Page 1

VEGA LT

Back

Exit

INSTALLATION

AND

COMMISSIONING

MANUAL

TM0081

PROPRIETARY RIGHTS NOTICE

The information contained in this manual is the property of Kidde Fire Protection Services Limited and may not

be reproduced or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or

otherwise, nor stored in any retrieval system of any nature without the express written authority of Kidde Fire

Protection Services Limited.

© Copyright 2003 Kidde Fire Protection Services Ltd

TM0081 Page 1 of 51 Issue 1.01

Page 2

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................................................4

1.1 DESCRIPTION ...........................................................................................................................................4

1.2 ABOUT THIS MANUAL ..............................................................................................................................5

1.3 SYSTEM DESIGN ......................................................................................................................................5

1.4 ELECTRICAL SAFETY...............................................................................................................................5

2. GLOSSARY OF TERMS AND ABBREVIATIONS......................................................................................6

3. INSTALLATION ..........................................................................................................................................7

3.1 SYSTEM SCHEMATIC ...............................................................................................................................7

3.2 APPROVED CABLES.................................................................................................................................8

3.3 INTERNAL CABLE ROUTING....................................................................................................................8

3.4 ENCLOSURE MOUNTING .........................................................................................................................9

3.5 EXTERNAL CONNECTIONS ...................................................................................................................10

3.5.1 Mains Wiring ............................................................................................................................................. 10

3.5.2 Detection Loop Wiring...............................................................................................................................10

3.5.3 Sounder Circuit Wiring..............................................................................................................................12

3.5.4 Auxiliary Output Wiring .............................................................................................................................12

3.5.6 Auxiliary Input Wiring ................................................................................................................................13

3.5.7 Battery Installation .................................................................................................................................... 14

3.5.8 Network and Repeater Cable Wiring ........................................................................................................14

4. ACCESS CONTROL LEVELS..................................................................................................................15

4.1 ACCESS INHIBIT KEYSWITCH...............................................................................................................15

5. CONTROLS AND INDICATION ...............................................................................................................16

5.1 PANEL DISPLAY ......................................................................................................................................16

5.2 CONTROL BUTTON FUNCTIONS ..........................................................................................................16

5.3 STATUS WINDOW INDICATION .............................................................................................................17

5.4 LIQUID CRYSTAL DISPLAY LAYOUT.....................................................................................................17

6. OPERATION .............................................................................................................................................18

6.1 STATUS NORMAL ...................................................................................................................................18

6.2 GAINING ACCESS TO LEVEL 2 OR 3 ....................................................................................................18

6.2 FIRE CONDITION.....................................................................................................................................18

6.3 RESETTING THE SYSTEM AFTER A FIRE CONDITION ......................................................................20

6.4 FAULT CONDITIONS ...............................................................................................................................20

6.4.1 System Faults ........................................................................................................................................... 20

6.4.2 Zone Fault Conditions ............................................................................................................................... 21

6.4.3 Group Fault Conditions .............................................................................................................................22

7. PRIORITY ALARM STRUCTURE ............................................................................................................23

8. FIRE & PLANT ZONE INDICATIONS ......................................................................................................23

9. MENU STRUCTURE ................................................................................................................................23

9.1 MAIN MENU .............................................................................................................................................23

9.2 ISOLATE \ DE-ISOLATE MENU...............................................................................................................24

9.3 LIST MENU ...............................................................................................................................................25

9.4 SET MENU ...............................................................................................................................................26

9.5 TEST MENU .............................................................................................................................................27

10. COMMISSIONING ....................................................................................................................................28

10.1 SYSTEM CHECKS ...................................................................................................................................28

10.2 INITIAL POWER UP .................................................................................................................................28

10.3 POWERING DOWN .................................................................................................................................29

10.4 CONNECTING THE DETECTION LOOP.................................................................................................29

10.5 ADDING OR REMOVING LOOP DEVICES .............................................................................................29

10.5.1 Power Down..............................................................................................................................................29

10.5.2 Processor Restart .....................................................................................................................................30

10.5.3 Auto Learn ................................................................................................................................................30

10.6 CONNECTING SOUNDER CIRCUITS.....................................................................................................30

11. PROGRAMMING STANDARD & CUSTOM FEATURES.........................................................................31

11.1 PANEL SET-UP ........................................................................................................................................31

11.2 ZONE FIRE INFORMATION ....................................................................................................................32

11.3 LOOP DEVICE INFORMATION ...............................................................................................................32

11.4 PANEL FUNCTIONS (STANDARD OR BLC OUTPUTS) ........................................................................34

11.5 OUTPUT GROUP INFORMATION...........................................................................................................34

11.5.1 Fire Output ................................................................................................................................................35

11.5.2 Isolate Output Group................................................................................................................................. 35

TM0081 Page 2 of 51 Issue 1.01

Page 3

11.6 SET ACTIVATIONS ..................................................................................................................................35

11.6.1 Common Alarm Installations.....................................................................................................................35

11.6.2 Zone by Zone Alarm Installations .............................................................................................................36

11.6.3 Activation Styles........................................................................................................................................ 37

11.6.4 Zone and Output Group Timers................................................................................................................37

11.6.5 Single Device to Output Group Programming ..........................................................................................38

11.6.6 Plant Alarm to Output Group Programming..............................................................................................38

11.7 REPEATER INFORMATION ....................................................................................................................39

11.8 MOTHERBOARD INFORMATION ...........................................................................................................39

11.9 PRIORITY HEADER TEXT.......................................................................................................................39

11.10 CUSTOM DEVICE TEXT..........................................................................................................................39

11.11 PLANT ALARM INFORMATION...............................................................................................................40

11.12 NETWORK INFORMATION .....................................................................................................................40

12 PLUG IN OPTIONS – INSTALLATION AND COMMISSIONING.............................................................41

12.1 VEGA LOOP CARD - Part Number 44782-K074 .....................................................................................41

12.2 REPEATER CARD - Part Number 44782-K076.......................................................................................42

12.3 PRINTER ASSEMBLY- Part Number VR0053 .........................................................................................43

12.4 VEGANET NETWORK CARD - Part Number VN2107 ............................................................................44

12.5 CZN NETWORK CARD - Part Number VN2108 ......................................................................................46

13 MAINTENANCE........................................................................................................................................47

13.1 ROUTINE MAINTENANCE.......................................................................................................................47

13.2 TEST MODE .............................................................................................................................................47

14. PANEL AND LOOP DEVICE FAULT CODES..........................................................................................48

15. FAULT DIAGNOSIS..................................................................................................................................49

16. RECOMMENDED SPARES LIST.............................................................................................................50

17. TECHNICAL SPECIFICATION .................................................................................................................51

TM0081 Page 3 of 51 Issue 1.01

Page 4

1. INTRODUCTION

This manual covers the Vega LT2000 and LT2001 Control Panel. The Vega LT fire control panel provides

analogue addressable detection of fire and is compatible with devices manufactured by Apollo and Hochiki.

Designed to comply with EN54: parts 2 & 4, the Vega LT provides a single detection loop and can cover 16

zones. The panel is mains powered and also has space for two 12 amp-hour standby batteries (not supplied) A

range of optional equipment is available to enhance the panel’s standard, fixed format configuration.

The Vega LT2000 provides support for Apollo series 90,95, Discovery and Explorer detectors and the Vega

LT2001 supports the Hochiki ESP range of detectors. Both versions of control panel provide the following key

features: -

!

Single detection loop

!

Two conventional programmable sounder circuits

!

Two auxiliary volt free programmable relay contacts

!

Fault volt free relay contact

!

Four auxiliary input connections

!

Membrane control fascia

!

8 system status indications

!

16 zone indications

!

8 line – 40 character liquid crystal display

!

Integral 2.5 amp power supply unit

!

Battery back-up facility

Figure 1: Vega LT Fire Control Panel

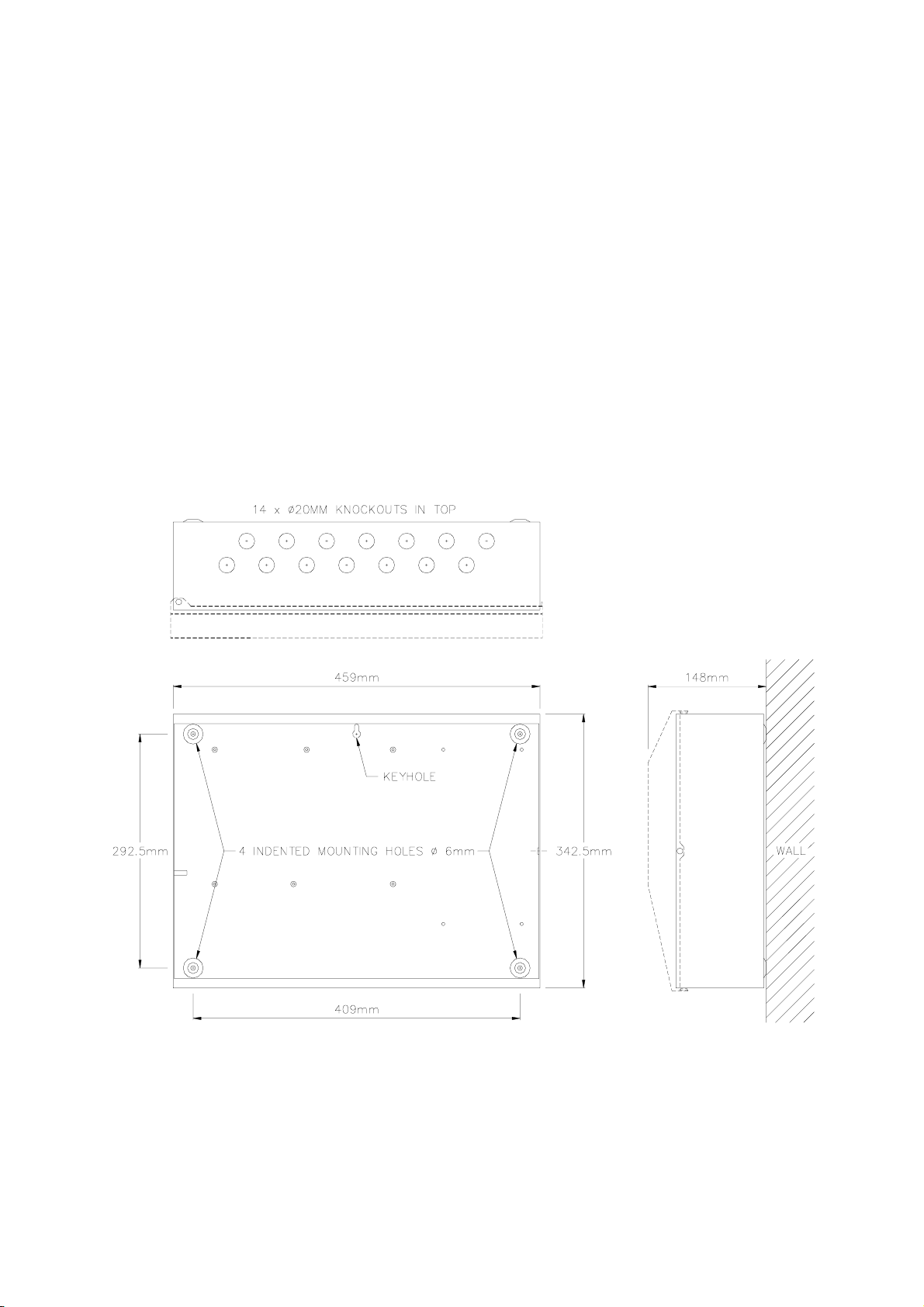

1.1 DESCRIPTION

The Vega LT consists of a backbox with 20 mm knockouts for cable entry and has a hinged, removable door

which is retained with a locking screw and incorporates the panel display membrane. The panel display has 16

zonal windows, status windows, user control and a liquid crystal display. The backbox has a keyhole locating

hole for positioning and can be secured through the four 4 mm indented holes located near each corner. Refer

to Figure 1.

A range of optional add-ons can be supplied separately and installed during commissioning to enhance the

systems capabilities. These options include: -

!

Loop card – to extend the panel to a maximum of two detection loops.

!

Repeater driver card – enables the Vega LT to communicate with VR3000 repeater panel(s)

!

Event printer – 24 character, thermal type. VR0053.

!

Network interface – provides communication to VegaNET graphics display system. VN2107.

!

Network interface – provides communication to Common Zone Network CZN System. VN2108.

TM0081 Page 4 of 51 Issue 1.01

Page 5

1.2 ABOUT THIS MANUAL

This installation manual details how to install and commission the Vega LT fire control panel and range of

optional equipment. It has been carefully checked for accuracy and is presumed to be correct. The

manufacturer assumes no responsibility for inaccuracies and reserves the right to modify the contents without

notice.

1.3 SYSTEM DESIGN

The design of the fire detection and alarm system should be in accordance with BS 5839 part 1 Fire detection

and fire alarm systems for buildings -“Code of practice for system design, installation, commissioning and

maintenance” and may be supplemented with customer’s specific installation requirements. The fire alarm

system design is beyond the scope of this document. It is therefore assumed that a basic knowledge of general

fire alarm system practices, components and their use is understood.

We recommend that a suitably qualified and competent person is consulted in connection with the design of the

fire alarm system and that the system is commissioned and services in accordance with the laid down

specification and national standards.

The Fire Officer responsible for the property should be contacted at an early stage to discuss of any site-specific

requirements.

1.4 ELECTRICAL SAFETY

Before handling any part of the control panel, ensure that adequate precautions are taken against damage to

the sensitive electronic components located within the control panel. Operators and engineers should discharge

themselves of any personal electro-static charge by momentarily touching a convenient earthed object.

Static charges are collected on adjacent conductors and are delivered in the form of sparks passing between

the conductors through insulating space or material. The sweat layer on the human skin is a sufficient medium

to store induced static charges and deliver them to any receptive conductor such as an electronic component or

printed circuit board. Following these guidelines can reduce static discharges:

!

Always use conductive or anti-static containers for transportation and storage.

!

Wear an earth wrist strap whilst handling devices, ensuring a good earth connection is maintained.

!

Never subject a static sensitive device to sliding movement over any surface and avoid any direct

contact with the pins.

!

Avoid placing sensitive devices onto plastic or vinyl surfaces.

!

Minimise the handling of sensitive devices and printed circuit boards.

All static sensitive devices are marked accordingly, but it is good engineering practice to treat all components

and boards with the same degree of protection.

WARNING:

The static handling procedures must be adhered to and extreme caution must be exercised when

working inside the control panel due to the presence of mains voltage 230 V AC. Failure to do so may

invalidate product warranty.

TM0081 Page 5 of 51 Issue 1.01

Page 6

2. GLOSSARY OF TERMS AND ABBREVIATIONS

Abbreviation Translation Description

MCP Main Control Processor Part number 44782-K071, the MCP card is located on the

back of the outer door and is responsible for controlling the

LCD Display, event printer, LED indications, reading in the

control button key actions, VIPER upload \ download

software. The card is also responsible for communicating

with BLC loop processor cards, repeater output ports and

network cards.

BLC Basic Loop Controller There are two types of BLC cards, the master and slave.

MBLC Master Basic Loop Controller Part number 44782-K073, the MBLC card is responsible for

communicating externally with detection loops 1 and 2. The

card also provides 2 monitored sounder circuits, 2 auxiliary

VFCO contacts & a failsafe fault VFCO contact. The MBLC

card also provides connections to the repeater and network

interface cards.

SBLC Slave Basic Loop Controller Not applicable on Vega LT

CCT Circuit Reference to loop or sounder monitored circuitry.

SND Sounder

VFCO Voltage Free Change Over Also known as dry contact

PCB Printed Circuit Board

BGU Break Glass Unit Also known as Manual Call Point

EMC Electro Magnetic Compatibility

EOL End of Line EOL monitoring device used on sounder circuits

LED Light Emitting Diode

PSU Power Supply Unit

LCD Liquid Crystal Display

SLA Sealed Lead Acid Type of battery used within fire control panels

Cause & Effect Operation of programmable outputs and functions as a

result of an event being registered.

I/O Input / Output

PC Personal Computer

mA Milli amp

BS British Standard

EN European Norm

Ah Amperes Hour

dB (A) Decibel

IP Ingress Protection

m! Milli ohm

K! Kilo ohm

Comms Communications Communications abbreviated to fit display

Config Configuration Configuration abbreviated to fit display

TM0081 Page 6 of 51 Issue 1.01

Page 7

3. INSTALLATION

Installation of the fire detection and alarm system must comply with the current editions of:

!

The IEE wiring regulations.

!

The British Standard for Fire Detection and Alarm Systems for buildings BS 5839: part 1

!

Local country legislation if outside of the United Kingdom.

Take care not to install the cables in the proximity of high voltage cables or in areas likely to induce electrical

interference. Junction boxes should be avoided, but if they have to be installed then they must be clearly

labelled "FIRE ALARM".

Special attention should be made in the selection of loop wiring conductor size to ensure that the voltage drop

does not prevent devices operating within their specification even under minimum supply and maximum load

conditions. Consideration should also be given for future expansion of the system.

It is not permissible to run more than one detection loop in single cable, but a four-core cable can be used for

the feed and return of an individual loop. However, to increase the integrity of the loop it is recommended that

the feed and return cable pairs use different paths around the building.

It is not permissible to run any other circuits in the same cable as a detection loop, i.e. sounder circuits, power

supplies, plant shut downs etc, as the induction capacities of the cable can cause corruption of loop information

and/or inter-loop "cross talk".

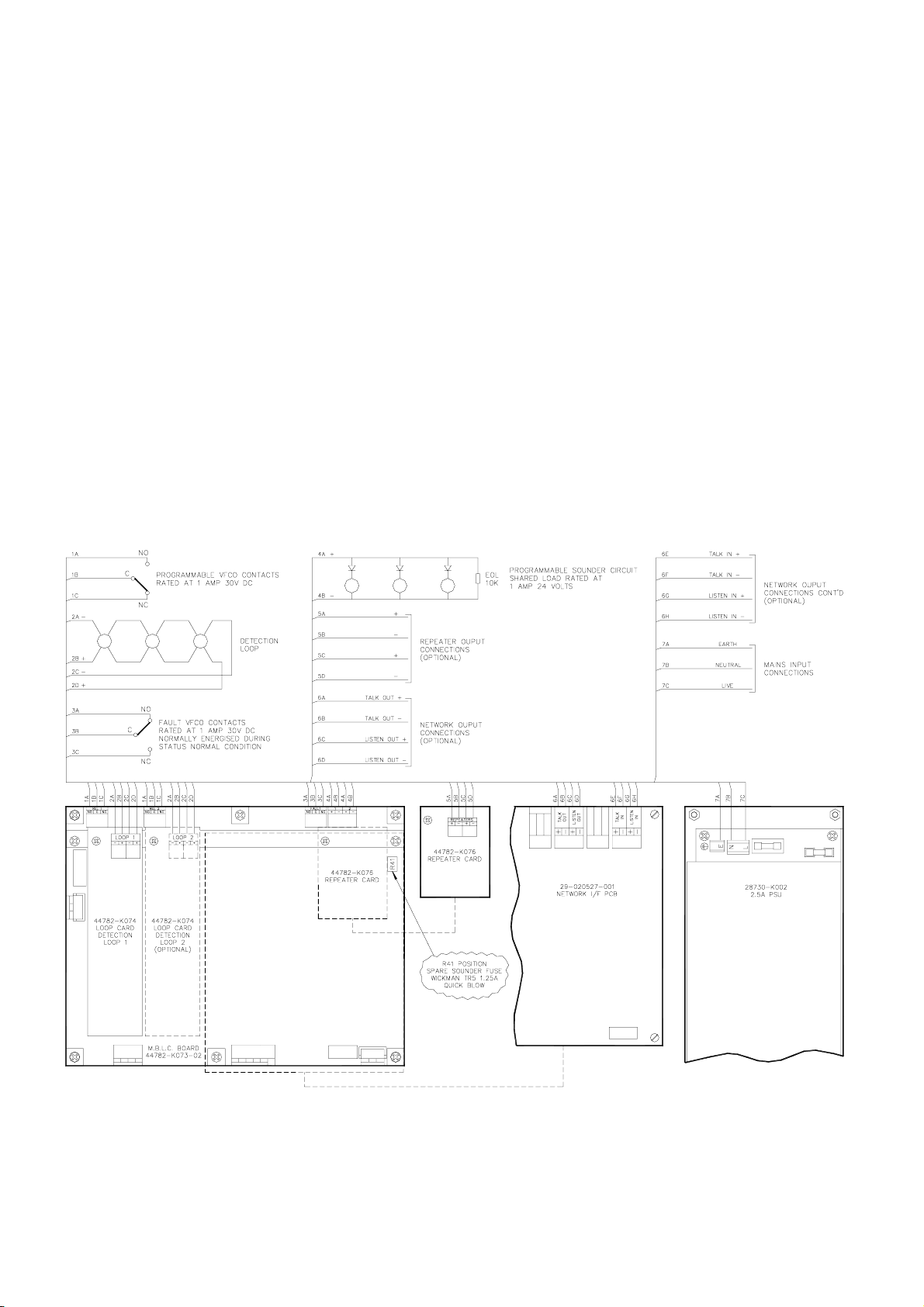

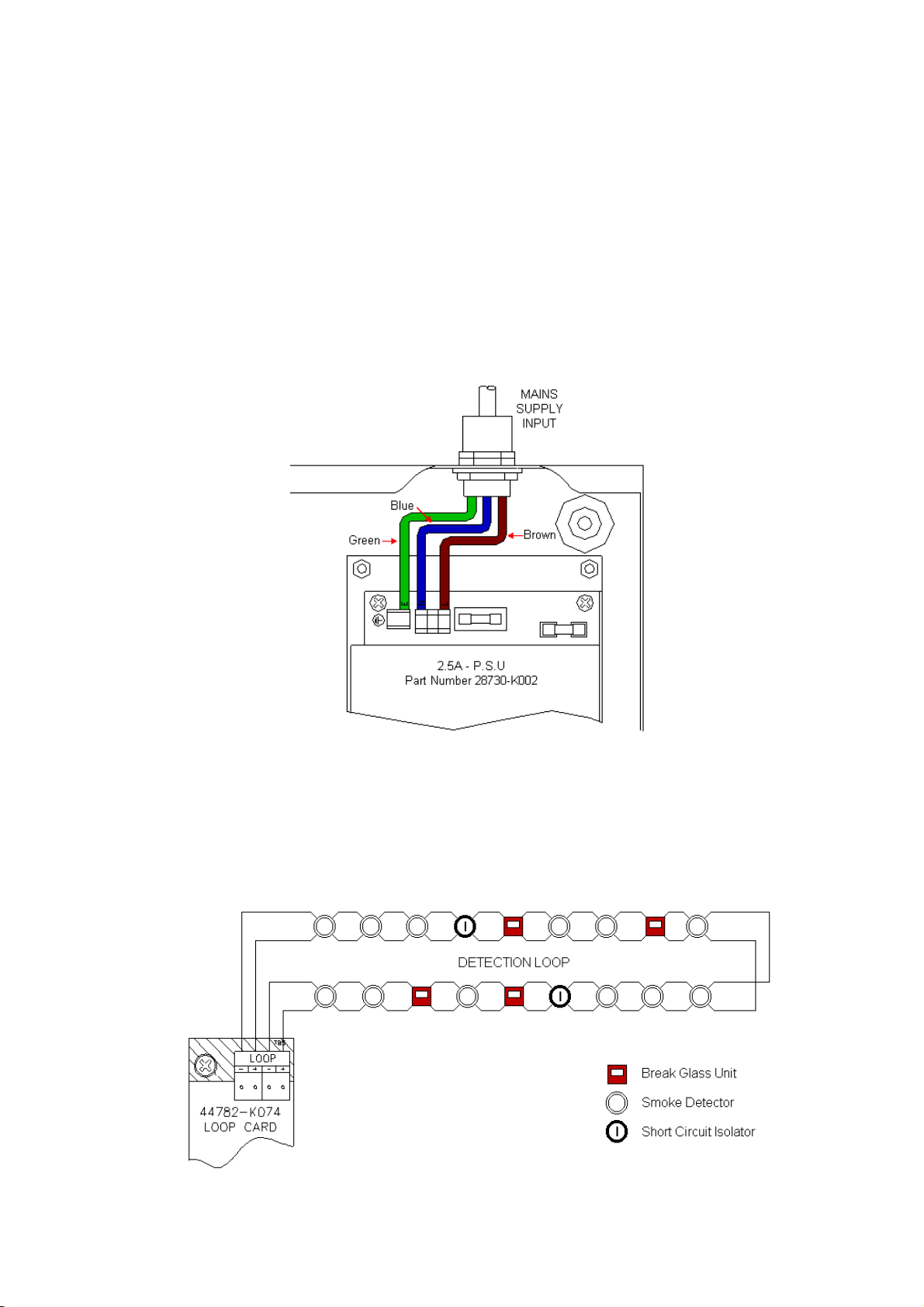

3.1 SYSTEM SCHEMATIC - Figure 2

Figure 2: System Schematic Diagram

The control panel has a number of internal 2.5mm terminals for connection to the external field cables.

TM0081 Page 7 of 51 Issue 1.01

Page 8

3.2 APPROVED CABLES

To comply with EMC (Electro Magnetic Compatibility) regulations and to reduce the risk of electrical interference

in the system wiring, it is recommended that screened cables be used throughout the installation. Reference to

BS 5839 part 1, states there is two categories of cable,

!

Category 1: required to operate for prolonged periods during a fire condition

!

Category 2: not required to operate for prolonged periods during a fire condition

Cables complying to BS 6387 categories C,W, Z can be used for both categories 1 and 2, Cables deemed

suitable as Category 1 can be used as category 2, but not visa versa. The following commonly available

screened cables have been approved for use on sounder and detection circuits:

!

Pirelli FP200 Gold™

!

MICC (Pyro™)

!

Firetuff™

!

Firecel™

Connection to the Kidde network and repeater panels should be made using Beldon 9729, UL2493 or MICC.

Satisfactory operation of the system with inferior cable types cannot be guaranteed especially when not wired in

accordance with to the appropriate regulations, i.e. loop wiring run in proximity to high voltage (AC mains and

above) cabling.

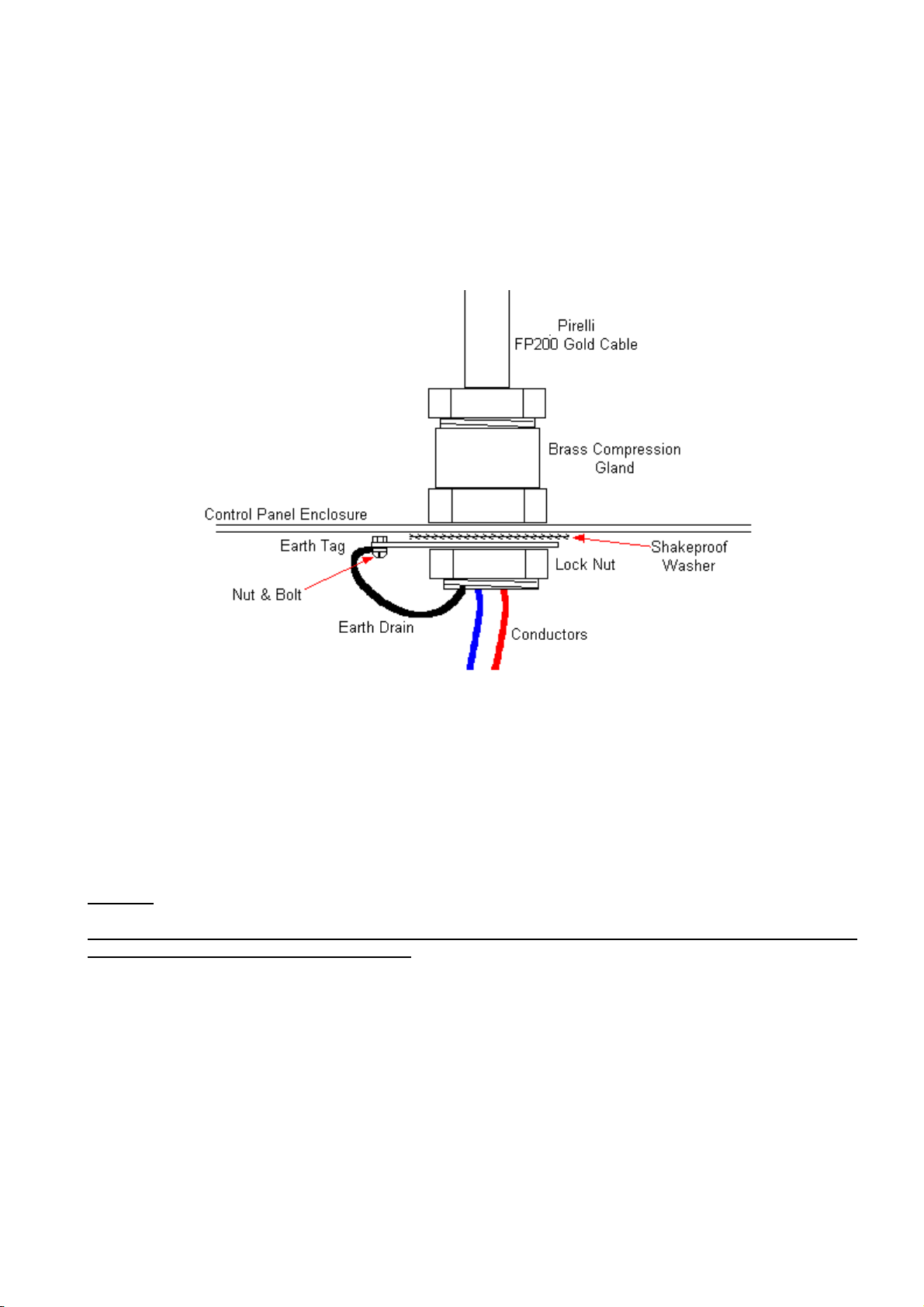

3.3 INTERNAL CABLE ROUTING

It is important that the following procedures on internal cable routing and cable terminations inside the control

panel are adhered to fully. These procedures have been established to ensure the control panel complies with

the European Directive on Electromagnetic Compatibility (89/336/EEC).

The external cables must be kept to an absolute minimum length from the cable entering the enclosure to the

terminating position on the relevant printed circuit board. Special attention should be made to ensure that cables

do not cross over other cables where possible, as this may generate interference/electrical noise.

The detection loop and sounder circuit cabling is classed as Low Voltage and should be segregated from mains

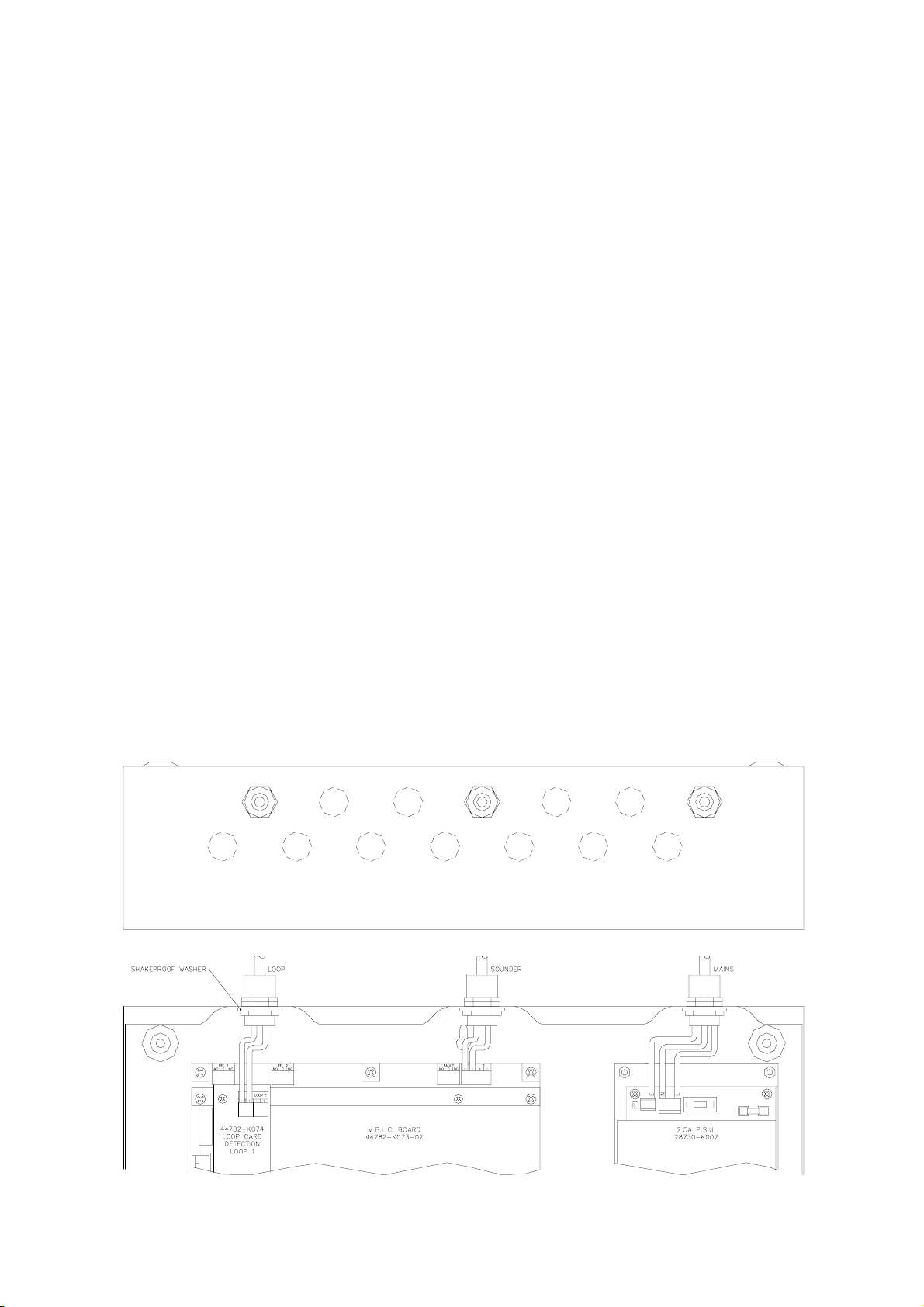

voltages. The pre-formed knockouts shown in figure 3 must be carefully removed, where required, using a flat

broad-bladed screwdriver and hammer. Use of excessive force should not be required and may damage the

enclosure around the knockout. The surrounding paint must be carefully removed to permit metal to metal

contact between the enclosure and cable gland.

Figure 3: Knockouts and Cable Routing

TM0081 Page 8 of 51 Issue 1.01

Page 9

Care must be taken to ensure metal filings or swarf does not fall onto the printed circuit boards. An adequate

number of pre-formed knockouts have been provided on the top of the enclosure so there should be no

requirement to drill any additional holes. Ensure that if a knockout is removed and unused, that the hole is filled

with a good quality cable gland that is securely blanked off.

3.4 ENCLOSURE MOUNTING

The control panel should be installed within the building to be protected at a prominent location and at a height

where it can be easily accessed during an emergency. The control panel should ideally be located in the

entrance, foyer or hallway of the building at eye level. The panel should not be positioned where conditions may

affect its performance. Areas prone to salt air, moisture, high humidity, physical abuse, and extreme

temperatures should be avoided.

Remove the control panel from its packing and unlock the door using the Allen Key provided.

Note, A spare parts bag is not provided with this control panel. Battery leads and End of Line resistors are

factory fitted to the associated output terminals. A spare sounder fuse is provided. Refer figure 2 for location.

Hold the panel to the wall at the desired mounting height and mark the position of the top centre keyhole. The

enclosure fixing positions are shown in figure 4. The keyhole is provided on the backbox to allow the panel to be

hooked onto the wall whilst the remaining four screws are located, marked and drilled accordingly. Secure the

panel to the wall using suitable fixings such that adequate support is provided.

Figure 4: Enclosure Fixing Positions

TM0081 Page 9 of 51 Issue 1.01

Page 10

3.5 EXTERNAL CONNECTIONS

3.5.1 Mains Wiring

The Vega LT control panel receives power from either a 230V, 50Hz or 120V, 60Hz power supply. The mains

supply cable must take the shortest route possible from entering the enclosure to the mains supply terminals.

Refer figure 5. The cable must maintain an air gap of 50mm minimum between it and any other conductors.

The mains supply requirement for the fire alarm panel is fixed wiring, using three core cable (no less than

0.75mm² and no more than 2.5mm²) or a suitable three conductor system and should be fed from an isolating

switched fused spur rated at 5amp. The fused spur isolator cover should be red and marked: FIRE ALARM –

DO NOT SWITCH OFF. The fused spur isolator must be fed from a dedicated switch or protective device at the

local mains supply distribution board.

The incoming power feed cable Earth (Green or Green/Yellow) wire should be connected to the terminal block

earth connection – Left hand terminal. The Neutral (Blue) wire should be connected to the middle terminal

marked (N) and the Live (Brown) wire connected to the right hand terminal marked (L). Refer to Figure 5.

Figure 5: Mains Supply Input

3.5.2 Detection Loop Wiring

The external detection circuit wiring should be wired to form a loop to allow the system to maintain a degree of

integrity and still function even if a section of cable becomes open circuit. It is also recommended during the

system design that short circuit isolators are fitted to the detection loop, so that in the event of an external short

circuit no more than 32 addressable devices will be lost. Refer to Figure 6.

Figure 6: Typical Loop Wiring

TM0081 Page 10 of 51 Issue 1.01

Page 11

The detection loop connections are made on the Loop card terminals marked LOOP. The loop card has built in

isolators so it is not required to fit additional isolators directly on the loop output. Additional short circuit isolators

should be fitted at the boundaries of each fire zone.

Reference should be made to the detector manufacturer’s data sheets and installation guides supplied with the

detector or module for information on terminal connection etc. Ensure that the devices connected to the

detection loop wiring are correctly orientated for positive and negative connections.

The detection loop cable must be stripped in accordance with the manufacturer's guidelines. The cable must be

secured to the enclosure using metal compression glands and metal locking nuts in conjunction with a metal

shake proof washer to ensure that the cable metal sheath is bonded to the enclosure. Refer to figure 7.

Figure 7: Loop and Sounder Circuit Compression Gland Details

When all bases are connected but before any devices are installed and with loop isolators linked out, the

following tests should be carried out: -

!

Loop short-circuit. Using an ohmmeter, check for short-circuit between +ve and -ve feeds.

!

Loop open-circuit. Check continuity of the +ve and -ve leads. +ve to +ve and –ve to –ve.

!

Loop short to earth. Check using an ohmmeter between the +ve and -ve leads and an earth connection.

Warning.

Do not undertake high voltage insulation testing on external wiring after loop devices are installed as

this could seriously damage the equipment.

TM0081 Page 11 of 51 Issue 1.01

Page 12

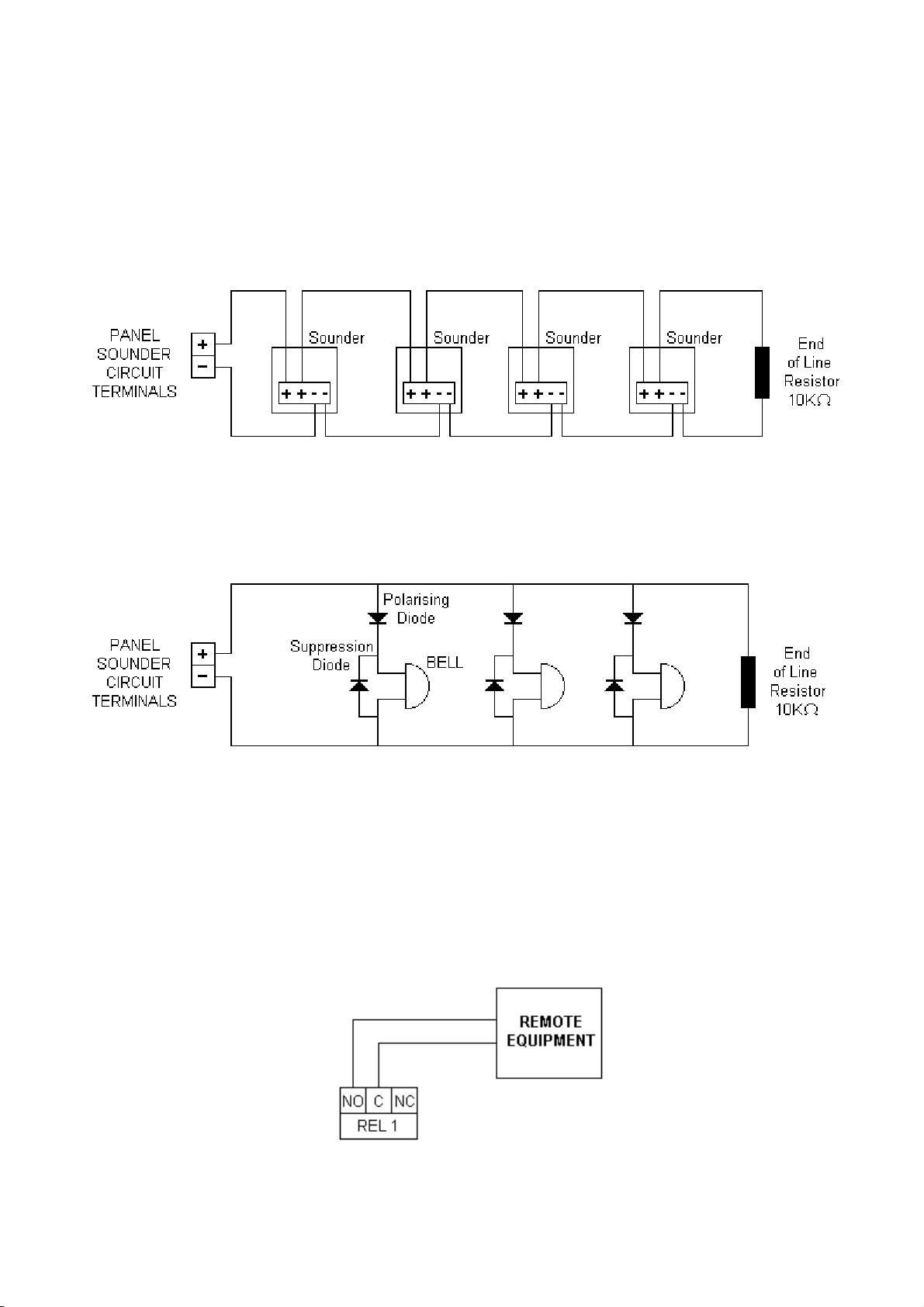

3.5.3 Sounder Circuit Wiring

Two programmable conventional sounder circuits are available on the control panel. Each circuit is rated at

1amp however it is recommended that the maximum total load shared between both circuits should not exceed

1amp. Each sounder circuit is monitored for open and short circuits. An end of line (EOL) 10 K" resistor 0.5W

minimum should be fitted after the last sounder attached to the circuit to allow the wiring to be monitored.

All sounders must be polarised, as non-polarised sounders will signal a fault condition on the control panel.

Refer to figure 8. Each sounder therefore must have an integral blocking diode that prevents the sounder from

using power during normal monitoring. The polarity of the sounder output voltage is reversed when the sounder

circuit is operated allowing the sounders devices to operate.

Figure 8: Typical Polarised Sounder Circuit Wiring

Should non polarised alarm devices such as mechanical bells be connected to the system, then a diode will

have to be placed in line with the device to prevent faults occurring and to enable fault monitoring. A

suppression diode will also be required across the device. Refer to Figure 9.

Figure 9: Typical Bell Circuit Wiring

The sounder circuit cable must be stripped in accordance with the manufacturer's guidelines and must be

secured to the enclosure using metal compression glands as shown in figure 7.

3.5.4 Auxiliary Output Wiring

Auxiliary Fire Output

Two voltage free (dry contact) changeover contacts are provided which operate during any fire condition and

can be used for driving local fire fighting equipment such as sprinkler systems, door release systems and roller

shutter doors etc. Refer to Figure 10.

Figure 10: Typical Auxiliary Fire Output Wiring

TM0081 Page 12 of 51 Issue 1.01

Page 13

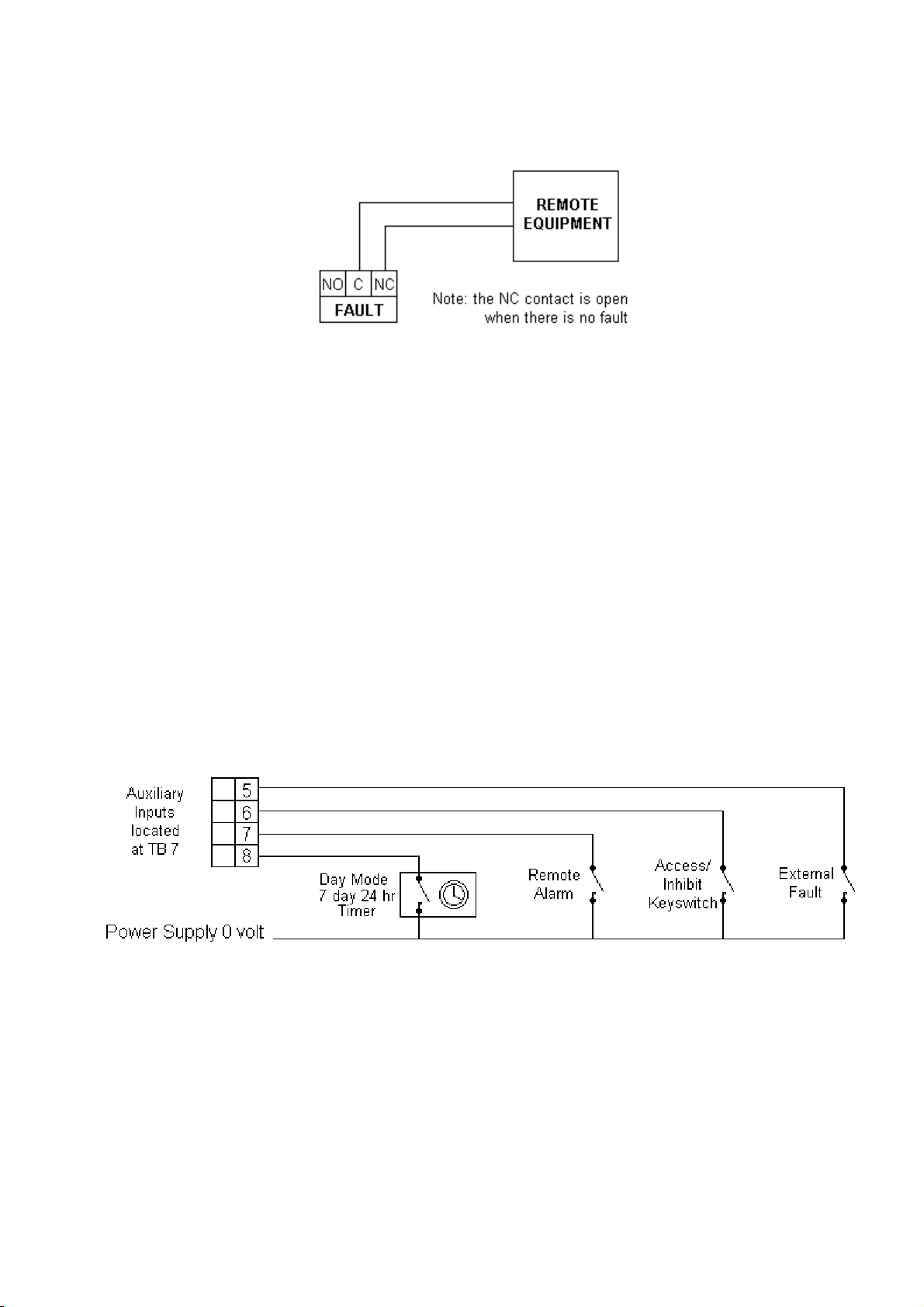

Auxiliary Fault output

A single voltage free changeover contact is provided and operates on any panel fault condition. This output is

failsafe and is normally energised. When a fault occurs, the output turns off to ensure failsafe operation, or

should the system suffer a failure to all power supplies. Refer to Figure 11.

Figure 11: Typical Auxiliary Fault Output Wiring

External cables connected to the auxiliary contacts should be secured to the enclosure using metal

compression glands as shown in figure7.

3.5.6 Auxiliary Input Wiring

Four non-latching input connections are available on the fire alarm panel. The inputs are located on the loop

processor card, part number 44782-K073 at terminal block TB7. Applying a 0-volt connection to the terminal

activates the inputs. Refer to Figure 12. The inputs are provided at the following terminal numbers: -

1 External Fault Input

2 Level 2-access/inhibit override

3 Programmable Input A

4 Programmable Input B

The programmable input settings are:

!

Remote Alarm (Class Change): operates the sounders continuously (default setting for input A) or

!

Day Mode: initiates pre programmed day mode settings (default setting for input B) or

!

Isolate Outputs: inhibits the operation of pre-programmed isolation group setting

Figure 12: Typical Auxiliary Input Wiring

Cables connected directly to the auxiliary inputs should not be taken external to the control panel. Interposing

relays located within interface enclosures and mounted directly adjacent to the control panel should be used.

TM0081 Page 13 of 51 Issue 1.01

Page 14

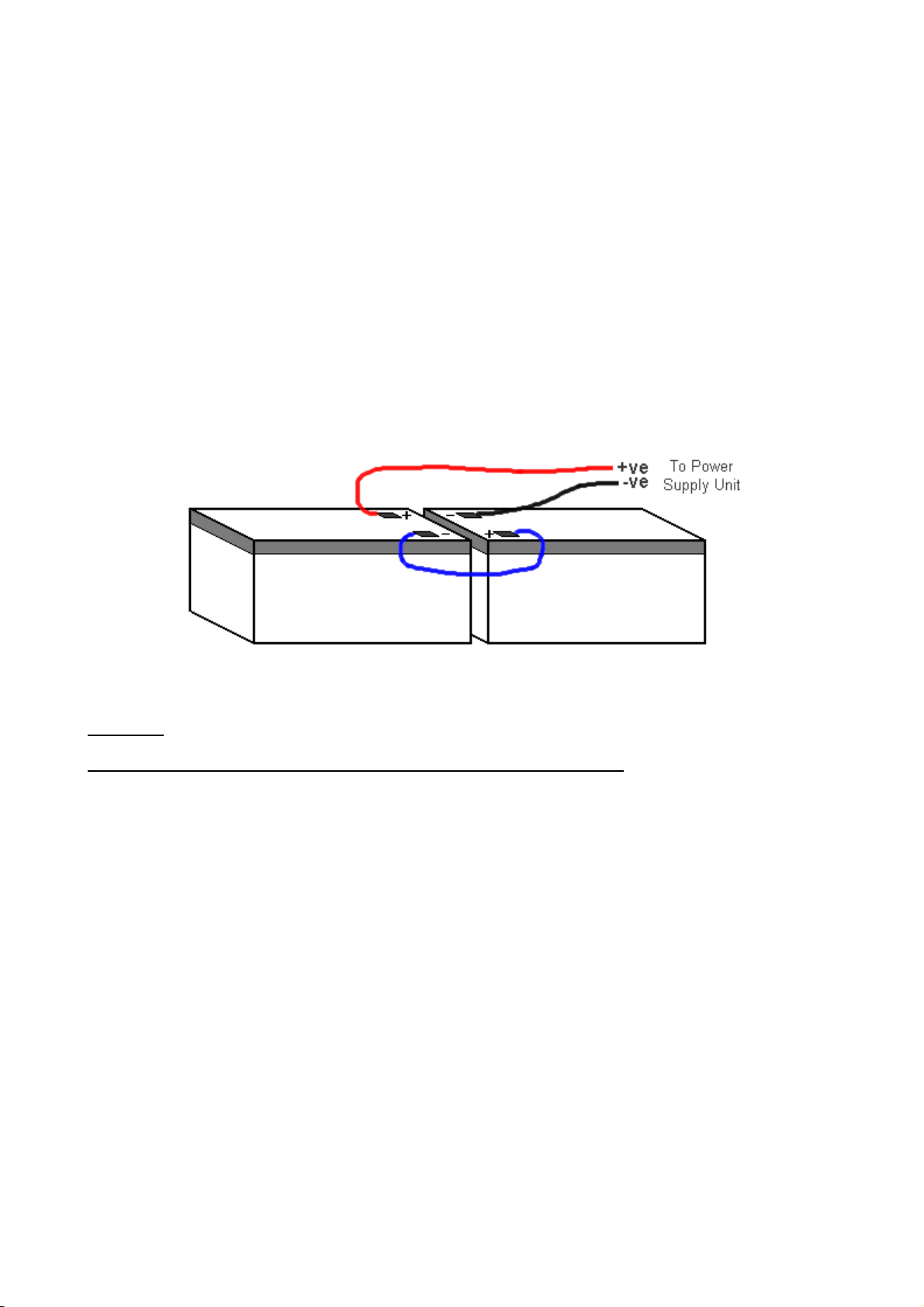

3.5.7 Battery Installation

To provide an emergency battery back up facility in the event of mains failure for the system, two new fully

charged 12 volt sealed lead acid batteries are required. The batteries should be connected in series using the

battery leads connected to the power supply unit and should be located in the bottom left hand corner of the

control panel enclosure. The enclosure has space for 2x 12 Ah SLA batteries. The capacity of the batteries used

will depend upon the required stand-by time and the system configuration. For battery sizes greater than 12 Ah

these should be installed in a separate enclosure suitable for fire protection equipment using appropriate metal

gland fixings and cables.

Before installing the batteries carry out the following procedures:

!

Check the batteries for transit damage.

!

Check the battery open circuit terminal voltage.

!

Record the installation date.

The +ve of one battery is connected to the red battery lead and the –ve of the second battery is connected to

the black battery lead. The –ve of the first battery is connected to the +ve of the second battery using the battery

link supplied. Refer to Figure 13.

Figure 13: Internal Battery Connections

CAUTION:

Do not connect the batteries to the power supply unit leads at this stage.

The control panel power supply unit has a thermistor, which monitors the temperature of the batteries and

automatically adjusts the charging current accordingly. This should be placed as close as possible to the first

battery.

3.5.8 Network and Repeater Cable Wiring (Optional)

When connecting to optional network and repeater wiring, the outer insulating sheath of the cable must be

removed using a proprietary cable stripper. This will expose a number of cable pairs, which will be individually

wrapped in a protective sheath. This sheath must be folded back over the remaining outer insulating sheath and

the metallic compression gland to ensure that the protective metallic sheath has a permanent bonding to the

enclosure. The compression gland must be secured to the enclosure using a metal locking nut in conjunction

with a metal shake proof washer.

TM0081 Page 14 of 51 Issue 1.01

Page 15

4. ACCESS CONTROL LEVELS

The Vega LT has four levels of system control. Refer to Table 1. The control panel will indicate the true status

condition of the installation during all four levels using the membrane display panels. Pass codes are entered on

the numeric keypad. Each operation of the keypad operates an internal buzzer and updates the liquid crystal

display to confirm entry.

Access

Level

1Normal

2 User 7179 All control buttons are functional with restricted menu

3 Engineer &

4Kidde

The operation of the control panel is dependent upon the selected pass code, as certain keys only operate in

specific access levels. Table 2 details the control keys and the access levels they are allowed to operate in.

Operating

Level

operation

Installer

Engineer

Control Button Access Level 1 Access Levels 2&3

Numeric Keys

Cancel (←)

Enter (↵)

Arrow Keys

Silence Buzzer

Scroll

Delay Override

Silence Alarms Reset Evacuate -

Default Pass

Code

N/A Control buttons inhibited. During an alarm condition certain

7134 All control buttons are functional, All menu levels become

N/A As level 3 with option to clear panel memory back to factory

""

""

""

""

""

""

""

Comments

control buttons are functional.

access. System configuration inhibited.

available and system configuration is possible.

default setting.

Table 1: Access Levels

"

"

"

Table 2: Control buttons

4.1 ACCESS INHIBIT KEYSWITCH

An input terminal (TB7) labelled input 6 is positioned on Master Basic Loop Controller MBLC card (refer to

Figure 12 for wiring information) which when shorted to 0-volts, via a switch, causes the control panel to enter

into access level 2. Only by removal of the 0-volt input to the terminal will the access level be terminated.

TM0081 Page 15 of 51 Issue 1.01

Page 16

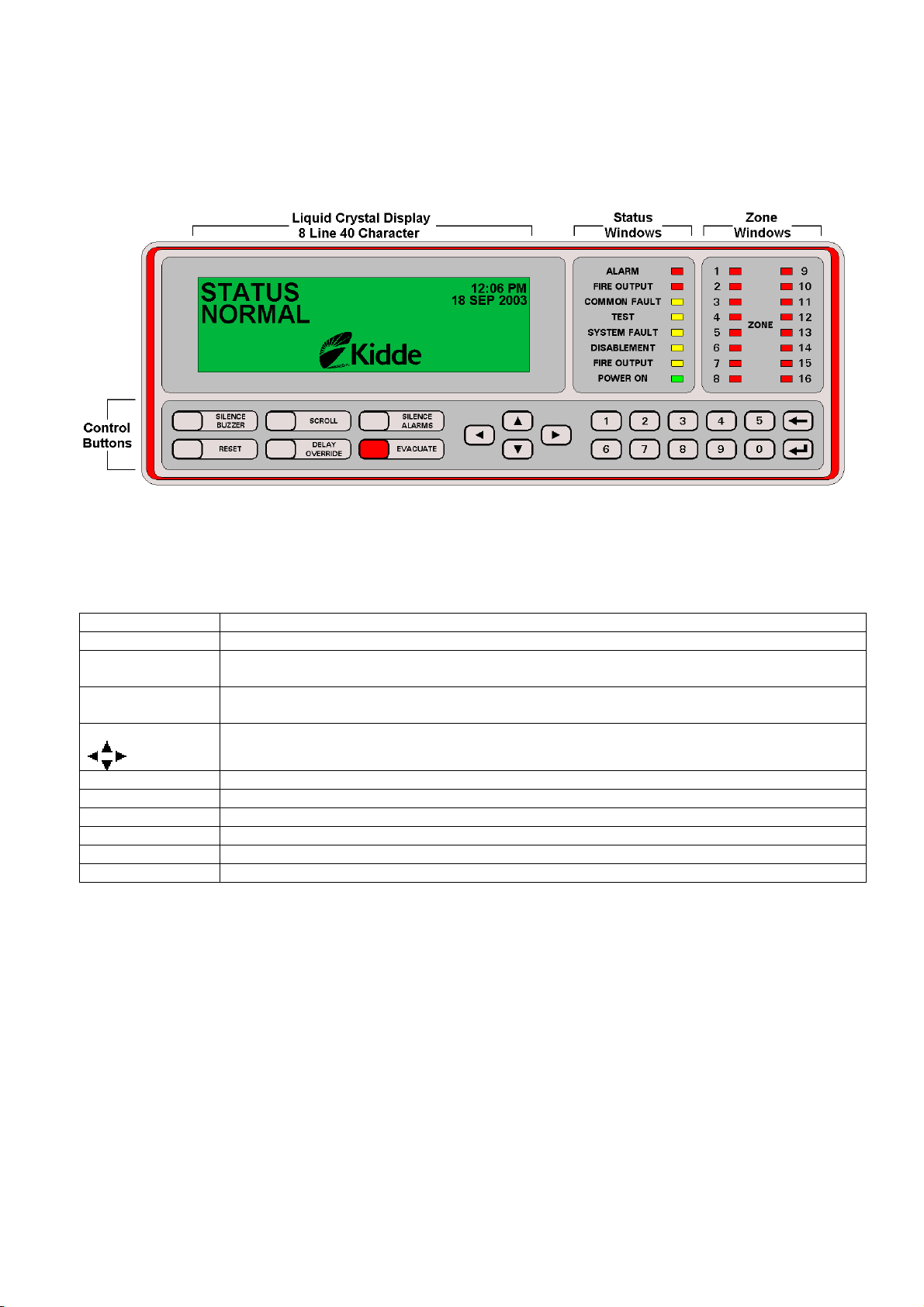

5. CONTROLS AND INDICATION

5.1 PANEL DISPLAY

The Vega LT front panel display is divided into four discrete sections containing the control buttons, zone

windows, status windows and liquid crystal display (LCD). Refer to Figure 14.

Figure 14: Front Panel Display

5.2 CONTROL BUTTON FUNCTIONS

The control buttons located on the panel front perform a number of operations. Refer to Table 3.

Control Button Function

Numeric Keys Allows the user to enter numbers 0 – 9.

Cancel (

Enter (

Arrow Keys Allows the user to scroll through menu display options, active alarm messages and view

Silence Buzzer Silences the internal buzzer for any fire or fault alarm condition.

Scroll Press to display the next alarm message at the current event level.

Delay Override Overrides any pre-programmed delays and immediately operates the outputs.

Silence Alarms Press to turn off All sounder circuits

Reset Press to cancel All fire & fault alarm conditions and reset the system back to normal.

Evacuate Press to turn on All sounder circuits and evacuate the building.

←←←←

)

↵↵↵↵

)

Allows the user to answer No, quit menu display options or terminate access levels 2 & 3

completely.

Allows the user to answer Yes, enter menu display options, and confirm input for numeric

information.

priority pending alarm messages. Also used during programming of the control panel.

Table 3: Control Button Functions

TM0081 Page 16 of 51 Issue 1.01

Page 17

5.3 STATUS WINDOW INDICATION

The status windows located on the front of the control panel provide the user with system indications. Refer to

Table 4.

Indicator Colour Function

Fire Red Pulses when the panel detects a new fire condition, continuous when the user

has silenced the alarms.

Fire Output Red Pulses during any fire condition when pre-programmed outputs assigned to Fire

Alarm Routing equipment operate, continuous when alarms are silenced.

Common Fault Yellow Pulses when the panel detects an internal or external fault condition.

Test Yellow Pulses when system in test mode. Operates in conjunction with zone indications.

System Fault Yellow Constant when main processor card is reset or a system fault has occurred.

Disablement Yellow Constant to indicate the user has isolated some part of the system, zone or

individual input or output device.

Fire Output Yellow Pulses to indicate a fault condition on output(s) assigned to Fire Alarm Routing

equipment.

Power On Green On when power supply is present, mains or battery.

Table 4: System Status Indications

5.4 LIQUID CRYSTAL DISPLAY LAYOUT

The liquid crystal display (LCD) provides graphical information to the user and is back lit to provide enhanced

viewing under low ambient lighting conditions. The LCD provides 8 lines of 40 characters with information

presented to the user in pre-defined locations depending upon the type of alarm, or user prompt. The display is

generally divided into five discrete areas. Refer to Figure 15.

Area 1 (line 1 & 2) is reserved for the priority alarm header text and is located in the top left-hand corner of the

display. Consisting of a maximum of 12 double height characters, the header text defines the type of active

alarm or status condition.

Area 2 (line 1 top right hand corner) is used to display date & time, current access level and low priority system

status information.

Area 3 (line 3) is used to display the total number of active alarms, by zone within the indicated priority queue

and to indicate to the user that further alarms may be present in lower priority queues.

Area 4 (lines 4,5 & 6) is used to display zone, group or system specific alarm information. For example, during a

priority one fire alarm condition, the first zone in a fire condition is displayed on line 4, the second zone line 5

and the fourth or last zone line 6. During a priority four, fault alarm condition line 4 is reserved for system faults,

line 5 zone faults and line 6 group faults.

Area 5 (line 7 & 8) is used for additional information relating to alarms shown on lines 4,5 & 6. To view the

additional alarm information press enter (↵) button.

Figure 15: Display layout

TM0081 Page 17 of 51 Issue 1.01

Page 18

6. OPERATION

6.1 STATUS NORMAL

Under normal operation conditions, the green POWER ON light is on. The remaining status and zone window

lights are off and the LCD status is as shown below.

Figure 16: Display – Status Normal Condition

6.2 GAINING ACCESS TO LEVEL 2 OR 3

To gain access to level 2 or 3 control buttons or menus from Status Normal condition, press any numeric button.

The display will them update as shown in Figure 17.

Figure 17: - Pass Code Request

Enter the four-digit pass code (7179) and press the enter (↵) button. A pop up message will appear to confirm

that the correct pass code has been accepted or not. Should an incorrect pass code be entered, repeat the

procedure. Once the correct pass code is entered the display will then update and the control buttons become

active. Access level status will be indicated on the display top right line. Refer to Figure 18.

Figure 18: Pass Code Accepted

If there is no activity of the panel control buttons for a 5-minute period, the Access Level automatically reverts

back to normal access level 1.

6.2 FIRE CONDITION

When a fire is detected:

!

The relevant red zone alarm light flashes

!

The red ALARM light flashes

!

The alarm sounder circuits are activated (unless delays are programmed)

!

An audible buzzer on the panel sounds

!

The event printer prints out the full alarm details (when installed)

!

The display updates providing the user with the alarm header text, total number of alarms, zone

number and 24 character zone location text. Refer to Figure 19.

TM0081 Page 18 of 51 Issue 1.01

Page 19

Figure 19: Fire Condition – Zone information

!

To view additional device information, press enter (↵) button.

!

The display updates providing additional device specific information, device loop, zone and address

numbers, total number of active devices within the zone, device type and 24 characters of device

specific location text. Refer to Figure 20.

Figure 20: Fire Condition – Zone & Device Information

Should additional fire conditions be detected within the same zone, then the total fire counter will increase and

the event printer prints out the full alarm details (when installed). The total number of active zones counter will

remain as one. Refer to Figure 21. The scroll button is used to view the additional device within the zone in

alarm.

Figure 21: Multiple Fire Conditions – Same Zone

Should a second zone fire condition be detected,

!

The relevant red zone alarm light flashes

!

The red ALARM light flashes

!

The alarm sounders circuits are activated (unless already active or delays are programmed)

!

An audible buzzer on the panel sounds

!

The event printer prints out the full alarm details (when installed)

!

The display updates providing the user with the alarm header text, total number of alarms, zone

number and 24 character zone location text. Refer to Figure 22.

Figure 22: Multiple Fire Conditions – Different Zones

Note, The highlighted zone location text indicates to the user which zone the device specific information relates

to. Using the navigation arrow keys in conjunction with the scroll button, the user can browse through the

various alarms present on the display.

TM0081 Page 19 of 51 Issue 1.01

Page 20

6.3 RESETTING THE SYSTEM AFTER A FIRE CONDITION

To silence and reset the system after a genuine fire condition within the building and to switch off the internal

audible buzzer:

!

Press the SILENCE BUZZER button (the audible buzzer stops, the zone light(s) and ALARM light

continue flashing. The audible alarm circuits continue to sound unless programmed off)

When the fire condition has been rectified, to reset the system:

!

Enter access level 2 using the appropriate pass code – default 7179.

!

The display will confirm access has been granted.

!

Press the SILENCE ALARMS button (the audible alarms stop). The red zone alarm light(s) and the

ALARM light stay on (If another zone alarm condition occurs, the new red zone alarm light and the

ALARM lights, the buzzer and audible alarms sound and the original red zone alarm stays on).

Note: if a second device within the original zone occurs, then the original zone light will begin to

flash again.

!

When all zone fire conditions have been rectified, press the RESET button. Press the cancel (←)

button. The panel reverts to access level 1.

Note: It is not possible to reset the panel until the SILENCE ALARMS button has been pressed.

If the fire condition still exists, the panel will revert to the alarm condition. To reset the panel it may be necessary

to clear smoke or heat from the detectors and to replace the glass in the manual fire call point.

6.4 FAULT CONDITIONS

When a fault occurs on a critical part of the fire alarm system, the panel responds by activating, in pulsed mode,

the internal audible buzzer and operating the COMMON FAULT light. The LCD display is updated with specific

information relating to the fault and the panels fault relay output is de-activated. Faults indicated on the LCD

display are categorised as System Faults, Zone Faults and Group Faults. Repairing any particular fault

condition will automatically clear the fault from the panel. If the panel is reset when faults are present, the faults

will reappear after a short period of time.

6.4.1 System Faults

System status faults generally relate to control circuits and monitoring inputs wired directly inside the control

panel. The types of system status faults are:

!

Earth faults

!

Loop faults

!

Repeater comms faults

!

MBLC \ SBLC comms faults

!

Power Supply fault

!

External fault

!

Log on fault

!

Config fault

!

Interrupt fault

If a system fault occurs on one of the circuits inside the control panel:

!

The yellow COMMON FAULT light flashes

!

An audible buzzer on the panel sounds intermittently

!

The event printer prints out the full alarm details (when installed and fully enabled)

!

The display updates providing the user with the alarm header text, total number of alarms, system

fault indication and total number of system faults present. Refer to Figure 23.

TM0081 Page 20 of 51 Issue 1.01

Page 21

Figure 23: System Fault

!

To review additional system fault information, press enter (↵) button.

!

The display updates providing additional system fault specific information. Refer to Figure 24.

Figure 24: System fault – Power Supply Fault

Should additional system faults be detected, then the total number of faults counter will increase. The total

number of active system faults will also increase. To view the new system fault information, press the enter (↵)

button followed by the scroll button. Refer to Figure 25.

Figure 25: System Fault Number 2 – Loop 01 Fault

6.4.2 Zone Fault Conditions

Zone faults generally relate to detection loop input type devices such as smoke detectors, heat detectors, break

glass units and the input channel of the input \ output module. These types of devices are programmed during

commissioning to geographical zone numbers located within the installation.

If a zone fault occurs, generally as a result of a faulty loop device:

!

The yellow COMMON FAULT light flashes

!

An audible buzzer on the panel sounds intermittently

!

The event printer prints out the full fault alarm details (when installed and fully enabled)

!

The display updates providing the user with the alarm header text, total number of alarms within the

fault priority queue, zone fault information and total number of zone faults present. Refer to Figure

26.

Figure 26: Zone Fault Condition

Note: Figure 26 shows an example of multiple faults – Total number of priority 4 fault conditions is 3, 2 x system

faults and 1 x zone fault.

TM0081 Page 21 of 51 Issue 1.01

Page 22

!

To review additional zone fault information, press enter (↵) button.

!

The display updates providing additional zone fault specific information. Refer to Figure 27.

Figure 27: Zone Fault Condition – Zone & Device information

6.4.3 Group Fault Conditions

Group faults relate to detection loop output modules such as sounder circuit controllers, loop powered sounders

and the output channel of the input \ output modules. These types of devices are assigned during

commissioning to output group numbers, which are then programmed into cause & effect strategies. Output

groups then operate during a zone priority 1 fire condition ringing sounders, bells and operating shutdown etc.

Note: Input devices (Smokes, Break Glass, Input modules) are assigned to Zones while output devices

(Sounder modules, Output modules & Loop sounders) are assigned to output groups.

If a group fault occurs, generally as a result of a faulty loop device:

!

The yellow COMMON FAULT light flashes

!

An audible buzzer on the panel sounds intermittently

!

The event printer prints out the full fault alarm details (when installed and fully enabled)

!

The display updates providing the user with the alarm header text, total number of alarms within

the fault priority queue, group fault information and total number of group faults present. Refer

to Figure 28.

Figure 28: Group Fault Condition

!

To review additional zone fault information, press enter (↵) button.

!

The display updates providing additional group fault specific information. Refer to Figure 29.

Figure 29: Group Fault Condition – Group & device Information

TM0081 Page 22 of 51 Issue 1.01

Page 23

7. PRIORITY ALARM STRUCTURE

The Vega control panel has 10 priority alarm queues which will determine how the panel will respond to an

alarm condition. The default settings for loop detectors and panel associated fault conditions are set

accordingly:

!

Fire condition Priority 1

!

Pre-alarm condition Priority 3

!

Fault condition Priority 4

Using the priority structure in conjunction with the header text, systems can be customised to enable alarms of a

more critical nature to override those of lesser importance. The header text is used to differentiate the type of

alarm on the display while the priority queue number will determine what parameters are available to be used.

Refer to Table 5.

Priority

Level

0

1

2

3

4

5

6

7

8

9

Header

Text

Alarm Handling Indication

Latching Non

Latching

LCD

Display

Status

LED

Zone or

Plant

Buzzer Printer

Output

Control

Evacuate Yes No Yes Alarm Zone On Yes Program

Fire Yes No Yes Alarm Zone On Yes Program

Alert Optional Optional Yes None Zone On Yes Program

Pre-alarm No Yes Yes Pre-alarm Zone Pulsed Yes No

Fault No Yes Yes Fault Zone Pulsed Yes No

Unassigned Optional Optional Yes None Z or P Pulsed Yes Program

Unassigned Optional Optional Yes None Z or P Pulsed Yes Program

N/A No Yes No None Plant No Yes Program

N/A No Yes No None Plant No No Program

N/A No Yes No None Plant No No Program

Table 5: Priority Alarm Structure

8. FIRE & PLANT ZONE INDICATIONS

The control panel has the facility to display a maximum of 16 Fire zone alarms using both the LCD display and

the 16 LED zone indications. A further 104 zones can be configured which are indicated on LCD display only

therefore providing a maximum of 120 fire zones.

Plant zones can be described as non-fire related zones and although there are no LED indications available

plant zones can still be configured for use within the control panel. Each individual input device can be assigned

to a fire zone or plant zone.

9. MENU STRUCTURE

9.1 MAIN MENU

Access to the top-level menu structure can be performed at Access Level 2 or greater. This can be achieved

during an alarm condition or from the Status Normal condition by entering the appropriate pass code followed by

the operation of a numeric button 0 to 9. Refer to Figure 30.

Figure 30: Display – Level 3 Main Menu

TM0081 Page 23 of 51 Issue 1.01

Page 24

9.2 ISOLATE \ DE-ISOLATE MENU

The isolate menu list Table 6 provides the user dependent upon Access level with the following options.

ISOLATE – Menu Functions

Sub-Menu 1 Sub- Menu 2 Access

Level 2

Zones

Loop devices Single device

Isolate range

De-Isolate range

Output groups Single groups

""

""

""

""

""

Isolate Range

De-Isolate Range

Panel functions BLC outputs

""

""

Access

Level 3

Function

Enter fire zone number to be isolated and confirm isolation

using enter (↵)

isolate, select isolated (flashing) zone from list and press

enter (↵) button to de-isolate.

Enter loop & device parameters and confirm isolation using

enter (↵) button from the list of devices presented. To de-

isolate, select isolated (flashing) device from the list and

confirm de-isolation using enter (↵) button.

Enter range of device parameters and confirm isolation

using enter (↵) button.

Enter range of device parameters and confirm de-isolation

using enter (↵) button.

Enter output group number and confirm isolation using enter

(↵) button from the list of output groups presented. To de-

isolate the output group, select isolated (flashing) group

from the list and confirm de-isolation using enter (↵) button.

Enter range of output group numbers and confirm isolation

using enter (↵) button.

Enter range of device numbers and confirm de-isolation

using enter (↵) button.

Select from the list the MBLC output to be isolated and

confirm isolation using enter (↵) button. To de-isolate, select

(flashing) output to be de-isolated and press enter (↵)

button.

button from list of zones presented. To de-

Motherboard - - N\A

Plant

Local Buzzer -

""

"

Enter plant zone number to be isolated and confirm isolation

using enter (↵)

isolate, select isolated (flashing) zone from list and press

enter (↵) button to de-isolate.

button from list of zones presented. To de-

Table 6: Isolation \ De-isolation Menu

TM0081 Page 24 of 51 Issue 1.01

Page 25

9.3 LIST MENU

The List menu Table 7 provides the user dependent upon Access level with the following options. When the

event printer is installed within the control panel, the user will also have the option to view or print the requested

listing.

LIST – Menu Functions

Sub-Menu 1 Sub- Menu 2 Access

Level 2

Zones All Zones

Zone Information

Loop devices Single loop

Device range

""

""

""

""

Forward scan Reverse scan Analogue values -

Single device value -

Loop current Loop integrity -

Output groups All groups

Group information

Panel functions BLC outputs

""

""

""

Access

Level 3

"

"

"

"

"

"

Function

View text message allocated to each fire zone.

View fire zone parameters (T1, T2, BGU override & double

knock) and devices assigned to the zone.

View all devices connected to the specified loop. Provides

device type, text message & zone allocation.

View range of devices attached to specified loop. Provides

device type, text message & zone allocation.

View devices in one direction only. Used to identify break or

open circuit on loop detection cable.

View additional analogue threshold values, current & fire

levels for each individual device attached to specified loop.

View a specified device information including type, text

message & threshold values.

Determine the amount of current used by the detection loop.

View the number of scans against errors reported by the

detection loop since the last panel reset.

View text message allocated to specified range of output

groups.

View output group parameters (T3, T4, Evacuate, silence &

activation control) and devices assigned to the group.

View MBLC Sounder & Relay output location text

messages.

Motherboard - - N\A

Plant All plants

Plant information

Isolations Zones

Loop devices

Output groups

Panel functions

Plant

Event log All events

Range (date) Priority event -

Engineer info Panel setup -

Activations -

Fault codes Logon faults -

Config faults -

Loop quantity -

Database Check EOC indexs -

""

""

""

""

""

""

""

""

"

"

"

"

"

"

"

"

"

"

View text message assigned to the plant zones (when

installed).

View devices assigned to plant zones (when installed).

View complete isolated fire zones.

View single devices that are currently isolated.

View isolated output groups.

View isolated MBLC sounder and or relay outputs.

View isolated plant zones.

View all events occurring on the panel in date \ time order.

View events for the specified date.

View events by priority (1 = Fire events)

Review the setup configuration for the control panel.

Review the cause & effect strategy for a specified Fire zone,

Device, plant Zone or Output group.

View the list of engineers fault codes.

View new devices that have not currently been accepted

onto the system. Adding or removing devices from the

detection loop will produce a logon fault.

Download configuration device faults. Devices that do not

match the VIPER upload download site file.

View the total number of devices present on each detection

loop.

Not applicable

Not applicable

Table 7: List Menu

TM0081 Page 25 of 51 Issue 1.01

Page 26

9.4 SET MENU

The Set menu Table 8 provides the user dependent upon Access level with the following options.

SET – Menu Functions

Sub-Menu 1 Sub- Menu 2 Access

Level 2

Time & Date

Printer Status Printer type

Printer status

Select type

Select status

Activate day

Day mode status

""

""

""

""

""

""

Access

Level 3

Function

Enter revised Time, select AM or PM, 12 hr or 24 hr format

and enter Day/Month/Year and press enter (↵) button to

confirm.

Confirms the type of printer currently installed. Standard Dot

Matrix or Thermal type. Note: Vega LT uses Thermal only.

Confirms the current status of the printer – enabled or

disabled.

Select type of printer installed – Standard or Thermal and

press enter (↵) button to confirm selection.

Controls the operation of the printer – Select Enable or

Disable and press enter (↵) button to confirm. Note: When

the printer is installed correctly and disabled status is set,

the printer will automatically print priority 0 & 1 events.

Confirms the current day mode status – active or inactive.

mode

Select status

Standard features Custom features Clear memory Zone info -

Plant info Group info -

Device info BLC outputs Activations Motherboard info -

User passwords Change level 2 -

Change level 3 -

Loop config Accept logon

count

Accept config

count

Autolearn -

""

"

"

"

"

"

"

"

"

"

"

"

-

-

"

"

"

Controls the operation for day mode – Select Activate or

Deactivate and press enter (↵) button to confirm.

Refer to Programming section of this manual.

To clear Fire Zone info - press enter (↵) button to confirm.

To clear Plant Zone info - press enter (↵) button to confirm.

To clear Output Group info - press enter (↵) button to

confirm.

To clear loop device info - press enter (↵) button to confirm.

To clear MBLC info - press enter (↵) button to confirm.

To clear Activations info - press enter (↵) button to confirm.

N/A

Enter new level 2 pass code ####, Re-enter new level 2

code #### and press enter (↵) button to confirm.

Enter new level 3 new pass code ####, Re-enter new level

3 pass code #### and press enter (↵) button to confirm.

An option is provided to view new devices added or

removed from the specified detection loop. Select ‘Yes’ and

press enter (↵) button to confirm devices accepted.

Download configuration device faults. Devices that do not

match the VIPER upload download site file are flagged as a

config fault and are listed.

Enables the user to automatically re learn devices for the

specified loop number.

Table 8: Set Menu

TM0081 Page 26 of 51 Issue 1.01

Page 27

9.5 TEST MENU

The Test menu Table 9 provides the user dependent upon Access level with the following options.

Sub-Menu 1 Access

Level 2

Panel Test

""

Device Test -

Output group test -

Alarm simulation -

Key test -

Test mode -

Access

Level 3

"

"

"

"

"

Function

Press enter (↵) button to initiate a panel LED, LCD display & Buzzer test and MCP

software version installed.

Enter the device parameters to be tested and press enter (↵) button to confirm.

Automatic detectors pulse the base alarm LED during the test.

Enter the output group number to be operated and press enter (↵) button. WARNING,

ensure that output groups programmed to operate release units are isolated locally.

Press silence alarms button to de-activate the output group and reset to select a new

group to be tested or cancel to return to menus.

Enter the device parameters to be tested and press enter (↵) button. WARNING,

Output Groups will operate, ensure that groups programmed to operate release units

are isolated locally. Press silence buzzer, silence alarms & reset buttons to return to

status normal.

Press enter (↵) button to initiate test and operate fascia key buttons as required. To

exit test option, press the cancel (←) button.

Select activate & press enter (↵) button. Enter zone number to be tested & press enter

(↵) button. To quit zone test mode, select de-activate & press enter (↵) button.

Table 9: Test Menu

TM0081 Page 27 of 51 Issue 1.01

Page 28

10. COMMISSIONING

The total system should be tested in accordance with the commissioning requirements of the relevant standards

or national codes. Commissioning is to be carried out only after successfully completing the installation of the

systems as per the installation instructions.

10.1 SYSTEM CHECKS

Check that the system has been installed to the project requirements as defined by the “As Fitted Drawings” and

if appropriate, instruct the installer to carry out changes to the system. Using a multimeter, check to ensure that

the mains supply is NOT present and take the precautionary steps to avoid accidental application of the supply.

10.2 INITIAL POWER UP

Disconnect any cables connected to terminals located within the control panel such as loop, sounder and

auxiliary circuits. Ensure that all external wiring is clearly identified and using a multimeter, check that the cables

are free from fault conditions such as earth, short-circuit and open circuits.

Connect insulated wire links to the loop terminals, +ve to +ve and –ve to –ve and fit end-of-line 10K resistors to

all sounder output terminals.

Before powering up the panel, carry out these preliminary checks:

!

Check for any visible signs of damage that may have been caused during the installation.

!

Verify that all installation instructions have been adhered to.

!

Physically check that all PCBs are secured in their mountings

!

Check all ribbon cables are secured and correctly connected.

!

Check all temporary cable terminations are secured.

!

All damage and/or faults must be rectified before proceeding.

CAUTION:

Always apply mains power first. Do not power up using battery first as this may damage critical

components.

Apply the mains supply from the remote source. Using a multimeter check that the supply is present at the onboard mains terminals (110 or 230 Vac) and check that the panel performs the following:

1. The POWER ON status light comes on.

2. The SYSTEM FAULT status light comes on.

3. The internal buzzer operates in a constant mode.

4. The LCD display updates and confirms operation of system diagnostics and verification routines in

progress.

5. The fault relay de-energises.

After a short period of time the panel performs the following:

1. The COMMON FAULT status light flashes.

2. The PSU FAULT status light flashes.

3. The display updates and confirms a FAULT – ‘BLC 1 power supply flt’ is present.

The SYSTEM FAULT status light can be reset by the operation of SW2 marked RESET located within the

control panel on the MCP card, part number 44782-K071.The internal buzzer can be silenced by operation of

the SILENCE BUZZER button located on the front of the panel.

Connect the batteries to the power supply unit as detailed in the previous section and check that the panel

reverts to normal condition and the POWER ON status light is on and the display reads STATUS NORMAL.

Note: the panel display may indicate a SYSTEM FAULT - ‘BLC 1 Loop 01 logon flt’ condition as devices that

were previously logged onto the panel during its last power up are no longer attached. The fault can be cleared

using the ‘accept logon count’ menu option located at Set→Loop config→Accept logon count. (Refer to

Table 8) Select ‘Yes’ to accept revised logon count. This will remove the previous devices logged onto the panel

from its memory. No other faults should be present at this stage and if faults exist they will require clearing

before continuing.

TM0081 Page 28 of 51 Issue 1.01

Page 29

10.3 POWERING DOWN

To switch the control panel off always disconnect the batteries first followed by the mains ac supply.

10.4 CONNECTING THE DETECTION LOOP

With the control panel switched off to prevent accidental damage. Use an Ohmmeter to re-check the external

detection loop wiring to the control panel.

!

Check for continuity of the feed and return of the +ve and -ve legs of each detection loop.

!

Check that the +ve and -ve legs of each loop has a reading greater than 20M ohm with respect to the

panel earth stud.

Remove the wire links from the loop 1 terminals on the terminal board and insert the loop connections observing

the polarity (+ and -).

Power up the control panel (refer 10.2) remembering to apply the mains ac supply first.

The system will perform a number of calibration diagnostic routines, which can be viewed on the display. Each

detector address is checked to determine the device type. If more than one device is located at the same

address, or the type code is invalid a fault will be indicated on the display after the logging on process has

finished. Do not press any panel buttons during the logging on process. Upon completion check the following:

!

The panel will indicate a SYSTEM FAULT - ‘BLC 1 Loop 01 logon flt’ due to the newly added

device(s). Clear the fault using the ‘accept logon count’ menu option located at Set→Loop

config→Accept logon count. (Refer to Table 8) Select ‘Yes’ to accept revised logon count.

!

Check that the panel reverts to normal condition and the POWER ON status light is on and the display

reads STATUS NORMAL.

!

Check no other faults are present at this stage and if faults exist on the detection loop they will require

clearing before continuing.

!

Check that all devices attached to the detection loop are being monitored by the control panel. Use the

list loop device menu option to view the device attached. (Refer to Table 7)

!

Check the loop listings against installation drawings or programming sheets etc.

Repeat the above procedure for further detection loops to be connected to the control panel.

10.5 ADDING OR REMOVING LOOP DEVICES

Detection loop devices can be added or removed from the control panels memory using one of the following

procedures. The procedure used depends mainly upon the criteria for the work involved when adding or

removing the device(s) from the system.

Note: The detector manufacturers recommend that devices should be powered up for a minimum of 5 minutes

to enable optimum operational temperatures to be reached and calibration routines completed before the control

panel takes the returned data as valid information.

10.5.1 Power Down

Where the installation loop cabling has to be broken or disconnected at the device base, and to reduce noise

induced within the signalling loop cable, which may cause unwanted false alarms, the preferred method is to

power down the control panel using the following procedure:

!

Power down the control panel before work commences – remember batteries first followed by mains.

!

Make the modifications to the detection loop cabling as required.

!

Fit or remove any new devices and bases.

!

Power up the control panel – mains first.

!

Wait until the panel has re-calibrated the loop count.

!

Accept the revised logon count as described in the previous section. (Refer to Table 8)

This procedure is also recommended when adding or removing break glass call points or interface modules to

the detection loop.

TM0081 Page 29 of 51 Issue 1.01

Page 30

10.5.2 Processor Restart

Where detector bases have been installed without the detector head and the detection loop wiring integrity is

maintained, a processor restart can be applied to add or remove devices from the system. This procedure

negates the requirement to power down the control panel and can also be used when changing device types.

The control panel will display appropriate fault conditions as the devices are added or removed from the

detection loop wiring. To apply a processor restart the internal buttons MUST be operated in the following order.

!

Fit, remove or change the device(s) located in the detector base(s).

!

Press the processor restart button (SW1) located on the MBLC card, part number 44782-K073.

!

Press the processor restart button (SW1) followed by the processor Reset button (SW2) located on the

MCP card, part number 44782-K071.

!

Wait until the panel has re-calibrated the loop count.

!

Accept the revised logon count as described in the previous section. (Refer to Table 8)

Note: A processor restart will request all detection loops to begin logging the attached detectors.

10.5.3 Auto Learn

The auto learn facility is available through the Set menu structure (Refer Table 8) and saves considerable time

when installing a system as it allows the user to specify the loop to be logged. It is recommended that the auto

learn option is only used where detector bases are pre-installed without the detector head and the detection

loop wiring integrity is maintained.

!

Fit, remove or change the device(s) located in the detector base(s).

!

Select the Auto Learn menu option Set→Loop config→Autolearn. (Refer to Table 8)

!

Enter the loop to be re-learned.

!

Wait until the panel has re-calibrated the loop count.

!

Accept the revised logon count as described in the previous section. (Refer to Table 8)

10.6 CONNECTING SOUNDER CIRCUITS

With the control panel switched off to prevent accidental damage. Use an Ohmmeter to re-check the external

sounder circuit wiring to the control panel.

!

Transfer the end-of line resistor to the last device on each sounder circuit output.

!

From within the panel, check that all sounder circuits have a 10K resistance between the cable pairs

and that each cable has a reading greater than 20M ohm with respect to the panel earth stud.

Connect the sounder circuit cable to the sounder circuit terminals and power up the control panel.

For each sounder circuit carry out the following procedures:

!

Ensure that no sounder outputs are energised. Apply a short-circuit condition to one of the sounder

circuits and ensure that the COMMON FAULT and the SOUNDER FAULT status light comes on, a

SYSTEM FAULT is indicated on the LCD display and the internal buzzer operates pulsed.

!

Clear the fault condition and check that the panel reverts to the normal operating condition i.e. the

POWER ON status light is on and the display reads STATUS NORMAL.

!

Apply an open circuit condition to a sounder circuit and ensure that the COMMON FAULT and the

SOUNDER FAULT status light comes on, a SYSTEM FAULT is indicated on the LCD display and the

internal buzzer operates pulsed. Clear the fault condition and check that the panel reverts to normal

operation.

To check the operation of the sounder circuits enter the password and press the manual EVACUATE button

located on the panel Front Panel Display. The audibility level of the sounders should be checked to ensure that

they conform to relevant standard or national codes and to the customer’s satisfaction. Check that ALL sounder

devices are operating correctly. Press SILENCE BUZZER, SILENCE ALARM and RESET buttons to return the