Kingtex UH8000 User Manual

J1~8ffl~I~ffl~tt}J~

M®IIDJ111

UH8000

(

\

I

\

INDUSTRIAL SEWING MACHINE

e)

(user

ManuaD

~

a

r;iJ-

~

-~~1JUiimtflffi~~Sl,

http

://

www

.kingtexseWfng.com".

.

J(J:IJ..t:KL

CHI

MACHINE CO.,

tw

LTD

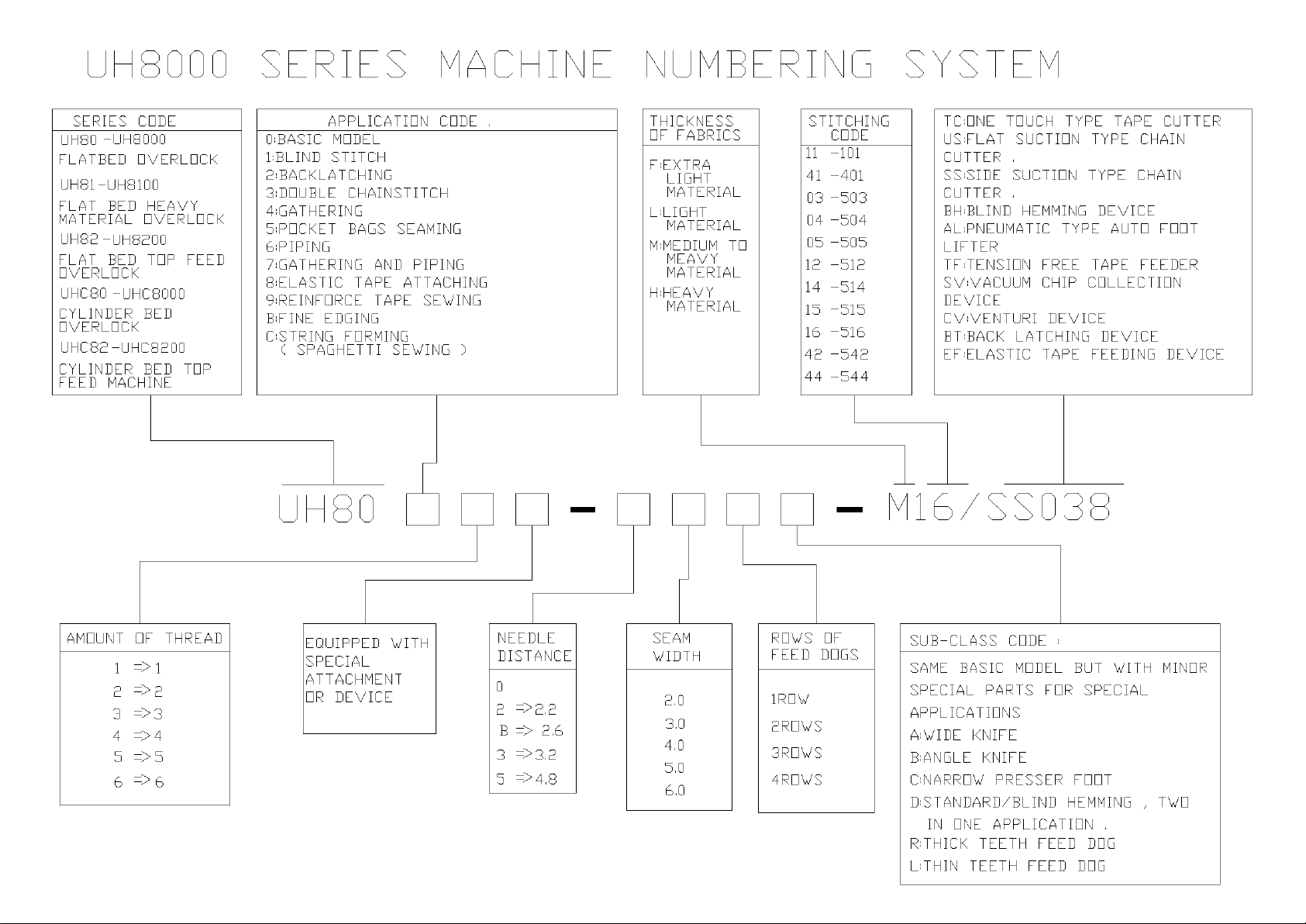

UHBOOO

SERIES

MASHI~~E

~~UMBERI~~G

SYSTEM

SERIES

UHBO

FLATBED

UH81-UH8100

FLAT

MATERIAL OVERLOCK

UH82

FLAT

OVERLOCK

UHCBO

CYLI~mER

OVERLOCK

UHC82

CYLI~mER

FEED MACHWE

CODE

-UHBOOO

OVERLOCK

BED

HEAVY

-UH8200

BED

TOP

-UHCBOOO

BED

-UHC8200

BED

FEED

TOP

APPLICA

D'BASIC

1'BLI~m

2'BACKLATCHHKi

],DOUBLE

4'GATHERH~G

5'PDCKET

5'PIPWG

7'GATHERH~G

B'ELASTIC

g,REI~~FDRCE

Bn~~E

DSTRWG

( SPAGHETTI

MODEL

STITCH

CHAWSTITCH

BAGS

Mm

TAPE A TT ACHWG

TAPE

EDGWG

FDRMWG

UHBO

Tim~

CODE

SEAMWG

PIPWG

SEwi~~G

SEwH~G

THICKr~ESS

OF

FABRICS

F'EXTRA

LIGHT

MATERIAL

L'LIGHT

MATERIAL

N'MEDIUM

NEAVY

MATERIAL

H'HEAVY

MATERIAL

l

TO

STITCHH~G

CODE

II

101

41

-401

03

-503

04

-504

05

-505

12

-512

14

-514

15

-515

15

-515

42

-542

44

-544

I

TC'm~E

US,FLA T

CUTTER

SS,SIDE

CUTTER

BH,BLHm

AL'P~~EUNA

LIFTER

TF,TEr~Sim~

SV,VACUUM CHIP

DEVICE

CV,VErHURI

BT,BACK

EF,ELASTIC

____[___

TOUCH

SUCTim~

SUCTim~

HENNmG

TIC

LATCHH~G

TYPE TAPE CUTTER

TYPE

TYPE

TYPE

FREE TAPE FEEDER

CDLLECTim~

DEVICE

TAPE FEEDWG

CHAH~

CHAm

DEVICE

AUTO

DEVICE

FOOT

DEVICE

-

-

AMOUNT

OF

=>I

2

=>2

3

=>3

4

=>4

5 => 5

5 => 5

THREAD

EQUIPPED

SPECIAL

ATTACHMErH

DR

DEVICE

wiTH

I

1

~~EEDLE

DISTM~CE

0

2

=>2.2

B => 2.5

3

=>3.2

5

=>4.8

I

SEAM

wiDTH

2.0

3.0

4.0

5.0

5.0

~DwS

R

F

EED

~D\J

2

ROwS

3

ROwS

4

ROwS

OF

DOGS

SUB-CLASS

SANE BASIC

SPECIAL

APPLICA

A'wiDE

B'Ar~GLE

D~~ARRDw

nSTMmARD/BLWD

Ir~

m~E

R'THICK TEETH FEED

L'THH~

CODE

MODEL

PARTS

Tim~s

KWFE

KrHFE

PRESSER FOOT

APPLICA

TEETH FEED

FOR

Tim~

BUT

wiTH

SPECIAL

HEMMWG

DOG

DOG

NI~mR

, TwO

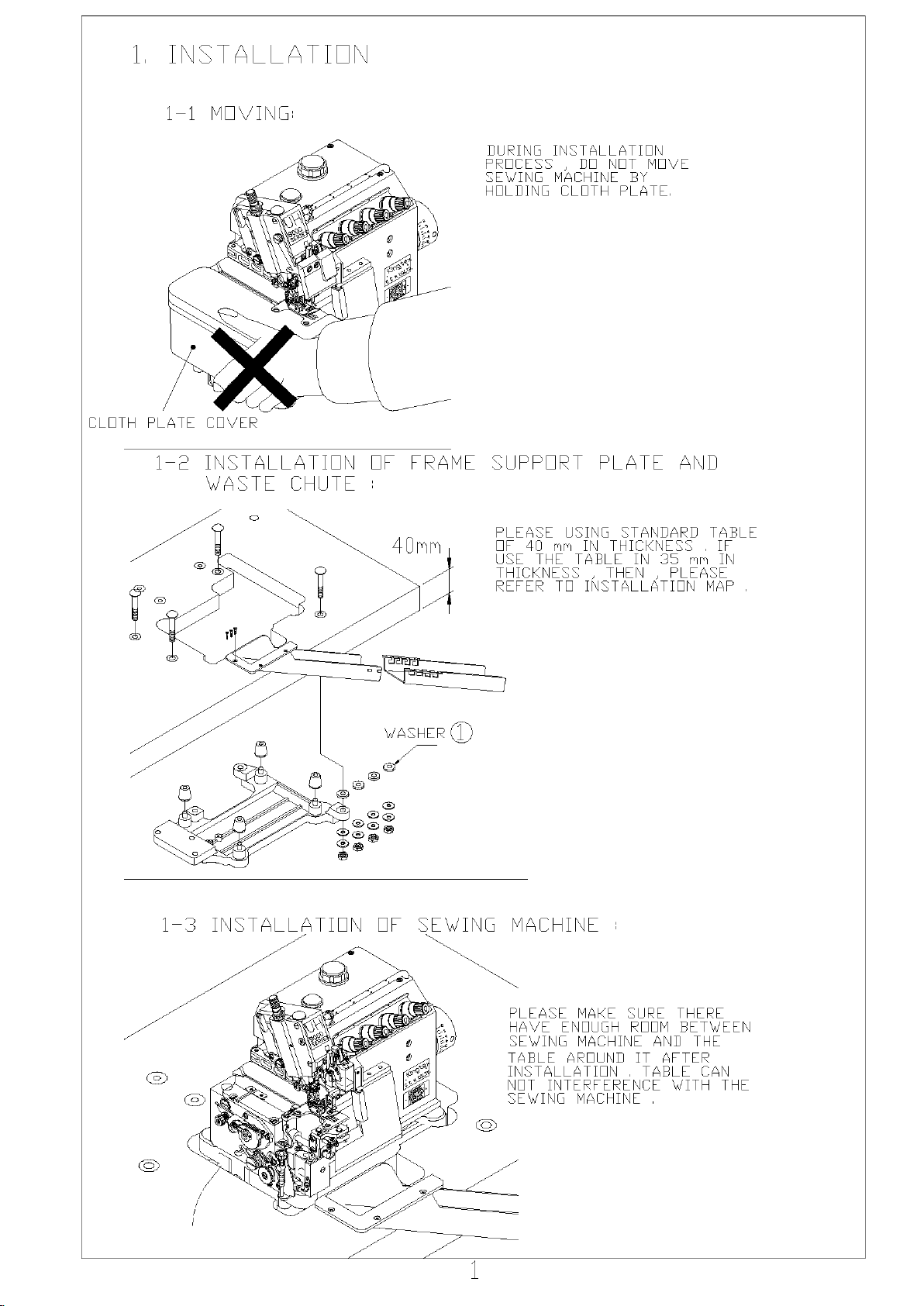

1.

INSTALLA

1-1

MOVING

TIDN

CLOTH

PLATE

1-2

COVER

INSTALLATION

wASTE

CHUTE

0

OF

FRAME

DURING

PROCESS , DO

SEwiNG

HOLDING

SUPPORT

PLEASE

OF

USE

THICKNESS , THEN , PLEASE

REFER

INSTALLATION

MACHINE

CLOTH

NOT

PLATE

USING

40

r1r1

IN

THE

TO

THICKNESS

TABLE

INSTALLATION

MOVE

BY

PLATE,

AND

STANDARD

IN

35 r1r1

TABLE

IF

IN

MAP

1-3

®

INSTALLATION

wASHER

~

®

OF

CD

SEwiNG

~

MACHINE

PLEASE

HAVE

SEwiNG

TABLE

INSTALLATION

NOT

SEwiNG

MAKE

ENOUGH

MACHINE

AROUND

INTERFERENCE

MACHINE

SURE

ROOM

AND

IT

AFTER

TABLE

THERE

BETwEEN

THE

CAN

wiTH

THE

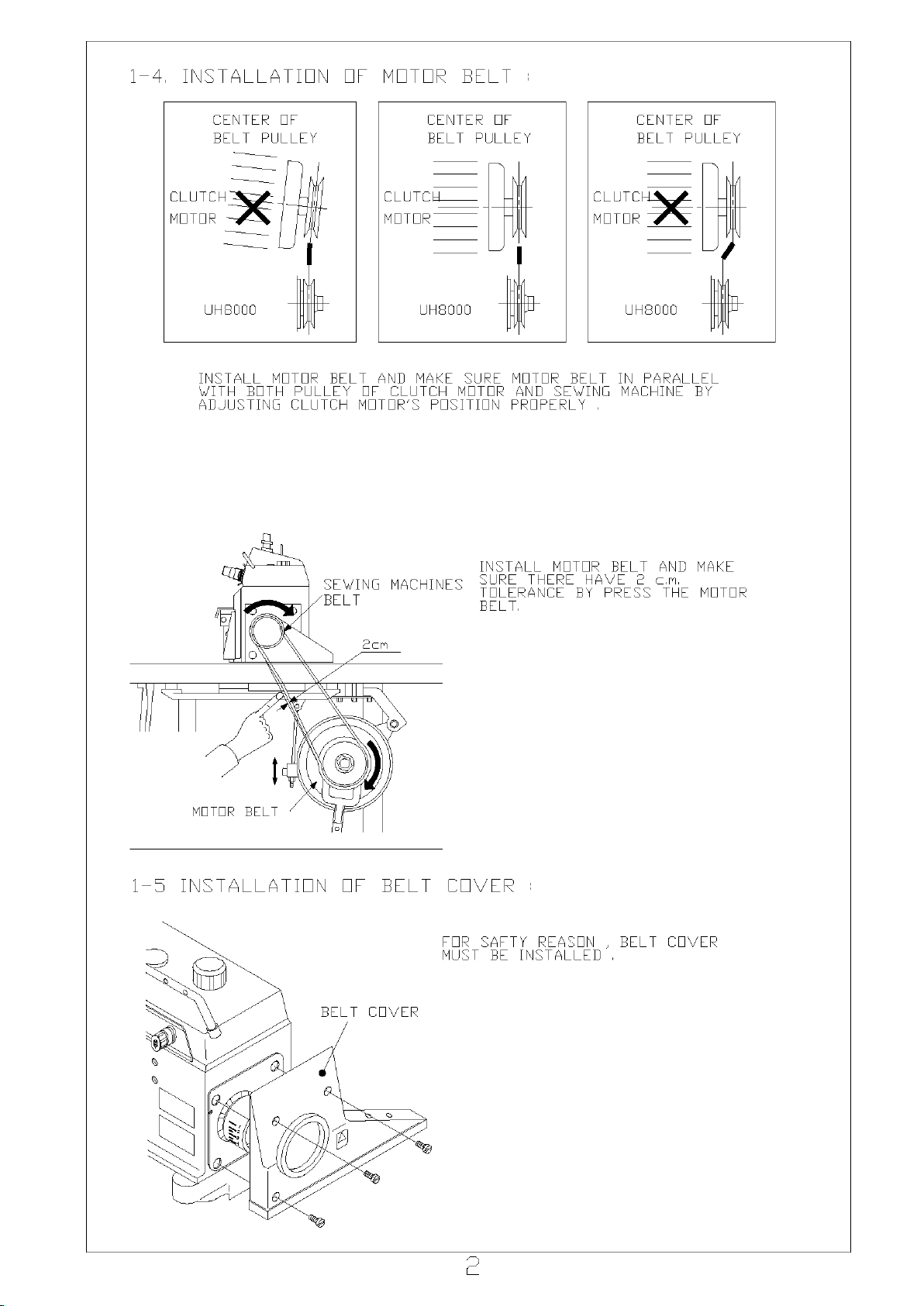

1-4.

INST ALLATIDN

OF

MOTOR

EEL T

CENTER

BELT

CLUTCH~_

MOTOR

UHBOOO

INSTALL

wiTH

ADJUSTING

PULLEY

----

----

----

--A

----

----

BOTH

OF

MOTOR

PULLEY

CLUTCH

BELT

OF

MOTOR'S

SEwiNG

BELT

CENTER

BELT

CLUTC

MOTOR--

"""""

AND

MAKE

CLUTCH

POSITION

MACHINES

OF

PULLEY

_M

[JlV

•

SURE

MOTOR

MOTOR

AND

PROPERLY

INSTALL

SURE

TOLERANCE

BELT.

BELT

SEwiNG

MOTOR

THERE

CENTER

BELT

--

CLUTC~

MOTOR~

UHBOOO

IN

PARALLEL

MACHINE

BELT

HAVE

BY

2 c.M.

PRESS

PULLEY

AND

THE

OF

c-

-I-Hl:I+-

-

'B-

BY

MAKE

MOTOR

1-5

MOTOR

INST ALLATIDN

BELT

OF

BELT

2m

EEL T COVER

FOR

MUST

COVER

SAFTY

BE

INSTALLED

REASON , BELT

COVER

2

2.

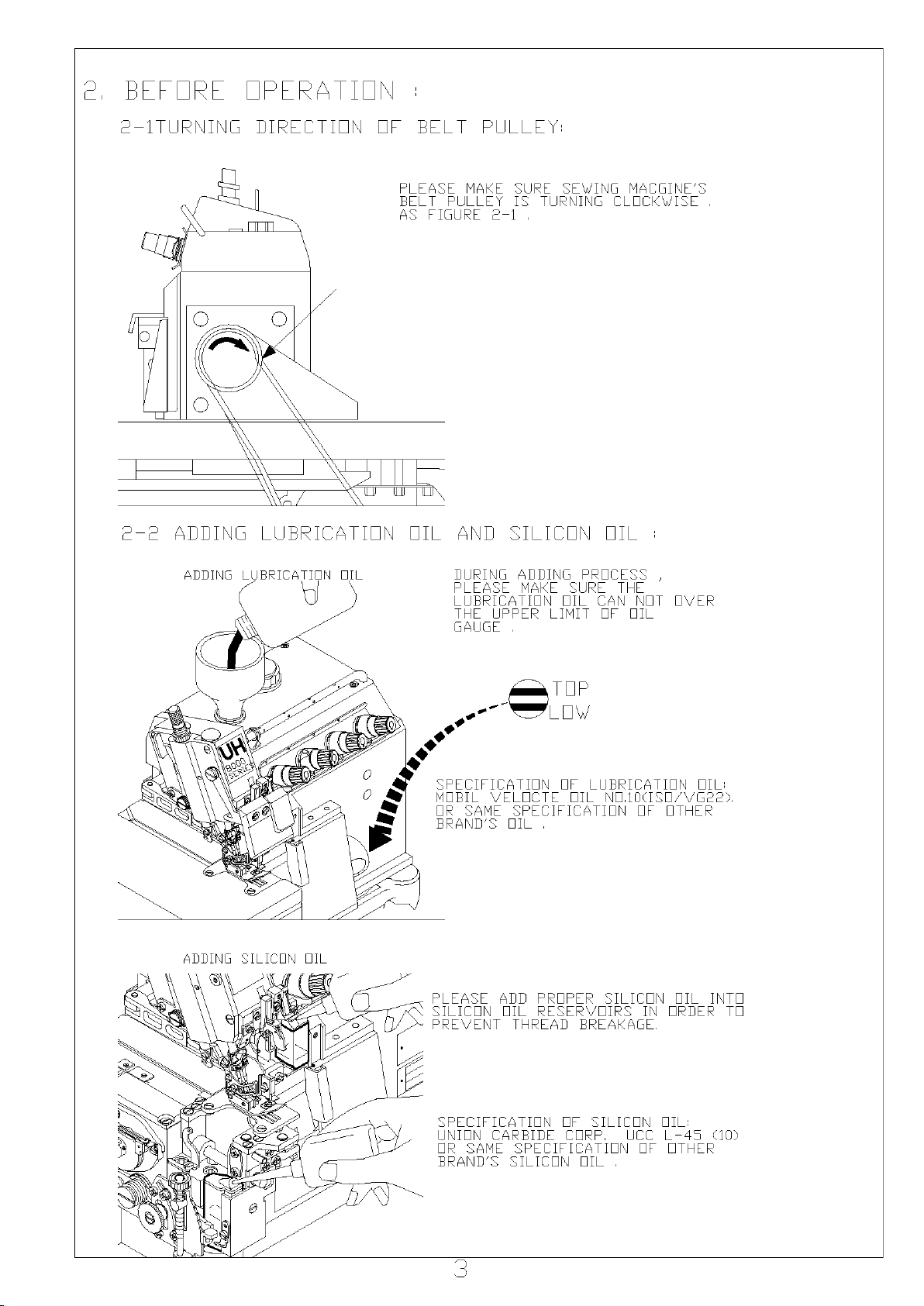

BEFORE OPERATION

2-lTURNING

2-2

ADDING

ADDING

DIRECTION

LUBRICATION

ICA

TIDN

IJ

OF

BELT

PLEASE

BELT PULLEY IS

AS

OIL

MAKE

FIGURE

AND

DURING

PLEASE

LUBRICA

THE

GAUGE

PULLEY

SURE SEwiNG MACGINE'S

2-1

TURNING

SILICON

ADDING

MAKE

TIDN

UPPER LIMIT

OIL

OIL

PROCESS

SURE

CAN

OF

CLOCKwiSE

THE

OIL

NOT

OVER

ADDING

SILICON

OIL

~TOP

~-~LOw

SPECIFICATION

MOBIL

DR

BRAND'S

SPECIFICA

UNION

DR

BRAND'S SILICON

VELDCTE

SAME

CARBIDE

SAME

SPECIFICATION

OIL

TIDN

SPECIFICATION

OF

LUBRICATION

OIL

NDJOCISD/VG22)

OF

SILICON

CORP.

OIL

UCC L -45

OF

OF

OIL•

OTHER

OIL•

(10)

OTHER

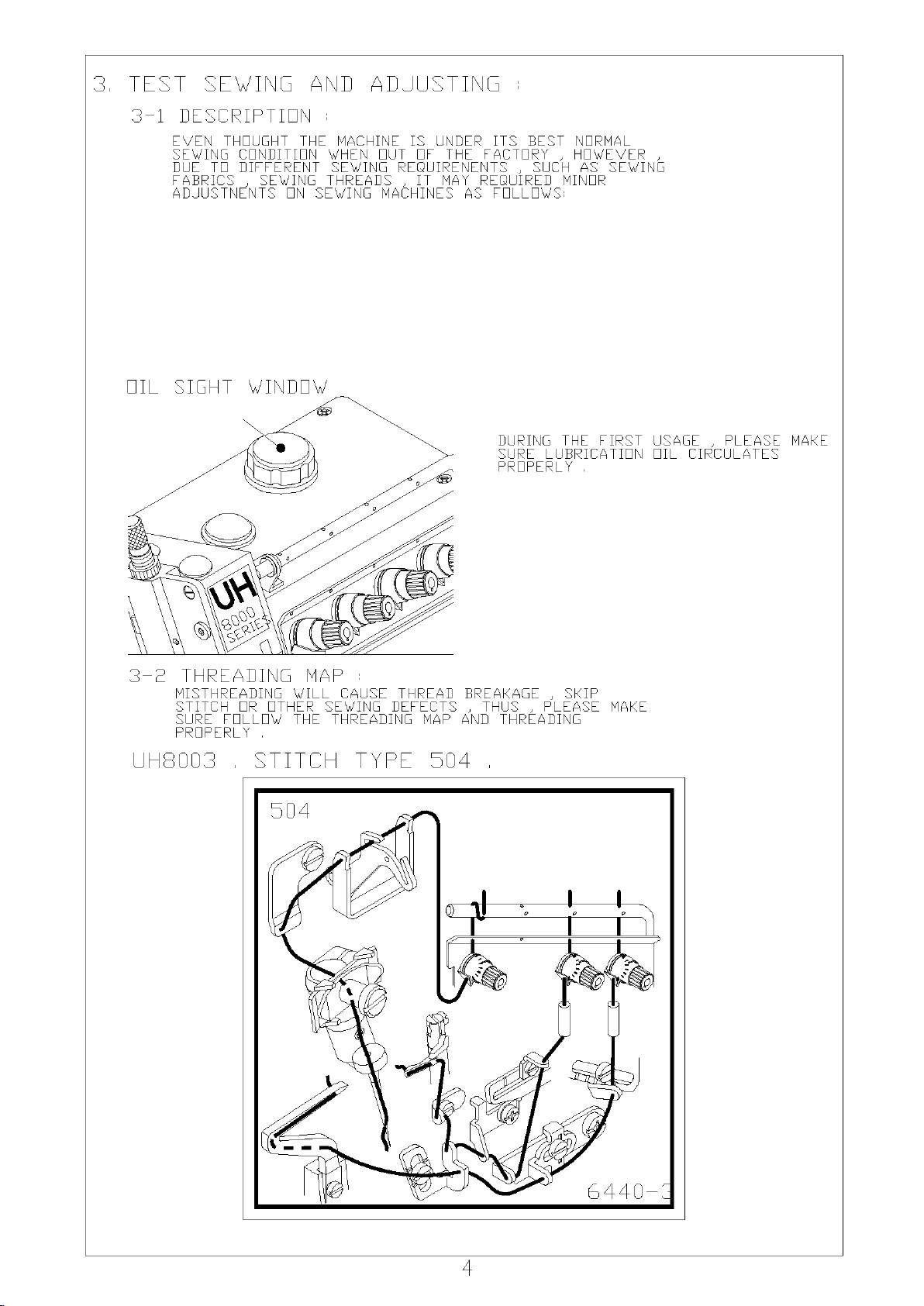

3.

TEST

SEwiNG

AND

ADJUSTING

3-1

OIL

DESCRIPTION

EVEN

SEwiNG

DUE

TO

FABRICS , SEwiNG

ADJUSTNENTS

SIGHT

THOUGHT THE MACHINE

CONDITION

DIFFERENT

wHEN

SEwiNG

THREADS , IT

ON

SEwiNG

OUT OF THE F ACTDRY ,

MACHINES

wiNDOw

IS

UNDER

REQUIRENENTS

NAY

ITS

REQUIRED

AS

FOLLOwS•

BEST

, SUCH AS

MINOR

DURING

SURE

PROPERLY

THE

LUBRICATION

NORMAL

HOwEVER

SEwiNG

FIRST

,

USAGE ,

OIL

CIRCULATES

PLEASE

MAKE

3-2

THREADING NAP

NISTHREADING

STITCH

SURE

PROPERLY

JH8003

DR

OTHER

FOLLOw

STITCH

wiLL

THE

504

CAUSE

SEwiNG

THREADING

TYPE

THREAD

DEFECTS

NAP AND

504

BREAKAGE , SKIP

, THUS ,

PLEASE

THREADING

MAKE

4

6440-

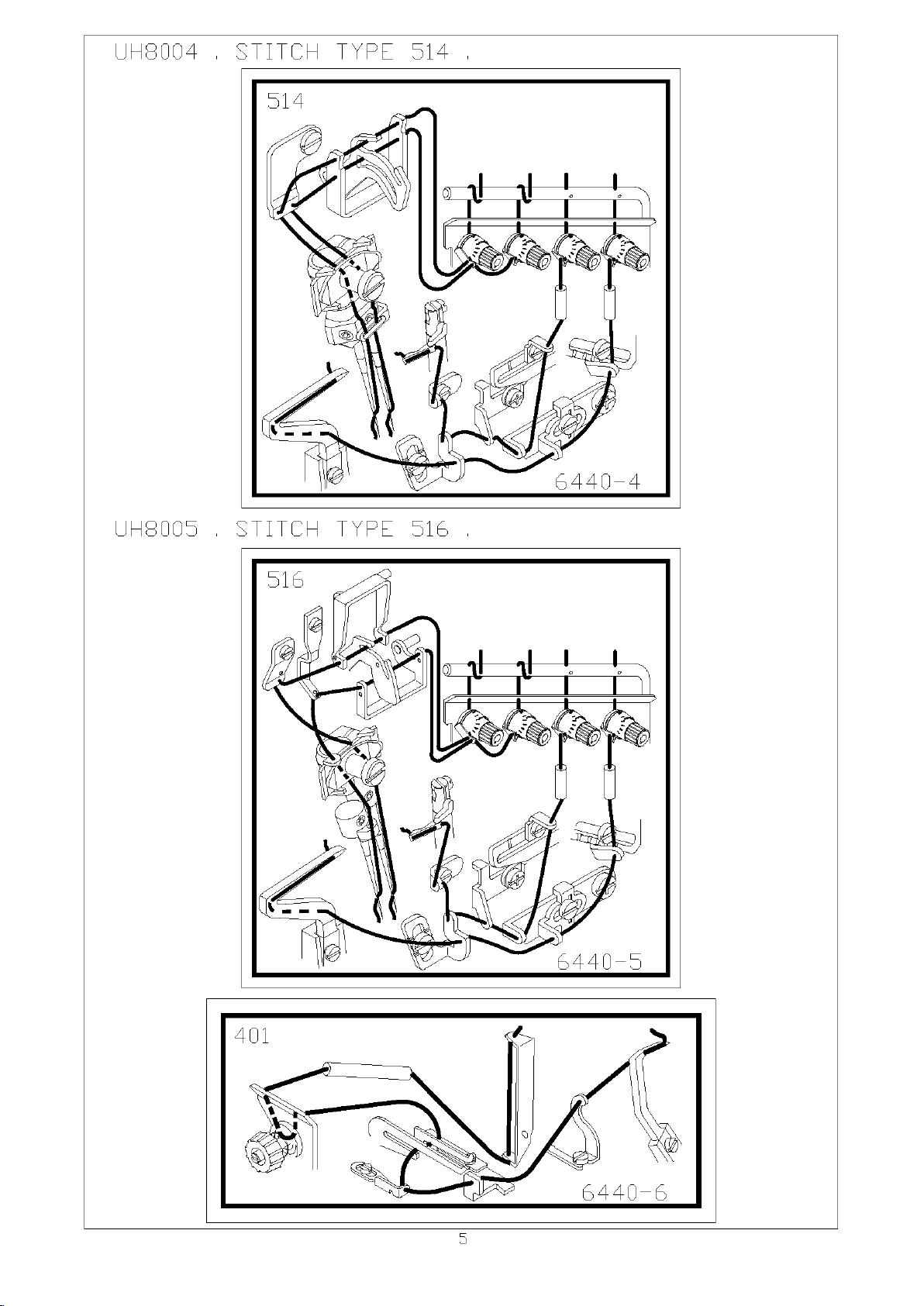

UH8004

STITCH

514

TYPE 514

6440-4

UH8005

STITCH

TYPE 516

401

5

6440-6

Loading...

Loading...