Page 1

KING CANADA

16 SPEED DRILL PRESS

BENCH OR FLOOR MODEL

MODELS:

16C

KC-1

KC-1

(BENCH MODEL)

16FC

(FLOOR MODEL)

INSTRUCTION MANUAL

COPYRIGHT © 2000 ALL RIGHTS RESERVED BY KING CANADA TOOLS INC.

Page 2

IMPORTANT INFORMATION

2-YEAR

LIMITED WARRANTY

FOR THIS DRILL PRESS

PROOF OF PURCHASE

Please keep your dated proof of purchase for warranty and servicing purposes.

REPLACEMENT PARTS

Replacement parts for this tool are available at our authorized KING CANADA service centers across Canada. For servicing, contact or

return to the retailer where you purchased your product along with your proof of purchase.

LIMITED TOOL WARRANTY

KING CANADA makes every effort to ensure that this product meets high quality and durability standards. KING CANADA warrants

to the original retail consumer a 2-year limited warranty as of the date the product was purchased at retail and that each product is free

from defects in materials. Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence or accidents, repairs

or alterations and lack of maintenance. KING CANADA shall in no event be liable for death, injuries to persons or property or for

incidental, special or consequential damages arising from the use of our products. To take advantage of this warranty, the product or

part must be returned for examination by the retailer. Shipping and handling charges may apply. If a defect is found, KING CANADA

will either repair or replace the product.

OFFERS A 2-YEAR LIMITED WARRANTY

KING CANADA TOOLS

FOR NON-COMMERCIAL USE.

KING CANADA TOOLS INC.

DORVAL (MONTREAL), QUÉBEC, CANADA H9P 2Y4

Page 3

GENERAL SAFETY RULES

FOR POWER TOOLS

1. KNOW YOUR TOOL

ead and understand the owners manual and labels affixed to

R

the tool. Learn its application and limitations as well as its

pecific potential hazards.

s

2. GROUND THE TOOL.

his tool is equipped with an approved 3-conductor cord and

T

a 3-prong grounding type plug to fit the proper grounding

type receptacle. The green conductor in the cord is the

grounding wire.

terminal.

NEVER connect the green wire to a live

3. KEEP GUARDS IN PLACE.

Keep in good working order, properly adjusted and aligned.

4. REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

5. KEEP WORK AREA CLEAN.

Cluttered areas and benches invite accidents. Make sure the

floor is clean and not slippery due to wax and sawdust

build-up.

6. AVOID DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations or expose

them to rain. Keep work area well lit and provide adequate

surrounding work space.

7. KEEP CHILDREN AWAY.

All visitors should be kept a safe distance from work area.

8. MAKE WORKSHOP CHILD-PROOF.

-with padlocks, master switches or by removing starter keys.

9. USE PROPER SPEED.

A tool will do a better and safer job when operated at the

proper speed.

10. USE RIGHT TOOL.

Don’t force the tool or the attachment to do a job for which it

was not designed.

1. WEAR PROPER APPAREL.

1

Do not wear loose clothing, gloves, neckties or jewelry (rings,

watch) because they could get caught in moving parts. Nonslip footwear is r

to contain long hair. Roll up long sleeves above the elbows.

ecommended. Wear pr

otective hair covering

12. ALWAYS WEAR SAFETY GLASSES.

lways wear safety glasses (ANSI Z87.1). Everyday

A

eyeglasses only have impact resistant lenses, they are

afety glasses. Also use a face or dust mask if cutting operation

s

s dusty.

i

13. DON’T OVERREACH.

Keep proper footing and balance at all times.

14. MAINTAIN TOOL WITH CARE.

Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS.

Before servicing, when changing accessories or attachments.

16. AVOID ACCIDENTAL STARTING.

Make sure the switch is in the ‘’OFF’’ position before plugging

in.

17. USE RECOMMENDED ACCESSORIES.

Consult the manual for recommended accessories. Follow the

instructions that accompany the accessories. The use of

improper accessories may cause hazards.

18. NEVER STAND ON TOOL.

Serious injury could occur if the tool tips over. Do not store

materials such that it is necessary to stand on the tool to reach

them.

19. CHECK DAMAGED PARTS.

Before further use of the tool, a guard or other parts that are

damaged should be carefully checked to ensure that they will

operate properly and perform their intended function. Check

for alignment of moving parts, breakage of parts, mounting,

and any other conditions that may affect its operation. Aguard

or other parts that are damaged should be properly repaired or

eplaced.

r

20. NEVER LEAVE MACHINE RUNNING

UNATTENDED.

Turn power ‘’OFF’’. Don’t leave any tool running until it comes

to a complete stop.

NOT

SPECIFIC SAFETY RULES

FOR DRILL PRESS

TS BEING THROWN

1. TO AVOID INJURY FROM P

BY THE SPRING

Follow the instructions exactly as given and shown in

“Adjusting the quill return spring”.

2. USING A DRILL

When using a drill press vise, always fasten it to the table.

PRESS VISE

3. NEVER DO “FREEHAND WORK”

Never do any work “Freehand” (Hand holding the workpiece

rather than supporting it on the table) except when you have

polishing to do.

AR

4. SECURE the lock head to the column, table support to

column and table to table support before operating the drill

press.

5. NEVER move the head or table while the drill press is

unning.

r

6. USE THE RECOMMENDED SPINDLE SPEED for the

specific operation and workpiece material. Check the panel

inside the guard cover for drill information. For accessories,

use the instructions provided with the accessories.

7. NEVER climb on the drill press table, you could break or pull

the entire drill press down on you.

Page 4

SPECIFICATIONS

SPECIFICATIONS FOR 13” MODELS (KC-116C, KC-116FC)

VOLTAGE ........................................................................................................................................................................................................................110V

AMPS ................................................................................................................................................................................................................................7.5A

MOTOR R.P.M. ................................................................................................................................................................................................................1700

Hz ..........................................................................................................................................................................................................................................60

PHASE ....................................................................................................................................................................................................................................1

CHUCK CAPACITY ......................................................................................................................................................................................................5/8”

SPINDLE TAPER ..........................................................................................................................................................................................................MT#2

NUMBER OF SPEEDS ........................................................................................................................................................................................................16

Page 5

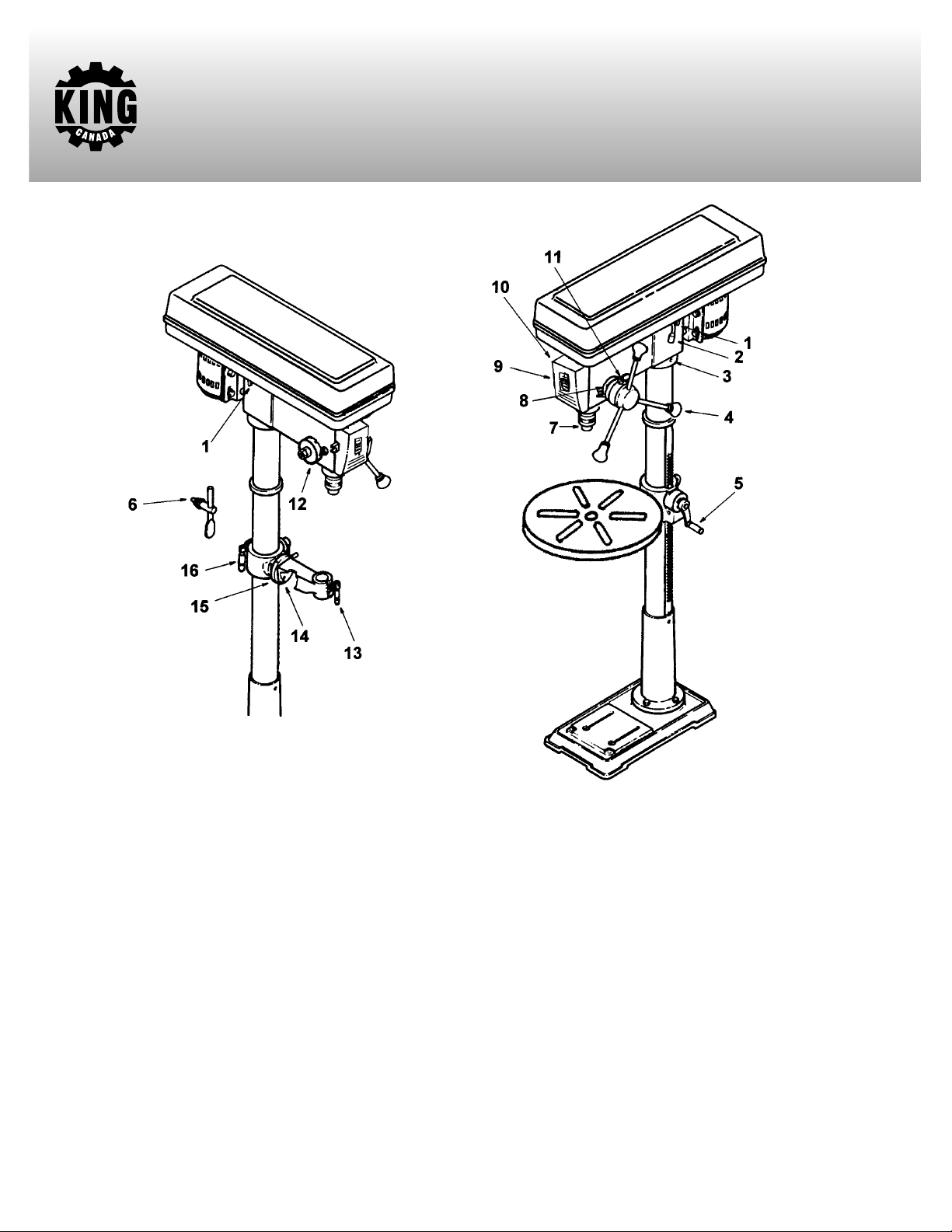

GETTING TO KNOW YOUR DRILL PRESS

FIGURE 1

LOCATION AND FUNCTION OF CONTROLS

1. Belt tension lock handles...Tightening handles locks motor

bracket support to maintain correct belt distance and tension.

2. Belt tension handle...Turn handle counterclockwise to apply

tension to the belt, turn clockwise to release belt tension.

3. Head locking set screws...Locks the head to the column. Always

have them locked in place while operating the drill press.

4. Feed handle...For moving the chuck up or down. One or two of

the handles may be r

workpiece is of such unusual shape that it interferes with the

handles.

5. Table crank...Turn clockwise to elevate the table. Support lock

must be released before operating crank.

6. Chuck key...Used to tighten a drill into the chuck and also to

loosen the chuck for drill r

7. Chuck...Holds the drill bit or other r

perform desired operations.

8. Depth scale...Allows the operator to adjust the drill press to drill

to a desired depth.

9. Drill “ON-OFF” Switch...Has a locking feature to prevent

unauthorized and possible hazardous use by children and

others.

emoved if necessary whenever the

emoval.

ecommended acessory to

10. Light “ON-OFF” Switch...Turns the light on and off.

11. Depth scale lock...Locks the depth scale at the selected depth.

12. Spring cap...Provides means to adjust the quill spring tension.

13. Table lock...Allows the table to be rotated in various positions

and locked.

14. Table bevel lock...Locks the table in any position from 00to 450.

15. Bevel scale...Shows the degr

bevel operations. The scale is mounted on the side of the arm.

16. Support lock handle...Tightening locks the table support to the

column.

press.

Note and follow the safety warnings and instructions that appear

on the panel on the right side of the head.

Always have it locked in place while operating the drill

ee in which the table is tilted for

Page 6

UNPACKING/TOOLS NEEDED

TABLE OF BOX CONTENTS

Head assembly ..............................................................................1

A-

B- Table ................................................................................................1

C- Column and table support ..........................................................1

D- Base..................................................................................................1

E- Box of loose parts ..........................................................................1

F- Bag of loose parts ..........................................................................1

G- Instruction manual........................................................................1

TABLE OF LOOSE PARTS

- Hex. hd. bolts ..................................................................................4

1

2- Set screws ........................................................................................2

3- M3 hex. key......................................................................................1

4- M5 hex. key......................................................................................1

6- Key drift............................................................................................1

7- Support lock handle ......................................................................1

8- Crank ................................................................................................1

9- Feed handles ....................................................................................3

10- Chuck key ......................................................................................1

11- Chuck ..............................................................................................1

12- Safety key ......................................................................................1

TOOLS NEEDED

- Combination square

1

1- 8” Ajustable wrench

1- Medium Phillips screwdriver

WARNING! To avoid injury from unexpected starting or

electrical shock, never connect the plug to an outlet until all the

assembly instructions are completed.

TOOLS NEEDED

FIGURE 2

Page 7

ELECTRICAL CONNECTIONS

!

!

!

!

!

ARNING

W

ALL ELECTRICAL CONNECTIONS MUST BE DONE BY A QUALIFIED ELECTRICIAN. FAILURE TO COMPLY MAY RESULT IN

SERIOUS INJURY!ALL ADJUSTMENTS OR REPAIRS MUST BE DONE WITH THE DRILL PRESS DISCONNECTED FROM THE POWER

SOURCE. FAILURE TO COMPLY MAY RESULT IN SERIOUS INJURY!

ROPERLY GROUNDED OUTLET

POWER SUPPLY

P

WARNING:

YOUR DRILL PRESS MUST BE CONNECTED TO

A 110V, 15-AMP, BRANCH CIRCUIT AND USE A 15-AMP TIME

DELAY FUSE OR CIRCUIT BREAKER. FAILURE TO CONNECT IN

THIS WAY CAN RESULT IN INJURY FROM SHOCK OR FIRE.

Your drill press must be properly grounded. Not all outlets are

properly grounded. If you are not sure if your outlet is properly

grounded, have it checked by a qualified electrician.

WARNING: IF NOT PROPERLY GROUNDED, THIS DRILL

PRESS CAN CAUSE ELECTRICAL SHOCK, PARTICULARLY

WHEN USED IN DAMP LOCATIONS. TO AVOID SHOCK OR FIRE,

IF THE POWER CORD IS WORN OR DAMAGED IN ANY WAY,

HAVE IT REPLACED IMMEDIATELY.

GROUNDING

This drill press must be grounded. If it should malfunction or

breakdown, grounding provides a path of least resistance for electric

current, to reduce the risk of electric shock. This drill press is

equipped with a cord having an equipment-grounding conductor

and grounding plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in accordance with all

local codes and ordinances.

WARNING: TO MAINTAIN PROPER GROUNDING OF YOUR

DRILL PRESS, DO NOT REMOVE OR ALTER THE GROUNDING

PRONG IN ANY MANNER.

110V OPERATION

As received from the factory, your drill press is ready to run for 110V

operation. This drill press is intended for use on a circuit that has an

outlet and a plug which looks like the one illustrated in Fig.3.

ARNING:

W

DO NOT USE A TWO-PRONG ADAPTOR FOR

THEY ARE NOT IN ACCORDANCE WITH LOCAL CODES AND

ORDINANCES. NEVER USE IN CANADA.

EXTENSION CORDS

MOTOR

CURRENT CARRYING

PRONGS

GROUNDING

PRONG

LENGTH OF

CONDUCTOR

0-25 FEET

26-50 FEET

51-100 FEET

110V WIRING DIAGRAM

BLACK

MOTOR CORD

GREEN

WHITE

LIGHT

POWER CORD

FIGURE 3

WIRE SIZES REQUIRED

(AMERICAN WIRE GAUGE)

FIGURE 4

GREEN

WHITE

WHITE

WHITE

WIRE

CONNECT

BLACK

BLACK

GREEN

110V LINES

NO.16

NO.14

NO.12

BLACK

POWER

SWITCH

BLACK JUMPER

LIGHT

SWITCH

The use of any extension cord will cause some loss of power. Use the

following table to determine the minimum wire size (A.W.G.-American

Wire Gauge) extension cord. Use only 3-wire extension cords which

have 3-prong grounding type plugs and 3-hole receptacles which

accept the tool’s plug.

For circuits that are further away from the electrical circuit box, the wire

size must be increased pr

oportionately in or

der to deliver ample

voltage to the motor. Refer to Fig. 4 for wire length and size.

FIGURE 5

Page 8

ASSEMBLY INSTRUCTIONS

BASE AND COLUMN ASSEMBLY (FIG.6)

1. Position the base on the floor. Remove the protective covering and

discard.

2. Remove protective sleeve from the column and discard. Place the

column assembly on the base, align the holes in the column support

with the holes in the base.

. Locate four long bolts from the parts bag.

3

4. Install a bolt in each hole through the column support and the base

and tighten with the adjustable wrench.

5. Locate table crank and support lock in loose parts box.

6. Install support lock from left side into the table support and

tighten by hand. (Fig.7).

7. Install table crank assembly and tighten set screw with M3 hex. key.

Do not overtighten. The set screw should be tightened against the

flat section of the shaft. NOTE: To minimize crank backlash,

tighten support lock, rotate elevation worm shaft clockwise, then

assemble crank tight against the table support and tighten set

screw.

8. Check column collar for proper adjustment. The collar should not

be angled on the column and it should be positioned so the rack

will slide freely in the collar when the table is rotated 360

the column table. If re-adjusted, only tighten set screw enough to

keep the collar in place. NOTE: To avoid column or collar damage,

do not overtighten set screw. (Fig.8).

0

around

Column

Support lock

Table support

Column collar

Column

Rack

Column

Base

FIGURE 6

Table support

Elevation worn shaft

Handle

Table crank

FIGURE 7

Do not

overtighten

set screw

INSTALLING THE TABLE (Fig.9,10)

1. Loosen support lock and raise table support by turning the crank

clockwise until the support is at a working height level. T

support lock.

2. Remove protective covering from the table and discard. Place table

in table support and tighten table lock knob located under the table

by hand. NOTE:

open the table support with a flat head screwdriver.

If the table won’t fit in the table support easily, pry

ighten

Support lock

able support

T

Column

Table lock

FIGURE 8

Table crank

Rack

FIGURE 9

Table support

Table

FIGURE 10

Page 9

INSTALLING THE HEAD (FIG.11)

ASSEMBLY INSTRUCTIONS

1. Remove the protective covering from the head assembly.

2. Carefully lift the head above the column and slide it down on the

column as far as it will go. Align the head with the table and the

base.

3. Using a hex. wrench, tighten the head set screws on the right side

of the head.

PULLEY ALIGNMENT AND SPEED ADJUSTMENT

Checking pulley alignment

Warning:

always turn drill press off and remove safety key before making belt

adjustments.

The pulleys and motor are assembled at the factory and should

require no further adjustment. If the pulleys or motor are removed for

service, follow the pulley alignment instructions below.

1. Place a straightedge such as a piece of wood, metal, or framing

square across the top of the pulleys.

2. The top of all three pulleys should touch the straightedge.

3. If not, a) Loosen motor mount nuts. b)Move motor until the pulleys

are in line. c) Retighten the motor mount nuts.

NOTE: To avoid rattles or other noises, motor frame must not touch

lower belt guard.

Speed adjustment

To reduce the risk of injury due to accidental starting

Lower belt

guard

FIGURE 11

Belt tension

lock handle

FIGURE 12

Head

Head

Motor mount

nuts

Head locking

et screws

s

Motor

1. Release belt tension lock handles located on each side of the drill

press by turning them counterclockwise.

2. Loosen belt tension by turning the belt tension handle clockwise.

3. Use the speed chart inside the belt guard to choose the speed for the

drilling operation. Install belts in the correct position for the

desired speed. The longer of the two belts is always positioned

between the spindle pulley and the idler pulley.

NOTE: Refer to inside belt guard for r

TENSIONING BEL

1. Apply tension to the belt by turning belt tension handle counterclockwise until belt deflects appr

pressure at its center.

2. Tighten belt tension lock handles.

cause the motor not to start or damage bearings.

3. If belt slips while drilling, r

T

eajust belt tension.

ecommended drilling speeds.

oximately 1/2” by thumb

NOTE: Over tensioning belt may

Belt tension

handle

Spindle pulley

Idler pulley

FIGURE 13

Belt tension

lock handle

Belt tension handle

FIGURE 14

Page 10

ASSEMBLY INSTRUCTIONS

INSTALLING THE CHUCK

. Clean out the tapered hole in the chuck, clean the spindle nose with

1

a clean cloth. Make sure there are no foreign particles sticking to the

urfaces. The slightest piece of dirt on the spindle nose or on the

s

chuck will prevent the chuck from seating properly. This will cause

the drill to “wobble”.

2. Slide the chuck up over the arbor as illustrated in Fig.15.

3. Unlock the table support lock and raise the table so that it is two

inches below the tip of the chuck.

4. Turn the chuck sleeve clockwise and open jaws in chuck completely.

5. Turn the feed handles counterclockwise and force the chuck against

the table until the chuck is secure.(Fig.16).

Quill

Arbor

huck

C

FIGURE 15

Feed

handle

REMOVING CHUCK AND ARBOR

1. With the switch off, adjust the depth scale to hold the drill at a depth

of 3” (see instructions for “Locking chuck at desired height”).

2. Align key holes in spindle and quill by rotating the chuck by hand.

3. Insert key drift into key holes.

4. Tap key drift lightly until the chuck and arbor fall out of the spindle.

NOTE: Place one hand below the chuck to catch it when it falls out.

(Fig.17).

INSTALLING LIGHT BULB

1. Install a light bulb (no larger that 60Watts) into the socket inside the

head. (Fig.18).

FIGURE 16

Key

drift

Chuck

sleeve

Chuck

body

FIGURE 17

FIGURE 18

Page 11

ADJUSTMENTS

ADJUSTING THE TABLE SQUARE TO THE HEAD

: The combination square must be “true”.

NOTE

1. Insert precision round steel rod or straight drill bit approximately 3”

ong into the chuck and tighten.

l

2. With the table raised to work height and locked to the column, place the

ombination square flat on the table beside the rod or drill bit.(Fig.19).

c

3. If an adjustment is necessary, loosen the set screw under the bevel lock

with 3mm hex. key, then loosen the table bevel lock bolt with the open

wrench included. This adjustment is located under the work table.

4. Align the table square to the rod or drill bit by pivoting the table they

are in line.

5. Retighten table bevel lock.

6. Retighten set screw.

BEVEL SCALE

: The bevel scale has been included to provide a quick method for

NOTE

beveling the table to approximate angles. If precise accuracy is necessary,

a square, or other precision measuring tool should be used to position the

table.

Set screw

Table

Table

bevel lock

FIGURE 19

Table

1. To use the bevel scale do the following: a) Loosen set screw and table

bevel lock (See step 3 above for reference). b) Move table so that desired

angle on the bevel scale is straight across from the zero line on the table.

c) Retighten table bevel lock and set screw.

DRILLING TO A SPECIFIC DEPTH

To drill a blind hole (not all the way through) to a given depth, proceed as

follows.

1. Mark the depth of the hole on the workpiece.

2. Loosen the depth scale lock.

3. With the switch OFF, bring the drill bit down until the tip of the lips of

the drill bit are even with the mark.

urn the depth scale counter

4. T

5. Tighten the depth scale lock.

6. The drill bit will stop at this depth until the depth scale is readjusted.

ANOTHER WAY-DEPTH SCALE

1. With the power OFF, loosen the depth scale lock.

2. Place workpiece on table. Adjust table until the tip of the drill is just a

little above the top of the workpiece, turn the depth scale counterclockwise to zero.

3. Turn the depth scale clockwise until the depth scale indicator points to

the desired drilling depth on the depth scale.

4. Tighten the depth scale lock.

5. The chuck or drill will now be stopped after traveling downward the

distance selected on the depth scale.

clockwise until it stops moving.

Pointer

Depth sacle

indicator

Depth scale

Mark

Scale

FIGURE 20

Depth scale lock

FIGURE 21

Page 12

AJUSTEMENTS & OPÉRATIONS

OCKING CHUCK AT DESIRED DEPTH

L

1. With the switch off, loosen the depth scale lock.

2. Turn the feed handles until the chuck is at the desired height. Hold the

feed handles at this position.

3. Turn the depth scale clockwise until it stops.

4. Tighten the depth scale lock.

. The chuck will now be held at the depth when the feed handles are

5

released.

BASIC DRILL PRESS OPERATIONS

INSTALLING DRILL BITS

Insert drill bit into chuck far enough to obtain maximum gripping of the

chuck jaws (fig.23). The jaws are approximately 1” long. When using a

small drill bit, do not insert it so far that the jaws touch the flutes (spiral

grooves) of the drill bit. Make sure the drill bit is centered in the chuck

before tightening the chuck with the key.

Tighten the drill bit sufficiently, so that it does not slip while drilling. Turn

the chuck key clockwise to tighten, counterclockwise to loosen.

POSITIONNING THE TABLE AND WORKPIECE

Lock the table to the column in a position so that the tip of the drill bit is

just a little above the top of the workpiece.

Always place backup material (wood, plywood...) on the table underneath

the workpiece. This will prevent “splintering” or making a heavy burr on

the underside of the workpiece as the drill bit breaks through. To keep the

backup material from spinning out of control, it must contact the left side

of the column, as illustrated in fig.24.

Depth scale lock

Depth scale

Adjust to

desired depth

FIGURE 22

Chuck key

Chuck

WARNING! If the backup material is not long enough to reach the left

side of the column, clamp it to the table. Failure to do this could result in

personnal injury.

For small workpieces that can’t be clamp to the table, use a drill press vise

(optional accessory) (Fig.25). See authorized KING CANADA retailer for

more information on purchasing drill press vises.

WARNING! The vise must be clamped or bolted to the table to reduce the

risk of injury from spinning work or vise or tool breakage.

orkpiece

W

Drill press

vise

Jaws

FIGURE 23

Workpiece

Backup

material

Bolt or clamp vise securely

FIGURE 25

FIGURE 24

Page 13

TILTING TABLE

ADJUSTMENTS & OPERATIONS

To use the table in a bevel (tilted) position (Fig.26), loosen the set

screw under the table bevel lock with a 3mm hex. key. Loosen bevel

lock using open end wrench included. Tilt the table to the desired

angle by reading the bevel scale. Retighten bevel lock and set screw.

WARNING: To reduce the risk of injury from spinning work or

tool breakage, always clamp workpiece and backup material

securely to the table before operating the drill press with the table

tilted.

To return the table to its original position, loosen the set screw and

bevel lock, tilt the table back to zero on the bevel scale and

retighten set screw, then retighten the bevel lock.

HOLE LOCATION

Make a dent in the workpiece where you want the hole to be, using

a center punch or a nail. Before turning the switch on, bring the

drill down to the workpiece and line up with the dent in the

workpiece and clamp into place.

FEEDING

Pull down on the feed handles with only enough effort to allow the

drill to cut. Feeding too slowly might cause the drill to burn.

Feeding too rapidly might stop the motor, cause the belt or drill to

slip, tear the workpiece loose or break the drill bit. When drilling

metal, it may be necessary to lubricate the tip of the drill bit with

cutting oil or motor oil to prevent burning of the drill tip.

10. Proper tension is achieved when the quill returns gently to the

full up position when released from 3/4” depth.

11. When there is enough tension after checking, replace outer nut

and tighten inner nut. Do not over tighten against the inner nut.

12. Check quill while feeding to have smooth and unrestricted

movement. If movement is too tight, loosen outer nut and

slightly loosen inner nut until unrestricted. Retighten outer nut.

Bevel lock

Bevel scale

Set screw

FIGURE 26

ADJUSTING THE QUILL RETURN SPRING

: The return spring tension is set at the factory and should

NOTE

not require further adjustment.

ith the chuck at its highest possible position, turn the depth

1. W

scale clockwise until it stops and tighten the depth scale lock.

This will prevent the quill from dropping while tensioning the

spring.

2. Lower the table for additional clearance.

3. Work from the left side of the drill press.

4. Place scr

hold it in place while loosening and removing the outer nut

(only).

5. W

(approx. 1/8”) until the notch disengages from the boss on the

head. Do not remove this nut.

6. Carefully turn screwdriver counterclockwise and engage the

next notch in the boss. Do not r

7. Tighten standard nut with wr

Do not over tighten as this will restrict quill movement.

8. Move stop nuts and depth pointer to upper most position and

check tension while turning feed handles.

9. If there is not enough tension on the spring, repeat steps 4-8

moving only one notch each time and checking tension after

each repetition.

ewdriver in the lower fr

ith screwdriver remaining in the notch, loosen inner nut

ont notch of the spring cap, and

emove scr

ench only enough to engage boss.

ewdriver

.

Notch

(outer)

Nut

Nut

(inner)

Boss

Spring

cap

Notch

FIGURE 27

Page 14

MAINTENANCE / TROUBLESHOOTING

UBRICATION

L

All of the ball bearings are packed with grease at the factory. They require no further lubrication. Periodically lubricate the splines

(Grooves) in the spindle and the rack (Teeth of the quill).

WARNING! For your own safety, turn the switch “OFF” and remove the plug from the power source before maintaining or lubricating

your drill press.

Frequently blow out any dust that may accumulate inside the motor. After operation, remove chips or dirt on the machine and apply a

coat of furniture-type paste wax to the table and the column, this will help keep the surfaces clean and free of rust.

PROBLEM

Noisy operation.

Drill bit burns.

Wood splinters on

underside of workpiece.

Workpiece torn loose

om hand.

fr

Drill bit binds in workpiece.

Excessive drill bit

wobbling.

PROBABLE CAUSE

1. Incorrect belt tension.

2. Dry spindle.

3. Loose spindle pulley.

4. Loose motor pulley.

1. Incorrect speed.

2. Chips not coming out of hole.

3. Dull drill bit.

4. Feeding too slow.

5. Not lubricated.

1. No “Back-up material” under the workpiece.

1. Not supported or clamped properly.

1. Workpiece is pinching the drill bit or

there is an excessive feeding pressure.

2. Improper belt tension.

1. Bent drill bit.

2. Worn spindle bearings.

3. Drill bit is not pr

chuck.

4. Chuck not properly installed.

operly installed in the

SOLUTION

1. Adjust the tension.

2. Lubricate the spindle.

3. Tighten the retaining nut on the pulley as needed.

4. Tighten the set screws which hold the pulleys in place.

1. Change the speed.

2. Retract the drill bit frequently to clear the chips.

3. Resharpen the drill bit.

4. Feeding too fast...allow the drill bit to cut.

5. Lubricate the drill bit with cutting or motor oil.

1. Support the workpiece or clamp it.

1. Support the workpiece or clamp it.

1. Support the workpiece or clamp it.

2. Adjust the tension of the belt.

1. Use a straight drill bit.

2. Replace the bearings.

3. Install drill bit pr

4. Install chuck properly.

operly.

Quill r

eturns too fast or

too slow

Chuck will not stay

attached to the spindle.

It falls off when trying

to install it.

PARTS DIAGRAM & P

Refer to the Parts section of the King Canada web site for the most updated parts diagram and parts list.

.

1. Spring has impr

1. Dirt, grease or oil on the tapered inside

surface of the chuck or on the spindle

tapered surface.

TS LISTS

AR

oper tension.

1.

Adjust the spring tension.

1. Using a household detergent, clean the tapered surfaces of the chuck and the spindle to remove the dirt,

grease and oil.

Page 15

INSTRUCTIONS FOR DUAL LASER GUIDE SYSTEM

USING/ADJUSTING DUAL LASER GUIDE SYSTEM

WARNING! Do not look directly at the laser beams. Do not aim the laser beams at any person or any object other than

your workpiece. Do not deliberately aim the beams into the eye of a person for any length of time.

guide system aimed at a reflective workpiece, wood or rough coated surfaces are acceptable. This is to avoid the laser beams

from being reflected back at the operator.

Using the dual laser guides system;

Your laser guides are battery operated (2 x AA batteries) and

must be installed inside the laser switch/battery cover (A)

Fig.1. To remove this cover pressure must be applied to the

top and bottom, then you simply pull gently on the cover. Do

not yank the switch off, internal wires are attached to it. When

positioning the batteries, make sure they are positioned with

the correct polarity. Replace the laser/battery cover. Turn the

laser switch on to make sure the dual laser guide system

works.

1) Mark the drilling point on your workpiece.

2) Plug in the drill press and turn the motor on.

3) Switch on the laser guides and align the drilling point with the intersecting point of the laser guides.

4) Secure workpiece to the table with a vise or clamps.

5) Slowly feed the drill bit into the workpiece.

6) Switch off the dual laser guide system on completion of the drilling operation.

Fig.1

Do not use the laser

Fig.2

Adjusting the dual laser guide system;

If adjustments to the laser guides are necessary, proceed as follows;

1) Loosen set screw (A) Fig.2 (one set screw for each laser) and then slightly turn laser guide (B) Fig.2 in either direction, this

will reposition the laser beams trajectory, adjust the position of the laser guides this way until both beams intersect at the point

where the drill bit touches the workpiece. Retighten set screw (A) after each adjustment.

Caution: Remove the laser guide batteries from the battery compartment if you plan on storing your drill press for more than a

few days. If left in position, the batteries could leak and damage the laser guide assembly. Damage due to leaking batteries is

not covered under warranty.

Loading...

Loading...