Kipor KDP20, KDP20E, KDP30, KDP30E, KDP40 Owner's Manual

...

All information, illustrations, directions and specifications included in this publication are

based on the latest product information available at the time of approval for printing.

KIPOR POWER CO., LTD, reserves the right to make changes without incurring any obligation.

No part of this publication may be reproduced without written permission.

SERVICE MANUAL

www.kipor.com.au

For more information contact Customer Service on 1300 555 197

Distributed by

PRIMUS AUSTRALIA PTY LTD

Bundoora VIC 3083

www.primusaustralia.com.au

PREFACE

Thank you for purchasing a Kipor Diesel Water Pump.

This manual covers the operation and maintenance of model KDP20/E, KDP30/E & KDP40/E High

Volume Water Transfer Pumps.

All information in this publication is based on the latest product information available at the time

of approval for printing.

We reserve the right to make changes at any time without notice and/or incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual should be considered a permanent part of the water pump and should remain with it

if it is resold.

Pay special attention to statements preceded by the following words;

Indicates a strong possibility of severe personal injury or death if

instructions are not followed.

Indicates a possibility of equipment damage or property damage if

instructions are not followed.

Gives helpful information.

If a problem should arise, or if you have any questions about the water pump, consult an authorised

dealer.

This water pump is designed to give safe and dependable service if operated according to the

instructions.

Read and understand the Owner's Manual before operating the water pump.

WARRANTY & SERVICE

Toll Free 1300 555 197

(for further information see page 19)

1

1. SAFETY INSTRUCTIONS

To ensure safe Operation -

•

This water pump is designed to give safe and dependable service if

operated according to instructions. Read and understand the Owner's

Manual before operating the water pump. Failure to do so could result

in personal injury or equipment damage.

•

The muffler becomes very hot during operation and remains hot for

several minutes after stopping the engine. Be careful not to touch the

muffler or exhaust system while it is hot. Let the engine cool before

storing or transporting the water pump.

•

To prevent burns, pay attention to the warning mark lo cated o n

the engine muffler.

•

Never operate the water pump in an enclosed or confined area. Exhaust

gas contains poisonous carbon monoxide gas, exposure can cause loss

of consciousness and may lead to death.

•

Diesel fuel is extremely flammable and explosive under certain

conditions. conditions. Stop the engine before refuelling – Do not overfill.

•

Keep away from cigarettes, sparks and other flammable materials when

refuelling or operating the water pump. Always refuel in a wellventilated location.

•

Wipe up spilled diesel fuel immediately.

•

For safety, never pump flammable or corrosive liquids such as petrol or

acid. To avoid pump corrosion never pump sea water, chemical

solutions, caustic liquids eg. used oil, wine or milk.

•

Always complete a pre-operation check before you start the engine. You

may prevent an accident or equipment damage.

•

Read the Owner’s Manual before use and understand the operation of

all controls especially how to stop the water pump quickly. Never allow

anyone to operate the water pump without proper instruction.

•

To prevent fire hazards and to provide adequate ventilation, keep the water pump at least 1m

(3 ft) away from any buildings or other equipment during operation. Do not place flammable

objects close to the water pump.

•

Only operate the water pump on a firm level surface.

•

Keep children and pets away from the water pump when it is in operation.

CONTENTS

1. SAFETY INSTRUCTIONS 3

2. IDENTIFICATION OF COMPONENTS 4

3. PRE-OPERATION CHECK 5

4. STARTING THE ENGINE 8

5. STOPPING THE ENGINE 10

6. MAINTENANCE 11

7. TRANSPORTING AND STORAGE 15

8. TROUBLESHOOTING 17

9. SPECIFICATIONS 18

10. WARRANTY 19

2 3

KIP224_kipor manual water pumpfinal_dieselv2.qxd:Layout 1 4/2/10 4:21 PM Page 2

3. PRE-OPERATION CHECK

•

Be sure to check the water pump is on a firm level surface with the engine stopped.

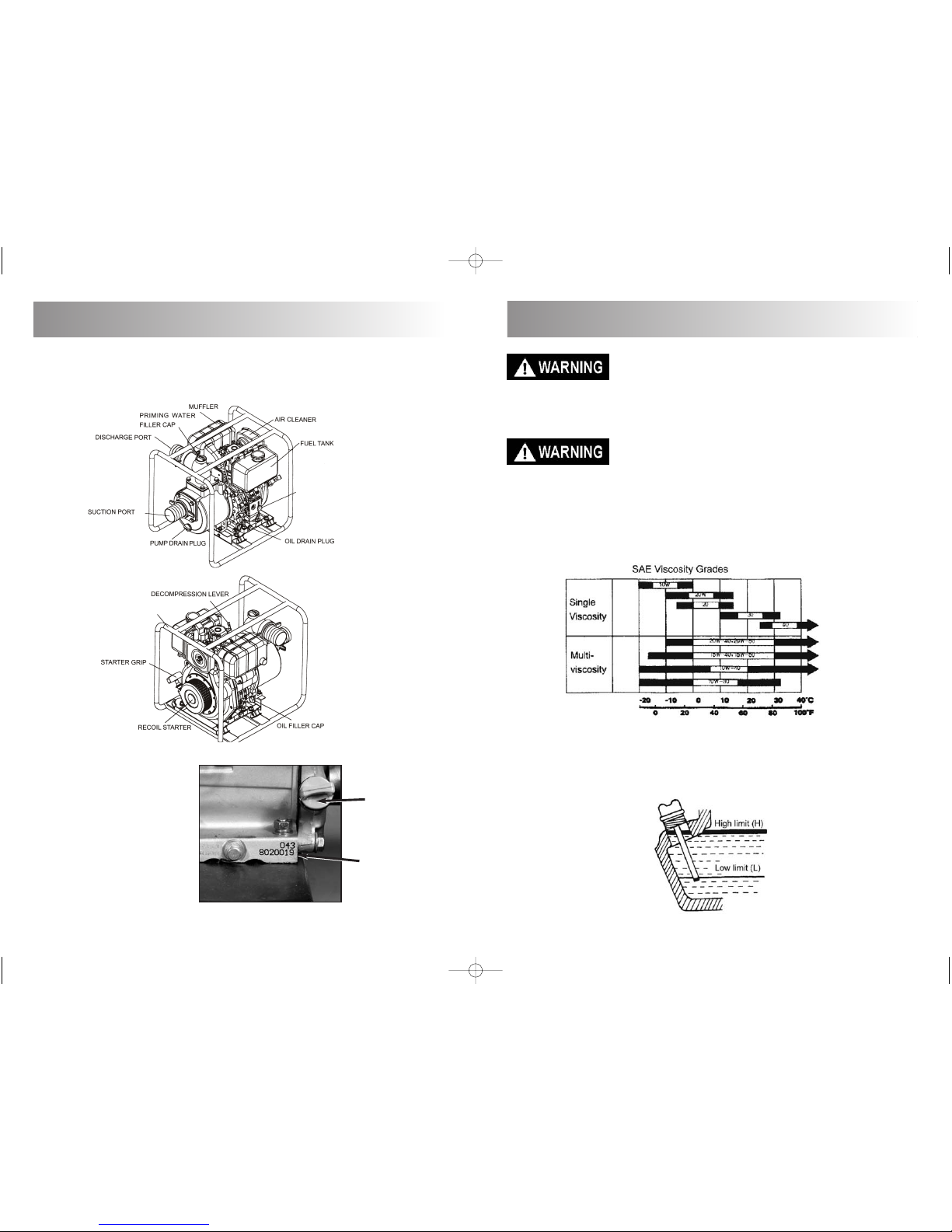

STEP 1. Check the engine oil level.

•

Using a non-detergent oil or 2-stroke engine oil could shorten the engine's service life.

It is recommended to use SAE 10W-30 Grade engine oil.

Can use Part No. 06.2251 Jamec Pemsmall engine oil 1L.

Only use a high-detergent, premium quality 4-stroke engine oil, certified to meet or exceed U.S.

automobile manufacturer's requirements for API Service Classification for diesel engines

CC/CD/CE/CF.

To Check Oil Level - Remove the oil filler dipstick, and wipe the dipstick with a clean rag.

Insert the oil filler dipstick into the filler hole without rotating it.

If the oil level is below or at the lower end of the dipstick, refill with the recommended oil up to the

upper level mark. Tighten the oil filler dipstick.

Oil Capacity:

KDP20/E 0.75L

KDP30/E 1.10L

KDP40/E 1.62L

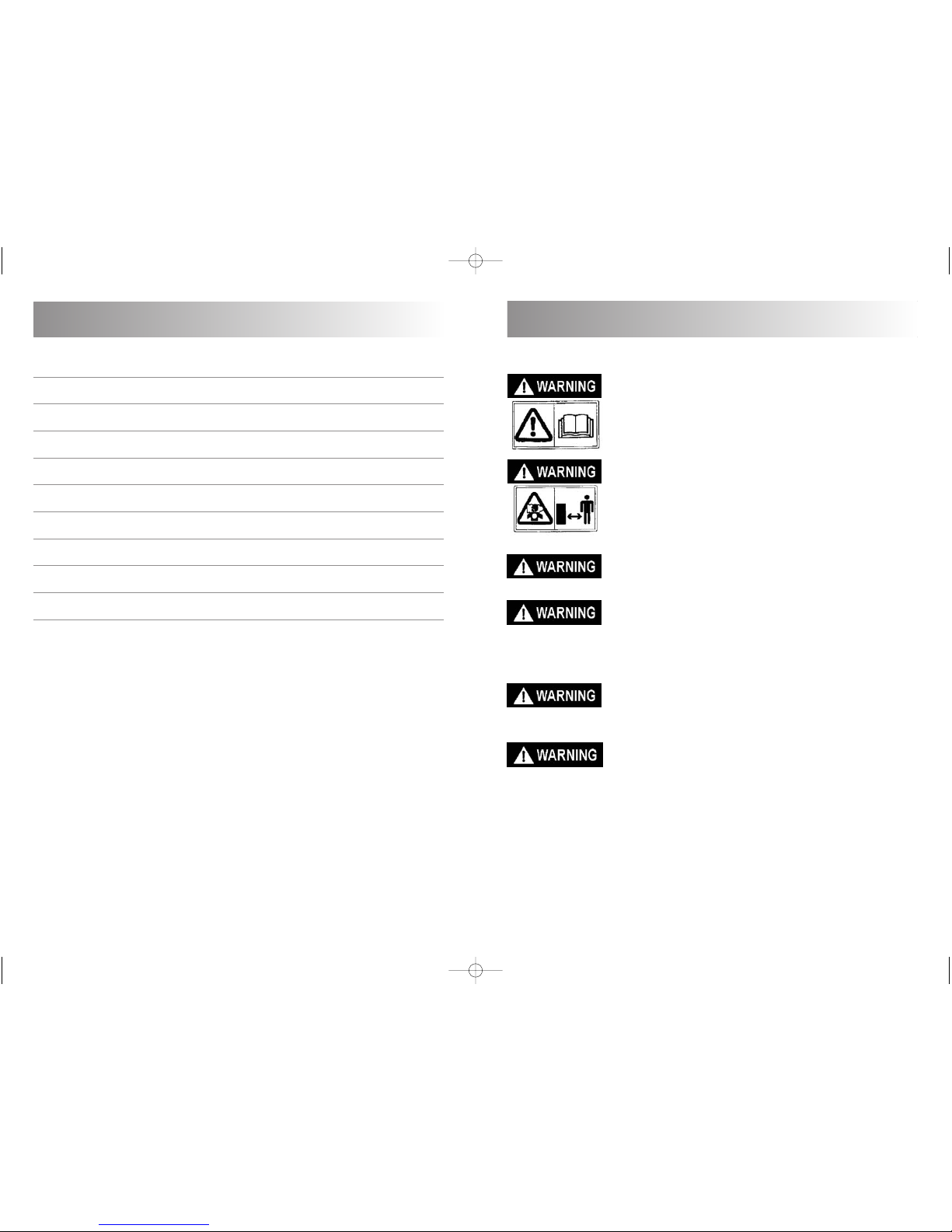

2. IDENTIFICATION OF COMPONENTS

Read all labels, safety instructions and precautions described in this Owner’s Manual carefully.

These labels warn you of potential hazards that can cause serious injury.

If a label comes off or becomes hard to read, contact your authorised dealer for a replacement.

SERIAL NUMBER LOCATION

The serial number identifies the

particular water pump and is

important when ordering spare

parts for any warranty or

service maintenance.

The serial number can be found

stamped on the engine block

below the oil filler dipstick.

4 5

Serial Number

Oil Filler Dipstick

THROTTLE LEVER

FRAME

KIP224_kipor manual water pumpfinal_dieselv2.qxd:Layout 1 4/2/10 4:21 PM Page 4

3. PRE-OPERATION CHECK cont.

STEP 3. Check the air cleaner.

Unscrew the wing nut and remove the air cleaner cover.

Remove the air cleaner and inspect both the foam outer air cleaner element (if fitted) and the paper

inner air cleaner element.

Check to ensure both are clean and in good condition.

Clean or replace the element/s if necessary (refer page 13 for air cleaner service maintenance).

•

Never run the engine without the air cleaner. Rapid engine wear will result from contaminants

such as dust and dirt being drawn through the carburettor into the engine.

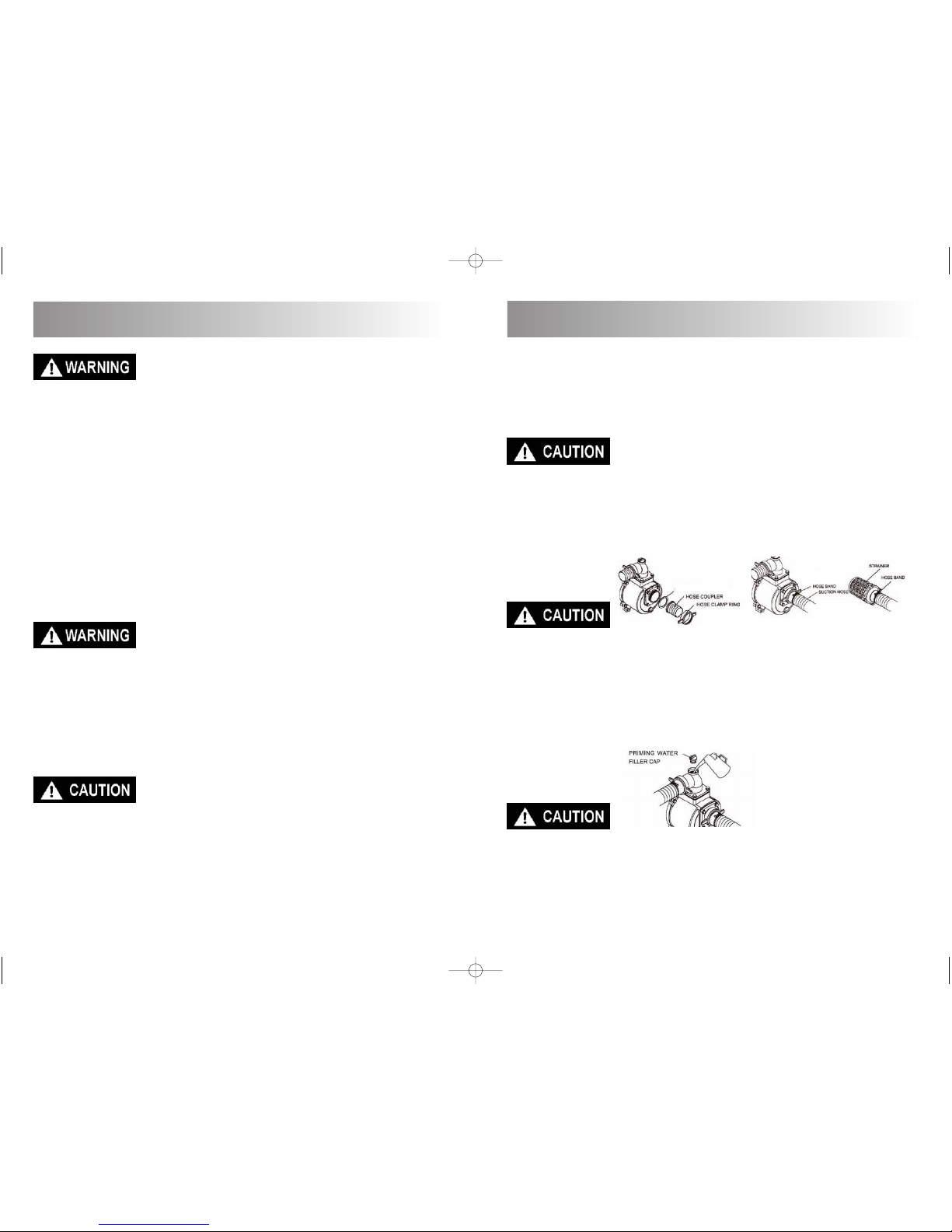

STEP 4. Check connection of the Suction and Discharge hoses

Ensure the hose clamp ring, hose coupler are firmly connected to the Suction Hose. Check that

the rubber seal is seated corrected onto the suction port. Install the strainer on the other end of

the suction hose with a hose band. Tighten securely.

•

Always operate the water pump with the strainer installed on the end of the suction hose. The

strainer will exclude debris from clogging or damaging the pump impeller.

Check that the hose clamp ring of the discharge hose is firmly connected to the discharge port.

Check that the rubber seal is seated corrected onto the discharge port.

STEP 5. Check and Prime the water pump.

The pump chamber must be filled with clean water and primed prior to operating the water pump.

Unscrew the water filler cap at the top of the discharge port and fill with clean water.

•

Never attempt to operate the water pump without priming the pump – overheating and rapid

pump and seal damage will result.

3. PRE-OPERATION CHECK cont.

•

Running the engine with insufficient oil can cause serious engine damage.

NOTE: The Low Oil Alert System will automatically stop the engine before the oil level falls below

the safe limit. However, to avoid the inconvenience of an unexpected shutdown, it is still advisable

to visually inspect the oil level on a daily and regularly basis.

STEP 2. Check the fuel level.

Use ONLY Diesel Fuel

Remove fuel tank cap (anti-clockwise). If the fuel level is low, refill the fuel tank.

Do not use petrol or add oil to the fuel tank. Do not use dirty or contaminated diesel fuel.

Avoid getting dirt, dust or water in the fuel tank. After refuelling, tighten the fuel tank cap securely.

•

Diesel fuel is extremely flammable and is explosive under certain conditions.

•

Refuel in a well-ventilated area with the engine stopped. Do not smoke or allow flames or sparks

in the area where the water pump is being refuelled.

•

Do not overfill the fuel tank - there should be no fuel above the upper limit mark. After refuelling,

make sure the fuel filler cap is tightened securely.

•

Be careful not to spill fuel when refuelling. Spilled fuel or fuel vapour may ignite. If any fuel is

spilled, make sure the area is dry before starting the engine.

•

Avoid repeated or prolonged contact of diesel fuel with skin or breathing of fuel vapour.

•

KEEP OUT OF REACH OF CHILDREN.

•

Fuel system damage or engine performance problems resulting from the use of fuels other than

diesel fuel, are not covered under the warranty policy.

6 7

Fuel Tank Capacity:

KDP20/E 2.5L

KDP30/E 3.5L

KDP40/E 5.5L

RUBBER SEAL

KIP224_kipor manual water pumpfinal_dieselv2.qxd:Layout 1 4/2/10 4:21 PM Page 6

Loading...

Loading...