Page 1

10/2015

MILLING DRILLING MACHINE

WITH DIGITAL READOUTS

MODEL: KC-20VS-2

INSTRUCTION MANUAL

COPYRIGHT © 2015 ALL RIGHTS RESERVED BY KING CANADA TOOLS INC.

Page 2

WARRANTY INFORMATION

2-YEAR

LIMITED WARRANTY

FOR THIS MILLING/DRILLING MACHINE

OFFERS A 2-YEAR LIMITED WARRANTY

KING CANADA TOOLS

FOR INDUSTRIAL USE.

PROOF OF PURCHASE

Please keep your dated proof of purchase for warranty and servicing purposes.

REPLACEMENT PARTS

Replacement parts for this product are available at our authorized King Canada service centers across Canada.

LIMITED TOOL WARRANTY

King Canada makes every effort to ensure that this product meets high quality and durability standards. King Canada warrants to the

original retail consumer a 2-year limited warranty as of the date the product was purchased at retail and that each product is free from

defects in materials. Warranty does not apply to defects due directly or indirectly to misuse, abuse, normal wear and tear, negligence or

accidents, repairs done by an unauthorized service center, alterations and lack of maintenance. King Canada shall in no event be liable

for death, injuries to persons or property or for incidental, special or consequential damages arising from the use of our products.

To take advantage of this limited warranty, return the product at your expense together with your dated proof of purshase to an authorized

King Canada service center. Contact your retailer or visit our web site at www.kingcanada.com for an updated listing of our authorized

service centers. In cooperation with our authorized serviced center, King Canada will either repair or replace the product if any part or

parts covered under this warranty which examination proves to be defective in workmanship or material during the warranty period.

NOTE TO USER

This instruction manual is meant to serve as a guide only. Specifications and references are subject to change without prior notice.

PARTS DIAGRAM & PARTS LISTS

Refer to the Parts section of the King Canada web site for the most updated parts diagram and parts list.

KING CANADA INC. DORVAL, QUÉBEC, CANADA H9P 2Y4

www.kingcanada.com

Page 3

GENERAL & SPECIFIC

SAFETY INSTRUCTIONS

VOLTAGEWARNING: Before connecting the tool to a power source (receptacle, outlet, etc.) be sure the voltage supplied is the same as that

specified on the nameplate of the tool. A power source with voltage greater than that for the specified tool can result in SERIOUS INJURY to the

user - as well as damage to the tool. If in doubt DO NOT PLUG IN THE TOOL. Using a power source with voltage less than the nameplate is

harmful to the motor.

1. KNOW YOUR TOOL

Read and understand the owners manual and labels affixed to the

tool. Learn its application and limitations as well as its specific potential hazards.

2. GROUND THE TOOL.

This tool is equipped with an approved 3-conductor cord and a 3prong grounding type plug to fit the proper grounding type receptacle. The green conductor in the cord is the grounding wire.

NEVER connect the green wire to a live terminal.

3. KEEP GUARDS IN PLACE.

Keep in good working order, properly adjusted and aligned.

4. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

5. KEEP WORK AREA CLEAN.

Cluttered areas and benches invite accidents. Make sure the floor

is clean and not slippery due to wax and sawdust build-up.

6. AVOID DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations or expose them to

rain. Keep work area well lit and provide adequate surrounding

work space.

7. KEEP CHILDREN AWAY.

All visitors should be kept a safe distance from work area.

8. MAKE WORKSHOP CHILD-PROOF.

Use padlocks, master switches or remove starter keys.

9. USE PROPER SPEED.

A tool will do a better and safer job when operated at the proper

speed.

10. USE RIGHT TOOL.

Don’t force the tool or the attachment to do a job for which it was

not designed.

11. WEAR PROPER APPAREL.

Do not wear loose clothing, gloves, neckties or jewelry (rings,

watch) because they could get caught in moving parts. Non-slip

footwear is recommended. Wear protective hair covering to contain

long hair. Roll up long sleeves above the elbows.

12. ALWAYS WEAR SAFETY GLASSES.

Always wear safety glasses (ANSI Z87.1). Everyday eyeglasses

only have impact resistant lenses, they are NOT safety glasses.

Also use a face or dust mask if cutting operation is dusty.

13. DON’T OVERREACH.

Keep proper footing and balance at all times.

14. MAINTAIN TOOL WITH CARE.

Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS.

Before servicing, when changing accessories or attachments.

16. AVOID ACCIDENTAL STARTING.

Make sure the switch is in the ‘’OFF’’ position before plugging in.

17. USE RECOMMENDED ACCESSORIES.

Consult the manual for recommended accessories. Follow the instructions that accompany the accessories. The use of improper

accessories may cause hazards.

18. NEVER STAND ON TOOL.

Serious injury could occur if the tool tips over. Do not store materials

such that it is necessary to stand on the tool to reach them.

19. CHECK DAMAGED PARTS.

Before further use of the tool, a guard or other parts that are damaged should be carefully checked to ensure that they will operate

properly and perform their intended function. Check for alignment

of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other parts that are

damaged should be properly repaired or replaced.

20. NEVER LEAVE MACHINE RUNNING

UNATTENDED.

Turn power ‘’OFF’’. Don’t leave any tool running until it comes to a

complete stop.

SPECIFIC SAFETY INSTRUCTIONS

1. USING SAFETY GUARD AND WEAR SAFETY GLASSES

To prevent bodily injuries during milling/drilling operations, always

use the safety guard and wear safety glasses.

2. NEVER DO “FREEHAND WORK”

Never do any work “Freehand” (hand holding the workpiece rather

than workpiece secured to the table). Always secure or clamp workpiece before turning on machine.

3. SPINDLE DIRECTION

NEVER reverse the spindle direction while the spindle is

turning. Wait until the spindle has come to a complete stop

before changing spindle direction.

4. USER MUST RECEIVE TRAINING BEFORE USE.

The user must know the functions and principals of operation. The

user must also be familiar with the safety devices and regulations.

5. YOU ARE ENDANGERING YOURSELF and other personel if you

bypass, remove or override a safety device such as the transparent

auto-shut-off spindle safety guard. Only use this milling/drilling if all

safety devices are working properly, if any are damaged or altered,

replace them with identical replacement parts.

6. CLEANING AFTER USE

Do not use your hands to clear metal chips, use protective gloves or

a brush.

Page 4

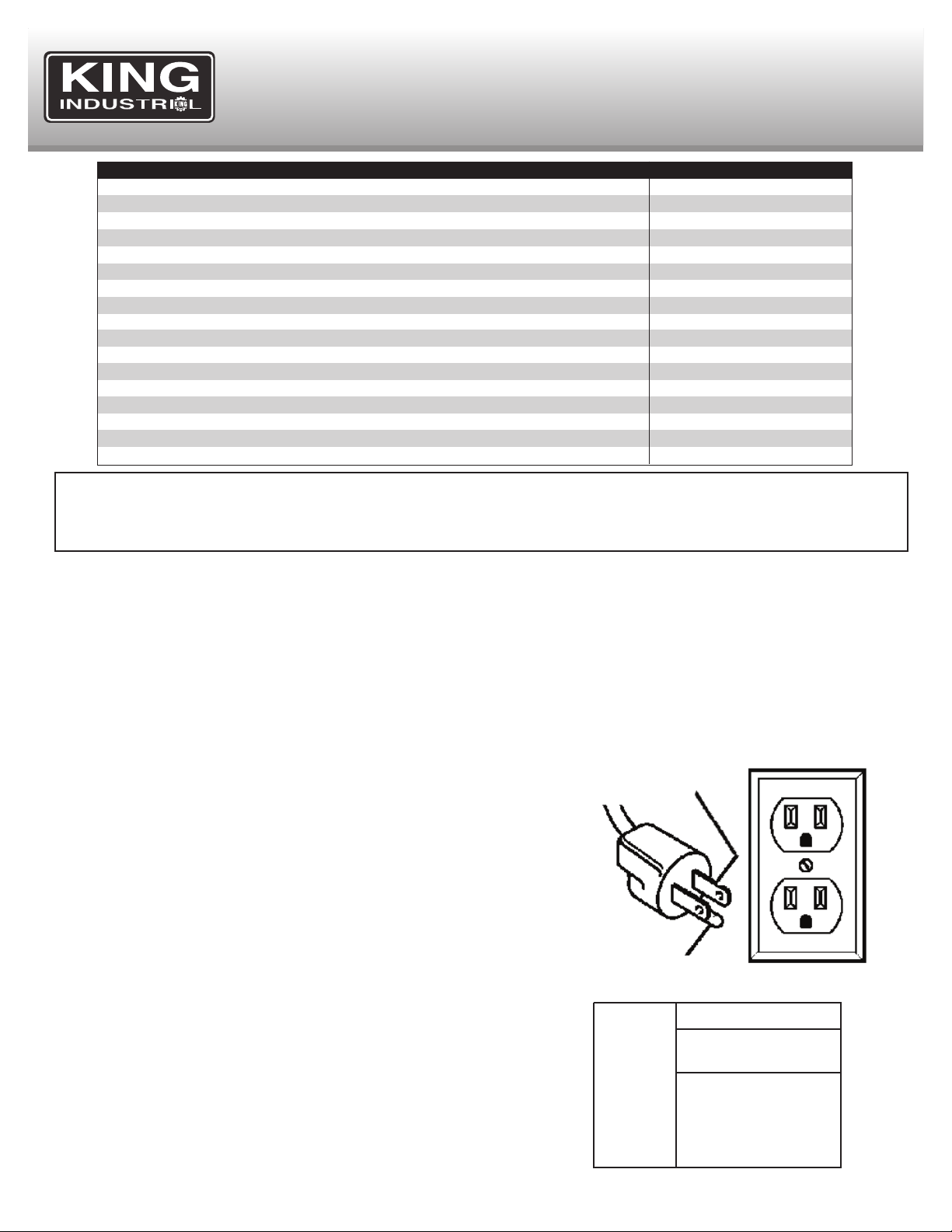

SPECIFICATIONS &

ELECTRICAL INFORMATION

MODEL KC-20VS-2

Drilling capacity in cast-iron 3/4”

Drilling capacity in steel 5/8”

Max. distance spindle nose to table 13”

Swing 13”

Spindle taper R8

Spindle stroke 2”

Variable speeds 2 (50-1125 / 100-2250) RPM

Face mill capacity 2-1/2”

End mill capacity 3/4”

Max. longitudinal travel 18-7/8”

Cross travel 6-7/8”

Working area of the table 7-1/16” x 27-1/2”

Size of T-slot on table 1/2”

Motor 4.8 Amp., 5,600 RPM

Voltage 110V, 1 phase, 60 Hz

Dimensions (LxWxH) 35-1/2” x 22” x 36-1/4”

Weight 265 lbs

WARNING!

ALL ELECTRICAL CONNECTIONS MUST BE DONE BY A QUALIFIED ELECTRICIAN. FAILURE TO COMPLY MAY RESULT IN SERIOUS INJURY! ALL ADJUSTMENTS OR REPAIRS MUST BE DONE WITH THE MACHINE DISCONNECTED FROM THE POWER

SOURCE. FAILURE TO COMPLY MAY RESULT IN SERIOUS INJURY!

POWER SUPPLY

WARNING: YOUR MACHINE MUST BE CONNECTED TO A 110-

120V, 15-AMP CIRCUIT BREAKER. FAILURE TO CONNECT IN

THIS WAY CAN RESULT IN INJURY FROM SHOCK OR FIRE.

GROUNDING

This machine must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for electric current, to reduce the risk of electric shock. This machine is equipped

with a cord having an equipment-grounding conductor and grounding

plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Your machine must be properly grounded. Not all outlets are properly

grounded. If you are not sure if your outlet is properly grounded, have

it checked by a qualified electrician.

WARNING: TO MAINTAIN PROPER GROUNDING, DO NOT REMOVE OR ALTER THE GROUNDING PRONG IN ANY MANNER.

WARNING: IF NOT PROPERLY GROUNDED, THIS MACHINE CAN

CAUSE ELECTRICAL SHOCK, PARTICULARLY WHEN USED IN

DAMP LOCATIONS. TO AVOID SHOCK OR FIRE, IF THE POWER

CORD IS WORN OR DAMAGED IN ANY WAY, HAVE IT REPLACED

IMMEDIATELY.

110-120V OPERATION

As received from the factory, your machine is ready to run for 110V

operation. This machine is intended for use on a circuit that has an

outlet and a plug which looks like the one illustrated in Fig.1.

WARNING: DO NOT USE A TWO-PRONG ADAPTOR FOR THEY

ARE NOT IN ACCORDANCE WITH LOCAL CODES AND ORDINANCES. NEVER USE IN CANADA.

EXTENSION CORDS

The use of any extension cord will cause some loss of power. Use the

following table to determine the minimum wire size (A.W.G-American

Wire Gauge) extension cord. Use only 3-wire extension cords which

have 3-prong grounding type plugs and 3-hole receptacles which accept

the tool’s plug.

For circuits that are further away from the electrical circuit box, the wire

size must be increased proportionately in order to deliver ample voltage

to the motor. Refer to Fig.2 for wire length and size.

PROPERLY GROUNDED

OUTLET

CURRENT CARRYING

PRONGS

GROUNDING PRONG

FIGURE 1

Tool’s

Amperage

Rating

3-6

6-8

8-10

10-12

12-16

Cord Size in A.W.G.

Cord Length in Feet

25 50 100 150

18 16 16 14

18 16 14 12

18 16 14 12

18 16 14 12

14 12 - -

FIGURE 2

Page 5

GETTING TO KNOW

YOUR MILLING/DRILLINGMACHINE

Optional stand model SS-20VS

GETTING TO KNOW YOUR

MILLING/DRILLINGMACHINE

Main Components

1. Motor cover

2. Draw bar cover- Draw bar secures

arbor to spindle.

3. High/Low speed selector- Selects

the low range (L) or high range (H)

for the spindle speed.

4. Head handwheel- Raises or lowers

head.

5. Downfeed lever lock knob-

Engages the fine feed knob for

precise control of the vertical

quill travel.

6. Head lock handles- Lock the

position of the head on the column.

7. Downfeed handle- Vertical travel

of the quill.

8. Milling table.

9. Coolant trough- Supplied to

adapt a recirculating coolant

system.

10. Longitudinal travel handwheels-

Move the table from side to side

(X axis).

11. Cross travel lock handles- Lock

the cross position.

12. Longitudinal travel lock

handles- Lock the longitudinal

position.

13. Cross travel handwheel-Move

the table forward or backward

(Y axis).

14. Chuck.

15. Safety guard with limit switch Milling/drilling machine will only

operate when the safety guard is

closed.

Control Panel

16. Spindle depth digital readout

“Off” button- Turns the depth

digital readout “Off”.

17. Spindle depth digital readout Displays the depth of the spindle.

18. Spindle depth fine feed knob Provides fine control of the vertical

quill travel.

19. Spindle depth digital readout

“On”- Press once to turn the depth

digital readout “On”. Press again to

reset display to “0”.

20. button- Decreases the current

spindle depth.

21. button-Increases the current spindle depth.

22. IN/MM button (inches/mm)- Toggles between inch or

millimeter readings.

23. Forward/Reverse switch- Changes the direction of

spindle rotation.

24. Spindle variable speed dial- Changes the speed of

spindle rotation.

25. On/Off w/emergency Stop button- Press the

emergency STOP button to stop machine. Squeeze

the tab next to the emergency STOP button, pull it

open, press the green “ON” button to start machine.

26. Spindle speed digital readout- Displays the speed of

the spindle rotation in RPM’s.

27. Quill lock handle- Locks the position of the quill.

Optional

28. Optional stand (model SS-20VS)

Page 6

ASSEMBLY

CLEANING BEFORE ASSEMBLY

After removing the drilling machine from its wooden crate using proper equipment and

fixing it permanently to a workbench or optional stand, all the surfaced (non-painted)

parts of the machine are coated with an anti-rust compound and must be cleaned.

Clean with a rag and kersosene or a petroleum base solvent. Do not use paint

thinner, gasoline or lacquer thinner, these will damage painted surfaces. Then

lubricate all movable parts with gear oil (SAE 30 non detergent) or grease.

ASSEMBLY

Installing Handwheel Handles

1) Install the large handwheel handle (A) Fig.3 onto the elevation handwheel (B) using

a flat head screwdriver.

2) Install the three small handwheel handles (A) Fig.4 onto the table travel hand

wheels (B) using a flat head screwdriver.

Installing Drill Chuck to Arbor

Before the drill chuck can be installed to the machine spindle, it must be installed onto

the arbor. Before attempting this installation, it is very important that all grease, oil and

debris have been removed to ensure a tight fit.

FIGURE 3

1) Fully open the chuck jaws by turning the body of the chuck (A) Fig.5 counterclock wise. Position the chuck on a solid surface with its jaws facing downwards.

2) Insert the arbor (B) into the chuck and lightly tap the arbor with a rubber hammer.

This installation is semi-permanent. If you wish a permanent installation, freeze the

arbor for 15 minutes before following the above installation. The arbor will expand

as the arbor regains temperature, permanently locking the chuck.

3) The operation is the same if you wish to install a milling cutting tool in the arbor.

Installing Drill Chuck and Arbor in the Machine Spindle

Disconnect the power cord from the power source before attempting to install drill chuck

and arbor into the machine spindle.

1) Remove the drawbar cap (A) Fig.6 by simply pulling it upwards.

2) Insert the chuck and arbor fully up into the spindle, making sure to line up the slot

in the arbor with the pin in the spindle.

3) Insert the drawbar (B) into the top end of the spindle and thread it into the arbor.

At this point, tighten the drawbar by hand.

4) Thread the drawbar nut (C) onto the drawbar and tighten the drawbar nut by

hand.

5) Place an 8mm wrench on the drawbar flat (D) to prevent the spindle from turning

while you use a 17mm wrench on the drawbar nut flat (E) to secure the drawbar.

Do not overtighten the drawbar and nut, this will only make the removal of the

chuck and arbor more difficult and could damage the arbor and threads.

6) Reinstall the drawbar cap (A).

Removing Drill Chuck and Arbor from the Machine Spindle

FIGURE 4

FIGURE 5

1) Remove the drawbar cap (A) Fig.6 by simply pulling it upwards.

2) Unscrew the drawbar nut (C) and the drawbar (B) using the 8mm and 17mm

wrenches.

3) Using the drawbar, lightly tap the drawbar with a rubber hammer to dislodge the

chuck and arbor from the spindle. Make sure you position your hand under the

chuck to prevent it from falling out.

FIGURE 6

Page 7

BREAK-IN PROCEDURE

& OPERATIONAL GUIDELINES

TEST RUN AND BREAKING-IN THE SPINDLE BEARINGS:

Proper break-in procedures must be followed to ensure the spindle bearings break-in

and seat before putting any milling load on the machine. Failure to follow start up and

spindle bearings break-in procedures will likely cause rapid deterioration of spindle

and other related parts.

1) Make sure the forward/reverse switch (A) Fig.7 is set in the "0" (OFF) position

and then press the emergency STOP button (B).

2) Connect the milling/drilling power cord to the power source.

3) Turn the high/low speed selector knob (A) Fig.8 to the "L" (low) position and

rotate the spindle variable spindle knob (C) Fig.7 all the way to the left (slowest)

position.

4) Squeeze the tab (D) Fig.7 on the emergency STOP button, pull it open, then

press the green “ON” button. Place the forward/reverse switch (A) Fig.7 in the "F"

(Forward) position. The spindle will begin to turn at a low RPM.

5) Press the emergency STOP button. The machine should stop. If the machine

does not stop, the emergency STOP button safety feature is not working

correctly. This safety feature must work properly before proceeding with regular

operations.

6) Open the emergency STOP button cover and press the green “ON” button to

start the spindle.

7) While watching the spindle speed digital readout (E) Fig.7, turn the spindle

variable speed knob until the milling/drilling reaches approximately 600 RPM,

then let it run for a minimum of 10 minutes.

8) Increase the speed to 1000 RPM and let it run for another ten minutes.

9) Increase the speed to 2200 RPM and let it run for another ten minutes.

10) Turn the milling/drilling OFF by pressing the emergency STOP button.

11) Set the spindle to rotate in the opposite direction, and let it run at 1000 RPM for

another ten minutes. DO NOT leave the area during the break-in procedure. You

may need to stop the machine if a problem occurs.

FIGURE 7

OPERATIONAL GUIDELINES

The following is only a general guideline of a typical operation with this milling/drilling.

To complete a typical operation, the operator must do the following:

1) Loosen the head travel locking handles, then adjust the head height above the table to ensure there is sufficient room to install the tooling in

the spindle and the workpiece on the table.

2) Install the desired accessory.

3) Position the workpiece as needed for the operation, then clamp the workpiece using applicable clamping devices, or a vise that is already

mounted on the table to ensure the workpiece does not move during the milling/drilling operation.

4) Position the cutter or drill bit near the workpiece, then tighten the head travel lock handles.

5) Select the appropriate spindle speed for the milling or drilling operation using the speed selector knob and spindle variable speed knob.

6) For milling operations, unlock the longitudinal and cross (X- and Y-axis) table lock handles. For drilling operations, make sure the the

longitudinal and cross (X- and Y-axis) table lock handles are locked.

7) Wear safety glasses or a face shield.

8) Turn the spindle direction selection knob to the desired direction.

9) Loosen the quill lock lever and use the quill feed levers or the fine feed knob to set the cutting tool height according to the workpiece.

10) For milling operations, use the table handwheels to move the table so the cutter removes material evenly from the workpiece. For drilling

operations, uses the quill feed lever or fine feed knob to lower the drill bit into the workpiece, then raise the drill bit out of the workpiece

using the same controls.

11) Turn the spindle direction knob to the "0" position to stop the spindle.

FIGURE 8

Page 8

ADJUSTMENTS & OPERATION

SPINDLE DEPTH DIGITAL READOUT & SCALE

The spindle depth digital readout (Fig.9) indicates the vertical position of the quill. It

can be zeroed at any position and manually increased or decreased.

To use the spindle depth digital readout:

1) Press the “On” button (A) Fig.9. The digital readout should display a reading.

2) Select the displayed unit of measurement by pressing the IN/MM button (B).

Pressing this button will toggle through inch and millimeter readings.

3) If you want to “zero” the display, press the “On” button (A). This will clear the

current reading and the scale will be reset to 0.000.

4) If you want to increase or decrease reading, press the corresponding up or down

arrows (C & D).

5) When the operation is finished, press the “Off” button (E), this will help conserve

the digital readout battery. This digital readout has an auto-Off function to save

battery life.

FIGURE 9

SPINDLE SPEED AND DIRECTION

The two gear headstock and the variable speed motor provide an overall speed range

of 50-2250 RPM. To set the spindle speed and direction, follow these steps;

1) Select the appropriate speed range using the high/low speed selector (A) Fig.10.

The “H” or high on the speed selector stands for high speed range (100-2250

RPM), the “L” or low on the speed selector stands for low speed range (50-1125

RPM).

Note: To maximize spindle torque, use the low range speed except when the required

spindle speed is above 1125 RPM.

2) Turn the spindle variable speed dial (B) Fig.10 all the way to the left (slowest

position), then press the green “On” button to turn the machine on.

3) Set the spindle travel direction using the forward/reverse switch (C) Fig.10.

4) Turn the spindle variable speed dial (B) Fig.10 clockwise to increase the spindle

speed, watch the spindle RPM digital readout (D) and adjust until desired speed

is reached.

CALCULATING CORRECT SPINDLE SPEED

Using the proper spindle speed will produce desired results, increase operator safety

and reduce wear and tear on the machine. The chart information in Fig.11 is only a

guideline to help you determine the correct spindle speed for the workpiece material.

To determine the needed spindle speed, use the following calculation;

(Cutting speed x 4) ÷ Tool diameter (inches) = Spindle RPM

Example: Mild Steel (90 x 4) = 360 ÷ 1/2” cutting tool (0.5”) = 720 Spindle RPM.

FIGURE 10

Workpiece Material

Plastic

Wood

Aluminum/ alloy

Brass/ bronze

Copper

Mild steel

Cast steel

Soft cast-iron

Stainless steel

Hard cast-iron

Tool steel

Titanium

Hard alloy steel

FIGURE 11

Cutting speed

300-800

300-500

300

150

100

90

80

80

60

50

50

50

40

Page 9

ADJUSTMENTS & OPERATION

SPINDLE DEPTH MANUAL CONTROLS

The spindle depth can be manually controled by the downfeed handles and the fine

feed knob. Refer to fig.12 & 13.

Changing spindle depth using downfeed handles

1) Unlock the quill lock handle (A) Fig.12.

2) Loosen the fine feed lock knob (A) Fig.13.

3) Pull down on the downfeed handles (B) Fig.13 to adjust the depth of the spindle.

Observe the spindle depth digital readout (C) or scale (D) to monitor the

movement.

Note: To prevent cutting tool chatter, it is recommended to keep the spindle

rectracted into the headstock as far as possible. Instead, move the head down

towards your workpiece.

Changing spindle depth using fine feed knob

1) Unlock the quill lock handle (A) Fig.12.

2) Tighten the fine feed lock knob (A) Fig.13.

3) Rotate the fine feed knob (B) Fig.12 to lower or raise the spindle in small

increments. Observe the spindle depth digital readout (C) Fig.13 or the fine feed

scale (C) Fig.12 to monitor the movement.

RAISING OR LOWERING HEAD, TILTING HEAD

The height of the head is adjustable vertically (Z-axis) to accept small or large

workpieces. The head can also be tilted towards the right or the left between 0

and 900.

Raising or lowering head

1) Unlock the head lock handles (E) Fig.13.

2) Turn the head handwheel (F) Fig.13 to raise or lower the head, once the position

is adjusted, retighten head lock handles (E) Fig.13.

FIGURE 12

0

FIGURE 13

Tilting head

Warning! The head is top heavy and will swing if it is not supported, especially once

the center bolt and lock nut are loosened. Always support head with one hand.

1) Support the head with one hand, then loosen the head center bolt (A) Fig.14 and

angle lock nut (B) Fig.14.

2) Tilt the head to the desired angle using the angle scale (C) Fig.14 as reference,

then tighten the head center bolt (A) Fig.14 and angle lock nut (B) Fig.14.

FIGURE 14

Page 10

ADJUSTMENTS & OPERATION

MILLING TABLE TRAVEL

The table of your milling/drilling machine can be moved in the longitudinal (X-axis)

and cross (Y-axis) directions.

Longitudinal travel

1) The table can be moved in the longitudinal direction (X-axis) by turning the

handwheels (A) Fig.15. These handwheels will move the table side-to-side. One

complete revolution of either handwheel moves the longitudinal feed 0.100".

2) There is also a scale (A) Fig.16 on the front of the table for use when a tight

tolerance is not required. When tight tolerance is needed, use the scale (B)

Fig.15 on each handwheel.

3) The longitudinal travel can be locked in position by tightening table lock handles

(B) Fig.16 located on the front of the table.

Cross travel

1) The table can be moved in the cross direction (Y-axis) by turning the handwheel

(C) Fig.15 on the front of the table base. One complete revolution of the

handwheel moves the cross slide 0.100".

FIGURE 15

2) The cross travel can be locked in position by tightening table lock handles (C)

Fig.16 located on the right side of the base underneath the table.

3) When tight tolerance is needed, use the scale (D) Fig.16 of the cross travel

handwheel.

SAFETY GUARD WITH AUTOSHUT-OFF LIMIT SWITCH

This milling/drilling machine comes with a transparent safety guard (A) Fig.17

mounted to the head. Never operate this machine without this safety guard in place.

Do not modify this mechanism in any way.

This safety guard comes with a security limit switch shut-off. Before pressing the start

button, place the safety guard in the working position (closest position to

the cutting tool), otherwise the machine controls will not start.

Note: If the guard is opened when operating the machine, the machine will stop. Do

not remove the guard under any circumstances. Keep guard centered with the

cutting tool. This will ensure operator protection.

FIGURE 16

FIGURE 17

Page 11

MAINTENANCE

MAINTAINING YOUR MILLING/DRILLING MACHINE

Cleaning and lubrication

To ensure milling /drilling performance, regularly wipe all sliding surfaces with a light

machine oil. Once light machine oil is applied, move the sliding surfaces back and forth

to ensure the machine oil has dispersed along the full lenght of the ways.

Every six months, lubricate all leadscrews using a multi-purpose lithium grease.

Refer below for lubrication points.

Lubrication points (refer to Fig.18)

Below is a list of the main lubrication points to lubricate.

Lubrication point #1- Head vertical way (both sides). Lower head and lubricate with

light machine oil.

Lubrication point #2- Head vertical leadscrew. Lower head, clean vertical

leadscrew using mineral spirits and a brush, then lubricate with a multi-purpose

lithium grease.

Lubrication point #3- Table cross leadscrew. Move the table forward as far as

possible, clean cross leadscrew using mineral spirits and a brush, then lubricate with

a multi-purpose lithium grease.

Lubrication point #4- Table cross way (both sides). Move the table backward as far

as possible and lubricate with light machine oil.

Lubrication point #5- Table longitudinal leadscrew. Move the table forward as far as

possible, clean cross leadscrew using mineral spirits and a brush, then lubricate

with a multi-purpose lithium grease.

Lubrication point #6, refer to Fig.20- Vertical leadscrew ring and pinion gears. Remove the head raising/lowering handwheel by undoing the acorn nut and washer that

secure it to the machine. Remove the four cap screws (A) Fig.19 that secure the pinion

gear housing (B) Fig.19 & 20, then remove the pinion gear housing as

shown in Fig.20.

Clean the ring gear (A) Fig.20 and pinion gear (C) using mineral spirits and a brush,

then apply a generous amount of multi-purpose lithium grease. Reassemble in the

reverse order.

Lubrication point #7- Vertical leadscrew bushing. Remove the leadscrew bushing

cap (C) Fig.19. Apply light machine oil to the edge of the bushing (D) Fig.20.

FIGURE 18

FIGURE 19

FIGURE 20

Page 12

MAINTENANCE

MAINTAINING YOUR MILLING/DRILLING MACHINE

Replacing spindle depth digital readout battery

If you notice the digital readout stops functioning, the battery must be replaced.

1) Using a screwdriver or a coin, unscrew the battery cover (A) Fig.21 and remove

it.

2) Remove the old battery and dispose of it accordingly to local regulations. replace

the battery with a new CR2032 battery. Reinstall battery cover.

Adjusting gibs

Gibs are wedge-shaped pieces of metal that fill the gap between the sliding surfaces

of the machine. By adjusting the position of the gib in its gap, you can remove any play

that might exist between the adjacent components. The gibs are pre-adjusted at the

factory but due to storage, break-in, and usage, they may require adjustment. If movement seems too tight at first, make sure that all the rust preventative that was shipped

on the machine is removed from the ways. Lubricate the

ways with light machine oil, and work the table back-and-forth or the head up-anddown several times until the movement is easier.

To adjust the table gibs (Fig.22):

1) Loosen the table longitudinal and cross travel lock handles.

2) Loosen or tighten the front and rear cross travel gib screws (A & B) Fig.22 in an

alternating manner to adjust the cross travel gibs. The table should slide smoothly

in the cross direction with no play or looseness. Do not overtighten the gibs or

premature slide and gib wear will occur.

3) Lubricate the cross way and gibs with light machine oil.

4) Repeat the process for the longitudinal way gibs using the gib adjustment screws

(C & D) on the left and right sides of the table base.

To adjust the head gibs (Fig.23):

1) Remove the two cap screws that secure the top end of the accordion shaped way

cover (C) Fig.23, pull it down to expose the lower gib screw (B), then loosen the

vertical head travel lock handles.

2) Loosen or tighten the upper and lower gib screws (A & B) Fig.23 in an alternating

manner to adjust the head gibs. The head should slide smoothly with no play or

looseness. Do not overtighten the gibs or premature slide and gib wear will

occur.

3) Lubricate the head way and gibs.

4) Re-install the accordian shaped way cover.

FIGURE 21

FIGURE 22

Maintaining the motor

The bearings inside the motor are shielded and lubricated for the life of the bearing

and require no routine maintenance. This motor is equipped with long life carbon

brushes. Brush life expectancy is affected by motor loading.

To inspect and replace the motor brushes (Fig.24):

1) Undo the motor cover by removing the four cap screws that secure it.

2) Unscrew one of the brush caps (B) Fig.24 to expose the brush assembly.

3) Remove the old brush assembly (C). If the brush is worn down to less than 1⁄4”

(6mm) then replace it with a new one (replace both carbon brushes). Otherwise

re-install the brush.

4) Replace the brush cap to secure the brush in place.

5) Repeat for second brush assembly on the other side of the motor (A).

FIGURE 23

FIGURE 24

Page 13

WIRING DIAGRAM

MODEL: KC-20VS-2

Loading...

Loading...