Kipor KDD03, KDD05, KDD06, KDD08, KDD10 Operation Instructions Manual

KIPOR Machinery Co., Ltd.

Operation Instructions

Please read it carefully.

It contains important operation guidance for safety.

KDD03/05/06/08/10

Loader

Foreword

Operation and Maintenance Instructions of KDD Wheel Loader is prepared for driver and servicemen of

loader. It introduces operations of loader and contains some safety information. Therefore all

operators, servicemen and management staff must read and understand it thoroughly so that loader can

be operated effectively and safely.

Driver particularly shall read it carefully and operate the loader as specified herein. Operation and

maintenance of diesel engine and other auxiliary components as well as selection of spare parts are

described in respective Operation and Maintenance Instructions of Diesel Engine and Manual of Spare

Parts as attachments. Instructions of loader must be attached with loader for possible usage reference.

We hope that driver can be aware of the importance of correct operation and periodic maintenance,

which benefits the performance of functions, extends the duration, reduces unnecessary loss and

creates better economic income for you.

Instructions will not be altered unless there are some great changes and it must be reprinted with

improving and upgrading structure and technical performance of loader. If there is any discrepancy

between loader and information herein, conditions of received loader shall prevail. Please note any

revision or addition in reprinted Instructions in the future and thank you for understanding.

Your suggestions or comments on the Instructions and/or improvement of loader such as structure are

warmly welcomed. Please mail them to us at any time. Then we can advance the quality of loader and

serve you better.

If there is any doubt or question, please contact Sales Department of Wuxi KIPOR Machinery Co., Ltd. or

your agent.

W

W

W

u

u

u

x

x

x

i

i

i

K

K

K

I

I

I

P

P

P

O

O

O

R

R

R

M

M

M

a

a

a

c

c

c

h

h

h

i

i

i

n

n

n

e

e

e

r

r

r

y

y

y

C

C

C

o

o

o

.

.

.

,

,

,

L

L

L

t

t

t

d

d

d

.

.

.

Contents

1.Notes to Safety

1.1 Basic information........................................ 1

1.2 Notes to pre-start......................................... 2

1.3 Notes to operations .................................... 2

1.4 Notes to post-operation .............................. 4

1.5 Notes to maintenance and service .............. 4

2. Components and Safety Labels

2.1Components ................................................. 6

2.2 Label............................................................ 7

2.3 Maintenance of safety labels ....................... 9

3. Operation of components

3.1 Safety components.................................... 10

Start the engine at the neutral position............ 10

Lock button of operating lever of bucket..............

........................................................................ 10

Stop brake ..................................................... 10

Lock connection ............................................ 10

Support of lifting cylinder ............................... 10

3.2Name and functionsof components .............11

Start key (stop with start lock).......................... 12

Operating lever of forward and backward........ 12

Switch of turning lamp ................................... 12

Horn button...................................................... 12

Fuse box ........................................................ 12

Instruments...................................................... 12

Simple measures ........................................... 13

Switch of head lamp ...................................... 14

Switch of stop brake ..................................... 14

Switch of high/ low speed shift ........................ 14

Alert switch...................................................... 14

Throttle pedal .................................................. 14

Brake pedal and pedal of stable movement .... 14

Fuel tank cover On/off ..................................... 14

Operating lever of bucket ................................ 14

Lock button of operating lever of bucket.......... 15

Automatic resetting of bucket .......................... 15

3.3 Leveler of bucket ....................................... 15

Engine hood ON/OFF...................................... 15

3.4 Engine hood ON/OFF and driver’s seat ... 15

Engine hood ON/OFF ................................... 15

Adjustment of driver’s seat ........................... 15

Document box .............................................. 15

3.5 Operation of cab ..................................... 16

Door ON/OFF ............................................... 16

Cab lamp ...................................................... 16

Buttons of windshield wiper and cleaner ...... 16

Safety belt .................................................... 16

4. Using and adjusting loader

4.1Running-in driving(operating new car ....... 17

4.2 Check before driving .............................. 17

4.3 Start engine ............................................ 17

4.4 Start when it is cold ................................ 17

4.5 Preparation at low temperature ................ 17

4.6Precautions after operation in low temperature

......................................................................... 18

4.7 Check after starting ..................................18

Precaution of overheat ................................. 18

4.8 Stop motor ............................................... 18

4.9 Start, drive and stop................................. 19

Start ................................................................. 19

Changing speed ........................................... 19

Rotate .............................................................. 19

Precautions during driving ............................ 19

Stop .................................................................20

4.10Using method of soft moving pedal........... 20

Operation of soft moving pedal ........................ 20

Suitable operation method ............................... 20

4.11 Main operation using the loader ............... 21

Digging and loading ......................................... 21

Filling operation ............................................ 21

Soil preparation ............................................ 21

Loading on the truck ..................................... 21

4.12Exhaust of the fuel system .................... 22

4.13Exhaust of the brake fluid system ............. 22

4.14 Replace shovel ..................................... 22

5. Maintenance

5.1 Check......................................................... 23

5.2 Inspection before starting up...................... 23

Check and filling of cooling water ................... 25

Check list before starting up ............................24

Check and fill of engine oil ........................... 25

Clean and inspection of vehicle embedding in soil

or marsh........................................................... 25

Check and filling of hydraulic oil..................... 26

Check and fill of fuel .................................... 26

Check and filling of oil level in brake fluid cup . 26

Check of cleaning agent in windshield washer 26

Grease filling position at working machine of

shovel.............................................................. 26

Grease filling on universal joint ...................... 27

Grease filling on center pin.............................. 27

Filling grease on shaft of connection device.... 27

Filling grease on steering cylinder pin ........... 27

Check of tyre pressure, wearing, damage and

loosened bolt ................................................ 27

Check working of steering wheel ................... 27

Check contamination and damages of license

plate ................................................................ 27

Check each lamp and instrument .................... 27

Check working status of horn .......................... 27

Rear mirror check ......................................... 27

Oil or water leakage check ........................... 27

Check and cleaning of cooling fan and engine oil

cooling fan .................................................... 28

Check effectiveness of parking brake ............ 28

Check function of brake pedal ....................... 28

Check and tightening each bolt and nut .......... 28

Check for electrical wiring for any disconnection,

short circuit and loosened joint ...................... 28

Cleaning of batteries, wiring and silencer........ 28

5.3 Precaution for vehicle washing.................. 28

5.4 Periodic inspection and maintenance........ 28

List of period check and maintenance ............. 29

5.5Check and maintenance every 50 hours .... 30

Batterycheck.................................................... 30

Drainage in fuel ............................................... 30

Water drainage of oil-water separator ............. 30

Replacement of element of engine oil filter...... 32

5.6Check and maintenance every 200 hours .. 31

Check and adjusting of tension of fan belt....... 31

Check radiator pipe ......................................... 31

Cleaning and check off air filter element.......... 31

5.7Check and maintenance every 250 hours .. 31

Check and tightening of nuts on tyre hubs ...... 31

Replacement of engine oi .............................. 31

5.8Check and maintenance every 500 hours .. 32

Replacement of suction filter element in hydraulic

oil tank............................................................. 32

Check and filling of oil in differential case at front

and rear half shaft............................................ 32

Replacement of element of oil return filter .......33

5.9 Check and maintenance every 1000 hours....

......................................................................... 33

Replacement of engine oil in differential case at

front and rear half shaft .................................. 33

Replacement of oil-water separator filter .........33

Replacement of hydraulic oil in working oil tank ..

......................................................................... 34

5.10Maintenance every 1000 hours or one year

......................................................................... 34

Replacement of element of air filter .................34

5.11Check and repair once every 2000 hours . 34

Check of DC generator and battery motor ....... 34

5.12 Check and repair once every two years... 34

Check and replace of pipes .............................34

Using method of antifreeze .......................... 35

5.13 Use of tyres.............................................. 35

Tyres maintenance ....................................... 35

Tyre pressure ............................................. 35

Replacement of tyre ....................................... 35

Installation direction of tyre ........................... 35

5.14 Check and use of batteries .................... 36

Check and maintenance of battery .................. 36

Precaution while battery charging.................... 36

Check of battery fluid level............................... 36

5.15 Periodic replacement of safety parts........ 37

5.16 Maintenance for long-term storage .......... 37

Replacement of radiator pipe........................... 34

Replacement of cooling water.......................... 34

5.17 Check of electrical wiring and use of fuse....

......................................................................... 37

Fuse replacement .......................................... 37

6. Reason and solution

6.1 Engine failure........................................... 38

6.2 Driving........................................................ 39

6.3 Hydraulic.................................................. 40

6.4 Pulling method when failure occurs ...........41

7. Attached table

7.1 Main technology parameters.................... 42

7.2 Recommended lubricate oil, lubricate and fuel

....................................................................... 44

7.3 Selective parts and assistant tool............... 44

Please read the Operation Instructions carefully for safety.

1. Notes to Safety

Please read the Operation Instructions carefully and understand it thoroughly before use. Following

notes shall be observed for safety concern. In addition, it contains information on Danger, Warning and

Caution.

※ Nevertheless it may contain some information not corresponding to your product. Please

understand it (if any).

1.1 Basic information

1) Please read it and understand it thoroughly

before use in order to ensure safe driving.

2) If the loader is lent to others, instruct the user

operation methods in details and to read the

Operation Instructions carefully in advance.

3) Do not make mechanical modifications willfully

because it is dangerous. Otherwise unexpected

incidents may occur and damage the safety of

loader.

4) Wear safety helmet, shoes and clothing during

driving, check and maintenance. If required by

specific jobs, wear goggles, dust-proof respirator,

sound-proof device, protective gloves, safety belt

and others. However confirm functions of

protective articles in advance. Keep the driving

seat clean around. If there is any oil, grease,

ice, snow or mud on the step or rail, driver may

fall. Additionally check if mud or any foreign

matter at the sole.

5) Please carry out pre-start check.

● Check if early operation causes such abnormal

changes as oil/water leakage, loose bolt, nut or

connection and broken wire on mechanical parts.

Resolve abnormality (if any) immediately.

● Use specific fuel and grease.

● Check pneumatic pressure, wear-out and

damage of tyres.

6) Lubricate the loader. Stop the running engine

during check and regulation. Forbid the open

flame when filling the fuel and prevent the

overflow of fuel.

7) Do not lift or drive any person with bucket of

loader.

8) Forbid persons under lifting bucket.

9) Do not touch overhead wire or obstacles when

lifting up the bucket. Touch may cause electric

shock even death.

10) Do not drive it if driver drinks alcohol, takes

some medicine or is unwell. Otherwise

unexpected incidents may happen.

1

Please read the Operation Instructions carefully for safety.

1.2 Notes to pre-start

1) Hold rails tightly to avoid the slip. Do not

jump on or down the loader. It is danger! Do

not hold operating levers when entering or

leaving the cab.

2) Adjust the seat properly. Improper seat causes

wrong operation and fatigue even unexpected

incidents.

3) Please check followings before starting the

engine.

·Check if any person is around the loader.

·Sit in the driver cab before startup.

·Check if operating levers are at the neutral

position

·Check if shovel touches the ground and stop

brake is normal.

·Check if any inflammable materials around the

engine.

4) Check working conditions of bucket, moving

arm, driving and turning after engine starts in

place free of person and block. If any

abnormality, settle and repair it.

1.3 Notes to operations

1) Sit in the cab and drive the loader correctly.

Do not gaze around, jump on or down the cab

during driving. Forbid unessential operators in

the cab.

2) Do not use it for unintended applications.

Otherwise it may not only damage the loader but

also cause unexpected incidents.

3) Check if the loader is exposed to any danger

before start. Increase the rotation speed of

engine and drive the loader slowly. Do not start

and drive the loader quickly.

4) Prohibit the entry of any person in the

operating area.

5) Fix the bucket tightly when loader runs on the

road or a long distance. Unintentionally touching

the operating lever will change the pose of

running loader, leading to incidents. The correct

pose of running loader is to keep bucket about

40m above the ground.

6) Abnormal drive such as quick start, brake,

rotation, driving in the zigzag form and high speed

will contribute to the turnover of loader and cause

serious injury even death. In particular, quick

rotation of loader at high speed can cause the

turnover to side. It is extremely dangerous.

7) Lower the bucket as much as possible when

loader delivers the sand to keep the center of

gravity at a low level. Loader cannot keep the

balance if bucket of running loader is raised

beyond the upper limit. Loader is exposed to

the danger due to higher center of gravity.

8) Uneven operating area may contribute to one

factor of turnover incident. Therefore select the

flat operation ground for driving. If there is any

stone or obstacles on the route, do not pass it by

inclining loader or at high speed. Such incorrect

operation may lead to turnover. The correct way

is to reduce the speed and run across an obstacle

when stability of loader is ensured. Check the

capacity of load of bridge or structure before

loader drives on it. If capacity of load is

insufficient, strengthen it.

9) Avoid any operation along a slope as much as

possible. Loader will lose balance and be

exposed to danger if excavating the inclined

section.

2

Please read the Operation Instructions carefully for safety.

10) According to Rule for Labor Safety and

Health, machine must be provided with protective

cover if it is used for application that labor is

exposed to hazard such as falling stone. In such

dangerous situation, do not use machine without

protective covers.

11) To ascend an abrupt slope, select the

Backward and keep the loader stable. Drive the

loader slowly and lift the bucket about 20-40cm

above the ground. To descend a slope, select the

Forward and keep the loader stable. Drive the

loader slowly with bucket close to the ground.

12) Do not make a turn on a slope as much as

possible. Make a turn on the flat ground if

possible.

13) Drive the loader at the relatively low speed in

the confined space, room and place with stored

matters. Meanwhile pay attention to surrounding

conditions.

14) Consider the possibility of collapse when

loader moves along cliff or abrupt slope.

Strengthen it or take other appropriate measures

if necessary. It turns more dangerous after it

rained. Do not approach such places willfully and

position where stone may slide down.

15) Soft ground may catch tyres, leading to

imbalance. In such case, check the capacity of

ground before operation. If loader descends a

slope or slides to side and ground is soft, lower

the bucket immediately as brake.

16) When loader drives or brakes on the

snow-covered or frozen ground, skid or lateral

slippage may occur. Do not carry out quick

brake, start, rotation and other dangerous

actions. Front wheels are typically furnished with

anti-skid chains. In case of jobs under snowy

conditions or requiring traction, both front and

rear wheels must be fitted with anti-skid chains.

17) When speeding down a slope, do not brake

wildly.

If pressing down the “low-speed securing” button,

speed descends and shifts rapidly when loader

drives at the high speed. Then rear section of

loader may be lifted a little and float. Sometimes

it causes danger. Reduce the rotation speed of

engine and shift slowly.

(1) Stop the engine when descending a long

slope. In such case, trigger the “low-speed

securing” button and brake of engine at the same

time.

(2) Operate the brake pedal for over-speed.18)

Do not operate the Stop Brake when loader is

running. Sudden stop is extremely dangerous.

19) It is very likely to happen that loader slides to

side or loses the balance in case of inclined

connection. It poses a great danger.

20) The steering wheel of loader is different from

that in car. It cannot return to original position

automatically after it is operated for turning.

Thus reset the steering wheel manually

21) If any tyre bursts, operate the loader as

emergency stop or lower the speed mildly but not

work the steering wheel in a hurry.

22) Goods may fall down to one side of cab if

loader operates unstable goods or jobs at a

relatively high level. Therefore do not lift bucket

too high or lean back when loader operates

unstable goods.

23) Turnover is very likely to happen due to

counterforce in case of abrupt descending or

emergency stop, particularly it is loaded.

24) Know positions of cable, gas pipe, running

water pipe, sewer and other underground

facilities before excavation.

25) Excavation under cliff is exposed to collapse,

falling stone and other possible great risks.

26) Indoor job may generate the waste gas and

cause toxic conditions. Ensure sufficient

ventilation for indoor jobs (in the shelter). Check

the loader outside in advance.

3

Please read the Operation Instructions carefully for safety.

1.4 Notes to post-operation

1) Park the loader on the flat ground. If loader

has to be parked on a slope, bucket shall fall

down to the ground. And place stop blocks

around wheels.

2) If driver leaves the cab,

·Bucket falls to the ground.

·Stop the engine and move operating lever to

release the pressure.

·Place operating lever of forward and backward

at the neutral position and lock the operating

lever of bucket at the neutral position.

·Take away the triggering key.

3) Before storage, cool the silencer and other hot

parts then close the protective hood. Otherwise

it may cause fire accident.

1.5 Notes to maintenance and service

1) Check and clean the loader and operating

parts. Stop the engine before each check,

adjustment and leave. It is dangerous to check

the running loader. Carry out any check at safe,

solid and flat ground.

2) During check and maintenance, identify the

serviced part with Label “In check and

maintenance” in order to avoid unessential

person from touching or operating the loader.

Place some warning marks around the loader.

3) Do not use materials that easily ignite fuel or

battery during mechanical maintenance and fuel

supply.

4) Ensure sufficient ventilation if maintenance is

done indoor or at place with poor ventilation

conditions. Local ventilation is a must when

exposure to waste gas, fuel, cleaning oil and

paint.

5) Use the approved service kits. Unapproved

service kits will not only reduce the working

efficiency but also cause injury.

6) Support and fix the engine hood and other

components before maintenance and check

around the engine.

7) Place the start button at Off position when

welding the loader. Do not place hazardous

materials between welding and earthing parts

because welding may generate heat and cause

the electrical spark. Otherwise energized cylinder,

sealing bearing and other devices may pose

danger.

8) Water in the electrical system can cause the

short circuit or abnormality. Keep battery,

sensor, connection and other electrical parts

away from water.

9) Wear goggles and position the oil leakage with

heavy board if leakage is found in a invisible small

aperture. If oil touches the skin, it may irritate skin

seriously. Seek for physicians immediately.

10) Cool the engine completely before check,

addition or change of cooling water in the radiator.

Silencer is hot just after engine stops. Touch can

cause the injury!

11) Lock the operating lever before check and

maintenance on the lifting bucket. Use the

support of lifting arm to prevent them from

descending.

12) Do not lift the loader with bucket before

service and maintenance. Do not allow persons

under lifted loader. If some persons have to

work under the lifted loader, place the safety mat

and support in advance to avoid unexpected

falling. And lock the operating lever.

13) Do not use any tyre with serious damage.

Otherwise it may burst.

14) Consult the distributor of tyre, inner tube and

wheel rim for replacement and repair.

(Replacement and repair shall be done by

specially trained expert if possible.)

4

Please read the Operation Instructions carefully for safety.

15) Gas in the battery may cause fire and/or

explosion.

·Do not produce the spark near the battery or

keep the battery away from open flame.

·Do not check the battery by shorting two poles.

Use the voltmeter or specific gravity meter for

check.

·Do not charge the frozen battery. Otherwise it

may cause battery explosion. In such

circumstance, heat the frozen battery above

15 in ℃ advance.

·When indicator turns red, please replace the

battery.

·Battery acid (thin H2SO4) can cause blindness

or heat injury. Rinse skin or clothes with clean

water if touching the battery acid. If touching

the eye, wash eyes then seek for physician.

16) After the loader is started, all mechanical

components, operating oil and lubricant are

exposed to high temperature and pressure. Hot

operating oil may cause scald. In addition oil

spraying under pressure can penetrate the skin

and cause serious injury. Ejected plugs and

screws under pressure may also hurt persons.

Therefore disassemble components in the

hydraulic system after temperature fall down and

pressure is released completely. Do not face

any plug and/or screw to be loosened directly.

Do not stay near fuel and/or oil leakage because

pressure is high. Touching oil and/ or fuel leakage

is dangerous.

5

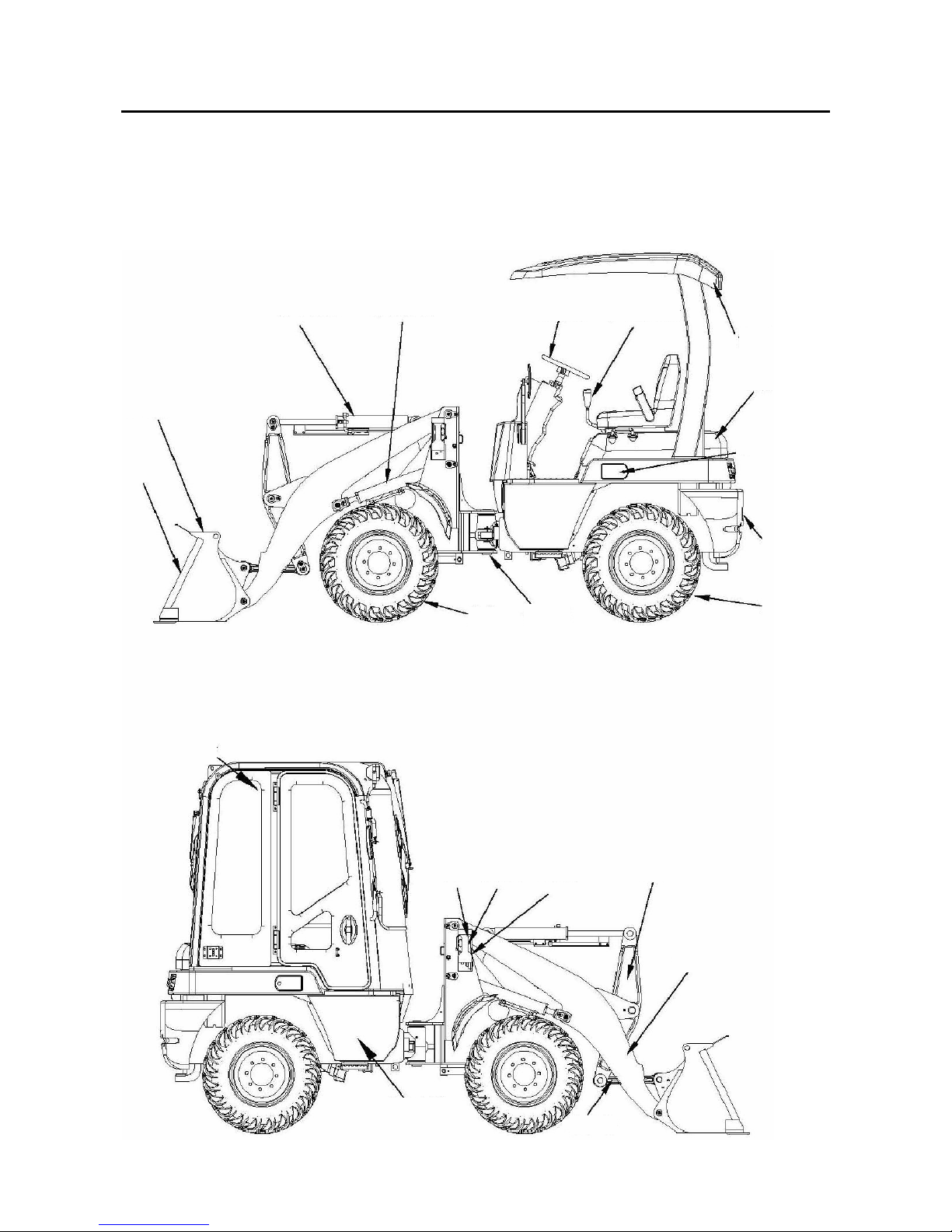

2 Components and safety labels

2. Components and Safety Labels

2.1 Components

6

Front wheel

Steering wheel

ting cylinder

pping cylinde

r

Bucket

Bucket leveler

Hinged connection

Operating lever

of bucket

Simple cover

Engine hood

Intake of diesel

Counterweight

Rear wheel

Cab

Hydraulic oil box

Front lamp

Clearance position lamp

Rocker

Moving arm

Push rod

2 Components and safety labels

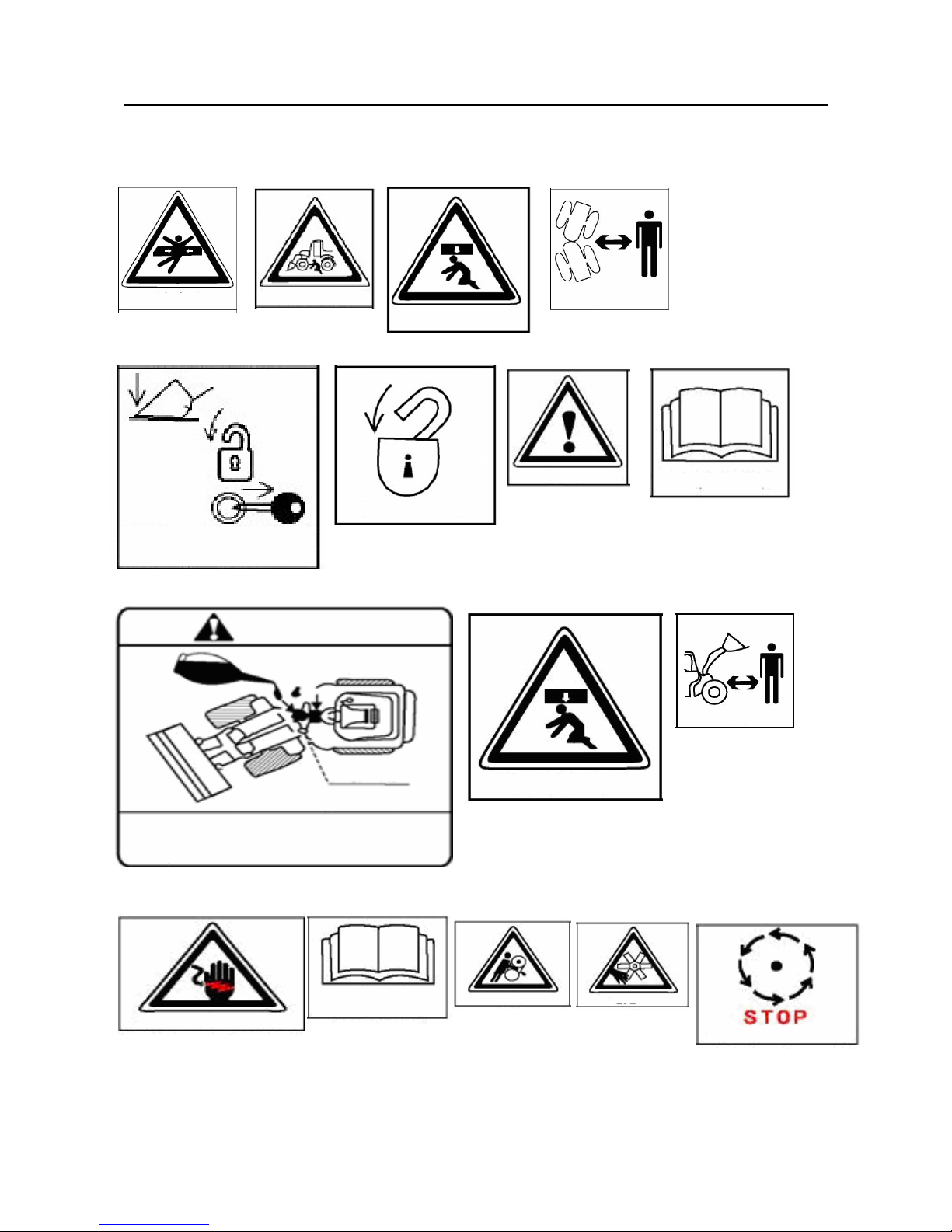

2.2 Label

◆There are many safety labels on the loader. Please read and understand them thoroughly before

usage. Please read following information carefully.

7

Seized

Sudden start

A

way from moving

arm and bucket

Kee

p

awa

y

L

ower and lock the bucket

to the ground and stop the

en

g

ine if driver leaves

Lock f

or maintenance

W

arnin

g

and transportation

.

Read Instructions

A

ttention

Center pin

Grease the center pin before usage every day.

Insufficient lubrication causes bearing to

A

way from moving

rotate discontinuously It is dangerous

arm and bucket

Keep away

Electric shock during cabling

Read Instructions

Caught

Caught

running during maintenance

2 Components and safety labels

8

Warning

According to Rule for Labor Health, the

loader and auxiliary components cannot be

used for unintended purpose.

Read Instructions in advance and operate

the loader safely.

■If the loader is used to lift goods as lifter, goods

may fall down or loader may turn over. Forbid

such dangerous usage.

Attention

Use special ISO VG32 brake

oil but not common vegetable

oil.

Warning

Please pay attention to followings during operation.

1. Sudden turning or rotation will cause turnover if

bucket is lifted. Position the bucket as required

during driving.

2. Turnover may occur when loader runs across a

slope or changes the direction during running.

Change of direction shall be done on the flat ground

as much as possible.

3. Do not operate the loader near pool, reservoir, cave

and other place exposed to risk of fall.

Attention

1. Read Instructions and understand the

correct method of operation in advance.

2. Sound the horn to check if there is any

person around the loader when engine

starts.

3. Sit on the driver’s seat and operate the

loader.

4. Lower the bucket to the ground, trigger

the Stop Brake, stop the running engine

and take away the start key before leave.

5. Do not activate the Stop Brake when

loader is running. Sudden brake poses a

great danger.

6. It will be difficult to handle the steering

wheel easily if engine stops when loader is

running. Therefore do not stop the engine

without reason.

Warning

·Use the lock connection to fix front and rear

carriages during maintenance, transportation and

lift.

·Remove the lock connection and hide it as original

when loader is on the way and in service. Loader

cannot turn if carriage is fixed, possibly leading to

injury incidents.

Warning

·When loader is used to load or unload goods in a

truck, please observe following practices for safety

concern.

1. Load or unload goods at a high level.

2. If access board is used, do not change the direction

when loader is on the access board.

3. The correct way of stop brake is to fit tyres with stop

blocks and fix the loading space of truck and loader

tightly with wires.

· Lock the operating lever and use the support of lifting

arm for maintenance and check on lifting bucket in

order to avoid the descent of bucket.

Scald

Not open

Scald

Not touch

9

2 Components and safety labels

2.3 Maintenance of safety labels

1) Keep the label clean. Do not contaminate or damage the label.

If there is any dirt on the label, clean it with soapsuds and dry it with soft cloth.

2) If loader is washed with high-pressure water gun, label may fall off. Do not inject the water stream

directly against any label.

3) Order labels from your agent, if damaged or missed and apply good ones.

4) Clean any contamination and wait for dryness before sticking new labels on original positions

correspondingly.

5) Replace labels with corresponding parts.

3 Operation of components

3. Operation of components

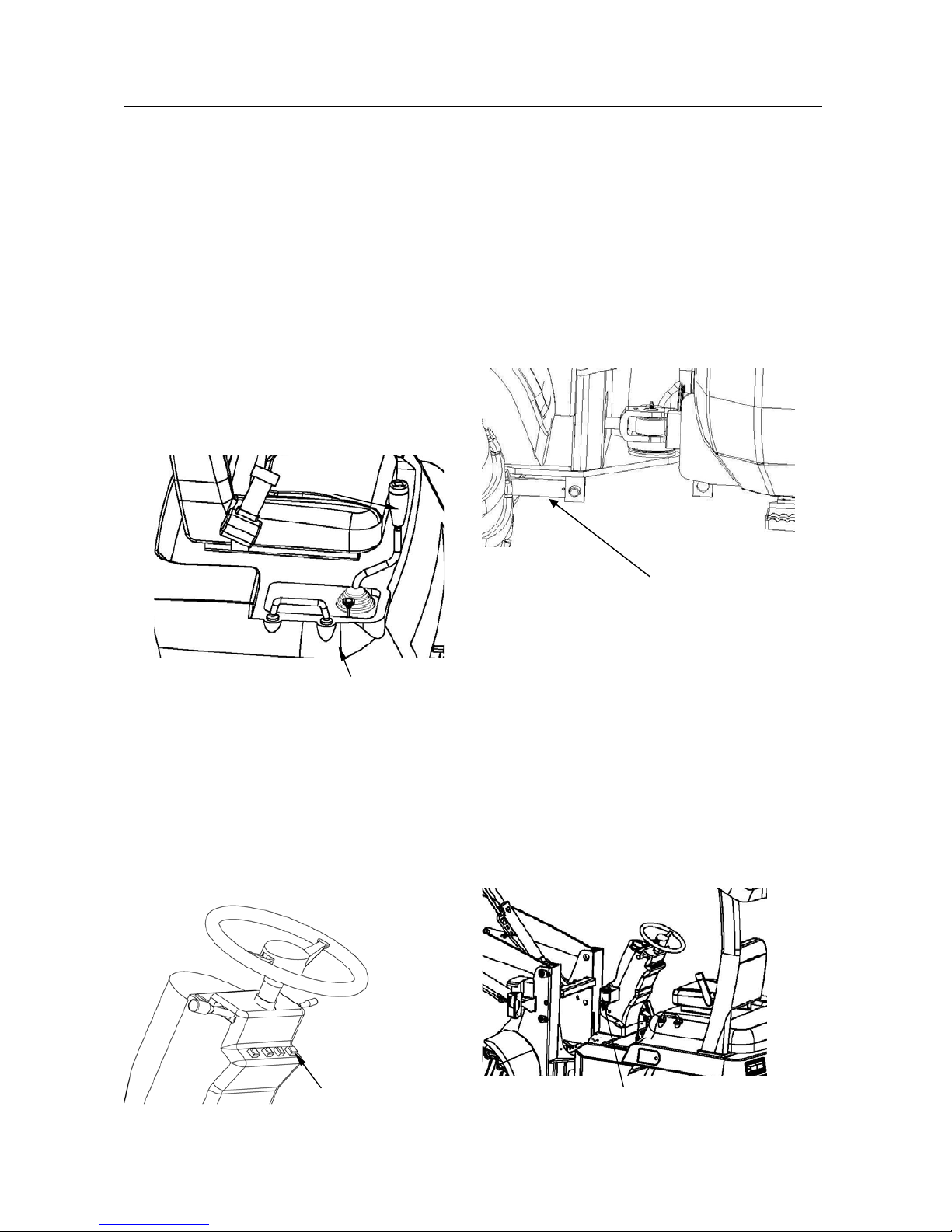

3.1 Safety components

▅ Start the engine at the neutral position

It is the safety component to avoid the sudden

start of loader when engine starts. It is allowed

to start the engine only when forward and

backward operating lever are at the neutral

position. Return the operating lever to the

neutral position in order to disconnect the loader

with engine after parking.

▅Lock button of operating lever of bucket

It is used to lock the operating lever of bucket.

Place the operating lever of bucket to the

neutral position and enter down the lock button

to lock the operating lever.

Operating lever of bucket

▆ Stop brake

It is used to stop or park the loader. Stop brake

is activated by pressing down the button of stop

brake and alert indicator on the panel lights. It

is mainly used when loader is stopped, serviced

or transported or driver leaves the loader.

Take all required measures for stop brake.

Loader cannot start if stop button is not

released.

▅Lock connection

It is used to lock the front and rear carriages to

avoid unintended turning of them during check,

maintenance and transportation. Mount it on

seats of front and rear carriages at the lower left

and fix it with split pin. Then front and rear

carriages are aligned. Remove the connection

lock before loader drives normally and hide it in the

front carriage. Drive with active lock connection

will invalidate the steering wheel and lead to risks.

Hidden space

▆Support of lifting cylinder

It is used to support the moving arm during the

check on lifted moving arm. It aims to prevent the

descent of moving arm. It is hidden in the front

carriage.

[Handling]

1. Raise the lifting cylinder to top.

2. Stop the running engine and take away the start

key.

3. Raise the piston rod of cylinder to approach the

support.

4. Insert the pin to fix it.

5. Lower the moving arm slowly till no gap is left.

Operating leve

r

of bucket

10

Support device of lifting cylinder

Stop button

Loading...

Loading...