Page 1

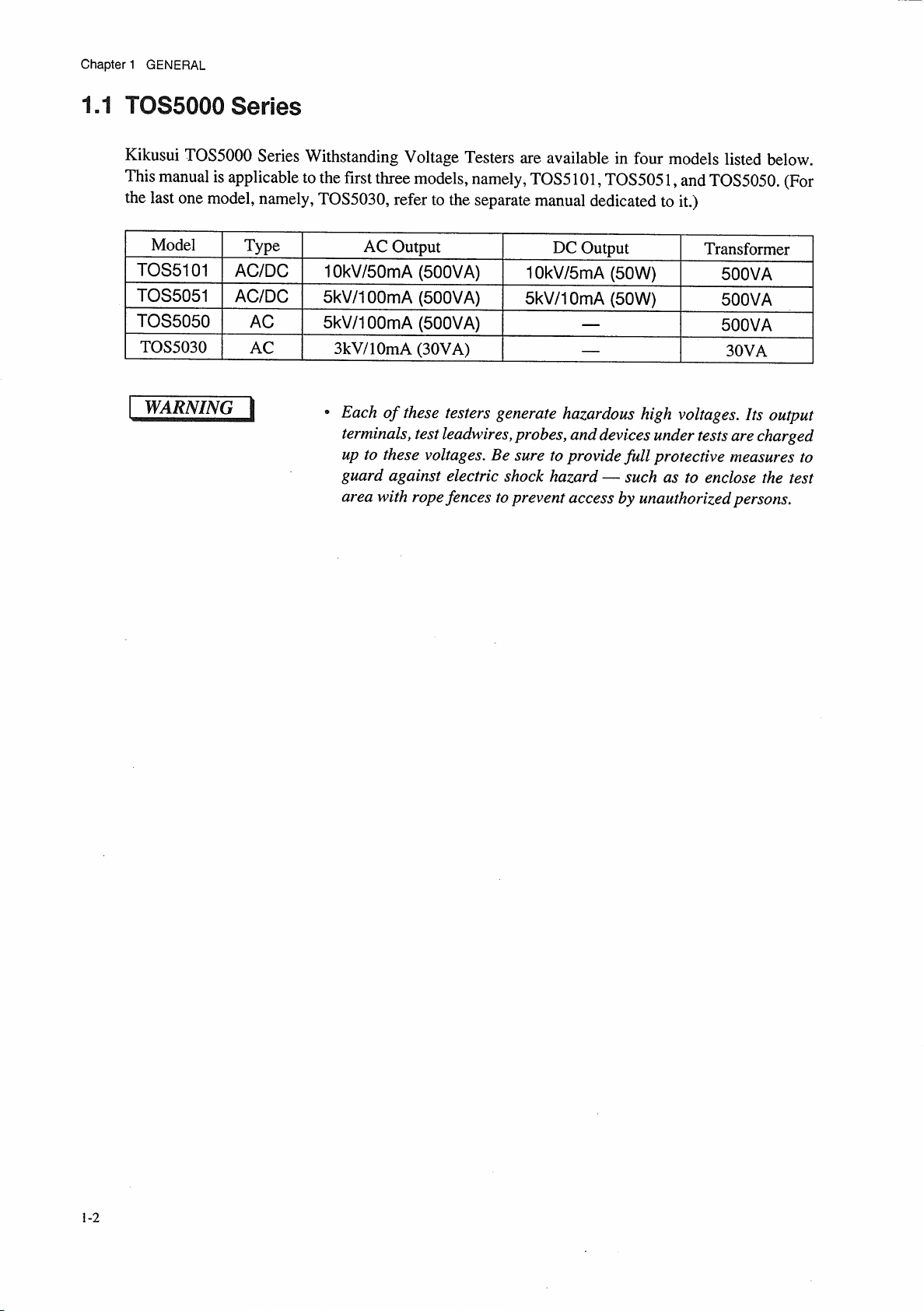

OPERATION MANUAL

TOS5000 SERIES

WITHSTANDING VOLTAGE TESTER

TOS5101

TOS5051

TOS5050

DANGER

WARNINGS Against HIGH VOLTAGE

• This Tester generates high voltage.

• Any incorrect handling may cause death.

• Read Chapter 3 "WARNINGS AND CAUTIONS FOR OPERATING THE TESTER"

in this manual to prevent accident.

• This manual should be placed within the reach of the operator so that he or she

may read it whenever necessary.

PartNo.Z1-000-632IB000598,MAR/2004

Page 2

All or any parts of this manual may not be reproduced in any forms, without express written

permission of Kikusui Electronics Corporation.

The contents of this manual, including the specifications of the instrument, are subject to change

without notice.

©1993-2004 Copyright Kikusui Electronics Corporation.

Printed in Japan. All rights reserved.

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

4.1.1 Turning ON/OFF the AC Input Power ................................................................ 4-3

4.1.2 Start/Stop of Test .................................................................................................. 4-5

4.1.3 Test Voltage .......................................................................................................... 4-9

4.1.4 Cutoff Currents ..................................................................................................... 4-12

4.1.5 Test Time .............................................................................................................. 4-15

4.1.6 Others .................................................................................................................... 4-17

4.2 Display Items ................................................................................................................ 4-18

4.2.1 Test Voltage Display ............................................................................................. 4-18

4.2.2 Readout for Cutoff Current and Measured Current .............................................. 4-21

4.2.3 Test Time Display ................................................................................................. 4-23

4.2.4 READY Message .................................................................................................. 4-24

4.2.5 TEST Message ...................................................................................................... 4-24

4.2.6 PASS Message ...................................................................................................... 4-24

4.2.7 FAIL Messages ..................................................................................................... 4-24

4.2.8 PROTECTION Message ....................................................................................... 4-25

4.2.9 Others .................................................................................................................... 4-25

4.3 Description of Rear Panel Items ................................................................................. 4-26

5. PREPARATIVE TEST PROCEDURES .............................................................. 5-1

5.1 Initial Setup ................................................................................................................... 5-2

5.1.1 Initial Setup of Switches and Controls .................................................................. 5-2

5.1.2 Initial Test Setup Data........................................................................................... 5-2

5.1.3 Procedure for the Initial Test Setup Data .............................................................. 5-3

5.2 Checking the Tester Operation ................................................................................... 5-4

5.3 Checkout Before Starting Test Operation ................................................................. 5-6

6. TEST PROCEDURES .................................................................................................. 6-1

6.1 AC Withstanding Voltage Test Procedure ................................................................ 6-2

6.1.1 Selecting an AC Test Voltage Range .................................................................... 6-2

6.1.2 Setting the Upper Cutoff Current .......................................................................... 6-3

6.1.3 Setting the Lower Cutoff Current ......................................................................... 6-4

6.1.4 Setting the Test Time ............................................................................................ 6-5

6.1.5 Setting the Test Voltage ........................................................................................ 6-6

6.1.6 Connecting the DUT ............................................................................................. 6-7

6.1.7 Executing a Test .................................................................................................... 6-7

6.2 DC Withstanding Voltage Test Procedure ................................................................. 6-12

6.2.1 Selecting a DC Test Voltage Range ...................................................................... 6-12

6.2.2 Setting the Upper Cutoff Current .......................................................................... 6-13

6.2.3 Setting the Lower Cutoff Current ......................................................................... 6-14

6.2.4 Setting the Test Time ............................................................................................ 6-16

6.2.5 Setting the Test Voltage ........................................................................................ 6-17

6.2.6 Connecting the DUT ............................................................................................. 6-17

6.2.7 Executing a Test .................................................................................................... 6-18

6.3 Remote Control .............................................................................................................. 6-22

6.3.1 Remote Control through REMOTE CONTROL Connector................................. 6-23

6.3.2 Remote Control through SIGNAL I/O connector ................................................. 6-24

6.3.3 Interlock Function ................................................................................................. 6-26

VII

Page 10

6.4 Output Signals ................................................................................................................ 6-27

6.4.1 Output Signals of SIGNAL I/O Connector ........................................................... 6-27

6.4.2 Output Signal of STATUS SIGNAL OUTPUT receptacle .................................. 6-30

6.5 Settings for Special Test Modes ................................................................................. 6-31

6.5.1 DOUBLE ACTION Switch .................................................................................. 6-31

6.5.2 PASS HOLD Switch ............................................................................................. 6-31

6.5.3 MOMENTARY Switch ........................................................................................ 6-32

6.5.4 FAIL MODE Switch ............................................................................................. 6-32

7. OPERATING PRINCIPLE .......................................................................................... 7-1

7.1 Block Diagrams ............................................................................................................ 7-2

7.2 Componential Circuits and Devices .......................................................................... 7-3

7.3 Zero-turn-on Switch ..................................................................................................... 7-4

7.4 Delay Time for Pass/Fail Judgement in DC Mode .................................................. 7-5

7.5 Automatic Discharge Function ................................................................................... 7-5

8. MAINTENANCE ............................................................................................................... 8-1

8.1 Cleaning the Outer Surfaces ....................................................................................... 8-2

8.2 Checking the Cord and Leadwires ............................................................................. 8-2

8.2.1 Checking the AC Power Cable ............................................................................. 8-2

8.2.2 Checking the HV Test Leadwires ......................................................................... 8-2

8.2.3 Overhaul ................................................................................................................ 8-3

8.3 Calibration ..................................................................................................................... 8-3

9. SPECIFICATIONS .......................................................................................................... 9-1

9.1 TOS5050 ........................................................................................................................ 9-2

9.2 TOS5101 and TOS5051 .............................................................................................. 9-9

9.3 Overall Dimensions ...................................................................................................... 9-18

9.3.1 Dimensions of Models TOS5050 and TOS5051 .................................................. 9-18

9.3.2 Dimensions of Model TOS5101 ........................................................................... 9-18

10. OPTIONS .......................................................................................................................... 10-1

10.1 Model RC01-TOS/RC02-TOS Remote Control Box ........................................... 10-2

10.2 Model HP01A-TOS/HP02A-TOS High Voltage Test Probe ............................... 10-3

10.3 Model PL01-TOS Warning Light Unit ................................................................... 10-4

10.4 Model BZ01-TOS Buzzer Unit ................................................................................ 10-4

10.5 High Voltage Test Leadwires ................................................................................... 10-4

INDEX ............................................................................................................................................ I-1

VIII

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

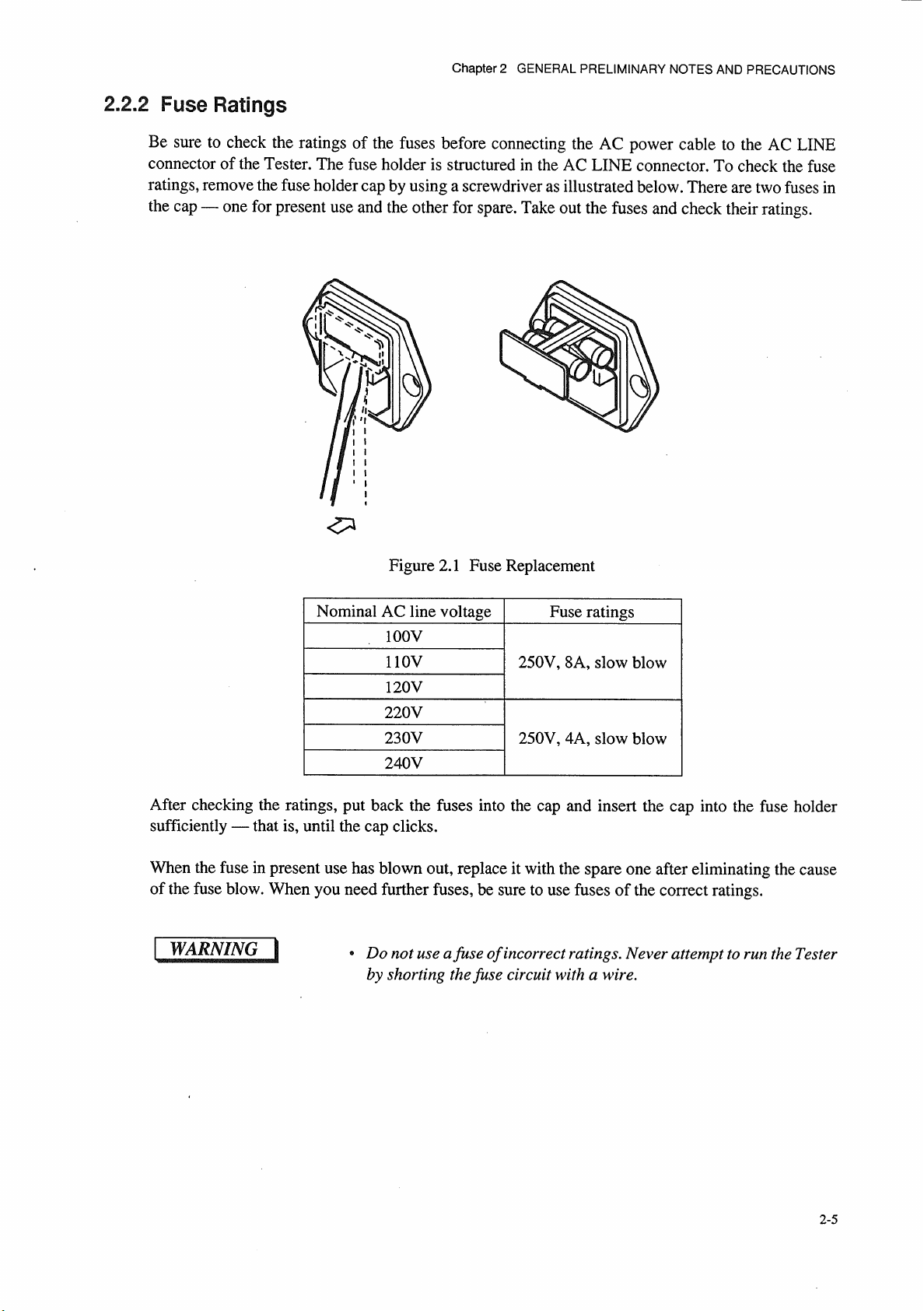

Chapter 2 GENERAL PRELIMINARY NOTES AND PRECAUTIONS

2.1 Checking for Shipping Damages and Accessories

When you receive the Tester, inspect it for any obvious damages that may have occurred during

shipment. Immediately report any damages to the carrier and your Kikusui agent.

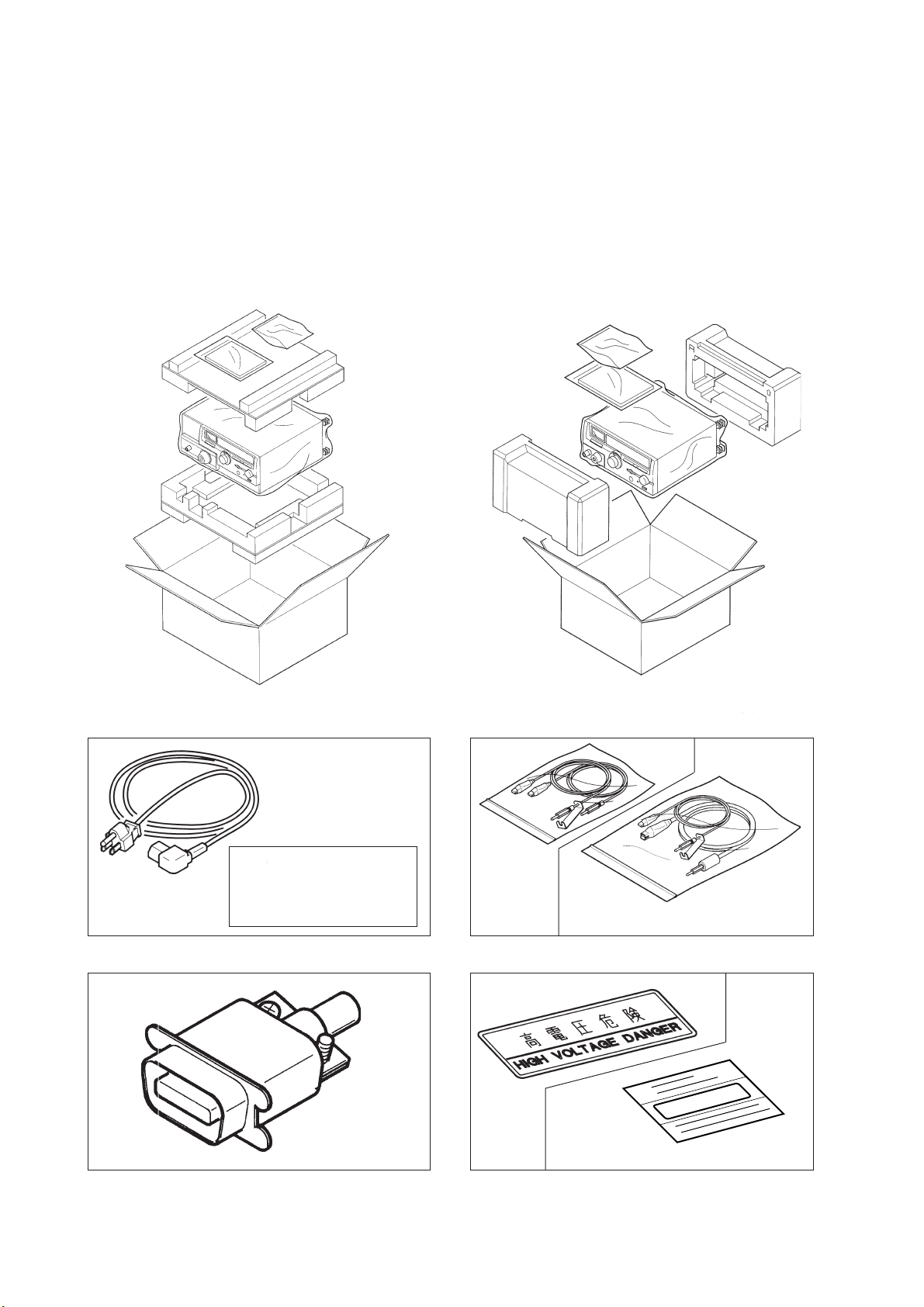

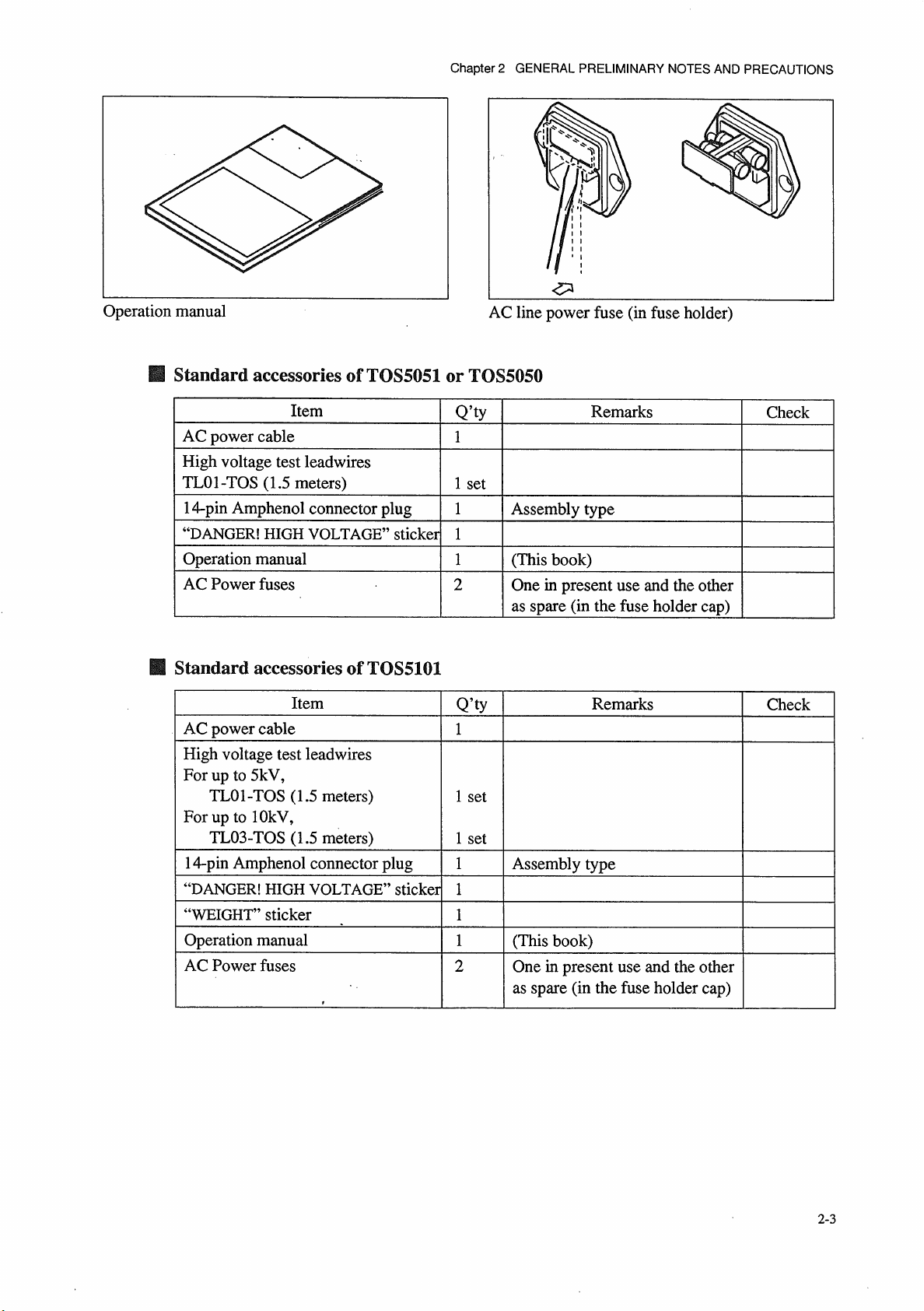

You should also find the standard accessories as shown below accompany the Tester in the same

package.

TOS5101 TOS5050/TOS5051

Do not use the AC power

cable attached to this

product for the AC power

cable of other instruments.

TL01-TOS

AC power cable HV Test Leadwires

TL03-TOS

(TOS5101 only)

○○kg

WEIGHT

(TOS5101 only)

14-pin Amphenol plug (assembly type) DANGER and WEIGHT sticker

2-2

Page 23

Page 24

Page 25

Page 26

Chapter 2 GENERAL PRELIMINARY NOTES AND PRECAUTIONS

2.2.3 Environmental Conditions

Be sure to observe the following precautions when installing the tester.

■ Do not use the tester in a flammable atmosphere.

To prevent explosion or fire, do not use the tester near alcohol, thinner, or other combustible

materials, or in an atmosphere containing such vapors.

■ Avoid locations where the tester is exposed to high temperatures or direct

sunlight.

Do not locate the tester near a heater or in areas subject to drastic temperature changes.

Operating temperature range: 0 ˚C to +40 ˚C

Storage temperature range: -20 ˚C to +70 ˚C

■ Avoid humid environments.

Do not locate the tester in a high-humidity environment-near a boiler, humidifier, or water supply.

Operating humidity range: 20 % to 80 % RH

(no dew condensation permitted)

Storage humidity range: 80 % RH or less

(no dew condensation permitted)

Condensation may occur even within the operating humidity range. In that case, do not start using the

tester until the location is completely dry.

■ Do not place the tester in a corrosive atmosphere.

Do not install the tester in a corrosive atmosphere or one containing sulfuric acid mist or the like. This

may cause corrosion of various conductors and imperfect contact with connectors, leading to

malfunction and failure, or in the worst case, a fire.

■ Do not locate the tester in a dusty environment.

Dirt and dust in the tester may cause electrical shock or fire.

■ Do not use the tester where ventilation is poor.

Prepare sufficient space around the tester to allow for air flow.

■ Do not place the tester on a tilted surface or in a location subject to

vibrations.

If placed on a non-level surface or in a location subject to vibration, the tester may fall, resulting in

damage and injury.

■ Do not use the tester in locations affected by strong magnetic or electric

fields.

Operation in a location subject to magnetic or electric fields may cause the tester to malfunction,

resulting in electrical shock or fire.

2-6

Page 27

Chapter 2 GENERAL PRELIMINARY NOTES AND PRECAUTIONS

■ Do not use the tester in locations near a sensitive measuring instrument or

receiver.

Operation in a location subject, may cause such equipment may be affected by noise generated by the

tester. At a test voltage exceeding 3 kV, corona discharge may be generated to produce substantial

amounts of RF broadband emissions between grips on the test leadwire. To minimize this effect,

secure a sufficient distance between alligator clips.

In addition, keep the alligator clips and test leadwire away from the surfaces of conductors (particularly

sharp metal ends).

■ Secure adequate space around the power plug.

Do not insert the power plug to an outlet where accessibility to the plug is poor. And, do not place

objects near the outlet that would result in poor accessibility to the plug.

2-7

Page 28

Chapter 2 GENERAL PRELIMINARY NOTES AND PRECAUTIONS

2.2.4 Notes for Moving the Tester

When moving the tester to the installation site or otherwise transporting it, take the following

precautions:

■ Before moving the tester, turn off the power switch.

Transporting the tester with its POWER switch on can lead to electric shock and damage.

■ When moving the tester, Disconnect all wires from it.

Moving the tester without disconnecting the cables may result in breakage of the wire or injury due to

the tester tipping over.

■ For transportation, use the special packing material for the tester.

Transport the tester in its original package to prevent vibration and falls, which may damage the

tester. If you require packing material, contact Kikusui distributor/agent.

■ Have two or more people move the tester.

The TOS5101 weighs approximately 21 kg. Two persons are required to carry the TOS5101.

Take extreme care when moving the TOS5101.

2-8

Page 29

Page 30

Page 31

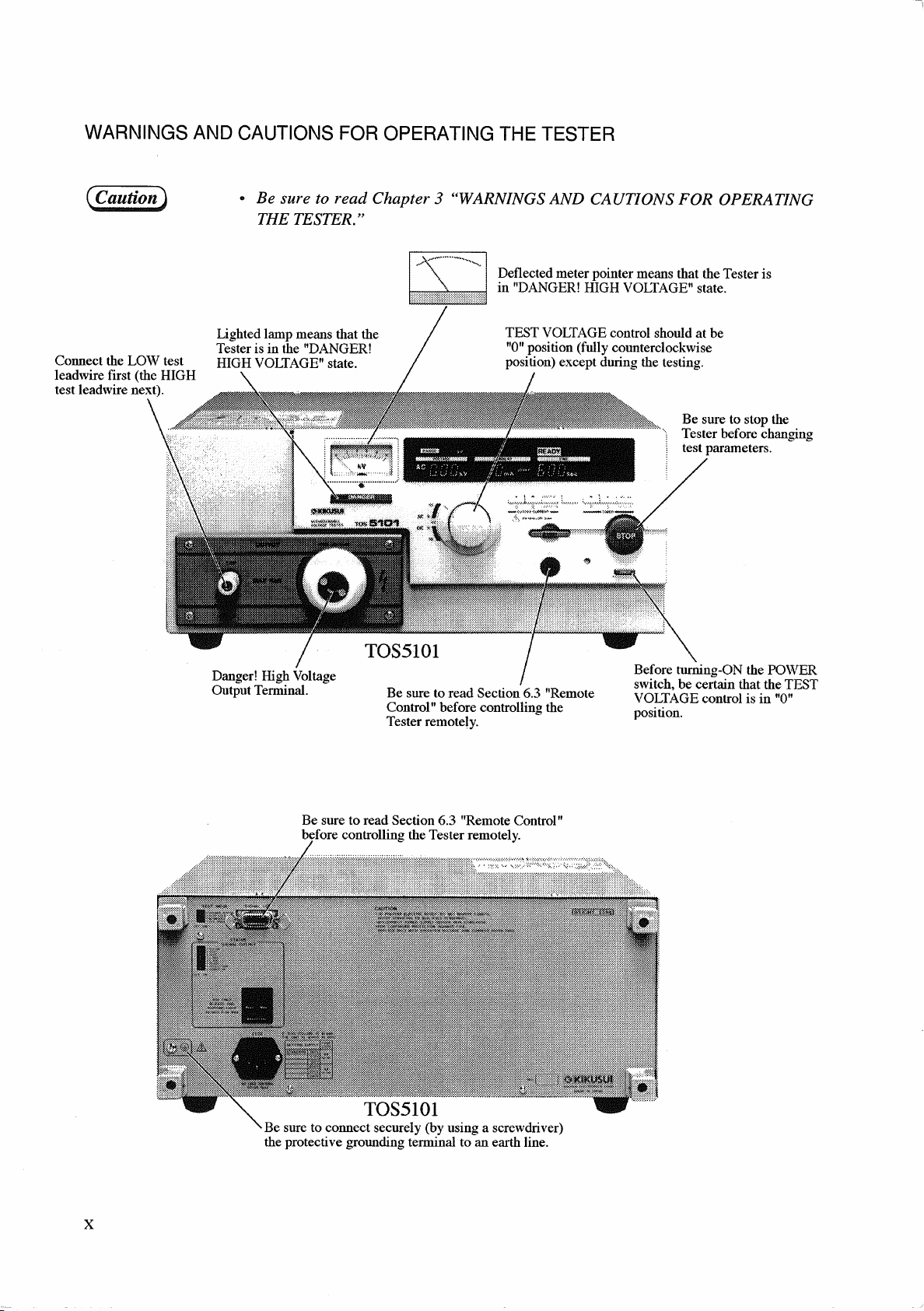

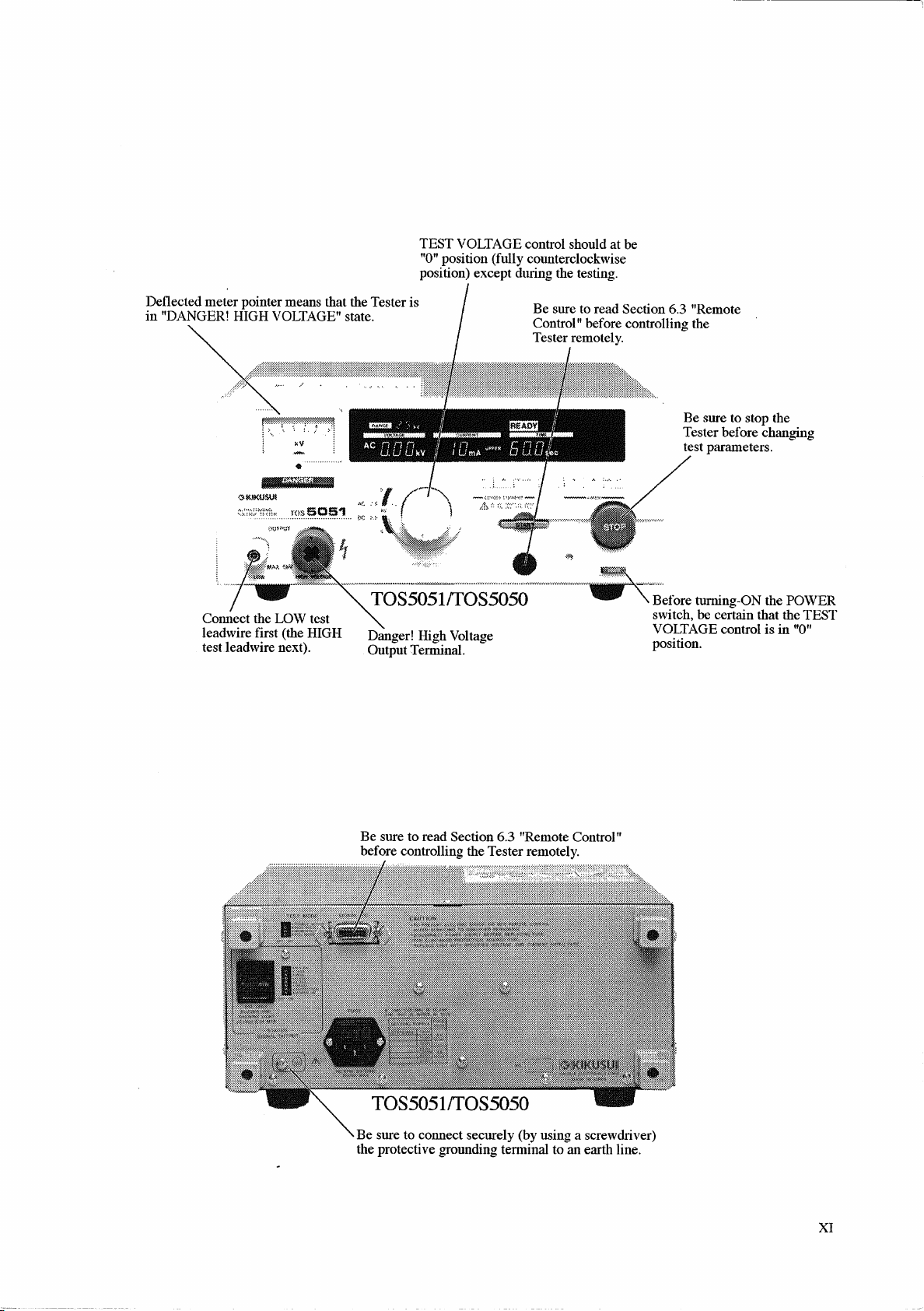

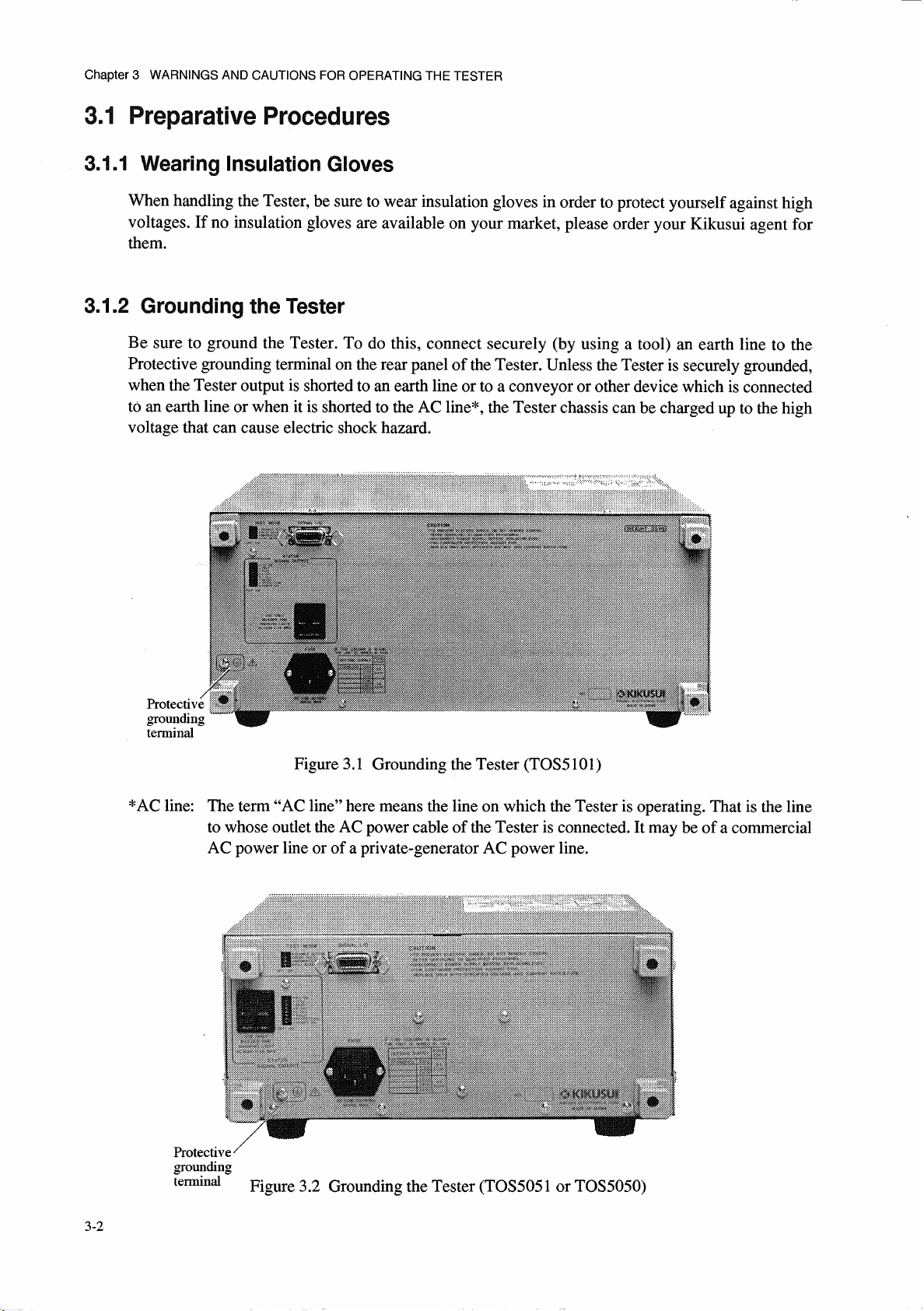

Chapter 3 WARNINGS AND CAUTIONS FOR OPERATING THE TESTER

3.2 Warnings and Cautions when Operating the Tester

3.2.1 Connecting the LOW Test Leadwire

For the connection method of the LOW test leadwire to the LOW output terminal of the Tester, see

Figure 3.3. Each time before start using the Tester, check that the LOW test leadwire is not broken.

When connecting the Tester to a DUT (device under test), connect the LOW test leadwire first (and

the HIGH test leadwire next) and be sure that it securely connects the LOW output terminal of the

Tester to the corresponding terminal (chassis protective grounding terminal) of the DUT. If the

connection is imperfect, overall DUT can be charged up to a hazardous high voltage.

LOW output terminal

Test leadwire (black) to DUT

Install the leadwire clamp as this

Figure 3.3 Connecting the LOW Test Leadwire (TOS5101)

3.2.2 Connecting the HIGH Test Leadwire

Be sure to observe the order of leadwire connections — the LOW test leadwire first and the HIGH test

leadwire next. To connect the Tester to a DUT, proceed as follows:

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Press the

Check that the output voltmeter reading is zero.

Check that the

Connect the HIGH test leadwire to the HIGH VOLTAGE output terminal.

Short the LOW and HIGH test leadwires, and check that no high voltage is output.

Connect the Tester to the DUT, with the LOW output leadwire first and and HIGH

output leadwire next.

STOP

switch.

DANGER

lamp is OFF.

3-3

Page 32

Page 33

Page 34

Chapter 3 WARNINGS AND CAUTIONS FOR OPERATING THE TESTER

3.3.2 Residual High Voltages

Warning for Residual High Voltages

When you do a test with the DC output, the DUT, test leadwires, probes, and output terminals and

their vicinities are charged up to high voltages. Even after you turned off the DC output, these

voltages remain there for a period that depends on the conditions of the test. Within this period, never

touch the DUT, test leadwires, probes, or output terminals or their vicinities to avoid electric shock

hazard.

Before touching any of them, be sure of the following two matters and short the LOW and HIGH test

leadwires.

(a) The output voltmeter indicates “zero”.

(b) The DANGER lamp has gone out.

Discharge Time of Residual High Voltages

The period of time the residual high voltages take to be discharged vary depending on test conditions

— such as the properties of DUT and the test voltage delivered by Tester (Model TOS5101 or

TOS5051). When no DUT is connected, the period the Tester itself (internal capacitor of the Tester)

takes to be discharged is as follows:

Discharge time of Tester itself

Discharge time of Tester itself

Tester model

5kV 10kV

TOS5101 Approx. 22ms Approx. 24ms

TOS5051 Approx. 16ms —

(Period the Tester output terminal voltage takes to be reduced to 30V)

When a DUT whose capacitance is 0.05

µ

F is connected to the Tester, the discharge time is as follows:

Discharge time of Tester itself

Tester model

5kV 10kV

TOS5101 Approx. 140ms Approx. 170ms

TOS5051 Approx. 50ms —

(Period the Tester output terminal voltage takes to be reduced to 30V)

The Tester has an internal circuit to discharge the residual high voltage of its output circuit when its

output is turned off. Do not disconnect the DUT from the Tester when in test. If you do this, the

residual high voltage on the DUT may remain undischarged for a long period.

3-6

Page 35

Page 36

Page 37

Page 38

Page 39

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

Chapter 4

DESCRIPTION OF FRONT

AND REAR PANEL ITEMS

This chapter describes the items on the front and rear panels of the Tester.

Table of contents Page

4.1 Description of Front Panel Items ...................................... 4-2

4.1.1 Turning ON/OFF the AC Input Power ..................... 4-3

4.1.2 Start/Stop of Test ...................................................... 4-5

4.1.3 Test Voltage.............................................................. 4-9

4.1.4 Cutoff Currents ......................................................... 4-12

4.1.5 Test Time.................................................................. 4-15

4.1.6 Others ....................................................................... 4-17

4.2 Display Items .................................................................... 4-18

4.2.1 Test Voltage Display ................................................ 4-18

4.2.2 Readout for Cutoff Current and

Measured Current ..................................................... 4-21

4.2.3 Test Time Display .................................................... 4-23

4.2.4 READY Message ..................................................... 4-24

4.2.5 TEST Message.......................................................... 4-24

4.2.6 PASS Message.......................................................... 4-24

4.2.7 FAIL Messages......................................................... 4-24

4.2.8 PROTECTION Messages......................................... 4-25

4.2.9 Others ....................................................................... 4-25

4.3 Description of Rear Panel Items ....................................... 4-26

4-1

Page 40

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

4.1 Description of Front Panel Items

9 10 11 18 12 13 16 14 15

Figure 4.1 TOS5050 Front Panel

9

10

11

18

12

13

16

14

31172 45678

15

4-2

5

Figure 4.2 TOS5051 Front Panel

678

4

31172

Page 41

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

16

9

10 11

Figure 4.3 TOS5101 Front Panel

4.1.1 Turning ON/OFF the AC Input Power

18

5 678

12

13

4

14

15

31172

1

POWER

The

The Tester has a “resume” function. When you turn ON the

Switch

POWER

switch turns ON/OFF the AC mains power of the Tester.

POWER

switch, the Tester

automatically resumes the conditions of test (settings of cutoff current, test period, etc.) that

existed when you turned OFF the

By pressing the

POWER

switch while keeping the

POWER

switch last time.

SHIFT

key 16 depressed, you can

initialize the test conditions to the initial setup (factory default setup) as shown below. If you do

this, the data on the test conditions that existed when you turned OFF the

POWER

switch last

time is lost.

Item Initial setup data

Upper cutoff current 0.2mA

Lower cutoff current 0.1mA

Lower pass/fail judgement OFF

Test period 0.5 s

Timer function ON

Keylock function OFF

4-3

Page 42

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

37

3

3

5

19

0

5

Caution

• Be sure to read Chapter 3 “WARNINGS AND CAUTIONS FOR

OPERATING THE TESTER” (Page 3-1) of this manual before start

using the Tester.

• Before turning ON the

VOLTAGE

control 6 is in the fully counterclockwise position (“0”

POWER

switch, be sure that the

TEST

position).

• If you want to enter a setting value you have selected, wait approximately 0.5 seconds before turning OFF the POWER switch. If you

turn off the switch without waiting for this period, the value may not

be successfully entered.

• Normally, as you turn ON the

POWER

switch, the TESTER will

become the READY state (the READY lamp 28 will light up).

However, the lamp will not light up in the following cases:

(a) The Tester is in the PROTECTION status.

i. The interlock pins of the SIGNAL I/O connector

on the rear

panel are open.

(For detail, refer to Section 6.3.3 “Interlock Function”)

If the above is the case, eliminate the interlock signal and reset

from the PROTECTION status with the

STOP

switch

and then start operating the Tester.

ii. When in DC test (for TOS5101 and TOS5051 only), the high

voltage supply section is overheated.

If the above is the case, wait until the Tester cools off and then

reset from the PROTECTION status with the

STOP

switch

and then start operating the Tester.

(b) The lower cutoff current setting is higher than the upper cutoff

current setting and the lower pass/fail judgement function is ON.

If the above is the case, make the lower cutoff current setting

lower than the upper cutoff current or turn OFF the lower pass/

fail judgement function and then start operating the Tester.

(c) The

switch

POWER

switch is turned ON while the TEST VOLTAGE

is caught on a midway in turning from one range

position to another range position.

When in the above state, the TEST VOLTAGE RANGE message

will indicate 0 kV, both AC / DC test mode message

2

will

appear at the same time (except for TOS5050) and will blink to

show that no range selection has been successfully accomplished.

If the above is the case, turn the TEST VOLTAGE switch

accurately to a range position you may require and then start

operating the Tester.

4-4

Page 43

4.1.2 Start/Stop of Test

2

8

18

4

4

7

8

7

4

3

9

9

7

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

START

If you press the

READY message

display screen

If the REMOTE message

Switch

START

switch 2 when the Tester is in the READY state (state that the

2

appears), the Tester will execute the test with parameters shown on the

(Vaccum Fluorescent Display).

3

is shown, the

START

switch 2 is disabled and the remote start

control signal applied through the REMOTE CONTROL connector

SIGNAL I/O connector

If the MOMENTARY switch of TEST MODE switch

will be executed only during the period you keep depress the

3

is enabled.

3

on the rear panel is set to ON, the test

START

switch 2. For details,

refer to Section 6.5 “Settings for Special Test Modes.”

Caution

• Do not remote-control the Tester simultaneously from both

MOTE CONTROL

connector 4 and

you do this, the REMOTE message

SIGNAL I/O

3

will go out and the

connector

switch 2 will be enabled. For details, refer to Section 6.3 “Remote

Control.”

STOP

Switch

or the

RE-

3

. If

START

The

STOP

switch 3 is to stop the test and reset the Tester. As you press this switch, the Tester

will act as follows:

1.

Reset from TEST status (status that the TEST message

2

appears)

The Tester will stop the test and act as follows:

(a) Turns OFF the output with the highest priority.

(b) Brings the discharge function into effect if the test is in the DC mode.

(c)

Turns OFF the DANGER lamp 9 , provided that there is no residual test voltage in

the output circuit.

(d)

Lets the TEST message

2

disappear.

(e) Turns OFF the TEST signal and the HV ON signal fed through the SIGNAL I/O

connector

3

.

4-5

Page 44

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

0

0

7

1

1

7

7

2

7

7

8

8

7

2. Reset from PASS status (status that the PASS message

3

appears)

The Tester will reset from the PASS status and act as follows:

Lets the PASS message

(a)

3

disappear.

(b) Turns OFF the PASS signal fed through the SIGNAL I/O connector

3.

Reset from FAIL status (status that the FAIL message

3

appears)

The Tester will reset from the FAIL status and act as follows:

(a)

Lets the UPPER FAIL message 31 disappear.

(b)

Lets the LOWER FAIL message

3

disappear.

(c) Turns OFF the U FAIL (upper fail) signal fed through the SIGNAL I/O connector

(d) Turns OFF the L FAIL (lower fail) signal fed through the SIGNAL I/O connector

4. Reset from PROTECTION status

3

.

3

.

3

.

The Tester will reset from the PROTECTION status and act follows:

(a)

Lets the PROTECTION message

3

disappear.

(b) Turns OFF the PROTECTION signal fed through the SIGNAL I/O connector

However, the Tester will not reset from the PROTECTION status if the interlock pins of

the SIGNAL I/O connector

3

are open or if the high voltage supply section is overheated

in DC test (for TOS5101 and TOS5051 only). If this is the case, eliminate the interlock

signal (For detail refer to Section 6.3.3 “Interlock Function”) or wait until the Tester cools

off and then reset from the PROTECTION status with the

5.

Reset from READY status (status that the READY message

STOP

switch 3.

2

appears)

The Tester will reset from the READY status and act as follows:

(a)

Lets the READY message

(b) Turns OFF the READY signal fed through the SIGNAL I/O connector

2

disappear.

3

3

.

.

4-6

Page 45

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

8

7

9

3

8

8

8

1

2

Normally, as you release the

(status that the READY message

STOP

switch 3, the Tester will become the READY status

2

appears). In the following cases, however, the Tester will

not become the READY status.

1. The cause of PROTECTION status remaining un-eliminated

(a) The interlock pins of the SIGNAL I/O connector

3

on the rear panel are open. (For

details, refer to Section 6.3.3 “Interlock Function.”)

(b) When in DC test (for TOS5101 and TOS5051 only), the high voltage supply section is

overheated.

2. The test voltage remaining undischarged

This is such state that the DANGER lamp 9 remains lighted in spite of that the

TEST message

3. A period of approximately 0.5 seconds has elapsed after releasing the

when the DOUBLE ACTION switch of the TEST MODE switch

If the DOUBLE ACTION switch of the TEST MODE switch

will become the READY state as you release the

2

has disappeared.

STOP

STOP

3

is set for ON.

3

is set for ON, the Tester

switch 3. Then, when a period

of approximately 0.5 seconds has elapsed, the Tester will automatically reset from the

READY status. For details, refer to Section 6.5 “Settings for Special Test Modes.”

switch

4. The

Caution

STOP

switch 3 is released while the

• If the FAIL MODE switch of the

ON, resetting from the FAIL status (status that the FAIL message

3

appears) or from the PROTECTION status (status that the

PROTECTION message

switch 3 only. For details, refer to Section 6.5 “Settings for Special

Test Modes.”

START

switch 2 is pressed.

TEST MODE

3

appears) can be done with the

switch

3

is set for

STOP

4-7

Page 46

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

4

4

2

4

2

7

7

4

REMOTE CONTROL Connector

This connector is for remote control of start/stop of test operation from an optional device such

as Remote Control Box (RC01-TOS or RC02-TOS) or H.V Test Probe (HP01A-TOS or

HP02A-TOS).

As you connect the plug of the optional device, the remote control circuit is established and the

REMOTE message

3

appears and the local

Tester becomes the PROTECTION status (status that the PROTECTION message

appears) and the high voltage output is cut off. The STOP operation can be done either locally

from the

STOP

switch 3 on the front panel or remotely from the optional device.

START

switch 2 is disabled. In this case, the

3

As you disconnect the plug of the optional device, the REMOTE message

START

the

PROTECTION message

Caution

switch 2 is enabled. The Tester becomes the PROTECTION status (status that the

3

appears) and the high voltage output is cut off.

• For remote-control of the test start/stop operation of the Tester from

other device than one of the optional devices of the Tester, do not use

the

REMOTE CONTROL

the

SIGNAL I/O

connector

connector 4 on the front panel but use

3

on the rear panel.

• Of the optional H.V Test Probe (HP01A-TOS or HP02A-TOS), the

maximum allowable test voltage is 4 kV when in the AC test mode or

5 kV when in the DC test mode.

• Do not remote-control the Tester simultaneously from both

MOTE CONTROL

connector 4 and

you do this, the REMOTE message

START

switch 2 will be enabled.

SIGNAL I/O

3

will disappear and the

• If the Remote Control Box is with its UNCONDITIONAL STOP

function effected, the Tester will not become the PROTECTION

status when the plug of the box is connected to the

CONTROL

connected to the

connector 4. When the plug of the HV Test Probe is

REMOTE CONTROL

connector 4. the Tester

will not become the PROTECTION status because the probe is in the

state that its UNCONDITIONAL STOP function is effected.

3

disappears and

connector

REMOTE

RE-

3

. If

• Be sure to read Section 6.3 “Remote Control” before remote-controlling the Tester.

• To reset the Tester from the PROTECTION status, press the

STOP

switch 3.

4-8

Page 47

4.1.3 Test Voltage

5TEST VOLTAGE Switch

The TEST VOLTAGE switch 5 selects a test voltage range and test mode for AC or DC

(TOS5050 has no DC test mode).

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

The TEST VOLTAGE switch

the READY message

(status that the TEST message

FAIL judgement (when the PASS message

5

is enabled when the Tester is in the READY status (status that

28

appears); it is disabled when the Tester is in the TEST-ON status

29

appears) or when the Tester is delivering the result of PASS/

30

or the FAIL message

31

appears).

The Tester takes approximately 0.5 seconds to respond to a range change by this switch. The test

cannot be started during this period. (If the READY message

28

has been displayed, it

disappears for this period.)

When the range you selected is entered, the TEST VOLTAGE RANGE message

AC / DC test mode message

message can be reset from blinking by pressing the

pressing the

START

switch 2.

blinks to indicated that the entry has been completed. The

20

STOP

switch 3 or by starting the test by

19

or

Model Selectable ranges and mode

TOS5101 10kV AC 5kV AC 10kV DC 5kV DC

TOS5051 5kV AC 2.5kV AC 5kV DC 2.5kV DC

TOS5050 5kV AC 2.5kV AC - -

Caution

• Before turning the

TEST VOLTAGE

TEST VOLTAGE

switch 5, be sure that the

control 6 is in the fully counterclockwise posi-

tion (“0” position).

•

During the TEST-ON period (period that the TEST message

appears), the

TEST VOLTAGE

switch 5 is disabled. During this

period, it is possible that the actual position of the switch does not

conform with the TEST VOLTAGE RANGE message

AC / DC test mode message

. When the test period has elapsed,

20

19

or the

the switch is enabled and the selected test voltage range and AC/DC

mode (mode selection is for TOS5101 and TOS5051 only) are effected. Do not operate the Tester in this manner — that is, do not

change the

TEST VOLTAGE

switch 5 during the TEST-ON pe-

riod.

• Do not let the

TEST VOLTAGE

switch 5 caught on a midway in

turning it from one range position to another range position. If you

turn ON the POWER switch while the

TEST VOLTAGE

switch 5 is

caught on a midway, the TEST VOLTAGE RANGE message

indicate 0 kV, both AC / DC test mode messages

will appear at

20

the same time (except for TOS5050) and will blink to show that no

range selection has been successfully accomplished. When changing

the

TEST VOLTAGE

switch 5, turn it securely to the required

range position.

19

29

will

4-9

Page 48

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

6

5

7

8

8

TEST VOLTAGE Control

This control is to adjust the test voltage. As you turn the control clockwise from the “0” position,

the test voltage increases. The “MAX” position is for the highest test voltage corresponding to

the voltage range value selected by the TEST VOLTAGE switch

For the AC/DC models (TOS5101 and TOS5051), the control is for both AC and DC test modes.

Model Selectable ranges and mode

TOS5101 0 to 10kV AC or more 0 to 5kV AC or more

0 to 10kV DC or more 0 to 5kV DC or more

TOS5051 0 to 5kV AC or more 0 to 2.5kV AC or more

0 to 5kV DC or more 0 to 2.5kV DC or more

TOS5050 0 to 5kV AC or more 0 to 2.5kV AC or more

.

Caution

• Be sure to keep the

TEST VOLTAGE

control 6 in the fully

counterclockwise position (“0” position) whenever no test is done.

• When the

TEST VOLTAGE

control 6 is set in the fully clockwise

position (“MAX” position) in the no load state, the output voltage in

the DC mode may be higher than the test voltage range value you

selected with the

TEST VOLTAGE

switch 5. In the AC mode, the

output voltage may be higher still depending on change of the AC line

voltage. Although higher voltages may be available, be sure to

operate the Tester with voltages lower than the corresponding range

value.

HIGH VOLTAGE Terminal

This terminal is for the high line of the Tester output. The output voltage is delivered between

this terminal and the LOW terminal

. For the AC/DC models (TOS5101 and TOS5051), this

terminal serves in common for both AC and DC modes of test operation.

WARNING

• Never touch the

HIGH VOLTAGE

terminal 7 when in the

TEST-ON status (status that the DANGER lamp 9 lights or the

TEST message 29 appears).

LOW Terminal

This terminal is for the low line of the Tester output. This terminal is directly connected to the

Tester chassis.

4-10

Page 49

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

9

DANGER Lamp

This red lamp illuminates to indicate that the test voltage is being delivered. It remains

illuminating so far as there remains the test voltage in the output circuit.

WARNING

• When the DANGER lamp 9 is illuminating, never touch the

VOLTAGE

terminal 7, test leadwires, DUT, or other charged

objects.

10

Analog Voltmeter

The VOLTAGE display (analog voltmeter)

10

indicates directly the output terminal voltage. Of

the AC/DC models (TOS5101 and TOS5051), the voltmeter serves in common for both AC and

DC.

Model Measuring Range

TOS5101 0 to 10kV AC 0 to 10kV DC

TOS5051 0 to 5kV AC 0 to 5kV DC

TOS5050 0 to 5kV AC —

11

Zero Adjustment of Analog Voltmeter

This is for mechanical zero adjustment of the analog voltmeter. Before making zero adjustment,

be sure that the POWER switch is OFF.

HIGH

4-11

Page 50

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

12

8

3

9

0

1

2

2

8

4.1.4 Cutoff Currents

Caution

• Test time and pause period are limited by setting upper cutoff current.

"ON

…

" of the front panel character shows a maximum test time and

"OFF

…

" shows a minimum pause period. For details, refer to

chapter 9 "Specifications" (Pages 9-2, 9-3, 9-9 , 9-10 and 9-11).

Keys

The

keys 12 are for increment/decrement of cutoff currents (reference currents for pass/

fail judgement). The keys are enabled when the Tester is in the READY status (status that the

READY message

2

appears) and the KEYLOCK message

when in the TEST-ON status (status that the TEST message

is delivering the result of PASS/FAIL judgement (when the PASS message

FAIL message

3

appears).

3

has disappeared. It is disabled

2

appears) or when the Tester

3

or the

There are two cutoff currents, namely, UPPER cutoff current and LOWER cutoff current. You

can select either cutoff current with the

cutoff current with the

If you press the

or

keys 12.

key alone, the rate of increment/decrement is the basic resolution

UP/LOW

shown below. If you press it together with the

key 13 and increment/decrement the selected

SHIFT

key 16, the rate of increment/decrement

is ten times of the basic resolution. If you keep them pressed, increment/decrement repeats

automatically.

1.

key

This key increments the cutoff current setting. The set value is shown on the CURRENT

display (digital ammeter)

2.

key

2

.

This key decrements the cutoff current setting. The set value is shown on the CURRENT

display (digital ammeter)

Caution

• The UPPER and LOWER cutoff currents can be set mutually inde-

2

.

pendently and therefore it is possible that the latter is set at a value

higher than the former. If this is the case and the pass/fail judgement

function for the LOWER cutoff current is ON, however, the mA

display (unit of current measure) blinks and the READY message

2

disappears to indicate that the test in this condition cannot be

done. The READY status resumes if the LOWER cutoff current is set

at a value lower than the UPPER cutoff current or if the pass/fail

judgement function for the LOWER cutoff current is turned OFF.

4-12

Page 51

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

UPPER/LOWER cutoff

current range

Basic resolution Display format

0.1 to 9.9mA 0.1mA □.□mA

10 to 110mA 1mA □□□mA

Model

AC mode of test

Upper cutoff current range Lower cutoff current range

TOS5101 0.1 to 55mA 0.1 to 55mA, OFF

TOS5051 0.1 to 110mA 0.1 to 110mA, OFF

TOS5050 0.1 to 110mA 0.1 to 110mA,OFF

Model

DC mode of test

Upper cutoff current range Lower cutoff current range

TOS5101 0.1 to 5.5mA 0.1 to 5.5mA, OFF

TOS5051 0.1 to 11mA 0.1 to 11mA, OFF

TOS5050 — —

For the AC/DC models (TOS5101 and TOS5051), the upper and

lower cutoff currents can be set for AC and DC modes of tests. The

settings of cutoff currents for the AC mode and DC mode, however,

are mutually independent.

4-13

Page 52

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

13

8

3

9

0

1

3

4

3

2

4

2

5

UP/LOW

key

The key selects the upper or lower cutoff current. If you press the key while keeping the

key 16 pressed, the lower pass/fail judgement function is turned ON or OFF.

The

UP/LOW

READY message

when in the TEST-ON status (status that the TEST message

delivering the result of judgement (when the PASS message

key is enabled when the Tester is in the READY status (status that the

2

appears) and the KEYLOCK message

3

has disappeared. It is disabled

2

appears) or when the Tester is

3

or the FAIL message

appears).

1. When

UP/LOW

Each time as you press the

the UPPER message

The UPPER message

is displayed on the CURRENT readout

key alone is pressed

UP/LOW

2

or the LOWER message

2

means that the upper cutoff current has been selected, the value

key, the upper or lower cutoff current is selected and

2

appears.

2

, and you can adjust the value with the

keys 12.

The LOWER message

is displayed on the CURRENT readout

2

means that the lower cutoff current has been selected, the value

2

, and you can adjust the value with the

keys 12.

SHIFT

3

For the AC/DC models (TOS5101 and TOS5051), the upper and lower cutoff currents for

both AC and DC modes of tests can be selected with this key. The settings of cutoff

currents for the AC mode and DC mode, however, are mutually independent.

2. When

UP/LOW

Each time as you press the

key is pressed while keeping

UP/LOW

key, the LOWER ON message

SHIFT

key 16 pressed

2

disappears indicating that the lower pass/fail judgement function has been brought into or

out of effect.

For the AC/DC models (TOS5101 and TOS5051), the lower pass/fail judgement function

is turned ON of OFF with the

UP/LOW

key. This test condition is applied to both AC and

DC modes of tests — that is, the setting for one mode applies automatically to the other

mode also.

appears or

4-14

Page 53

4.1.5 Test Time

14

8

3

9

0

1

6

6

Keys

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

The

when the Tester is in the READY status (status that the READY message

KEYLOCK message

(status that the TEST message

FAIL judgement (when the PASS message

If you press the

shown below. If you press it while keeping the

keys 14 are for increment/decrement of test period of time. The keys are enabled

2

appears) and the

3

has disappeared. They are disabled when in the TEST-ON status

2

appears) or when the Tester is delivering the result of PASS/

or

3

or the FAIL message

key alone, the rate of increment/decrement is the basic resolution

SHIFT

key 16 pressed, the rate of increment/

3

appears).

decrement is ten times of the basic resolution. If you keep them pressed, increment/decrement

repeats automatically.

1.

2.

key

This key increments the test period. The set value is shown on the TIME display

key

This key decrements the test period. The set value is shown on the TIME display

2

.

2

.

Test period setting range Basic resolution Display format

0.5 to 99.9 s., OFF 0.1 s. □□.□s

100 to 999 s., OFF 1 s. □□□s

For the AC/DC models (TOS5101 and TOS5051), the test period can be set with the

keys 14 for both AC and DC modes of tests. This test condition applies in common to both AC

and DC modes of tests.

4-15

Page 54

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

15

7

7

6

7

6

26

6

8

3

9

0

1

3

3

12

13

14

15

ON/OFF

The

If you press it while keeping the

Key

ON/OFF

key 15 turns ON or OFF the timer function.

SHIFT

key 16 pressed, it turns ON or OFF the keylock

function.

1. When the

ON/OFF

key 15 alone is pressed

Each time as you press the key, the timer function is turned ON or OFF. If you press it

while the TIMER ON message

the TIMER ON message

the test period indicated on the TIME display

As you press the

TIMER ON message

ON/OFF

2

when the test period indicated on the TIME display

timer function ON, the TIME display

with the timer function OFF, the TIME display

The

ON/OFF

READY message

key 15 is enabled when the Tester is in the READY status (status that the

2

appears) and the KEYLOCK message

2

has disappeared, the timer function is turned ON and

2

appears. The test done under this condition terminates when

2

has elapsed.

key 15 again, the timer function is turned OFF and the

disappears. If in this status, the test does not terminates even

2

has elapsed. When in a test with the

indicates the remaining period; when in a test

2

indicates the elapsed period.

3

has disappeared. It is

disabled when the Tester is in the TEST-ON status (status that the TEST message

appears) or when the Tester is delivering the result of PASS/FAIL judgement (when the

PASS message

3

or the FAIL message

3

appears).

2

For the AC/DC models (TOS5101 and TOS5051), the timer function can be turned ON or

OFF with the

ON/OFF

key 15 for both AC and DC modes of tests. This test condition

applies in common to both AC and DC modes of tests.

2. When

If you press the

ON/OFF

key 15 is pressed while

ON/OFF

key 15 while keeping the

mentioned keys are locked and the KEYLOCK message

SHIFT

key 16 is kept pressed

SHIFT

key 16 pressed, the below-

3

appears or they are unlocked

and the message disappears. If you press them again, the below-mentioned keys are

unlocked and the KEYLOCK message

3

disappears.

When in the keylock function is ON, the following keys are locked.

(a)

(b)

(c)

(d)

keys

UP/LOW

keys

ON/OFF

key

key

4-16

Page 55

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

16

12

12

17

17

Therefore, the following conditions of test can be protected against inadvertent or unauthorized alterations.

(a) Upper cutoff current

(b) Lower cutoff current

(c) ON/OFF of lower pass/fail judgement function

(d) Test time

(e) ON/OFF of timer function

4.1.6 Others

SHIFT

1. If you press the

2. If you press the

3. If you press the

The

ON/OFF

key 15 is enabled regardless of the statuses of the Tester.

For the AC/DC models (TOS5101 and TOS5051), the keylock function applies in common

to both AC and DC modes of tests.

Key

POWER

switch 1 while keeping the

SHIFT

key 16 pressed, the

conditions of test are initialized.

key 12 while keeping the

SHIFT

cutoff current is incremented at a rate of ten times of that when you press the

key 16 pressed, the upper or lower

key

alone.

key 12 while keeping the

cutoff current is decremented at a rate of ten times of that when you press the

SHIFT

key 16 pressed, the upper or lower

key

alone.

4. If you press the

UP/LOW

key 13 while keeping the

SHIFT

key 16 pressed, the lower

pass/fail judgement function is turned ON or OFF.

5. If you press the

key 14 while keeping the

SHIFT

incremented at a rate of ten times of that when you press the

6. If you press the

key 14 while keeping the

SHIFT

decremented at a rate of ten times of that when you press the

7. If you press the

ON/OFF

key 15 while keeping the

key 16 pressed, the test period is

key 14 alone.

key 16 pressed, the test period is

key 14 alone.

SHIFT

key 16 pressed, the keylock

function is turned ON or OFF.

BUZZER Control

The BUZZER control

is to adjust the loudness of the buzzer that annunciates the results of

pass/fail judgements. FAIL annunciations are louder than PASS annunciations. The factory

default setting of this control is for the maximum loudness.

4-17

Page 56

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

18

19

5

5

9

19

0

5

19

4.2 Display Items

3219 28 29 30 31

RANGE

VOLTAGE

kV

AC

DC

20 21 22 23 25

Figure 4.4 Display

Vaccum Fluorescent Display

The vaccum fluorescent display indicats the test conditions, test results, and other items as

described in this section.

kV

4.2.1 Test Voltage Display

TEST VOLTAGE RANGE Message

This message, which is a 7-segment 2-digit message, indicates the test voltage range selected

with the TEST VOLTAGE switch

PROTECTION

CURRENT TIME

LOWER ON

UPPER

LOWER

mA

24

. The selectable test voltage ranges are as follows:

READY

TEST

TIMER ON

s

26 27 34 33

PASS

UPPER LOWER

FAIL

KEYLOCK

REMOTE

Model Test voltage range

TOS5101 10kV 5kV

TOS5051 5kV 2.5kV

TOS5050 5kV 2.5kV

Caution

• As you change test voltage ranges with the

, the TEST VOLTAGE RANGE message 19 blinks to indicate that

the ranges have been changed. Blinking stops as you press the

STOP

switch 2.

• During the TEST-0N period (period that the TEST message

appears), the

period, it is possible that the actual position of the switch does not

conform with the TEST VOLTAGE RANGE message

AC / DC test mode message

• Do not let the

turning it from one range position to another range position. If you

turn ON the

is caught on a midway, the TEST VOLTAGE RANGE message

TEST VOLTAGE

switch 3 or as you start the test by pressing the

TEST VOLTAGE

TEST VOLTAGE

POWER

switch 1 while the

switch 5 is disabled. During this

.

2

switch 5 caught on a midway in

TEST VOLTAGE

switch

START

2

or the

switch

4-18

Page 57

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

0

8

0

5

0

9

19

0

5

19

0

8

8

will indicate 0 kV, both AC / DC test mode messages

appear at the same time (except for TOS5050) and will blink to show

that no range selection has been successfully accomplished. When

this has occurred, turn the

TEST VOLTAGE

switch 5 accurately to

a range position. As you do so, the Tester will become the READY

2

appears). When in this

STOP

switch 3 or as you

switch 2.

AC/DC Test Mode Message

2

status (status that the READY message

status, blinking stops as you press the

start the test by pressing the

START

This message indicates whether the AC or DC test mode has been selected with the TEST

VOLTAGE switch

. The selectable modes are as follows:

Model Test Mode

TOS5101 AC DC

TOS5051 AC DC

TOS5050 AC —

Caution

• The TOS5050 is for the AC test mode only. It has no DC test mode

message

2

.

2

will

• As you change the modes with the

TEST VOLTAGE

switch 5, the

message blinks to indicate that the modes have been changed. Blinking stops as you press the

by pressing the

START

STOP

switch 2.

switch 3 or as you start the test

• During the TEST-ON period (period that the TEST message

appears), the

TEST VOLTAGE

switch 5 is disabled. During this

period, it is possible that the actual position of the switch does not

conform with the TEST VOLTAGE RANGE message

AC / DC test mode message

• Do not let the

TEST VOLTAGE

2

.

switch 5 caught on a midway in

or the

turning it from one range position to another range position. If you

turn ON the

POWER

switch 1 while the

TEST VOLTAGE

switch

is caught on a midway, the TEST VOLTAGE RANGE message

will indicate 0 kV, both AC / DC test mode messages

2

appear at the same time (except for TOS5050) and will blink to show

that no range selection has been successfully accomplished, and the

READY message

not in the READY status. When this has occurred, turn the

VOLTAGE

switch 5 accurately to a range position. As you do so,

2

will disappear to show that the Tester is

TEST

the Tester will become the READY status (status that the

READY message

as you press the

the

START

switch 2.

2

appears). When in this status, blinking stops

STOP

switch 3 or as you start the test by pressing

2

will

4-19

Page 58

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

1

21

1

5

2

VOLTAGE Readout (Digital Voltmeter)

The VOLTAGE display (digital voltmeter)

indicates the output voltage with a 3-digit 7-

segment readout. It constantly monitors the output terminal voltage.

For the AC/DC models (TOS5101 and TOS5051), the digital voltmeter

2

acts either as an AC

voltmeter or a DC voltmeters in response to the AC or DC mode selected by the TEST

VOLTAGE switch

.

1. Measuring ranges and resolutions

Model Measuring Range Resolution

TOS5101 AC 10kV range 0 to 14.162kV 55.54V

AC 5kV range 0 to 7.081kV 27.77V

DC 10kV range 0 to 12.750kV 50.00V

DC 5kV range 0 to 6.375kV 25.00V

TOS5051 AC 5kV range 0 to 7.081kV 27.77V

AC 2.5kV range 0 to 3.540kV 13.88V

DC 5kV range 0 to 6.375kV 25.00V

DC 2.5kV range 0 to 3.186kV 12.50V

TOS5050 AC 5kV range 0 to 7.081kV 27.77V

AC 2.5kV range 0 to 3.540kV 13.88V

2. Display formats

Voltage range Display format

0.00 to 9.99kV □.□□kV

9.99 to kV □□.□kV

Caution

• Due to the measuring resolutions, the readout may not be “0.00 kV”

when the output terminal voltage is zero volts.

4-20

Page 59

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

2

9

2

8

3

3

4

8

3

8

4.2.2 Readout for Cutoff Current and Measured Current

2

CURRENT Readout (Digital Ammeter)

When the Tester is in the TEST-ON status (status that the TEST message

CURRENT readout

2

indicates the measured output current; when the Tester is in other status

2

appears), the

than the TEST-ON status, it indicates the preset upper or lower cutoff current. It is a 3-digit 7segment readout.

Display change between upper and lower cutoff current settings can be done with the

key 13 when the Tester is in the READY status (status that the READY message

and the KEYLOCK message

3

has disappeared. The UPPER message

2

Tester is in the status for setting the upper cutoff current; the LOWER message

UP/LOW

2

appears)

means that the

2

means that

the Tester is in the status for setting the lower cutoff current.

You can increment/decrement the upper or lower cutoff current with the

the Tester is in the READY status (status that the READY message

KEYLOCK message

3

has disappeared. (If you press the

SHIFT

key 16 at the same time,

keys 12 when

2

appears) and the

the increment/decrement rate is multiplied by 10.)

If the lower cutoff current is higher than the upper cutoff current and the lower pass/fail

judgement function is ON, the mA display (unit of measure) blink and the READY message

2

disappears to alert you to that the setting is illogical and the test cannot be done. When the

lower cutoff current has become lower than the higher cutoff current or when the lower pass/fail

judgement function is turned OFF, the mA display automatically stops blinking and the Tester

resumes the READY status.

Of the AC/DC models (TOS5101 and TOS5051), the upper cutoff currents can be preset

mutually independently for AC test mode and DC test mode, and the lower cutoff currents also

can be preset mutually independently for AC test mode and DC test mode.

1. Displayed items

When in READY status When in TEST-0N status

When UPPER is ON When LOWER is ON

Upper cutoff current Lower cutoff current Measured current

2. Setting ranges

Model

AC mode of test

Upper cutoff current range Lower cutoff current range

TOS5101 0.1 to 55mA 0.1 to 55mA, OFF

TOS5051 0.1 to 110mA 0.1 to 110mA, OFF

TOS5050 0.1 to 110mA 0.1 to 110mA, OFF

Model

DC mode of test

pper cutoff current range Lower cutoff current range

TOS5101 0.1 to 5.5mA 0.1 to 5.5mA, OFF

TOS5051 0.1 to 11mA 0.1 to 11mA, OFF

TOS5050 — —

4-21

Page 60

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

3

2

8

3

9

3

4

2

4

2

8

3

9

3

4

2

5

8

3

3. Setting resolutions and display formats

UPPER/LOWER cutoff

current range

Basic resolution Display format

0.1 to 9.9mA 0.1mA □.□

10 to 110mA 1mA □□□

2

UPPER Message

This message means that the value shown on the CURRENT readout

2

is of the upper cutoff

current. Switchover between the upper and lower cutoff currents can be done with the

key 13 when the Tester is in the READY status (status that the READY message

and the KEYLOCK message

When in the TEST-ON status (status that the TEST message

message

2

and LOWER message

3

has disappeared.

2

disappear and the CURRENT readout

2

appears), both UPPER r

measured output current.

2

LOWER Message

This message means that the value shown on the CURRENT readout

2

is of the lower cutoff

current. Switchover between the upper and lower cutoff currents can be done with the

key 13 when the Tester is in the READY status (status that the READY message

and the KEYLOCK message

3

has disappeared.

UP/LOW

2

appears)

2

indicates the

UP/LOW

2

appears)

When in the TEST-ON status (status that the TEST message

message

2

and LOWER message

2

disappear and the CURRENT readout

2

appears), both UPPER i

2

indicates the

measured output current.

2

LOWER ON Message

This message means that the lower pass/fail judgement function is ON. When the function is

ON, the message appears; when it is OFF, the message disappears.

The function can be turned ON or OFF by pressing the

SHIFT

appears) and the KEYLOCK message

key 16 when the Tester is in the READY status (status that the READY message

3

has disappeared. Even when the lower pass/fail is

UP/LOW

key 13 together with the

turned OFF and the LOWER ON message has disappeared, display and adjustment of the

preset cutoff current can be done.

For the AC/DC models (TOS5101 and TOS5051), this test condition setting is applied in

common to both AC and DC modes of tests.

2

4-22

Page 61

4.2.3 Test Time Display

6

9

6

8

3

7

7

7

7

7

6

6

ON/OFF

8

3

2

TIME Display

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

When in the TEST-ON status (status that the TEST message

2

indicates the remaining or elapsed test time on a 3-digit 7-segment readout.

The preset test period can be incremented/decremented with the

is in the READY status (status that the READY message

message

3

has disappeared. If you press the

keys together with the

or

2

appears), the TIME display

keys 14 when the Tester

2

appears) and the KEYLOCK

SHIFT

key 16,

the increment/decrement rate is multiplied by a factor of 10.

If the timer function is ON (status that the TIMER ON message

2

appears), the displayed

period decreases as test time elapses and the test terminates when the preset test period has

elapsed. If the timer function is OFF (status that the TIMER ON message

2

has disappeared),

the displayed period starts by zero and increases as test time elapses—the test does not

terminates even when the preset test period has elapsed.

For the AC/DC models (TOS5101 and TOS5051), the preset test period applies in common to

both AC and DC modes of tests.

1. Displayed items

Desplayed items

When in READY status When in TEST-ON status

TIMER ON appears TIMER ON disappears

Period displayed Remaining period Elapsed period

2. Setting ranges, resolutions, and display formats

Setting range Basic resolution Display format

0.5 to 99.9 s, OFF 0.1 s □□.□

100 to 999 s, OFF 1 s □□□

2

TIMER ON Message

This message appears to mean that the TIMER function is ON. If the Tester is in the TIMER-ON

status (status that the TIMER ON message

2

appears), the test terminates when the preset test

time has elapsed. If Tester is in the TIMER-OFF status (status that the TIMER ON message

has disappeared), the test does not terminates even when the preset test period has elapsed.

When in the TIMER-ON status, the TIME display

in the TIMER-OFF status, the TIME display

The TIMER function can be turned on or off with the

READY status (status that the READY message

2

indicates the remaining test period; when

2

indicates the elapsed test period.

key 15 when the Tester is in the

2

appears) and the KEYLOCK message

has disappeared.

For the AC/DC models (TOS5101 and TOS5051), the same test condition applies in common to

both AC and DC modes of tests.

2

3

4-23

Page 62

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

8

18

9

0

8

1

1

4.2.4 READY Message

2

READY Message

This message means that the Tester is ready to start the test operation. As you press the

START

switch 2 while this message is displayed, the Tester will start the test operation with

the test parameters displayed on the display screen

4.2.5 TEST Message

2

TEST Message

This message (red) means that the Tester is in the TEST-ON status (status that the Tester is

executing the test by delivering the test voltage). When you want to reset from this status, press

the

STOP

switch 3.

4.2.6 PASS Message

3

PASS Message

.

This message (green) appears when the result of pass/fail judgement is PASS. (It appears when

the result is PASS within the test period. So it does not appear if the TIMER function is OFF or

the test is aborted.)

Normally, it appears only for a short period — approximately 0.2 seconds. If you set to ON the

PASS HOLD switch of TEST MODE switch

To reset the message from the held state, press the

4.2.7 FAIL Messages

3

UPPER FAIL message

This message (yellow) appears when the result of upper pass/fail judgement is FAIL, indicating

that the leak current that flowed through the DUT was larger than the preset high limit (upper

cutoff current). To reset the message, press the

3

LOWER FAIL message

This message (yellow) appears when the result of lower pass/fail judgement is FAIL, indicating

that the leak current that flowed through the DUT was less than the preset low limit (lower cutoff

current). To reset the message, press the

STOP

3

, the message is held displayed continuously.

STOP

STOP

switch 3.

switch 3.

switch 3.

4-24

Page 63

4.2.8 PROTECTION Message

2

3

4

7

7

3

12

13

14

15

15

4

4

7

3

PROTECTION Message

This message (yellow) appears when the Tester has tripped into the PROTECTION status and

its output voltage is cut off, due to any of the causes as mentioned below. To reset the Tester

from the PROTECTION status, eliminate the cause of the trip and then press the

.

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

STOP

switch

1. The plug is connected to or disconnected from the REMOTE CONTROL connector

2. The status of the REMOTE ENABLE signal input pins of the SIGNAL I/O connector

3. The INTERLOCK signal input pins of the SIGNAL I/O connector

4. The high voltage supply circuit of the DC test section (TOS5101 and TOS5051 only) is

4.2.9 Others

3

KEYLOCK Message

This message appears when the keylock function is ON; it disappears when the function is OFF.

The keylock function disables the following keys:

1.

2.

3.

4.

has changed.

overheated.

keys

UP/LOW

keys

ON/OFF

key

key

3

are make open.

.

3

Thus, the settings of the following test conditions are protected.

1. Upper cutoff current

2. Lower cutoff current

3. ON/OFF of lower pass/fail judgement

4. Test time

5. ON/OFF of timer function

The keylock function can be turned ON or OFF at any time, by pressing the

while keeping the

3

REMOTE Message

SHIFT

key 16 key pressed.

ON/OFF

This message appears to indicate that the Tester is being remote-controlled via the REMOTE

CONTROL connector

the

START

switch 2 is disabled. For details. refer to Section 6.3 “Remote Control.”

or the SIGNAL I/O connector

3

. When this message has appeared,

key

4-25

Page 64

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

5

5

4.3 Description of Rear Panel Items

39

3840 37

35 36

Figure 4.5 TOS5050/TOS5051 Rear Panel

39

40

38

37

35

36

Figure 4.6 TOS 5101 Rear Panel

3

Protective Grounding Terminal

This terminal is for grounding the Tester to an earth ground.

WARNING

• Be sure to connect securely (by using a screwdriver) an earth ground

line to the Protective grounding terminal

3

. Unless the Tester is

securely grounded, when the Tester chassis can be charged up to the

high voltage than can cause electric shock hazard. For details, refer

to Section 3.1.2 “Grounding the Tester.”

4-26

Page 65

3

6

6

7

7

8

8

9

9

0

AC LINE Connector

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

The AC LINE connector

3

is for the AC input power. It serves also as an input power fuse

holder.

3

SIGNAL I/O Connector

The SIGNAL I/O connector

3

is a 14-pin Amphenol connector for the interlock input signal,

remote control signal for test start/stop, and status output signal. For details, refer to Section

6.3.3 “Interlock Function,” Section 6.3.2 “Remote Control through Signal I/O Connector,” and

Section 6.4.1 “Output Signals of SIGNAL I/O Connector.”

3

TEST MODE Switches

The TEST MODE switches

3

allows you to select the following four test modes:

1. DOUBLE ACTION mode

2. PASS HOLD mode

3. MOMENTARY mode

4. FAIL mode

Caution

• Before changing the settings of these switches, be sure that the

POWER

switch 1 is OFF.

For details, refer to Section 6.5 “Settings for Special Test Modes.”

3

STATUS SIGNAL OUTPUT Receptacle and Switches

The output receptacle delivers a 100V AC signal to drive an optional Warning light Unit or a

Buzzer Unit. The status signal is delivered if one of the following items is set to ON. If two or

more items are set to ON, the status signal is delivered on the logical sum of such items.

1. HV ON 5. L FAIL

2. TEST 6. READY

3. PASS 7. PROTECTION

4. U FAIL 8. POWER ON

For details, refer to Section 6.4.2 “Status Signal Output.”

Caution

• Even when the Tester is operating on an AC line voltage of other than

nominal 100V AC, the signal output delivered through the

3

is 100V AC.

4

AC Power Cable Takeups

SIGNAL OUTPUT

receptacle

The four corrugated poles at the four corners on the rear panel are to take up the AC power cable

when the Tester in not in use.

STATUS

Caution

• The poles are for cable takeup and are not for legs of the Tester.

Never attempt to use the poles as legs for operating the Tester in the

vertical position (with its front panel faced up.). If you do, the Tester

will become unstable and very dangerous.

4-27

Page 66

Chapter 4 DESCRIPTION OF FRONT AND REAR PANEL ITEMS

4-28

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Chapter 6 TEST PROCEDURES

6.1.2 Setting the Upper Cutoff Current

This procedure is to set the upper cutoff current — criterion for pass/fail judgement on the DUT. If the

leak current that flows through the DUT is larger than this limit, the DUT is judged to be FAIL.

Caution

• Test time and pause period are limited by setting upper cutoff current.

"ON

…

" of the front panel character shows a maximum test time and

"OFF

…

"Specifications" (Pages 9-2, 9-3, 9-9 and 9-10).

Setting Procedure

Step 1

Select the upper cutoff current setting mode with the

UPPER message

on the CURRENT readout

Step 2

Adjust the preset upper cutoff current value as you may require, with the

12

. If you press the

by a factor of 10. The current value is displayed on the CURRENT readout

Upper Cutoff Current Setting Range

Model Upper cutoff current range

TOS5101 0.1 to 55mA

TOS5051 0.1 to 110mA

TOS5050 0.1 to 110mA

" shows a minimum pause period. For details, refer to chapter 9

UP/LOW

23

will appear and the preset upper limit current will be indicated

22

.

key 13 and the

keys

SHIFT

key 16 at the same time, the adjusting speed is increased

22

.

Resolution and Display Formats

Upper cutoff current range Basic resolution Display format

0.1 to 9.9mA 0.1mA □.□mA

10 to 110mA 1mA □□□mA

Caution

• The

keys 12 are enabled when the Tester is in the READY

status (status that the READY message

KEYLOCK massage

33

has disappeared. It is disabled when in the

TEST-ON status (status that the TEST message

Tester is delivering the result of PASS/FAIL judgement (when the

PASS message

30

or the FAIL message

• The upper and lower cutoff currents can be set mutually independently

and therefore it is possible that the latter is set at a value higher than the

former. If this is the case and the pass/fail judgement function for the lower

cutoff current is ON, however, the mA display (unit of current measure)

blinks and the READY message

28

this condition cannot be done. The READY status resumes and the blinking

stops if the lower cutoff current is set at a value lower than the upper cutoff

current or if the pass/fail judgement function for the lower cutoff current is

turned OFF.

28

appears) and the

29

appears) or when the

31

appears).

disappears to indicate that the test in

6-3

Page 78

Page 79

Chapter 6 TEST PROCEDURES

26

• The upper and lower cutoff currents can be set mutually independently

and therefore it is possible that the latter is set at a value higher than the

former. If this is the case and the pass/fail judgement function for the lower

cutoff current is ON, however, the mA display (unit of current measure)