Kioti CK30 Engine Manual

CHAPTER 2

ENGINE SYSTEM

1. FEATURE

ENGINE SYSTEM

704W201A

The TD1300 and 3A150 engines are vertical, water-cooled, 4-cycle, three or four cylinders diesel engines. They

concentrate DAEDONG’s foremost technologies.

With swirl combustion chamber, bosch K type fuel injection pump, well-balanced designs, they feature greater power,

low fuel consumption, less vibration and noise, and low emission.

D704-W00 Dec. 2004

2-3

CHAPTER 2 CK25(H)/30(H)

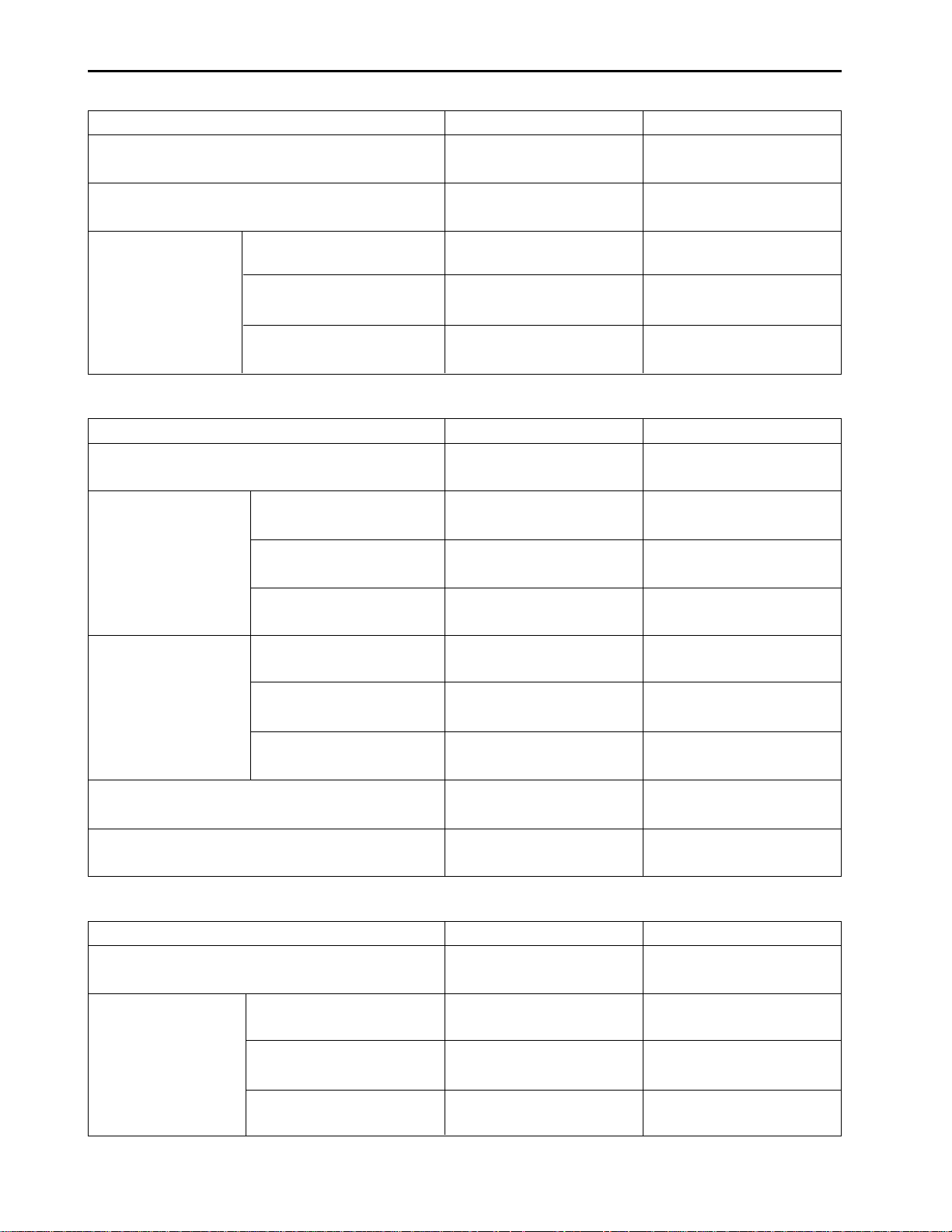

2. LUBRICA TING SYSTEM

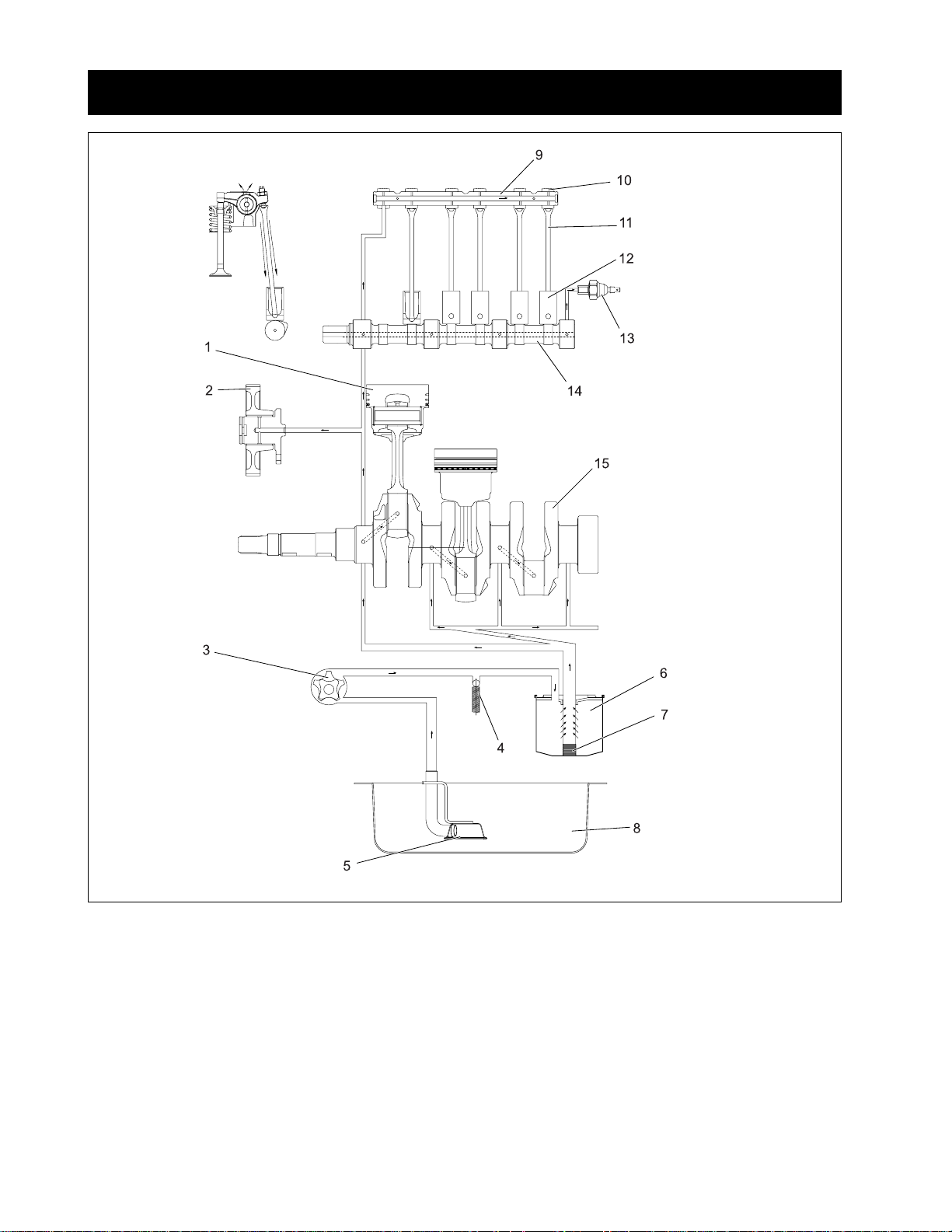

(1) Piston (5) Strainer (9) Rocker Arm Shaft (13) Oil Pressure Switch

(2) Idle Gear (6) Oil Filter Element (10) Rocker Arm (14) Camshaft

(3) Oil Pump (7) Bypass Valve (11) Push Rod (15) Crankshaft

(4) Relief Valve (8) Oil Pan (12) Tappet

The lubricating oil is forced to each journal through the

oil passages of the cylinder block, cylinder head and

shafts. The oil, splashed by the crankshaft or thrown off

from the bearings, lubricates other engine parts such

as the push rods (11), tappets (12), camshaft (14), and

crankshaft (15).

2-4

D704-W00 Dec. 2004

704W217A

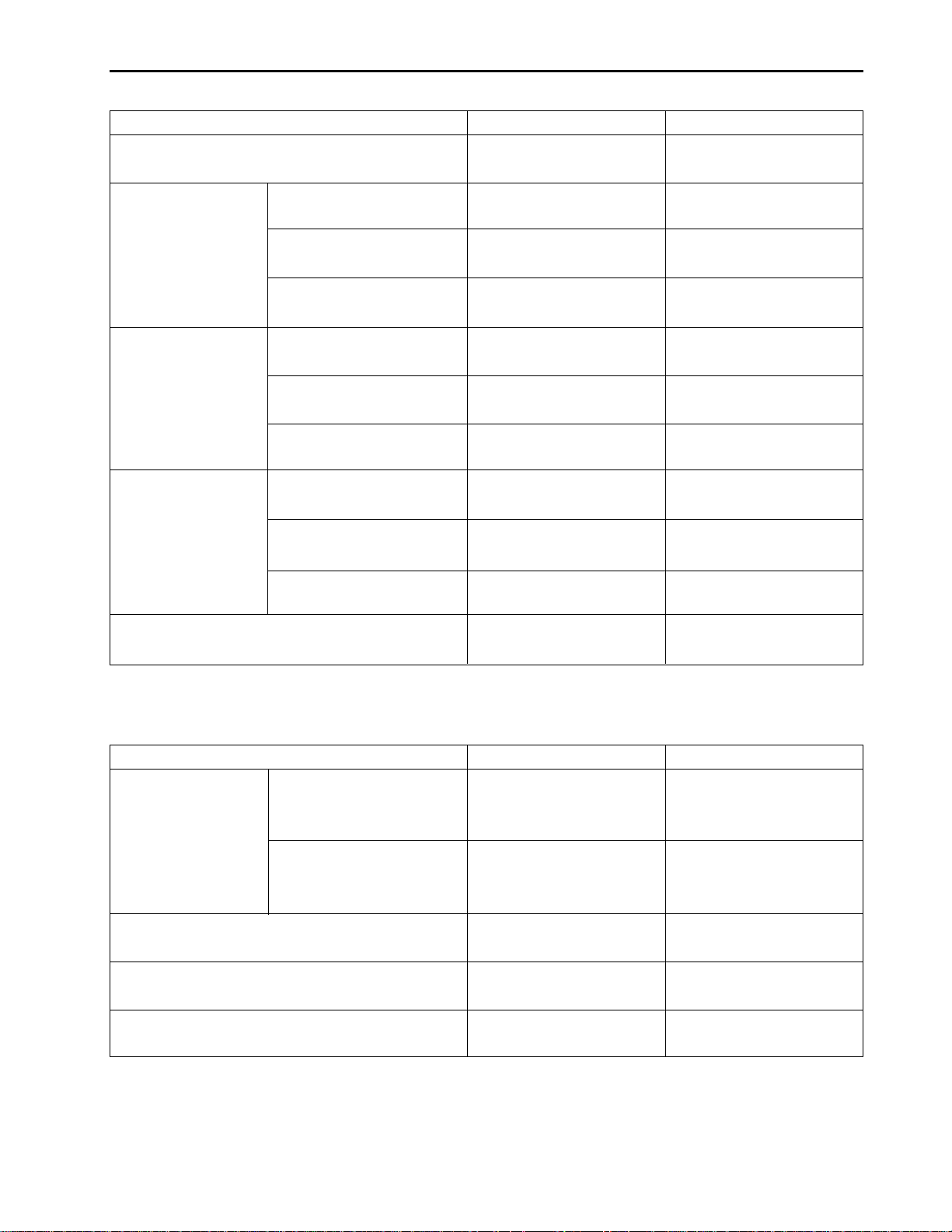

3. COOLING SYSTEM

ENGINE SYSTEM

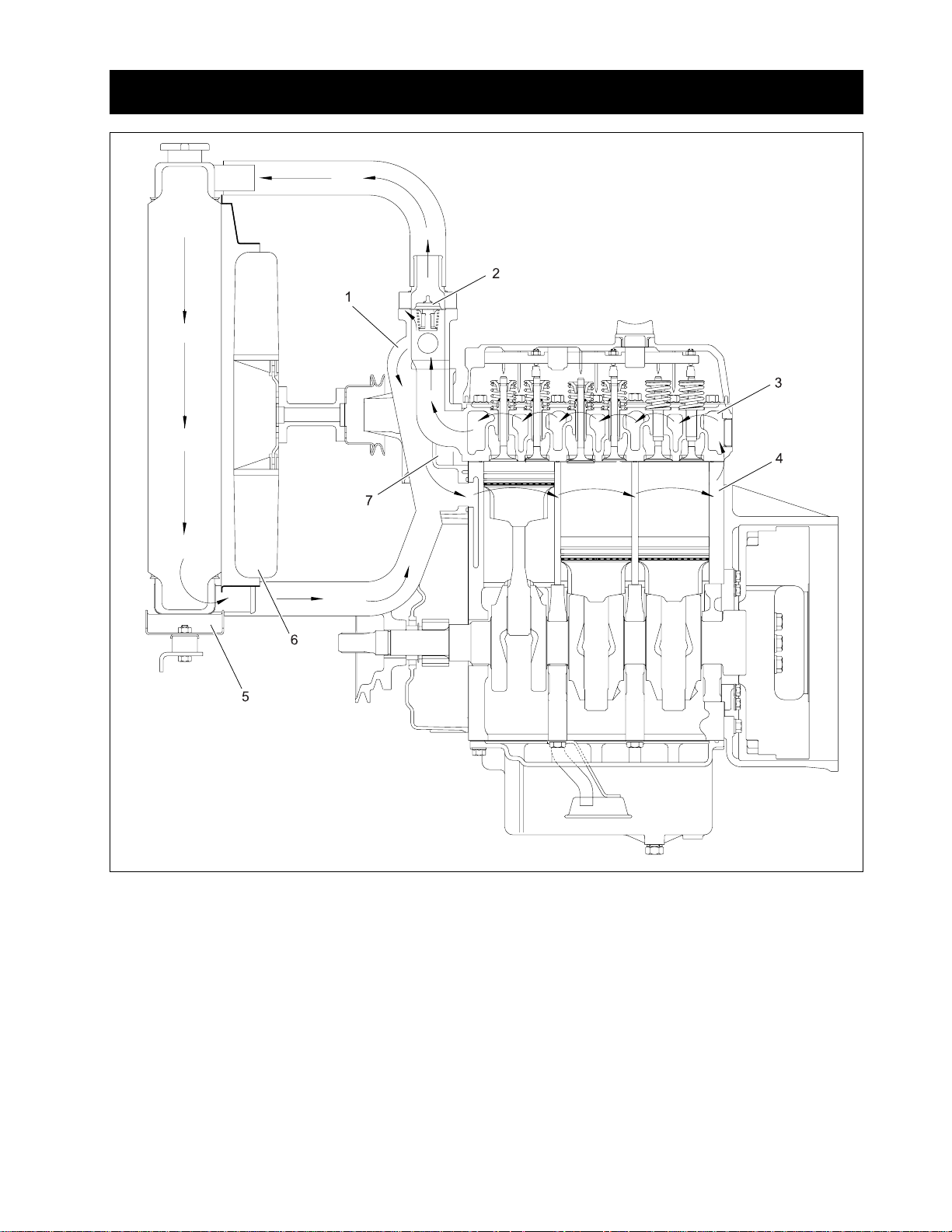

(1) Water Return Pipe

(2) Thermostat

(3) Cylinder Head Water Jacket

(4) Cylinder Block Water Jacket

The cooling system consists of a radiator (5), a centrifugal water pump (7), a cooling fan (6) and a thermostat (2). The water is cooled as it flows through the radiator core, and the fan behind the radiator pulls the

cooling air through the radiator core. The water pump

receives water from the radiator or from the cylinder

head and forces it into cylinder block. The thermostat

open or closes according to the water temperature.

D704-W00 Dec. 2004

704W221A

(5) Radiator

(6) Cooling Fan

(7) Water Pump

When the water temperature is high, the thermostat

opens to allow the water to flow from the cylinder block

to the radiator. When the water temperature is low, the

thermostat closes and the flow stays within the block.

The opening temperature of the thermostat is approx.

71 °C (160 °F).

2-5

CHAPTER 2 CK25(H)/30(H)

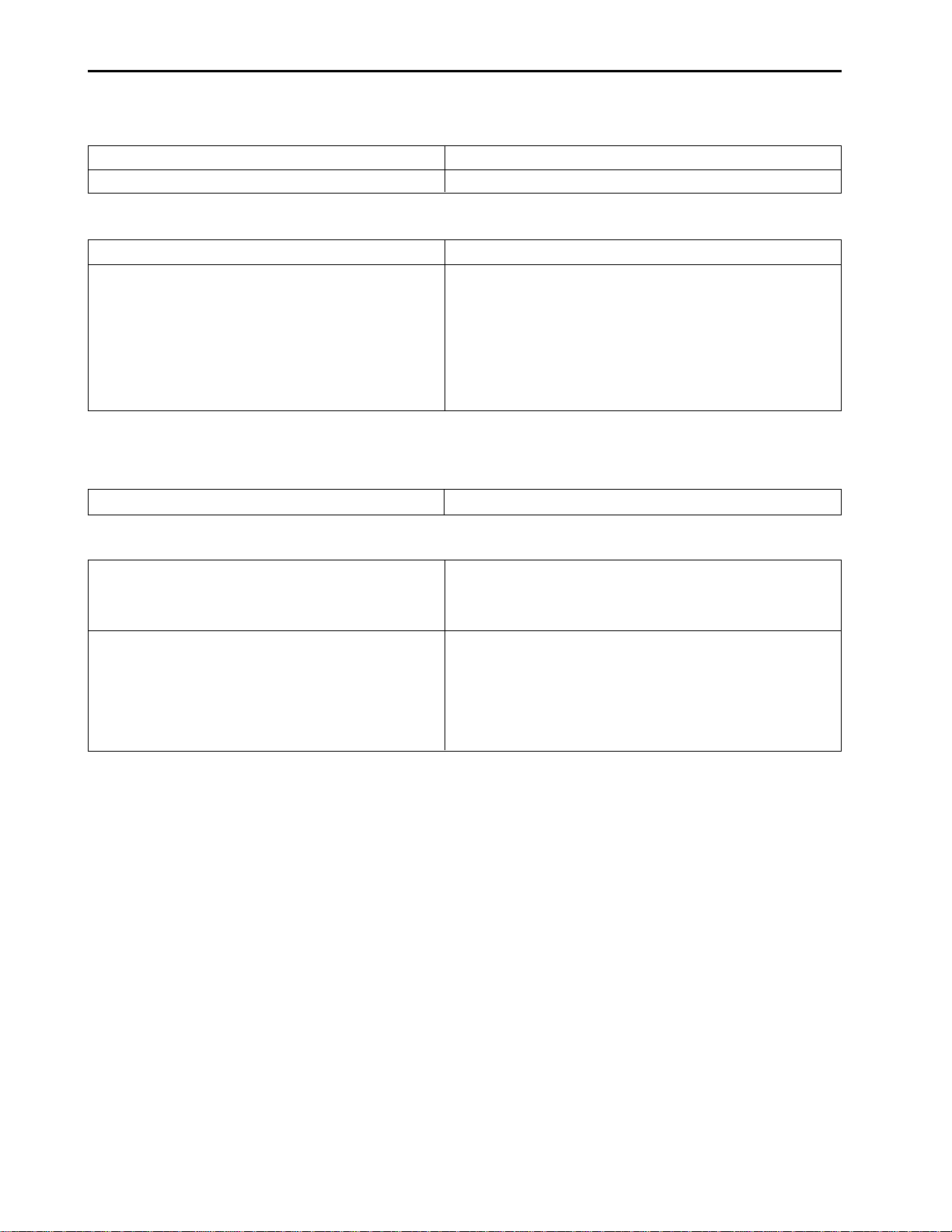

4. FUEL SYSTEM

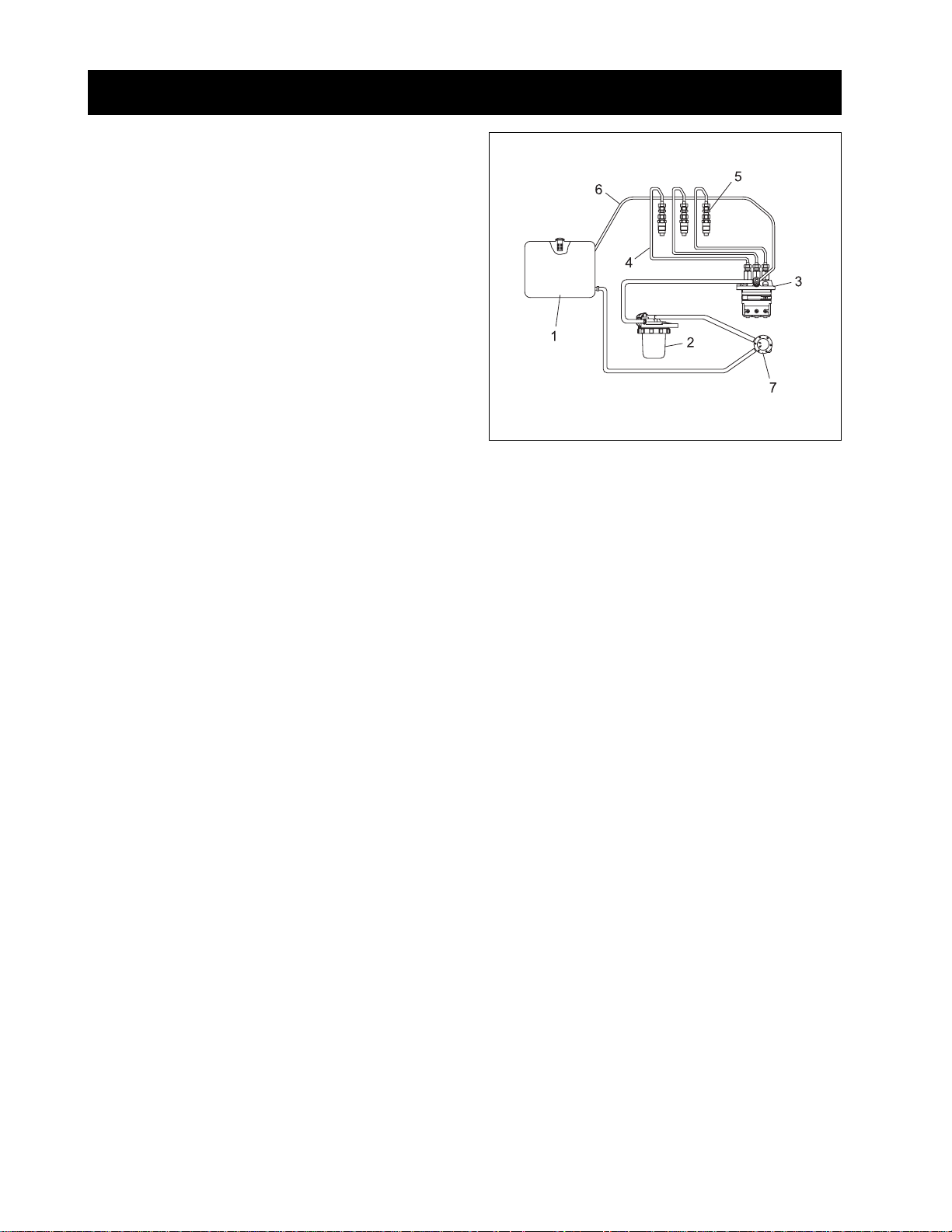

The fuel is fed from the fuel tank (1) through the fuel

feed pump (7), through the fuel filter, and then to the

injection pump (3). The injection pump force-feeds the

fuel to the injection nozzles (5), which inject the fuel

into the cylinders for combustion. The excess fuel from

the injection pump and the injection nozzles (5), is collected in the fuel overflow pipes (6) and returns to the

fuel tank.

704W226A

(1) Fuel Tank (5) Injection Nozzle

(2) Fuel Filter (6) Fuel Overflow Pipe

(3) Injection Pump (7) Fuel Feed Pump

(4) Injection Pipe

2-6

D704-W00 Dec. 2004

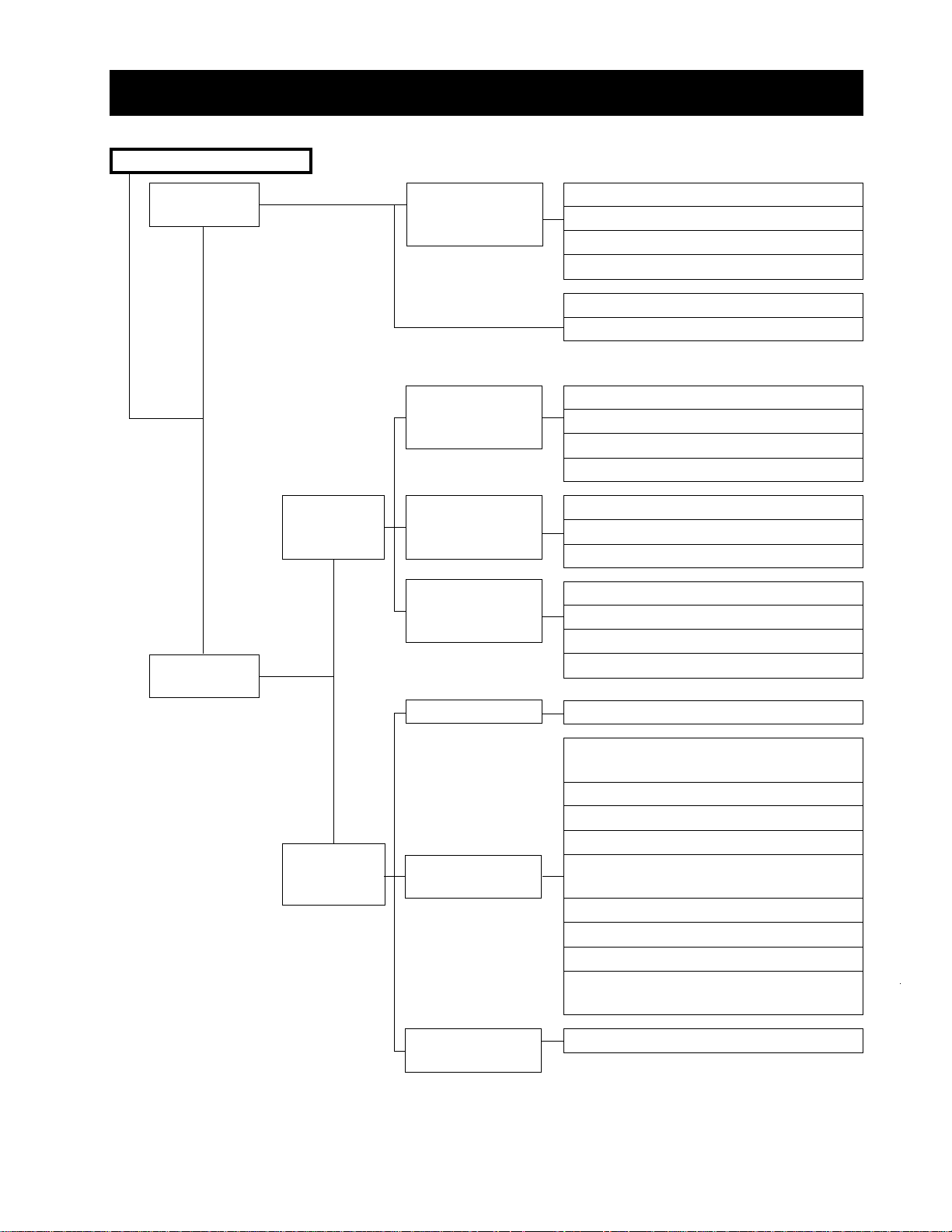

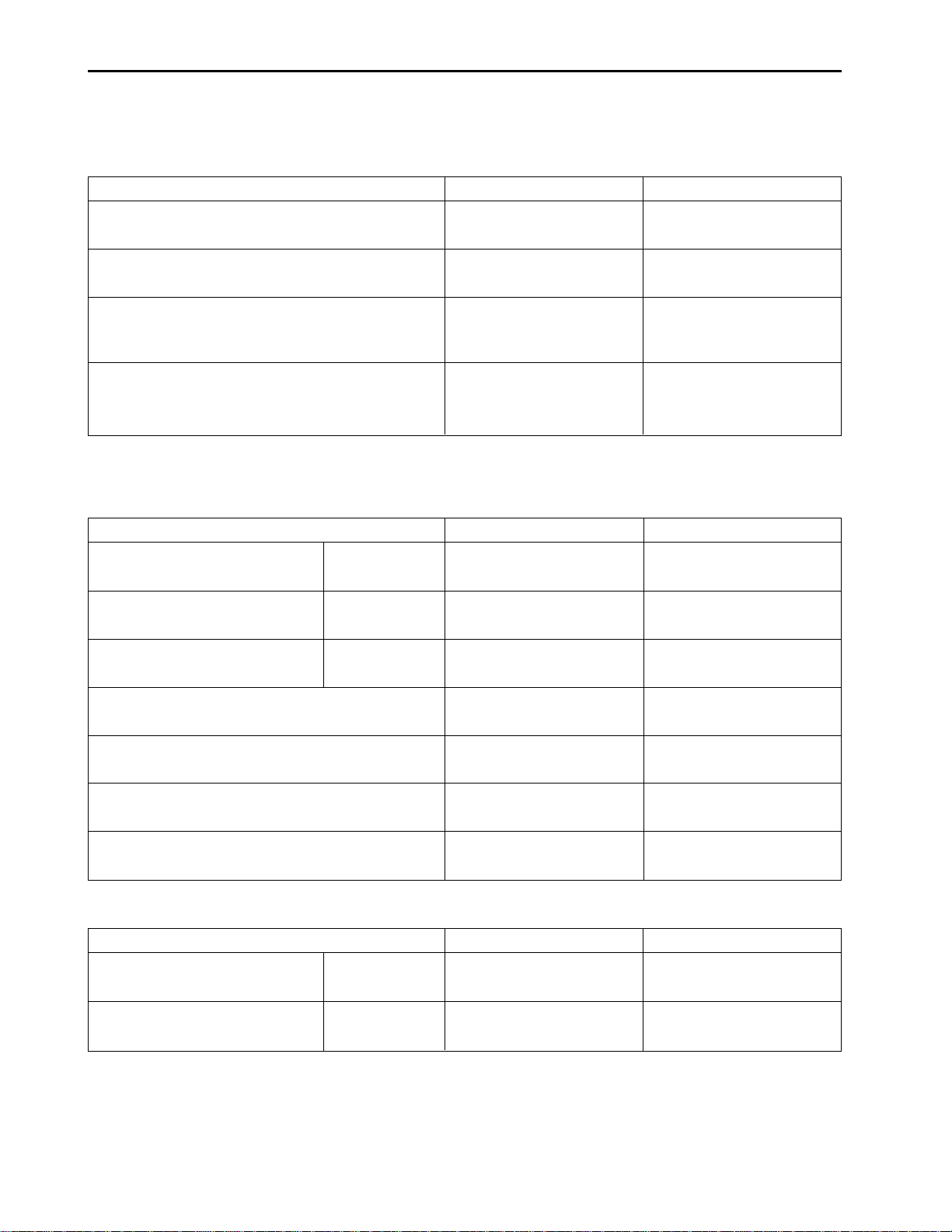

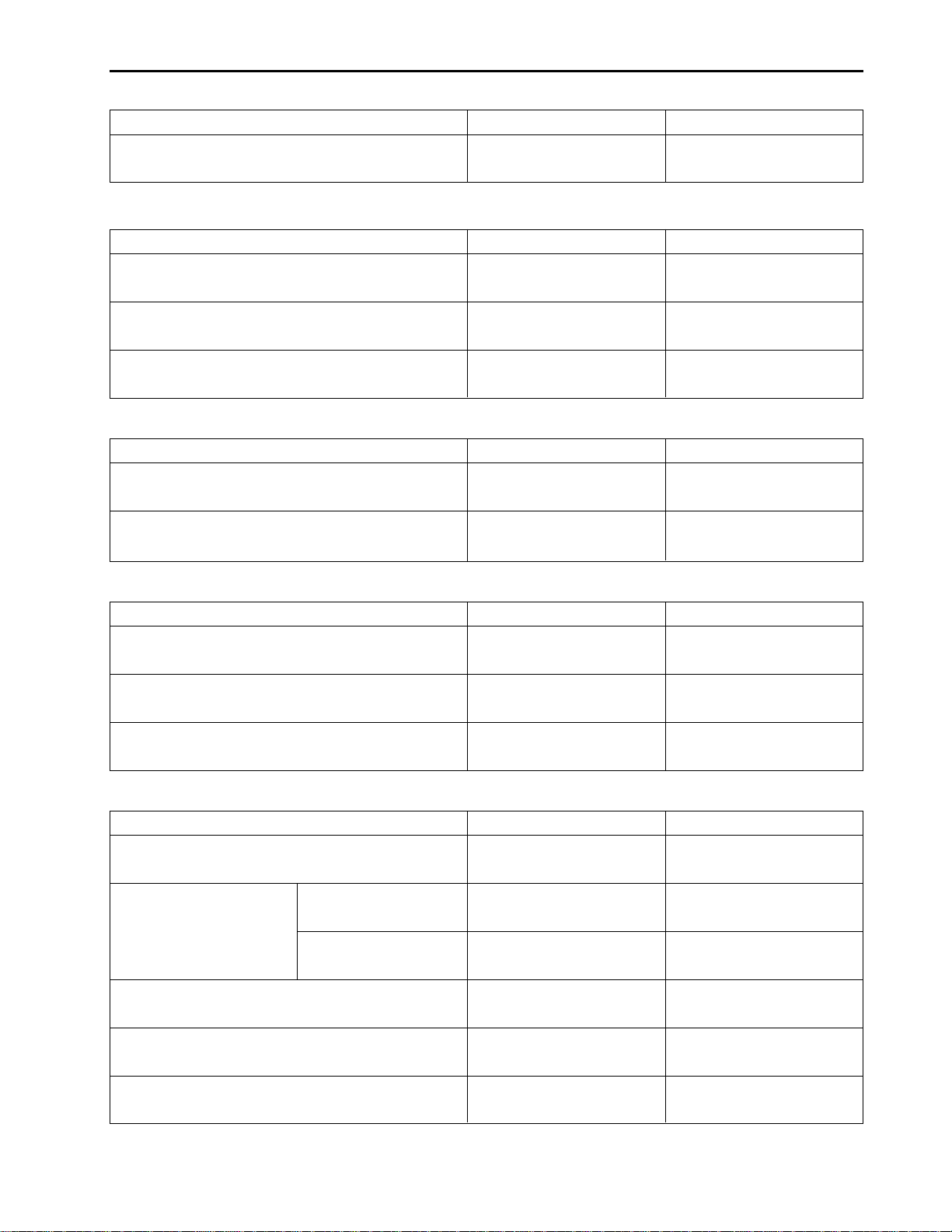

5. TROUBLESHOOTING

ENGINE DOES NOT START .

ENGINE SYSTEM

Crankshaft

does not turn

Crankshaft

turns

No or small

fuel injection

sounds.

Frictional resistance of moving

parts is too much

Fuel supply to

injection pump is

insufficient.

Injection pump

does not send on

fuel.

Fuel does not

inject through

injection nozzle.

Injection mistimed.

Crankshaft and camshaft have seized up.

Piston and cylinder liner have seized up.

Bearings are oil-stuck.

Lubrication system not working property.

Starter faulty.

Battery capacity is low or terminal loose.

Fuel pipe broken.

Air enters fuel pipe through connection.

Fuel filter clogged.

Fuel pump faulty.

Plunger has worn or seized up.

Delivery valve spring broken.

Delivery valve not completely oil-tight.

Needle valve stuck.

Needle spring broken.

Injection pressure maladjusted.

Injection pipe mounting nut loose.

Injection timing maladjusted.

D704-W00 Dec. 2004

Regular fuel

injection

sounds.

Compressed air

leaks.

Valve action

timing improper.

Contact between intake/exhaust valve and

seat not tight.

Intake/exhaust valve spring broken.

Intake/exhaust valve stuck.

Gasket faulty.

Tightness torque of cylinder head not

enough.

Piston ring stuck.

Piston ring worn.

Cylinder liner worn.

Tightness torque of injection nozzle and

glow plug not enough.

Valve clearance excessive.

2-7

CHAPTER 2 CK25(H)/30(H)

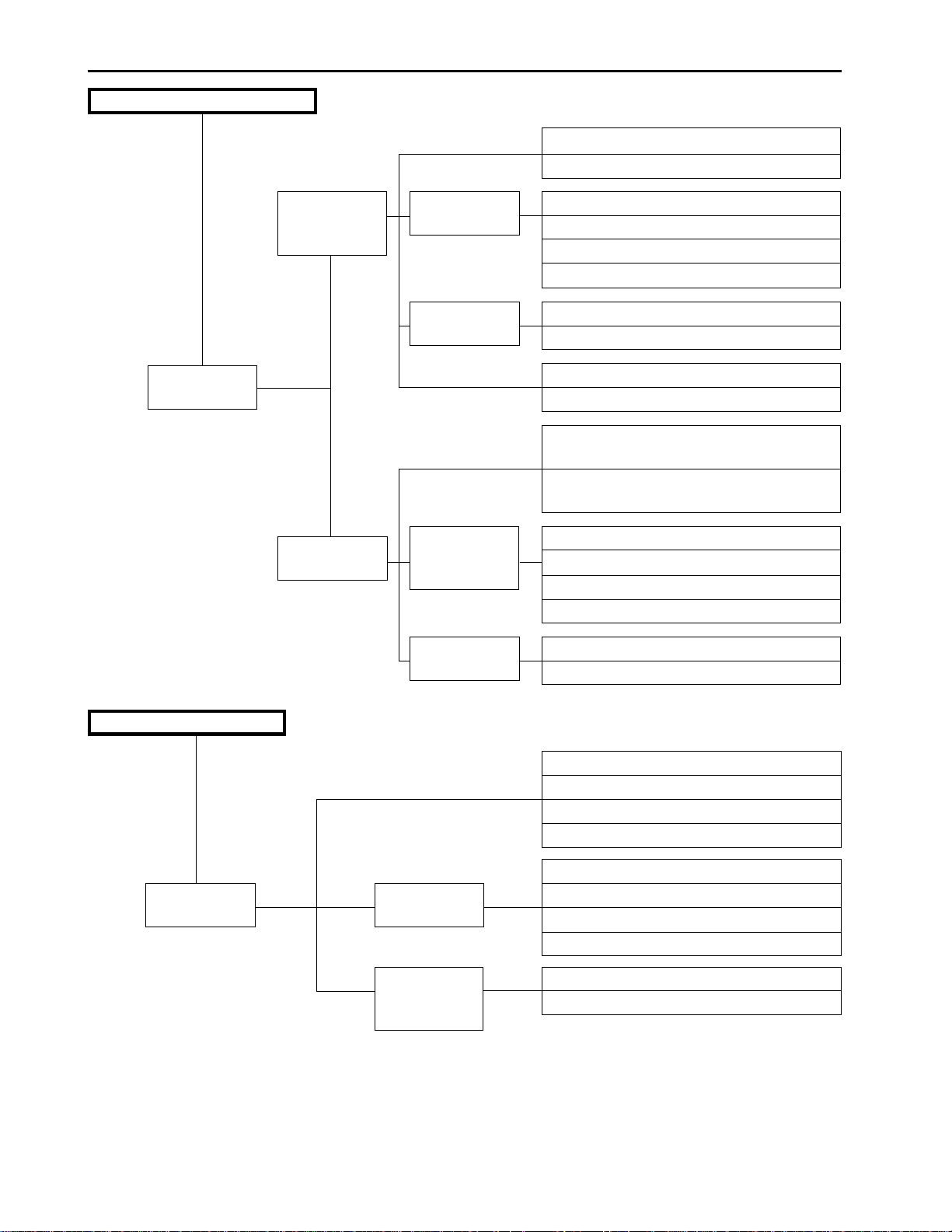

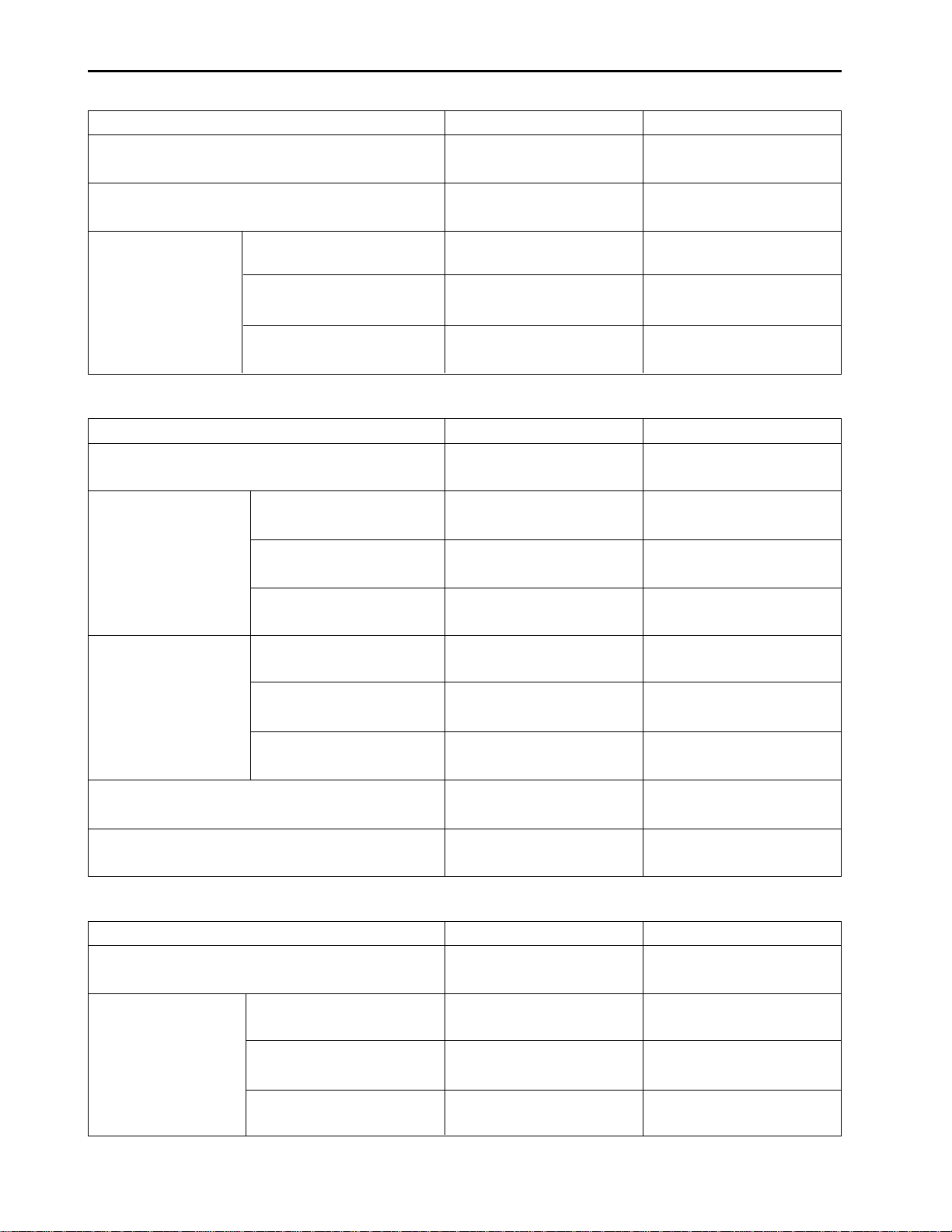

Engine does not turn normally.

Fuel filter clogged.

Fuel pipes broken or loose.

Irregular

Revolution

Revolution is

not smooth at

high speeds.

Idling not

smooth.

Injection

pump wrong.

Injection

nozzle faulty.

Governor not

functioning

normally.

Idling

maladjusted.

Air in pump.

Pump capacity not constant.

Tappet roller and pin worn.

Delivery valve not completely oil-tight.

Fuel leaks from nozzle tip.

Fuel not spraying properly.

Governor spring deformed.

Valve clearance incorrect.

Injection pump or nozzle not functioning

normally.

Compression pressure is different among

cylinders.

Governor sleeve not sliding property.

Fork lever not functioning normally.

Start spring deformed.

Control rack not sliding property.

Idling regulator maladjusted.

Accelerator rod maladjusted.

Engine output insufficient.

Slow engine

revolutions.

Fuel supply

insufficient.

Compression

pressure not

enough.

Main moving parts have almost seized up.

Engine overheated.

Injection mistimed.

Governor not functioning normally.

Filter clogged.

Fuel pipe broken or loose.

Injection pump’s capacity not enough.

Nozzle needle valve worn.

Air leaking.

Air cleaner clogged.

2-8

D704-W00 Dec. 2004

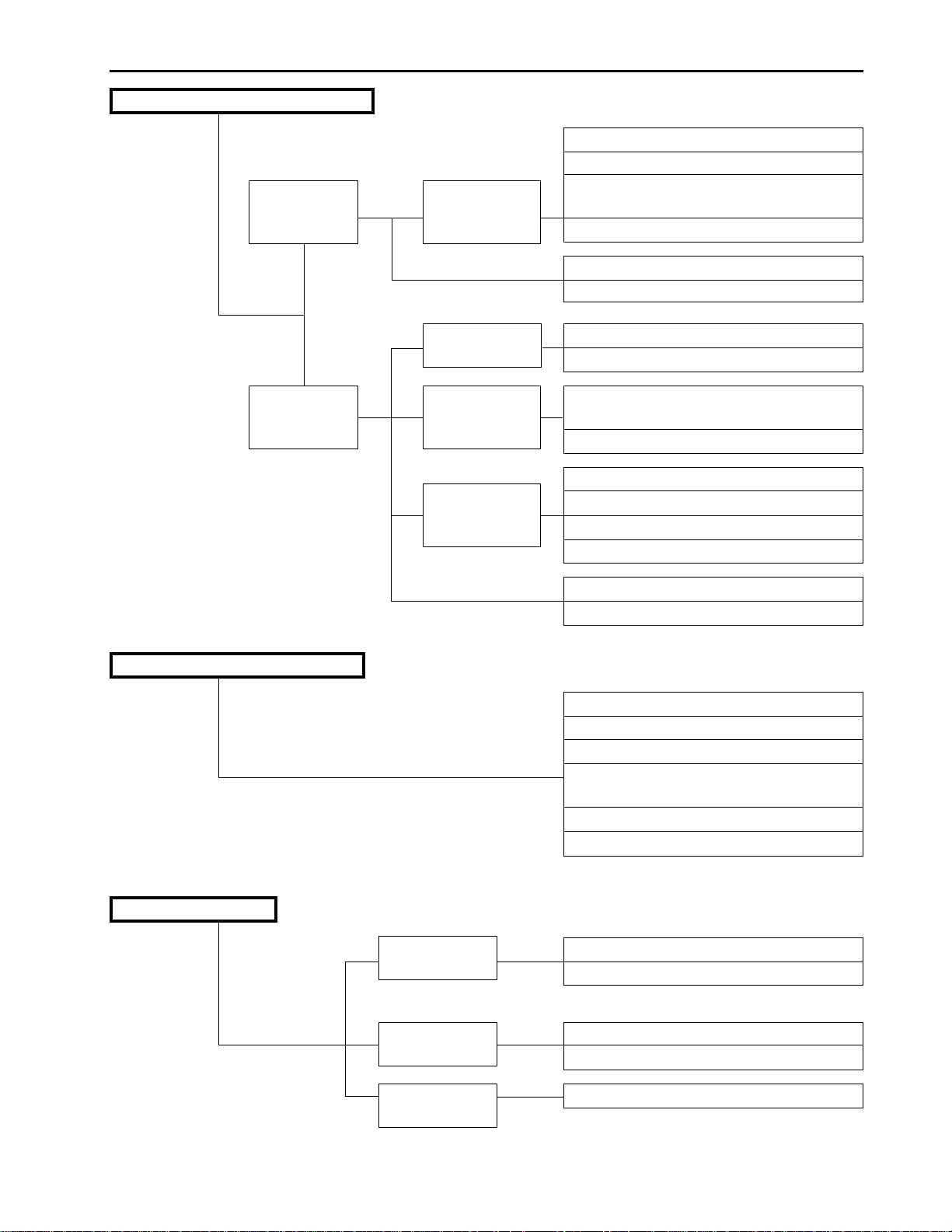

Color of exhaust fumes not normal.

White or blue

exhaust

fumes.

Lubricant

rises through

piston gap.

ENGINE SYSTEM

Piston ring stuck.

Piston ring worn.

Excessive gap between cylinder liner and

piston.

Too much oil.

Injection delayed.

Compression pressure insufficient.

Black or dark

gray exhaust

fumes.

Excessive lubricant consumption.

Injection

mistimed.

Fuel pump’s

injecting

capacity varies.

Nozzle does

not inject fuel

properly.

Injection too early.

Injection delayed.

Plunger does not return completely

because spring is stuck or broken.

Plunger worn.

Needle valve stuck.

Nozzle spring broken.

Too much carbon sticks to nozzle tip.

Injection pressure too low.

Compressed air leaks.

Not enough air.

Excessive gap between piston and liner.

Piston ring stuck.

Piston ring worn.

Excessive gap between intake/exhaust

valve and valve stem.

Valve stem seal broken.

Oil leaks from defective packings.

Lubricant increasing.

D704-W00 Dec. 2004

Fuel mixed

with oil.

Water mixed

with oil.

Gear oil mixed

with oil.

Injection pump plunger leaks much fuel.

Fuel pump leaks much fuel.

Head gasket packing faulty.

Crankcase cracked.

Hydraulic pump’s oil seal broken.

2-9

CHAPTER 2 CK25(H)/30(H)

6. SERVICING SPECIFICA TIONS

TD1300

A. ENGINE BODY

a. Cylinder Head

Item Factory Specification Allowable Limit

Cylinder Head Surface Flatness

Top Clearance

Thickness of gasketFree

Compression Pressure

(When cranking with starting motor)

* Variance of compression pressure among cylinders should be 10% or less.

0.7 ~ 0.9 mm

0.0276 ~ 0.0354 in.

When tightened

1.18 ~ 1.28 mm

0.0465 ~ 0.0504 in.

3.24 ~ 3.73 MPa

33 ~ 38 kgf/cm

469 ~ 540 psi

0.05 mm / 100 mm

0.002 in. / 3.94 in.

-

-

2.55 MPa

2

26 kgf/cm

370 psi

2

b. Valves

Item

Valve Clearance (Cold) IN.

EX.

Valve Seat Angle IN.

EX.

Valve Face Angle IN.

EX.

Valve Recessing

Clearance Between Valve Stem and Valve

Guide

Valve Stem O.D

Valve Stem I.D

c. Valve Timing

Item Factory Specification Allowable Limit

Inlet Valve Open

Close

Exhaust Valve Open

Close

Factory Specification

0.1 mm 0.0039 in.

0.1 mm 0.0039 in.

0.785 rad. 45°

0.785 rad. 45°

0.785 rad. 45°

0.785 rad. 45°

1.1 ~ 1.3 mm

0.0433 ~ 0.0512 in.

0.025 ~ 0.055 mm

0.0010 ~ 0.0022 in.

7.960 ~ 7.975 mm

0.31339 ~ 0.31398 in.

8.0 ~ 8.015 mm

0.31496 ~ 0.315 55 in.

0.349rad 20° before T.D.C

0.785rad 45° after B.D.C

0.873rad 50° before B.D.C

0.262rad 15° after T.D.C

Allowable Limit

1.6 mm

0.0630 in.

0.10 mm

0.004 in.

-

-

-

-

2-10

D704-W00 Dec. 2004

d. Cylinder Bore

Item Factory Specification Allowable Limit

Cylinder bore inner

diameter

e. Valve Spring

Item Factory Specification Allowable Limit

Free length

Assembling load / assembling length

Squareness

f. Rocker Arm

Item Factory Specification Allowable Limit

Rocker arm shaft O.D

Rocker arm bushing I.D

82.000 ~ 82.022 mm

3.2283 ~ 3.2292 in.

41.7 ~ 42.2 mm

1.6417 ~ 1.6614 in.

12.0 kgf / 35.15 mm

26.5 lbs / 1.3839 in.

-

13.973 ~ 13.984 mm

0.55012 ~ 0.55055 in.

13.998 ~ 14.023 mm

0.55110 ~ 0.55209 in.

ENGINE SYSTEM

0.15 mm

0.0059 in.

41.2 mm

1.6220 in.

10.2 kgf / 35.15 mm

22.5 lbs / 1.3839 in.

1.0 mm

0.039 in.

-

-

g. Tappet

Item Factory Specification Allowable Limit

Clearance between tappet and guide

Tappet O.D

Tappet guide I.D

h. Camshaft

Item Factory Specification Allowable Limit

Camshaft alignment

Cam height IN.

EX.

Clearance between camshaft

Camshaft journal O.D

Camshaft counter bore I.D

0.020 ~ 0.062 mm

0.00079 ~ 0.00244 in.

23.959 ~ 23.980 mm

0.94327 ~ 0.94410 in.

24.000 ~ 24.021 mm

0.94488 ~ 0.94571 in.

0.01 mm

0.0004 in.

33.5 ~ 33.6 mm

1.319 ~ 1.323 in.

33.5 ~ 33.6 mm

1.319 ~ 1.323 in.

0.050 ~ 0.091 mm

0.00197 ~ 0.00358 in.

39.934 ~ 39.950 mm

1.57221 ~ 1.57284 in.

40.000 ~ 40.025 mm

1.57480 ~ 1.57579 in.

0.07 mm

0.0028 in.

-

-

0.05 mm

0.0020 in.

33.45 mm

1.3169 in.

33.45 mm

1.3169 in.

0.15 mm

0.0059 in.

39.88 mm

1.5701 in.

-

D704-W00 Dec. 2004

2-11

CHAPTER 2 CK25(H)/30(H)

I. Timing Gear

Item Factory Specification Allowable Limit

Timing gear backlash

Idle gear side clearance

Clearance between Idle gear shaft and idle

gear bushing

Idle gear shaft O.D

Idle gear bushing I.D

j. Piston Ring

Item Factory Specification Allowable Limit

Piston pin-bore I.D

Clearance between Oil ring and ring groove

Oil ring groove width

Oil ring width

Clearance between 2nd ring and ring groove

2nd ring groove width

2nd ring width

Top ring, oil ring end gap

2nd ring end gap

0.04 ~ 0.11 mm

0.0016 ~ 0.0043 in.

0.20 ~ 0.51 mm

0.0079 ~ 0.0201 in.

0.020 ~ 0.054 mm

0.00079 ~ 0.00213 in.

27.967 ~ 27.980 mm

1.10106 ~ 1.10157 in.

28.000 ~ 28.021 mm

1.10236 ~ 1.10319 in.

23.00 ~ 23.013 mm

0.90551 ~ 0.90602 in.

0.020 ~ 0.060 mm

0.00079 ~ 0.00236 in.

5.01 ~ 5.03 mm

0.19724 ~ 0.19803 in.

4.97 ~ 4.99 mm

0.19567 ~ 0.19646 in.

0.065 ~ 0.100 mm

0.00256 ~ 0.00394 in.

2.055 ~ 2.070 mm

0.08091 ~ 0.08150 in.

1.97 ~ 1.99 mm

0.07756 ~ 0.07834 in.

0.25 ~ 0.40 mm

0.0098 ~ 0.01570 in.

0.25 ~ 0.40 mm

0.0098 ~ 0.01570 in.

0.15 mm

0.0059 in.

0.9 mm

0.035 in.

0.1 mm

0.0039 in.

-

-

23.053 mm

0.9076 in.

0.15 mm

0.0059 in.

-

-

0.15 mm

0.0059 in.

-

-

1.25 mm

0.0492 in.

1.25 mm

0.0492 in.

k. Connecting Rod

Item Factory Specification Allowable Limit

Connecting rod alignment

Clearance between Piston and small end

bushing

Piston pin O.D

Small end bushing I.D

2-12

-

0.014 ~ 0.038 mm

0.00055 ~ 0.00150 in.

23.002 ~ 23.011 mm

0.90560 ~ 0.90594 in.

23.025 ~ 23.040 mm

0.90650 ~ 0.90708 in.

0.05 mm

0.0020 in.

0.15 mm

0.0059 in.

-

-

D704-W00 Dec. 2004

l. Crankshaft

Item Factory Specification Allowable Limit

Crankshaft alignment

Clearance between Crankshaft and crank-

shaft bearing 1

Crankshaft O.D

Crankshaft bearing 1 I.D

Clearance between Crankshaft and crank-

shaft bearing 2

Crankshaft O.D

Crankshaft bearing 2 I.D

Clearance between Crank pin and Crank pin

bearing

Crank pin O.D

Crank pin bearing

I.D

Crankshaft side clearance

-

0.040 ~ 0.118 mm

0.00157 ~ 0.00465 in.

51.921 ~ 51.940 mm

2.04414 ~ 2.04488 in.

51.980 ~ 52.039 mm

2.04646 ~ 2.04878 in.

0.040 ~ 0.104 mm

0.00157 ~ 0.00409 in.

51.921 ~ 51.940 mm

2.04414 ~ 2.04488 in.

51.980 ~ 52.025 mm

2.04646 ~ 2.04823 in.

0.035 ~ 0.093 mm

0.0014 ~ 0.0037 in.

43.959 ~ 43.975 mm

1.73067 ~ 1.73130 in.

44.010 ~ 44.052 mm

1.73268 ~ 1.73433 in.

0.15 ~ 0.31 mm

0.0059 ~ 0.0122 in.

ENGINE SYSTEM

0.08 mm

0.0031 in.

0.20 mm

0.0079 in.

-

-

0.20 mm

0.0079 in.

-

-

0.20 mm

0.0079 in.

-

-

0.5 mm

0.020 in.

B. LUBRICATING SYSTEM

a. Oil Pump

Item Factory Specification Allowable Limit

Engine oil pressure

(oil temp. 85 ~ 95 °C,

185 ~ 203 °F)

Clearance between inner rotor and outer rotor

Radial clearance between outer rotor and pump

End clearance between inner rotor and cover

At idle speed

At rated speed

more than 68.6 kPa

0.7 kgf/cm

2

9.95 psi

294.2 ~ 441 kPa

3.0 ~ 4.5 kgf/cm

2

42.7 ~ 64.0 psi

0.10 ~ 0.16 mm

0.0039 ~ 0.0063 in.

0.11 ~ 0.19 mm

0.0043 ~ 0.0078 in.

0.105 ~ 0.150 mm

0.00413 ~ 0.00591 in.

-

294.2 kPa

3.0 kgf/cm

42.7 psi

0.2 mm

0.0079 in.

0.25 mm

0.0098 in.

0.2 mm

0.00787 in.

2

D704-W00 Dec. 2004

2-13

CHAPTER 2 CK25(H)/30(H)

C. COOLING SYSTEM

a. Thermostat

Valve opening temperature at beginning

Opened completely (height 8 mm 0.315 in.)

b. Radiator

Radiator tightness

Radiator cap tightness

Fan belt tension

[deflection at 78 N (8 kgf, 18 lbs) of force]

D. FUEL SYSTEM

a. Inject Pump

Injection timing (BTDC)

b. Injection Nozzle

Fuel injection pressure

Fuel tightness of nozzle valve seat

69.5 ~ 72.5 °C (157.1 ~ 162.5 °F)

85 °C (185 °F)

No leak at 137 kPa, 1.4 kgf/cm2, 20 psi

10 seconds or more for pressure

falling from 88 ~ 59 kPa

from 0.9 ~ 0.6 kgf/cm

2

from 13 ~ 9 psi

7 ~ 9 mm

0.28 ~ 0.35 in.

20°

14.709 MPa

150 kgf/cm

2

2,134 psi

No fuel leak for 5 sec.

at pressure

12.75 MPa

130 kgf/cm

2

1,849 psi

NOTE:

• Injection Sequence

Three Cylinders: 1 → 2 → 3

(The cylinder number is given in order from the gear

case end.)

2-14

D704-W00 Dec. 2004

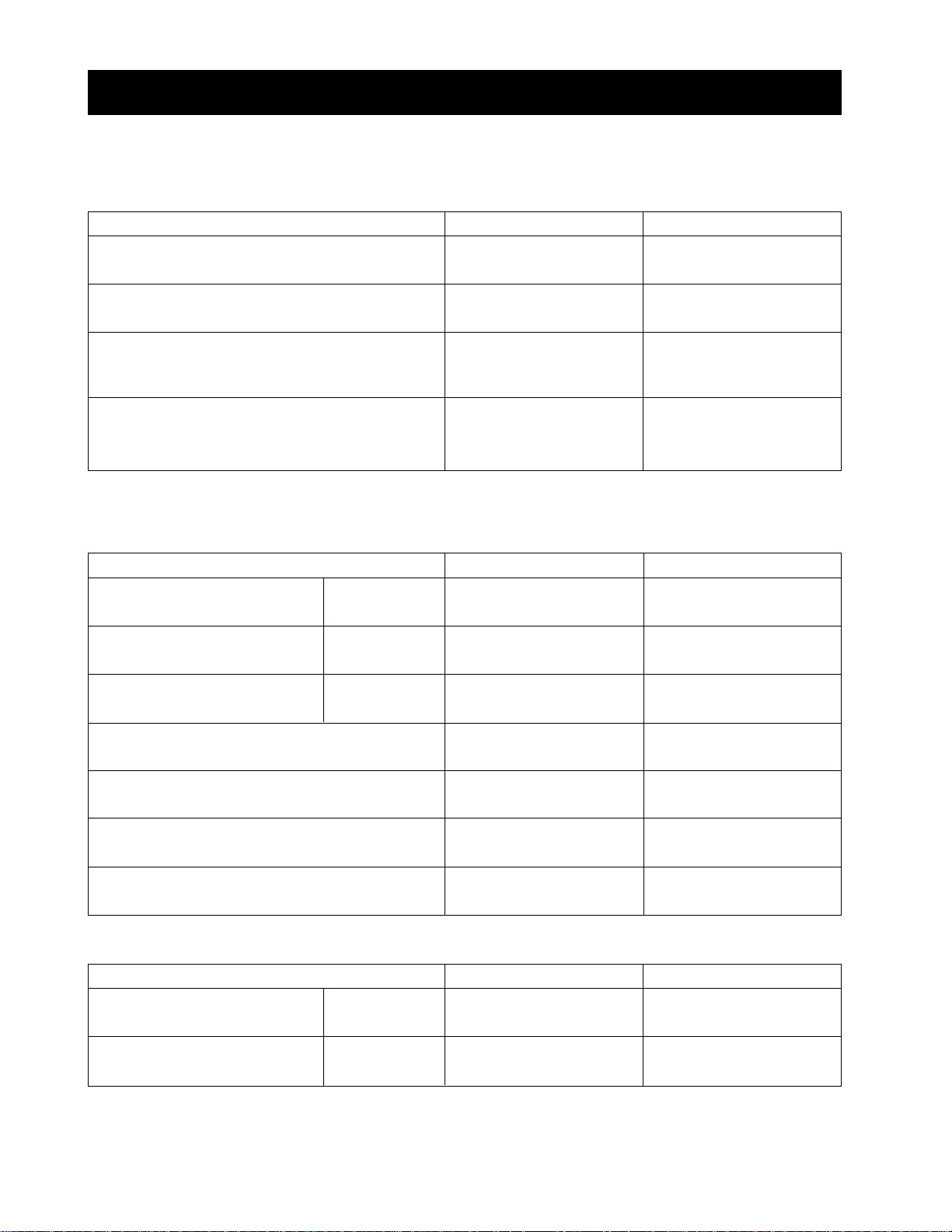

E. TIGHTENING TORQUES

ENGINE SYSTEM

Item

Cylinder head screws

Head cover bolts

* Bearing case screw 1

* Bearing case screw 2

* Flywheel screw

* Connecting rod screws

Rocker arm support bolts

Drain plug

Glow plugs

Oil switch

Nozzle locating screws

Injection pipe nuts

Size x Pitch

M11 x 1.25

M6 x 1.0

M9 x 1.25

M10 x 1.25

M12 x 1.25

M8 x 1.0

M10 x 1.25

M12 x 1.25

M10 x 1.25

PT1/8

M20 x 1.5

M12 x 1.5

NOTE:

• For *marked screw, bolts and nuts on the table,

apply engine oil to their threads and seats before

tightening.

• The letter “M” in Size x Pitch means that the screw,

bolt or nut dimension stands for metric. The size is

the nominal outside diameter in mm of the threads.

The pitch is the nominal distance in mm between

two threads.

N•m

103.0 ~ 107.9

8.8 ~ 11.8

46.1 ~ 51.0

68.6 ~ 73.6

98.1 ~ 107.9

46.1 ~ 51.0

68.0 ~ 70.6

32.4 ~ 37.3

19.6 ~ 24.5

14.7 ~ 19.6

49.1 ~ 68.7

24.5 ~ 34.3

kgf•m

10.5 ~ 11.0

0.9 ~ 1.2

4.7 ~ 5.2

7.0 ~ 7.5

10.0 ~ 11.0

4.5 ~ 5.0

6.2 ~ 7.2

3.3 ~ 3.8

2.0 ~ 2.5

1.5 ~ 2.0

5.0 ~ 7.0

2.5 ~ 3.5

lbf·ft

75.9 ~ 79.6

6.5 ~ 8.7

34.0 ~ 37.6

50.6 ~ 54.2

72.3 ~ 79.6

34.0 ~ 37.6

44.8 ~ 52.1

23.9 ~ 37.3

14.5 ~ 18.1

10.8 ~ 14.5

36.2 ~ 50.6

18.1 ~ 25.3

D704-W00 Dec. 2004

2-15

CHAPTER 2 CK25(H)/30(H)

3A150

F. ENGINE BODY

a. Cylinder Head

Item Factory Specification Allowable Limit

Cylinder Head Surface Flatness

Top Clearance

Thickness of gasketFree

Compression Pressure

(When cranking with starting motor)

* Variance of compression pressure among cylinders should be 10% or less.

b. Valves

0.750 ~ 0.9 mm

0.0294 ~ 0.0354 in.

When tightened

1.17 ~ 1.26 mm

0.0466 ~ 0.0496 in.

3.24 ~ 3.73 MPa

33 ~ 38 kgf/cm

469 ~ 540 psi

0.05 mm / 100 mm

0.002 in. / 3.94 in.

-

-

2.55 MPa

2

26 kgf/cm

370 psi

2

Item

Valve Clearance (Cold) IN.

EX.

Valve Seat Angle IN.

EX.

Valve Face Angle IN.

EX.

Valve Recessing

Clearance Between Valve Stem and Valve

Guide

Valve Stem O.D

Valve Stem I.D

c. Valve Timing

Item Factory Specification Allowable Limit

Inlet Valve Open

Close

Exhaust Valve Open

Close

Factory Specification

0.25 mm 0.0098 in.

0.30 mm 0.0118 in.

0.785 rad. 45°

0.785 rad. 45°

0.785 rad. 45°

0.785 rad. 45°

0.2 ~ 0.5 mm

0.0079 ~ 0.0197 in.

0.040 ~ 0.070 mm

0.0016 ~ 0.0028 in.

7.960 ~ 7.975 mm

0.31339 ~ 0.31398 in.

8.015 ~ 8.030 mm

0.3156 ~ 0.316 1 in.

0.14rad 8° before T.D.C

0.611rad 35° after B.D.C

0.785rad 45° before B.D.C

0.140rad 8° after T.D.C

Allowable Limit

0.8 mm

0.0315 in.

0.10 mm

0.0039 in.

-

-

-

-

2-16

D704-W00 Dec. 2004

d. Cylinder Bore

Item Factory Specification Allowable Limit

Cylinder bore inner

diameter

e. Valve Spring

Item Factory Specification Allowable Limit

Free length

Assembling load / assembling length

Squareness

f. Rocker Arm

Item Factory Specification Allowable Limit

Rocker arm shaft O.D

Rocker arm bushing I.D

83.000 ~ 83.022 mm

3.2677 ~ 3.2690 in.

41.7 ~ 42.2 mm

1.6417 ~ 1.6614 in.

12.0 kgf / 35.15 mm

26.5 lbs / 1.3839 in.

-

18.955 ~ 18.980 mm

0.7463 ~ 0.7472 in.

19.000 ~ 19.025 mm

0.7480 ~ 0.7490 in.

ENGINE SYSTEM

0.15 mm

0.0059 in.

41.2 mm

1.6220 in.

10.2 kgf / 35.15 mm

22.5 lbs / 1.3839 in.

1.0 mm

0.039 in.

-

-

g. Tappet

Item Factory Specification Allowable Limit

Clearance between tappet and guide

Tappet O.D

Tappet guide I.D

h. Camshaft

Item Factory Specification Allowable Limit

Camshaft alignment

Cam height IN.

EX.

Clearance between camshaft

Camshaft journal O.D

Camshaft counter bore I.D

0.020 ~ 0.062 mm

0.00079 ~ 0.00244 in.

23.959 ~ 23.980 mm

0.94327 ~ 0.94410 in.

24.000 ~ 24.021 mm

0.94488 ~ 0.94571 in.

0.01 mm

0.0004 in.

33.9 mm

1.3224 in.

33.69 mm

1.326 in.

0.050 ~ 0.091 mm

0.00197 ~ 0.00358 in.

39.934 ~ 39.950 mm

1.57220 ~ 1.57283 in.

40.000 ~ 40.025 mm

1.57480 ~ 1.57579 in.

0.07 mm

0.0028 in.

-

-

0.05 mm

0.0020 in.

33.54 mm

1.3205 in.

33.64 mm

1.3244 in.

0.15 mm

0.0059 in.

39.88 mm

1.5701 in.

-

D704-W00 Dec. 2004

2-17

CHAPTER 2 CK25(H)/30(H)

I. Timing Gear

Item Factory Specification Allowable Limit

Timing gear backlash

Idle gear side clearance

Clearance between Idle gear shaft and idle

gear bushing

Idle gear shaft O.D

Idle gear bushing I.D

j. Piston Ring

Item Factory Specification Allowable Limit

Piston pin-bore I.D

Clearance between Oil ring and ring groove

Oil ring groove width

Oil ring width

Clearance between 2nd ring and ring groove

2nd ring groove width

2nd ring width

Top ring, oil ring end gap

2nd ring end gap

0.04 ~ 0.11 mm

0.0016 ~ 0.0043 in.

0.20 ~ 0.51 mm

0.0079 ~ 0.0201 in.

0.025 ~ 0.066 mm

0.00098 ~ 0.00250 in.

37.9590 ~ 37.9950 mm

1.49445 ~ 1.49508 in.

38.000 ~ 38.025 mm

1.49608 ~ 1.49705 in.

25.00 ~ 25.006 mm

0.98425 ~ 0.98448 in.

0.020 ~ 0.060 mm

0.00079 ~ 0.00236 in.

5.01 ~ 5.03 mm

0.19724 ~ 0.19803 in.

5.97 ~ 5.99 mm

0.23504 ~ 0.23583 in.

0.065 ~ 0.100 mm

0.00256 ~ 0.00394 in.

2.055 ~ 2.070 mm

0.08091 ~ 0.08150 in.

1.97 ~ 1.99 mm

0.07756 ~ 0.07834 in.

0.25 ~ 0.40 mm

0.0098 ~ 0.01570 in.

0.25 ~ 0.40 mm

0.0098 ~ 0.01570 in.

0.15 mm

0.0059 in.

0.9 mm

0.035 in.

0.1 mm

0.0039 in.

-

-

25.03 mm

0.9854 in.

0.15 mm

0.0059 in.

-

-

0.15 mm

0.0059 in.

-

-

1.25 mm

0.0492 in.

1.25 mm

0.0492 in.

k. Connecting Rod

Item Factory Specification Allowable Limit

Connecting rod alignment

Clearance between Piston and small end

bushing

Piston pin O.D

Small end bushing I.D

2-18

-

0.014 ~ 0.038 mm

0.00055 ~ 0.00150 in.

25.002 ~ 25.011 mm

0.98433 ~ 0.98469 in.

25.025 ~ 25.040 mm

0.98524 ~ 0.98583 in.

0.05 mm

0.0020 in.

0.15 mm

0.0059 in.

-

-

D704-W00 Dec. 2004

l. Crankshaft

Item Factory Specification Allowable Limit

Crankshaft alignment

Clearance between Crankshaft and crank-

shaft bearing 1

Crankshaft O.D

Crankshaft bearing 1 I.D

Clearance between Crankshaft and crank-

shaft bearing 2

Crankshaft O.D

Crankshaft bearing 2 I.D

Clearance between Crank pin and Crank pin

bearing 2

Crank pin O.D

Crank pin bearing

I.D

Crankshaft side clearance

-

0.040 ~ 0.118 mm

0.00157 ~ 0.00465 in.

51.921 ~ 51.940 mm

2.04414 ~ 2.04488 in.

51.980 ~ 52.039 mm

2.04646 ~ 2.04878 in.

0.040 ~ 0.104 mm

0.00157 ~ 0.00409 in.

51.921 ~ 51.940 mm

2.04414 ~ 2.04488 in.

51.980 ~ 52.025 mm

2.04646 ~ 2.04823 in.

0.035 ~ 0.093 mm

0.0014 ~ 0.0037 in.

43.959 ~ 43.975 mm

1.73067 ~ 1.73130 in.

44.010 ~ 44.052 mm

1.73268 ~ 1.73433 in.

0.15 ~ 0.31 mm

0.0059 ~ 0.0122 in.

ENGINE SYSTEM

0.08 mm

0.0031 in.

0.20 mm

0.0079 in.

-

-

0.20 mm

0.0079 in.

-

-

0.20 mm

0.0079 in.

-

-

0.5 mm

0.020 in.

G. LUBRICATING SYSTEM

a. Oil Pump

Item Factory Specification Allowable Limit

Engine oil pressure

(oil temp. 85 ~ 95 °C,

185 ~ 203 °F)

Clearance between inner rotor and outer rotor

Radial clearance between outer rotor and pump

End clearance between inner rotor and cover

At idle speed

At rated speed

more than 68.6 kPa

0.7 kgf/cm

2

9.95.11 psi

245.1 kPa

2.5 kgf/cm

2

35.5 psi

0.10 ~ 0.16 mm

0.0039 ~ 0.0063 in.

0.11 ~ 0.19 mm

0.0043 ~ 0.0078 in.

0.105 ~ 0.150 mm

0.00413 ~ 0.00591 in.

-

294.2 kPa

3.0 kgf/cm

42.7 psi

0.2 mm

0.0079 in.

0.25 mm

0.0098 in.

0.2 mm

0.00787 in.

2

D704-W00 Dec. 2004

2-19

Loading...

Loading...