Page 1

09/2013

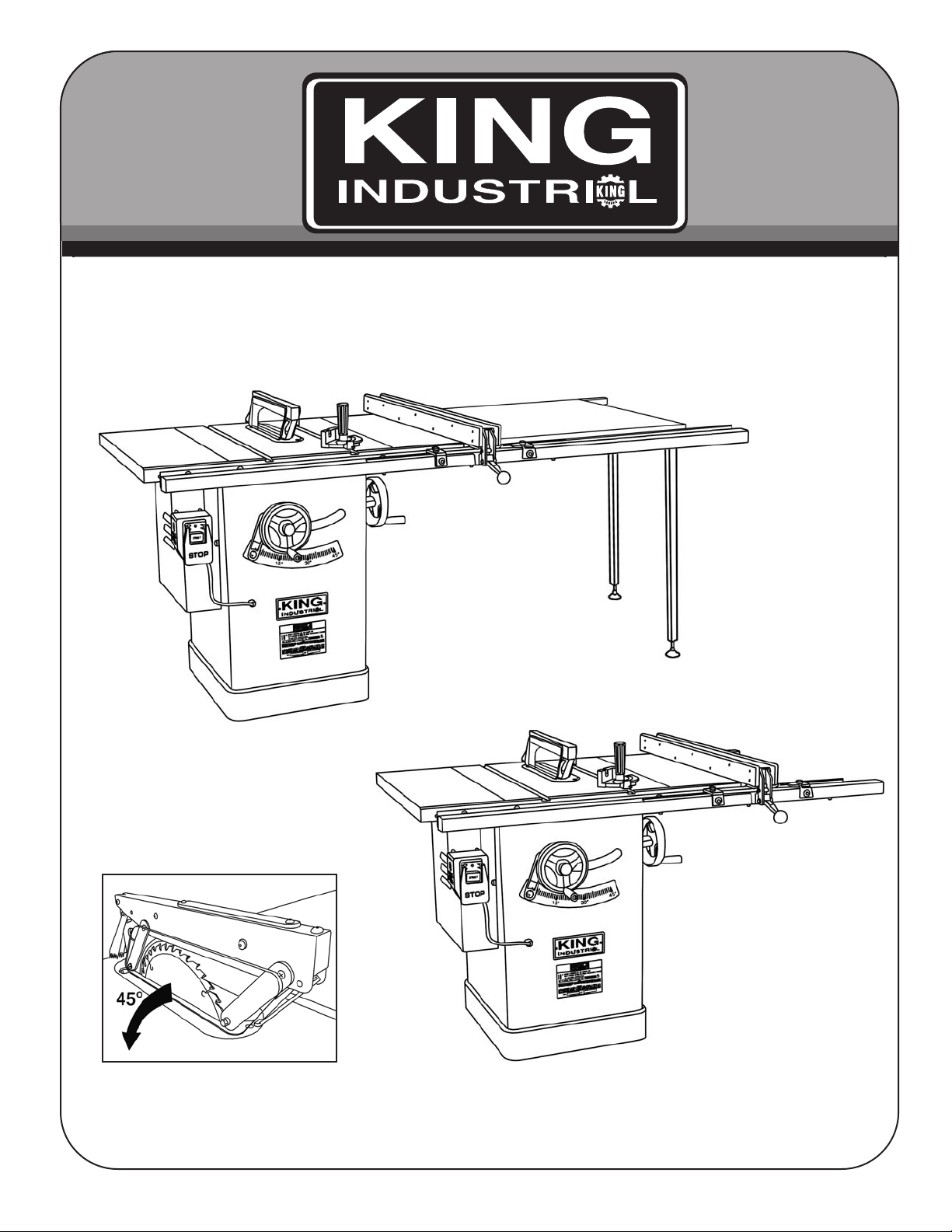

10” CABINET TABLE SAWS

WITH RIVING KNIFE

OPTIONAL

MODEL:

KC-10JCS/J52

(52” Max Rip)

KC-10JCS/J52 shown here with

optional 33 1/4” laminated

melamine extension table and 2

sturdy adjustable supporting legs

(mod. EXT-5052)

Left Tilt

MODEL:

KC-10JCS/J30

(30” Max Rip)

INSTRUCTION MANUAL

COPYRIGHT © 2010 ALL RIGHTS RESERVED BY KING CANADA TOOLS INC.

Page 2

WARRANTY INFORMATION

2-YEAR

LIMITED WARRANTY

FOR THIS 10” CABINET SAW

OFFERS A 2-YEAR LIMITED WARRANTY

KING CANADA TOOLS

FOR INDUSTRIAL USE.

PROOF OF PURCHASE

Please keep your dated proof of purchase for warranty and servicing purposes.

REPLACEMENT PARTS

Replacement parts for this product are available at our authorized King Canada service centers across Canada.

LIMITED TOOL

King Canada makes every effort to ensure that this product meets high quality and durability standards. King Canada warrants to the

original retail consumer a 2-year limited warranty as of the date the product was purchased at retail and that each product is free from

defects in materials. Warranty does not apply to defects due directly or indirectly to misuse, abuse, normal wear and tear, negligence

or accidents, repairs done by an unauthorized service center, alterations and lack of maintenance. King Canada shall in no event be

liable for death, injuries to persons or property or for incidental, special or consequential damages arising from the use of our products.

To take advantage of this limited warranty, return the product at your expense together with your dated proof of purshase to an

authorized King Canada service center. Contact your retailer or visit our web site at www.kingcanada.com for an updated listing of our

authorized service centers. In cooperation with our authorized serviced center, King Canada will either repair or replace the product if

any part or parts covered under this warranty which examination proves to be defective in workmanship or material during the

warranty period.

WARRANTY

NOTE TO USER

This instruction manual is meant to serve as a guide only. Specifications and references are subject to change without prior notice.

ARTS DIAGRAM & PARTS LISTS

P

Refer to the Parts section of the King Canada web site for the most updated parts diagram and parts list.

2Y4

KING CANADA

INC. DOR

AL, QUÉBEC, CANADA

V

H9P

www.kingcanada.com

Page 3

GENERAL SAFETY INSTRUCTIONS

FOR POWER TOOLS

1. KNOW YOUR TOOL

Read and understand the owners manual and labels affixed to

he tool. Learn its application and limitations as well as its

t

specific potential hazards.

2. GROUND THE TOOL.

his tool is equipped with an approved 3-conductor cord and a

T

3-prong grounding type plug to fit the proper grounding type

receptacle. The green conductor in the cord is the grounding

ire. NEVERconnect the green wire to a live terminal.

w

3. KEEP GUARDS IN PLACE.

Keep in good working order, properly adjusted and aligned.

4. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

5. KEEP WORK AREA CLEAN.

Cluttered areas and benches invite accidents. Make sure the

floor is clean and not slippery due to wax and sawdust build-up.

6. AVOID DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations or expose them

to rain. Keep work area well lit and provide adequate

surroun-ding work space.

7. KEEP CHILDREN AWAY.

All visitors should be kept a safe distance from work area.

8. MAKE WORKSHOP CHILD-PROOF.

-with padlocks, master switches or by removing starter keys.

9. USE PROPER SPEED.

A tool will do a better and safer job when operated at the

proper speed.

10. USE RIGHT TOOL.

Don’t force the tool or the attachment to do a job for which it was

not designed.

11. WEAR PROPER APPAREL.

Do not wear loose clothing, gloves, neckties or jewelry (rings,

watch) because they could get caught in moving parts. Non-slip

footwear is recommended. Wear protective hair covering to

ontain long hair. Roll up long sleeves above the elbows.

c

12. ALWAYS WEAR SAFETY GLASSES.

Always wear safety glasses (ANSI Z87.1). Everyday eyeglasses

nly have impact resistant lenses, thet are

o

Also use a face or dust mask if cutting operation is dusty.

13. DON’T OVERREACH.

eep proper footing and balance at all times.

K

14. MAINTAIN TOOL WITH CARE.

Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS.

Before servicing, when changing accessories or attachments.

16. AVOID ACCIDENTAL STARTING.

Make sure the switch is in the ‘’OFF’’ position before plugging in.

17. USE RECOMMENDED ACCESSORIES.

Consult the manual for recommended accessories. Follow the

instructions that accompany the accessories. The use of

improper accessories may cause hazards.

18. NEVER STAND ON TOOL.

Serious injury could occur if the tool tips over. Do not store materials

such that it is necessary to stand on the tool to reach them.

19. CHECK DAMAGED PARTS.

Before further use of the tool, a guard or other parts that are damaged

should be carefully checked to ensure that they will operate

properly and perform their intended function. Check for alignment

of moving parts, breakage of parts, mounting, and any other

conditions that may affect its operation. A guard or other parts that

are damaged should be properly repaired or replaced.

20. NEVER LEAVE MACHINE RUNNING UNATTENDED.

Turn power ‘’OFF’’. Don’t leave any tool running until it comes to

a complete stop.

NOTs

afety glasses.

SPECIFIC SAFETY INSTRUCTIONS FOR TABLE SAWS

YS USE A

A

W

AL

1.

Always use a guard, splitter and anti-kickback fingers on all “thrusawing” operations. Thru-sawing operations are those when the

blade cuts completely through the workpiece as in ripping or

crosscutting.

2. ALWAYS HOLD THE WORK.

Always hold the work firmly against the miter gauge or fence.

AYS USE A PUSH STICK.

W

3. AL

For ripping narrow stock. Refer to ripping applications in

instruction manual where push sticks are covered in detail.

4. NEVER.

Never perform any operations “free-hand” which means using

your hands to support or guide the workpiece.

the fence or the miter gauge to position and guide the workpiece.

5. NEVER.

Never stand or have any part of your body in line with the path of

the saw blade.

6. NEVER REACH BEHIND.

Never reach behind or over the cutting tool with either hand for

any reason.

7. MOVE THE RIP FENCE.

Move the rip fence out of the way when crosscutting.

8. WHEN CUTTING MOULDINGS.

Never run the stock between the fence and the moulding cutter-

GUARD.

Always use either

head. Refer to moulding applications in the accessory manual for

details.

9. DIRECTION OF FEED.

Feed work into the blade against the direction of rotation.

10. NEVER.

Never use the fence as a cut-off gauge when you are cross-

cutting.

1. NEVER.

1

Never attempt to free a stalled saw blade without first turning the

saw OFF

12. PROVIDE

To the rear and sides of the table saw for wide or long workpieces.

VOID KICKBACKS.

A

13.

void kickbacks (work thrown back towards you) by keeping the

A

blade sharp, by keeping the rip fence parallel to the saw blade, by

keeping the splitter and anti-kickback fingers and guard in place

and operating, by not releasing work before it is pushed all the

way past the saw blade, and by not ripping work that is twisted or

warped or does not have a straight edge to guide along the fence.

VOID AWKWARD OPERATIONS.

A

14.

Avoid awkward operations and hand positions where a sudden

slip could cause your hand to move into the spinning blade.

.

ADEQUA

SUPPORT.

TE

Page 4

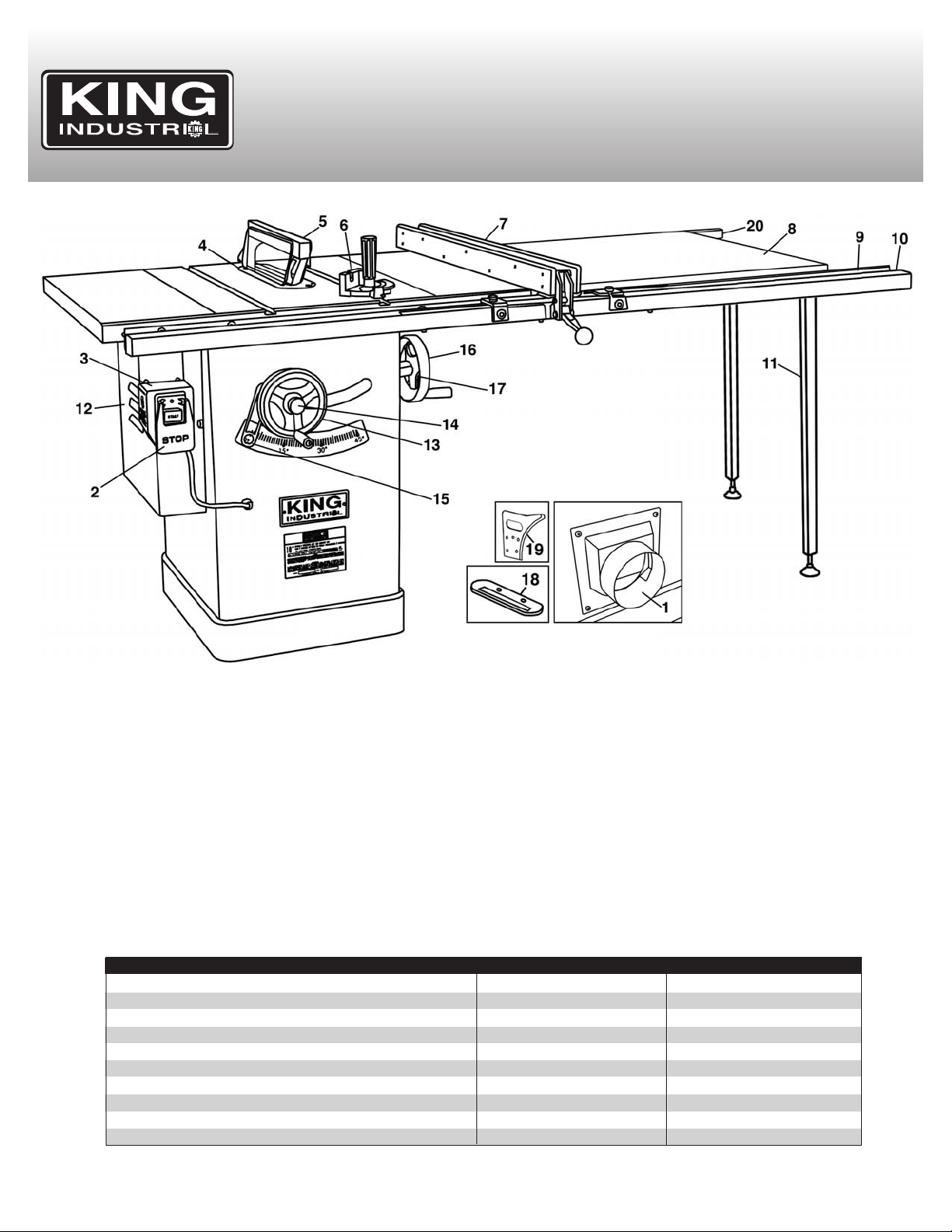

GETTING TO KNOW YOUR 10” TABLE SAW

AND SPECIFICATIONS

Model KC-10JCS/J52

shown here with optional

melamine extension table

mod. EXT-5052

1. 4” Dust chute

2. Emergency stop

3. Switch with reset button

4. Table insert

5. 2pc. blade guard with riving knife

6. Miter gauge

7. T-square rip fence

8. Laminated table (Optional accessory EXT-5052)

9. Front rail

10. Slide tube

11. Support legs/adjustable feet (Optional accessory EXT-5052)

12. Motor access door

13. Blade raising handwheel

14. Handwheel lock knob

15. Angle pointer and scale

16. Blade tilting handwheel

17. Handwheel lock knob

18. Dado table insert

19. Riving knife

20. Rear rail

SPECIFICATIONS CHART

MODEL

Blade diameter 10” 10”

Blade tilts Left Left

Depth of cut at 45° 2 3/16” 2 3/16”

Depth of cut at 90

Table size with extensions 40” x 27” 40” x 27”

Diameter of arbor 5/8” 5/8”

Dado width capacity 13/16” 13/16”

Dado maximum blade diameter 8” 8”

Motor

Voltage (pre-wired: 220V)

°

KC-10JCS/J30 KC-10JCS/J52

3 1/8”

2 HP, 3,450 RPM 2 HP, 3,450 RPM

120V/240V

, 1 phase, 60 Hz

3 1/8”

120V/240V

, 1 phase, 60 Hz

Page 5

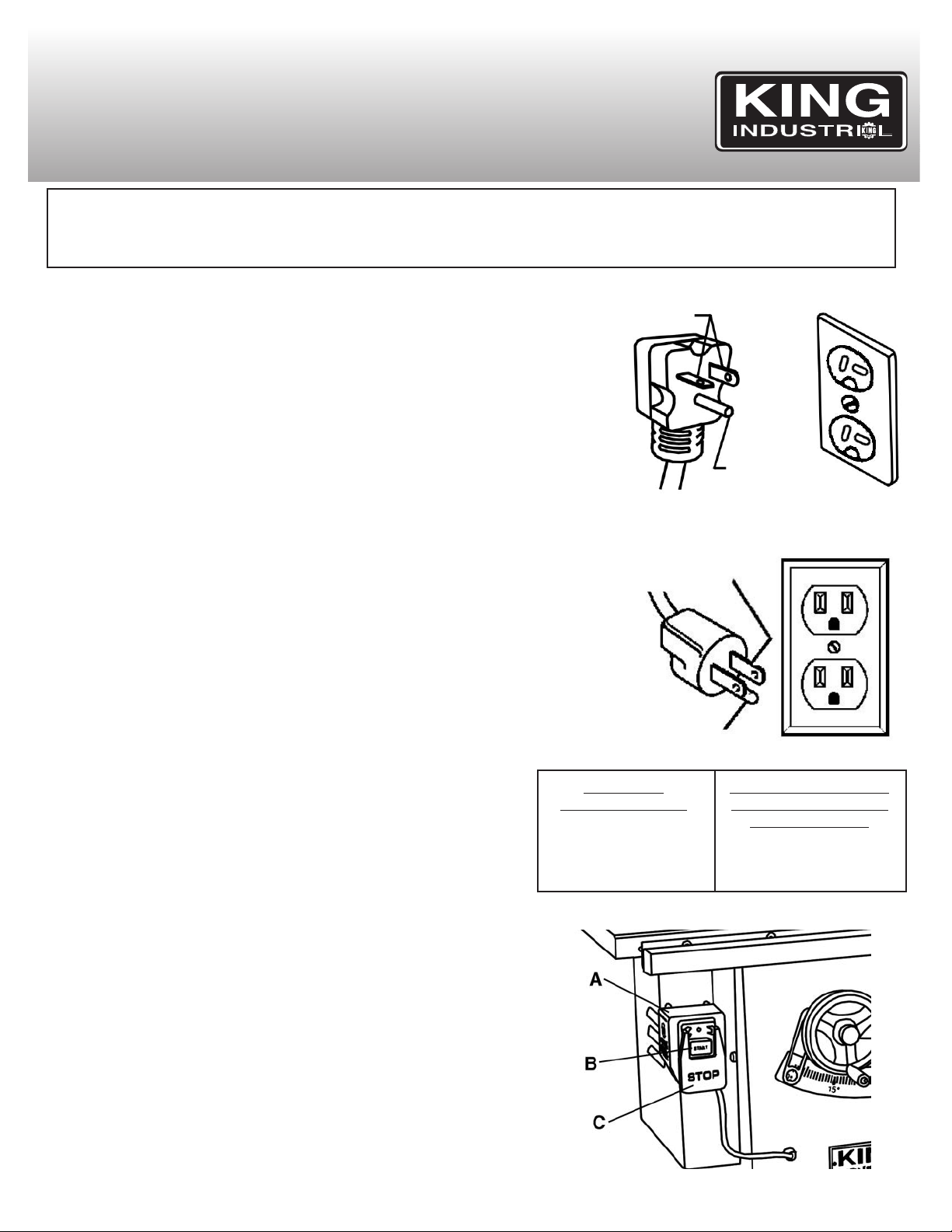

ELECTRICAL REQUIREMENTS &

SWITCH OPERATION

ARNING!

W

ALL ELECTRICAL CONNECTIONS MUST BE DONE BY A QUALIFIED ELECTRICIAN. FAILURE TO COMPLY MAY RESULT IN

ERIOUS INJURY! ALL ADJUSTMENTS OR REPAIRS MUST BE DONE WITH THE MACHINE DISCONNECTED FROM THE

S

POWER SOURCE. FAILURE TO COMPLY MAY RESULT IN SERIOUS INJURY!

POWER SUPPLY (240V)

ARNING:

W

OPERATION AND MUST BE CONNECTED TO AN APPROPRIATELY

GROUNDED 240V OUTLET AS SHOWN IN FIG.1.

GROUNDING

WARNING:

SAW CAN CAUSE ELECTRICAL SHOCK, PARTICULARLY WHEN USED IN

DAMP LOCATIONS. TO AVOID SHOCK OR FIRE, IF THE POWER CORD IS

WORN OR DAMAGED IN ANY WAY, HAVE IT REPLACED IMMEDIATELY.

Not all outlets are properly grounded. If you are not sure if your outlet is

properly grounded, have it checked by a qualified electrician.

This cabinet saw must be grounded, if it should malfunction or breakdown,

grounding provides a path of least resistance for electric current, which

reduces the risk of electric shock.

WARNING: TO MAINTAIN PROPER GROUNDING OF YOUR TABLE SAW,

DO NOT REMOVE OR ALTER THE GROUNDING PRONG IN ANY MANNER.

POWER SUPPLY (120V)

WARNING!

single phase operation is desired. It is recommended to contact your

authorized service center or qualified electrician to install the plug, change

reset and change the connections from 240V to 120V.

1. Disconnect the machine from its power source.

2. The table saw comes with four motor leads that are connected for 240V

operation. Reconnect these four motor leads for 240V operation, as

indicated on the inside of the motor and/or capacitor cover.

3. The 240V plug supplied with the table saw must be replaced with a CSA

listed plug suitable for 120V operation. This plug is illustrated in Fig.2.

10A reset must also be changed to a 20Amp reset. Contact your authorized

service center or qualified electrician to install the plug, change reset and

change the connections from 240V to 120V. The table saw must comply

with all local and national codes after the 120V plug is installed.

4. A table saw with a 120V plug should only be connected to an outlet having

the same configuration as illustrated by the grounded outlet box in Fig.2. No

adaptor is available or should be used for 120V operation.

EXTENSION CORDS

The use of any extension cord will cause some loss of power. Use the

following table to determine the minimum wire size (A.W.G-American Wire

Gauge) extension cord you will need. Use only 3-wire extension cords which

have 3-prong grounding type plugs and 3-hole receptacles which accept the

tool’s plug. For circuits that are further away from the electrical circuit box, the

wire size must be increased proportionately in order to deliver ample voltage

to the cabinet saw motor. Refer to Fig.3 for wire length and size.

HIS CABINET SAW CAME PRE-WIRED FOR 240V

T

IF OUTLET IS NOT PROPERLY GROUNDED, THIS CABINET

This table saw must be connected to a 30 amp. circuit if 120V,

The

CURRENT CARRYING

PRONGS

CURRENT CARRYING

PRONGS

GROUNDING PRONG

LENGTH OF

EXTENSION CORD

0-25 FEET

26-50 FEET

51-100 FEET

PROPERLY

GROUNDED OUTLET

GROUNDING

PRONG

FIGURE 1

PROPERLY

GROUNDED OUTLET

FIGURE 2

WIRE SIZES REQUIRED

(AMERICAN WIRE GAUGE)

240V LINES ONLY

NO.12

NO.12

NO.10

FIGURE 3

SWITCH OPERATION

The switch (A) Fig.4 needs to be installed to underside of the front rail, see

assembly section in this manual for further instructions. Do not turn the

cabinet saw on until all assembly and adjustment instructions have been

done.

To start the cabinet saw, press the green start button (B) Fig.4 and to stop the

cabinet saw, press the red emergency stop button (C).

This switch is equipped with a thermal overload protector, if motor is overloaded during use, the reset will trip and stop the motor

allow motor to cool down, press the reset button (on right side of switch) and

turn cabinet saw on to continue.

ait a few minutes to

. W

FIGURE 4

Page 6

ASSEMBLY

DISASSEMBLING MOTOR BRACKET

For shipping purposes, a motor bracket (A) Fig.5 is bolted to the cabinet and

attached to the motor mount. This motor bracket must be removed before

assembling, adjusting or operating this cabinet saw. You should keep this motor

racket for shipping or transporting your cabinet saw.

b

IMPORTANT: The cap screw (B) Fig.5 is used to tension the V-belt, once the

motor bracket (A) has been removed, reinstall cap screw (B) and proceed to the

“Maintenance” section to properly tension the V-belt.

INSTALLING MOTOR ACCESS DOOR

To prevent air born saw dust, the motor access door (A) Fig.6 should be

installed to the cabinet. Slide the motor access door hinge pins (B) into the

hinge supports in the cabinet. Swing and close the access door and lock it into

place using the supplied lock knob (C).

FIGURE 5

ASSEMBLING EXTENSION WINGS

Important Note: There is a right and a left side extension wing, each extension

wing has a beveled edge, this beveled edge must be positioned towards the

front of the saw.

Fasten each extension wing to the table using 3 cap screws, spring washers

and washer. To allow adjustment, do not fully tighten the cap screws. Align the

beveled edge of each extension wing with the beveled edge of the table.

Using a straight edge, level the extension wings to the table surface as shown

in Fig.7. Verify the adjustments, once the extension table is flush with the front

and top of the table, tighten the cap screws.

ASSEMBLING HANDWHEELS

Position a key into the keyway of the shaft, align the keyway of the handwheel

(A) Fig.8 and slide it onto the shaft. Tighten the set screw on the handwheel hub

to secure it in place. Insert the center lock knob (B) into the center hole in the

shaft and tighten in a clockwise direction.

(C) into the handwheel. Repeat for the second handwheel.

Then thread the handwheel handle

FIGURE 6

FIGURE 7

FIGURE 8

Page 7

ASSEMBLY

INSTALLING FRONT RAIL AND TUBE ASSEMBLY

Place and align the mounting holes of the front rail and tube

ssembly (A) Fig.9 with the holes in the front lip of the table (C)

a

nd extension wings (D & E). Install the front rail and tube

a

assembly to the table and extension wings using 4 countersunk

head bolts, 8 washers, 4 spring washers and 4 hex. nuts.

Before securing it in place, adjust it up or down to ensure the front

rail edge is set at 1/8” below the lowest edge of the miter gauge

T-slot. Once adjusted, tighten all 4 countersunk head bolts.

INSTALLING REAR RAIL

Place and align the mounting holes of the rear rail (B) Fig.9 with

the holes in the rear lip of the table (C) and extension wings (D &

E). Install the rear rail to the table using 2 hex. bolts and 2

washers.

Then 2 use hex. bolts, 4 washers, 2 spring washers and 2 hex.

nuts to fix the rear rail to the extension wings. Before securing it

in place, adjust it up or down to ensure the rear rail edge is set

flush with the lowest edge of the miter gauge T-slot (to allow free

movement of the miter gauge). Once adjusted, tighten all 4 bolts.

FIGURE 9

INSTALLING OPTIONAL LAMINATED EXTENSION TABLE (KC-10JCS/J52)

Once both rails are installed, place the optional laminated extension table (F) Fig.9

between the front and rear rails

bolts, washers, spring washers and hex. nuts. Before securing it in place, adjust it

up or down to ensure the top of the laminated extension table is set flush with the

top of the right side extension wing (E). Once adjusted, tighten all bolts.

INSTALLING MEASURING TAPE

Only proceed with this step once the rip fence system has been adjusted and that

the fence is perfectly parallel with the saw blade. See “Fence

the fence against the saw blade. Place the measuring tape on the tube (A) Fig.9

under the pointer window (A) Fig.10. The pointer window contains 2 small red lines

which represent the thickness of the blade kerf, line up the zero mark of the

measuring tape underneath the red line on the left side. Make sure the measuring

tape is positioned perfectly parallel to the tube and that the measurements are

clearly visible. Remove the fence. Peel away a small portion at a time of the

measuring tape backing and carefully install. We suggest taking your time during

this installation, if a mistake is made and the zero mark does not align perfectly

loosen the pointer window screws (B), reposition the pointer window in the correct

position and retighten the screws.

INSTALLING OPTIONAL SUPPORT LEGS FOR LAMINATED EXTENSION

TABLE (KC-10JCS/J52)

Fasten the 2 support legs to the inner edge of the laminated extension table using

4 hex. bolts, 8 washers, 4 spring washers and 4 hex. nuts. Refer to the parts

diagram for assembly.

(KC-10JCS/J52 Only). Fix it in place using hex.

Adjustments”. Slide

FIGURE 10

,

Once installed, the adjustment feet must be adjusted properly to offer adequate

support. Turn the adjustment feet until they both bottom out against the floor and

tighten the upper hex. nut against each support leg to secure them in place.

INSTALLING SWITCH TO FRONT RAIL

The switch (A) Fig.11 comes attached to a mounting bracket (B), mount the

mounting bracket to the underneath the left end of the front rail (C) using 2 hex.

bolts and washers.

FIGURE 11

Page 8

ASSEMBLY

NSTALLING / CHANGING BLADE

I

1. Make sure the cabinet saw is Off and the power cord is disconnected.

2. If you are replacing a blade, raise the saw blade to its maximum height and lock

the saw at 0 degrees. Remove the table insert.

. Jam a large piece of scrap wood into the blade teeth at the front.

3

4. Place the blade wrench (A) Fig.12 on the arbor nut (B).

5. Press the spindle lock button (A) Fig.13 and pull the wrench toward you

(counterclockwise to loosen). Remove the arbor nut, flange (under arbor nut) and

saw blade (C) Fig.12.

6. Place the new or different blade on the arbor shaft making certain the teeth point

down towards the front of the saw. Reposition the flange and arbor nut.

7. Place the scrap wood in the blade’s teeth in the rear. Hold carefully so if it slips

or the blade turns, your hand will not contact the blade.

8. Press the spindle lock button (A) Fig.13, using the wrench provided, securely

tighten the arbor nut by pushing the wrench away from you (clockwise to

tighten). Remove the wrench and reposition the table insert.

FIGURE 12

Riving Knife specifications:

Thickness: 2.2mm

Blade diameter: 254mm

Blade body: 1.8-2.4mm

Blade kerf: 2.6-3.2mm

Make sure you follow these specification guidelines for replacement blades.

ADJUSTING TABLE INSERT

A table insert (A) Fig.14 gets placed in the opening in the saw table and should be

perfectly flush with the surface of the saw table. T

straight edge over the table insert and the table. Turn the 4 adjusting set screws

(B) in the insert, turn them in or out until all 4 corners of the insert are flush with

the table top.

ASSEMBLING BLADE GUARD/RIVING KNIFE

WARNING!

KNIFE IN THE PROPER OPERATING POSITION. FALIURE TO DO THIS MAY

CAUSE SERIOUS INJUR

Through-cut operations- For all through-cut operations, the blade guard with

splitter (A) Fig.15 must be installed.

NEVER OPERATE SAW WITHOUT BLADE GUARD OR RIVING

Y!

o adjust the table insert, place a

FIGURE 13

FIGURE 14

Install the blade guard splitter (A) Fig.15 in between the mounting plates below the

table insert. Push blade guard splitter all the way down, then pull the locking pin

wheel (B) away from the blade, push blade guard splitter further down in between

the mounting plates until the locking pin engages the splitter. Give the splitter an

upward tug to make sure that it is properly locked. The clearance between the

blade and the splitter should be between 1/8” to 5/16” (3-8mm).

FIGURE 15

Page 9

SSEMBLING BLADE GUARD/RIVING KNIFE

A

ADJUSTMENTS

Non through-cut operations

knife (A) Fig.16 must be installed. The riving knife gets installed the same way as the

blade guard splitter, see

ighest point of the riving knife (A) Fig.16 should never exceed the highest point of the

h

blade teeth, generally 1/8” to 3/16” (1-5mm). See adjustments for more information.

WARNING!

OME CUTTING OPERATIONS (DADO BLADE, MOLDING CUTTERHEAD) WON’T

S

ALLOW USE OF THE BLADE GUARD OR RIVING KNIFE. USE EXTREME CAUTION

DURING THESE OPERATIONS AS THE BLADE OR CUTTERHEAD WILL BE EXPOSED

AND COULD CAUSE SERIOUS INJURY.

POSITIONING AND ADJUSTING MITER GAUGE

The miter gauge shown in Fig.17 normally gets positioned on the left side of the blade by

sliding the miter gauge bar (A) into the table T-slot. To operate the miter gauge, loosen

lock knob (B) Fig.17, pull out the positive stop pin (C) and pivot the miter gauge body (D)

to the desired angle, retighten lock knob (B).

If you desire a preset positive stop such as 0

pull out the positive stop pin (C) and slightly pivot the miter gauge body (D). Once you get

close to the desired angle, push and hold the positive stop pin, continue to rotate the miter

gauge body to the desired angle, the positive stop pin will engage that positive stop

position, then retighten lock knob (B).

BLADE RAISING AND TILTING MECHANISM

To raise or lower the blade, loosen lock knob (A) Fig.18. and turn the raising handwheel

(B). When desired height is obtained, retighten lock knob. The blade should be raised 1/8”

to 1/4” above the top surface of the material being cut. With hollow ground blades the

blade should be raised to the maximum to provide chip clearance. To tilt the saw blade,

loosen lock knob (C) and turn tilting handwheel (D). When desired angle is obtained,

retighten lock knob.

- For non through-cut operations with a 10” blade, the riving

Through-cut operations instructions. For safety reasons, the

0

or 450setting, loosen lock knob (B) Fig.17,

FIGURE 16

FIGURE 17

ADJUSTING RIP FENCE

The rip fence must be perfectly aligned with the table T-slot, to verify this, align the edge

of the rip fence with the table T-slot and lower the locking lever (A) Fig. 19 to lock in into

place. Check to see if the edge of the rip fence and the table T-slot are parallel. If they are

not parallel, unlock the rip fence and turn it upside down. Adjust the set screws (A) Fig.20

in or out, verify your adjustment, repeat if necessary.

The lock lever pressure can be adjusted by loosening the front lock nuts (B) Fig.19 and

adjusting the set screws (C) the same amount, make sure the fence remains parallel with

the table

square on the table and against the side of the fence, loosen the top lock nuts (D) and

adjust the set screws (E) until the fence is perpendicular. Retighten lock nuts. The

pointer window (F) Fig.19 position can be adjusted if needed, loosen pan head screws

(G), reposition the pointer window and retighten pan head screws.

-slot. Retighten lock nuts. To set the fence perpendicular to the table, place a

T

FIGURE 18

FIGURE 19

FIGURE 20

Page 10

ADJUSTMENTS

ALIGNING TABLE T-SLOT PARALLEL WITH BLADE

The table T-slot must be aligned parallel with the blade. Using a combination

square (A) Fig.21, measure the distance from the back edge of the blade to the

table T-slot. Pivot blade forward 180º and remeasure the distance using the

xact same point on the blade. The difference between both measurements

e

must be equal to or less than 1/64”.

If an adjustment is necessary, loosen the four cap screws (A) Fig.22 which fix

the table top to the cabinet, make the needed adjustment to the table top

position until both measurements are equal or less than 1/64” and retighten the

four cap screws (A).

ALIGNING BLADE GUARD SPLITTER OR RIVING KNIFE WITH BLADE

The blade guard splitter and/or riving knife must be aligned with the blade. If not

properly aligned, the splitter/riving knife will force the workpiece sideways

during the cut, increasing risk of kickback.

Place a straightedge against the blade and the splitter or riving knife and check

for parallelism. If an adjustment is needed, the mounting position of the riving

knife support plate (A) Fig.23 can be adjusted into alignment with the blade.

1. Disconect saw from power source.

2. Remove the table insert.

3. Loosen the 2 cap screws (B) Fig.23 and adjust the position of the riving knife

support plate (A) until the alignement is perfectly parallel.

4. Reinstall the table insert.

FIGURE 21

FIGURE 22

For safety reasons, the highest point of the riving knife (A) Fig.24 should never

exceed the highest point of the blade teeth, generally 1/8” to 3/16” (1-5mm).

FIGURE 23

FIGURE 24

Page 11

ADJUSTMENTS & OPERATION

ADJUSTING 45 AND 90 DEGREE POSITIVE STOPS

he blade tilting mechanism of your saw is equipped with a positive stop at 45 and

T

90 degrees. To check and adjust these positive stops, proceed as follows:

1. Raise the saw blade to its maximum height.

. Set the blade at 90 degrees to the table by turning the blade tilting handwheel

2

counterclockwise as far as it will go.

3. Place a square on the table and check to see if the blade is at a perfect 90 degree

angle to the table.

4. If the blade is not at 90 degrees, adjust the 90 degree adjustment cap screw (A)

Fig. 25 in or out. The cap screw should stop against the front trunnion bracket

when the blade is at 90 degrees to the table. Recheck and adjust further if

necessary.

5. If the 45 degree postive stop is not set properly, turn the same handwheel clock-

wise as far as it will go and follow the same procedure by using the 45 degree

adjustment cap screw (B) Fig. 25 in or out. The cap screw should stop against the

front trunnion bracket when the blade is at 45 degrees to the table. Recheck and adjust further if necessary.

SAFETY PRECAUTIONS BEFORE OPERATION

The operation of power tools involves a certain amount of hazard for the operator. Before attempting regular work we recommend you get the

feel of operations using scrap lumber to check settings. Read entire instructions before you start to cut workpiece. Always pay attention to

safety precautions to avoid personal injury.

FIGURE 25

OPERATION

Plain sawing includes ripping and crosscutting, plus a few other standard operations of a fundamental nature. The following methods feature

safety. As with all power tools there is a certain amount of hazard involved with the operation and use of the tool. Using the tool with the respect

and caution demanded as far as safety precautions are concerned will considerably lessen the possibility of personal injury. However, if normal

safety precautions are overlooked or completely ignored, personal injury to the operator can develop. It is good practice to make trial cuts using

scrap material when setting up you saw for operation.

CROSSCUTTING

Crosscutting requires the use of the miter gauge to position and guide the work. Place the work against the miter gauge and advance both the

miter gauge and work toward the saw blade, as shown in Fig.26. The miter gauge may be used in either table slot, however, most operators

prefer the left groove for average work. When bevel cutting (blade tilted), use the table groove that does not cause interference of your hand

or miter gauge with the saw blade guard.

Start the cut slowly and hold the work firmly against the miter gauge and the table.

One of the rules in running a saw is that you never hang onto or touch a free piece

of work. Hold the supported piece, not the free piece that is cut off. The feed in

crosscutting continues until the work is cut in two, then the miter gauge and work are

pulled back to the starting point. Before pulling the work back it is good practice to

give the work a little sideways shift to move the work slightly away from the saw

blade.

Never pick up any short length of free work from the table while the saw is running.

A smart operator never touches a cut-off piece unless it is at least a foot long. Never

use the fence as a cut-off gauge when crosscutting. Never use the miter gauge in

combination with the rip fence.

FIGURE 26

Page 12

OPERATION

RIPPING

ipping is the operation of making a lengthwise cut through a board, as shown in

R

Fig.27, and the rip fence is used to position and guide the work. One edge of the

ork rides against the rip fence while the flat side of the board rest on the table.

w

Since the work is pushed along the fence, it must have a straight edge and make

solid contact with the table. The saw guard must be used. The guard has antikickback fingers and a splitter to prevent the saw kerf from closing.

Start the motor and advance the work holding it down and against the fence.

Never, stand in the line of the saw cut when ripping. Hold the work with both

hands and push it along the fence and into the saw blade as shown in Fig.27.

work can then be fed through the saw blade with one or two hands.

When this is done the work will either stay on the table, tilt up slightly and be

caught by the rear end of the guard or slide off the table to the floor. Alternately,

the feed can continue to the end of the table, after which the work is lifted and

brought back along the outside edge of the fence. The waste stock remains on

the table and is not touched with the hands until the saw is stopped unless it is a

large piece allowing safe removal.

The

FIGURE 27

USING DADO BLADE SET (OPTIONAL) AND DADO INSERT

Dadoing is cutting a rabbet or a wide groove into the work. Most dado head sets

are made up of two outside blades and four or five inside cutters, as shown in Fig.

28. Various combination of saws and cutters are used to cut grooves from 1/8” to

13/16” for use in shelving, making joints, tenoning, grooving, ect. The cutters are

heavily swaged and must be arranged so that this heavy portion falls in the gullet

of the outside blades, as shown in Fig. 29. The saw and cutter overlap is shown

in Fig.29 (A) being the outside blade, (B) and inside cutter, and (C) a paper

washer which can be used as needed to control the exact width of groove. A 1/4”

groove is cut by using the two outside blades. The teeth of the blades should be

positioned so that the raker on one saw is beside the cutting teeth on the other

saw.

The dado head set is assembled to the saw arbor in the same manner as the saw

The guard splitter and anti-kickback finger assembly can not be used when

blade.

dadoing operations and must be removed from the saw. The included dado head

table insert must be used in place of the standard table insert.

NEVER USE THE DADO HEAD IN A BEVEL POSITION UNLESS YOU MAKE

YOUR OWN DADO INSERT!

ALWAYS INSTALL BLADE GUARD AFTER OPERATION IS COMPLETE!

PUSH STICK CONSTRUCTION

FIGURE 28

A

FIGURE 29

B

C

A push stick is not supplied with this table saw and should be used whenever

possible. Fig.30 shows an illustration of how to make one yourself. It is

recommended to use a good quality plywood or solid wood, 1/2” and 3/4” thick.

FIGURE 30

Page 13

MAINTENANCE &

OPTIONAL ACCESSORIES

his table saw requires very little maintenance other than minor lubrication

T

and cleaning. The following sections detail what will need to be done in

rder to assure continued operation of your saw.

o

LUBRICATION

he table saw has sealed lubricated bearings in the motor housing and the

T

arbor assembly, they will not require any additional lubrication. Use a wire

brush to clean off the worm gears and trunnions and apply a white lithium

grease to keep them lubricated.

CLEANING

Keep the inside of the cabinet clear of saw dust and wood chips. With the

table saw unplugged, open the motor access door. Vacuum out the inside

of the cabinet or blow out the inside with an air hose.

CHANGING BELTS

MAKE SURE THE POWER CORD IS DISCONNECTED FROM THE

POWER SOURCE.

FIGURE 31

To remove the V-belt, first lower the blade to its lowest point. Loosen the

large cap screw (A) Fig.31 and then take the tension off of the V-belt by

lifting up on the motor. Remove the V-belt (B) from the arbor shaft and the

motor pulley and replace it with a new one. Lower the motor, the weight of

the motor should apply enough tension and retighten large cap screw (A).

Check the V-belt tension after the saw has been used for a few hours.

Adjust as necessary.

OPTIONAL ACCESSORIES

Router Table Attachment

model KRT-100 (Fig.32)

Sliding Table Attachment

model KST-101 (Fig.33)

FIGURE 32 FIGURE 33

These optional accessories are designed to fit table saw model KC-10JCS and also fit most table saws having a 27” deep table.

Page 14

TROUBLESHOOTING

ROBLEM

P

SAW WILL NOT START

1. Saw not plugged in.

2. Fuse blown or circuit breaker tripped.

3. Cord damaged.

OVERLOAD KICKS OUT FREQUENTLY

1. Extension cord too light or too long.

2. Feeding stock too fast.

3. Blade in poor condition (dull, warped,

gummed).

4. Blade binding due to misaligned rip fence.

5. Blade binding due to warped wood.

6. Low house current.

DOES NOT MAKE ACCURATE 450AND 90

RIP CUTS

1. Positive stop(s) not adjusted properly.

2. Tilt angle pointer not set properly.

MATERIAL PINCHES BLADE WHEN RIPPING

1. Rip fence not aligned with blade.

2. Warped wood.

MATERIAL BINDS ON SPLITTER

1. Splitter not aligned correctly with blade kerf.

OLUTION

S

1. Plug in saw.

2. Replace fuse or reset circuit breaker.

3. Have cord replaced by a certified electrician.

1. Replace with adequate size cord.

2. Feed stock more slowly.

3. Clean or replace blade.

4. Check and adjust the rip fence. See rip fence instructions.

5. Select another piece of wood.

6. Contact your electrical company.

0

1. Check blade with square and adjust positive stop.

2. Check blade with square and adjust pointer to zero.

1. Check and adjust rip fence.

2. Select another piece of wood.

1. Check and align splitter with blade kerf.

SAW MAKES UNSATISFACTORY CUTS

1. Dull blade.

2. Blade mounted backwards.

3. Gum or pitch on blade.

4. Incorrect blade for work being done.

5. Gum or pitch on table causing erratic feed.

BLADE DOES NOT COME UP TO SPEED

1. Extension cord too light or too long.

2. Low house current.

3. Motor not wired for correct voltage.

MACHINE VIBRATES EXCESSIVELY

able not mounted securely to cabinet stand.

1. T

2. Stand is on uneven floor

3. Damaged saw blade.

4. Bad V-belt.

-belt not tensioned properly

5. V

6. Bent pulley

7. Improper motor mounting.

8. Loose hardware.

BLADE DOES NOT RAISE OR TIL

1. Sawdust or dirt in raising or tilting

mechanisms.

.

.

.

T FREELY

1. Replace blade.

2.Turn blade around.

3. Remove blade and clean with terpentine and steel wool.

4. Change the blade.

5. Clean the table with turpentine and steel wool.

1. Replace with adequate size extension cord.

2. Contact your electric company

3. Refer to motor and /or nameplate.

ighten all mounting hardware.

1. T

2. Reposition on flat level surface.

3. Replace blade.

4. Replace V-belt.

Adjust V

5.

6. Replace pulley

7. Check and adjust motor mounting.

8. Tighten all nuts, bolts and set screws.

1. Brush or blow out loose dust or dirt.

-belt tension.

.

.

Loading...

Loading...