jf~ftffi~I~ffl~nt}J~ INDUSTRIAL SEWING MACHINE

M@IIDJ111

UH9000

...

-\

-2

3

,_._

~

(user

ffiffl\ffl\~JH~f,fffillffl_~q]

http://www.kingtexsewing.com.

CHING

Manua!)

CHI

MACHINE CO.,

tw

LTD

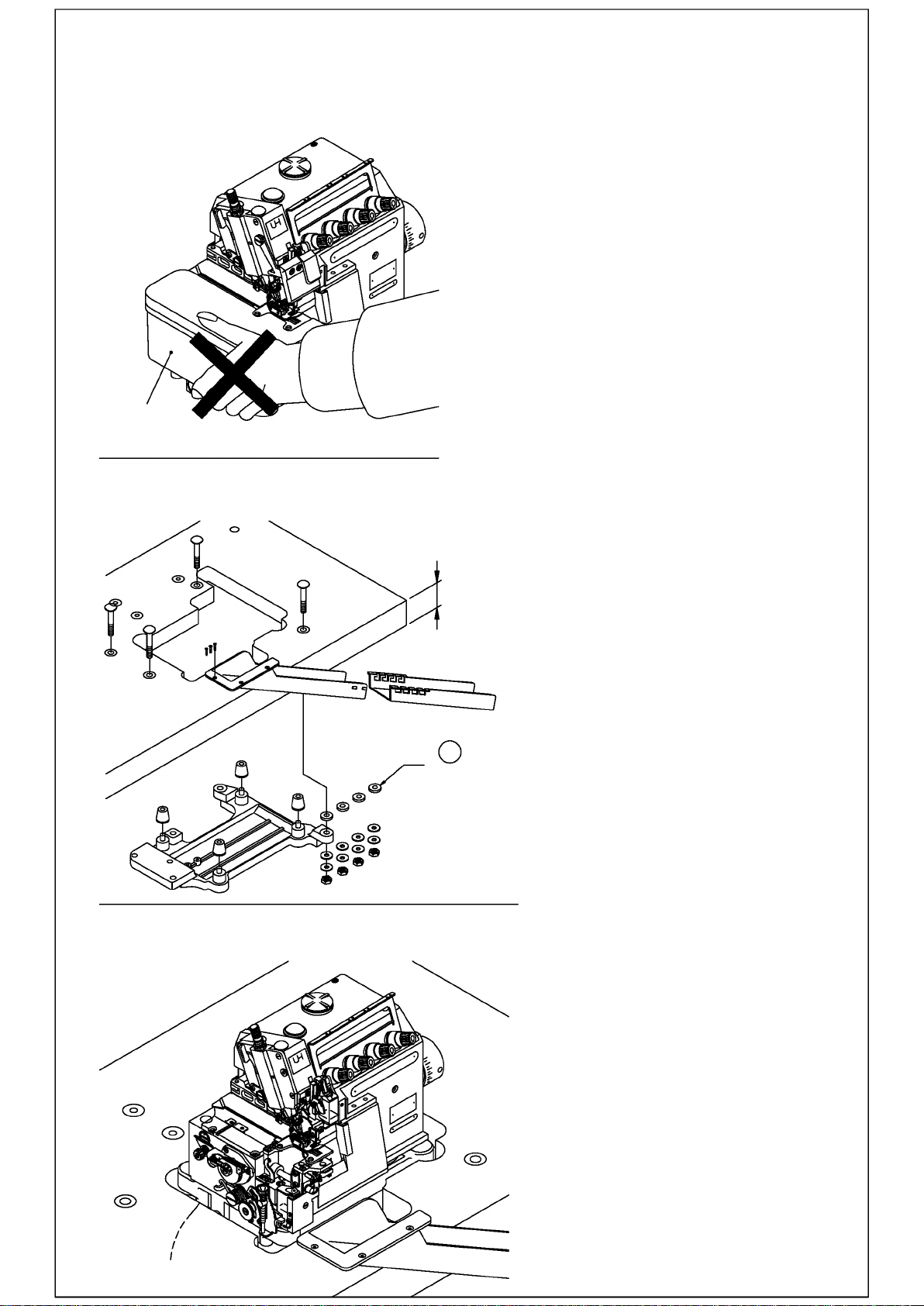

1. INSTALLATION

1-1 MOVING:

CLOTH PLATE COVER

1-2 INSTALLATION OF FRAME SUPPORT PLATE AND WA S TE CHUTE:

DURING INSTALLATION

PROCESS , DO NOT MOVE

SEWING MACHINE BY

HOLDING CLOTH PLATE.

22

33

90009000

44

55

66

40mm

WASHER

1

0

~

1-3 IN STALLATIO N OF SEWIN G MACHINE :

PLEASE USING STANDARD TABLE

OF 40 mm IN THICKNESS . IF

USE THE TABLE IN 35 mm IN

THICKNESS , THEN , PLEASE

REFER TO INSTALLATION MAP .

7

PLEASE MAKE SURE THERE

22

33

90009000

44

55

66

HAVE ENOUGH ROOM BETW EEN

SEWIN G MACHIN E AND THE

TABLE AROUND IT AFTER

INSTALLATIO N . TABLE CAN

NOT INTERFERENCE WIT H THE

SEWING MACHINE .

--

++

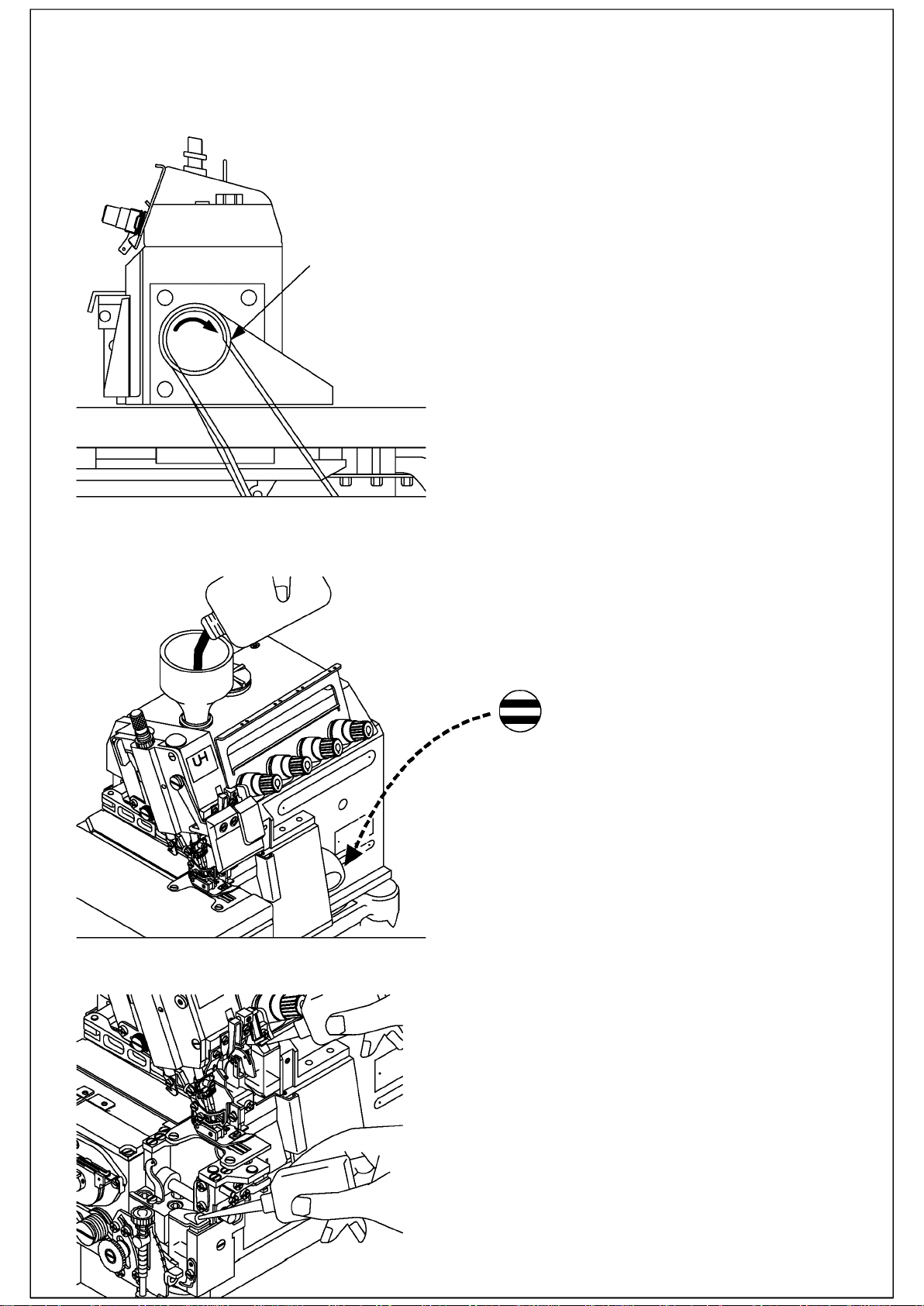

1-4. INSTALLATION OF MOTOR BELT :

CENTER OF

BELT PULLEY

-

-

CLUTCH

MOTOR MOTOR

-

CLUTCH

CENTER OF

BELT PULLEY

-

-,

I '

'

-

-

UH9000 UH9000 UH9000

INSTALL MOTOR BELT AND MAKE SURE MOTOR BELT IN PARALLEL

WITH BOTH PULLEY OF CLUTCH MOTOR AND SEWING MACHINE BY

ADJUSTING CLUTCH MOTOR'S POSITION PROPERLY .

CENTER OF

BELT PULLEY

CLUTCH

MOTOR

SEWING MACHINES

BELT

2cm

MOTOR BELT

1-5 INSTALLATION OF BELT COVER :

INSTALL MOTOR BELT AND MAKE

SURE THERE HAVE 2 c.m.

TOLERANCE BY PRESS THE MOTOR

BELT.

FOR SAFTY REASON , BELT COVER

MUST BE INSTALLED .

BELT COVER

11

22

33

44

2. BEFORE OPERATION :

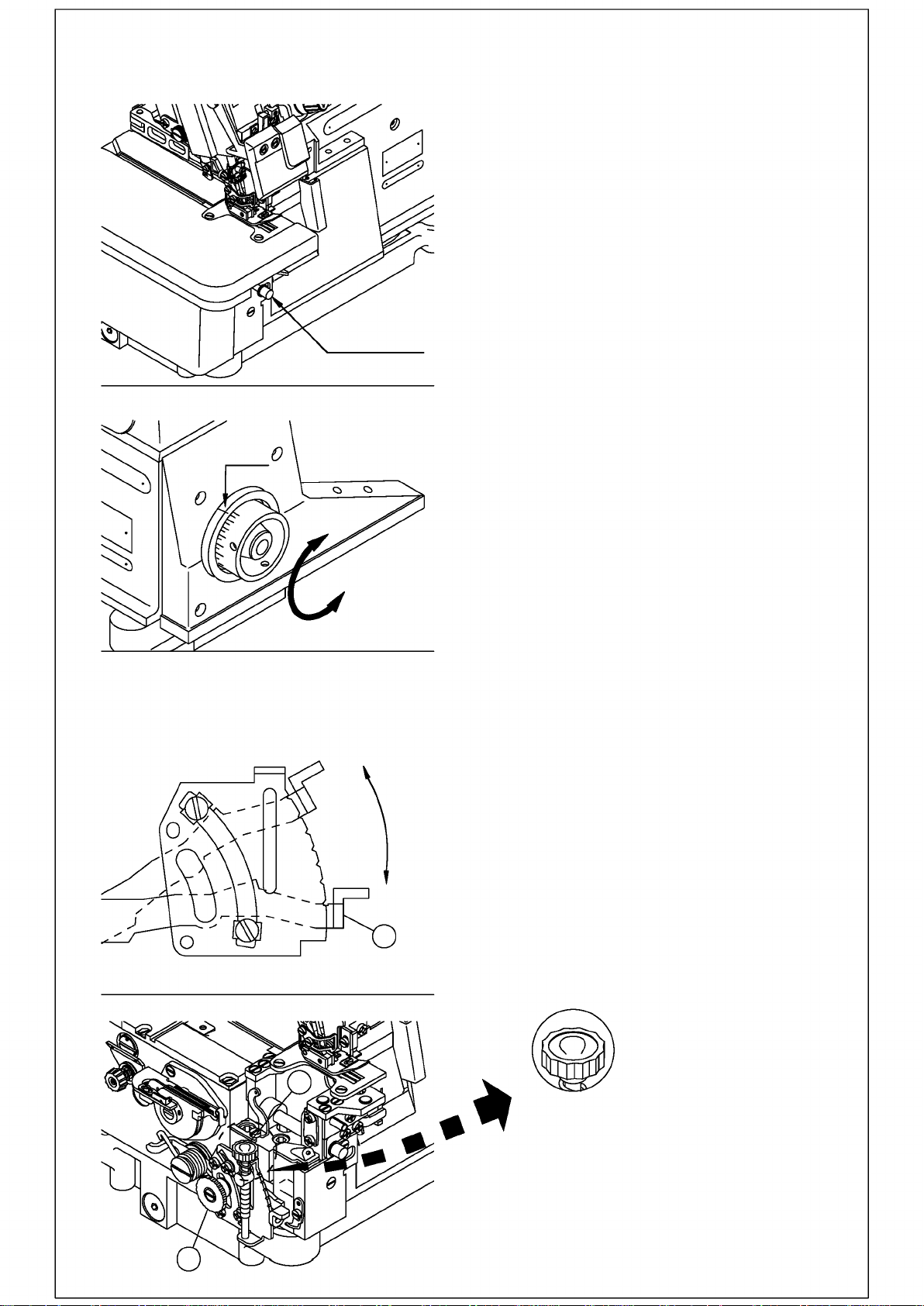

2-1TURNING DIRECTION OF BELT PULLEY:

PLEASE MAKE SURE SEWING MACGINE'S

BELT PULLEY IS TURNING CLOCKWISE .

AS FIGURE 2-1 .

SEWING MACHINES

BELT

2-2 ADDING LUBRICATION OIL AND SILICON OIL :

ADDING LUBRICATION OIL DURING ADDING PROCESS ,

PLEASE MAKE SURE THE

LUBRICATION OIL CAN NOT OVER

THE UPPER LIMIT OF OIL

GAUGE .

TOP

000

9

SPECIFICATION OF LUBRICATION OIL:

MOBIL VELOCTE OIL NO.10(ISO/VG22).

OR SAME SPECIFICATION OF OTHER

BRAND'S OIL .

LOW

ADDING SILICON OIL

PLEASE ADD PROPER SILICON OIL INTO

SILICON OIL RESERVOIRS IN ORDER TO

PREVENT THREAD BREAKAGE.

SPECIFICATION OF SILICON OIL:

UNION CARBIDE CORP. UCC L-45 (10)

OR SAME SPECIFICATION OF OTHER

-

-

+

+

BRAND'S SILICON OIL .

3. TEST SEWING AND ADJUSTING :

3-1 DESCRIPTION :

EVEN THOUGHT THE MACHINE IS UNDER ITS BEST NORMAL

SEWING CONDITION WHEN OUT OF THE FACTORY , HOWE VER ,

DUE TO DIFFERENT SEWING REQUIRENENTS , SUCH AS SEWING

FABRICS , SEWING THREADS , IT MAY REQUIRED MINOR

ADJUSTNENTS ON SEWING MACHINES AS FOLLOWS:

OIL SIGHT WINDOW

DURING THE FIRST USAGE , PLEASE MAKE

SURE LUBRICATION OIL CIRCULATES

PROPERLY.

09 00

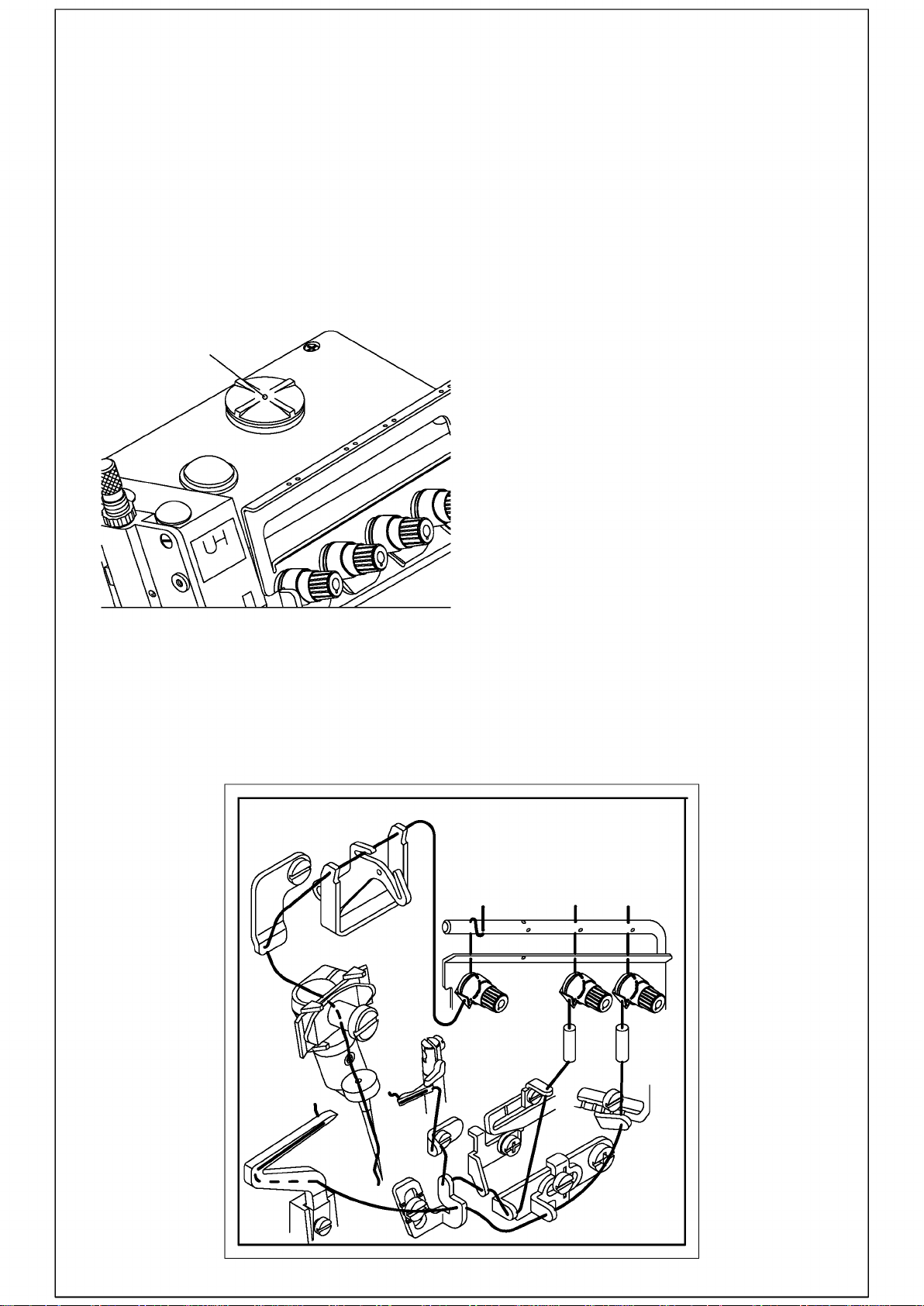

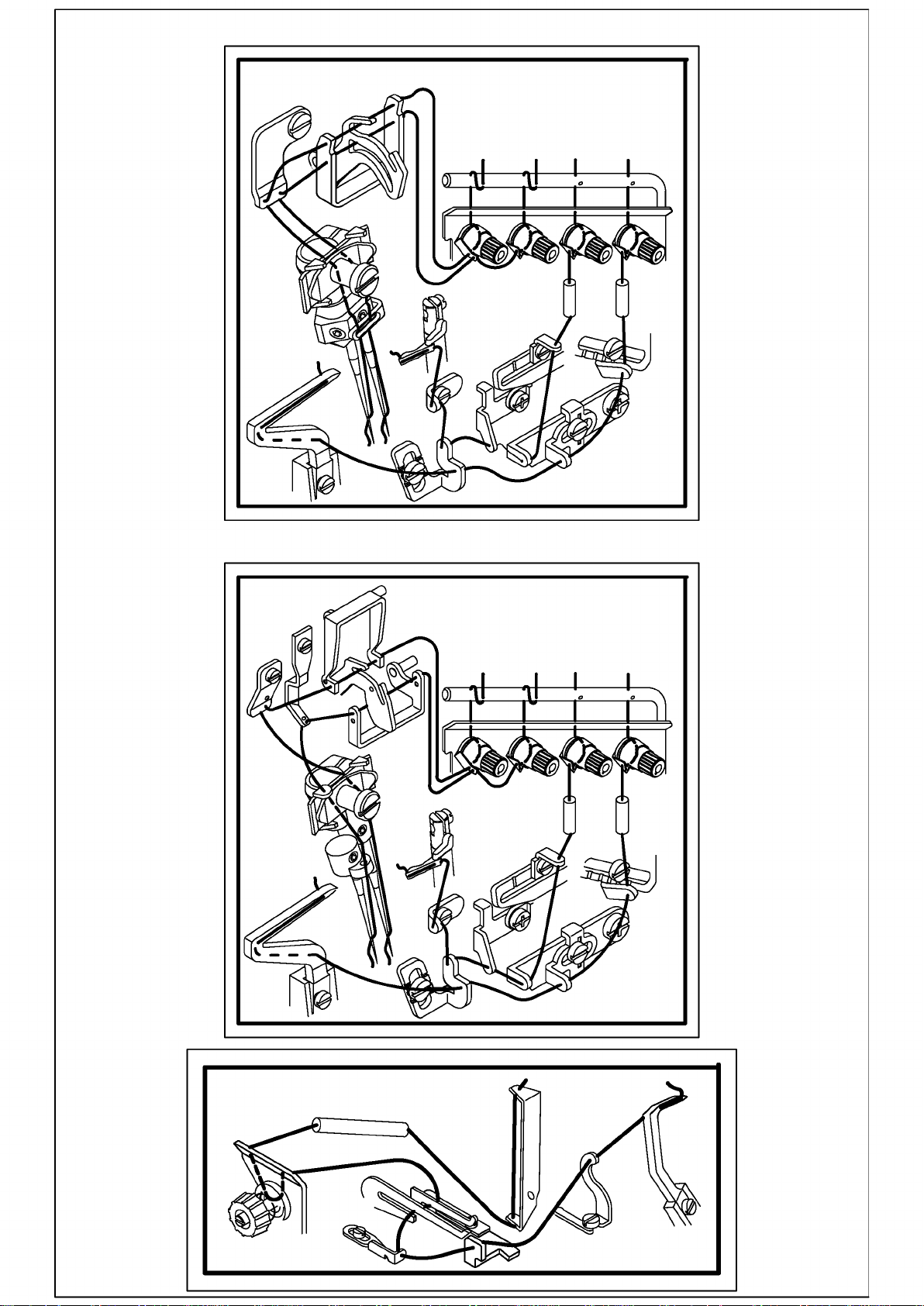

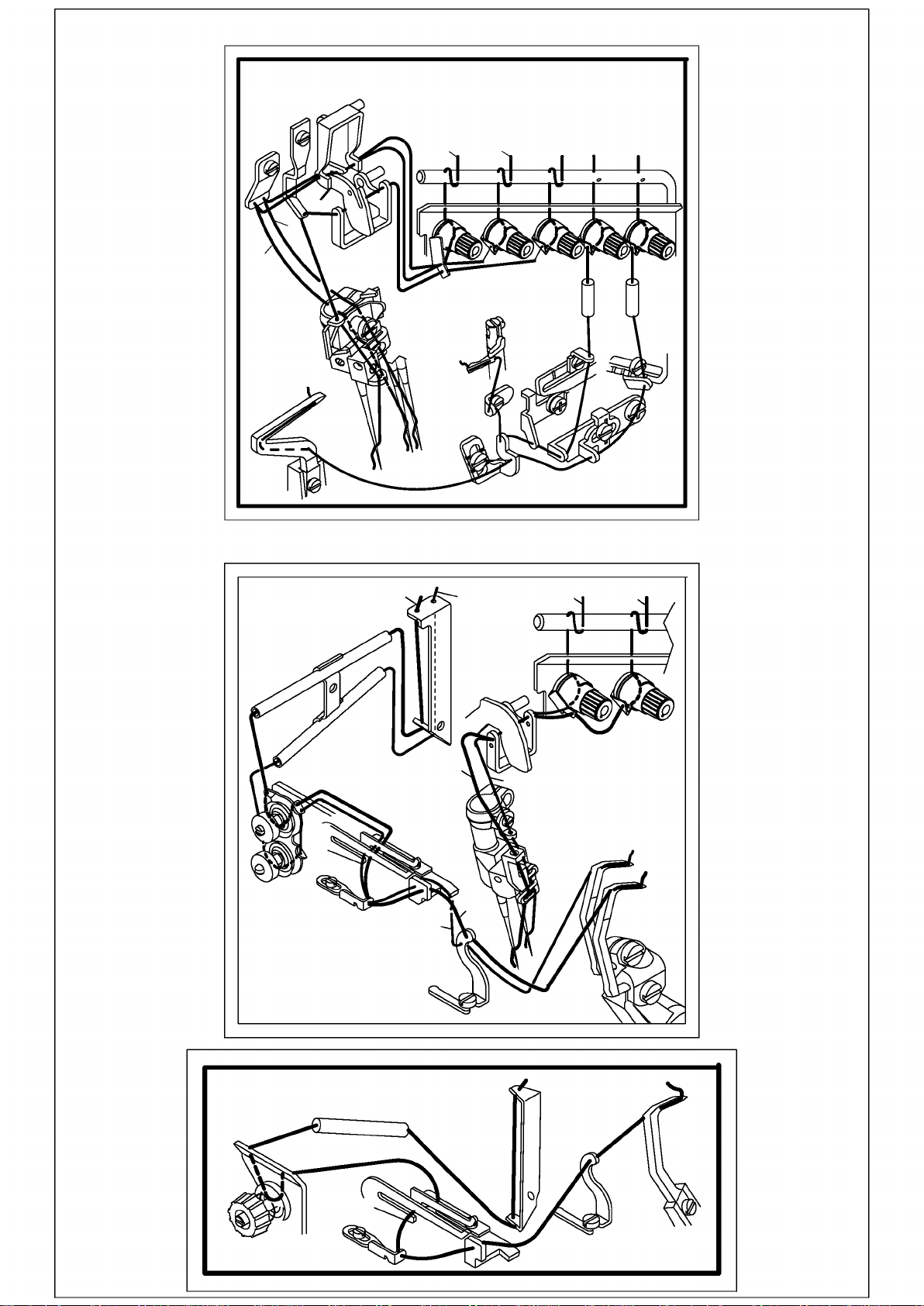

3-2 THREADING MAP :

MISTHREADING WILL CAUSE THREAD BREAKAGE , SKIP

STITCH OR OTHER SEWING DEFECTS , THUS , PLEASE MAKE

SURE FOLLOW THE THREADING MAP AND THREADING

PROPERLY .

Uh9003 . STITCH TYPE 504 .

504

6440-3

UH9004 . STITCH TYPE 514 .

514

UH9005 . STITCH TYPE 516 .

516

6440-4

401

6440-5

6440-6

UH9006 . STITCH TYPE 544 .

514+401

1

2

for 34

2

UH9034

4

1

6440-7

3

2

1

401

6440-8

1

3

2

4

6440-6

3-3 OPEN AND CLOSE THE CLOTH PLATE

CLOTH PLATE

CLOSE

OPEN

9000

HOOK

AND FRONT COVER :

PRESS DOWN HOOK AND PUSH TO

LEFT IN ORDER TO OPEN CLOTH

22

33

44

55

66

PLATE , PUSHING RIGHT TO ITS

HOOK SET POSOTION , THE CLOTH

PLATE WILL BE CLOSED .

00

90

OPEN AND CLOSE FRONT COVER :

PUSHING FRONT COVER TO RIGHT SET

UP

POSITION AND PULL DOWN TO OPEN

IT . AND ON THE OTHER HAND , PULL UP

TO ITS SET POSITION AND TO LEFT IN

DOWN

ORDER TO CLOSE FRONT COVER .

AFTER CLOSING FRONT COVER ,

PLEASE MAKE SURE THERE IS NO

INTERFERENCE BETWEEN FRONT

COVER AND OTHER PARTS .

RIGHT

LEFT

3-4 OPEN AND CLOSE THE PRESSER FOOT ARM AND ADJUSTING PRESSURE :

OPEN AND CLOSE THE PRESSER FOOT ARM :

PUSH LEVER DOWN TO ITS SET

LEVER

9 000

PRESSER

FOOT ARM

POSITION THEN TAKE OUT PRESSER FOOT ARM .

VICE VERSA , PUSH DOWN LEVER TO

ITS SET POSITION , CAN PUT PRESSER

FOOT ARM BACK .

WHEN PUT PRESSER FOOT ARM

BACK , PLEASE MAKE SURE IT WILL

BE BACK TO ITS SET POSITION .

OPEN

STRONG

WEAK

ADJUSTING PRESSURE

TURING ADJUSTING SCREW

CLOCKWISE IN ORDER TO INCREASE PRESSURE .

TURNING ADJUSTING SCREW

2

9000

COUNTERCLOCKWISE IN ORDER TO

DECREASE PRESSURE .

1

3-5 ADJUSTING STITCH LENGTH AND DIFFERENTIAL RATIO :

ADJUSTING STITCH LENGTH :

PUSHING THE PUSH BUT TON

LIGHTLY FIRST AND TURNING

PULLEY TO SET POSITION THEN

PUSHING DOWN THE PUSH BUT TON

INTO ITS SET POSITION AND ADJUST

THE LENGTH OF STITCH .

PUSH BUTTON

REMARK : THE DISTANCE MARK ON

MARK

11

22

33

44

55

66

77

LONG

SHORT

THE PULLEY ONLY REPRESENT

APPROX LENGTH OF STITCH AND

ACTUAL STITCH LENGTH NEEDED

SHOULD GET FROM TEST SEWING .

ADJUSTING DIFFERENTIAL RATIO :

DIFFERENTIAL RATIO WAS SET AT 1 : 1

SHRINK STITCH

WHEN MACHINES WERE OUT OF

FACTORY . ADJUST DIFFERENTIAL

RATIO AS NEEDED .

OPEN UP CLOTH PLATE , LOOSEN NUT

(2) MOVE LEVEL (1) UPWARD OR

DOWNWARN TO THE POSITION NEEDED.

THEN

TIGHTEN NUT (2) . FOR

MICRO-ADJUSTMENT PLEASE TURN

ADJUSTING SCREW (3) .

STRETCH STITCH

1

SHRINK STITCH

(+)

3

--

++

+

-

(-)

STRETCH STITCH

2

3-6 ADJUSTING THREAD TENSION AND TENSION AMOUNT :

WEAK

00 00

STRONG

NEEDLE THREAD TENSION AMOUNT :

aa

bb

AABBCC

ADJUSTING THREAD TENSION

THREAD TENSION CORRELATE WITH

THREAD TENSION AMOUNT . PLEASE

REFER TO THIS ITEM AND NEXT ITEM

TO ADJUST THREAD TENSION

AMOUNT IN ORDER TO GET BEST

RESULT .

TURNING CLOCKWISE IN ORDER TO

GET STRONG THREAD TENSION .

TURNING COUNTERCLOCKWISE IN

ORDER TO GET WEAK THREAD

TENSION .

A : FOR UH-9003 , UH-9004 USAGE .

TOWARD (+) DIRECTION GET

BIGGER THREAD TENSIION AMOUNT .

TOWARD (-) DIRECTION GET

SMALLER THREAD TENSION AMOUNT .

B : FOR UH-9005 USAGE .

TOWARD (+) DIRECTION IN ORDER

TO GET BIGGER THREAD TENSION AMOUNT

TOWARD (-) DIRECTION IN

ORDER TO GET SMALLER THREAD

TENSION AMOUNT .

C : IF CHAIN STITCH NEEDLE THREAD

LOOP FORMED TOO EARLY , PLEASE

ADJUST THREAD GUIDE TO

DIRECTION .

0

a

UPPER / LOWER LOOPER THREAD TENSION AMOUNT :

CHAINSTITCH LOOPER THREAD TENSION AMOUNT :

PLEASE ADJUST TENSION AMOUNT

ACCORDING TO ARROW DIRECTION

(+) INCREASE LOOPER THREAD

TENSION AMOUNT .

(-) DECREASE LOOPER THREAD

TENSION AMOUNT .

WHEN ADJUSTING CHAINSTITCH

LOOPER THREAD , IF THREAD LOOP

COLLAPSE , UNSTABLE OR CAN NOT

FORM THREAD LOOP , PLEASE ADJUST

THREAD TENSION AMOUNT

ACCORDING TO ARROW DIRECTION

(+) INCREASE .

(-) DECRCASE .

4. REPAIRING AND MAINTENANCE :

4-1 CHANGING LUBRICATION OIL , OIL FILTER AND NEEDLES

CHANGE LUBRICATION OIL .

AFTER OPERATING SEWING

MACHINE FOR 160-200 HOURS

( APPROX ONE MONTH .) PLEASE

CHANGE LUBRICATION OIL AND

CHANGE LUBRICATION OIL EVERY 6

MONTHS THEREAFTER .

IF STOP USING SEWING MACHINE FOR

A LONG TIME , PLEASE CHANGE

LUBRICATION OIL BEFORE OPERATE

AGAIN . CHANGE LUBRICATION OIL

BY TAKE OFF PLUG .

PLUG

CHANGE OIL FILTER

OIL SIGHT WINDOW

CHANGE NEEDELS

9000

9000

PLEASE CHANGE OIL FILTER AFTER

APPROX 6 MONTHS USAGE OR FOUND

OUT OIL CIRCULATION WAS NOT

NORMAL FROM OIL SIGHT WINDOW .

1

MAKE SURE TO INSERT NEEDLES

ALL THE WAY TO THE BOTTOM OF

NEEDLE HOLES .

WHEN CHANGING NEEDLES , PLEASE

MAKE SURE NEEDLE GROOVE IS IN ITS

CORRENT POSITION AND ALSO MAKE

SURE NEEDELS BE INSERTED ALL THE

WAY TO THE BOTTOM OF NEEDLE

HOLES .

NEEDLE

GROOVE

FRONT

VIEW

SIDE

VIEW

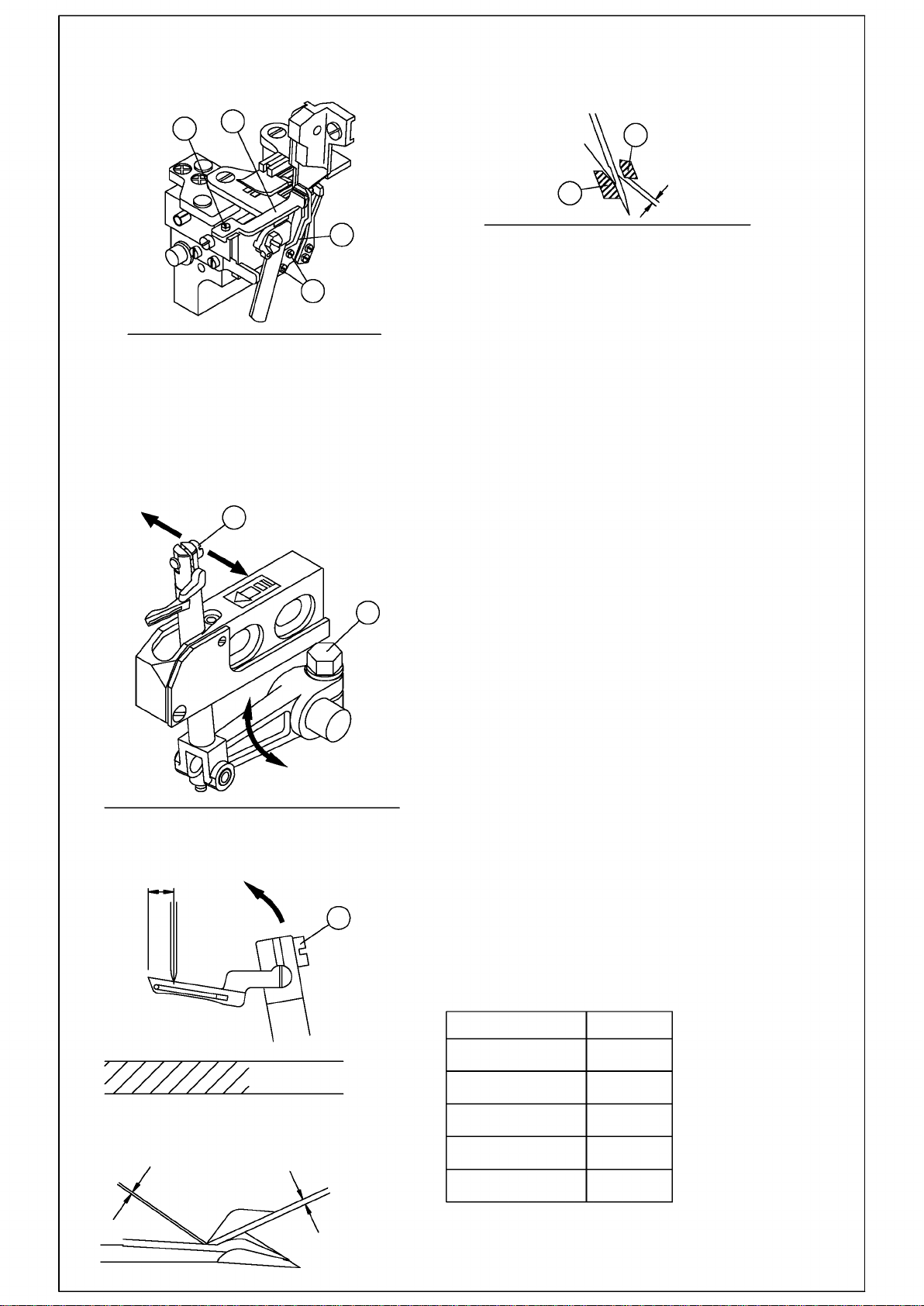

4-2 CHANGING UPPER , LOWER KNIFE :

CHANGING UPPER KNIFE:

3

4

1

2

7

6

5

8

A . LOOSEN SCREW (1) PUSH LOWER

KNIFE HOLDER (2) TO LEFT , THEN ,

TIGHTEN SCREW (1) LIGHTY .

B . TAKE OFF SCREW (3) CHANGE NEW

UPPER KNIFE (4) . THEN , TIGHTEN

SCREW (3) LIGHTLY .

C . LOOSEN SCREW (1) MAKE SURE

LOWER KNIFE (8) TOUCH UPPER

KNIFE CLOSELY .

D . TURNING HAND WHEEL TILL UPPER

KNIFE CLAMP REACH ITS LOWEST

POSITION . THEN , ADJUSTING THE

POSITION OF UPPER KNIFE IN ORDER

TO MAKE SURE UPPER KNIFE AND

LOWER KNIFE OVERLAP BY 0.5 mm .

E . TIGHTEN SCREW (3) , (1) .

CHANGING LOWER KNIFE

KNIFE TIP

8

9

NEEDLE

PLATE

A . LOOSEN SCREW (1) PUSH LOWER

KNIFE HOLDER (2) TO LEFT , THEN ,

TIGHTEN SCREW (1) LIGHTY .

B . LOOSEN SCREW (9) TAKE OFF OLD

LOWER KINFE (8) AND CHANGE NEW

LOWER KNIFE .

C . MAKE SURE THE TIP OF LOWER

KNIFE LINE EVEN WITH THE TOP OF

NEEDLE PLATE . THEN , TIHGTEN

SCREW (9) .

D . LOOSEN SCREW (1) MAKE SURE

LOWER KNIFE TOUCH UPPER KNIFE

(4) CLOSELY . THEN , TIGHEN

SCREW (1) .

UPPER AND LOWER

KNIFE OVERLAP

AMOUNT 0.5 mm

TOP OF NEEDLE PLATE

DIAGRAM 1

4-3 CHANGING AND ADJUSTING FEED DOGS .

CHANGING FEED DOGS .

LOOSEN SCREW (1) CAN CHANGE

1

2

ADJUSTING FEED DOGS AFTER CHANGED :

0.8-1mm

3

TOP OF

2

2

1

NEEDLE PLATE

TOP OF

NEEDLE PLATE

1

4

MAIN FEED DOG (4) ,

LOOSEN SCREW (2) CAN CHANGE

DIFFERENTIAL FEED DOG (3) .

AFTER CHANGED FEED DOGS ,

TIGHTEN SCREWS LIGHTLY . PLEASE

REFER TO FOLLOWING ITEMS IN

ORDER TO SET UP CORRECT

POSITION OF FEED DOGS . THEN ,

TIGHTEN SET SCREWS .

AFTER CHANGE FEED DOGS , MUST

ADJUST FEED DOGS TO ITS

CORRECT POSOTION . TURNING BELT

PULLEY , MAKE SURE MAIN FEED

DOG (2) TO ITS HIGHEST POSITION ,

MAKE SURE THE TIP OF FEED DOG

TEETH HIGHER THAN TOP OF

NEEDLE PLATE BY 0.8-1 mm .

( STANDARD SETTING VALUE )

THEN , TURNING BELT PULLEY ,

LOWERING MAIN FEED DOG , MAKE

SURE THE TIP OF TEETH LINE EVEN

WITH TOP OF NEEDLE PLATE , THEN ,

ADJUSTING THE TIP OF TEETH OF

DIFFERENTIAL FEED DOGS LINE

EVEN WITH TOP OF NEEDLE PLATE .

AFTER SET UP , TIGHTEN SCREW (1) ,

(2) AND MAKE SURE FEED DOGS ARE

AT ITS CORRECT POSITION AGAIN .

AFTER ADJUSTING , PLEASE TIGHTEN SCREW (1) , (2)

AND IN THE SAME TIME , PLEASE MAKE SURE

a. IF FEED DOGS WILL RAISE 0.8~1 mm . ABOVE

THE TOP OF NEEDLE PLATE BY TURNING BELT PULLEY

AND MOVING FEED DOG UP .

b. IF FEED DOGS WILL HIDE UNDERNEATH THE NEEDLE

PLATE BY KEEP TURNING BELT PULLEY .

ADJUSTING FEED DOGS LEVEL (TILT AMOUNT) :

2

1

ADJUSTING THE HEIGHT OF AUXILIARY FEED DOG:

1

0.5mm

THE HEIGHT OF AUXILIARY FEED DOG SHOULD BE

0.5 mm LOWER THAN MAIN FEED DOG ( STANDARD

SETTING VALUE ) AND ADJUSTMENT CAN BE MADE

BY LOOSEN SCREW (2) .

2

DURING FEED DOGS MOVEMENT , THE TEETH OF

FEED DOGS MUST BE LEVEL OFF ALWAYS .

ADJUSTING ITS LEVEL OR DURING SOME SPECIAL

REQUIREMENTS , FEED DOG TEETH MUST TILT TO

FRONT OR REAR .

A . LOOSEN SCREW (2) .

B . TURNING SHAFT (1) IN ORDER TO ADJUST

LEVEL OF FEED DOGS .

0

4-4 CHANGING AND ADJUSTING PRESSER FOOT SET

CHANGE PRESSER FOOT SET :

TURNING ADJUSTING SCREW (1)

1

90009000

2

ADJUSTING:

PRESSER FOOT MUST BE INSTALLED CORRECTLY IN ORDER TO

OBTAIN BEST SEWING EFFECTS .

COUNTERCLOCKWISE IN ORDER TO

LOOSE PRESSURE SPRING .

LOOSEN SCREW (2) CAN TAKE OFF

PRESSER FOOT SET .

SET SCREW

PRESSER

FOOT

NEEDLE PLATE

UH9003 UH9004

3

UH9005

NEEDLE HOLE NEEDLE HOLE

0-500-50

2

X

1. TURNING HAND WHEEL IN ORDER

2

TO LOWER THE NEEDLE BAR TO ITS

LOWEST SET POSITION AND

NEEDLE CAN BE MOVED INTO

NEEDLE HOLE .

2. MAKE SURE THE NEEDLE HOLE OF

PRESSER FOOT IN LINE WITH THE

NEEDLE HOLE OF NEEELE PLATE

AND SEWING NEEDLE IS IN THE

CENTER OF NEEDLE HOLE . IN THE

MEANTIME , THE BOTTOM OF

PRESSER FOOT SHOULD LAY FLAT

ON THE TOP OF NEEDLE PLATE

( LEFT DIAGRAM )

3. TIGHTEN SCREW (2)

4. THE BOTTOM OF PRESSER BAR

4

SHOULD HOLD PRESSER ARM

PROPERLY . SO , PRESSER ARM CAN

BE HELD AND RELEASED EASILY ,

WHILE ADJUSTING , LOOSEN SCREW

(4) MOVE SHAFT (3) TO RIGHT OR

LEFT IN ORDER TO SET UP

CORRECT POSITION .

6

5

5

4-5 ADJUDTING THE LIFTING HEIGHT OF PRESSER FOOT :

4

A

3

1

SETTING TOLERANCE UP :

THE TOLERANCE BETWEEN LEVEL (1)

AND STOPPER SHOULD BE 1 mm .

1. LOWER FEED DOGS UNDER NEEDLE

PLATE BY TURNING HAND WHEEL .

2. LOOSEN SCREW (3) LIGHTLY ( CAN

2

B

1mm

NOT LOOSEN SCREW COMPLETELY . )

3. HOLDING BUSHING FROM A AND B

SIDES TURNING COLLAR (4) IN

ORDER TO SET UP 1 mm TOLERANCE

BETWEEN LEVEL (1) AND STOPPER (2)

4. TIGHTEN SCREW (3) .

6

5

DIAGRAM 1

SETTING UP PRESSER FOOT LIFTING AMOUNT :

AS SHOWN ON DIAGRAM 2 (UH9003,UH9004) AND DIAGRAM 3 (UH-9005)

MAX . PRESSER FOOT LIFTING AMOUNT "a" IS 7 mm .

WHEN ADJUSTING , LOOSEN NUT (5) AND ADJUST THE

TOLERANCE TO DESIRED POSITION BETWEEN SCREW (6) AND

LEVEL (1) .

UH9003 UH9005

UH9004

a

DIAGRAM 2 DIAGRAM 3

4-6. ADJUSTING THE HEIGHT OF NEEDLE .

3

1

2

THE DISTANCE BETWEEN NEEDLE TIP

TO TOP OF NEEDLE PLATE SHOULD BE

10 mm ( STANDARD SETTING ).

PLEASE REFER TO LEFT DIAGRAM :

1. TUFNING BELT PULLEY IN ORDER

TO RAISE NEEDLE BAR TO ITS

HIGHEST POSITION .

2. OPEN UP PLUG (3) AND LOOSEN

SCREW (1) .

3. ADJUST THE HEIGHT OF NEEDLE

BAR .

4. AFTER ADJUSTMENT PLEASE

MAKE SURE TIGHTEN SCREW (1) .

A

UH9003

UH9004

10mm 10mm

UH9005

4-7. CHANGING LOOPERS.

4-7-1.

CHANGING LOWER

LOOPER:

CHANGING LOWER LOOPER BY

TAKE OFF SCREW (1)

WHEN INSTALLING,PLEASE MAKE

SURE THE CRANK OF LOWER

LOOPER MUST ATTACH TO THE

BOTTOM OF GROOVE OF LOWER

LOOPER ARM CLOSELY.

4-7-2.

4-7-3.

CHANGING UPPER CHANGING CHAIN

LOOPER:

1

1

CHANGING LOWER LOOPER BY

TAKE OFF SCREW (1)

LOOPER:

1

CHANGING THE CHAIN LOOPER BY

LOOSEN SCREW (1),

WHEN INSTALLING,PLEASE MAKE

SURE THE CRANK OF CHAIN

LOOPER MUST ATTACH TO THE

BOTTOM OF GROOVE OF CHAIN

LOOPER ARM CLOSELY.

4-8. CHANGING NEEDLE GUARD:

4-8-1. CHANGING NEEDLE GUARD OF UH-9003,UH-9004

3

4

4-8-2. CHANGING NEEDLE GUARD OF UH-9005

CAN TAKE OFF REAR NEEDLE GUARD (2)

BY LOOSEN SCREW (1) . LOOSEN SCREW (3)

CAN TAKE OFF FRONT NEEDLE GUARD (4)

2

1

3

4

2

4

3

PLEASE TAKE OFF REAR NEEDLE

GUARD (2) BY LOOSEN SET SCREW

(1) . LOOSEN SET SCREW (3) CAN

TAKE OFF FRONT NEEDLE GUARD.

1

LOOSEN SET SCREW (1) CAN

TAKE OFF REAR

CHAINSTITCH NEEDLE

GUARD . LOOSEN SET SCREW (3)

CAN TAKE OFF FRONT CHAINSTITCH

NEEDLE GUARD,

2

1

4-9. SETTING UP LOOPER AND NEEDLE GUARD

4-9-1. SETTING UP LOWER LOOPER

EDGING NEEDLE/

RIGHT NEEDLE

A

APPROX

0.03mm~0.05mm

INTERENCE

CENTER OF

NEEDLE

UTMOST

LEFT

POSITION

1

LOOSEN SCREW (1)

MODEL

THE DISTANCE A BETWEEN TIP OF

LOOPER AND THE CENTER OF NEEDLE(S)

9003

9004

9005

3.8~4

3.6~3.8

3.8~4

UNIT mm

WHEN LOWER LOOPER MOVES TO ITS UTMOST LEFT

POSITION , PLEASE REFER TO THE CHART ABOVE

FOR THE DISTANCE A BETWEEN THE TIP OF LOWER

LOOPER AND THE CENTER OF EDGING NEEDLE .

4-9-2. SETTING UP NEEDLE GUARD OF EDGING NEEDLE

LEFT

RIGHT

2

1

FRONT

WHEN LOWER LOOPER MOVES FROM RIGHT TO LEFT

AND THE TIP OF LOOPER MOVES TO EDGING

NEEDLE/RIGHT NEEDLE,THERE WILL HAVE A

INTERFERENCE APPROX 0.03mm TO 0.05 mm .

LOOSEN SCREW (1) AND ADJUSTMENT CAN BE

MADE BY MOVING LOOPER ARM FORWARD OR

BACKWARD.

REAR

UH9003 , UH9004

TOLERANCE

0~0.05mm

UH9005

2

1

1.AS MENTIONED ABOVE, WHEN LOWER LOOPER MOVES TO THE

CENTER OF EDGING NEEDLE, THERE WILL HAVE APPROX

0.03mm~0.05mm INTERFERENCE.

2

2.IN THE SAME TIME, ADJUSTING REAR NEEDLE GUARD (1)

3

0.1~0.2mm

IN ORDER TO PUSH NEEDLE FORWARD AND CREATE A

TOLERANCE OF 0~0.05mm BETWEEN NEEDLE AND THE TIP

OF LOWER LOOPER.

3.IN THE SAME TIME,ALSO ADJUSTING FRONT NEEDLE GUARD

1

(2) (UH-9003,UH-9004) (3) (UH-9005) TO CREATE A

TOLERANCE OF 0.1mm~0.2mm BETWEEN FRONT NEEDLE

GUARD AND NEEDLE.

3

1

4-9-3. SETTING UP CHAINSTITCH LOOPER

1.5mm~1.8mm

UTMOST

LEFT

POSITION

11

TOLERANCE

0~0.05mm

11

REAR

FRONT

WHEN CHAINSTITCH LOOPER MOVES TO ITS UTMOST

LEFT POSITION,THE DISTANCE BETWEEN TIP OF

CHAINSTITCH LOOPER AND THE CENTER OF

CHAINSTITCH NEEDLE SHOULD BE 1.5 mm .

ADJUSTMENT CAN BE MADE BY LOOSEN SCREW(1).

MOVEMENT ROUTE

FOR TIP OF LOOPER

FRONT AND REAR

a

MOVEMENT AMOUNT

OF TIP OF LOOPER

WHEN TIP OF LOOPER MOVES TO THE CENTER OF

CHAINSTITCH NEEDLE, THE TOLERANCE BETWEEN

LOOPER TIP AND NEEDLE GROOVE SHOULD BE

0~0.05mm.

ADJUSTMENT CAN BE MADE BY LOOSEN SCREW(1).

22

11

DIAGRAM 1.

WHEN CHANGING THE SIZE OF NEEDLE OR WHEN ADJUSTING THE FRONT AND REAR MOVEMENT

AMOUNT OF TIP OF LOOPER.

PLEASE REFER TO DIAGRAM 1.

1.PLEASE OPEN UP BACK COVER (1) OF SEWING MACHINE.

2.LOOSEN SCREW (3) A LITTLE BIT (PLEASE DO NOT LOOSEN SCREW (3) COMPLETELY.)

3.TURNING ADJUSTING SCREW (2).

4.TURNING TOWARD (+) DIRECTION IN ORDER TO OBTAIN BIGGER MOVEMENT.

TURNING TOWARD (-) DIRECTION IN ORDER TO OBTAIN SMALLER MOVEMENT.

5.AFTER ADJUSTMENT,PLEASE MAKE SURE TIGHTEN SCREW (3) AND BACK COVER (1).

33

4-9-4. SETTING UP NEEDLE GUARD OF CHAINSTITCH LOOPER.

4

ADJUSTMENT CAN BE MADE BY LOOSEN

SCREW (3),(4) AND AFTER ADJUSTMENT,

MUST MAKE SURE TIGHTEN SCREWS.

2

4-9-5. SETTING UP UPPER LOOPER

DIAGRAM 1.

2

TOLERANCE

0~0.05mm

1

1

WHEN CHAINSTITCH NEEDLE REACHED LOWEST

POINT OF ITS STROKE, THE TOLERANCE

3

BETWEEN REAR NEEDLE GUARD AND NEEDLE

IS 0~0.05mm AND THE TOLERANCE BETWEEN

FRONT NEEDLE GUARD AND NEEDLE IS 0.1~0.2mm.

1.WHEN UPPER LOOPER MOVES TO ITS HIGHEST POSITION,

THE DISTANCE BETWEEN TIP OF LOOPER AND CENTER

OF NEEDLE SHOULD BE AS SPECIFICATION CHART LISTED

BELOW AND ALSO PLEASE REFER TO DIAGRAM 2.

2

TOLERANCE

0.1~0.2mm

DIAGRAM 2.

a

1

2

2.WHEN UPPER LOOPER PASSING THROUGH THE BACK

OF LOWER LOOPER. PLEASE REFER TO DIAGRAM 3.

FOR CORRECT TOLERANCE BETWEEN UPPER LOOPER

AND LOWER LOOPER.

3.WHEN SETTING,PLEASE LOOSEN SCREW (1),(2) AS

PER DIAGRAM 1. AND SET UP THE TOLERANCES

BETWEEN UPPER LOOPER AND NEEDLE,UPPER LOOPER

AND LOWER LOOPER AS PER SPECIFICATION CHART.

THEN,TIGHTEN SCREW (1),(2).

SPECIFICATION CHART

MODEL

UH9003(L)

a

4.5~5.0

UH9003

DIAGRAM 3.

0.2mm

UH9004

UH9005

UH9005(H)

0.5mm

4.3~4.8

4.5~5.0

4.3~4.8

4.5~5.0

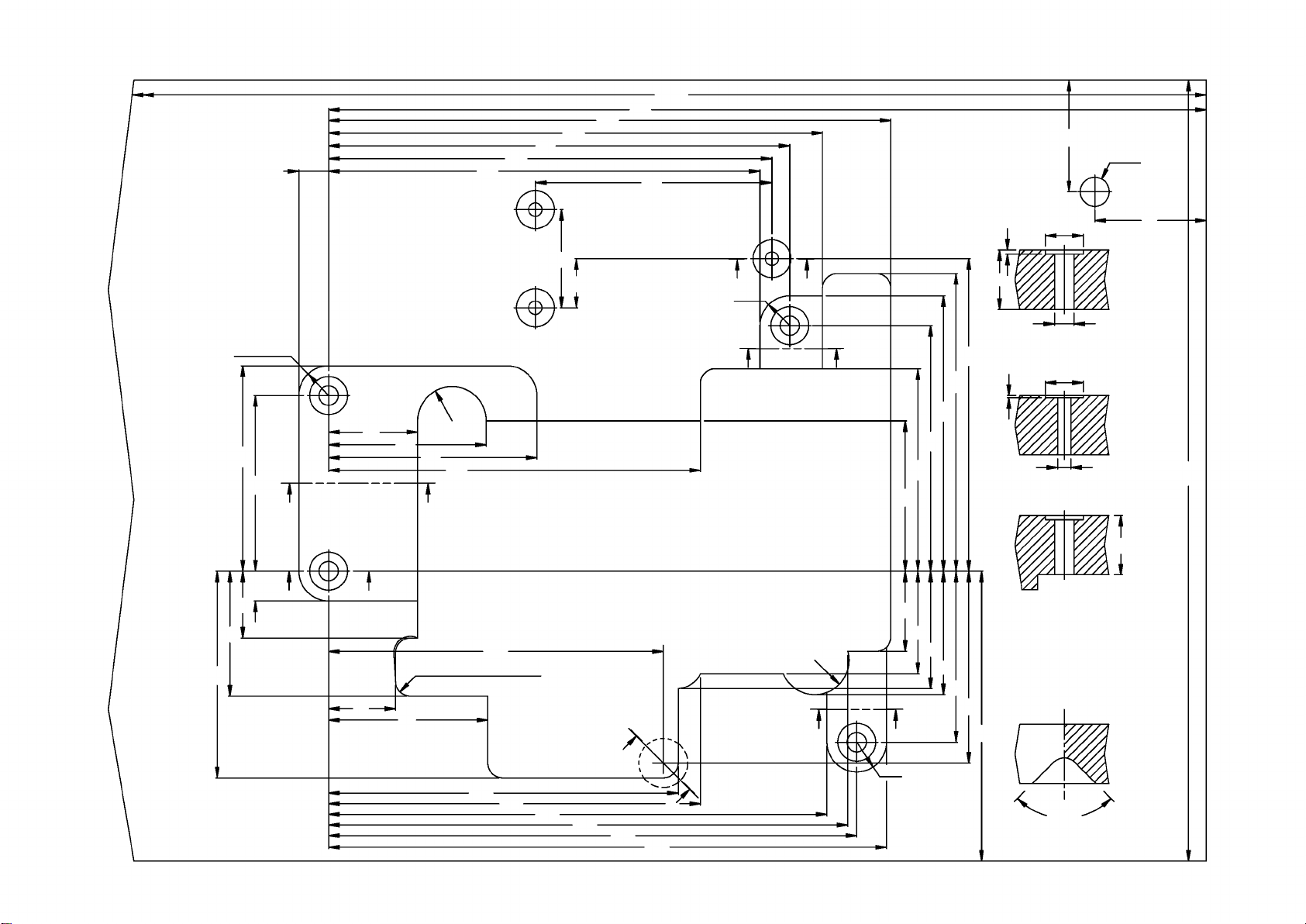

F======-==-==-==-==========-----

378

332

310

20

290

298

.

590

159

1200

-

-

@1

====+====:::::o

75

Ø19.5

l~

3

Ø25.5

75

84

139

共

R20

138

118

20

45

. '

處

3

'

~~

60

14-----

~------

C

1

A

l~

~

45

I

-

66

33

@~

(\\

140

T

R23

J

250

C

UH-9000

PATTERN PAPER FOR TABLE CUT-OUT

(SEMI-SUBMERGED INSTALLATION)

225

R10

\

235

250

335

系列 半沉式紙型

-

~

I

I

~

-

.,

'

r\.

~

F

375

349

F

~

355

./

\

I

-

106

A

,,

V

107

/

t t

tf

B

R20

~

Te--~-

E

R23

\.

B

' V

IT

"-

1

D

V

~

\~

'

'

EE

I

101

54

I

j j

---r-r

~

D

R20

m))

...

.I

200

185

165

136

69

79

83

~

t

115

I

--

40

• I

Ø13

A-A SIDE VIEW

210

129

TOTPH 4 PLACES

Ø25.5

1.5

.1 1.

-

IF TABLE THICKNESS IS MORE

THAN 40 mm , PLEASE THIN

OUT C , D , E SIDE VIEW

PLACES TO 40 mm .

195

Ø9

B-B SIDE VIEW

TOTPH 3 PLACES

C SIDE VIEW

D SIDE VIEW

E SIDE VIEW

90°

F SIDE VIEW

----+--i

I.

525

40

======~~-

2

1

---+

+----

R20

260

Dimensions for Fully Submerged Mounting

735

530

485

340

A

--=-=--=---==:-.I

30

rr·,----,

安裝

SS033

US040

TC011

時請削除

虛線指示部分

I

A

-+

R20

Ø26

3

部詳圖共 5 孔

A

Ø19.5

Ø13

265

225

90

A

i=-=$+-~1t,,~~~c

118

195

106

118

35

A

2

197

10

\

-r--·-

10

----Jr-

R20

455

I

I

I

------:---

530

555

580

4

2

UH-9000系列

全沉式紙型

PATTERN PAPER FOR TABLE CUT-OUT

(SEMI-SUBMERGED INSTALLATION)

C

15

660

810

C

A

R20

B

R40

40

36

60

90

105

115

140

195

45°

185

15

320

B-B

C-C

剖面

剖面

FT6503-0-56M

Tape Binding

MT4512P-050 /

12-Needle Double Chain Stitch Machine

(Lower

Feed

UH9055-353-M16

Pocket Bags Seaming

NT67

4 Needle Flat-Seame

PMD

/ FR0l

Metering Device , Elastic

r,

Feed-Off-The-Arm Machine

hemmer)

fflffltffltt)i~@fi(JH~q)

-

The specifications and /

~§tflnlilAilli.

~J!JJi~il!(Ji!,

CHING

http

this catalogue

liJjg;i,;j(iJMffl~.

CHI MACHINE CO., L

://

www

.kingtexsewing.

or

appearences

are

subject to change without further notice.

of

the equipments described in

imt.lA§i..z:9~111

.

.IJ!,1§,

1';13Jirr1Jil!(,

com.tw

TD

fl'tt•ll'!•aa•~-

Loading...

Loading...