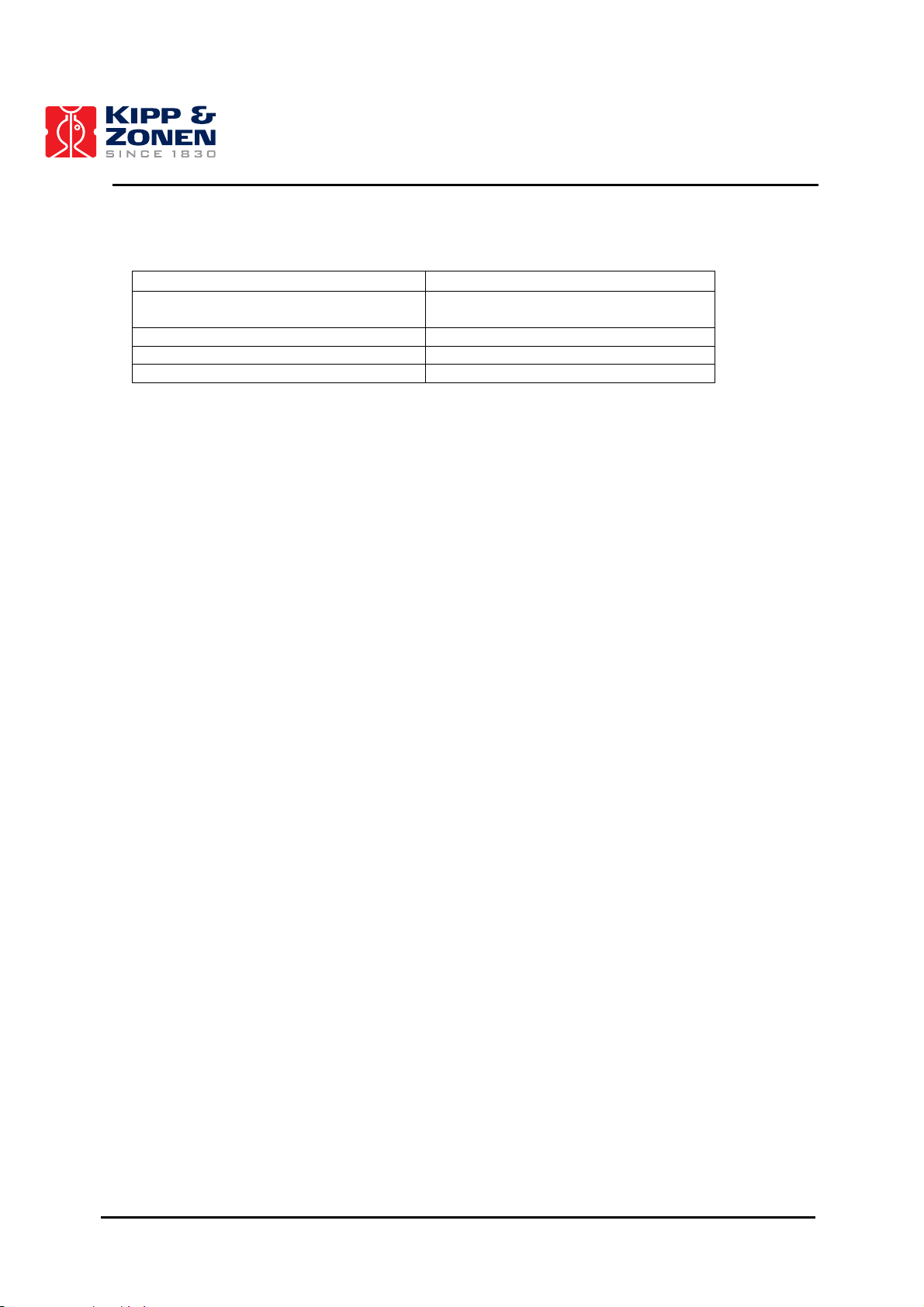

Table 1: Operating specifications of the 2AP.

Gear Drive

Temperature:

Standard 2AP

2AP with Cold Weather Cover

2AP with Cold Weather Cover and Heaters

Altitude To 2000m above sea level

Voltage 115/230 VAC (±10%),

Power 50VA Standard

Communication

Surge Protection power and heaters

Real Time Clock Accuracy 25 ppm - power off

Memory Back-up Battery Life 15 years with power on

Motor stepping motor

Motor Drive half/full step

Control Software Win2AP

Control open loop

Drive spur gear primary/

Rotation Limits optical switches (x4)

Reference Position optical switches (x2)

Accuracy

Repeatability

Resolution 0.0025°

Angular Velocity

Angular Acceleration

Torque 40 Nm

Payload 65 kg balanced

Rotation 90°/210º Zenith

(1)

1σ at constant temperature

(2)

1σ at constant temperature and for movement in the same direction

(3)

User programmable

(1)

(2)

<0.01°

(3)

up to 1.8°/sec

(3)

up to 3.6°/sec2

0° to +50°C

-20° to +50°C

-50° to +50°C

(no limit with 24V DC option)

60/50 Hz

24 VDC optional (23-26 VDC)

150VA with optional heater kit

200VA with extreme heater kit

RS-232, 3-wire, 8, N, 1

300 to 9600 baud

2 ppm - operating

6 months with power off

MS Windows™ based

double-involute worm final

<0.05°

540° Azimuth

(360° Azimuth limit option)

9

Page 11

TECHNICAL DATA

Table 2: 2AP Physical Dimensions.

Gear Drive

Length 35 cm (chassis only)

42 cm (including side mounting plates)

Width 29 cm

Height 38 cm

Weight 30 kg

10

Page 12

INSTALLATION AND SETUP

3 SAFETY INFORMATION

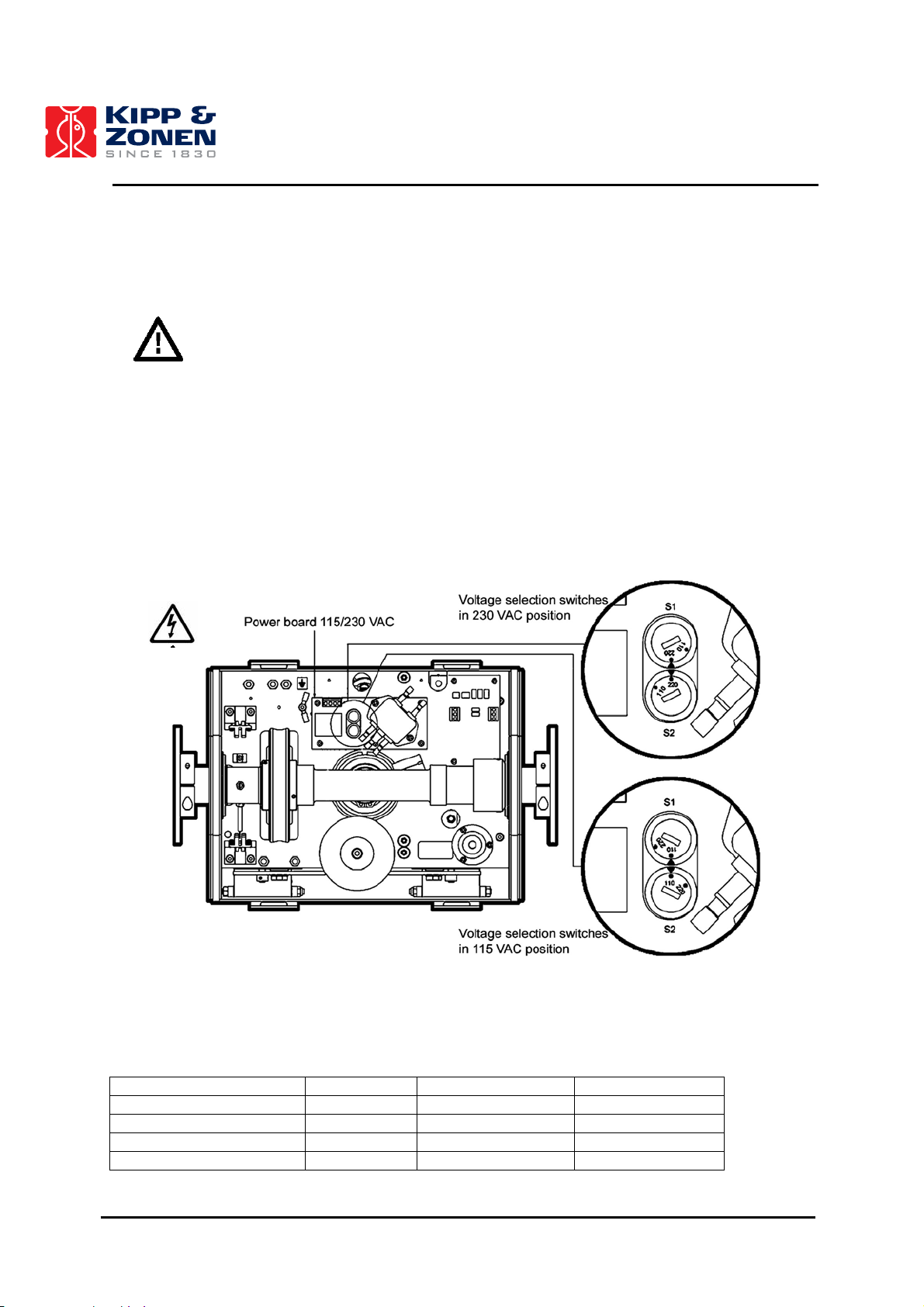

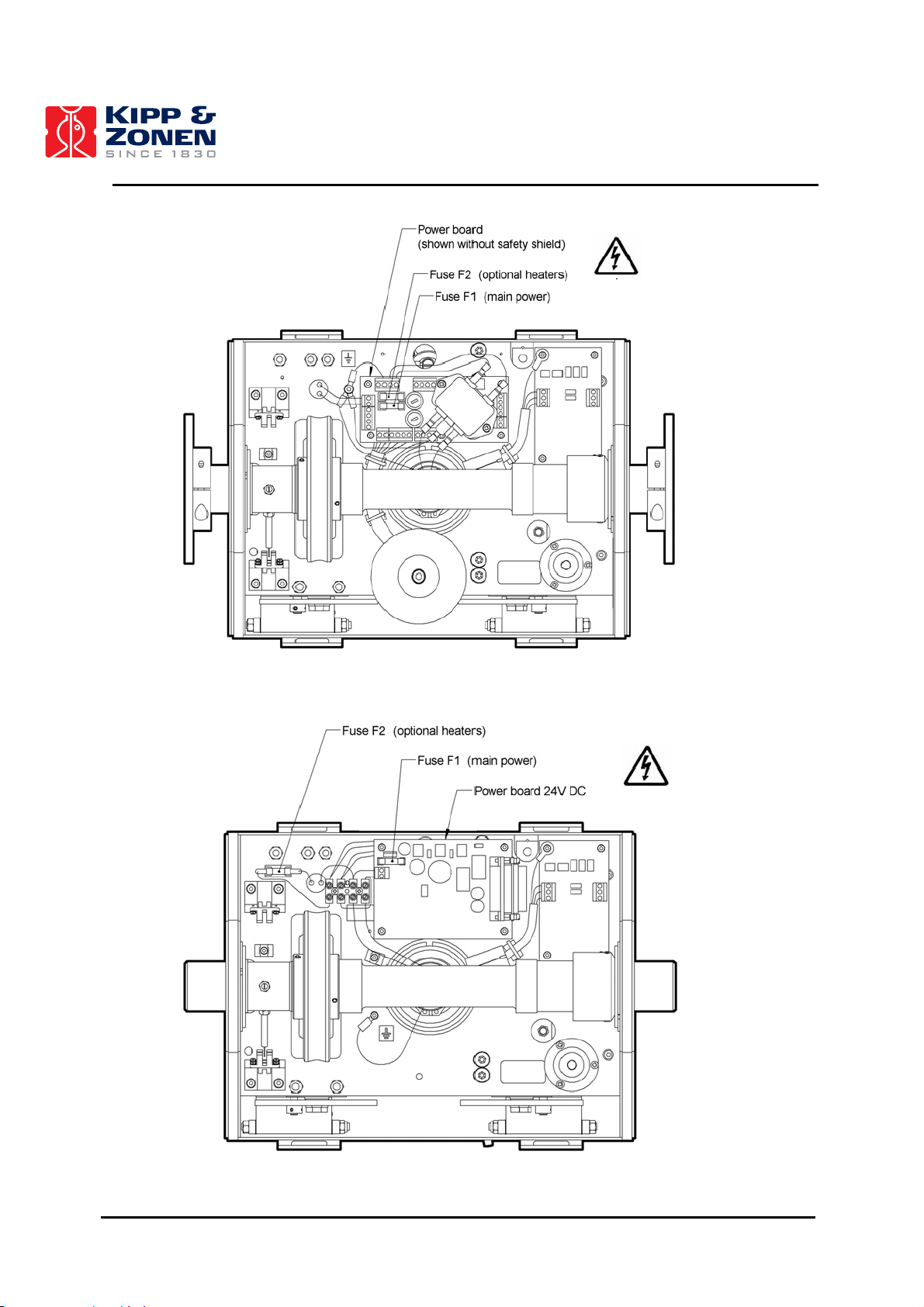

3.1 POWER SUPPLY AND FUSE RATINGS

Important: Power supply

Prior to turning the 2AP (115/230 VAC version) power on, ensure that the voltage selection

switches for main power and for the optional heaters (figure 3.1) are in the correct positions to

match the incoming power supply and that the appropriately rated fuses are fitted.

As the voltage selection switches are located on the power board ensure that the 2AP power is

turned off before continuing. Use a screwdriver to turn the 115/230 VAC switches as necessary.

Although the switches on the power board read 110/220V, they are suited to 115/230 mains

voltage, respectively. The switches are qualified for equipment of protection class II VDE 0630 (6.3

A/250 V). The mains voltage and fuse ratings for 115/230 VAC and 24 VDC are shown in table 3.

The fuses are according to IEC 60127-2, VDE, UL. The location of the fuses on the power board is

given in figures 3.2 and 3.3.

Figure 3.1: 115/230 VAC Power Switch Diagram.

Table 3: 2AP Power Supply and Fuse Ratings (slow-blow type).

230 VAC 115 VAC 24 VDC

Power supply ±10% VAC ±10% VAC 23-26VDC

F1 mains power 0.25A (slow) 0.5A (slow) 3.15 A (slow)

F2 heater kit 0.5 A (slow) 1 A (slow) 1 A (slow)

F2 extreme heater kit 1 A (slow) 2 A (slow) 2 A (slow)

11

Page 13

INSTALLATION AND SETUP

Figure 3.2: 115/230 VAC Power Fuse Diagram.

Figure 3.3: 24V DC Power Fuse Diagram.

12

Page 14

INSTALLATION AND SETUP

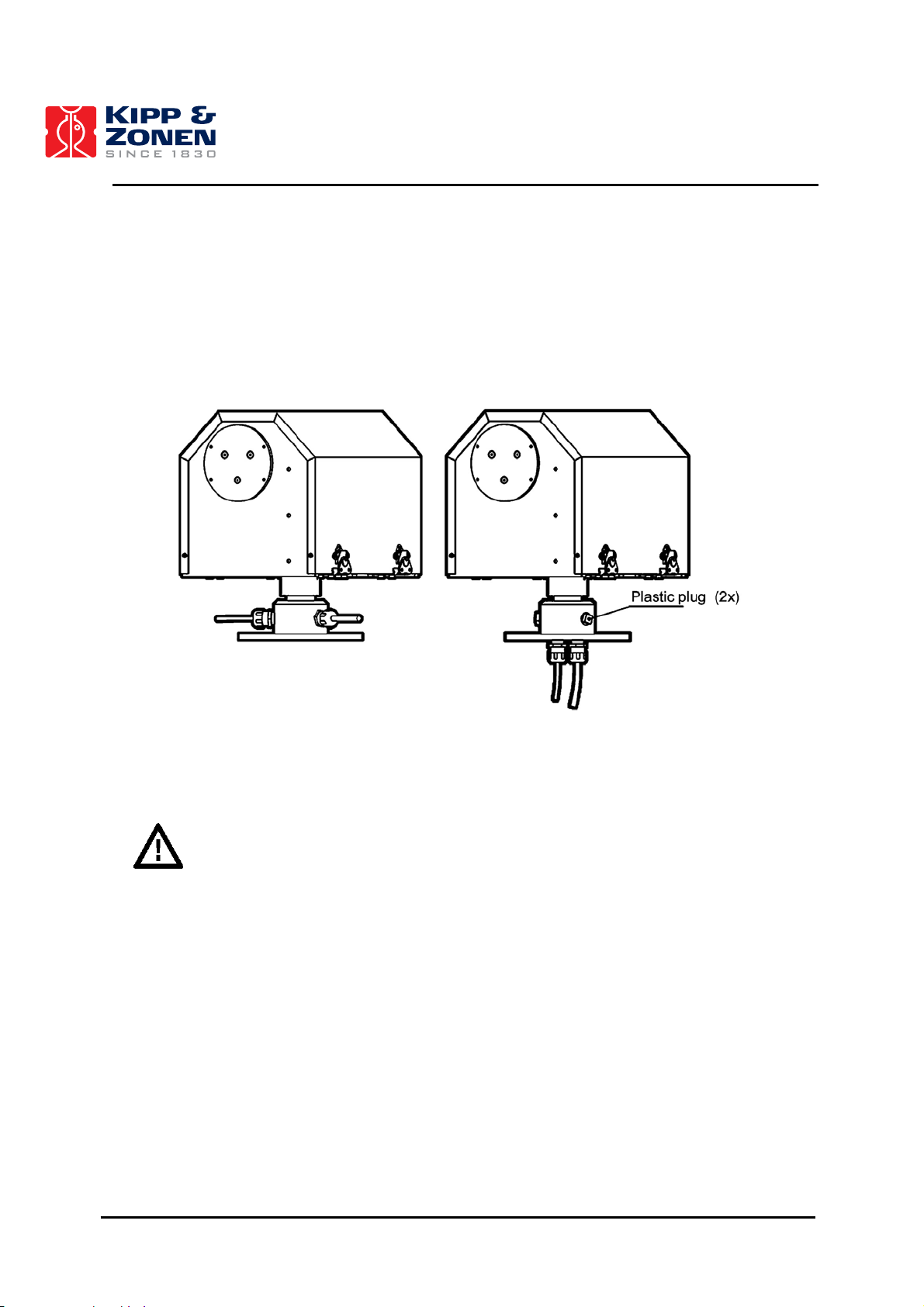

3.2 DATA AND POWER CABLE CONNECTIONS

All 2AP's have a temporary communication and permanent power cable installed at the factory. The

cables are routed through the side of the Azimuth shaft, see figure 3.4 a). An alternative cable

routing through the bottom flange of the 2AP is possible, figure 3.4 b). The Alternate Cable Routing

is advised for a 2AP mounted on a Height Extension Tube, it allows the power and communication

cables to go through the inside of the Stand.

a) b)

Figure 3.4: a) Standard Power and Communication Cable Routing.

b) Alternate Power and Communication Cable Routing.

Important: Power and communication cable

The 2AP is supplied with a 3 m power cable with a waterproof in-line connector type “Aqua-safe”.

The connector is in accordance with safety regulations for outdoor usage. The female plug must be

connected to an extension cable that has the proper cable diameter. The voltage drop over the

cable should not cause the supplied voltage to be out of specifications, see chapter 2. To connect

the female plug properly, it is recommended to read the “Aqua-safe” wiring & assembly instruction

that is attached to the cable assembly. The in-line connector provides two sealing caps that should

be fitted to either the male and female plug in case the in-line connector are left unmated in-situ.

This will maintain an ingress protection rating of IP68.

The present connector of the communication cable is not suitable for outdoor usage. It is

recommended to replace the cable by a new one of the proper length.

Note: Once the cable routing has been finalized, be sure to seal the unused threaded holes

(either in the bottom flange or in the azimuth spindle) with the threaded plastic plugs

supplied with the 2AP.

13

Page 15

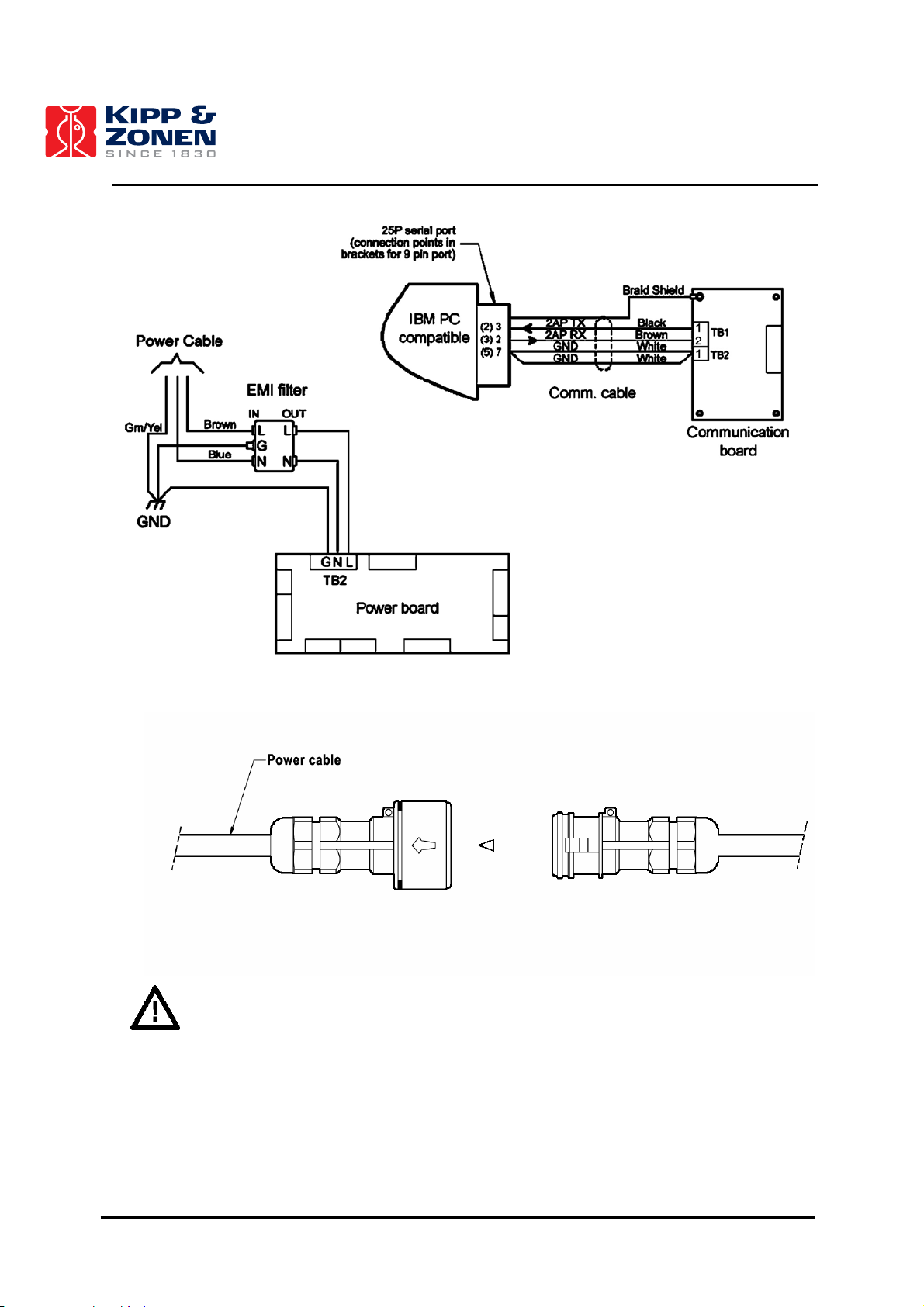

INSTALLATION AND SETUP

Figure 3.5: Communication and Power Cable Wiring.

Figure 3.6: Power Cable Connector

Important: Circuit breaker

A power on/off switch is not a part of the 2AP, requirements for electrical equipment installed

outdoors specify that:

• A power isolator (switch or circuit-breaker) must be included in the cable installation.

• The isolator must be in close proximity to the equipment and within easy reach of the

operator.

• The isolator must be marked as the power disconnection device for the equipment.

14

Page 16

INSTALLATION AND SETUP

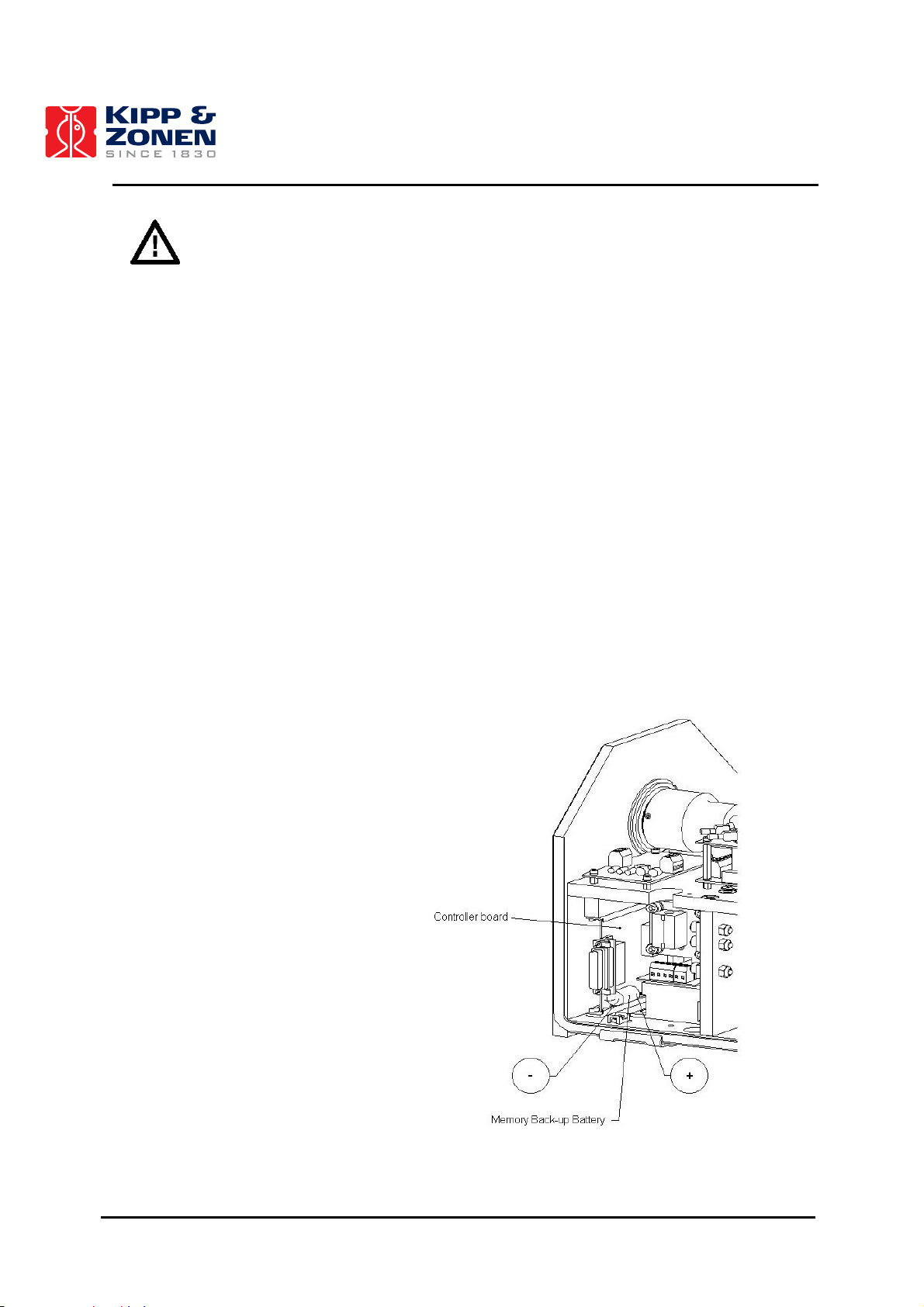

Important: Memory back-up battery

A memory back-up battery is installed on the 2AP controller board. The function of the back-up

battery is to keep the specific 2AP configuration parameters stored in the controller board and to

power the high accuracy internal clock when the 2AP is disconnected from the mains voltage or

during a temporary power cut.

The system does not draw power from the memory back-up battery, when the 2AP is connected to

the power supply.

The battery life time depends on the use of the 2AP. When the 2AP is constantly powered the

battery will function for about 15 years, if the power to the 2AP is turned off the battery life time is

about 6 months.

It is important to have a working back-up battery installed to avoid loss of time and the configuration

settings stored in the 2AP. When the power is turned on again e.g. after a power cut the 2AP will

automatically resume its assigned tasks, as the 2AP can rely on the internal clock time and

configuration settings.

The battery type is Lithium ½ AA, 3.6V, 0.8Ah, non-rechargeable with axial wire terminals soldered

to the controller board. When the battery is ready for replacement the controller board can be taken

out from the 2AP for easy access and re-soldering. Ensure to have downloaded the latest

configuration parameters from the 2AP to the PC before removing the old battery from the controller

board. See section 5.4 on how to download the configuration parameters from the 2AP. Reload the

configuration files when the new back-up battery is installed. The time can be reset by using the

“Set Time” item from the 2AP pull down menu in the Run Suntracker or Run Positioner monitor

window.

Memory Back-up Battery:

- Lithium, ½ AA, 3.6V, 0.8Ah

- With axial wire terminals to be

soldered to the controller board

- Non-rechargeable

- Size: length 23 mm, ∅ 14 mm

Figure 3.6: Location of the Memory Back-up Battery.

15

Page 17

INSTALLATION AND SETUP

3.3 ENVIRONMENTAL CONDITIONS

Important: 2AP cover

Do not operate the 2AP with the cover removed. Doing so can defeat the over-travel sensors which

may result in physical damage to the 2AP and/or any attached equipment. Such damage is not

covered under warranty.

The 2AP cover protects the internal drives and electronics of the 2AP. When the cover of the 2AP is

fitted back onto the unit be sure to reconnect the detachable ground wire to the chassis to maintain

electrical safety and RFI screening. All four latch handles and security screws must be secured.

Proper worm/spur gear mesh is a critical factor in the operation of the 2AP GD. To ensure that the

mesh is in no way affected, it is recommended that the 2AP NOT be operated for extended periods

of time with the main cover removed. This is especially important in any dusty, windy or high

moisture environments. Any debris adhering to the worm and/or spur gear can adversely affect the

operational accuracy of the 2AP and cause premature wear.

A standard 2AP has an operating temperature range of 0°C to +50°C. For remote locations with

harsh temperature conditions, the Cold Weather Cover combined with two (optional) internal

heaters can increase the operating range to -50°C to +50°C, see table 4.

Table 4: 2AP Operating Temperature Range.

To ensure that the 2AP operates without failure due to extreme temperature conditions, it is

recommended that the Cold Weather Cover installation / removal be determined as per the

following:

Below 0°C : Cold Weather Cover must be installed.

0°C to +20°C : 2AP may be operated with Cold Weather Cover installed or removed.

Above +20°C (for more than 8 hours continuously): Cold Weather Cover must be removed to

prevent overheating.

With the 2AP cover installed properly such that all four of the latch handles and security screws are

secured the 2AP is environmentally protected to IP65, according EN 60529: 1991 + CI 1993. This

qualifies the 2AP to be used in weather conditions with all types of precipitation.

Important: Worm / Spur Gear Drive Contamination

Important: Operating Temperature

Standard 2AP

2AP with Cold Weather Cover

2AP with Cold Weather Cover and Heater Kit

2AP with Cold Weather Cover and Extreme Heater Kit

Important: Precipitation

0°C to +50°C

-20°C to +50°C

-50°C to +50°C

-50°C to +50°C (prolonged

exposure and wind-chill)

16

Page 18

INSTALLATION AND SETUP

Important: Altitude restriction

According to the EC guideline (Electrical safety of electric equipment) the 115/230V AC versions of

the 2AP are not aproved for use at altitudes higher than 2000 m. This restriction is related to

clearance (air) and creepage (surface) insulation distances on the power board. Factors such as

humidity, temperature and dry pollution are of great influence.

The 2AP 24 VDC version is not restricted to 2000 m due to the lower voltage.

3.4 SUNTRACKER AND POSITIONER

Attention! Combined Suntracker and Positioner usage of the 2AP Gear Drive

When it is the intention to use the 2AP for both the Suntracker and Positioner purposes it is

recommended to set up the 2AP as a Suntracker. As Suntracker the 2AP must be mounted in a

specific way, with the arrow on the 2AP bottom flange aligned due East. As Positioner, according to

your needs, the 2AP may be mounted in any direction. Setting up the 2AP as Suntracker first will

save having to repeat the set up twice. Read section 4.7 for more information on the possibilities of

the 2AP set up as Positioner.

Important: Information for 2AP Gear Drive users who have used their 2AP for an

extended period of time for Suntracker purposes only and want to

The 2AP is designed for Suntracker purposes. Therefore Win2AP provides all the relevant

information to set up, commission and operate a 2AP as a Suntracker.

With the Win2AP software the 2AP can also be used for Positioner purposes. The 2AP can be

programmed to cycle through a list of targets (positions) determined by the user.

However, some problems might occur when changing over from Suntracker to Positioner operation

with an older 2AP Gear Drive. The problem might occur with older Gear Drive units that have been

running for an extended period of time with limited positioning movement, due to repeated sun

cycling.

Technical explanation: If a 2AP Gear Drive has been used as a Suntracker for an extended

period of time the gears on both the axes become worn in a particular area and deformation of the

worm final gears and the spur primary gears takes place. When changing over to Positioner

operation the 2AP Gear Drive can come to a standstill, because of the transition from the worn part

of the metal gears to the area where the gears have never been used. In the worst case the spur

gears or the nylon gears of the stepper motors will experience the main forces and may get

damaged.

The gear wear as described above produces no effect on the Suntracker accuracy of a 2AP Gear

Drive that is used for Suntracker operation only.

change over to Positioner operation.

17

Page 19

INSTALLATION AND SETUP

4 INSTALLATION AND SETUP

The following sections provide information on the installation of the software and the 2AP setup.

The 2AP has various accessories to enhance and expand its operation, including:

• Tripod Floor Stand

• Height Extension Tube (60 cm)

• Rear Mounting Plate

• Large Side Mounting Plate

• Pointing & Shading Ball Assembly:

Including Large Side Mounting Plates (x2) and a Rear Mounting Plate (x1)

• 2AP Cold Weather Cover

• Ventilation units for Pyranometers/Pyrgeometers

• Sun Sensor

Both the Manual and Win2AP software (see Setup Preparation in the Main Menu) are supplied with

various drawings with technical accessory dimensions that will aid specific 2AP setup demands and

adjustments for alternative mountings.

4.1 WIN2AP SOFTWARE

4.1.1 System Requirements

The minimum computer hardware requirement for the Win2AP software is a 133 MHz Pentium

computer running Windows 95/98/NT/2000/ME, 32 MB of RAM, 200 MB of free hard-disk space,

CD-ROM drive, one free serial port.

For the 2AP installation on site a laptop is needed, with the same minimum system requirements.

Dependent on several conditions, the initial 2AP setup can take up to 1-2 days. Therefore an AC

power supply, or other power backup, for the laptop is necessary.

Tip: It is helpful to use some type of sun shield to shade the laptop during setup of the 2AP.

The intensity of the sun can overheat the computer and/or decrease the readability of the

LCD screen.

4.1.2 Installation

The Win2AP software is supplied on a CD-ROM, a win2ap.ini configuration file is supplied on a

separate floppy disk. The installation of the software is as follows:

• Place the CD-ROM into the PC

• Double click on setup.exe.

• Follow the setup instructions on the screen.

• The configuration file must be installed in the same directory as the Win2AP software.

Tip: Keep the win2ap.ini disk, or a copy of the contents, in a safe place. It will come in handy

when doing a complete re-installation of the instrument.

18

Page 20

INSTALLATION AND SETUP

The Win2AP software is compatible with older 2AP’s that run with DOS software. To upgrade the

software continue with:

• Connect the 2AP communication cable to the PC.

• Double click on Win2AP.exe with the Kipp & Zonen logo to open the software.

• Press the “Troubleshooting” button in the Main Menu.

• Press the “Run CMD” button on the bottom of page 1.

• Select the correct com port.

• To communicate with the 2AP, press the “Connect” button.

• Press the “Read Config From 2AP” button.

• Enter a file name (e.g. Win2AP.ini) to save the configuration file on your PC.

• If the Password reads 65535 it has been set to a default integer. Press the “Disconnect”

button in the CMD window and follow the steps on page 2 of the Troubleshooting Procedure

to reconfigure a Password. You will find the original 2AP password in the baseline.ini file of

the DOS software.

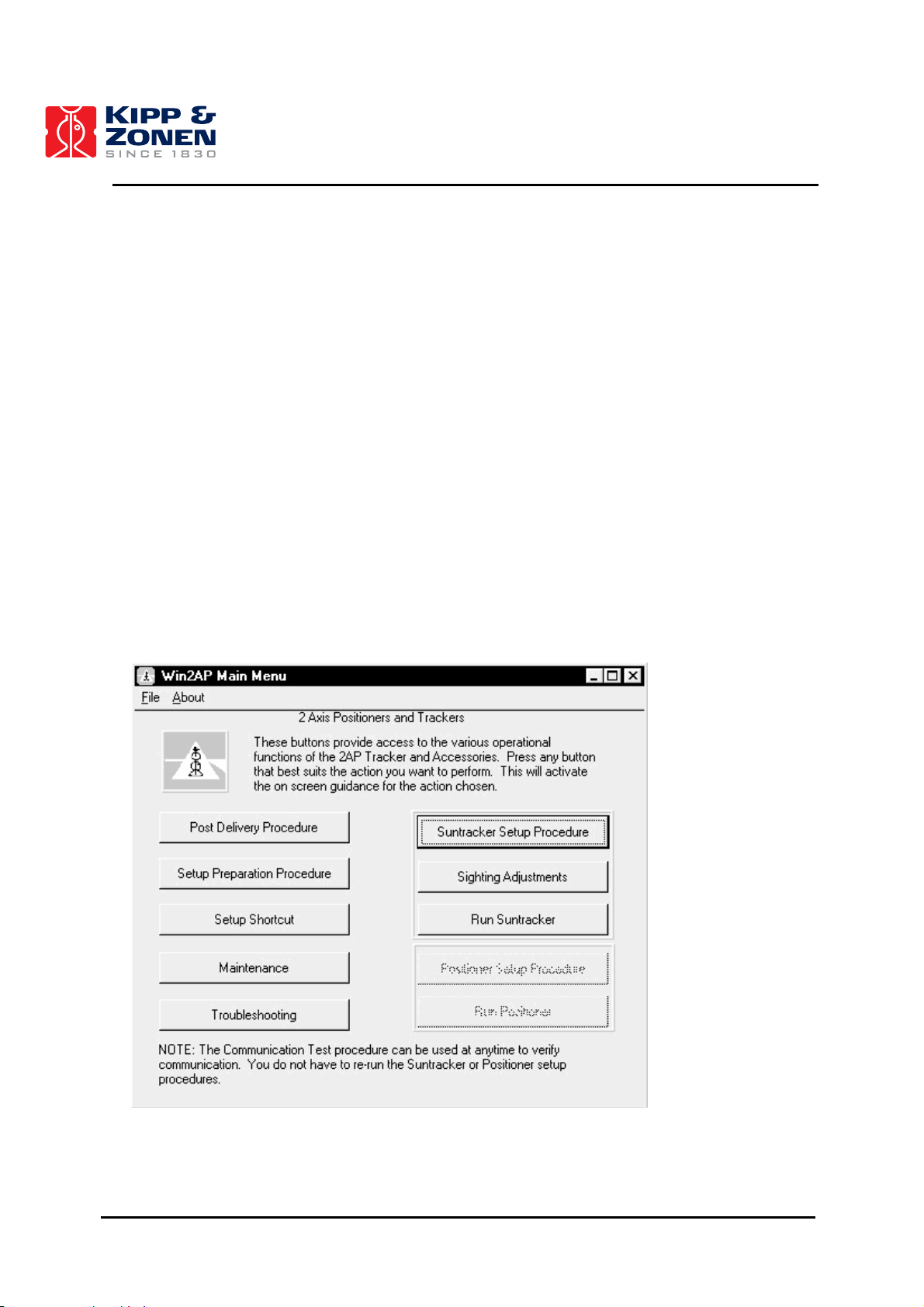

4.1.3 Win2AP Overview

Double clicking on Win2AP.exe with the Kipp & Zonen logo will open the software. The buttons in

the Main Menu of the Win2AP software provide access to the various pages for 2AP instalment, see

figure 4.1. An overview of the various pages behind the buttons in the Main Menu is given in figure

4.2.

Figure 4.1: Win2AP Main Menu.

19

Page 21

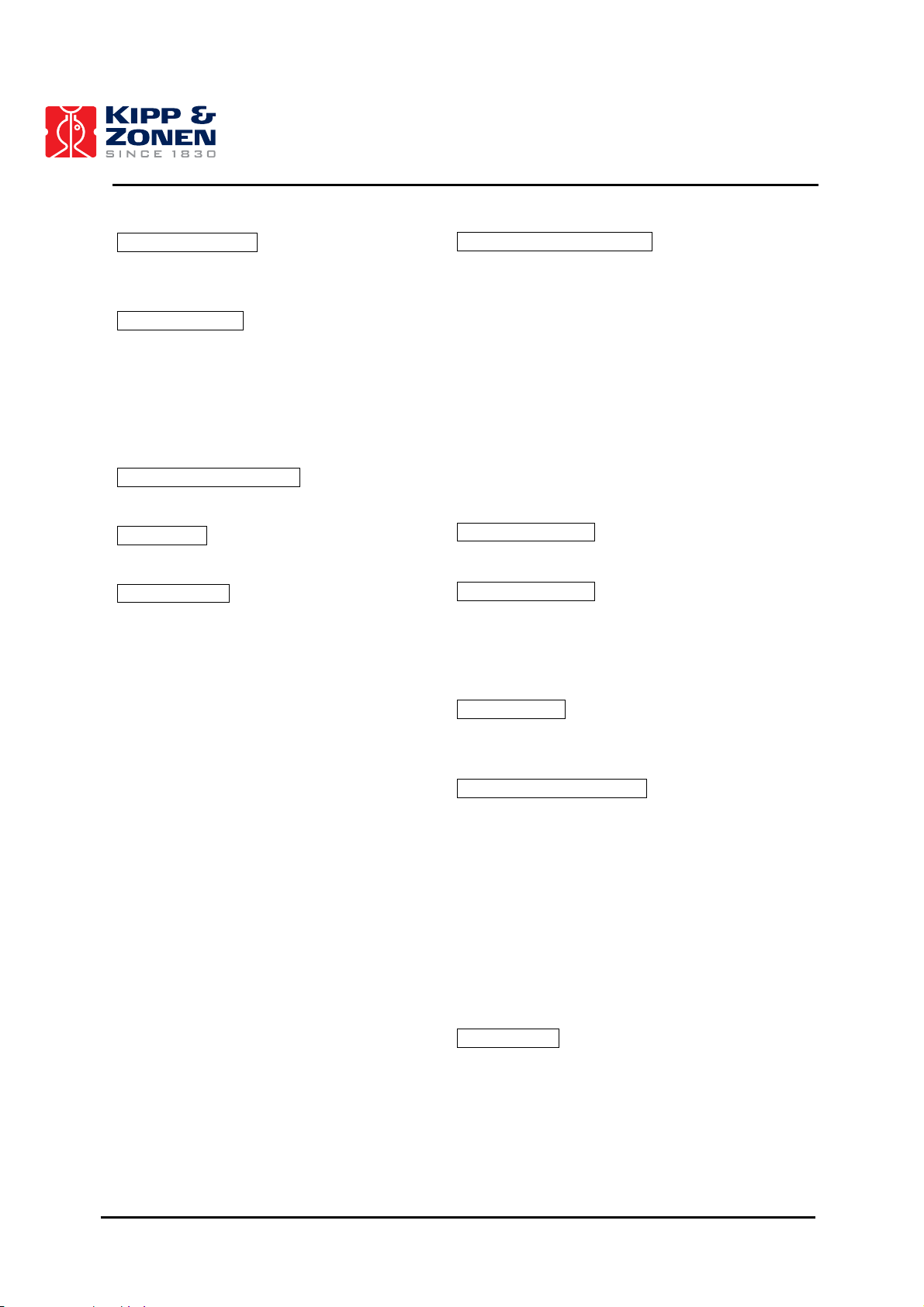

INSTALLATION AND SETUP

Post Delivery Check

1. Accessory List

2. Power Use Verification

Setup Preparation

1. Getting Acquainted with the 2AP

2. Communication Test

3. Password Activation / Deactivation

4. Alternate Montage of the 2AP

5. 360º Limit Option (Gear Drive only)

6. Minimum Setup Requisites

Software Setup Procedure

1. Setup Shortcut

Maintenance

1. Maintenance

Troubleshooting

1. Troubleshooting

2. Change Password

3. Cold Start

4. Contact Manufacturer

Suntracker Setup Procedure

1. Mounting Suntracker

2. Power Up Procedure

3. Levelling Gear Drive

4. Rear Mounting Plate Assembly

5. Large Side Mounting Plate Assembly

6. Pointing and Shading Ball Assembly

7. Mounting Sun Sensor

8. Pyrheliometer Installation

9. Pyranometer Installation

10. Verification of Levelling

11. Cold Weather Cover Installation

12. Setting Time and Location

13. Conclusion

Sighting Adjustment

1. Sighting Adjustment without Sun Sensor

Sighting Adjustment

1. Azimuth orientation

2. Sun Sensor Alignment

3. Tilt Correction

4. Active Time Correction

Run Suntracker

1. Suntracker Monitor Window

Positioner Setup Procedure

1. 2AP Azimuth Orientation

2. Mounting the 2AP as Positioner

3. Power Up Procedure

4. Levelling Gear Drive

5. Large Side Mounting Plate Assembly

6. Adapting 2AP Zenith Range

7. Configuring the 2AP for Positioner Purpose

8. Attaching Instruments to the Side Plates

9. Verification of Levelling

10. Cold Weather Cover

11. Conclusion

Run Positioner

1. Positioner Monitor Window

Figure 4.2: Overview of the various pages in Win2AP.

20

Page 22

INSTALLATION AND SETUP

Summarized the normal procedure from the 2AP delivery to the setup at the site is as follows.

Post Delivery Check:

The purpose of going through the Post Delivery Check is two-fold. Primarily it functions as a

delivery check. Appended diagrams will help you become familiar with the 2AP and its optional

accessories.

Secondly, selecting the 2AP purpose and specific accessories will activate the on-screen guidance

for the 2AP setup. Selecting the “Pyrheliometer mounting support for direct solar irradiance

measurements” will provide you with information on how to install Kipp & Zonen radiometers on the

2AP. The selections in the “Post Delivery Check” activate the on screen guidance for your 2AP set

up. See section 4.1.4 for more information on selecting the 2AP purpose.

Setup Preparation Procedure:

The Setup Preparation can be done off-site. This procedure will help you become acquainted with

the 2AP and its optional accessories. Appended diagrams provide the information and technical

accessory dimensions that will help you with specific 2AP setup demands or adjustments.

Suntracker/Positioner Setup Procedure:

After the Setup Preparation you can move on to one of the 2AP Setup Procedures (as selected in

the Post Delivery Check). Follow the on-screen guidance for the 2AP setup at the site. Of course

you can go through the Setup Procedure at anytime. Press the “Connect” button in the Power-up

Procedure to gain access to the information on the accessory set up.

Sighting Adjustment:

If the Suntracker Setup Procedure is completely finished you can start to perform the 2AP Sighting

Adjustments procedure.

Run Suntracker/Positioner:

At this stage, when configured as a Suntracker, the 2AP is ready for unattended operation. The Run

Suntracker monitor window shows you all the 2AP operational parameters.

When used as a positioner, you will come to the main window for Positioner. This window gives you

all the information for target names and the current 2AP position and status.

4.1.4 Selecting the 2AP Purpose

Selecting the right purpose is of great importance for the correct set up of your 2AP. In the “Post

Delivery Check” procedure of the Win2AP software you are able to choose between three options

with respect to 2AP purpose:

1. Suntracking

2. Positioning

3. Suntracking and Positioning

Suntracking:

If the “Suntracking” purpose is selected the “Positioner” part in Win2AP is kept out of site for the

user, which makes section 4.7 of this manual is not applicable. According to the selections in the

“Post Delivery Check” you will be guided through the “Suntracker Setup Procedure” and the correct

“Sighting Adjustment Procedure”.

Positioning:

If the “Positioning” purpose is selected, you chose to not use the 2AP as a Suntracker at all.

Continue by following the instructions of section 4.7, in the Win2AP software you will be guided

through the designated “Positioner Setup Procedure”.

21

Page 23

INSTALLATION AND SETUP

Specify your Positioning needs in the boxes on the first page of the Positioner Setup Procedure.

These selections and the ones in the “Post Delivery Check” will guide you through the installation

procedure of your 2AP.

Suntracking and Positioning:

If the “Suntracking and Positioning” purpose is selected you will be able to interchange between

both purposes by pressing one specific button in the Win2AP “Run Suntracker” or “Run Positioner”

monitor window. As the 2AP is going to be used partly as a Suntracker it is a necessity first to set it

up as a Suntracker. When changing over to Positioner operation the Suntracker configuration

values will remain saved in the 2AP. The 2AP is set to a different operating mode, which allows the

2AP to respond to the Positioner commands. As there are different operating modes (such as sun

tracking, active tracking, active correction, positioning, etc.), when interchanging between the

Suntracker and Positioner the last used operating mode is saved in the win2ap.ini configuration file.

After the 2AP purpose has been determined select in the “Post Delivery Check” each 2AP

accessory that you want to install. Press any button on the right to view a picture of the item. Select

the Pyrheliometer and/or Pyranometer checkboxes for Kipp & Zonen radiometer mounting support

during the 2AP Setup Procedure. All the selections on this page will activate the Win2AP on-screen

guidance. Only the pages corresponding to your selected options will be shown.

4.2 MINIMUM OPERATING AREA

The 2AP, complete with all the accessories attached, requires a substantial amount of unobstructed

area to operate properly. This should be kept in mind when deciding where and how the unit is

going to be mounted. Figure 4.3 shows the minimum operating areas with respect to both the

Azimuth and Zenith axis of a 2AP complete with all accessories including Tripod Floor Stand and

Pointing & Shading Ball Assembly. See section 4.5.1 for more information on the exact dimensions

of the optional Tripod Floor Stand.

An optional Height Extension Tube (not shown in the diagram below) raises the 2AP by 60 cm.

Figure 4.3: Minimum Operating Area (with Accessories).

22

Page 24

INSTALLATION AND SETUP

Important:

It is important to consider the following points before/during the setup of a 2AP.

• Verify that the Power and Communication cabling is routed properly to prevent cables from

catching on any fasteners or supports.

• Ensure that the surface on which the Suntracker will be mounted is reasonably level, but

above all it is very important to create a very firm base for the feet of the Tripod to sit upon.

• Make sure that the site will be free from any obstructions within the operating circle and

above the horizontal mounting plane.

• Make sure that the 2AP and accessories will be accessible for maintenance purposes.

• Make sure that the 2AP is located in such a way that shadows will not be cast onto the

radiometers at any time.

• Ensure that before operation of the 2AP the Sun Sensor cable and other mounted

instrument cabling will not catch on any fasteners or supports.

• Avoid any possible cable binding or snagging on parts of the 2AP, supports or other

instrumentation.

23

Page 25

INSTALLATION AND SETUP

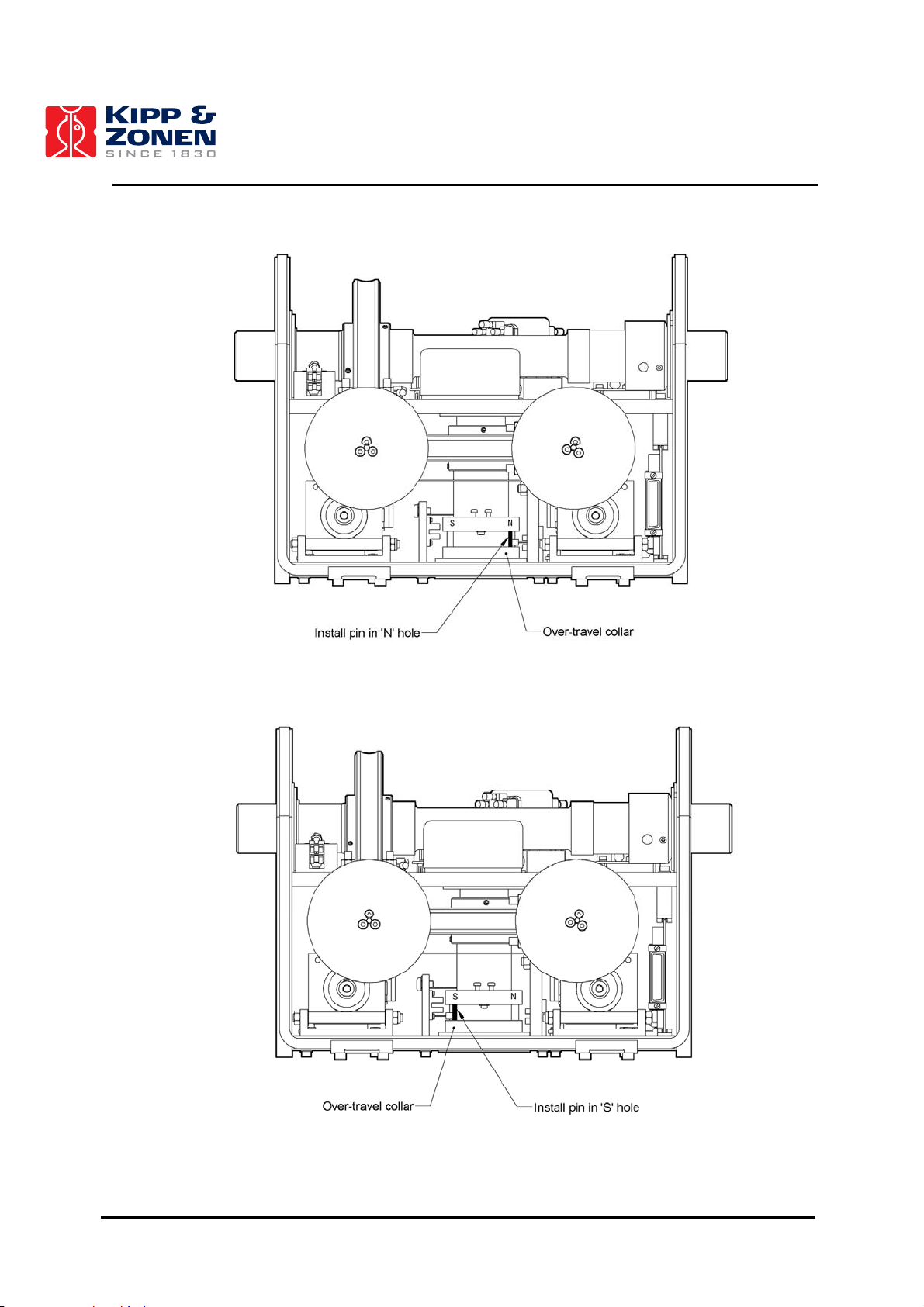

4.2.1 Installing the 360° Limit Option

A 2AP Gear Drive is delivered with the capability of approximately 540° rotation on the azimuth axis.

For certain installations it may be desirable to limit this rotation. With the installation of a pin in the

over-travel collar, the 540° rotation on the azimuth axis can be limited to approximately 360°.

Note: This rotational limit cannot be utilized if the 2AP is located anywhere within the tropics

(<25° Latitude North or South) as the 540° rotation on the azimuth axis is necessary to

ensure accurate tracking for all periods of the day.

To fit the 360° limit option the Win2AP software must be installed on a computer and

communication with the 2AP must be established. This procedure can be done as a part of the

Setup Preparation off-site.

The 360° limit option is as follows:

• Press the “Setup Preparation” button in the Main Menu of the Win2AP software. The 360°

limit option is given on page 5.

• If the 360° Limit Option is desired select the Terrestrial Hemisphere where the 2AP will be

located. "No function" implies the standard 540° Azimuth rotational configuration.

• For the instalment of the 360° Limit Option, the 2AP must be in the correct position for the

pin instalment. Press the “Position 2AP for pin instalment” button and wait for the 2AP to

stop moving.

• Disconnect the Power Supply.

• Remove the 2AP cover. While viewing the unit from the front (see figure 4.4 or 4.5), rotate

the over-travel collar in a clockwise direction (if >25° N) or in a counter-clockwise direction

(if >25° S) until the collar is stopped by the azimuth reference sensor blocker.

• See figure 4.4 or 4.5 on how to install the Limit Pin for North and South of the tropics

respectively. Install the supplied pin (located with the spare fuses) in the appropriate hole in

the over-travel collar. These are identified with an "N" stamped on the outside of the overtravel collar for the Northern Hemisphere and an "S" for the Southern Hemisphere.

• Reconnect the Power Supply.

• Once the pin has been installed and the power reconnected, the software limits must be set

to match the new 360° hardware limits. To do so press the “Set New Limits” button.

Important: When returning to original state of 540° azimuth rotation

If in the future there is a need to return the 2AP to a state where it is capable of 540° Azimuth

rotation, the pin must be removed and the azimuth limits reset to the factory default setting. See the

Setup Preparation procedure in Win2AP Main Menu, page 5, step 11.

• Remove the pin from the over-travel collar.

• Press the “Reset Limits” button .

24

Page 26

INSTALLATION AND SETUP

Figure 4.4: 360° Limit Pin Installation (North of tropics).

Figure 4.5: 360° Limit Pin Installation (South of tropics).

25

Page 27

INSTALLATION AND SETUP

4.3 MOUNTING THE 2AP

Proper placement of the unit is important when installing the 2AP, as it requires a specific amount of

space to operate. Refer to section 4.7 for additional information on how to mount and configure the

2AP as a Positioner instead of as a Suntracker.

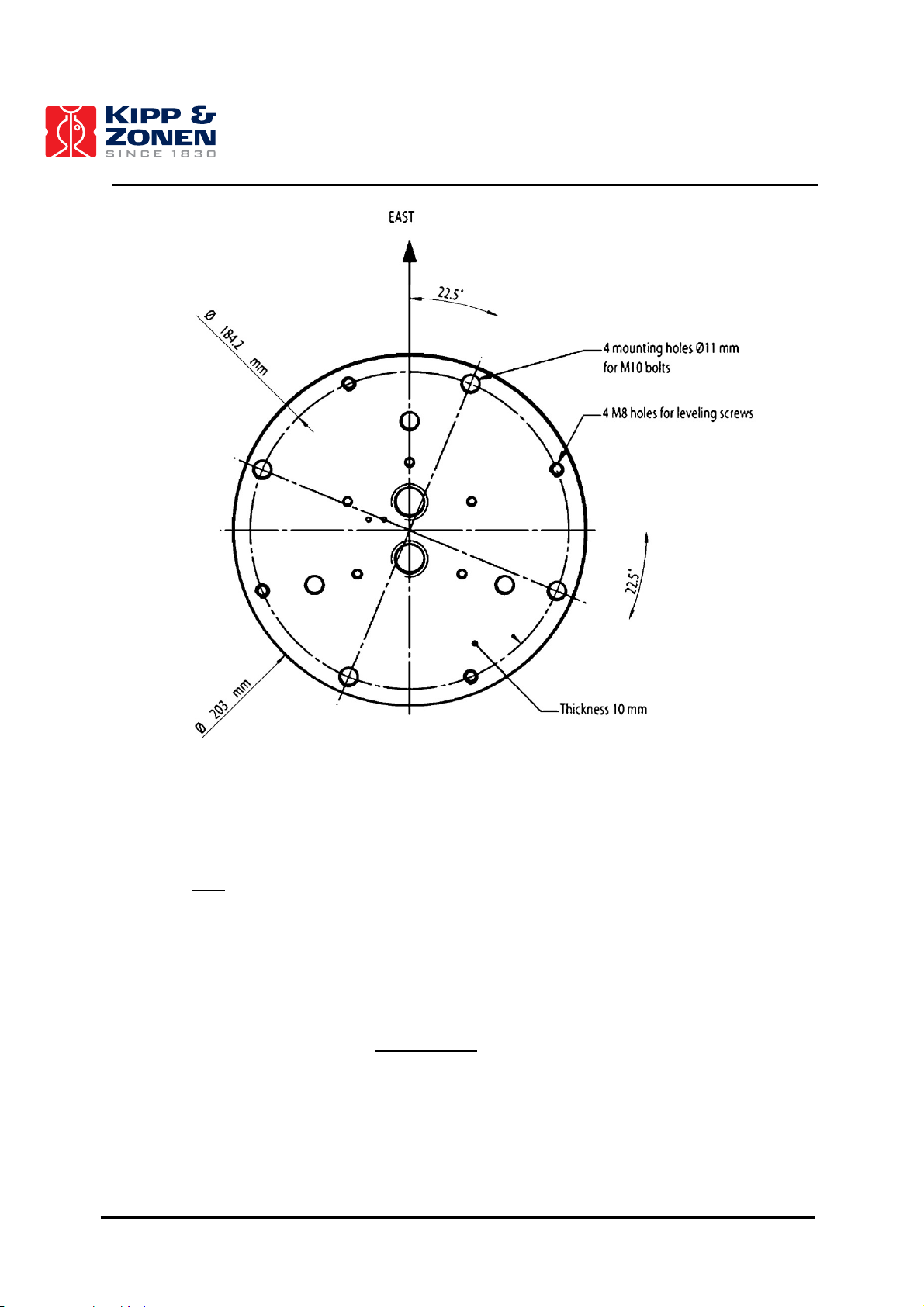

The 2AP is supplied with a standard ∅ 203 mm bottom flange, which has a 4-hole (∅ 11 mm)

mounting pattern to match that of the optional Height Extension Tube and Tripod Floor Stand with

levelling feet. See section 4.5.1 on how to install the optional Tripod.

The Height Extension Tube is an optional accessory. It extends the height of the 2AP by 60 cm.

Without the Height Extension Tube the 2AP can be mounted directly onto the mounting flange of

the Tripod Floor Stand.

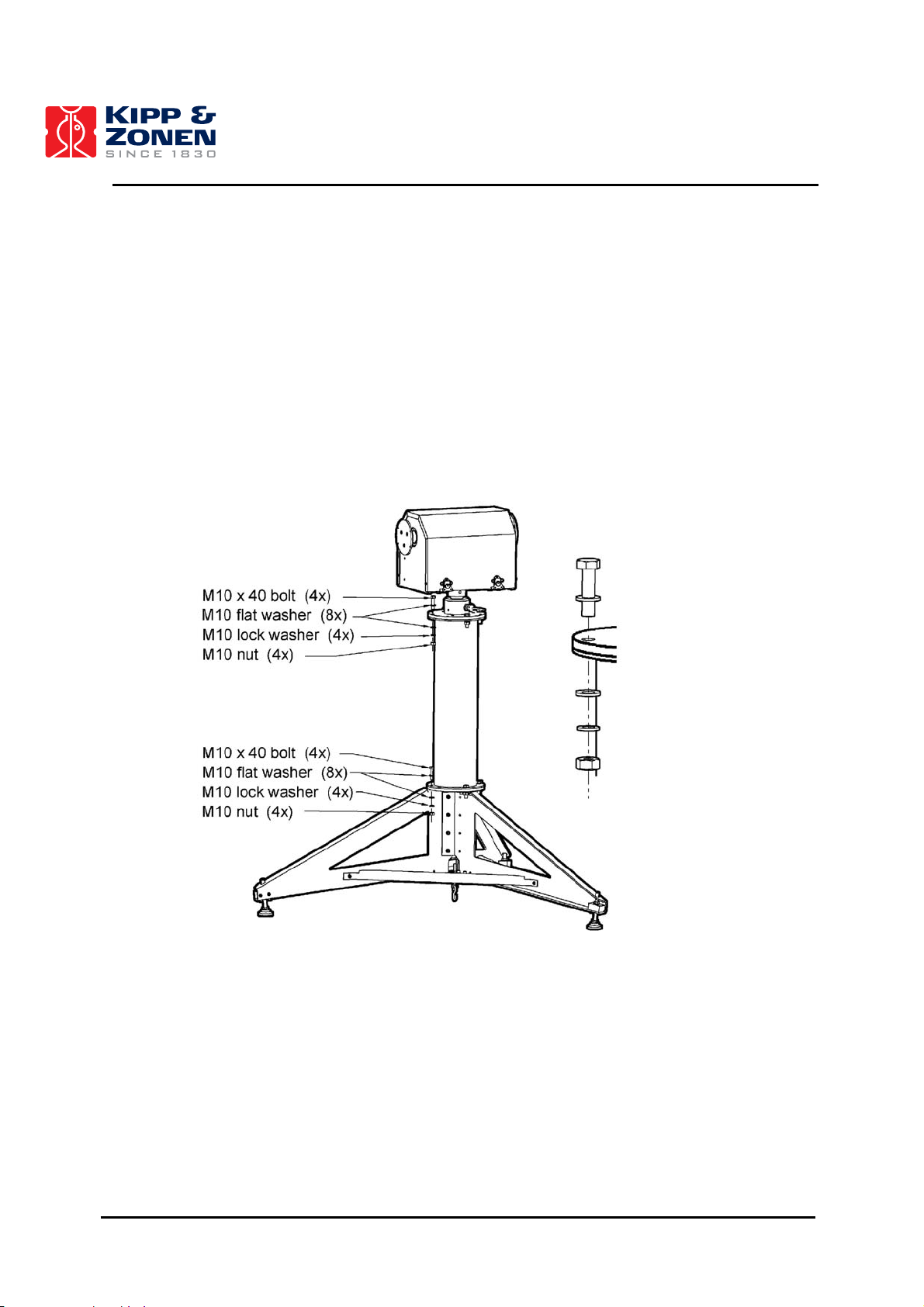

Figure 4.6: Mounting the 2AP on the Height Extension Tube and Tripod Floor Stand.

If it is intended to mount the 2AP on a customer-supplied platform, the bottom flange contains an

extra set of 4 holes, which are threaded, and a set of levelling screws. See figure 4.7 for details of

the bottom flange mounting hole pattern and thread type.

26

Page 28

INSTALLATION AND SETUP

Figure 4.7: 2AP Bottom Flange Dimensions.

When the 2AP is set up as a Suntracker the "E" label on the shaft and arrow on the bottom flange of

the 2AP must

be facing geographical East. Preliminary orientation will do at this stage of the Setup.

How to fine-tune the Azimuth orientation of the 2AP will be explained later on, in the Sighting

Adjustment Procedure.

Tip: For now, when installed as a Suntracker an initial Azimuth orientation due East with the

help of a compass will do. In the Home Position the 2AP Zenith axis is perpendicular to

the "E" label on the Azimuth shaft. So with the "E" label pointing due east, the Zenith axis

is pointing North-South.

Note: When the 2AP is used as Positioner only

the 2AP does not necessarily need to be

mounted facing the East. See section 4.7 of this manual for full information about the

different mounting and configuration possibilities for the Positioner purpose.

27

Page 29

INSTALLATION AND SETUP

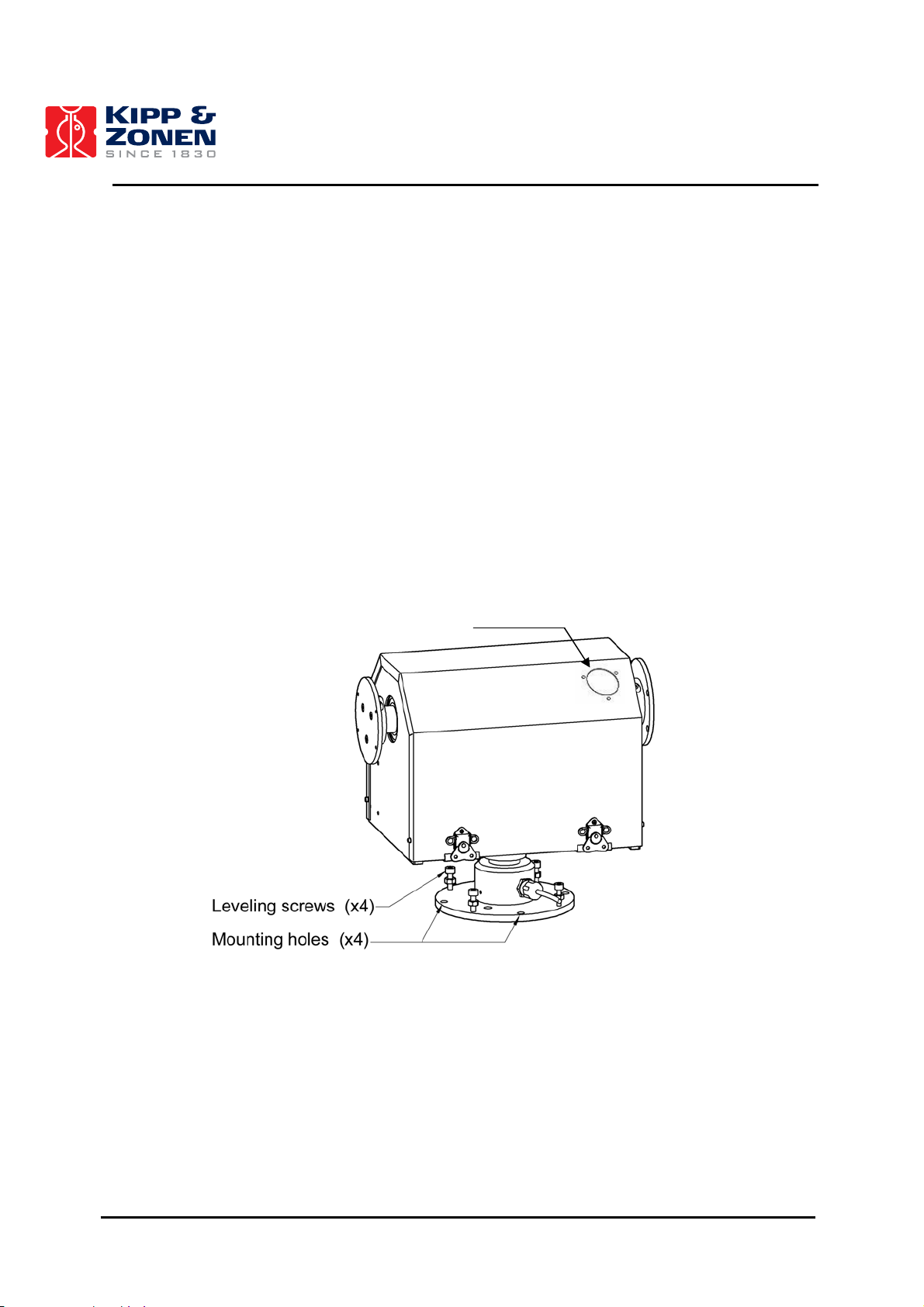

4.4 LEVELLING THE 2AP

For proper operation the 2AP must be levelled correctly on its stand. The 2AP levelling can be done

either by means of the four supplied levelling screws for mounting on a flat surface or by the three

levelling feet on the optional Tripod Floor Stand.

Prior to configuring the 2AP, it should be levelled on its mounting surface. To help accomplish this

task, the 2AP Gear Drive is equipped with a high accuracy bubble level visible through the viewing

window in the instrument cover.

• The standard bottom flange can function as levelling unit, if the 2AP was purchased without

the optional Tripod Floor Stand. With the main mounting bolts loosened off slightly, adjust

the levelling screws to move the bubble into the center of the level. Once the 2AP is level,

secure the levelling screws in place with the locking nuts and tighten the main mounting

bolts to ensure there will be no movement during operation, see figure 4.8.

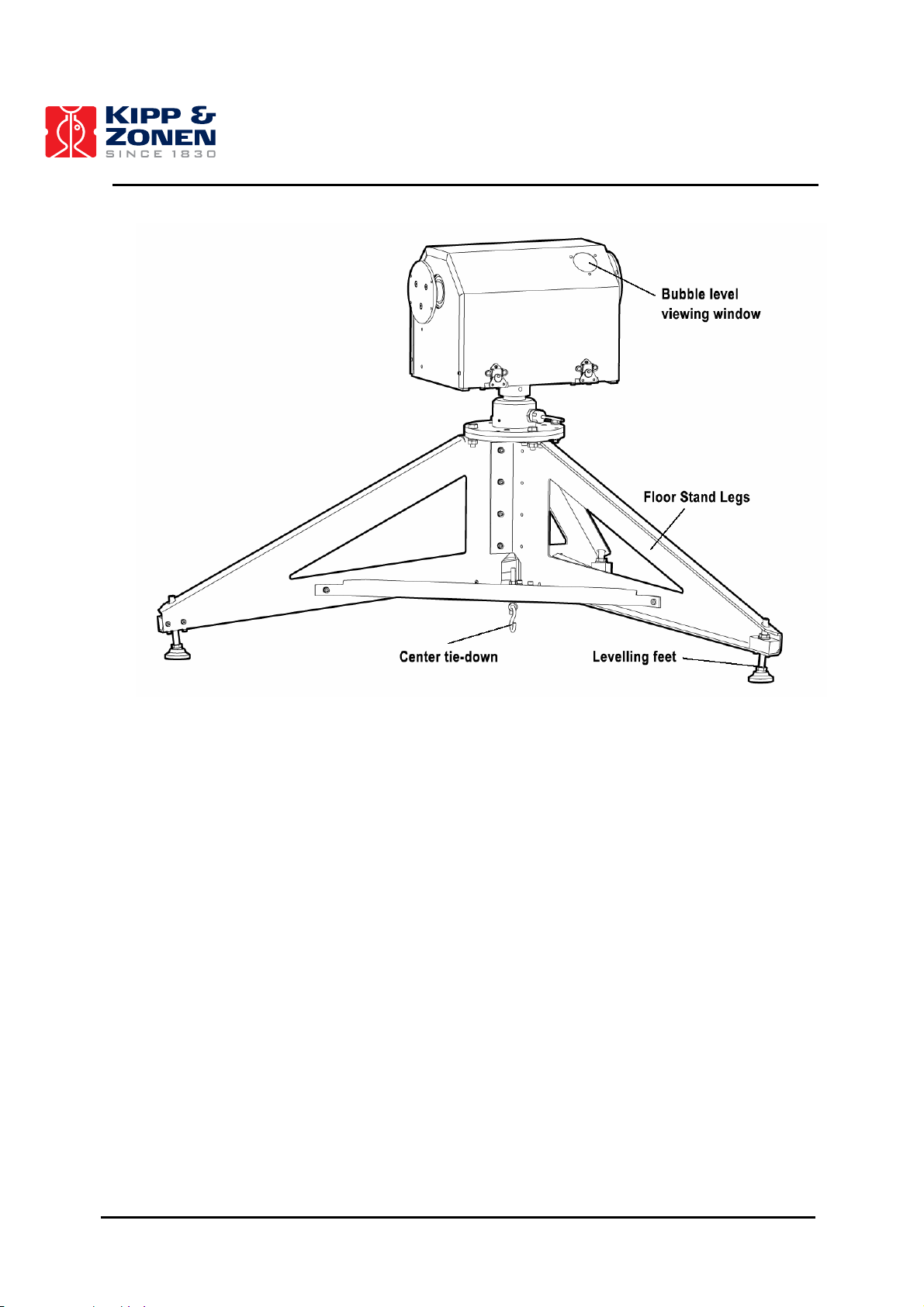

• If the 2AP was purchased with the optional Tripod Floor Stand the unit can be leveled using

the three levelling feet on the Stand. Adjust the levelling feet to move the bubble into the

center of the level, see figure 4.9.

Figure 4.8: Levelling 2AP without Tripod.

Bubble level

Viewing window

28

Page 30

INSTALLATION AND SETUP

Figure 4.9: Optional Tripod Floor Stand.

4.5 ACCESSORY INSTALLATION

This chapter provides all the information on the accessory installation of a 2AP set up. This

information is also given in the Win2AP software.

4.5.1 Tripod Floor Stand

The Tripod Floor Stand provides a solid and convenient means of mounting the 2AP for all aspects

of operation. Its heavy gauge aluminium construction and hardened paint finish ensure long lasting

durability in all weather conditions. It is equipped with three adjustable feet for easy levelling. Figure

4.11 shows the stand with applicable operating dimensions. Section 4.4 advises on how to level the

2AP properly.

29

Page 31

INSTALLATION AND SETUP

Figure 4.10: Tripod Stand Assembly

Figure 4.11: Tripod Floor Stand Dimensions.

30

Page 32

INSTALLATION AND SETUP

4.5.2 Rear Mounting Plate

Attach the two Upright Side Plates with insulating spacer bars onto the chassis first. You may have

to loosen the side plate screws on one side to get the Top Plate's holes to line up, see figure 4.12.

Do not completely tighten any top plate screws until all the screws have been installed.

Figure 4.12: Attaching Rear Mounting Plate.

31

Page 33

INSTALLATION AND SETUP

There are two mounting configurations for the Rear Mounting Plate height location, see figure 4.13:

• The higher position, specially designated for ventilated Kipp & Zonen Pyranometers. This

has a height of 129.5 mm with respect to the centres of the shading spheres.

• The lower position, which has a height of 171.7 mm with respect to the centres of the

shading spheres. This allows larger instruments to be mounted.

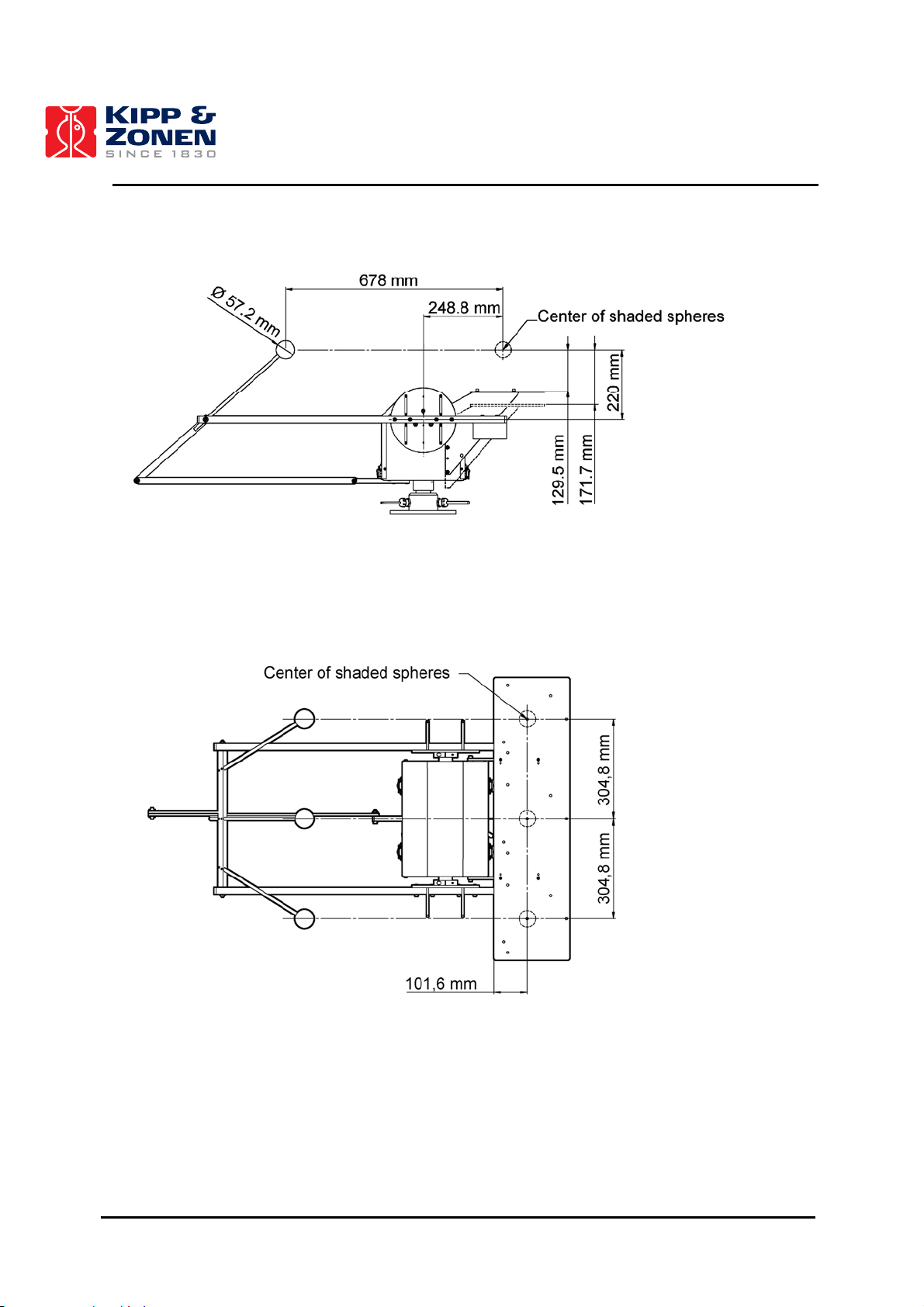

Figure 4.13: Upright Plate Mounting Patterns.

See figures 4.14 and 4.15 for more information on the height of the Rear Mounting Plate with

respect to the centres of the shading spheres of the Pointing & Shading Ball Assembly.

32

Page 34

INSTALLATION AND SETUP

Figure 4.14: Recommended Instrument Layout (Side View).

Figure 4.15: Recommended Instrument Layout (Top View).

33

Page 35

INSTALLATION AND SETUP

4.5.3 Large Side Mounting Plate

The 2AP is supplied with two standard 127 mm diameter by 6 mm thick instrument Side Mounting

Plates. Each plate is fastened to a split clamp and secured to the Zenith shaft using a cap screw.

Optional are the 203 mm diameter by 6 mm thick Large Side Mounting Plates, which are designed

to be used in conjunction with the Pointing & Shading Ball Assembly. The supplied plates can be

customized to meet your specific configuration requirements. The hole patterns of both the

Standard and the Large Side Mounting Plates are given in figures 4.16 and 4.17.

Figure 4.16: Standard Side Mounting Plate Hole Pattern.

Figure 4.17: Large Side Mounting Plate Hole Pattern.

34

Page 36

INSTALLATION AND SETUP

Prior to mounting the Large Side Mounting Plates, ensure that the 2AP is levelled (according to

section 4.4) and set to the reference position. If the optional Rear Mounting Plate is not installed yet

it is recommended to do this first, as the Large Side Mounting Plates cover the mounting holes of

the Rear Mounting Plate. The Large Side Mounting Plates need to be levelled and aligned properly

to ensure accurate pointing once the 2AP is tracking the sun.

Tip: If a Sun Sensor is to be mounted on one of the Large Side Mounting Plates it will be

easier to mount the special Sun Sensor Clamps with Adjustable Screws first, before

mounting the Large Side Mounting Plate to the zenith shaft, see figure 4.27.

• Level the 2AP according to section 4.4, Levelling The 2AP.

• Before continuing with the assembly of the Large Side Mounting Plate, press the “Home

Position” button in the Suntracker Setup Procedure (page 7 of Win2AP).

• Pre-assemble the Large Side Mounting Plate as shown in figure 4.18 and attach the Side

Plate Assembly to the Zenith shaft. Ensure that the plates are pushed up against the end of

the Zenith shaft.

• Check the circular bubble level once more to verify that the 2AP is still properly leveled.

• As shown in figure 4.19, use a tubular type bubble (spirit) level to level the mounting

clamps. Place the bubble level on the top side clamps. It may be helpful to install one of the

Shading Drive Arms (figure 4.22) to complete this task.

• Tighten the single screw inside the clamp collar to securely clamp it to the shaft.

• Tighten the three screws to securely attach the large side plate to the Clamp Collar.

• Recheck the bubble level on the Side Clamps. If they moved during tightening, slightly

loosen the screws and repeat the process.

Figure 4.18: Pre-assembling Large Side Mounting Plates.

35

Page 37

INSTALLATION AND SETUP

Figure 4.19: Large Side Mounting Plates Levelling.

36

Page 38

INSTALLATION AND SETUP

4.5.4 Pointing and Shading Ball Assembly

The Pointing and Shading Ball Assembly is comprised of several components which, when

assembled to the 2AP, provide a mechanical assembly to ensure accurate shading during normal

solar tracking operations, see figure 4.20.

Figure 4.20: Pointing & Shading Ball Assembly

Section 4.5.6 contains more information on the recommended Rear Mounting Plate layout for the

pyranometers to operate in conjunction with the Shading Balls.

Listed below is a recommended sequence of assembly:

• Install the Lower Pivot Bar on the underside of the chassis bottom plate with designated

screws, see figure 4.21.

• Attach both the Shading Drive Arms with the designated screws. Ensure the counter

weights are facing down. Do not completely tighten the screws yet, some room for installing

the T-bar is required, see figure 4.22.

• Install the T-Bar (without ball rods) as shown in figure 4.23. Install the plastic shoulder

washers onto the threaded studs of the T-Bar. Insert the shoulder washers into the side arm

end holes. Install the outer flat washers and the locking nuts ensuring that all the bushings

are properly seated into the side arms. Only loosely install the locking nuts at this stage.

37

Page 39

INSTALLATION AND SETUP

• Tighten the Side Arm screws. Now tighten the T-Bar locking nuts until most of the clearance

is gone between the arms and shoulder washers. Do not tighten snugly, ensure that the TBar rotates freely but has minimal sideways movement.

• Install the Shading Support Arm to the T-Bar, see figure 4.24. Install the shoulder washers

into the holes as shown. Only tighten the locking nut to minimize clearances, ensure free

rotational movement.

• Install the other end of the Shading Support Arm to the Shading Pivot Bar hole with the

nylon washers and locking nut shown in figure 4.25. Only tighten the locking nut to minimize

clearances, ensure free rotational movement.

• Install the Shading Ball Rods by sliding them into the designated holes. See figure 4.26 for

preliminary positioning of the Ball Rods in the T-Bar. Fine-tuning of the Ball Rods must be

done later in the setup after the Verification of Levelling Procedure. DO NOT OVERTIGHTEN the locking screws, it would make fine-tuning adjustments difficult later in the

procedure.

Note: To verify that the Shading Assembly will not interfere with any obstructions, press the

“Shading Assembly Motion Test” button. This will cycle the Suntracker through a complete

range of motion. Press the “Stop” button at any time to halt the testing motion.

• Mark the “Test Successful” checkbox to complete the Pointing and shading Ball Assembly

procedure.

Figure 4.21: Attaching Pivot Bar

38

Page 40

INSTALLATION AND SETUP

Figure 4.22: Attaching Side Drive Arms

Figure 4.23: Pivot Joint “A” Assembly

39

Page 41

INSTALLATION AND SETUP

Figure 4.24: Pivot Joint “B” Assembly

Figure 4.25: Pivot Joint “C” Assembly

40

Page 42

INSTALLATION AND SETUP

Figure 4.26: Shading Ball Rods Installation

4.5.5 Sun Sensor

The optional Sun Sensor accessory consists of a quadrant sensor fitted within a weather resistant

enclosure with 2AP mounting hard-ware and associated software. A 2AP with Sun Sensor can be

set to three different modes during operation:

1. Suntracking mode:

Normal mode provides operation where the 2AP follows a calculated solar position and logs the

deviation to the measured position. Also the only 2AP suntracking mode if no Sun Sensor is

attached.

2. Active mode:

When the sun is present this mode provides operation where the 2AP follows a measured solar

position and logs the deviation to the calculated position.

3. Correcting Time:

When the sun is present this mode provides operation where the 2AP follows a measured solar

position and logs the deviation to the calculated position. This mode enables the 2AP to correct

for any possible clock drift of the controller board.

41

Page 43

INSTALLATION AND SETUP

4.5.5.1 Sun Sensor Installation

The installation of the Sun Sensor is as follows:

• Remove two of the standard Pyrheliometer Clamps on a Large Side Mounting Plate.

• Instead attach the Adjustable Mounting Clamps supplied with the Sun Sensor Kit to the

Side Plate with the designated screws in the same manner as the Pyrheliometer Clamps,

see figure 4.27.

Figure 4.27: Attaching Sun Sensor with Adjustable Clamps.

Tip: It is recommended to change the Adjustable Mounting Clamps for the Sun Sensor before

going to the 2AP installation site. The standard clamps on the Large Side Mounting Plate

might be difficult to remove on-site.

Important:

Turn off the supply power to the 2AP before proceeding.

• Install the Extension Springs (x2) with the designated screws and washers. Do not tighten

the screws yet, leave some space.

• Ensure that the four Aluminium Adjusting Screws are not protruding past the inside surface

of the clamp. This will allow the Sun Sensor to mate up with the Base Clamp under the

Spring.

• Slide the Sun Sensor through the clamps and the springs. Ensure that the Sun Sensor is

mounted so that it’s decal is on top (facing upwards) and the protuding screw on the Sun

Sensor is facing down. The protruding screw is on the bottom of the Sun Sensor (not visible

in the diagram).

42

Page 44

INSTALLATION AND SETUP

• Ensure the Adjusting Screws are not touching the Sun Sensor body yet, this will be good

enough for a rough initial alignment.

• Tighten the screws which hold the springs.

• Pass the ground terminal and connector leads through the strain relief bushing, see figure

4.28.

Note: If the Strain Relief Bushing (Cable Gland) was not already installed at the factory, you will

have to install the supplied bushing into the underside of the chassis bottom plate.

Remove the plastic plug and then apply thread sealant/lubricant to the bushing threads.

Tighten the bushing into the plate snugly. Take care to not over-tighten the bushing;

removal in the future could be difficult.

Figure 4.28: Routing Sun Sensor Cable

• Once the cable has been routed as shown and secured in the Strain Relief Bushing, the

electrical connections can be made. Connect the Sun Sensor ground wire (ring-tongue

terminal) to the chassis, see figure 4.28.

• Clamp the ferrite core around the cable, as shown in the diagram above

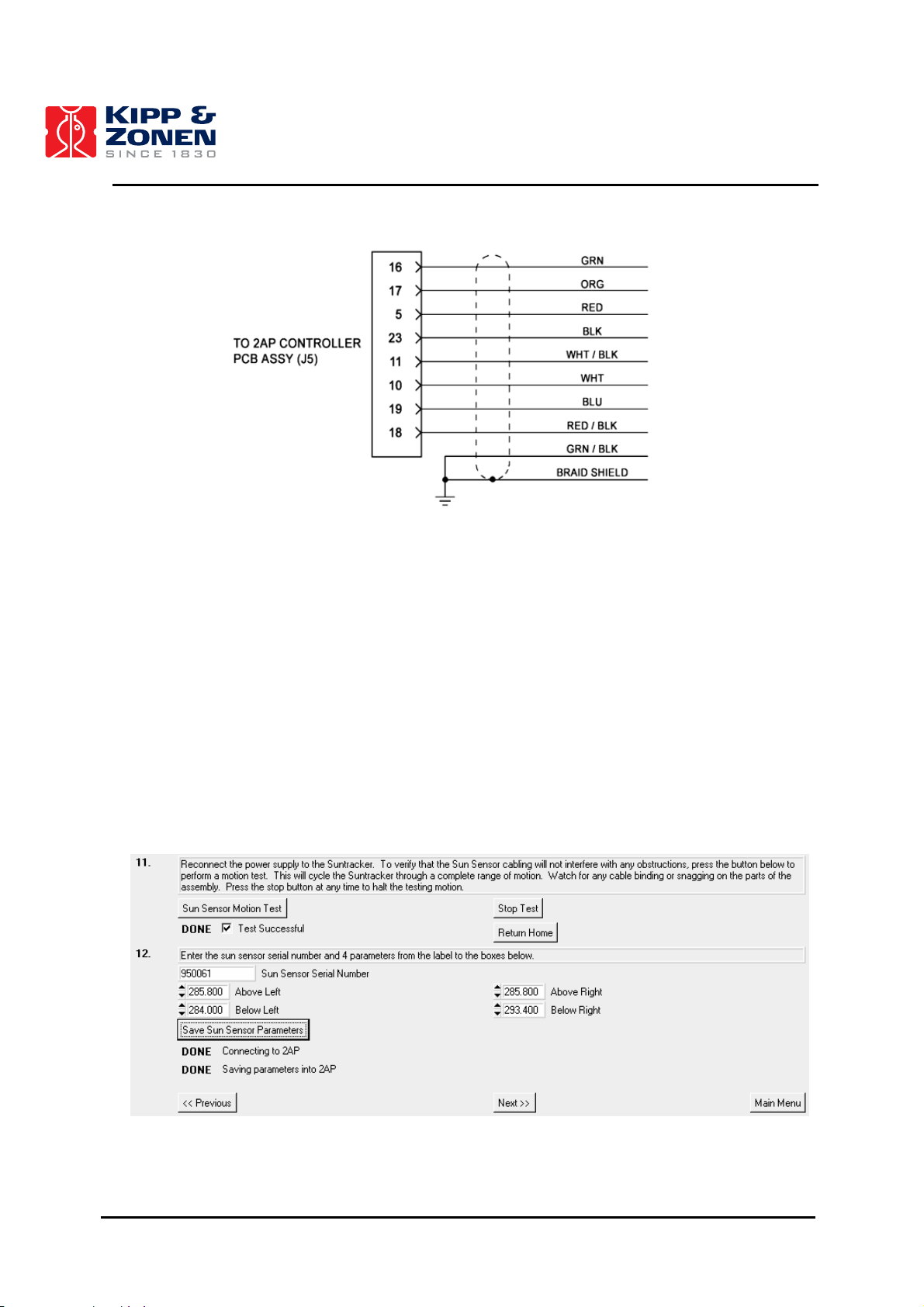

• Insert the connector pins from the end of the Sun Sensor cable into the j5 connector of the

wiring harness as per schematic, see figure 4.29.

• Turn on the supply power to the 2AP after the Sun Sensor cable has been connected.

• Press the “Sun Sensor Motion Test” button, this will cycle the Suntracker through a

complete range of motion. Watch for any possible cable binding or snagging.

43

Page 45

INSTALLATION AND SETUP

Figure 4.29: Sun Sensor Wire Connections.

Tip: It may be helpful to temporarily disconnect the connector from the PC board to install the

pins. A pin insertion & extraction tool is included to aid in this step (or removal, if required).

4.5.5.2 Setting Sun Sensor Parameters

The Sun Sensor is provided with a four-quadrant photodiode. Each quadrant has its own calibration

factor. To access the relevant page to set the Sun Sensor parameters, the optional Sun Sensor

needs to be selected in the “Post Delivery Check” in the Win2AP software. Selecting it will make

page 7 of the “Suntracker Setup Procedure” become accessible. Enter the Sun Sensor serial

number and the four calibration parameters in the designated boxes, see figure 4.30. Pressing the

“Save Sun Sensor Parameters” button will save the parameters into the 2AP.

Figure 4.30: Setting Sun Sensor Parameters

44

Page 46

INSTALLATION AND SETUP

4.5.6 Attaching Instruments to the 2AP

This section describes how to attach Kipp & Zonen radiometers for diffuse and direct solar

measurements. Section 4.5.6.3 provides additional information on the installation of other than

Kipp & Zonen instruments.

The 2AP is specially designed for direct and diffuse sunlight measurement applications. The

Shading Assembly provides mounting for three shaded pyranometers (diffuse radiation). Two Large

Side Mounting Plates provide mounting for 4 pyrheliometers, or 3 pyrheliometers and 1 Sun Sensor.

4.5.6.1 Attaching Kipp & Zonen Radiometers to the Large Side Mounting Plates

Figure 4.31 shows how to install Kipp & Zonen Pyrheliometers on the Large Side Mounting Plates.

See the Kipp & Zonen CH 1 Pyrheliometer and the datalogger installation manuals for more

information.

Figure 4.31: Pyrheliometer Installation Diagram.

Important: Mount the Pyrheliometer in the clamps far away enough from the Rear Mounting

Plate, such that the rear visor plate cannot hit the plate.

4.5.6.2 Attaching Kipp & Zonen Radiometers to the Rear Mounting Plate

A 2AP with Pointing & Shading Ball Assembly provides the ability to measure diffuse light irradiance

with up to three pyranometers/pyrgeometers. The 2AP Pointing and Shading Assembly is designed

for Kipp & Zonen radiometers fitted with the CV2 Ventilation System. Adapters for raising the

radiometers must be used to fill in the space when CV2 ventilation units are not used.

Figure 4.32 shows an example of how to install a Kipp & Zonen Pyranometer with CV 2 Ventilation

Unit on the Rear Mounting Plate. Figure 4.33 shows how to install a Kipp & Zonen Pyranometer

with adapter on the Rear Mounting Plate. Ensure that the radiometers are securely retained on the

Rear Mounting Plate. At a later stage, after verification of levelling of the 2AP, fine-tuning of the

radiometers will be required. See the Kipp & Zonen Pyranometer/Pyrgeometer instruction manual

for more information.

45

Page 47

INSTALLATION AND SETUP

Figure 4.32: Kipp & Zonen Pyranometer with CV 2 Installation Diagram.

Figure 4.33: Kipp & Zonen Pyranometer with Adapter Installation Diagram.

46

Page 48

INSTALLATION AND SETUP

The Win2AP Pyranometer Installation page is provided with a button to perform a motion test (page

9 of the Suntracker Setup Procedure). This allows verification that the installed instrumentation and

cabling will not interfere with any obstructions around the Suntracker Assembly. The Motion Test

procedure will cycle the Suntracker through a complete range of motion. Watch for any cable

binding or snagging. Press the stop button at any time to halt the testing motion.

Additional CV2 information:

The CV2 Ventilation Unit is designed for ventilating Kipp & Zonen solar radiation sensors

(pyranometers and pyrgeometers) and can be used outdoors under all weather conditions. The CV2

is available with or without a heater, see table 5. The reliability and accuracy of solar radiation

measurements are improved significantly by using this controlled heated airflow over the

radiometer. The main advantages of ventilating are:

1. No precipitation of morning dew, which otherwise would disturb the measurement.

2. No deposition of hoarfrost, which otherwise would disturb the measurement (heater

necessary).

3. Less infrared offset, due to infrared radiation exchange between the sensor element and

the glass dome under calm clear sky conditions.

Table 5: CV 2 Specifications.

Ventilation power

5 Watt continuous

Heating (optional) 5 Watt and 10 Watt

Operating temperature -30ºC to +70ºC

Air temperature rise caused by CV 2

< 0.25 K @ 0 Watt (blower only)

< 0.5 K @ 5 Watt (heater)

< 1 K @ 10 Watt (heater)

Offset caused by heater < 1 W/m2 using pyranometer CM11

Cable length 10 m

Power required 12 Volt DC, 1.25 A (with heater)

47

Page 49

4. INSTALLATION AND SETUP

INSTALLATION AND SETUP

4.5.6.3 Installation of other than Kipp & Zonen Instruments

The Manual and Win2AP software include diagrams that can be used to customize the accessories

to fit instruments other than those manufactured by Kipp & Zonen. This section also allows for the

mounting of equipment such as cameras when the 2AP is used as a Positioner.

Information: Points of consideration

Rear Mounting Plate:

Mounted in the lower position the Rear Mounting Plate can be used to gain height for instalment of

taller instruments. It might be necessary to customize special adapters to align with the centres of

the shaded spheres of the Pointing & Shading Ball Assembly. In combination with the Pointing &

Shading Ball Assembly the Rear Mounting Plate must not be mounted any lower than the

designated lower mounting hole pattern of the Upright Plates. This is to avoid the Shading Drive

Arms hitting the Rear Mounting Plate. See figure 4.14 and 4.15 for more information regarding the

dimensions of the centres of the shaded spheres.

Large Side Mounting Plates on the Gear Drive:

The Gear Drive is the heavy-duty version of the 2AP and can handle Side Plate payloads up to 65

kg, counter weights included. The Gear Drive also maintains its torque (and therefore its position)

when the power is turned off.

4.5.7 Cold Weather Cover

A standard 2AP has an operating temperature range of 0°C to +50°C. For remote locations with

harsh temperature conditions, the Cold Weather Cover combined with two (optional) 50W –

115/230V internal heaters can increase the operating range to -50°C to +50°C, see table 6.

Table 6: 2AP Operating Temperature Range.

Standard 2AP

2AP with Cold Weather Cover

2AP with Cold Weather Cover and Heater Kit

2AP with Cold Weather Cover and Extreme

Heater Kit

0°C to +50°C

-20°C to +50°C

-50°C to +50°C

-50°C to +50°C (prolonged exposure and

severe wind-chill)

The Cold Weather Cover is made of a durable nylon shell filled with insulation and provides

excellent protection in all weather conditions. The cover installs easily by slipping over the main

body of the 2AP and is equipped with convenient fastening flaps for quick and simple installation.

The 2AP Cold Weather Cover is designed to fit both the standard 2AP and a unit fitted with all

accessories. For a standard 2AP with no Shading Arms or Rear Mounting Plate, installation of the

cover is possible from both sides of the unit. For a 2AP fitted with the Shading Arms and Rear

Mounting Plate the cover must be installed from the Shading Arm side, allowing the Rear Upright

Mounting Plates to pass through the open seams on both sides.

The optional internal heaters must be factory-installed prior to delivery. The Extreme Heater Kit is

strongly recommended for harsh climates, such as Polar regions. Extra heating elements will

protect the 2AP against the extreme continuous cold and severe wind-chill and the extra torque of

the GD is capable of breaking ice that may form around the shafts of the 2AP.

48

Page 50

INSTALLATION AND SETUP

4.6 COMMISSIONING 2AP AS SUNTRACKER

The procedures described in this section are essential to insure good performance during operation.

Commissioning a 2AP covers the configuration with the Win2AP software. This includes setting the

time, setting the location parameters and performance of the final Sighting Adjustments.

4.6.1 Setting the Time

This step configures the 2AP to Greenwich Mean Time (GMT), which is required by the suntracking

algorithm in the firmware. When the command is given, the Win2AP gets the time from the PC

connected to the 2AP. Ensure that you have an accurate time reference at the 2AP installation site.

Greenwich Mean Time or Coordinated Universal Time is the standard time at longitude = 0

longitude line which goes through Greenwich, England), which is used as a standard around the

world to assist in synchronizing data collection.

There are two options:

1. The PC time can be set to local time,Win2AP will take the local time zone automatically into

account and calculate the GMT.

2. If the 2AP site is in a remote place the time and time zone can be difficult to determine.

Setting the PC time and time zone directly to Greenwich Mean Time will fix the time zone

problem.

Note: To calculate GMT Win2AP relies on the Daylight Saving Time of Windows. Although it is

possible to use the local time option, be aware that this procedure is not perfect. When

using the local time option, ensure GMT is set correctly at the moment of the 2AP set up.

The only way around this is to set the time and time zone directly to GMT.

Set the PC time as follows:

• Click on the Start button on the windows Taskbar.

• Click on Control Panel under Settings.

• Double click on the Date/Time icon.

• Set the time according to your accurate time reference.

• Go to the “time zone” tab and select the appropriate time zone.

Set the 2AP time as follows:

• With the 2AP power on and communications connected to the correct serial port, start the

Win2AP program.

• Go to the “Setting Time and Location” page in the Suntracker Setup Procedure .

• Press the “Get 2AP Time” button.

• In the text box on the right the time difference between the PC and the 2AP is shown.

• The difference in time must not be more than 10 seconds.

• Press the “Set 2AP Time” button to adjust the 2AP time to the PC time.

º (the

49

Page 51

INSTALLATION AND SETUP

Figure 4.34: Setting Time, Location, Mean Local Pressure and Start Suntracking.

Main Menu, Suntracker Setup Procedure, page 12.

Note: When the time has been set directly to GMT ensure that the Time Zone is set to

Greenwich Mean Time as well.

4.6.2 Setting the Location

The 2AP requires the correct local geographical coordinates (Latitude, Longitude) and mean local

pressure to accurately track the sun, see figure 4.34. The mean local pressure is mainly dependent

on the altitude of the 2AP’s set up location.

• Enter the Latitude and Longitude in the designated boxes in decimal numbers (at least

three decimal places). Use the “North/South” and “East/West” buttons on the right to

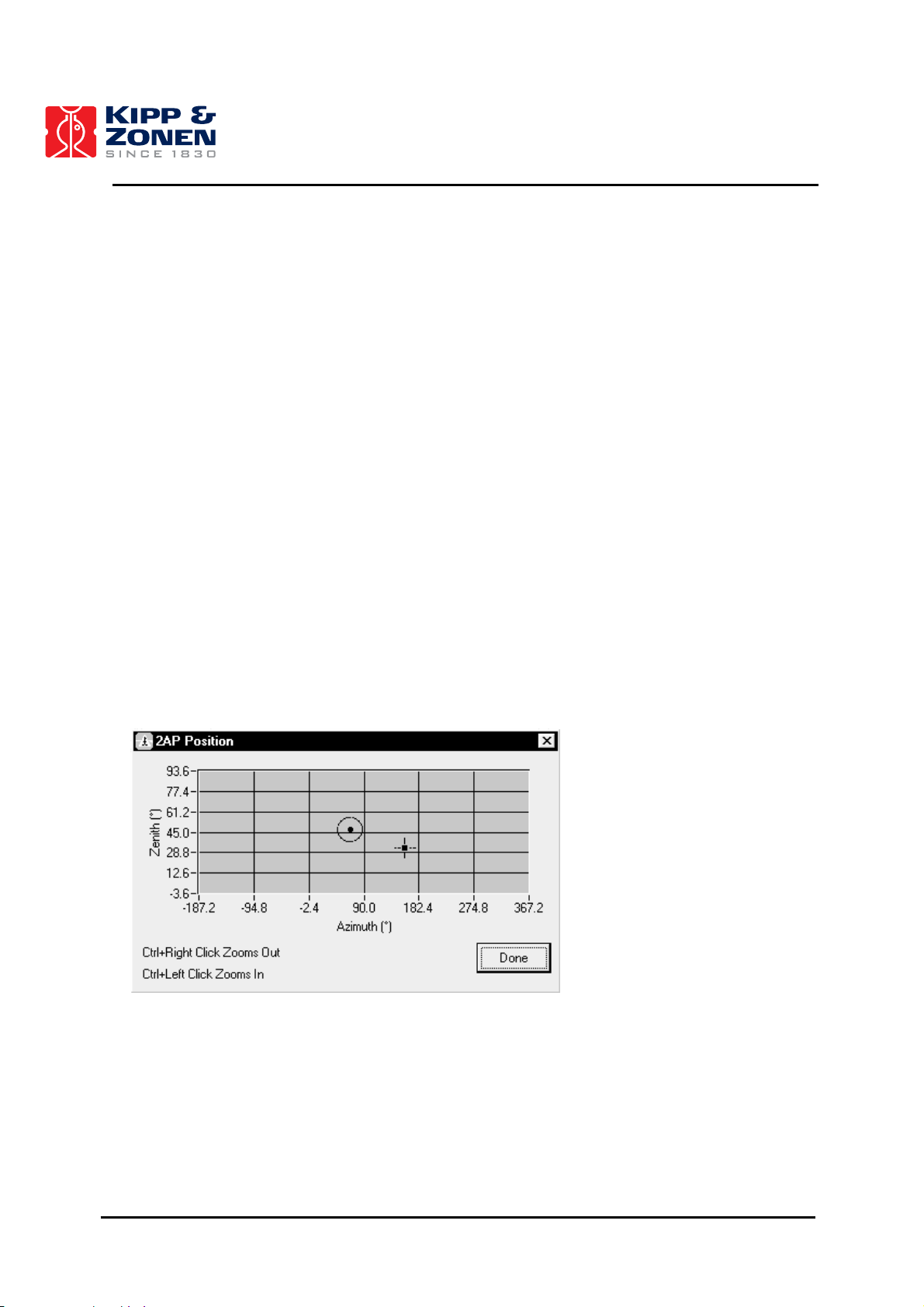

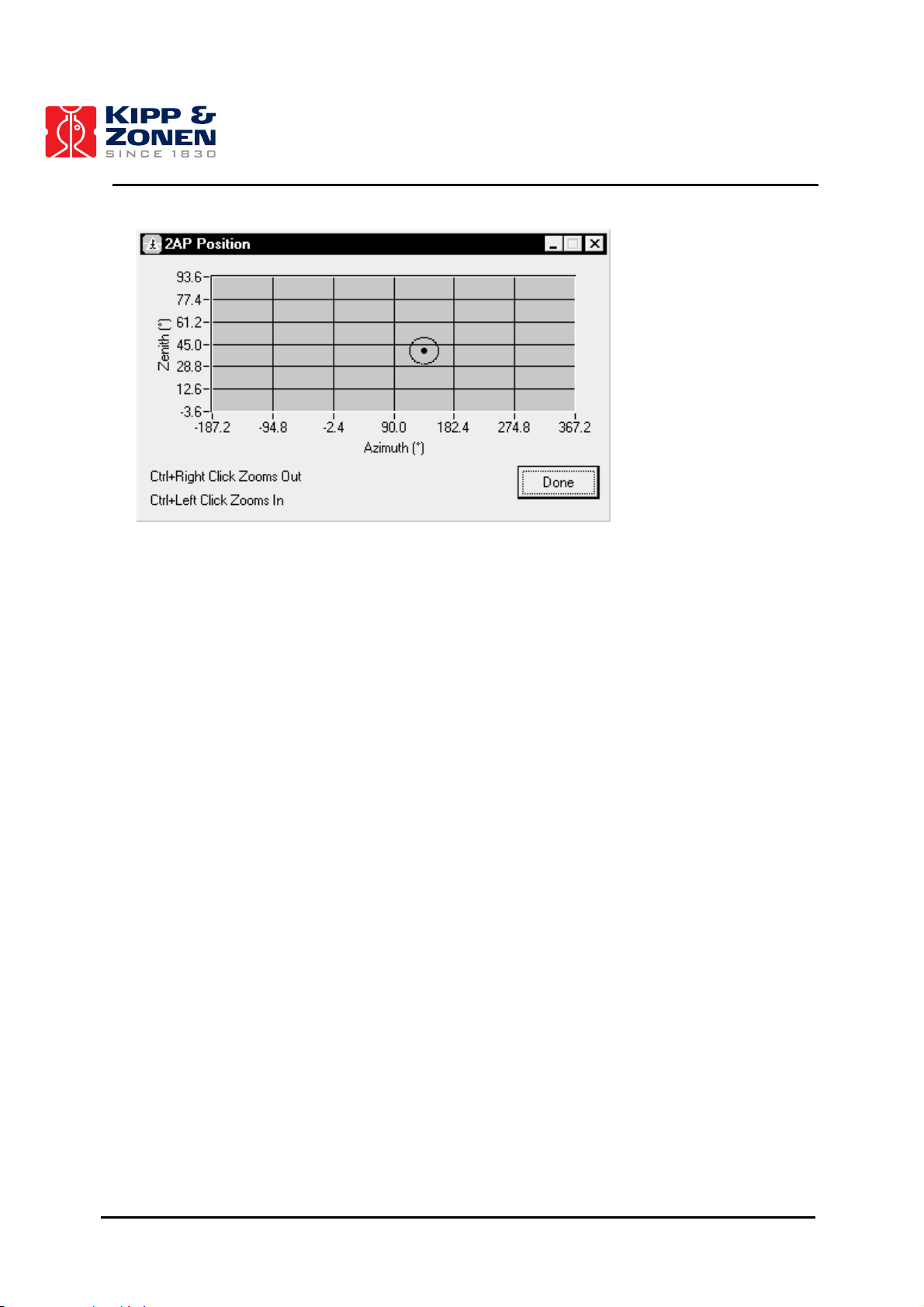

confirm the positive or negative terrestrial Hemispheres.

• Enter the mean local pressure at the site. If the mean pressure is unknown, enter the

altitude for the site (above sea level) and press the “Calculate Pressure” button. The correct

pressure will appear in the Mean Local Pressure text box.

• Press the “Set Location” button to save the instrument location into the 2AP.

50

Page 52

INSTALLATION AND SETUP

4.6.3 Start Suntracking

The time, location and pressure parameters are the necessary variables for the 2AP to calculate the

sun’s position in the sky, see figure 4.34. It is important that these variables have been entered

correctly and that the 2AP has been levelled properly. A final manual Azimuth correction can be

done during the Sighting Adjustment procedure later on.

Press the "Start Sun Tracking" button to set the 2AP function to "Sun Tracking". The "Following

Sun" indicator will light up green when this process successfully finishes (it will take a couple of

minutes to complete). Refer to the Troubleshooting procedure if "Start Sun Tracking" fails.

Now that all the accessories are installed and the 2AP is accurately levelled and located, one can

move on to the Sighting Adjustment procedure. The Sighting Adjustment procedures with and

without the optional Sun Sensor are different. Due to the selection of the optional Sun Sensor in the

“Post Delivery Check” the right procedure (with or without Sun Sensor) will be launched in the

software when pressing the “Sighting Adjustments” button.

4.6.4 Sighting Adjustment without Sun Sensor

This section applies only if you have not purchased the optional Sun Sensor.

The Sighting Adjustment will compensate for errors in the initial position of the 2AP. If, in the Home

Position, the 2AP is not pointing exactly to the East (Azimuth orientation) the Sighting Adjustment

will correct for this. This is a fixed offset. Hence it will correct for levelling inaccuracies of the (Large)

Side Mounting Plates. With the 2AP operating in Suntracking mode the sun can be used as a

pointing reference to visualise any positioning errors.

Notes: During the “Sighting Adjustment without Sun Sensor” procedure continuous sunlight is

required.

The Sighting Adjustment procedure will not compensate for a pointing error due to

levelling inaccuracies of the 2AP.

• Run the Sighting Adjustment procedure from the Main Menu of the Win2AP software.

• If the current 2AP mode shown in the text box at step 1 is not "Suntracking", select this

mode from the right.

• Go to, and finish the “Setting Time and Location” page of the Suntracker Setup Procedure if

the 2AP remains idle.

• Use one of the "Sighting Targets" of the Large Side Mounting Plate Clamps (or even better,

the "Manual Sighting Target" if an optional CH 1 Pyrheliometer is installed). The sun will

project a bright dot onto the Rear Clamp Target. If the Light Dot is not on the Target Hole,

do the following.

• If you have purchased the optional Tripod slightly lift the complete Tracker and turn it to

correct for an Azimuth error (if possible).

• Re-level the 2AP if you moved the 2AP and Tripod, to correct for the azimuth orientation.

• Step 6 of the Sighting Adjustment page can be used to correct for a possible final Azimuth

error and levelling inaccuracies of the Large Side Mounting Plates with the software. If the

Light Dot is close to, but not within the Target Hole, then an initial manual sighting will be

required. The entered corrections are interpreted as an offset.

51

Page 53

INSTALLATION AND SETUP

• It is recommended to start with the Azimuth Adjustment first (before performing any Zenith

adjustments consult the Note below). To do this, install Azimuth correction numbers (in

degrees) into the designated boxes (max. 4º at the time). Press the "Correct" button to

adjust the tracker, and wait until the "following sun" indicator is green. Repeat this step until

you have corrected for the Azimuth error.

- Azimuth Correction: Enter positive correction if 2AP is counter-clockwise (when

viewed from above), or negative correction when clockwise, from the desired position;

- Zenith Correction: Enter positive correction if 2AP is pointing above, or negative

when pointing below, the desired position.

Note: Theoretically, after correcting for the final Azimuth error, the Suntracker should be able to

follow the sun within a 0.1 degree error. However, small position, time, pressure and

levelling inaccuracies might be the reason for a remaining zenith error. Look at your

sighting target (after correcting for any Azimuth error) to get an impression of the Zenith

error due to these errors.

• Recheck the following points if necessary before adjusting for any zenith error:

1. Check if the 2AP itself is leveled properly (section 4.4).

2. Check if the time, time zone and location are set correctly (sections 4.6.1 and 4.6.2)

3. Check if the Side Plates are leveled properly (section 4.5.3)

Tip: If you are sure that the remaining Zenith error is due to levelling inaccuracies of the Large

Side Mounting Plate in the Home position (by excluding the time, location, pressure

parameters and 2AP levelling), you can unscrew the Side Plates, one by one, during

Suntracking and adjust for the Zenith error.