Page 1

Kidde XV™ Control System

P/N: 87-120099-002

FEATURES

• For Use in:

•WHDR

•IND

• Pneumatic Release of up to 20 Agent Cylinders

• Two Discrete Mechanical Detection Lines

• Cylinder or Wall Mount

• Up to 400 ft. Mechanical Detection Cable

DESCRIPTION

The Kidde XV Control System is a compact, versatile unit

used to actuate agent cylinders on Kidde WHDR and IND

Pre-Engineered fire suppression systems. The control

head can be operated via:

• Two Distinct Automatic Mechanical Detection Lines

(fusible links or thermo-bulb links)

• Optional Electrical Solenoid

• Remote or Local Manual Mechanical Control

Upon actuation, the XV Control System discharges the

nitrogen System Cartridge, pressurizing the actuation

lines and System Valve Actuators (SVA) mounted on the

cylinder valve(s). The SVA(s) open the cylinder valve(s),

™

Commercial Cooking Fire

Suppression Systems

™

Industrial Fire Suppression Systems

Effective: August 2013

K-87-027

• Operates 2 Gas Valves

• Available 24 V Electrical Actuation

• Multiple Remote Release Options

• Rugged, Die-Cast Aluminum Body

• Tamper/Lock Port for Cover

• Easy to Install and Maintain

• UL & ULC Listed

• FM Approved for IND Systems

discharging the WHDR wet chemical or IND dry chemical

suppression agent. The XV can be mounted on a wall or

directly to an SVA mounted on the cylinder.

The XV Control System is UL and ULC Listed with

WHDR Wet Chemical and IND Dry Chemical Fire

Suppression Systems. The XV is FM approved with the

IND Dry Chemical Systems.

The XV comes ready to install, with three EMT

connectors, one System Valve Actuator (SVA), two

microswitches, one nitrogen System Cartridge, and one

nitrogen test cartridge.

Figure 1. XV Control System, P/N 87-120099-002

Page 2

TECHNICAL DATA

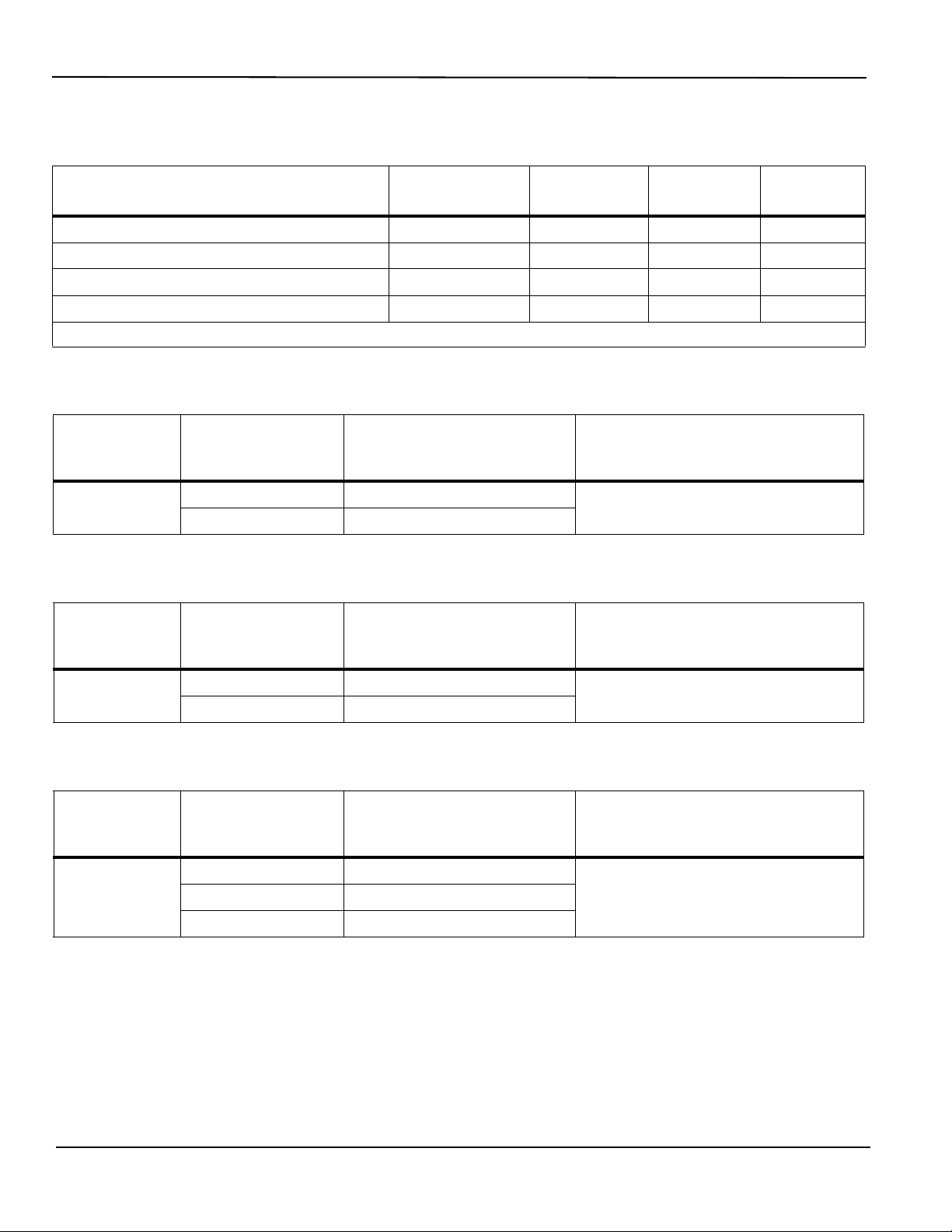

Table 1. Mechanical Cable Parameters for WHDR & IND Systems

XV Cable Line

Detection and Manual Release-to-Trip Line 1 200 ft. (60.96 m) 50 40 *

Detection and Manual Release-to-Trip Line 2 200 ft. (60.96 m) 50 40 *

Pull-to-Trip Remote Manual Release Line 100 ft. (30.48 m) 30 - 1*

Mechanical Gas Valve Line 100 ft. (30.48 m) 30 - 1*

*Tee pulleys count as two Corner Pulleys. Maximum is from XV Control, through the pulley, to each device.

Max. Cable

Length

Max. Corner

Pulleys

Max.

Detectors

Max. Tee

Pulleys

Table 2. Actuation Parameters for WHDR Wet Chemical Systems

Operating

Temperature

Range

°F to 120°F

0

(-18

°C to 49°C)

Number of

Extinguishing

System Cylinders

1-12 106 ft. (32.30 m)

13-20 91 ft. (27.73 m)

Maximum Total Length

Copper Actuation Tubing

Minimum Total Length of Copper

Actuation Tubing

5 ft. (1.52 m)

Table 3. Actuation Parameters for IND Industrial Dry Chemical and Open-Face Spray Booth Systems

Operating

Temperature

Range

Number of

Extinguishing

System Cylinders

Maximum Total Length

Copper Actuation Tubing

Minimum Total Length of Copper

Actuation Tubing

°F to 120°F

-40

(-40

°C to 49°C)

1-14 166 ft. (50.60 m)

5 ft. (1.52 m)

15-20 121 ft. (36.88 m)

Table 4. Actuation Parameters for IND Dry Chemical for Vehicle Spray Booths

Operating

Temperature

Range

°F to 120°F

0

(-18

°C to 49°C)

Number of

Extinguishing

System Cylinders

1-8 200 ft. (60.96 m)

16-20 140 ft. (42.67 m)

Maximum Total Length

Copper Actuation Tubing

Minimum Total Length of Copper

Actuation Tubing

5 ft. (1.52 m)9-15 160 ft. (48.76 m)

NOTES

1. Braided high pressure nitrogen tubing (P/N 87-120045-00X), is required to connect the XV Control System to the

System Valve Actuator (SVA) when the XV Control System is cylinder mounted.

2. Copper tubing shall be 1/4-inch O.D. x 0.031-inch wall high pressure tubing.

3. When Control System is cylinder mounted and two or more cylinders are being actuated, a minimum of 5 ft.

(1.52 m) of 1/4-inch O.D. x 0.031-inch wall tubing shall be used for actuation lines.

- 2 -

Page 3

4. When Control System is wall mounted, a minimum of 5 ft. (1.52 m) of 1/4-inch O.D. x 0.031-inch wall tubing shall

5-1/8 in.

(130 mm)

1-9/16 in.

(40 mm)

GRAY BAND

4 in.

(102 mm)

1 in.

(25 mm)

be used in the overall actuation line.

5. High pressure nitrogen tubing (P/N 87-120045-00X) may be used in place of copper tubing, not to exceed a maximum length of 30 feet (9 m).

6. In every system, either single cylinder or multiple cylinder, a 1/8-inch NPT plug or vent check (P/N WK-877810-

000) shall be used in the outlet port of the last System Valve Actuator(s) in the actuation line.

7. A maximum of 2 Pressure Switches (P/N 486536) may be used in the actuation line.

SYSTEM NITROGEN CARTRIDGE, P/N 87-120043-001

The XV Control System uses a nitrogen cartridge for actuating the system cylinders and is charged with dry nitrogen

(see Figure 2). The cartridge is mounted inside the XV Control System to protect it from tampering and provides the

date of manufacturing and space (gray band) for recording the installation date.

Figure 2. System Nitrogen Cartridge,

P/N 87-120043-001

TEST CARTRIDGE, P/N 87-120044-001

The Test Cartridge is used for functional testing of the Kidde WHDR Wet Chemical System and IND Dry Chemical

System*. The cartridge has a red band and is labeled “TEST CARTRIDGE” as shown in Figure 3.

*Note: The System Nitrogen Cartridge P/N 87-120043-001 is required for actuation and full discharge or "puff" tests,

and when a time delay is included (as in systems protecting Vehicle Spray Booths).

Figure 3. Test Cartridge, P/N 87-120044-001

- 3 -

Page 4

SYSTEM VALVE ACTUATOR (SVA), P/N 87-120042-001

1/8 in. NPT PLUG

(IF APPLICABLE)

5/16-18 UNC

THROUGH HOLE (TYP)

(NOT SHOWN)

PISTON IN ACTUATED

POSITION (TOWARDS

CYLINDER VALVE)

1-3/4 in.

(44 mm)

SPRING LOADED

PLUNGER

1/8 in.

NPT PORT

SVA PISTON IN

SET POSITION

1/8 in. NPT

THREAD

1/2 in. HEX,

1/4 in. 37 DEGREE

FLARE, SWIVEL

A

(END TO SEAT)

SEAT

1/8 in. NPT

(MALE) x 3/8-24

JIC ADAPTER

A System Valve Actuator (SVA) must be mounted to every system cylinder valve assembly (see Figure 4). The SVA

has ports for low profile tubing runs, and is also equipped with a spring loaded plunger that locks the piston in the

discharged position, ensuring complete discharge of the cylinder(s) contents.

Figure 4. System Valve Actuator (SVA), P/N 87-120042-001

HIGH-PRESSURE NITROGEN TUBING, P/N 87-120045-00X

The High-Pressure Nitrogen Tubing is used to connect the XV Control System to the SVA on all installations in which

the XV Control System is mounted to a wet or dry chemical cylinder. (see Figure 5). A 1/8-inch NPT (male) x 3/8-24 JIC

Adapter is included with the High Pressure Nitrogen Tubing.

Figure 5. External Tubing for XV Control System, P/N 87-120045-00X

Part Number Length "A"

87-120045-001 7-1/2 in. (191 mm)

87-120045-002 24 in. (610 mm)

87-120045-003 60 in. (1524 mm)

Table 5. External Tubing for XV Control System

- 4 -

Page 5

SOLENOID, P/N 83-100034-001

ELECTRICAL LEADS

24 in. (610 mm)

MOUNTING BRACKET

(DO NOT REMOVE)

PUSH PLATE

(DO NOT REMOVE)

SOLENOID BODY

9/64 in. ALLEN SCREWS (2)

FLAG ENGAGED

BY XV

TERMINAL 2 NOT USED

OPEN TERMINAL 2

ATTACH SOLENOID LEAD TO

TERMINAL 1 OF MICROSWITCH

COMMON

TERMINAL 1

ATTACH RELEASING CIRCUIT TO

TERMINAL 4 OF MICROSWITCH

CLOSED TERMINAL 4

SPLICE SOLENOID LEAD

TO RELEASING CIRCUIT

RELEASING CIRCUIT

IN COMPATIBLE CONTROL

PANEL ( )24 VDC ONLY

XV SOLENOID

P/N 83-100034-001

24 VDC ONLY

SWITCH POSITION WHEN FLAG/CAM IS IN SET POSITIONXV

ALARM WIRES TO

SOLENOID AND/OR OTHER

DEVICES

XV

WIRE TYPE KEY

MICROSWITCH (INTERNAL)

ALARM WIRES FROM

CONTROL PANEL

An optional solenoid can be installed into the XV Control

System, just under the actuation latch. The solenoid

operates directly on the actuation latch to activate the

system. This installation allows simultaneous usage of

mechanical detection lines, or the lines can be locked

out. The solenoid includes two mounting bolts, the

bracket and a push plate which mounts onto the solenoid

body (Figure 6). The solenoid coil is 24 Vdc at 1.5 Amp

and at 70°F (21°C). Refer to Figure 7 for Release Wiring with

Terminal Type Microswitch.

When actuating the XV Control System with an optional

solenoid, a UL Compatible and Listed fire control panel

with a supervised power supply is required, such as the

Kidde AEGIS or Kidde ARIES.

Figure 6. Solenoid, P/N 83-100034-001

Figure 7. Release Wiring with Terminal Type Microswitch

Note: Where electric detection and/or actuation is pro-

vided, supervision shall be provided in accordance with NFPA 72, National Fire Alarm and

Signaling Code. Alarms and indicators, along

with a supervised power source, shall be provided in accordance with NFPA 72. Electrical wiring and equipment shall be provided in

accordance with NFPA 70, National Electric

Code. All installations are subject to the approval

of the Authority Having Jurisdiction (AHJ).

KEEPER PIN, P/N 60-9197108-000

The Keeper Pin (P/N 60-9197108-000) is used to prevent

actuation while installing the system.

Figure 8. Keeper Pin, P/N 60-9197108-000

- 5 -

Page 6

9-3/4”

(248 mm)

8-1/2”

(216 mm)

3-3/4”

(95 mm)

TO OPERATE

PULL PIN

TURN HANDLE

FIRE SUPPRESSION SYSTEM

ORDERING INFORMATION

MOUNTING

HOLE

MOUNTING

HOLE

MOUNTING

HOLE

5-1/2 in.

(140 mm)

7-5/8 in.

(194 mm)

4-3/8 in.

(112 mm)

1-5/16 in.

(34 mm)

3/4 in.

(19 mm)

MOUNTING

HOLE

XV Control System includes:

(1) 87-120042-001 System Valve Actuator

(1) 87-120043-001 System Nitrogen Cartridge

(1) 87-120044-001 Test Cartridge

(1) 87-120058-001 EMT Connector Kit

(1) 87-120039-001 Microswitch Kit

(1) 87-120039-501 Microswitch Kit

System Valve Actuator 87-120042-001

System Nitrogen Cartridge 87-120043-001

Test Cartridge 87-120044-001

High Pressure Hose for Cylinder Mount 87-120045-001

EMT Connector Kit 87-120058-001

Solenoid Electric Actuator Kit 83-100034-001

Microswitch Kit (SPDT), Solid Color Leads 87-120039-001

Microswitch Kit (SPDT), Striped Color Leads 87-120039-501

Terminal Type Microswitch Kit (SPDT) 87-120047-001

Description Part Number

87-120099-002

REFERENCE INFORMATION

• WHDR Systems designed and installed according to

manual P/N 87-122000-001.

• IND Systems designed and installed according to

manual P/N 220423.

• Vehicle Spray Booth Systems designed and installed

according to manual P/N 83-100036-001.

Kidde is a registered trademark of Kidde-Fenwal, Inc.

WHDR, IND, XV, AEGIS, and ARIES are trademarks of Kidde-Fenwal,

This literature is provided for informational purposes only. KIDDE-FENWAL, INC.

assumes no responsibility for the product’s suitability for a particular application. The

product must be properly applied to work correctly.

If you need more information on this product, or if you have a particular question, contact

KIDDE-FENWAL, INC., Ashland, MA 01721. Telephone: (508) 881-2000.

K-87-027 Rev AG © 2013 Kidde-Fenwal Inc.

Figure 9. XV Control System Dimensions

400 Main Street

Ashland, MA 01721

Tel.: 508-881-2000

Fax: 508-881-8920

www.kiddefiresystems.com

Loading...

Loading...