Page 1

10” RIGHT TILT TABLE SAW

*KC-10GC is shown here with optional “TRU-RIP” rip fence system model KRF-1025.

INSTRUCTION MANUAL

COPYRIGHT © 2008 ALL RIGHTS RESERVED BY KING CANADA TOOLS INC.

MODEL: KC-10GC

Page 2

WARRANTY INFORMATION

2-YEAR

LIMITED WARRANTY

FOR THIS 10” CONTRACTORS CABINET TABLE SAW

FFERS A 2-YEAR LIMITED WARRANTY

O

KING CANADA TOOLS

FOR INDUSTRIAL USE.

2-YEAR LIMITED WARRANTY FOR KING INDUSTRIAL MACHINERY

PROOF OF PURCHASE

Please keep your dated proof of purchase for warranty and servicing purposes.

REPLACEMENT PARTS

Replacement parts for this Table Saw with new blade guard are available at our authorized King Canada service centers across

Canada.

LIMITED TOOL WARRANTY

King Canada makes every effort to ensure that this product meets high quality and durability standards. King Canada warrants to

the original retail consumer a 2-year limited warranty as of the date the product was purchased at retail and that each product is free

from defects in materials. Warranty does not apply to defects due directly or indirectly to misuse, abuse, normal wear and tear,

negligence or accidents, repairs done by an unauthorized service center, alterations and lack of maintenance. King Canada shall in

no event be liable for death, injuries to persons or property or for incidental, special or consequential damages arising from the use

of our products.

To take advantage of this limited warranty, return the product at your expense together with your dated proof of purshase to an

authorized King Canada service center. Contact your retailer or visit our web site at www.kingcanada.com for an updated listing of

our authorized service centers. In cooperation with our authorized serviced center, King Canada will either repair or replace the

product if any part or parts covered under this warranty which examination proves to be defective in workmanship or material during

the warranty period.

PARTS DIAGRAM & PARTS LISTS

Refer to the Parts section of the King Canada web site for the most updated parts diagram and parts list.

Page 3

GENERAL SAFETY INSTRUCTIONS

FOR POWER TOOLS

. KNOW YOUR TOOL

1

Read and understand the owners manual and labels affixed to

the tool. Learn its application and limitations as well as its

pecific potential hazards.

s

2. GROUND THE TOOL.

This tool is equipped with an approved 3-conductor cord and

a 3-prong grounding type plug to fit the proper grounding type

receptacle. The green conductor in the cord is the grounding

NEVER connect the green wire to a live terminal.

wire.

3. KEEP

GUARDS IN PLACE.

Keep in good working order, properly adjusted and aligned.

4. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

5. KEEP WORK AREA CLEAN.

Cluttered areas and benches invite accidents. Make sure the

floor is clean and not slippery due to wax and sawdust

build-up.

6. AVOID DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations or expose

them to rain. Keep work area well lit and provide adequate

surrounding work space.

7. KEEP CHILDREN AWAY.

All visitors should be kept a safe distance from work area.

8. MAKE WORKSHOP CHILD-PROOF.

-use padlocks, master switches or use starter keys.

9. USE PROPER SPEED.

tool will do a better and safer job when operated at the

A

proper speed.

10. USE RIGHT T

Don’t force the tool or the attachment to do a job for which it

was not designed.

OOL.

11. WEAR PROPER APPAREL.

Do not wear loose clothing, gloves, neckties or jewelry (rings,

watch) because they could get caught in moving parts. Non-

slip footwear is recommended. W

to contain long hair

. Roll up long sleeves above the elbows.

ear protective hair covering

2. ALWAYS WEAR SAFETY GLASSES.

1

Always wear safety glasses (ANSI Z87.1). Everyday eye-

glasses only have impact resistant lenses, they are

afety glasses. Also use a face or dust mask if cutting

s

operation is dusty.

13. DON’T OVERREACH.

Keep proper footing and balance at all times.

14. MAINTAIN TOOL WITH CARE.

Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS.

Before servicing, when changing accessories or attachments.

16. AVOID ACCIDENTAL STARTING.

Make sure the swich is in the ‘’OFF’’ position before plugging

in.

17. USE RECOMMENDED ACCESSORIES.

Consult the manual for recommended accessories. Follow the

instructions that accompany the accessories. The use of

improper accessories may cause hazards.

18. NEVER STAND ON TOOL.

Serious injury could occur if the tool tips over. Do not store

materials such that it is necessary to stand on the tool to reach

them.

19. CHECK DAMAGED PARTS.

Before further use of the tool, a guard or other parts that are

damaged should be carefully checked to ensure that they will

operate properly and perform their intended function. Check for

alignment of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A guard or

other parts that are damaged should be properly repaired or

replaced.

20. NEVER LEAVE MACHINE RUNNING

UNATTENDED.

urn power ‘’OFF’’. Don’t leave any tool running until it comes

T

to a complete stop.

NOT

Page 4

SPECIFIC SAFETY INSTRUCTIONS,

SPECIFICATIONS & TABLE OF CONTENTS

1. ALWAYS USE A GUARD.

Always use a guard, splitter and anti-kickback fingers on all

“thru-sawing” operations. Thru-sawing operations are those

when the blade cuts completely through the workpiece as in

ripping or crosscutting.

2. ALWAYS HOLD THE WORK.

lways hold the work firmly against the miter gauge or fence.

A

3. ALWAYS USE A PUSH STICK.

For ripping narrow stock. Refer to ripping applications in

instruction manual where push sticks are covered in detail.

4. NEVER.

Never perform any operations “free-hand” which means using

your hands to support or guide the workpiece. Always use

either the fence or the miter gauge to position and guide the

workpiece.

5. NEVER.

Never stand or have any part of your body in line with the path

of the saw blade.

6. NEVER REACH BEHIND.

Never reach behind or over the cutting tool with either hand for

any reason.

7. MOVE THE RIP FENCE.

Move the rip fence out of the way when cross cutting.

8. WHEN CUTTING MOULDINGS.

Never run the stock between the fence and the moulding

cutterhead. Refer to moulding applications in the manual for

details.

9. DIRECTION OF FEED.

Feed work into the blade or cutter against the direction or

rotation of the blade or cutter.

10. NEVER.

Never use the fence as a cut-off gauge when you are cross

cutting.

11. NEVER.

Never attempt to free a stalled saw blade without first turning

the saw OFF.

12. PROVIDE ADEQUATE SUPPORT.

To the rear and sides of the table saw for wide or long

workpieces.

13. AVOID KICKBACKS.

Avoid kickbacks (work thrown back towards you) by keeping

the blade sharp, by keeping the rip fence parallel to the saw

blade, by keeping the splitter and anti-kickback fingers and

guard in place and operating, by nor releasing work before it is

pushed all the way past the saw blade, and by not ripping work

that is twisted or warped or does not have a straight edge to

guide along the fence.

14. AVOID AWKWARD OPERATIONS.

Avoid awkward operations and hand positions where a

sudden slip could cause your hand to move into the cutting

tool.

SPECIFICATIONS

Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 HP

. . . . . . . . . . . . . . . . . . .18A @110V, 9A @ 220V

Amps/V

Pre-wired at

T

Miter angle . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Bevel angle

oltage

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

able size with extensions . . . . . . . . . . . . . . . . . . . . . .40” x 27”

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0

220V

Left & Right

0

90

to 45

0

Blade size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10”

Maximum cutting depth 90 bevel

Maximum cutting depth 45 bevel

Arbor speed

Arbor diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5/8”

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4500 R.P.M.

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

3-1/2”

2-1/8”

TABLE OF CONTENTS

Warranty ..................................................................................................................................................................................................1

General safety instructions ......................................................................................................................................................................2

Specific safety instructions, Specifications, Table of contents..................................................................................................................3

Assembly ..............................................................................................................................................................................................4-7

Electrical connections ..............................................................................................................................................................................8

Adjustments ..........................................................................................................................................................................................8-9

Operations ........................................................................................................................................................................................10-12

Troubleshooting ......................................................................................................................................................................................13

Parts diagrams ..................................................................................................................................................................................14-16

Parts lists ..........................................................................................................................................................................................16-17

Page 5

ASSEMBLY

TOOLS PROVIDED FOR ASSEMBLY

. Arbor-blade guard bracket wrench.

1

2. 12mm combination wrench.

3. Two allen wrenches.

ADDITIONAL TOOLS REQUIRED

1. Large flat-head screwdriver.

2. Phillips #1 point screwdriver

Note: The use of sockets with a ratchet will lessen the assembly time

required.

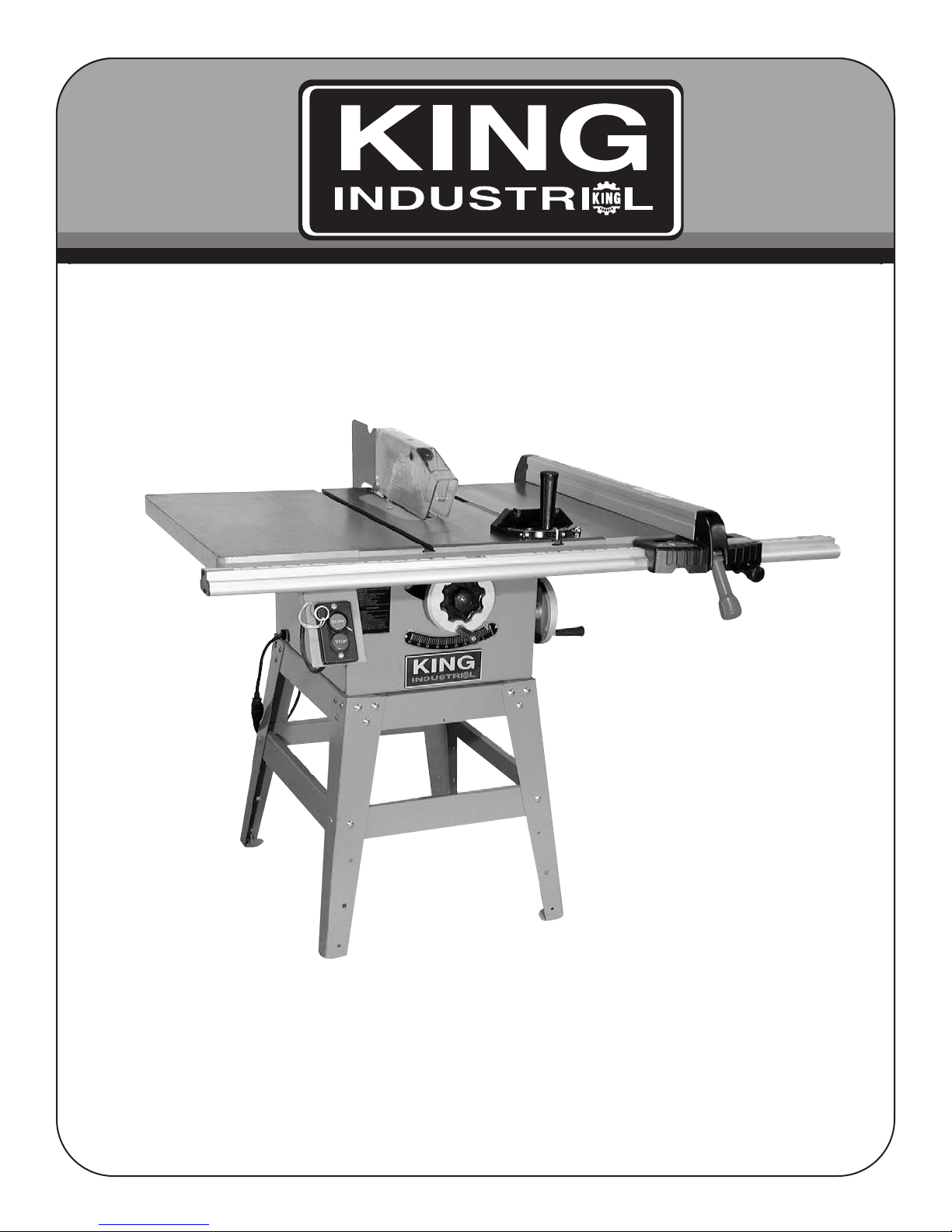

ASSEMBLING STAND

Assemble the top brace (B) and the tie bar (C) to the leg (A) of the stand, as

shown in Fig.1, using the carriage bolts, flat washers, lockwashers and nuts.

Fasten the rest in the same manner.

SUGGESTION: Do not tighten nuts until all hardware is in place. Then place

stand on a flat surface and square up the braces and tie bars, etc. before

final tightening of carriage bolts, washers, lockwashers and nuts.

B

FIGURE 1

A

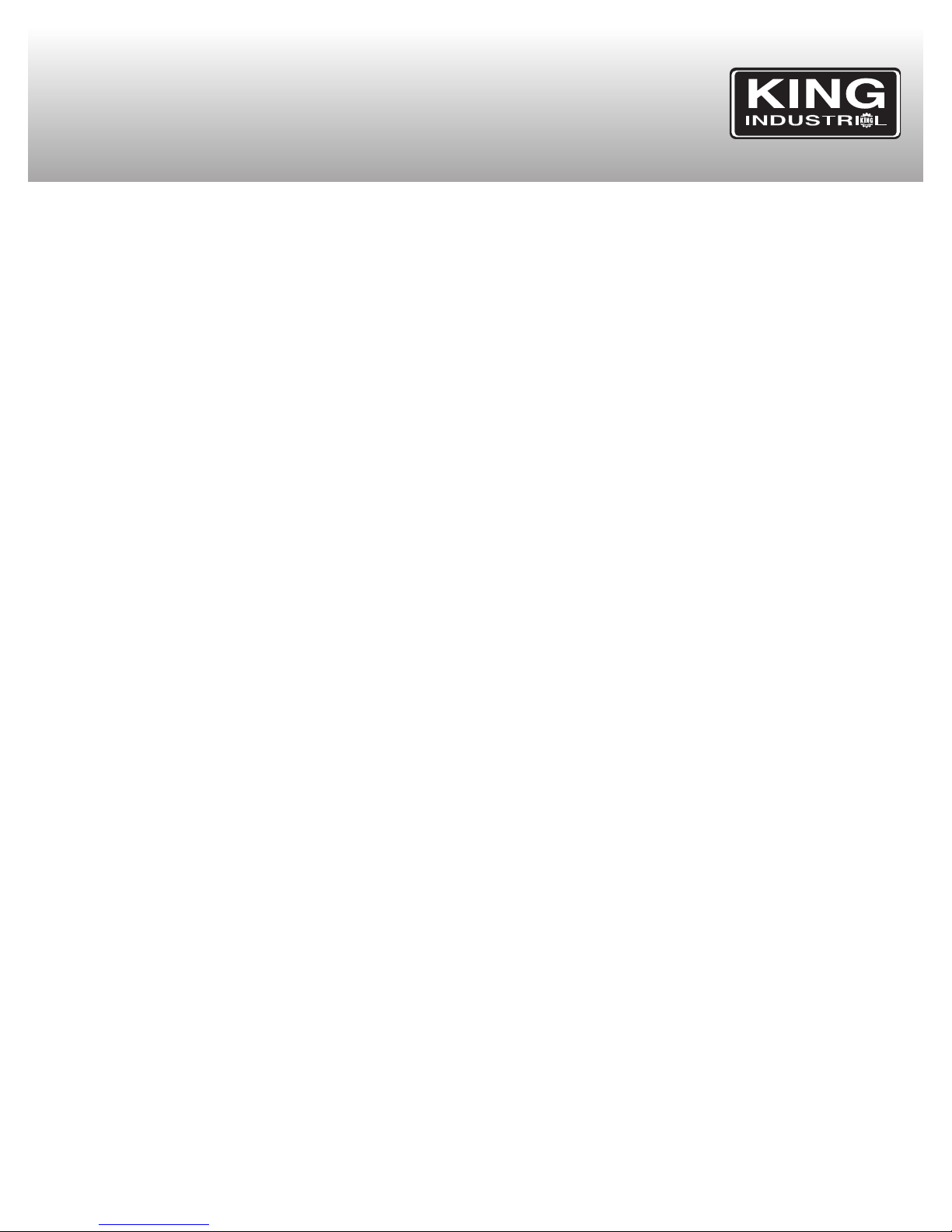

Four rubber feet are supplied with the stand and should be assembled to the

stand. Note: It is necessary to seat the truss head screw in the recess of the

foot. Fig.2 illustrates the stand assembled.

ASSEMBLING SAW TO STAND

Line up the holes in the bottom ledge of the saw cabinet with the four holes

(A) Fig.2, on the top shelf of the stand. The front of the saw should be at the

end of the stand indicated as (B) in Fig.2. Fasten the saw to the stand using

the four hex. bolts, flat washers, lockwashers and nuts supplied with the

stand.

ASTENING SAW TO A WOOD STAND OR BENCH

F

If the saw is to be used without the stand that is supplied with it, we suggest

that the saw always be fastened to a supporting surface using the holes on

the bottom ledge of the saw cabinet. Fig.3 illustrates the size and center to

center distance of the mounting holes in the saw cabinet. CARE MUST

TAKEN THAT A HOLE IS PROVIDED IN THE WOOD STAND OR BENCH

TO FACILITATE THE REMOVAL OF SAW DUST.

FASTENING STAND OR BENCH TO FLOOR

IF DURING OPERATION THERE IS ANY TENDENCY FOR THE TOOL TO

THE STAND

OVER, SLIDE OR W

TIP

OR BENCH MUST

ALK ON SUPPORTING SURF

BE SECURED TO THE FLOOR.

ACE,

BE

FIGURE 2

FIGURE 3

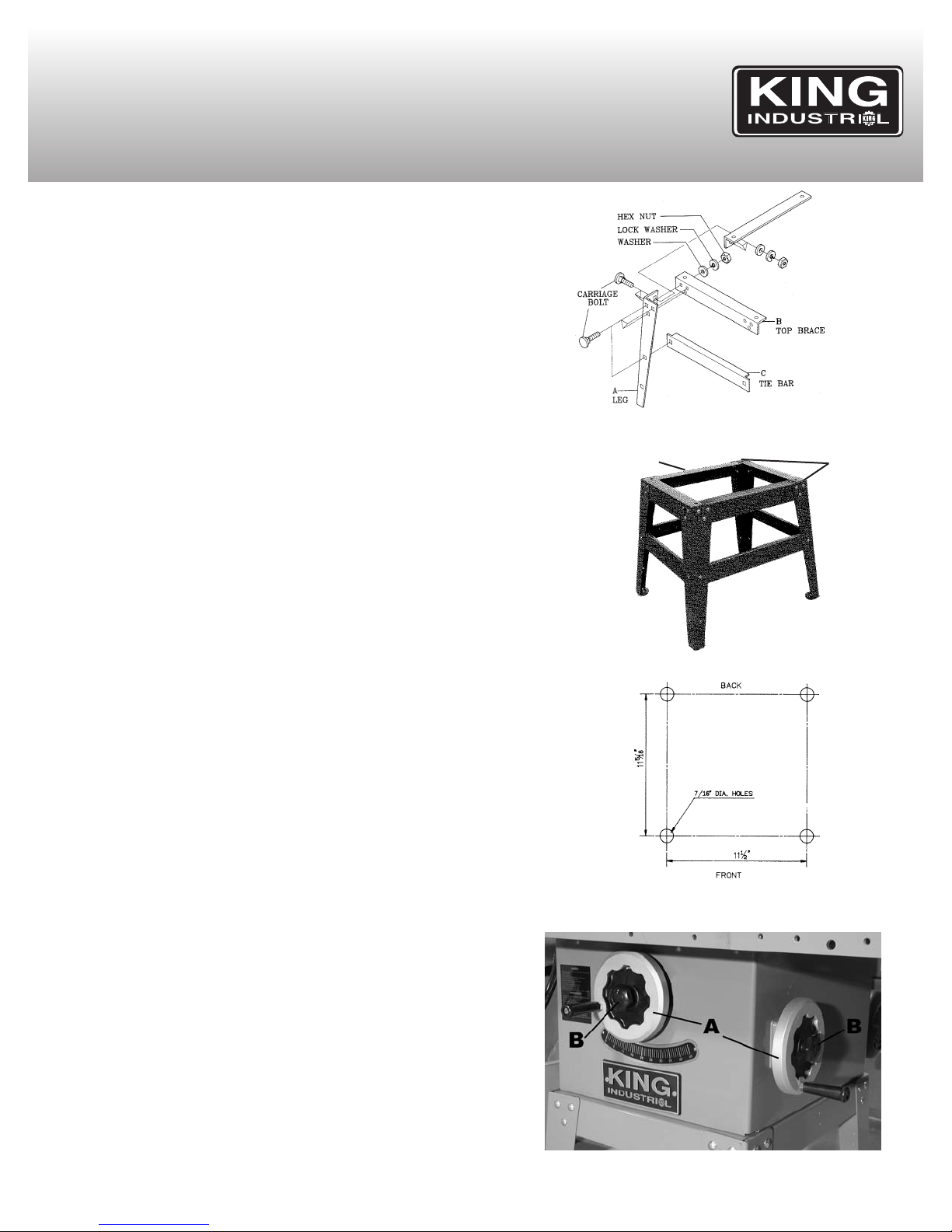

ASSEMBLING RAISING AND TILTING HANDWHEELS AND LOCK KNOBS

Assemble the raising and the tilting handwheels (A) and lock knobs (B) to

the raising and tilting screws, as shown in Fig.4. Make sure the slot in the

handwheels engage with the roll pins in the raising and tilting screws.

FIGURE 4

Page 6

ASSEMBLY

ASSEMBLING EXTENSION WINGS

Assemble the table extension wings to your saw as follows:

asten extension wings to the table using the six hex. bolts (A) Fig.6

F

supplied. Use a straight edge to level the extension wings to the table

surface. Also make sure the extension wings are flush with the front edge of

the table.

NOTE: The saw must be bolted to the supporting surface or a sturdy

outrigger support must be used if a table extension over 24’’ long is attached

to the saw.

ASSEMBLING SAW BLADE

1. Remove the arbor nut by turning clockwise as shown in Fig. 7.

2. Remove the flange and place saw blade on the arbor.

3. Replace arbor flange and nut then tighten the arbor nut using a piece of

wood to block the blade as shown in Fig.8.

FIGURE 6

TABLE INSERT

The table insert (A) is placed in the opening in the saw table, as shown in

Fig.9 and should be level with the surface of the saw table. To adjust the

table insert (A), use a straight edge as shown in Fig.9 and turn the four

adjusting screws in the insert, in or out, until the insert is flush with the table.

FIGURE 7

FIGURE 8

A

FIGURE 9

Page 7

ASSEMBLY

ASSEMBLING MOTOR, MOTOR PLATE AND GUARD BRACKET

Make sure the motor is DISCONNECTED from the power source and

assembled as follows:

1. Assemble the 2-1/2” carriage bolt (A) and washer (C) to the pulley guard

racket using nut (B) as shown in Fig.10.

b

2. Put the motor up-side down on the floor or bench and place the guard

bracket (A) and mounting plate (B) on the motor as shown in Fig.11.

3. Assemble motor plate and guard bracket to the motor frame using the four

hex bolts, eight flat washers, eight shakeproof lockwashers and four nuts

in the same order as shown in Fig.12. The guard bracket should be

positioned where it will not vibrate against the motor housing or rub

against the V-belt or pulley.

4. Fig.12 illustrates the proper relationship of the motor mounting hardware.

FIGURE 10

IMPORTANT: The proper grounding of the motor, to prevent shock hazard,

depends on the use of the shakeproof lockwashers in the manner shown in

Fig.12.

ASSEMBLING MOTOR BRACKET

1. Assemble motor bracket (A) and assemble rod (C) to the bracket as shown

in Fig.13. Make sure the screw that holds the rod (C) in place is tightened

into the V-groove on the rod.

2. Assemble the motor assembly onto the two posts (A) and secure with set

screws (B) as shown in Fig.14.

NOTE: Make sure the two posts are well into the motor bracket and are

evenly spaced.

FIGURE 11

FIGURE 12

FIGURE 13

FIGURE 14

Page 8

ASSEMBLY

ASSEMBLING BELT AND PULLEY COVER

1. Assemble the V-belt to the motor and arbor pulleys. Using a straight

edge, align the two pulleys as shown in Fig.15. If necessary move the

motor and/or motor pulley for proper alignment.

2. Place spacer (A), washer (B) and wing nut (C) on screw as shown in

Fig.16.

3. Assemble the belt cover (A) to the bracket and fasten in place using the

wing nut (B) and washer (C) as shown in Fig.17.

ASSEMBLING BLADE GUARD AND SPLITTER ASSEMBLY

IMPORTANT: Make sure the motor power cord is NOT connected to the

power source when assembling blade guard assembly.

1. Assemble support rod (C) to the hole in the saw trunnion Fig.18.

2. Assemble splitter mounting bracket (B) to the support rod (C) using hex.

bolts (D) and lockwashers as shown in fig.18.

3. Assemble blade guard and splitter assembly (A) to the bracket (B) and

fasten in place with the two hex. bolts (E) as shown in Fig.18. Using a

straight edge, align the splitter (A) to the saw blade. If necessary the

splitter mounting bracket (B) can be moved. It is very important that the

splitter be aligned with the saw blade in order to prevent kickbacks.

3. IMPORTANT: For safety reasons and to prevent binding, when

assembling the blade guard and splitter assembly, make sure the

supporting arm and the two guards are level with the table.

FIGURE 15

FIGURE 16

INSTALLING SWITCH

The switch must be installed to the left table extension wing, Fig. 19. The

switch plate must be placed underneath the table extension.IMPORTANT:

The bolts must be inserted and screwed from the rear, you must install the

switch in this manner to be able to slide a rip fence without interference on

the left side of the blade.

FIGURE 17

FIGURE 18

FIGURE 19

Page 9

ELECTRICAL CONNECTIONS

& ADJUSTMENTS

WARNING!

LL ELECTRICAL CONNECTIONS MUST BE DONE BY A QUALIFIED

A

ELECTRICIAN. FAILURE TO COMPLY MAY RESULT IN SERIOUS INJURY!

ALL ADJUSTMENTS OR REPAIRS MUST BE DONE WITH THE TABLE

SAW DISCONNECTED FROM THE POWER SOURCE. FAILURE TO

OMPLY MAY RESULT IN SERIOUS INJURY!

C

CONNECTING SAW TO POWER SOURCE

A separate electrical circuit should be used for your power tools. This circuit

should be no less than a #12 wire and should be protected by a 20 Amp time

lag fuse. If an extension cord is used, use only 3-wire extensions cords which

have 3-prong grounding type plugs and 3-pole receptacles which accept the

tools plug. For distances up to 100 feet use #12 wire. Before connecting the

motor to the power line, make sure the switch is in the ‘’OFF’’ position and be

sure the electric current is of the same characteristics as stamped on the

motor nameplate. All line connections should make good contact. Running

on low voltage will damage the motor.

PROPERLY GROUNDED OUTLET

CURRENT CARRYING PRONGS

GROUNDING PRONG

FIGURE 20

PROPERLY GROUNDED OUTLET

PLUG & GROUNDING INSTRUCTIONS

This tool must be grounded while in use to protect the operator from electric

shock. The motor recommended for use with your saw is shipped wired for

220 Volt, single phase and is not equipped with a 220V plug, it must be

purchased and installed, Figure 20 illustrates a 220V plug configuration. The

green conductor in the cord is the grounding wire. Never connect the green

wire to a live terminal. For 110V operation, internal motor wires must be

repositioned and a 110V plug must be installed. Figure 21 illustrates a 110V

plug configuration. ALL ELECTRICAL CONNECTIONS MUST BE DONE BY

A QUALIFIED TECHNICIAN OR ELECTRICIAN. FAILURE TO COMPLY

MAY RESULT IN SERIOUS INJURY!

MITER GAUGE OPERATION AND ADJUSTMENTS

The miter gauge supplied with your saw is accurately constructed and

equipped with adjustable index stops at 90

the miter gauge, simply loosen the lock knob (A) Fig.22, pull down stop (B),

rotate the miter gauge to the desired angle and then tighten lock knob (A). To

quick set the miter gauge at 90

so that it engages the screws in the miter gauge body.

To adjust the miter gauge, set it at 900, as shown in Fig.22. Make a cut on a

scrap piece of wood. Then with a square, check to see if the piece of wood

was cut at 90

make adjustment. Tighten screw (C) and make another cut. Continue this

adjustment until you are certain you have a 900cut and set the pointer to the

900mark on the scale.

0

. If an adjustment is necessary, loosen pointer screw (C) and

0

,450, 300right to left, push up on the stop (B)

0

, 450, 300right to left. To operate

CURRENT CARRYING

PRONGS

GROUNDING

PRONG

FIGURE 21

A

C

B

FIGURE 22

Page 10

ADJUSTMENTS

BLADE RAISING AND TILTING MECHANISM

To raise or lower the saw blade, loosen the lock knob (A), Fig.23 and turn

the raising handwheel (B). With the exception of hollow ground blades. The

blade should be raised 1/8’’ to 1/4’’ above the surface of the material being

cut. With hollow ground blades the blade should be raised to the maximum

to provide chip clearance.

To tilt the saw blade, loosen lock knob (C) Fig.23, and turn tilting handwheel

(D). When desired angle is obtained, tighten lock knob (C).

ADJUSTMENT FOR ‘’WEAR’’ IN RAISING MECHANISM

After a long period of time, it is possible that the raising worm and the teeth

on the arbor bracket will wear slightly resulting in play in the raising

mechanism. To compensate for this wear the raising worm and the arbor

bracket can be brought closer together. This can be done as follows:

1. Remove lock knob and raising handwheel but do not remove pointer.

2. Loosen lock nut (A) Fig.24 and using the pointer (B) as a lever turn to the

right or left until all the perceptable play between the worm and arbor

bracket is removed.

3. When this adjustment is completed, reset the pointer to 0

0

and then

tighten lock nut (A).

4. If mechanism is too tight, reverse above procedure.

ADJUSTING 450& 900POSITIVE STOPS

Your saw is equipped with a positive stop at 450and 900. To check and

adjust the positive stops, proceed as follows:

1. Raise the saw blade to its maximum.

2. Set the blade at 90

0

to the table by turning the blade tilting handwheel

clockwise as far as it will go.

3. Place a square on the table as shown in Fig.25 and check to see if the

blade is at a perfect 90

0

angle to the table.

4. If the blade is not at a 900angle to the table, loosen locknut (A) Fig.26

and turn adjusting stop screw (B) in or out. The adjusting stop screw (B)

should stop against the end of the tilting screw (C) when the blade is at

0

to the table. Recheck and adjust further if necessary.

90

5. If the 45

0

positive stop is not set properly, follow the same procedure

using screw (D) and nut (E).

FIGURE 23

FIGURE 24

FIGURE 25

FIGURE 26

Page 11

OPERATIONS

EMOVING SAW BLADE

R

When removing saw blades from the saw, make sure the saw is

disconnected from the power source. Standing in front of the table

saw, remove the table insert, place a block of wood against the front

of the saw blade and using the arbor nut wrench, turn the arbor nut

away from you.

OPERATION

Plain sawing includes ripping and crosscutting, plus a few other

standard operations of a fundamental nature. The following methods

feature safety. As with all power tools there is a certain amount of

hazard involved with the operator and his use of the tool. Using the

tool with the respect and caution demanded as far as safety

precautions are concerned will considerably lessen the possibility of

personal injury. However, if normal safety precautions are overlooked

or completely ignored, person injury to the operator can develop. It is

good practice to make trial cuts using scrap material when setting up

your saw for operation.

CROSSCUTTING

Crosscutting requires the use of the miter gauge to position and guide

the work. Place the work against the miter gauge and advance both

the gauge and the work toward the saw blade, as shown in Fig.27.

The miter gauge may be used in either table slot, however most

operators prefer the left slot for average work. When bevel cutting

(blade tilted), use the table slot that does not cause interference of

your hand or miter gauge with the saw blade guard.

FIGURE 27

Start the cut slowly and hold work firmly against the miter gauge and

the table. One of the rules in running a saw is that you never hang

onto or touch a free piece of work. Hold the supported piece, not the

free piece that is cut off. The feed in cross cutting continues until the

work is cut in two then the miter gauge and work are pulled back to

the starting point. Before pulling the work back it is good practice to

give the work a little sideways shift to move the work slightly away

from the saw blade. Never pick up any short length of free work from

smart operator never touches a

the table while the saw is running.

cut-off piece unless it is at least a foot long. Never use the fence as a

cut-off gauge when cross cutting.

For added safety and convenience the miter gauge can be fitted with

an auxiliary wood-facing that should be at least 1 inch higher than the

maximum depth of cut, and should extend 12 inches or more on either

side of the blade. This auxiliary wood-facing can be fastened to the

front of the miter gage by using two screws through the holes

provided in the miter gauge body and into the wood-facing.

RIPPING

Ripping is making a lengthwise cut with the grain through a board, as

shown in Fig.28, and the rip fence is used to guide the work. One

edge of the work rides against the rip fence while the flat side of the

board rests on the table. Since the work is pushed along the fence, it

must have a straight edge and make solid contact with the table. The

saw guard must be used. The guard has anti-kickback fingers and a

splitter to prevent the saw kerf from closing and binding the blade.

A

FIGURE 28

Start the motor and advance the work holding it down and against

the fence. Never stand in the line of the saw cut when ripping.

Hold the work with both hands and push it along the fence and

into the saw blade, as shown in Fig.28.

through the saw blade with one or two hands. After the work is

beyond the saw blade and anti-kickback fingers the hand is

removed from the work. When this is done the work will either stay

on the table, tilt up slightly and be caught by the rear end of the

guard or slide off the table to the floor

continue to the end of the table, after which the work is lifted and

brought back along the outside edge of the fence. The waste

stock remains on the table and is not touched with the hands until

the saw is stopped unless it is a large piece allowing safe removal.

The work can then be fed

. Alternately, the feed can

Page 12

OPERATIONS

If the ripped work is less than 3 inches wide, a push-stick should be

used to complete the feed, as shown in Fig.29. A typical push-stick is

shown in Fig.30, and can be easily made from scrap material. When

ipping 2 inches or narrower, make an auxiliary guide and fasten it to

r

the rip fence, and use a push-stick. When cutting the material such as

aneling, it is sometimes possible for the material to catch between

p

the bottom of the rip fence and the table surface.

To prevent this from happening, a wood-facing should be attached to

the fence as follows:

1. Cut a piece of wood approximately 3/4’’ thick to the length and

height of the rip fence.

2. Attach wood-facing (A) Fig.31 to the rip fence (B) by drilling four

holes and using four wood screws (C) inserted through the holes

as shown in Fig.31.

3. Care should be taken that the wood-facing fits flush to the table

surface along the edge (D) Fig.31, so that thin work material

cannot slide under.

USING ACCESSORY MOULDING CUTTERHEAD

Moulding is cutting a shape on the edge or face of the work. Cutting

mouldings with a moulding cutterhead in the table saw is a fast, safe

and clean operation. The many different knife shapes available make

it possible for the operator to produce almost any kind of moulding,

such as various styles of corner moulds, picture frames, table edges,

etc.

The moulding head consists of a cutterhead in which can be

mounted various shapes of steel knives, as shown in Fig.32. Each of

the knives in a set is fitted into a groove in the cutterhead and

securely clamped with a screw. The knife grooves should be kept free

of sawdust which would prevent the cutter from seating properly.

FIGURE 29

FIGURE 30

The moulding cutterhead (A) Fig.33, is assembled the saw arbor in

the same manner as the saw blade. The guard, splitter and anti-kickback finger assembly can not be used when moulding and must be

removed from the saw as shown. Also, the accessory moulding

cutterhead dado table insert (B) Fig.33, must be used in place of the

standard table insert.

FIGURE 32

FIGURE 31

FIGURE 33

Page 13

OPERATIONS

It is necessary when using the moulding cutterhead to add woodfacing to one or both sides of the rip fence. The wood-facing is

attached to the fence with wood screws. 3/4’’ stock is suitable for

most work.

Position the wood-facing over the cutterhead with the cutterhead

elow the surface of the table. Turn the saw on and raise the

b

cutterhead. The cutterhead will cut its own groove in the wood-facing.

Make sure not to cut into the rip fence. Fig.34 shows a typical

moulding operation. NEVER USE THE MOULDING CUTTERHEAD

IN A BEVEL POSITION.

IMPORTANT: NEVER RUN THE STOCK BETWEEN THE FENCE

AND THE MOULDING CUTTERHEAD AS IRREGULAR SHAPED

WOOD WILL CAUSE KICKBACK.

When moulding end grain, the miter gauge is used. The feed should

be slowed up at the end of the cut to prevent splintering. In all cuts,

attention should be given to the grain, making the cut in the same

direction as the grain whenever possible.

ALWAYS INSTALL BLADE GUARD AFTER OPERATION IS

COMPLETE.

FIGURE 34

USING ACCESSORY DADO HEAD

Dadoing is cutting a rabbet or a wide groove into the work. Dado

head sets (optional acc# KSC-8000) are made up of two outside

saws and four or five inside cutters, as shown in Fig.35. Various

combinations of saws and cutters are used to cut grooves from 1/8’’

to 13/16’’ for use in shelving, making joints, tenoning, grooving ,etc.

The cutters are heavily swaged and must be arranged so that this

heavy portion falls in the gullets of the outside saws as shown in

Fig.36. The saw and cutter overlap is shown in Fig.37, (A) being the

outside saw, (B) being the inside cutter, and (C) a paper washer or

washers which can be used as needed to control the exact width of

the groove. A 1/4’’ groove is cut by using the two outside saws. The

teeth of the saws should be positioned so that the raker on one saw

is beside the cutting teeth on the other saw.

The dado head set (A) Fig.38, is assembled to the saw arbor in the

same manner as the saw blade. The guard, splitter and anti-kickback

finger assembly cannot be used when dadoing and must be

removed from the saw, as shown. Also the accessory dado head

table insert (B-Acc# KW-065) Fig.38, must be used instead of the

standard table insert (Acc# KW-064).

NEVER USE THE DADO HEAD IN A

ALWAYS INSTALL BLADE GUARD AFTER OPERATION IS

COMPLETE.

BEVEL

POSITION.

FIGURE 35

FIGURE 37

FIGURE 36

* Moulding cutterhead accessory not available from King Canada, please contact

your local dealer for information on acquiring this accessory.

FIGURE 38

Page 14

TROUBLESHOOTING

PROBLEM

SAW WILL NOT START

1. Saw not plugged in.

. Fuse blown or circuit breaker tripped.

2

3. Cord damaged.

4. Overload relay not set.

OVERLOAD KICKS OUT FREQUENTLY

1. Extension cord too light or too long.

2. Feeding stock too fast.

3. Blade in poor condition (dull, warped,

gummed).

4. Blade binding due to misaligned rip fence.

5. Blade binding due to warped wood.

6. Low house current.

DOES NOT MAKE ACCURATE 450AND 90

RIP CUTS

1. Positive stop not adjusted properly.

2. Tilt angle pointer not set properly.

MATERIAL PINCHES BLADE WHEN RIPPING

1. Rip fence not aligned with blade.

2. Warped wood.

SOLUTION

1. Plug in saw.

. Replace fuse or reset circuit breaker.

2

3. Have cord replaced by a certified electrician.

4. Push overload resset button.

1. Replace with adequate size cord.

2. Feed stock more slowly.

3. Clean or replace blade.

4. Check and adjust the rip fence.

5. Select another piece of wood.

6. Contact your electrical company.

0

1. Check blade with square and adjust positive stop.

2. Check blade with square and adjust pointer to zero.

1. Check and adjust rip fence.

2. Select another piece of wood.

MATERIAL BINDS ON SPLITTER

1. Splitter not aligned correctly with blade.

SAW MAKES UNSATISFACTORY CUTS

1. Dull blade.

2. Blade mounted backwards.

3. Gum or pitch on blade.

4. Incorrect blade for work being done.

5. Gum or pitch on table causing erratic feed.

BLADE DOES NOT COME UP TO SPEED

1. Extension cord too light or too long.

2. Low house current.

3. Motor not wired for correct voltage.

MACHINE VIBRA

1. Saw not mounted securely to stand.

2. Stand is on uneven floor

3. Damaged saw blade

4. Bad V-belt.

-belt not tensioned properly

5. V

6. Bent pulley

7. Improper motor mounting.

8. Excessive play in raising mechanism.

9. Loose hardware.

TES EXCESSIVEL

.

Y

.

.

1. Check and align splitter with blade.

1. Replace blade.

2.Turn blade around.

3. Remove blade and clean with turpentine and steel wool.

4. Change the blade.

5. Clean the table with turpentine and steel wool.

1. Replace with adequate size cord.

2. Contact your electric company.

3. Refer to motor nameplate for correct wiring.

ighten all mounting hardware.

T

1.

2. Reposition on flat level surface. Fasten to floor if necessary

3. Replace blade.

4. Replace belt.

Adjust belt tension by moving motor and/or motor bracket.

5.

6. Replace pulley

7. Check and adjust motor mounting.

8. Adjust worm and arbor bracket.

9. Tighten all nuts, bolts and set screws.

.

.

BLADE DOES NOT RAISE OR TIL

1. Too much tension in the raising mechanism.

2. Sawdust or dirt in raising or tilting

mechanisms.

T FREEL

Y

1. Adjust raising worm and arbor bracket.

2. Brush or blow out loose dust or dirt.

Loading...

Loading...