Page 1

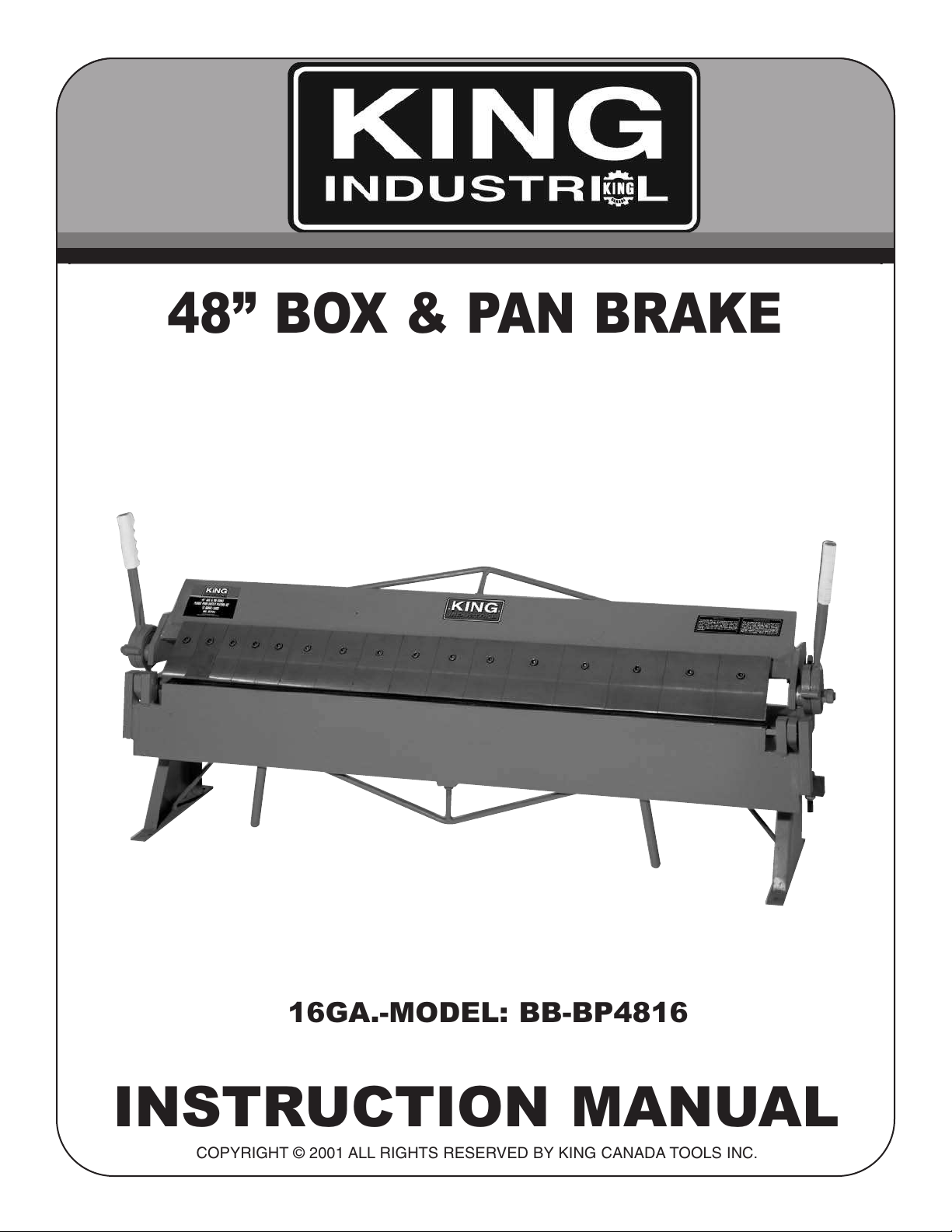

48” BOX & PAN BRAKE

16GA.-MODEL: BB-BP4816

22GA.-MODEL: BB-BP4822

INSTRUCTION MANUAL

COPYRIGHT © 2001 ALL RIGHTS RESERVED BY KING CANADA TOOLS INC.

Page 2

IMPORTANT INFORMATION

WARRANTY INFORMATION

2-YEAR

LIMITED WARRANTY

FOR THIS 48” BOX & PAN BRAKE

PR

OOF OF PURCHASE

Please keep your dated proof of purchase for warranty and servicing purposes.

REPLA

Replacement parts for this tool are available at our authorized service centers across Canada. For servicing, contact or return to the retailer where

you purchased your product along with your proof of purchase.

LIMITED

KING CANADA makes every effort to is made to ensure that this product meets high quality and durability standards. KING CANADA warrants

to the original retail consumer a 2-year limited warranty as of the date the product was purchased at retail and that each product is free from

defects in materials. Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents, repairs or

alterations and lack of maintenance. KING CANADA shall in no event be liable for death, injuries to persons or property or for incidental,

special or consequential damages arising from the use of our products. To take advantage of this warranty, the product or part must be returned

for examination by the retailer. Shipping and handling charges may apply. If a defect is found, KING CANADA will either repair or replace the

product.

IMPORTANT: IF THIS MACHINE IS DAMAGED DUE TO FEEDING MATERIALS THAT ARE A THICKER GAUGE STEEL

THAN (16GA.-BB-BP4816, 22GA.-BB-BP4822), THE WARRANTY WILL BE NUL AND VOID.

CEMENT PARTS

TOOL WARRANTY

THE WARRANTY WILL BE NULL AND VOID

.

Page 3

OPERATION

INTRODUCTION

The box and pan brake is the culmination of many year’s experience in

the development, manufacture and application of hand bending brakes.

This style of brake incorporates all the outstanding features of a

standard hand brake. In addition, it has removable, sectioned fingers,

offers added depth and increased clearances, providing greater

versatility and range of uses in the sheetmetal shop.

ADVANTAGES OF OPERATION

We offer this machine with a great deal of pride, because of its wide

range of applications and its many advantages. Some of the primary

benefits: the machine can be used to form a box or pan having four

sides and a bottom from one sheet of metal. In addition, a narrow return

flange on the top of a box can be made, as in the manufacture of

electric switchboxes.

APPLICATIONS AND USES

The box and pan brakes are used by manufacturers for forming

electrical and electronic switch boxes, cutout boxes and panel board

cabinets. They are also used extensively in the manufacture of

conveyor baskets, tote boxes and all classes of box and pan work, as

well as a wide variety of other work. The predominant application for

these machines today is in the forming of radio, TV and other

electronic chassis. The labor-saving features of the box and pan brakes

are obvious. They are in great demand due to their efficiency in

quantity production and in a variety of job work applications.

the rein-foreign angle bar must be in the normal or top position. When

the angle bar is removed, the capacity of the brake is reduced four

gauges.

FIG.A - Operator makes final bend in typical pan forming

operation.

NOSE BARS

Nose bars are quickly interchangeable so that special bars such as

radius types can be used. Radius bends such as those in modern metal

furniture and cabinets can be made with these round nose bars.

A full length nose bar can be used instead of the individual nose bars

for each size finger. With the full length nose bar in place, the machine

becomes a straight bending brake.

Tubular shapes can be formed by extending nose bars between

fingers. With the fingers set in the regular position, large tubular shapes

can be formed by allowing the metal to spring out of shape against the

top side of the fingers. In most metals the shape is distorted only while

it is being finished up. As soon as the tube is removed from the brake,

the metal springs back to the correct shape. Deep channels can be

formed with the help of the finger extension.

CAPACITY

Capacity of box and pan brakes is the same as that of standard hand

brakes. It is rated at 1” flange or weir on mild steel. Narrower flanges

can be bent on lighter metal. When the brake is used for capacity work,

FIG.B - The box and pan brake with typical completed box

shape.

Page 4

OPERATION & MAINTENANCE

BENDING EDGE ALIGNMENT

When bending leaf is in down position, edge of leaf should be flush with

edge of bottom bar. To maintain this alignment, ensure brake sets level

on floor:

1. Adjust bending leaf center with fruss nut.

2. Adjust bottom center with Truss nut.

3. Adjust bending leaf ends with hinge adjustment screws. Loosen

hinge bolts before and tighten again after adjustment.

BOWED BENDING LEAF ADJUSTMENT

If bending leaf becomes bowed in center after use, tighten both tension

bolts until center is brought into a straight line.

CAPACITY

The bending capacity of the brake is determined by the bending edge

thickness provided by the bending leaf bars when mounted on leaf.

1. Insert bar with angle bar and allow the full rated 1” minimum flange

on capacity material.

2. Inserting the bar alone without angle bar reduces capacity of the

brake four gauges.

3. Removing both insert bar and angle bar reduces capacity of brake

seven gauges. These bars are removed only to make narrow offset

bends.

RADIUS BENDS

Both the angle bar and insert bar must be mounted to leaf to wipe

material around radius nose bar.

OVERBENDING ADJUSTMENT

If sheet bends over further on one side than on the other, set the top

leaf back on the end where sheet is overbending.

1. Unclamp handles slightly on the side that is overbending.

2. Adjust top leaf with top adjustment handle.

3. Reclamp handle.

DUPLICATE BENDS

Adjustable stop gauge may be positioned at any point on rod by means

of lock bolt, to limit the degree of bend.

COUNTERBALANCE

Counterweight can be raised or lowered on rod to properly

counterbalance the bending leaf.

LUBRICATION

Lubricate occasionally with SAE-30 oil.

CAUTIONS

Never bend heavier material than rated capacity, even in shorter

lengths.

Never bend against seams unless links are adjusted to clamp the full

multiple thickness of seam and, top leaf is set back for clearance of the

same full multiple thickness.

Always use material with square-sheared edges. Rolled edges will

cause material to bow.

Always have both angle bar and insert bar mounted to leaf when

making capacity bends.

Never use brake to bend rods. These will nick the nose bar.

Always adjust for differences in gauges. Especially never force-clamp

the top on material heavier than that for which the links and top are set

by using pipe extensions on clamp handles for leverage.

NARROW OFFSET BENDS

Remove angle bar and insert bar, - use bending leaf only.

PARTS DIAGRAM & PARTS LISTS

Refer to the Parts section of the King Canada web site for the most updated parts diagram and parts list. (BB-BP 4822 only)

Powered by TCPDF (www.tcpdf.org)Powered by TCPDF (www.tcpdf.org)Powered by TCPDF (www.tcpdf.org)

Loading...

Loading...