3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

PRELIMINARY SPEC

Part Number: KT-3535SY9ZS-RV Super Bright Yellow

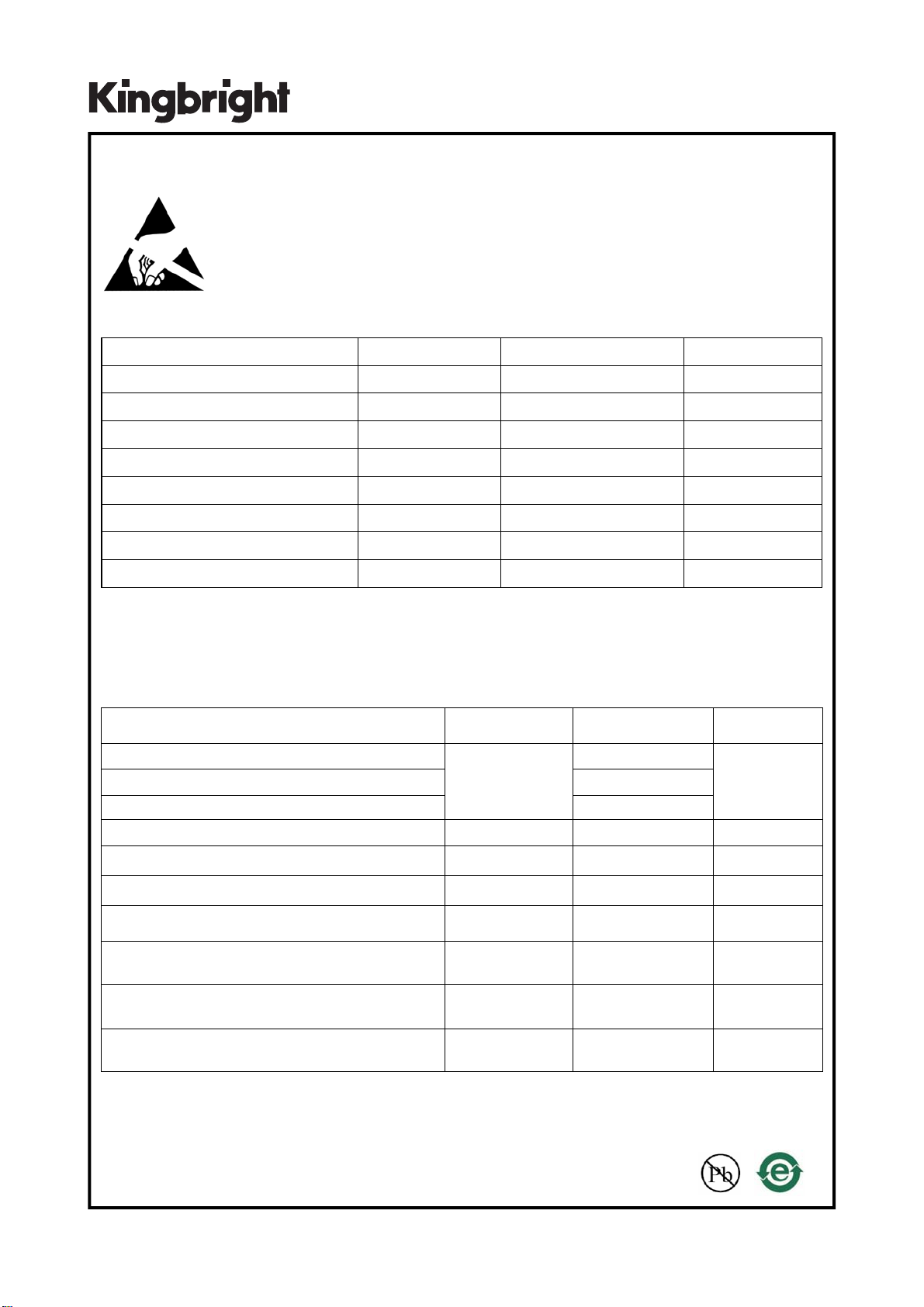

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

DISCHARGE

SENSITIVE

DEVICES

Absolute Maximum Ratings at TA = 25°C

Parameter Symbol Value Unit

DC Forward Current [1] IF 350 mA

Peak Forward Current [2] IFM 500 mA

Power dissipation Pt 0.98 W

Operating Temperature Top -40 To + 1 0 0 °C

Storage Temperature Ts tg -40 To + 12 0 °C

Junction temperature[1] TJ 120 °C

Thermal resistance [1] (Junction/ambient) Rth j-a 105 °C/W

Thermal resistance [1] (Junction/solder point) Rth j-s 31 °C/W

Notes:

1. Results from mounting on metal core PCB, mounted on pc board-metal core PCB is recommend

for lowest thermal resistance.

2. 1/10 Duty Cycle, 0.1ms Pulse Width.

Electrical / Optical Characteristics at T

A = 25°C

Parameter Symbol Value Unit

Forward Voltage IF = 350mA [Min.]

Forward Voltage IF = 350mA [Typ.] 2.3

Forward Voltage IF = 350mA [Max.] 2.8

Luminous Flux IF = 350mA [Typ.] Φv 13 lm

Wavelength at peak emission IF = 350mA [Typ.]

Dominant Wavelength IF = 350mA [Typ.]

Spectral bandwidth at 50% ΦREL MAX IF = 350mA [Typ.]

Temperature coefficient of λpeak

I

F = 350mA, - 10°C ≤ T ≤ 100°C [Typ.]

Temperature coefficient of λdom

I

F = 350mA, - 10°C ≤ T ≤ 100°C [Typ.]

Temperature coefficient of VF

IF = 350mA, - 10°C ≤ T≤ 100°C [Typ.]

Notes:

1.Wavelength : + / -1nm.

2. Forward Voltage : + / - 0.1V.

1.8

VF [2]

λpeak

λ dom [1]

Δλ

598 nm

591 nm

23 nm

V

TCλpeak 0.12 nm/°C

TCλdom 0.07 nm/ °C

TCV -3.0 mV/°C

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 1 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

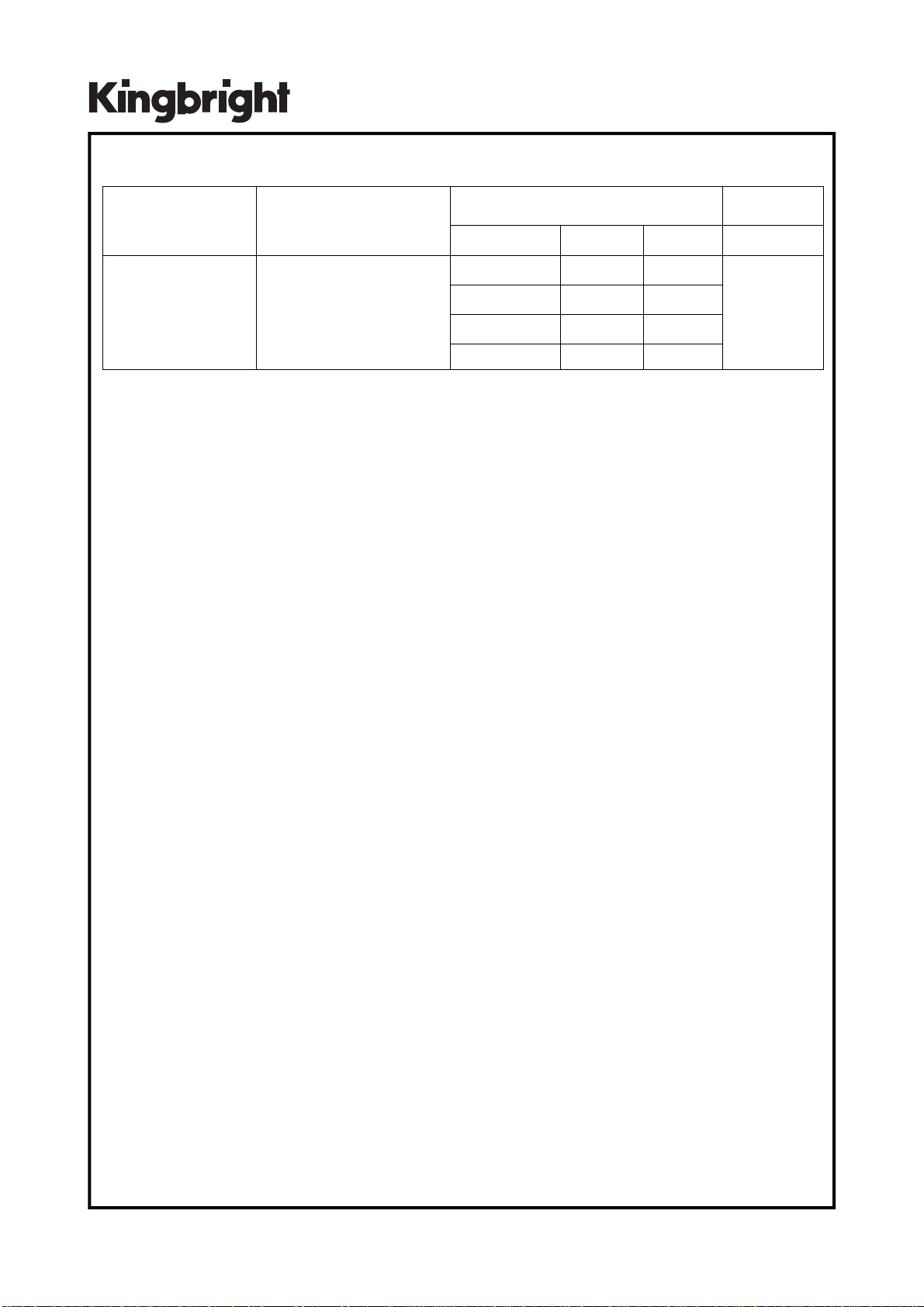

Selection Guide

V

Part No.

Dice

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

@ 350mA

Φv (lm) [2]

Code. Min. Max.

CB-L 5 10

iewing

Angle [1]

2θ1/2

KT-3535SY9ZS-RV Super Bright Yellow (InGaAlP)

Notes:

1. θ1/2 is the angle from optical centerline where the luminous intensity is 1/2 the optical centerline value.

2. Luminous intensity / luminous flux: +/-15%.

CC-L 10 15

CD-L 15 20

CE-L 20 25

Package Dimension And Materials

For package dimension please refer to page 10

Material as follows: Package : Ceramics

Encapsulating resin : Silicone resin

Electrodes : Ag plating

Features

1.Dimensions : 3.5mm X 3.5mm X 0.8mm.

2.Higher brightness .

3.Small package with high efficiency .

4.Surface mount technology .

5.ESD protection .

6.Moisture sensitivity level : level 2a.

7.Soldering methods: IR reflow soldering.

8.RoHS compliant.

120°

Packaging:

1.The LEDs are packed in cardboard boxes after taping.

2.The label on the minimum packing unit shows: Part Number, Lot Number, Ranking, Quantity.

3.In order to protect the LEDs from mechanical shock, we pack them in cardboard boxes for transportation.

4.The LEDs may be damaged if the boxes are dropped or receive a strong impact against them, so precautions

must be taken to prevent any damage.

5.The boxes are not water resistant and therefore must be kept away from water and moisture.

6.When the LEDs are transported, we recommend that you use the same packing methods as Kingbright’s.

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 2 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

Reliability Test Items And Conditions

The reliability of products shall be satisfied with items listed below

Lot Tolerance Percent Defective (LTPD) : 10%

No. Test Item Test Conditions

= 25 °C , IF = 350 mA

T

a

1 Continuous Operating Test

2 High Temperature Operating Test

3 Low Temperature Operating Test

4

High Temperature and Humidity

Storage Operating Test

5 Temperature Cycling Test

Tested with standard circuit

= 100 °C , IF = 50 mA

T

a

board

﹡

(note)

= -40 °C , IF = 350 mA

T

a

Tested with standard circuit

= 85 °C , RH = 85% , IF =

T

a

board

﹡

100 mA (note)

High temp: +100 °C 30 mins

∫

R.T: 5 mins

∫

Low temp: -40 °C 30 mins

∫

R.T: 5 mins

Test Times /

Cycles

1000 hrs 0/22

1000 hrs 0/22

1000 hrs 0/22

1000 hrs 0/22

10 cycles 0/22

Number of Damaged

High temp: +100 °C 5 mins

6

Thermal Shock Test

∫

1000 cycles 0/22

Low temp: -40 °C 5 mins

7 Soldering resistance Test T

Note: Thermal resistance of LED with Kingbright circuit board : R

= 260 °C , 10 secs 10 secs 0/22

sld

thj-a =105°C/W

Failure Criteria

Item

Symbol Test Conditions

Forward Voltage VF IF = 350mA - Initial Level x 1.1

Luminous Flux Φv IF = 350mA Initial Level x 0.7 -

Note: The test is performed after the board is cooled down to the room temperature.

Criteria for Judgement

Min. Max.

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 3 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

JEDEC Moisture Sensitivity:

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

Level

Time Conditions

2a 4 weeks

Floor Life

≤ 30 °C / 60% RH

Standard Accelerated Equivalent

Time (hours) Conditions Time (hours) Conditions

6962

+ 5 / - 0

30 °C / 60% RH

Soak Requirements

120

+ 1 / - 0

60 °C / 60% RH

Moisture Sensitivity Levels

Level

Time Conditions

1 Unlimited

2 1 year

2a 4 weeks

3 168 hours

4 72 hours

5 48 hours

5a 24 hours

6 Time on Label (TOL)

Notes:

1.CAUTION - The ‘‘accelerated equivalent’’ soak requirements shall not be used until correlation of damage response, including electrical, after

soak and reflow is established with the ‘‘standard’’ soak requirements or if the known activation energy for diffusion is 0.4 - 0.48 eV. Accelerated

soak times may vary due to material properties, e.g., mold compound, encapsulant, etc. JEDEC document JESD22-A120 provides a method for

determining the diffusion coefficient.

2.The standard soak time includes a default value of 24 hours for semiconductor manufacturer’s exposure time (MET) between bake and bag and

includes the maximum time allowed out of the bag at the distributor’s facility.

If the actual MET is less than 24 hours the soak time may be reduced. For soak conditions of 30 °C/60% RH the soak time is reduced by one hour

For each hour the MET is less than 24 hours. For soak conditions of 60 °C/60% RH, the soak time is reduced by one hour for each five hours the

MET is less than 24 hours.

If the actual MET is greater than 24 hours the soak time must be increased. If soak conditions are 30 °C/60% RH, the soak time is increased one

Hour for each hour that the actual MET exceeds 24 hours. If soak conditions are 60 °C/60% RH, the soak time is increased one hour for each five

Hours that the actual MET exceeds 24 hours.

3.Supplier may extend the soak times at their own risk.

Floor Life

≤ 30 °C / 85% RH

≤ 30 °C / 60% RH

≤ 30 °C / 60% RH

≤ 30 °C / 60% RH

≤ 30 °C / 60% RH

≤ 30 °C / 60% RH

≤ 30 °C / 60% RH

≤ 30 °C / 60% RH

Standard Accelerated Equivalent1

Time (hours) Conditions Time (hours) Conditions

168

+ 5 / - 0

168

+ 5 / - 0

6962

+ 5 / - 0

1922

+ 5 / - 0

962

+ 2 / - 0

722

+ 2 / - 0

482

+ 2 / - 0

TOL 30 °C / 60% RH

85 °C / 85% RH

85 °C / 60% RH

30 °C / 60% RH

30 °C / 60% RH

30 °C / 60% RH

30 °C / 60% RH

30 °C / 60% RH

Soak Requirements

120

+ 1 / - 0

40

+ 1 / - 0

20

+ 0.5 / - 0

15

+ 0.5 / - 0

10

+ 0.5 / - 0

60 °C / 60% RH

60 °C / 60% RH

60 °C / 60% RH

60 °C / 60% RH

60 °C / 60% RH

ESD Protection During Production

Electric static discharge can result when static-sensitive products come in contact with the operator or other conductors.

The following procedures may decrease the possibility of ESD damage:

1.Minimize friction between the product and surroundings to avoid static buildup.

2.All production machinery and test instruments must be electrically grounded.

3.Operators must wear anti-static bracelets.

4.Wear anti-static suit when entering work areas with conductive machinery.

5.Set up ESD protection areas using grounded metal plating for component handling.

6.All workstations that handle IC and ESD-sensitive components must maintain an electrostatic potential of 150V or less.

7.Maintain a humidity level of 50% or higher in production areas.

8.Use anti-static packaging for transport and storage.

9.All anti-static equipment and procedures should be periodically inspected and evaluated for proper functionality.

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 4 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

Handling Precautions

Compare to epoxy encapsulant that is hard and brittle, silicone is softer and flexible. Although its characteristic

significantly reduces thermal stress, it is more susceptible to damage by external mechanical force.

As a result, special handling precautions need to be observed during assembly using silicone encapsulated

LED products. Failure to comply might leads to damage and premature failure of the LED.

1. Handle the component along the side surfaces by using forceps or appropriate tools.

2. Do not directly touch or handle the silicone lens surface. It may damage the internal circuitry.

3. Do not stack together assembled PCBs containing exposed LEDs. Impact may scratch the silicone lens or

damage the internal circuitry.

4. The outer diameter of the SMD pickup nozzle should not exceed the size of the LED to prevent air leaks. The inner diameter

of the nozzle should be as large as possible.

5. A pliable material is suggested for the nozzle tip to avoid scratching or damaging the LED surface during pickup.

6. The dimensions of the component must be accurately programmed in the pick-and-place machine to insure precise pickup

and avoid damage during production.

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 5 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

Designing the Position of LED on a Board.

1.No twist/warp/bent/or other stress shall be applied to the board after mounting LED with

solder to avoid a crack of LED package.

Refer to the following recommended position and direction of LED.

Appropriate LED mounting is to place perpendicularly against the stress affected side

2.Depending on the position and direction of LED,the mechanical stress on the LED package can be changed.

Refer to the following figure.

3.Do not split board by hand.Split with exclusive special tool.

4.If an aluminum circuit board is used,a large stress by thermal shock might cause a solder crack.

For this reason,it is recommended an appropriate verification should be taken before use.

.

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 6 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

Reflow soldering is recommended and the soldering profile is shown below.

Other soldering methods are not recommended as they might cause damage to the product.

Heat Generation:

1.Thermal design of the end product is of paramount importance.Please consider the heat generation of the LED when making

the system design. The coefficient of temperature increase per input electric power is affected by the thermal resistance of the

circuit board and density of LED placement on the board ,as well as other components. It is necessary to avoid intense heat

generation and operate within the maximum ratings given in this specification.

2.Please determine the operating current with consideration of the ambient temperature local to the LED and refer to the plot

of Permissible Forward current vs. Ambient temperature on CHARACTERISTICS in this specification. Please also take

measures to remove heat from the area near the LED to improve the operational characteristics on the LED.

3.The equation ①

T

j = Ta + Rthj-a *W ……… ①

Tj = T

s + Rthj-s *W ……… ②

Tj = dice junction temperature: °C

T

a = ambient temperature:°C

indicates correlation between Tj and Ta ,and the equation ② indicates correlation between Tj and Ts

T

s = solder point temperature:°C

thj-a = heat resistance from dice junction temperature to ambient temperature : °C/ W

R

thj-s = heat resistance from dice junction temperature to Ts measuring point : °C/ W

R

W = inputting power (IFx VF) : W

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 7 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

Super Bright Yellow KT-3535SY9ZS-RV

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 8 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 9 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

Package Dimensions

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

Notes:

1. All dimensions are in millimeters (inches).

2. Tolerance is ±0.25(0.01") unless otherwise noted.

3. Specifications are subject to change without notice.

4. The device has a single mounting surface. The device must be mounted according to the specifications.

Recommended Soldering Pattern

(Units : mm ; Tolerance: ± 0.1)

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 10 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

Tape Dimensions

(Units : mm)

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

Reel Dimension

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 11 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

3.5X3.5mm SMD LED WITH CERAMIC

SUBSTRATE

Packing & Label Specifications KT-3535SY9ZS-RV

SPEC NO: DSAI6709 REV NO: V.3 DATE: JAN/04/2009 PAGE: 12 OF 12

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: D.M.Su ERP: 1212000013

Loading...

Loading...