Page 1

LHS™ Linear Heat Sensor

Installation Instructions

73-202

DESCRIPTION

The LHS™ Linear Heat Sensor cable is a flexible, durable

and cost-effective fixed-temperature fire detector, suitable

for protecting a wide range of commercial and industrial

fire applications.

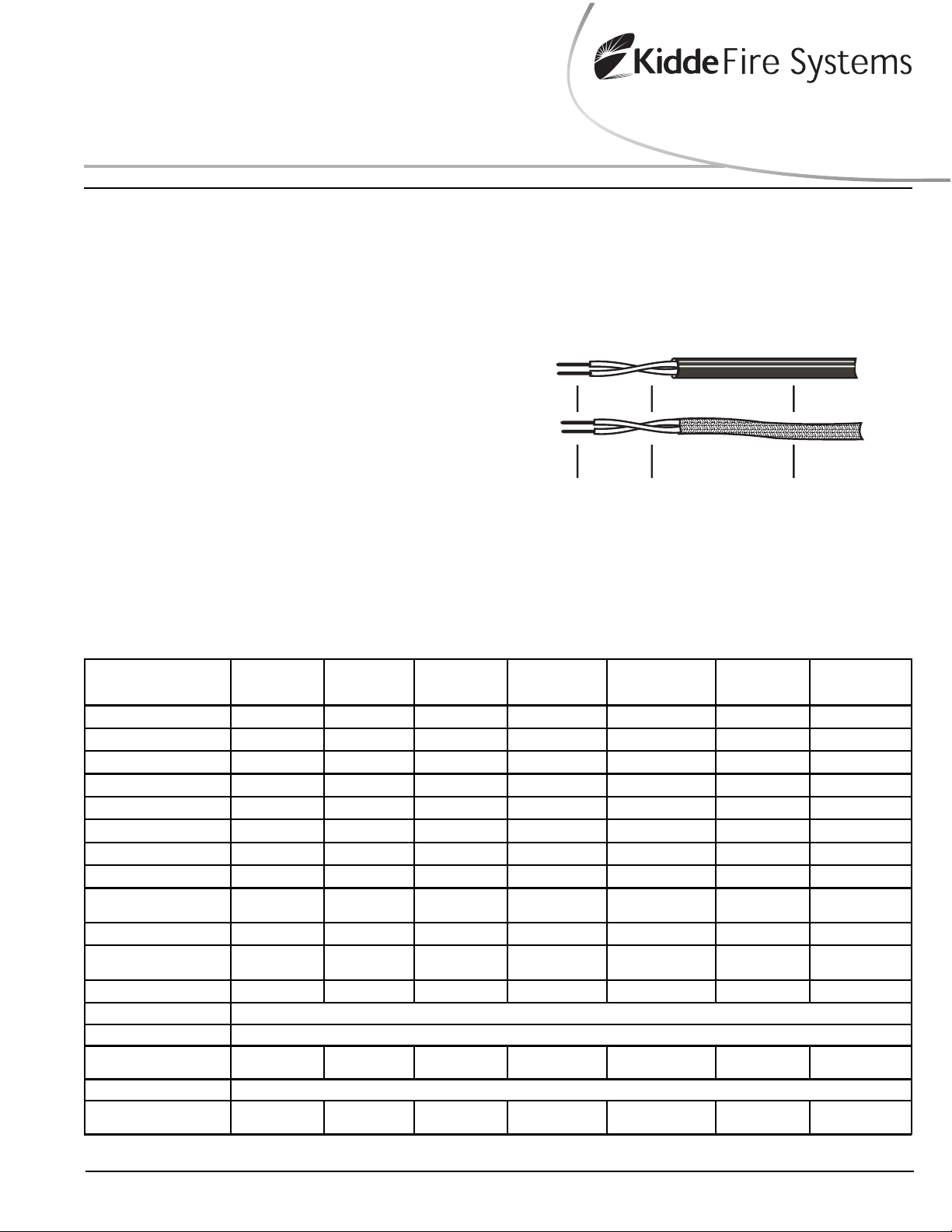

LHS is a small diameter cable capable of detecting heat

from a fire over its entire length. The sensor cable consists

of a twisted pair of 19 AWG copper coated steel conductors

covered by a temperature sensitive insulation, and protected

by either a plastic braid or jacket for various environmental

applications (see Figure 1).

LHS is designed for open area as well as proximity detection. A wide range of jackets and operating temperatures

(see Table 1) are available for proper system design, including confined areas or harsh environments which prohibit the use of other forms of detection. LHS cable is

compatible with any Fire Control Panel that is capable of

accepting contact closure type initiating devices.

The LHS linear heat detector is Factory Mutual Approved.

An FM Approved installation requires the LHS cable to be

connected to an FM Approved Fire Control Panel.

Effective: June 2006

OPERATION

The heat from a fire causes the LHS cable’s special insulation to melt at a specific temperature, allowing the two conductors to short together, thus creating an alarm condition

on the Fire Control Panel. The LHS cable may also be used

as a stand-alone contact device. The LHS normal operating state is an open circuit.

Conductor

Tinned

copper-covered

steel

Insulation

Temperature-sensitive

thermoplastic or

fluoropolymer

Figure 1. Cable Construction

Jacket

Thermoplastic strip

braid, PVC, nylon, or

fluoropolymer

Table 1. LHS Sensor Cable Specification

Part Number:

656 ft (200 m) length roll

3,280 ft (1000 m) length roll

Alarm Temperature

Ambient Storage Te mp. *

Min. Installatio n Temp.

Min. Operating Temp. **

Application

Approved Spacing

Flame Detection

Outer Jacket Materia l

Outer Jacket Color

Conductor Insulation

Conductor Color

External Diameter

Electrical Rating

Conductor Resistance

Conductor Capacitance

Insu la tio n Rat in g

Weight

* Do not store in direct sunlight. ** When not subjected to vibration.

73-200000-001

73-201000-001

155°F (68° C) 155°F (68° C) 185°F (8 5°C) 185°F (85 °C ) 220°F (105° C) 350°F (17 6° C) 465° F (24 0° C)

Up to 113°F (45° C) Up to 113°F (45° C) Up to 113° F (45° C) Up to 113°F (45° C) Up to 158° F (70° C) Up to 221° F (105° C) Up to 39 2° F (200° C)

5°F (-15° C) 5°F (-15° C) 5°F (-15°C) 5°F (-15° C) 32°F (0° C) 32°F (0° C) -4°F (-2 0°C)

-40°F (-40° C) -40°F (-40°C) -40°F (-40°C) -40°F (-40° C) -22°F (-30° C) -40°F (-40° C) -58° F (-50° C)

Indoor Only Indoor/Outdoor Indoor Only Indoor/Outdoor Indoor/Outdoor Indoor/Outdoor Indoor/Outdoor

20 ft. (6 m) maximum 20 ft. (6 m) maximum 20 ft. (6 m) maximum 20 ft. (6 m) maximum 20 ft. (6 m) maximum Proximity Detection Proximity Detectio n

5 seconds (max) 5 seconds (max) 5 seconds (max) 5 seconds (max ) 12 seconds (max) 20 seconds (max) 20 seconds (max)

Polypropylene Braid Nylon Polypropylene Braid Nylon PVC PVC FEP

Red/Green Tracer

EVA EVA EVA EVA Polythene Polypropylene FEP

1 Black

1 Red

0.146 in ch (3. 7 mm) 0.132 inc h (3. 35 mm) 0.146 inc h (3.7 m m) 0.132 inch (3. 35 mm) 0.1 67 inc h (4.25 m m) 0. 171 inc h (4. 35 mm) 0.138 in ch (3.5 mm)

20.2 1 pF/ft.

(66.32 pF/m)

11.29 lb./1000 ft.

(16.8 kg/km)

73-200000-011

73-201000-011

Black

Marke d H804 0N

1 Black

1 Red

20.21 pF/ft.

(66.32 pF/m)

10.65 lb./1000 ft.

(15.85 kg/km)

1000 megohm per 3280 ft. (1000 m) afte r 1 minute @ 500 Vdc Minimum

73-200000-002

73-201000-002

Red /B lac k Trace r

1 Blac k

1 Red

30.48 ohms/1000 ft. @ 68°F (1 0 0 o hms/1 0 0 0 m) @ 2 0 °C

25.42 pF/ft.

(83.41 pF/m)

11.29 lb./1000 ft.

(16.8 kg/km)

73-200000-012

73-201000-012

Black

Marke d H8045N

1 Blac k

1 Red

1 Amp maximum, 110 Vdc maximum

25.4 2 p F /ft.

(83.41 pF/m)

10.65 lb./10 00 ft.

(15.85 kg/km)

73-200000-003

73-201000-003

19.9 6 pF/ft.

(65.48 pF/m)

15.25 lb./1 000 ft.

(22.7 kg/km)

Black Red White

1 Blac k

1 Red

73-200000-004

73-201000-004

1 Black

1 Blac k /Whi te

17.52 pF/ft.

(57.48 pF/m)

12.67 lb./1000 ft.

(18.85 kg/km)

73-200000-005

73-201000-005

1 Black

1 White

19.22 pF/ft.

(63.07 pF/m)

14.65 lb./1000 ft.

(21.8 kg/km)

Page 2

DESIGN CONSIDERATIONS

The system design and installation must follow accepted

principles of fire protection engineering, as well as comply

with applicable codes and standards:

• NFPA-72, National Fire Alarm Code

• NEC 760, National Electric Code

• Any local installation requirements

• Requirements of the Authority Having Jurisdiction

(AHJ)

1. Selection of the appropriate part number for a specific

application must take into consideration the temperature of the hazard, the ambient temperature, and the

environment where the sensor is installed.

2. For open area protection, LHS must be mounted at the

ceiling, using the FM Approved spacing between p arallel runs. Distances from walls are half the spacing

shown. The thermal path to the LHS sensor must not

be obstructed. Maintain a 1” (25 mm) distance from the

ceiling for fastest detection.

3. For proximity detection, the LHS sensor must be tight

against the object being protected, to insure good thermal transfer. Exercise care to insure that vibration and

sharp edges do not cause abrasions to the cable, which

could result in a false activation.

4. Outdoor applications may need to be shielded from direct sunlight to prevent the LHS sensor’s operating temperature and/or maximum ambient temperature from

being exceeded, which may cause a false activation.

5. To use LHS sensor in hazardous locations (Class 1

Groups A,B,C,D; and Class 2 Groups E,F,G), FM Approved intrinsic safety barriers must be used to isolate

the sensor from the control panel.

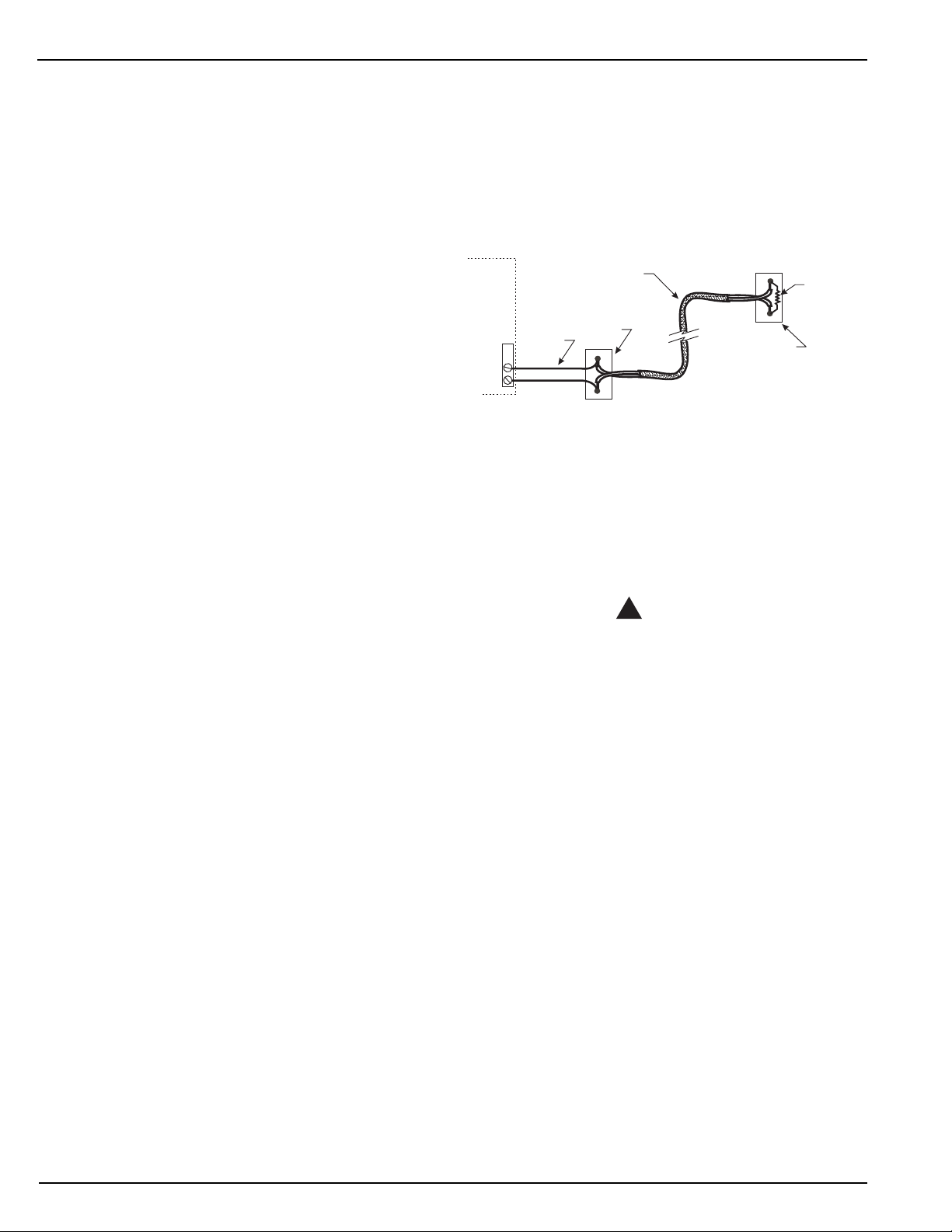

INITIA TING CIRCUIT WIRING

The LHS sensor connects to any Fire Control Panel (FCP)

as a dry-contact initiating device. Follow the installation instructions of the FCP for specific electrical requirements of

the initiating circuit (see figure 2).

1. The LHS sensor can be run as a Class B or Class A

circuit loop, with no T -t ap s.

2. The maximum LHS sensor zone length is determined

by the electrical characteristics of the FCP initiating circuit. Use the LHS resistance and capacitance as shown

in Table 1 to calculate the maximum length. For example, a FCP with input loop resistance of 50 ohms will

allow 820 feet (=50/(2 x 0.03048)) of LHS sensor.

3. If the FCP is some distance away from the protected

space, install LHS sensor only in the protected space,

and use lead-in cable to connect the LHS sensor to the

FCP. The lead-in cable can be any copper wiring approved for fire alarm use.

4. The LHS sensor in the protected space does not need

to be contiguous. Copper wiring approved for fire alarm

use may be used to connect the separate lengths of

LHS sensor.

5. If the initiating circuit is run as Class B (2 wire), then an

end-of-line device compatible with the FCP must be

installed at the end of the LHS sensor cable.

6. If allowed by the AHJ, other initiating devices (smoke

detectors, manual stations, etc.) may be installed on

the same zone as the LHS sensor. The LHS sensor

cable can be wired directly between these other devices.

Fire

Control

Panel

Initiating

Circuit

Lead-In

Cable

LHS Sensor

Cable

Junction

Box

End-of-Line

Device

Junction

Box

Figure 2. FCP with LHS Sensor Cable

SENSOR CABLE MOUNTING

The LHS sensor cable must be mounted in a professional

manner, in accordance with any applicable codes and requirements. The recommended mounting techniques described below do not preclude the use of alternate means

that are more suitable for a specific installation so long as

such means are acceptable to the local AHJ.

CAUTION

!

Where subject to mechanical damage, the

sensor cable should be protected to prevent

damage which could result in false activation.

> When designing the LHS layout, sensor cables

should be located where they will not be subject

to physical damage.

> If metal fasteners are used, non-metallic

bushings must be used to prevent chafing or

crushing of the sensor cables.

1. The cable should be adequately supported to prevent

sagging. It is not necessary to tension the cable, however on straight runs it is recommended that the cable

is supported every 3 feet (1 m). Reduced spacing may

be employed to suit local codes or conditions such as

around corners and transition points. Tension on the

sensor cable cannot exceed 50 Newtons. The sensor

cable can be bent around a radius no smaller than 2”

(50 mm)

2. Wherever possible, the sensor cable should be installed

in a continuous run with as few splices as possible.

3. The sensor cable should be the last item installed on a

project. If not installed last, it should be temporarily supported by cable ties to minimize the risk of damage.

Care should be taken to prevent damage due to foot

traffic, mechanical impact, kinking or any external heat

sources.

2

Page 3

4. Weather-Tight Connector, P/N 73-117068-027 is used

CAUTION

!

to provide appropriate strain-relief where the sensor

cable enters an electrical box or enclosure. It is recommended to secure tension on the end of a long sensor

cable run. The connector is designed to thread into a

standard 3/4" cast electrical box opening (3/4” NPT).

Nylon

Cable

Clamp

Sensor Cable

Sensor

Cable

Figure 3. Weather-Tight Connector

5. The sensor cable should be protected from mechanical

damage in non-detecting exposed areas by running it

in electrical metallic tubing (EMT). The sensor cable

should also be run in short pieces of EMT where the

sensor cable must pass through walls or partitions. The

ends of the EMT must have non-metallic bushings to

prevent damage to the sensor cable.

6. Selection of the mounting hardware that best suits the

application will depend upon the equipment or support

structures in the area being protected. Environmental

conditions and the practicality of mounting the clips

needs to be taken into consideration. The sensor cable

should always be attached to a support that permits the

least amount of movement, without crushing the cable

insulation. Three types of standard mounting hardware

(master clamp, flange clamp, nylon cable tie) permit

safe, secure sensor cable installation in most

applications.

7. The Master Clamp, P/N 73-1 17068-022 (box of 100), is

a multi-purpose fastener that fits all beam flanges up to

½” (13 mm) thick and resists vibration. Use the Nylon

Cable Clamp, P/N 73-117068-025 (box of 100) to fasten the sensor cable to the master clamp.

Nylon Cable

Clamp

Sensor Cable

Figure 4. Master Clamp

8. The Flange Clip is available in two sizes. P/N 73-117068-

023 (box of 100) fits up to 3/16" (4 mm) thick metal.

P/N 73-117068-024 (box of 100) fits 3/16" (4 mm) to ¼”

(6 mm) thick metal. They are easily hammered onto

metal flanges on roof trusses and shelving for secure

mounting which resists vibration. Use the Nylon Cable

Clamp, P/N 73-117068-025 (box of 100) to fasten the

sensor cable to both sizes of flange clips.

Figure 5. Flange Clip

9. The Nylon Cable Tie, P/N 73-117068-020 (box of 100),

is a heavy duty mounting tab cable tie that is strapped

to sprinkler or other fire protection pipes up to 8" (20

cm) in diameter. This method of mounting the LHS

sensor may be used if acceptable to the local AHJ. Use

the Nylon Cable Clamp, P/N 73-117068-025 (box of 100)

to fasten the sensor cable to nylon cable tie.

Pipe

Nylon Cable

Tie

Nylon Cable

Clamp

Sensor Cable

Figure 6. Nylon Cable Tie

When the LHS sensor cable is installed in below

freezing environments, special precautions

should be taken to avoid contact with or

movement of the sensor cable. At temperatures

below 32OF (0OC), the Nylon Cable Tie may break

as a result of jarring or physical contact.

10. Messenger cable must be used if the LHS sensor cable

needs to be suspended for some distance over an object

or an area, without a ceiling to attach the cable to. Commercially available stainless steel cable of a suitable size

should be used as messenger cable, tensioned appropriately . The sensor cable can be attached to the messenger

cable using cable ties, approximately every 3 feet (1 m).

SENSOR CABLE SPLICING

The LHS sensor cable must be spliced or electrically connected in a professional manner, in accordance with any

applicable codes or requirements. The recommended splicing techniques described below do not preclude the use of

alternate means that are more suitable for a specific installation. Because of the heat-sensitive nature of the sensor

cable insulation, soldering or heat-shrink tubing should never

be used when splicing LHS sensor cable.

Preferred Method - Using a junction box:

The preferred method for joining two lengths of sensor cable,

or for connecting sensor cable to copper lead-in wire, inter-

3

Page 4

-

h

.

-

L

connecting cable, or an end-of-line device, is to make the

connection inside a junction box.

1. The sensor cable can be joined using any industry standard method for connecting copper conductors. Positive, compression type connectors must be used, such

as wire nuts (3M/Highland H-30 or equal), butt splices

(Panduit BSN18 or equal), or a 2-position terminal block

(Molex/Beau C1502-151 or equal), following the

manufacturer’s installation instructions.

2. Any standard electrical junction box with a cover may

be used. In wet or damp locations, a waterproof box

must be used. The P/N 73-117068-027 Weather-Tight

Connector (or equivalent) must be used to provide strain

relief on the sensor cable where it enters the box. Do

not use “Romex” style cable clamps, as they may crush

the cable, possibly causing a false alarm.

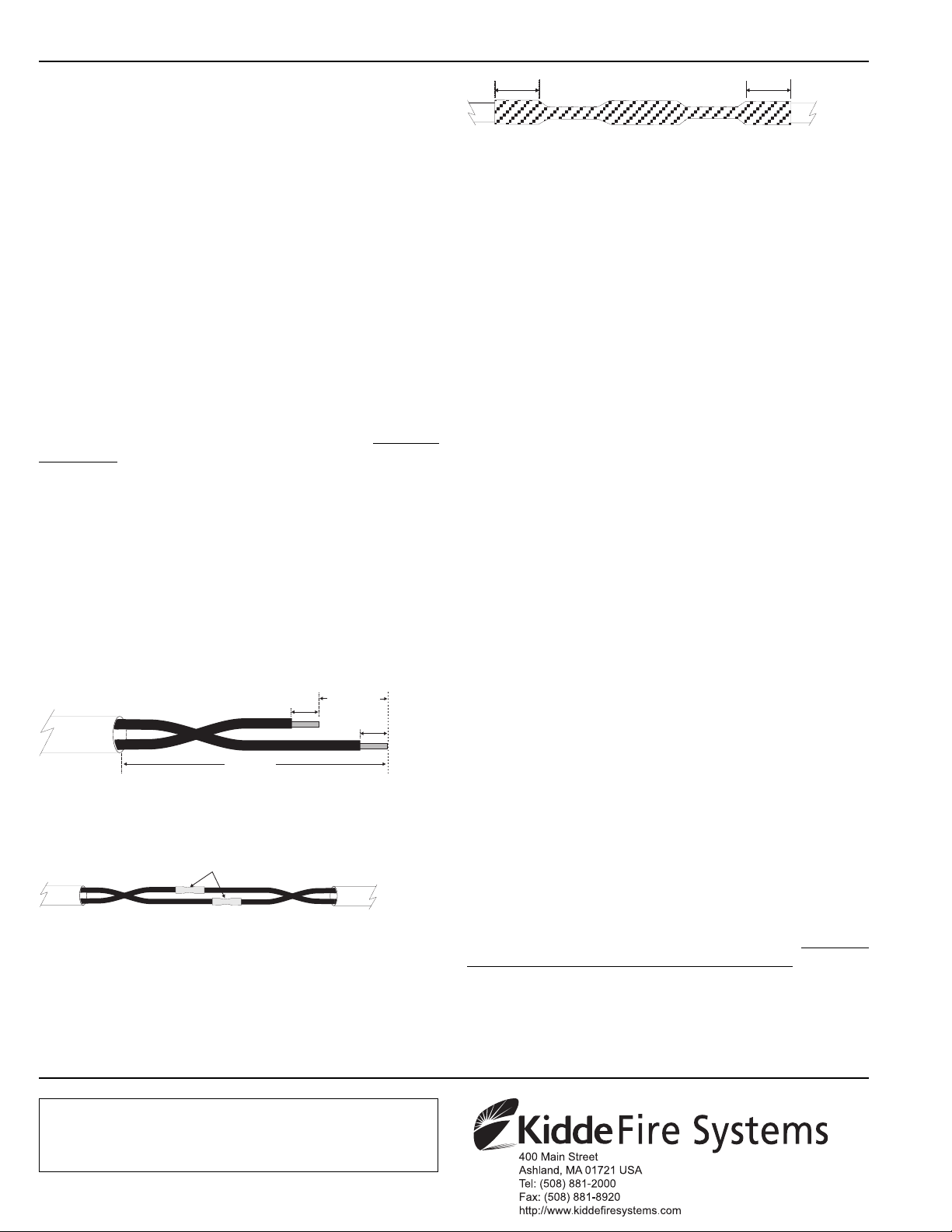

Alternate Method – In-line Splice:

Where permitted by the AHJ, in-line splicing of two lengths

of sensor cable may be permitted. In-line splicing is not recommended for connecting sensor cable to copper lead-in

wire, interconnecting cable, or an end-of-line device. In-line

splicing is also not recommended if the sensor cable is under any significant tension.

When used for proximity detection, loop the sensor cable,

as the splice area does not provide detection coverage.

1. The sensor cable must be joined using nylon insulated

compression butt splices (Panduit BSN18 or equal).

Offset the two butt splices from each other.

2. Strip the jacket and insulation from each cable as shown

in figure 7.Trim the two conductors with the offset as

shown.

1 1/4” (30 mm)

1/4” (6.4 mm)

1/4” (6.4 mm)

4” (100 mm)

Figure 7. Strip the Sensor Cable

3. Crimp on the two butt splices as shown in figure 8, using an approved crimp tool (Panduit CT-1550 or equal).

Butt Splice

Figure 8. Crimp the Sensor Cable

4. For dry locations, seal the splice by wrapping electrical

tape (3M/Scotch Super 33+ or equal) around the splice,

following the manufacturer’s instructions. Stretch and

overlap each turn of the tape by about 1/2 its width. The

tape should extend 2” (50 mm) beyond the ends where

the sensor cable jacket was cut. See figure 9.

2” (50mm)2” (50mm)2” (50mm)2” (50mm) 2” (50mm)2” (50mm)

Wrap over

Butt Splice

Figure 9. Seal the Splice

5. For damp or wet locations, seal the splice by wrapping

silicon fusion tape (Tyco Electronics/Amp 608036-1 or

equal) around the splice, following the manufacturer’s

instructions. The tape should extend 2” (50 mm) beyond the ends where the sensor cable jacket was cut.

See figure 9.

TESTING

Functional testing of the LHS sensor cable should follow

the guidelines for fixed-temperature non-restorable line type

heat detectors in Chapter 7 of NFP A-72, National Fire Alarm

Code. Consult with the AHJ for additional testing requirements that may apply to your specific installation. Functional

testing verifies the electrical operation of the sensor cable

and does not require a heat source.

1. Place a short across the end-of-line (EOL) device for

an LHS zone, and verify that the zone goes into alarm.

2. (If required by the AHJ) Remove one leg of the EOL for

an LHS zone, and verify that the zone goes into trouble.

3. (If required by the AHJ) Disconnect both conductors of

the LHS zone from the FCP. Place a short across the

EOL. At the FCP end of the zone, measure and record

the total loop resistance of the sensor cable. Compare

it to the acceptance test value.

MAINTENANCE

The LHS sensor cable requires no maintenance, other than

visual inspection to insure the integrity of the installation.

Damage To The Sensor Cable:

If the sensor cable is physically damaged, the conductors

may short together, causing an alarm. Locate the short circuit by visual inspection, by using an ohmmeter (comparing

to the value obtained during the acceptance test), or by using a tone generator & probe set. Splice in a new piece of

sensor cable. Replace at least 3 ft. (1 m) of the sensor cable

on both sides of the damaged piece.

After A Fire Event:

As the LHS sensor cable is non-restoring, it must be replaced after detecting a fire. If the entire zone is not being

replaced, splice in a new piece of sensor cable, extending

at least 10 ft. (3 m) beyond the affected section.

LHS is a trademark of Kidde-Fenwal, Inc.

These instructions do not purport to cover all the details or variations in the equipment de

scribed, nor do they provide for every possible contingency to be met in connection wit

installation, operation and maintenance. All specifications subject to change without notice

Should furhter information be desired or should particular problems arise which are not cov

ered sufficiently for the purchaser’s purposes, the matter should be referred to KIDDE-FENWA

INC., Ashland, MA 01721. Telephone: (508) 881-2000

06-236279-003 Rev AC ©2006 Kidde-Fenwal Inc. Printed in U.S.A.

Loading...

Loading...